U1000 NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 117 of 3171

DTC P0725 ENGINE SPEED SIGNAL

AT-109

D

E

F

G

H

I

J

K

L

MA

B

AT

Diagnostic ProcedureECS00FYD

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. While monitoring engine speed, check for engine speed change

corresponding to wide-open throttle position signal.

OK or NG

OK >> GO TO 3.

NG >> Perform self-diagnosis for “ENGINE” with CONSULT-II. Refer toEC-62, "

SELF-DIAGNOSTIC

MODE".

3.CHECK DTC

PerformAT- 1 0 8 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

Item name Condition Display value

ENGINE SPEED Engine runningClosely matches the tachome-

ter reading.

PCIA0041E

Page 124 of 3171

AT-116

DTC P1705 THROTTLE POSITION SENSOR

DTC P1705 THROTTLE POSITION SENSOR

PFP:22620

DescriptionECS00G43

The accelerator pedal position sensor sends a signal to ECM, and ECM sends signals to TCM with CAN com-

munication.

CONSULT-II Reference ValueECS00G44

On Board Diagnosis LogicECS00G45

Diagnostic trouble code “P1705 TP SEN/CIRC A/T” with CONSULT-II or 15th judgement flicker without CON-

SULT-II is detected when TCM does not receive the proper accelerator pedal position signals (input by CAN

communication) from ECM.

Possible CauseECS00G46

Harness or connectors

(The sensor circuit is open or shorted.)

DTC Confirmation ProcedureECS00G47

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Touch “START”.

4. Start engine and let it idle for 1 second.

5. If DTC is detected, go toAT- 11 6 , "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for 1 second.

2. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

3. If DTC is detected, go toAT- 11 6 , "

Diagnostic Procedure".

Diagnostic ProcedureECS00G48

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

Item name Condition Display value

ACCELE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

BCIA0031E

Page 125 of 3171

DTC P1705 THROTTLE POSITION SENSOR

AT-117

D

E

F

G

H

I

J

K

L

MA

B

AT

2.CHECK DTC WITH TCM

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Depress accelerator pedal and read the value of “ACCELE

POSI”.

4. Select “SELF-DIAG RESULTS” mode for “A/T” with CONSULT-

II. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK DTC WITH ECM

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ENGINE” with CON-

SULT-II. Refer toEC-59, "

CONSULT-II Function (ENGINE)".

OK or NG

OK >> GO TO 4.

NG >> Check the DTC detected item. Refer toEC-59, "

CON-

SULT-II Function (ENGINE)".

lIf CAN communication line is detected, go toAT- 9 1 ,

"DTC U1000 CAN COMMUNICATION LINE".

4.CHECK DTC

PerformAT- 11 6 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

5.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

Item name Condition Display value

ACCELE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

PCIA0070E

BCIA0030E

Page 134 of 3171

AT-126

DTC P1721 VEHICLE SPEED SENSOR MTR

Diagnostic Procedure

ECS00FZD

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is malfunction in the CAN communication indicated in the result?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Drive vehicle and read out the value of “VHCL/S SE-MTR”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK COMBINATION METER

Check combination meter. Refer toDI-18, "

Trouble Diagnosis".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK DTC

PerformAT- 1 2 5 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

5.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

Item name Condition Display value

VHCL/S SE-MTR During drivingApproximately matches the

speedometer reading.

