heater NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 337 of 3171

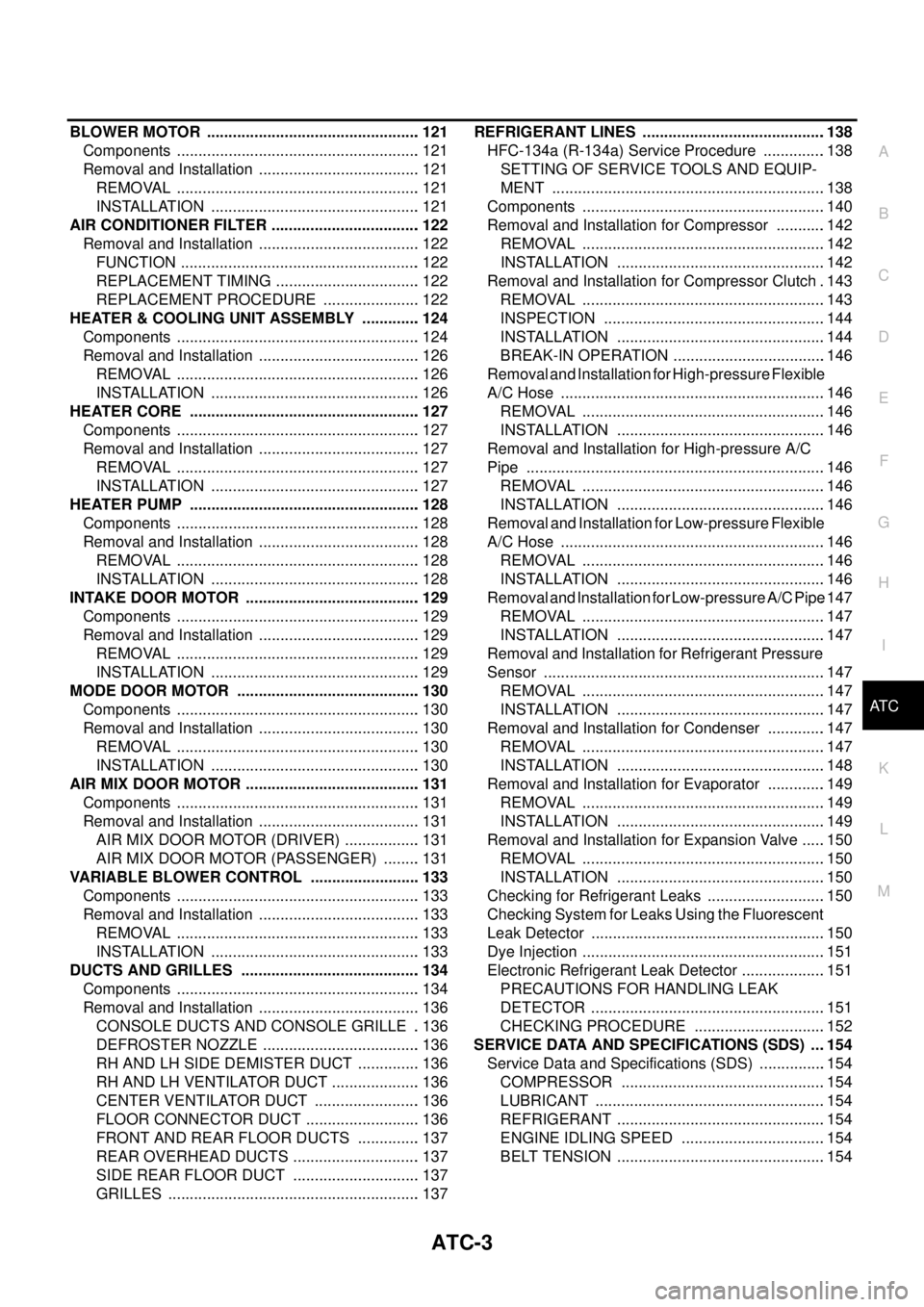

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C BLOWER MOTOR .................................................. 121

Components ......................................................... 121

Removal and Installation ...................................... 121

REMOVAL ......................................................... 121

INSTALLATION ................................................. 121

AIR CONDITIONER FILTER ................................... 122

Removal and Installation ...................................... 122

FUNCTION ........................................................ 122

REPLACEMENT TIMING .................................. 122

REPLACEMENT PROCEDURE ....................... 122

HEATER & COOLING UNIT ASSEMBLY .............. 124

Components ......................................................... 124

Removal and Installation ...................................... 126

REMOVAL ......................................................... 126

INSTALLATION ................................................. 126

HEATER CORE ...................................................... 127

Components ......................................................... 127

Removal and Installation ...................................... 127

REMOVAL ......................................................... 127

INSTALLATION ................................................. 127

HEATER PUMP ...................................................... 128

Components ......................................................... 128

Removal and Installation ...................................... 128

REMOVAL ......................................................... 128

INSTALLATION ................................................. 128

INTAKE DOOR MOTOR ......................................... 129

Components ......................................................... 129

Removal and Installation ...................................... 129

REMOVAL ......................................................... 129

INSTALLATION ................................................. 129

MODE DOOR MOTOR ........................................... 130

Components ......................................................... 130

Removal and Installation ...................................... 130

REMOVAL ......................................................... 130

INSTALLATION ................................................. 130

AIR MIX DOOR MOTOR ......................................... 131

Components ......................................................... 131

Removal and Installation ...................................... 131

AIR MIX DOOR MOTOR (DRIVER) .................. 131

AIR MIX DOOR MOTOR (PASSENGER) ......... 131

VARIABLE BLOWER CONTROL .......................... 133

Components ......................................................... 133

Removal and Installation ...................................... 133

REMOVAL ......................................................... 133

INSTALLATION ................................................. 133

DUCTS AND GRILLES .......................................... 134

Components ......................................................... 134

Removal and Installation ...................................... 136

CONSOLE DUCTS AND CONSOLE GRILLE .. 136

DEFROSTER NOZZLE ..................................... 136

RH AND LH SIDE DEMISTER DUCT ............... 136

RH AND LH VENTILATOR DUCT ..................... 136

CENTER VENTILATOR DUCT ......................... 136

FLOOR CONNECTOR DUCT ........................... 136

FRONT AND REAR FLOOR DUCTS ............... 137

REAR OVERHEAD DUCTS .............................. 137

SIDE REAR FLOOR DUCT .............................. 137

GRILLES ........................................................... 137REFRIGERANT LINES ...........................................138