SCIA2148E

Page 176 of 3171

AT-168

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

PFP:18002

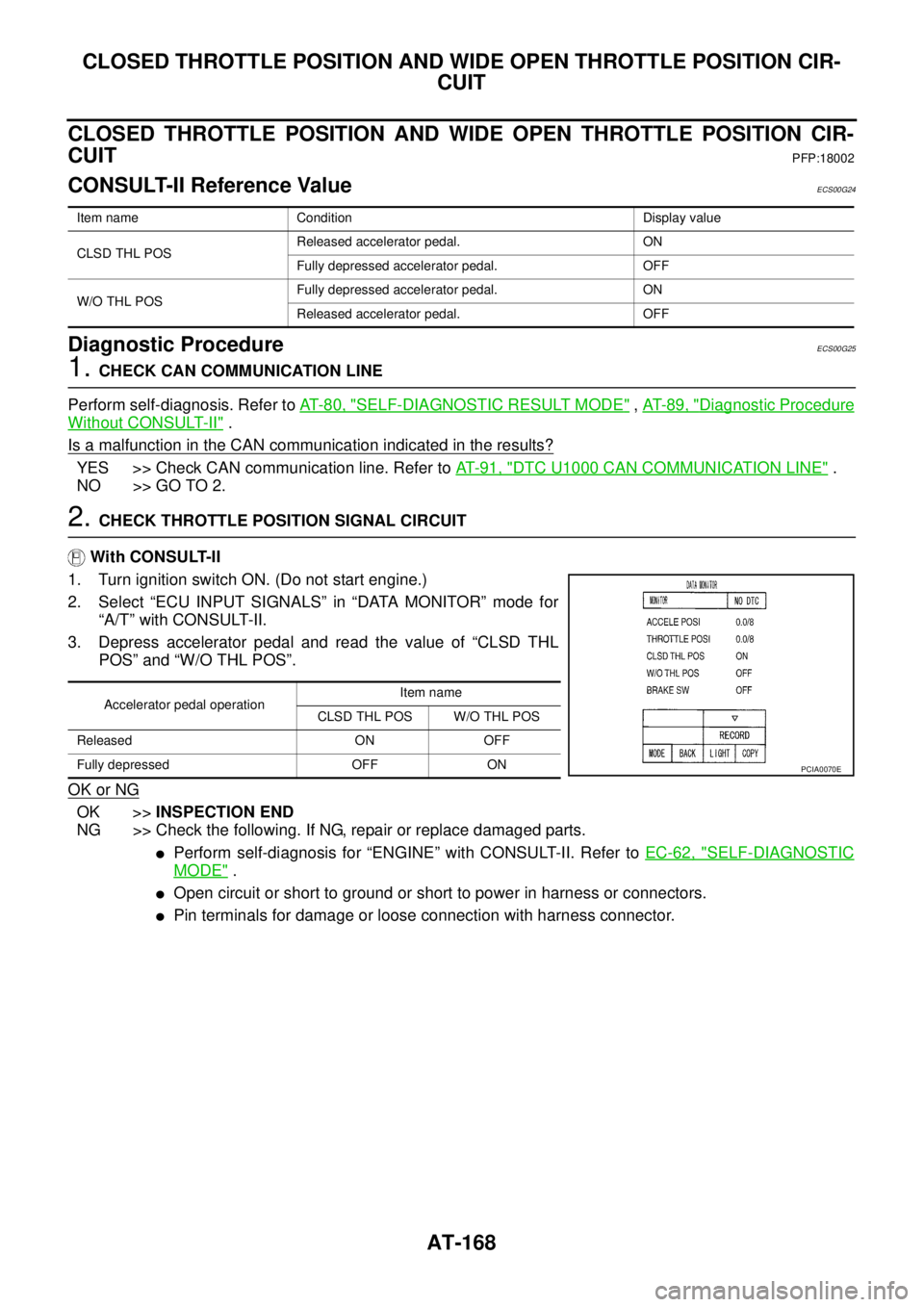

CONSULT-II Reference ValueECS00G24

Diagnostic ProcedureECS00G25

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK THROTTLE POSITION SIGNAL CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Depress accelerator pedal and read the value of “CLSD THL

POS” and “W/O THL POS”.

OK or NG

OK >>INSPECTION END

NG >> Check the following. If NG, repair or replace damaged parts.

lPerform self-diagnosis for “ENGINE” with CONSULT-II. Refer toEC-62, "SELF-DIAGNOSTIC

MODE".

lOpen circuit or short to ground or short to power in harness or connectors.

lPin terminals for damage or loose connection with harness connector.

Item name Condition Display value

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

Accelerator pedal operationItem name

CLSD THL POS W/O THL POS

Released ON OFF

Fully depressed OFF ON

PCIA0070E

Page 177 of 3171

BRAKE SIGNAL CIRCUIT

AT-169

D

E

F

G

H

I

J

K

L

MA

B

AT

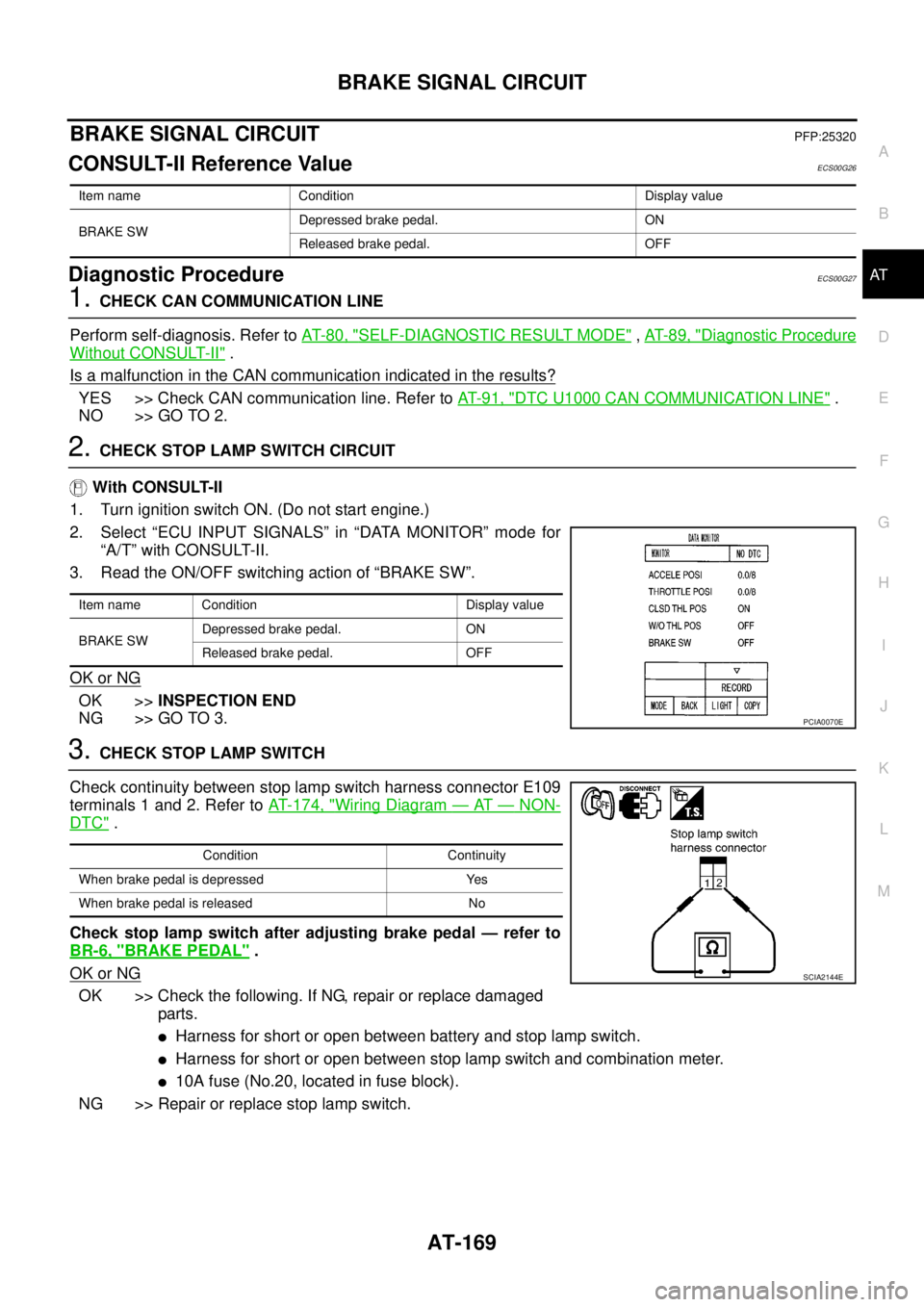

BRAKE SIGNAL CIRCUITPFP:25320

CONSULT-II Reference ValueECS00G26

Diagnostic ProcedureECS00G27

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read the ON/OFF switching action of “BRAKE SW”.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch harness connector E109

terminals 1 and 2. Refer toAT- 1 7 4 , "

Wiring Diagram—AT—NON-

DTC".