HFC-134a (R-134a) Service Procedure ...............138

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................138

Components .........................................................140

Removal and Installation for Compressor ............142

REMOVAL .........................................................142

INSTALLATION .................................................142

Removal and Installation for Compressor Clutch . 143

REMOVAL .........................................................143

INSPECTION ....................................................144

INSTALLATION .................................................144

BREAK-IN OPERATION ....................................146

Removal and Installation for High-pressure Flexible

A/C Hose ..............................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for High-pressure A/C

Pipe ......................................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for Low-pressure Flexible

A/C Hose ..............................................................146

REMOVAL .........................................................146

INSTALLATION .................................................146

Removal and Installation for Low-pressure A/C Pipe.147

REMOVAL .........................................................147

INSTALLATION .................................................147

Removal and Installation for Refrigerant Pressure

Sensor ..................................................................147

REMOVAL .........................................................147

INSTALLATION .................................................147

Removal and Installation for Condenser ..............147

REMOVAL .........................................................147

INSTALLATION .................................................148

Removal and Installation for Evaporator ..............149

REMOVAL .........................................................149

INSTALLATION .................................................149

Removal and Installation for Expansion Valve ......150

REMOVAL .........................................................150

INSTALLATION .................................................150

Checking for Refrigerant Leaks ............................150

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................150

Dye Injection .........................................................151

Electronic Refrigerant Leak Detector ....................151

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................151

CHECKING PROCEDURE ...............................152

SERVICE DATA AND SPECIFICATIONS (SDS) ....154

Service Data and Specifications (SDS) ................154

COMPRESSOR ................................................154

LUBRICANT ......................................................154

REFRIGERANT .................................................154

ENGINE IDLING SPEED ..................................154

BELT TENSION .................................................154

Page 357 of 3171

REFRIGERATION SYSTEM

ATC-23

C

D

E

F

G

H

I

K

L

MA

B

AT C

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilation duct

7. Heater and cooling unit assembly 8. Floor connector duct grilles 9. Floor connector duct

10. Front floor duct 11. Rear floor duct

Page 387 of 3171

TROUBLE DIAGNOSIS

ATC-53

C

D

E

F

G

H

I

K

L

MA

B

AT C

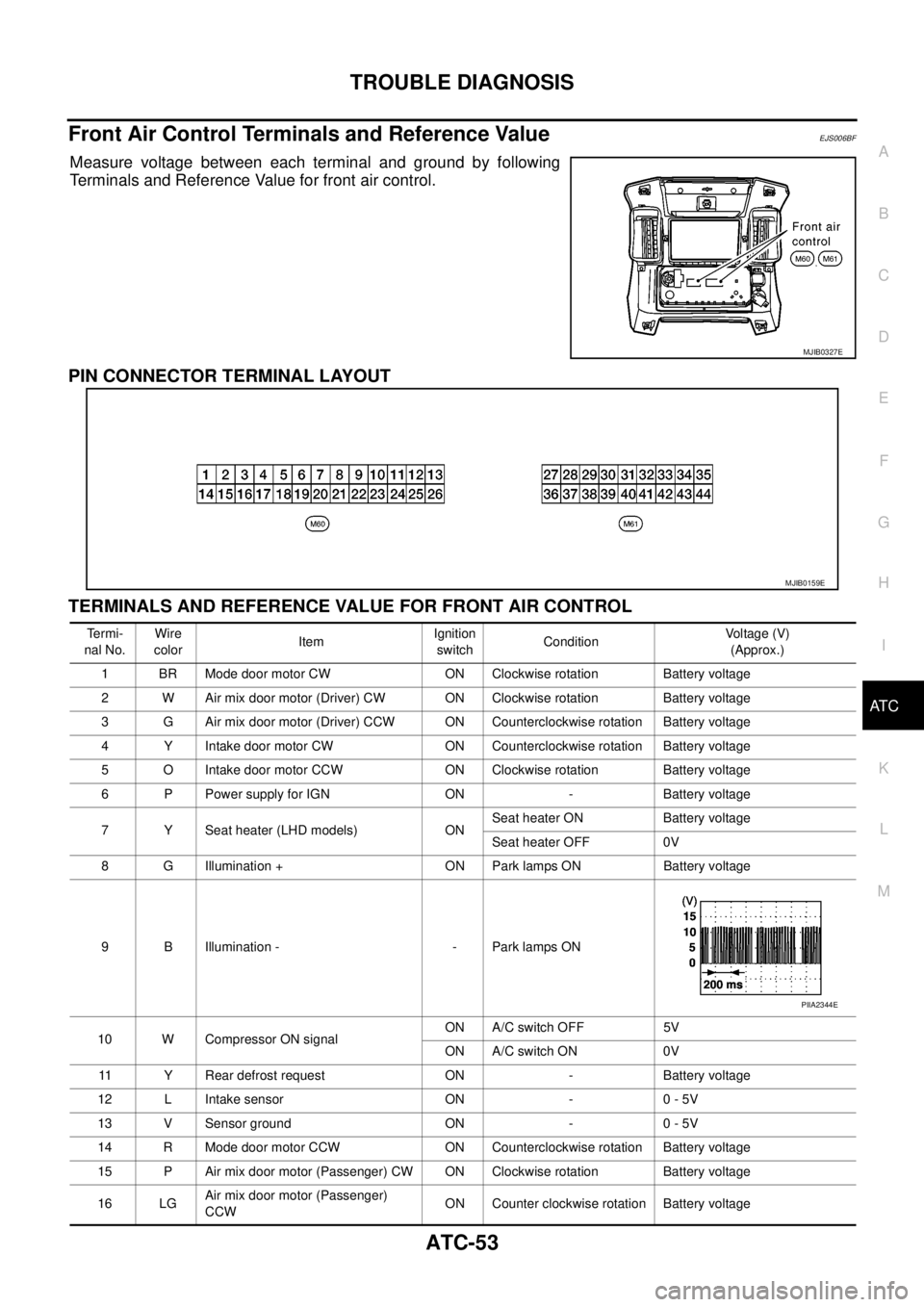

Front Air Control Terminals and Reference ValueEJS006BF

Measure voltage between each terminal and ground by following

Terminals and Reference Value for front air control.