Check stop lamp switch after adjusting brake pedal — refer to

BR-6, "

BRAKE PEDAL".

OK or NG

OK >> Check the following. If NG, repair or replace damaged

parts.

lHarness for short or open between battery and stop lamp switch.

lHarness for short or open between stop lamp switch and combination meter.

l10A fuse (No.20, located in fuse block).

NG >> Repair or replace stop lamp switch.

Item name Condition Display value

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

Item name Condition Display value

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

PCIA0070E

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2144E

Page 178 of 3171

AT-170

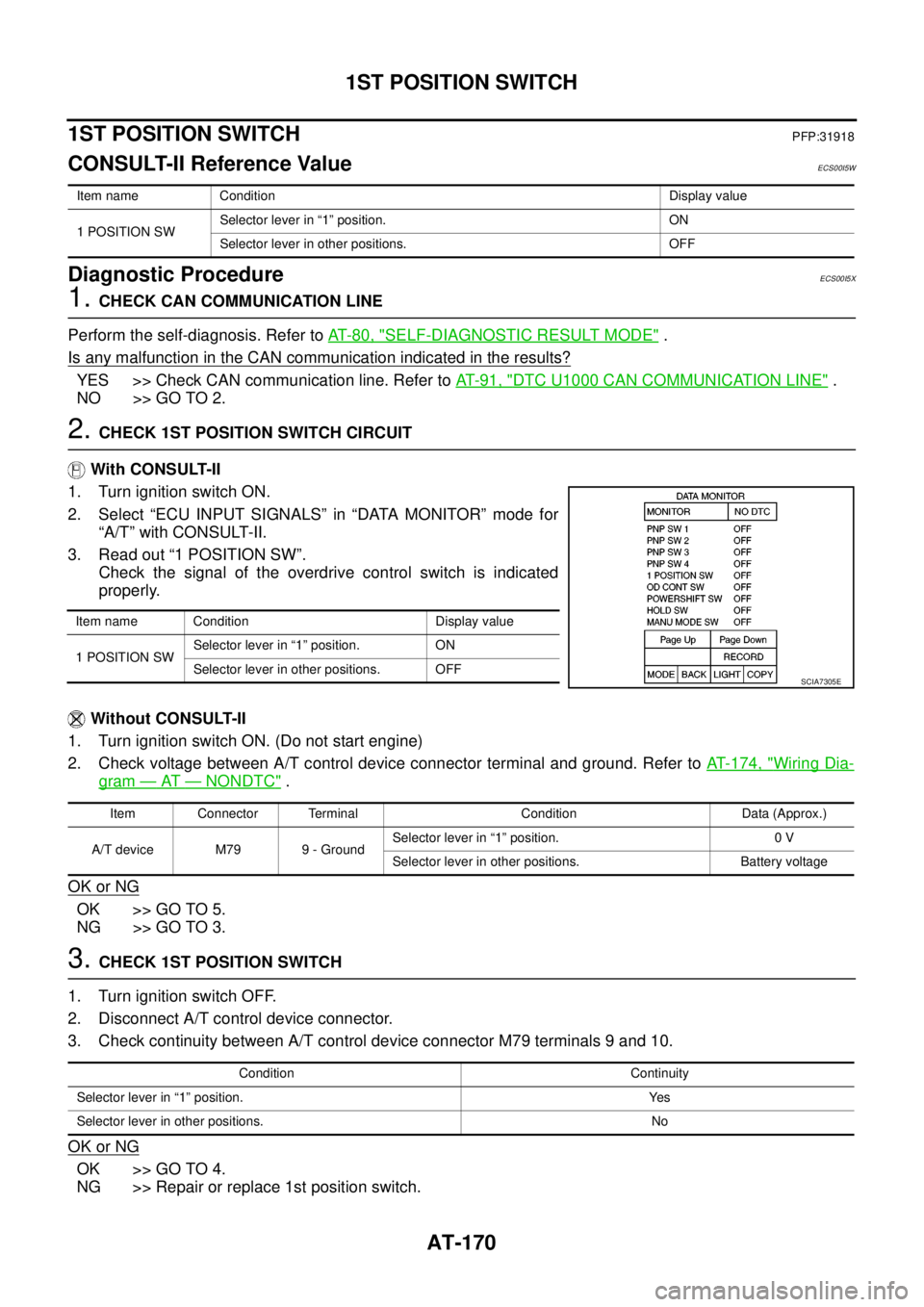

1ST POSITION SWITCH

1ST POSITION SWITCH

PFP:31918

CONSULT-II Reference ValueECS00I5W

Diagnostic ProcedureECS00I5X

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “1 POSITION SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK 1ST POSITION SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 9 and 10.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace 1st position switch.

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 9 - GroundSelector lever in “1” position. 0 V