PIN CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR FRONT AIR CONTROL

MJIB0327E

MJIB0159E

Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVo l ta g e (V )

(Approx.)

1 BR Mode door motor CW ON Clockwise rotation Battery voltage

2 W Air mix door motor (Driver) CW ON Clockwise rotation Battery voltage

3 G Air mix door motor (Driver) CCW ON Counterclockwise rotation Battery voltage

4 Y Intake door motor CW ON Counterclockwise rotation Battery voltage

5 O Intake door motor CCW ON Clockwise rotation Battery voltage

6 P Power supply for IGN ON - Battery voltage

7 Y Seat heater (LHD models) ONSeat heater ON Battery voltage

Seat heater OFF 0V

8 G Illumination + ON Park lamps ON Battery voltage

9 B Illumination - - Park lamps ON

10 W Compressor ON signalON A/C switch OFF 5V

ON A/C switch ON 0V

11 Y Rear defrost request ON - Battery voltage

12 L Intake sensor ON - 0 - 5V

13 V Sensor ground ON - 0 - 5V

14 R Mode door motor CCW ON Counterclockwise rotation Battery voltage

15 P Air mix door motor (Passenger) CW ON Clockwise rotation Battery voltage

16 LGAir mix door motor (Passenger)

CCWON Counter clockwise rotation Battery voltage

PIIA2344E

Page 388 of 3171

ATC-54

TROUBLE DIAGNOSIS

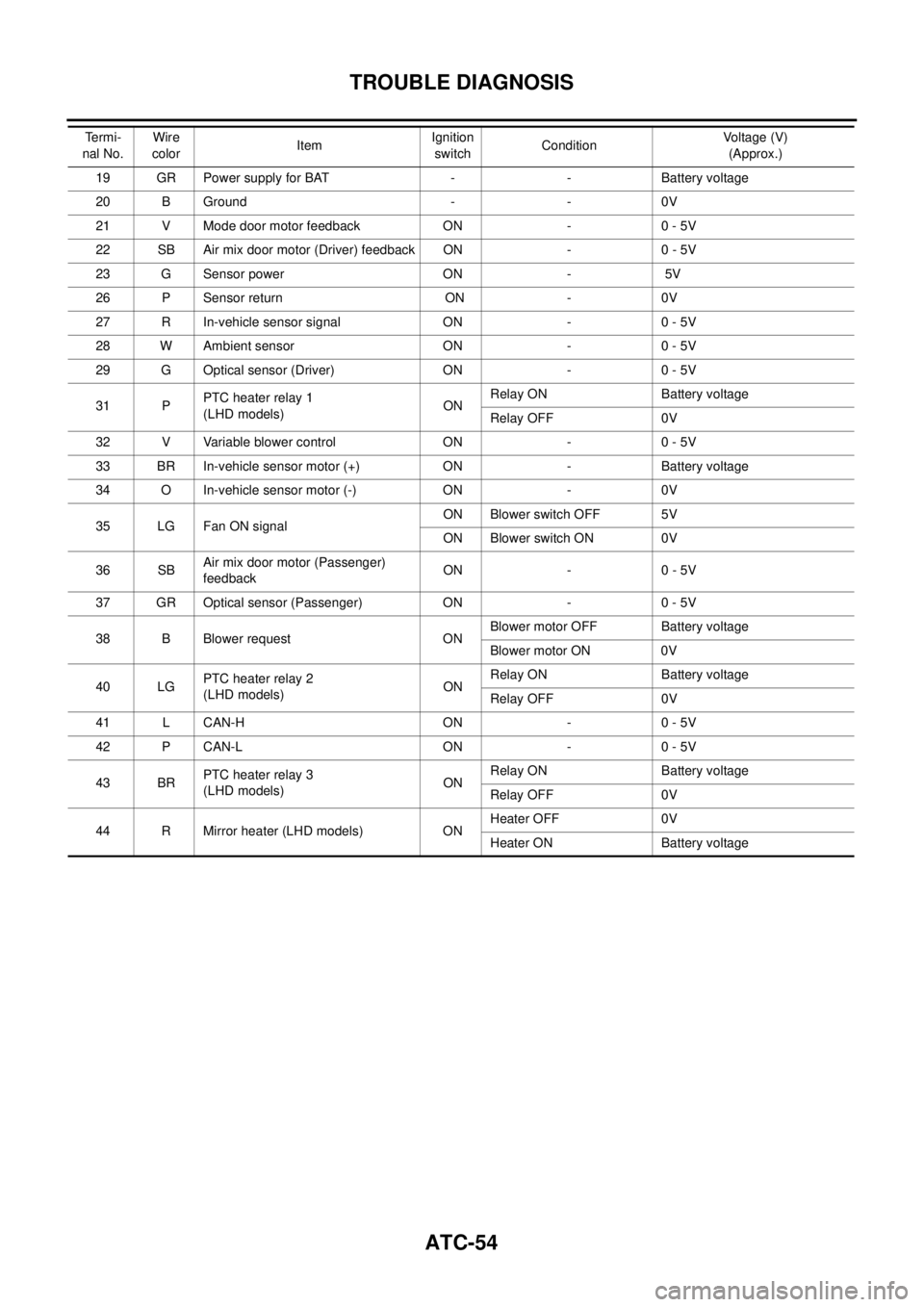

19 GR Power supply for BAT - - Battery voltage

20 B Ground - - 0V

21 V Mode door motor feedback ON - 0 - 5V

22 SB Air mix door motor (Driver) feedback ON - 0 - 5V

23 G Sensor power ON - 5V

26 P Sensor return ON - 0V

27 R In-vehicle sensor signal ON - 0 - 5V

28 W Ambient sensor ON - 0 - 5V

29 G Optical sensor (Driver) ON - 0 - 5V

31 PPTC heater relay 1

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

32 V Variable blower control ON - 0 - 5V

33 BR In-vehicle sensor motor (+) ON - Battery voltage

34 O In-vehicle sensor motor (-) ON - 0V

35 LG Fan ON signalON Blower switch OFF 5V

ON Blower switch ON 0V

36 SBAir mix door motor (Passenger)

feedbackON - 0 - 5V

37 GR Optical sensor (Passenger) ON - 0 - 5V

38 B Blower request ONBlower motor OFF Battery voltage

Blower motor ON 0V

40 LGPTC heater relay 2

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

41 L CAN-H ON - 0 - 5V

42 P CAN-L ON - 0 - 5V

43 BRPTC heater relay 3

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

44 R Mirror heater (LHD models) ONHeater OFF 0V

Heater ON Battery voltage Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

Page 399 of 3171

TROUBLE DIAGNOSIS

ATC-65

C

D

E

F

G

H

I

K

L

MA

B

AT C

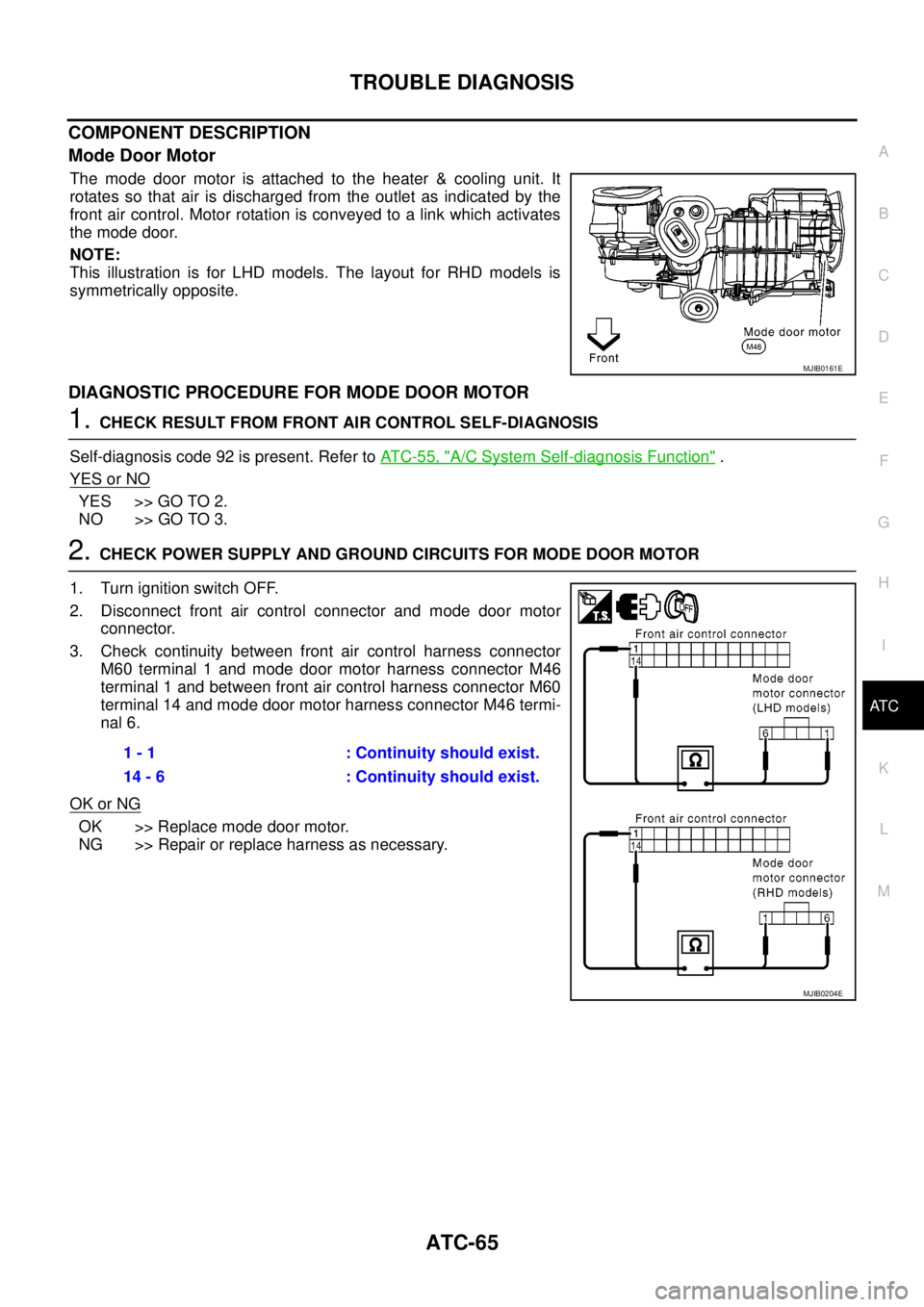

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet as indicated by the

front air control. Motor rotation is conveyed to a link which activates

themodedoor.

NOTE:

This illustration is for LHD models. The layout for RHD models is

symmetrically opposite.

DIAGNOSTIC PROCEDURE FOR MODE DOOR MOTOR

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 92 is present. Refer toAT C - 5 5 , "

A/C System Self-diagnosis Function".