Selector lever in other positions. Battery voltage

Condition Continuity

Selector lever in “1” position. Yes

Selector lever in other positions. No

Page 180 of 3171

AT-172

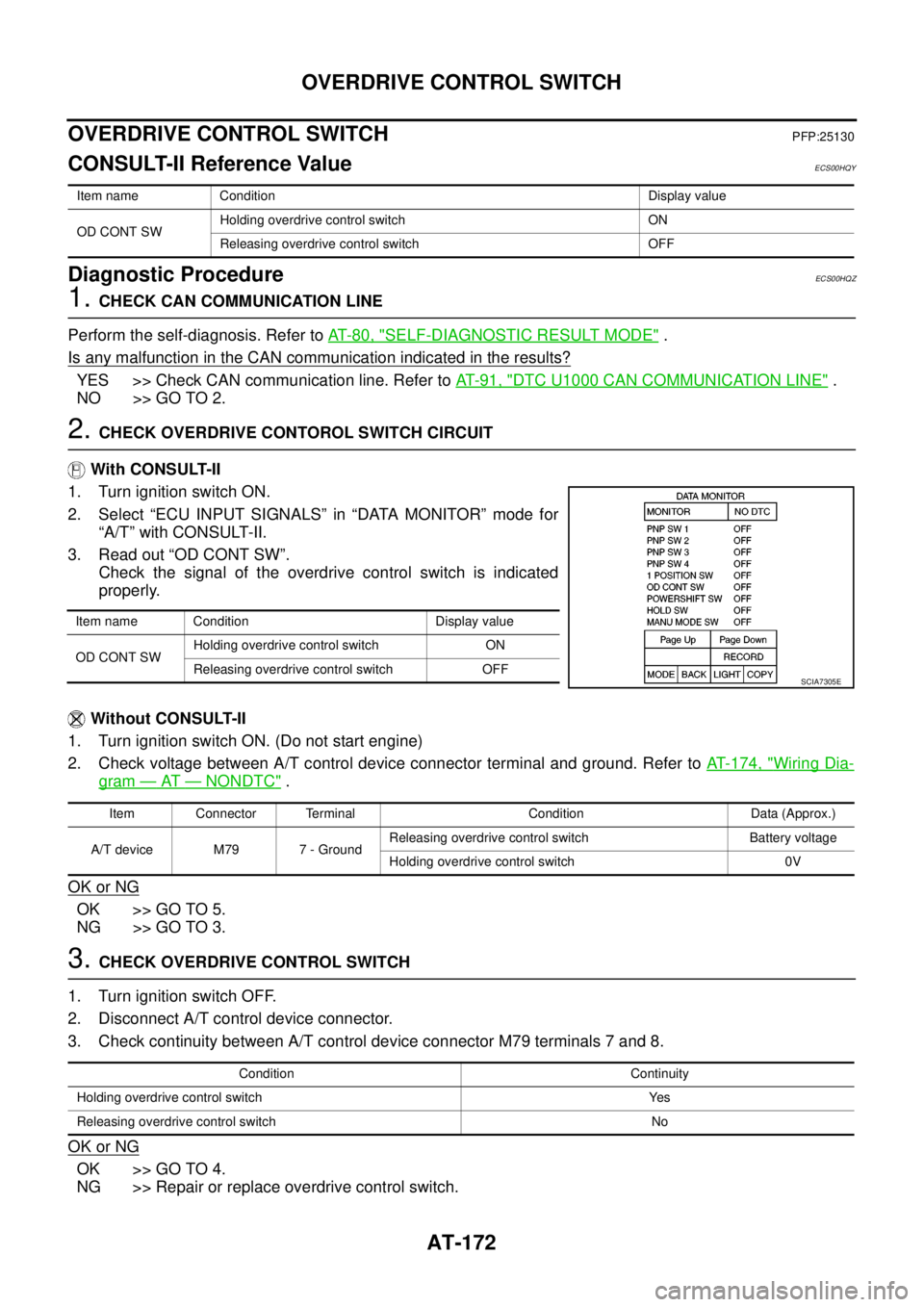

OVERDRIVE CONTROL SWITCH

OVERDRIVE CONTROL SWITCH

PFP:25130

CONSULT-II Reference ValueECS00HQY

Diagnostic ProcedureECS00HQZ

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OVERDRIVE CONTOROL SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “OD CONT SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 7 and 8.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace overdrive control switch.

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 7 - GroundReleasing overdrive control switch Battery voltage