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK POWER SUPPLY AND GROUND CIRCUITS FOR MODE DOOR MOTOR

1. Turn ignition switch OFF.

2. Disconnect front air control connector and mode door motor

connector.

3. Check continuity between front air control harness connector

M60 terminal 1 and mode door motor harness connector M46

terminal 1 and between front air control harness connector M60

terminal 14 and mode door motor harness connector M46 termi-

nal 6.

OK or NG

OK >> Replace mode door motor.

NG >> Repair or replace harness as necessary.

MJIB0161E

1 - 1 : Continuity should exist.

14 - 6 : Continuity should exist.

MJIB0204E

Page 404 of 3171

ATC-70

TROUBLE DIAGNOSIS

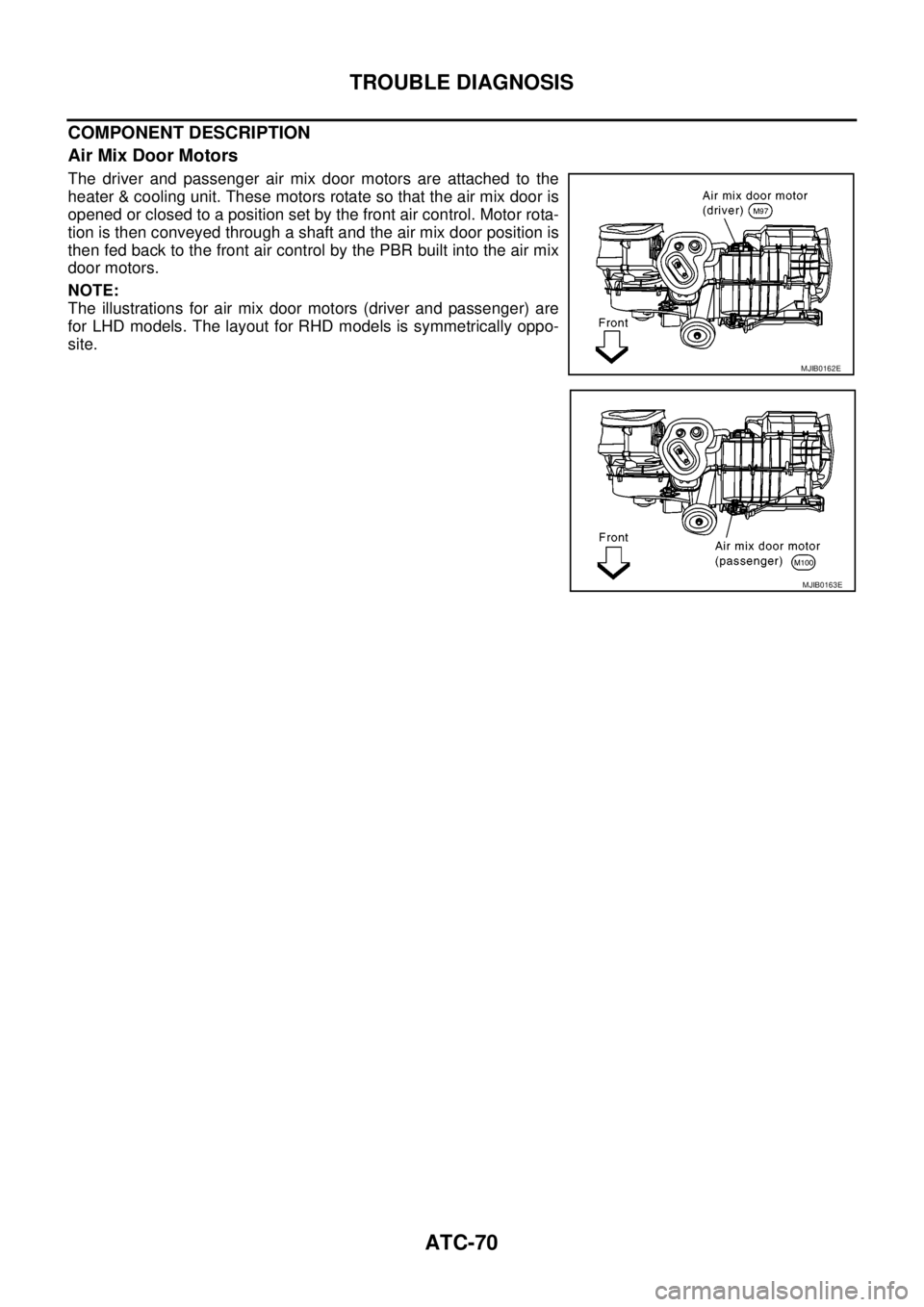

COMPONENT DESCRIPTION

Air Mix Door Motors

The driver and passenger air mix door motors are attached to the

heater & cooling unit. These motors rotate so that the air mix door is

opened or closed to a position set by the front air control. Motor rota-

tion is then conveyed through a shaft and the air mix door position is

then fed back to the front air control by the PBR built into the air mix

door motors.

NOTE:

The illustrations for air mix door motors (driver and passenger) are

for LHD models. The layout for RHD models is symmetrically oppo-

site.

MJIB0162E

MJIB0163E

Page 448 of 3171

ATC-114

TROUBLE DIAGNOSIS

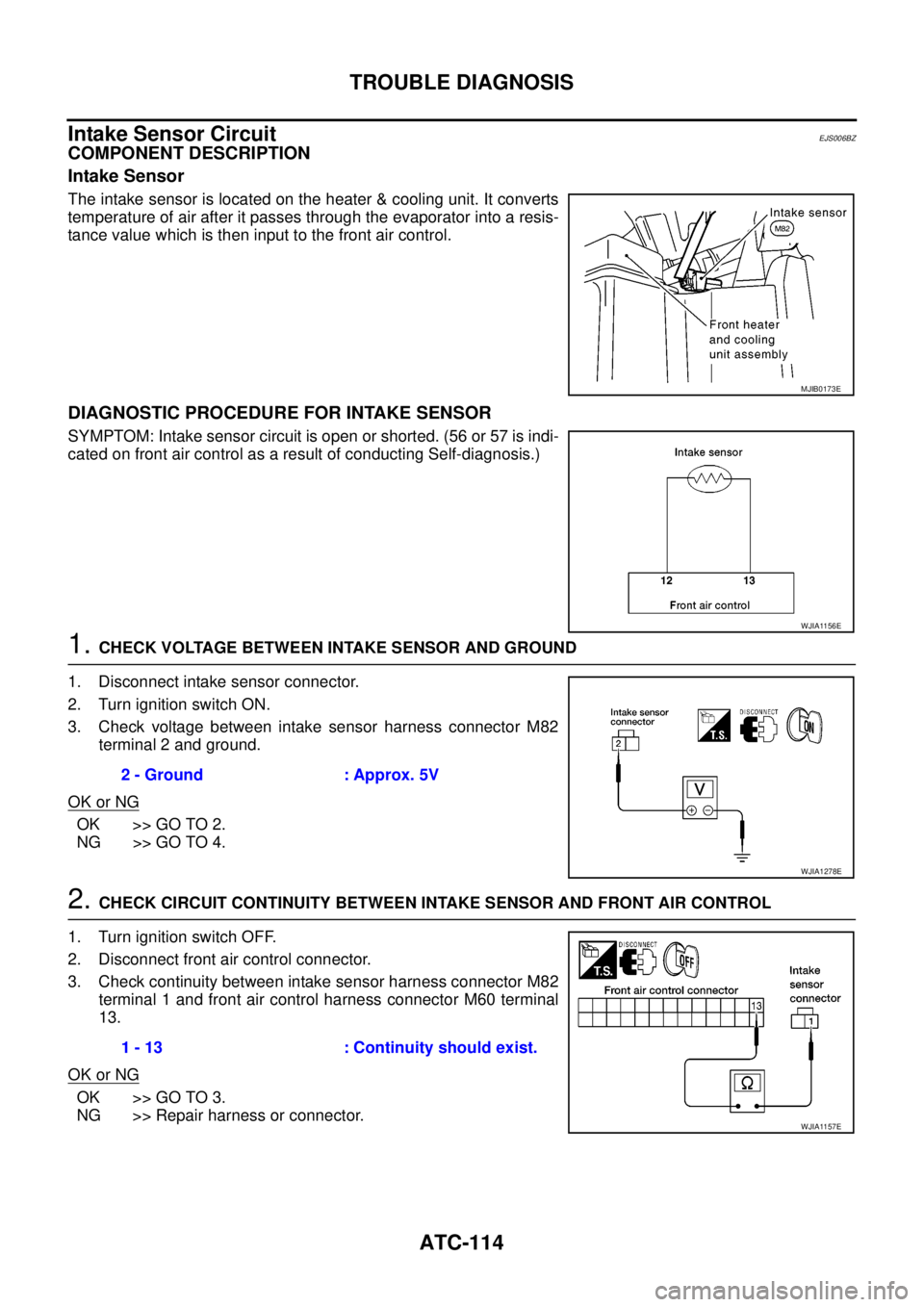

Intake Sensor Circuit

EJS006BZ

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (56 or 57 is indi-

cated on front air control as a result of conducting Self-diagnosis.)

1.CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M82

terminal 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check continuity between intake sensor harness connector M82

terminal 1 and front air control harness connector M60 terminal

13.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

MJIB0173E

WJIA1156E

2 - Ground : Approx. 5V

WJIA1278E

1 - 13 : Continuity should exist.