Holding overdrive control switch 0V

Condition Continuity

Holding overdrive control switch Yes

Releasing overdrive control switch No

Page 185 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-177

D

E

F

G

H

I

J

K

L

MA

B

AT

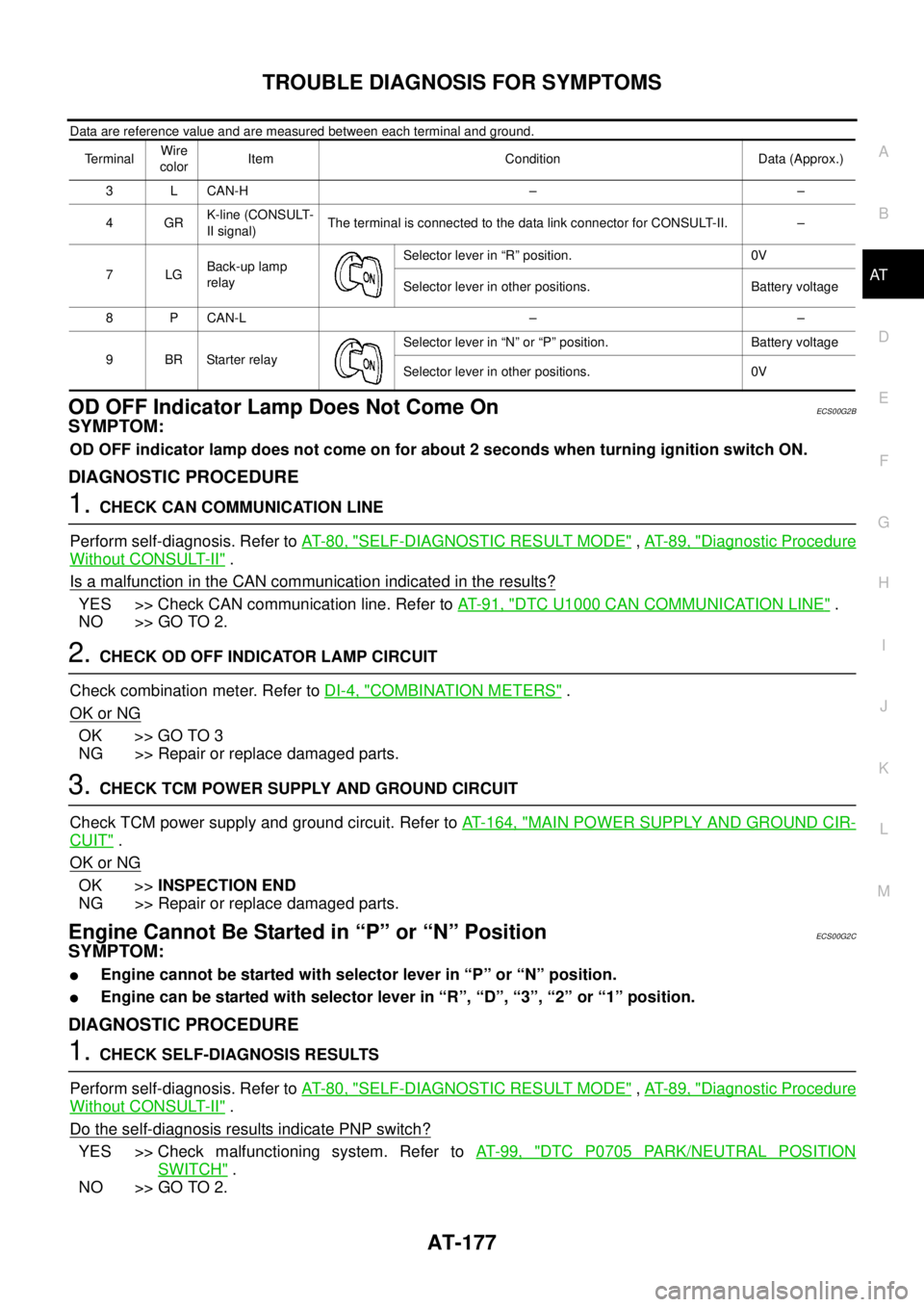

Data are reference value and are measured between each terminal and ground.

OD OFF Indicator Lamp Does Not Come OnECS00G2B

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OD OFF INDICATOR LAMP CIRCUIT

Check combination meter. Refer toDI-4, "

COMBINATION METERS".

OK or NG

OK >> GO TO 3

NG >> Repair or replace damaged parts.

3.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in “P” or “N” PositionECS00G2C

SYMPTOM:

lEngine cannot be started with selector lever in “P” or “N” position.

lEngine can be started with selector lever in “R”, “D”, “3”, “2” or “1” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Do the self-diagnosis results indicate PNP switch?

YES >> Check malfunctioning system. Refer toAT-99, "DTC P0705 PARK/NEUTRAL POSITION

SWITCH".

NO >> GO TO 2.

TerminalWire

colorItem Condition Data (Approx.)