WJIA1157E

Page 454 of 3171

ATC-120

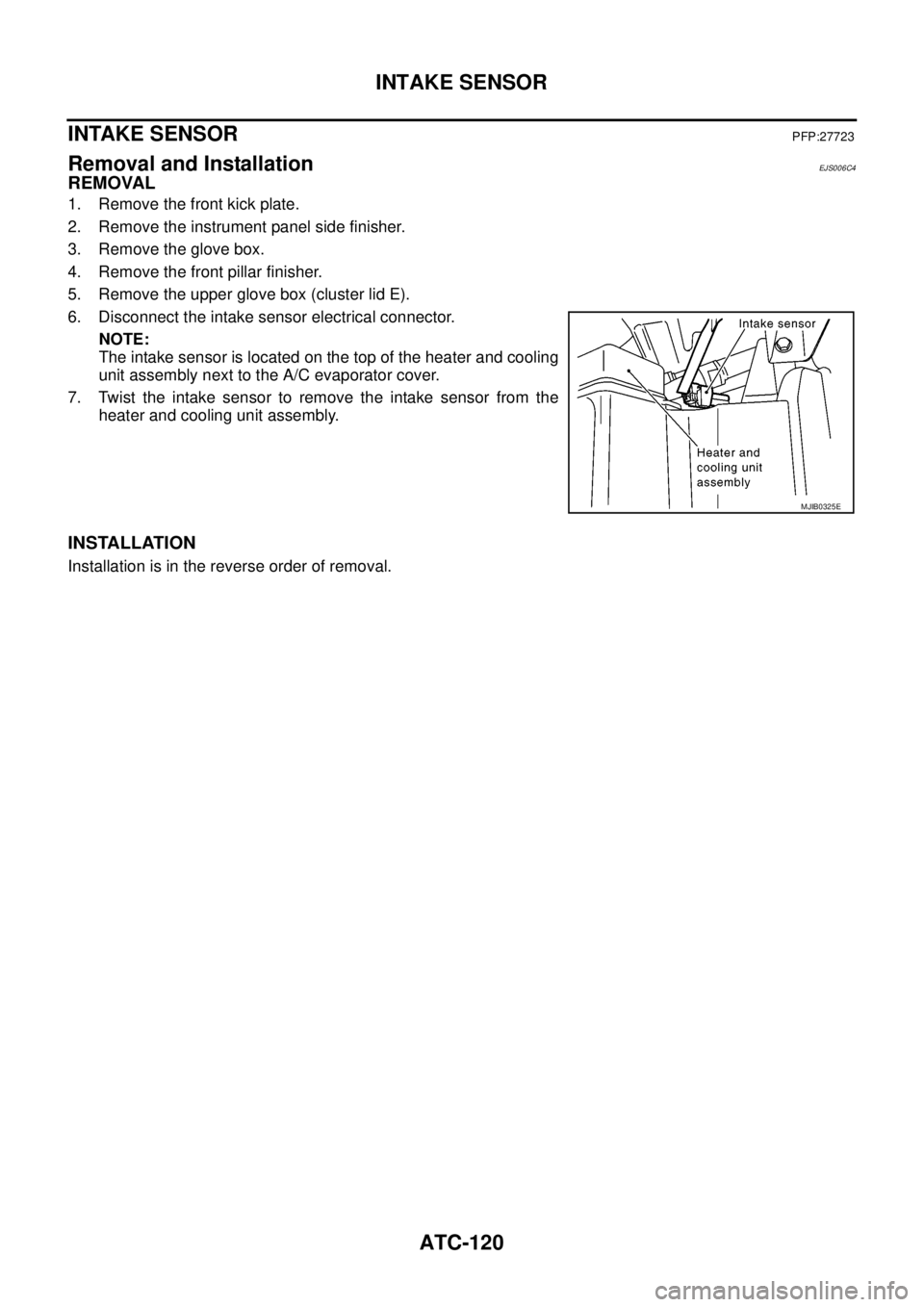

INTAKE SENSOR

INTAKE SENSOR

PFP:27723

Removal and InstallationEJS006C4

REMOVAL

1. Remove the front kick plate.

2. Remove the instrument panel side finisher.

3. Remove the glove box.

4. Remove the front pillar finisher.

5. Remove the upper glove box (cluster lid E).

6. Disconnect the intake sensor electrical connector.

NOTE:

The intake sensor is located on the top of the heater and cooling

unit assembly next to the A/C evaporator cover.

7. Twist the intake sensor to remove the intake sensor from the

heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

MJIB0325E

Page 455 of 3171

BLOWER MOTOR

ATC-121

C

D

E

F

G

H

I

K

L

MA

B

AT C

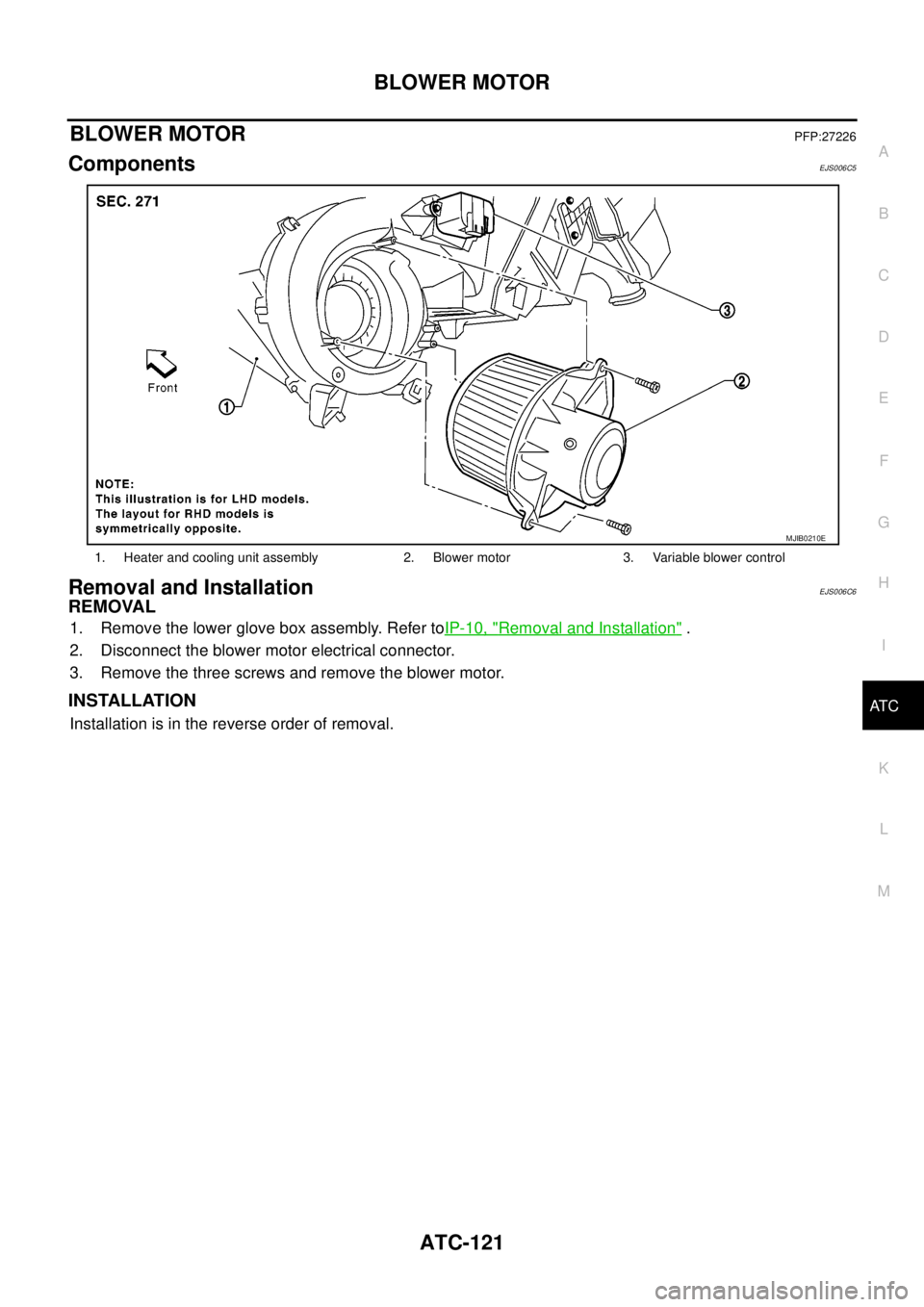

BLOWER MOTORPFP:27226

ComponentsEJS006C5

Removal and InstallationEJS006C6

REMOVAL

1. Remove the lower glove box assembly. Refer toIP-10, "Removal and Installation".

2. Disconnect the blower motor electrical connector.

3. Remove the three screws and remove the blower motor.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater and cooling unit assembly 2. Blower motor 3. Variable blower control

MJIB0210E

Page 456 of 3171

ATC-122

AIR CONDITIONER FILTER

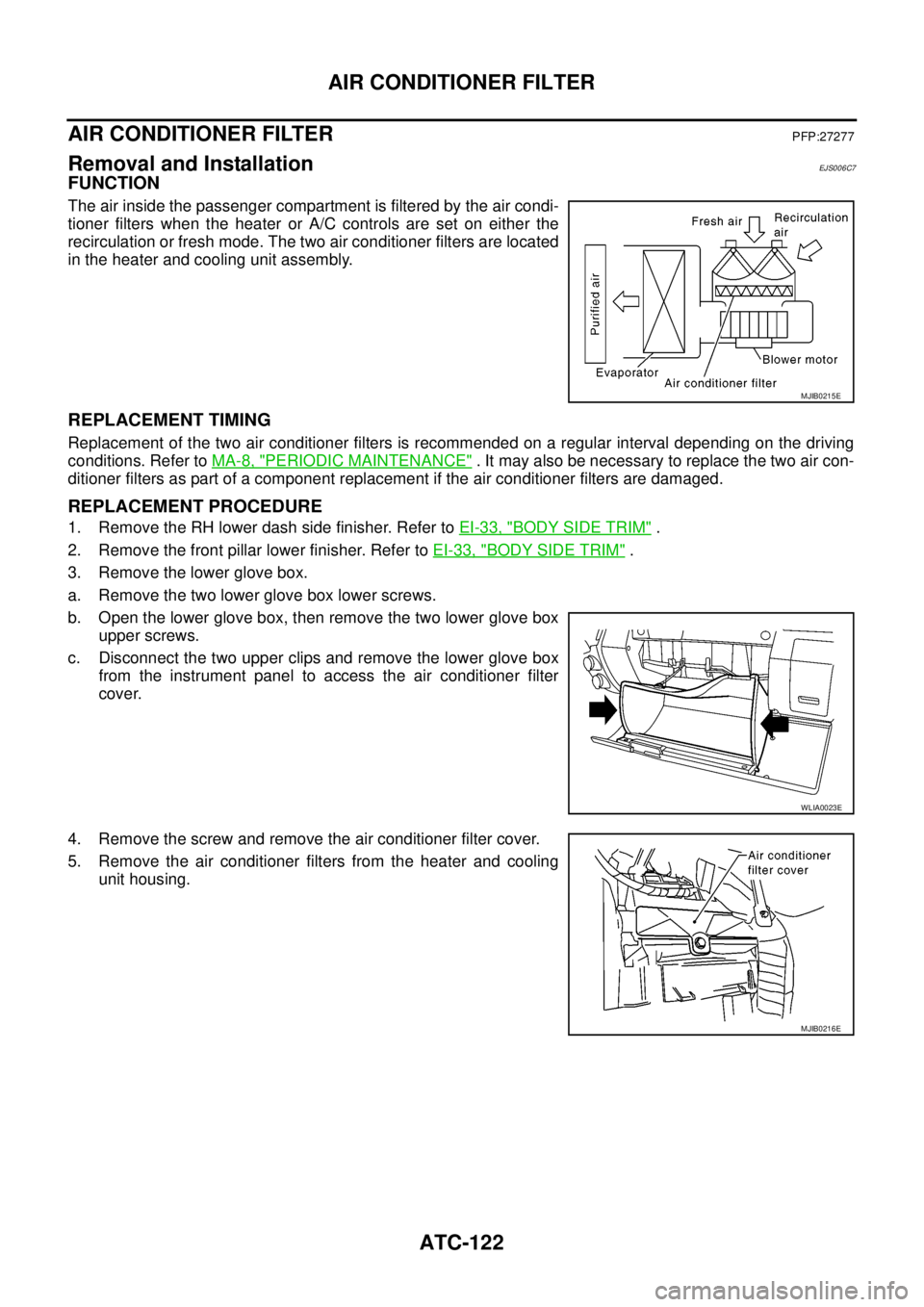

AIR CONDITIONER FILTER

PFP:27277

Removal and InstallationEJS006C7

FUNCTION

The air inside the passenger compartment is filtered by the air condi-

tioner filters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two air conditioner filters are located

in the heater and cooling unit assembly.

REPLACEMENT TIMING

Replacement of the two air conditioner filters is recommended on a regular interval depending on the driving

conditions. Refer toMA-8, "

PERIODIC MAINTENANCE". It may also be necessary to replace the two air con-

ditioner filters as part of a component replacement if the air conditioner filters are damaged.

REPLACEMENT PROCEDURE

1. Remove the RH lower dash side finisher. Refer toEI-33, "BODY SIDE TRIM".

2. Remove the front pillar lower finisher. Refer toEI-33, "

BODY SIDE TRIM".

3. Remove the lower glove box.

a. Remove the two lower glove box lower screws.

b. Open the lower glove box, then remove the two lower glove box

upper screws.

c. Disconnect the two upper clips and remove the lower glove box

from the instrument panel to access the air conditioner filter

cover.

4. Remove the screw and remove the air conditioner filter cover.

5. Remove the air conditioner filters from the heater and cooling

unit housing.

MJIB0215E

WLIA0023E

MJIB0216E