3 L CAN-H – –

4GRK-line (CONSULT-

II signal)The terminal is connected to the data link connector for CONSULT-II. –

7LGBack-up lamp

relaySelector lever in “R” position. 0V

Selector lever in other positions. Battery voltage

8 P CAN-L – –

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Page 544 of 3171

AV-56

DIAGNOSIS SYSTEM

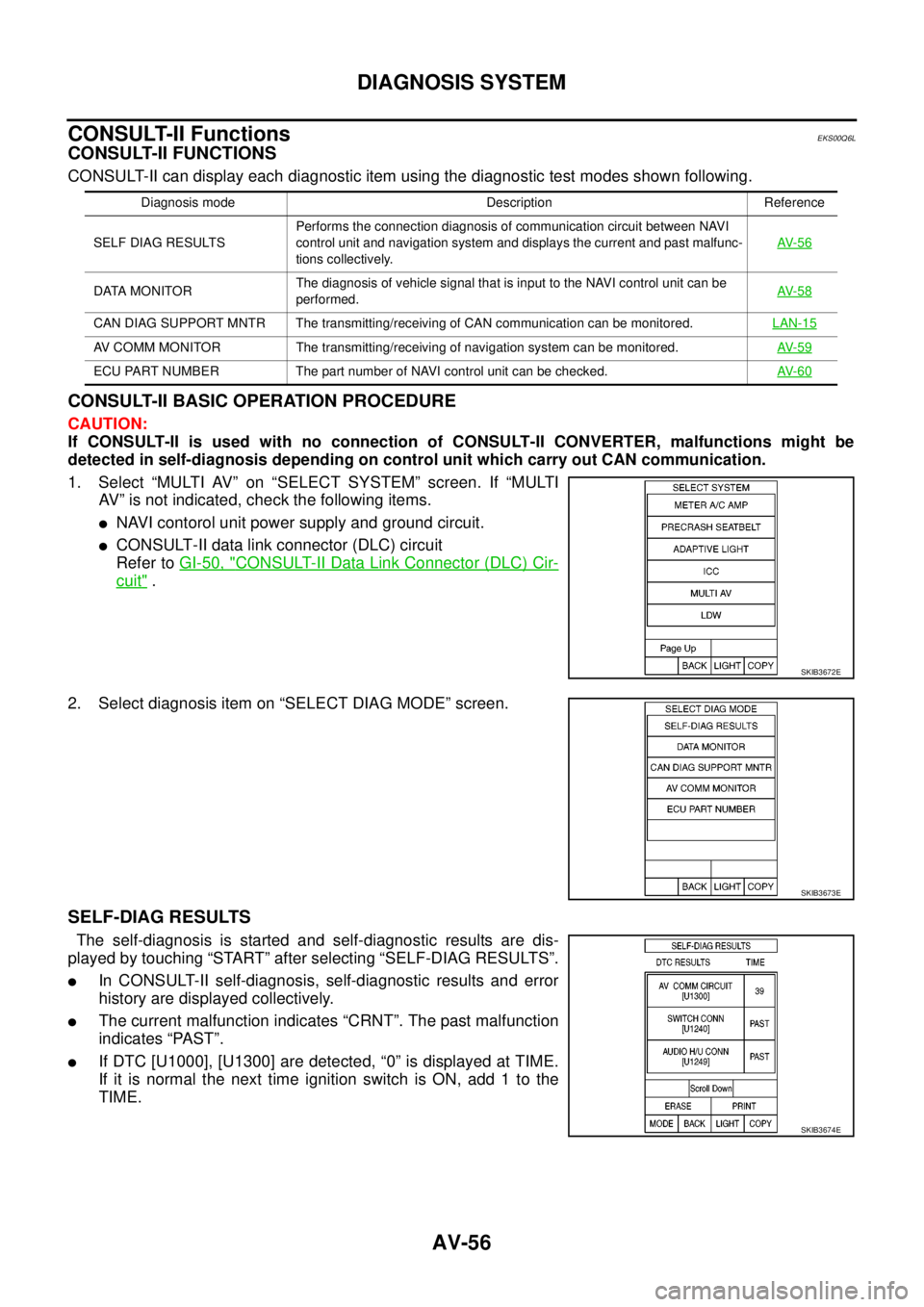

CONSULT-II Functions

EKS00Q6L

CONSULT-II FUNCTIONS

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Select “MULTI AV” on “SELECT SYSTEM” screen. If “MULTI

AV” is not indicated, check the following items.

lNAVI contorol unit power supply and ground circuit.

lCONSULT-II data link connector (DLC) circuit

Refer toGI-50, "

CONSULT-II Data Link Connector (DLC) Cir-

cuit".

2. Select diagnosis item on “SELECT DIAG MODE” screen.

SELF-DIAG RESULTS

The self-diagnosis is started and self-diagnostic results are dis-

played by touching “START” after selecting “SELF-DIAG RESULTS”.

lIn CONSULT-II self-diagnosis, self-diagnostic results and error

history are displayed collectively.

lThe current malfunction indicates “CRNT”. The past malfunction

indicates “PAST”.

lIf DTC [U1000], [U1300] are detected, “0” is displayed at TIME.

If it is normal the next time ignition switch is ON, add 1 to the

TIME.

Diagnosis mode Description Reference

SELF DIAG RESULTSPerforms the connection diagnosis of communication circuit between NAVI

control unit and navigation system and displays the current and past malfunc-

tions collectively.AV- 5 6

DATA MONITORThe diagnosis of vehicle signal that is input to the NAVI control unit can be

performed.AV- 5 8

CAN DIAG SUPPORT MNTR The transmitting/receiving of CAN communication can be monitored.LAN-15

AV COMM MONITOR The transmitting/receiving of navigation system can be monitored.AV- 5 9

ECU PART NUMBER The part number of NAVI control unit can be checked.AV- 6 0

SKIB3672E

SKIB3673E

SKIB3674E