battery replacement NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2086 of 3171

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT Combination Switch Reading Function ................. 115

CONSULT-II Function (BCM) ................................ 115

CONSULT-II OPERATION ................................. 115

DATA MONITOR ................................................ 116

Combination Switch Inspection ............................. 118

Removal and Installation ...................................... 120

Switch Circuit Inspection ...................................... 120

STOP LAMP ........................................................... 121

Wiring Diagram — STOP/L — .............................. 121

Bulb Replacement ................................................ 122

Removal and Installation ...................................... 122

BACK-UP LAMP .................................................... 123

Wiring Diagram — BACK/L — ............................. 123

Bulb Replacement ................................................ 124

Removal and Installation ...................................... 124

PARKING, LICENSE PLATE AND TAIL LAMPS ... 125

Component Parts and Harness Connector Location. 125

System Description .............................................. 125

OUTLINE ........................................................... 125

OPERATION BY LIGHTING SWITCH .............. 126

COMBINATION SWITCH READING FUNCTION. 126

CAN Communication System Description ............ 126

Schematic ............................................................ 127

WITHOUT DAYTIME LIGHT SYSTEM ............. 127

Wiring Diagram — TAIL/L — ................................ 128

WITHOUT DAYTIME LIGHT SYSTEM ............. 128

Schematic ............................................................ 131

WITH DAYTIME LIGHT SYSTEM ..................... 131

Wiring Diagram — TAIL/L — ................................ 132

WITH DAYTIME LIGHT SYSTEM ..................... 132

Terminals and Reference Values for BCM ........... 135

Terminals and Reference Values for IPDM E/R ... 135

How to Proceed With Trouble Diagnosis .............. 136

Preliminary Check ................................................ 136

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................. 136

CONSULT-II Functions (BCM) ............................. 137

CONSULT-II Functions (IPDM E/R) ..................... 137

Clarence, License Plate and Tail Lamps Do Not Illu-

minate .................................................................. 138

Clearance, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) ................... 141

Front Clearance Lamp ......................................... 142BULB REPLACEMENT .....................................142

Tail Lamp ..............................................................142

BULB REPLACEMENT .....................................142

REAR COMBINATION LAMP .................................143

Bulb Replacement ................................................143

REMOVAL .........................................................143

INSTALLATION .................................................143

Removal and Installation ......................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

INTERIOR ROOM LAMP ........................................145

Component Parts and Harness Connector Location.145

System Description ...............................................145

POWER SUPPLY AND GROUND ....................145

SWITCH OPERATION ......................................147

ROOM LAMP TIMER OPERATION ..................147

INTERIOR LAMP BATTERY SAVER CONTROL.147

Schematic .............................................................148

Wiring Diagram — INT/L — ..................................149

Terminals and Reference Values for BCM ............154

How to Proceed With Trouble Diagnosis ..............155

Preliminary Check ................................................155

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ...........................................155

CONSULT-II Function ...........................................157

CONSULT-II OPERATION .................................157

WORK SUPPORT .............................................158

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................159

Map Lamp Control Does Not Operate ..................160

All Interior Room Lamps Do Not Operate .............161

ILLUMINATION .......................................................162

System Description ...............................................162

ILLUMINATION OPERATION BY LIGHTING

SWITCH ............................................................162

CAN Communication System Description ............163

CAN Communication Unit .....................................163

Schematic .............................................................164

Wiring Diagram — ILL — ......................................166

BULB SPECIFICATIONS ........................................173

Headlamp .............................................................173

Exterior Lamp .......................................................173

Interior Lamp/Illumination .....................................173

Page 2779 of 3171

![NISSAN NAVARA 2005 Repair User Guide RFD-76

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK CONTROL UNIT

DIFFERENTIAL LOCK CONTROL UNIT

PFP:28496

Removal and InstallationEDS003BC

REMOVAL

1. Turn the ignition switch OFF and disco NISSAN NAVARA 2005 Repair User Guide RFD-76

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK CONTROL UNIT

DIFFERENTIAL LOCK CONTROL UNIT

PFP:28496

Removal and InstallationEDS003BC

REMOVAL

1. Turn the ignition switch OFF and disco](/img/5/57362/w960_57362-2778.png)

RFD-76

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

DIFFERENTIAL LOCK CONTROL UNIT

DIFFERENTIAL LOCK CONTROL UNIT

PFP:28496

Removal and InstallationEDS003BC

REMOVAL

1. Turn the ignition switch OFF and disconnect the battery cables.

2. Remove the lower instrument panel LH (LHD models) or lower instrument panel RH (RHD models). Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH"(LHD models) orIP-13, "LOWER INSTRUMENT PANEL

LH"(RHD models).

3. Disconnect the differential lock control unit connector.

4. Remove the two bolts and remove the differential lock control

unit.

INSTALLATION

Installation is in the reverse order of removal.

lWhen installing differential lock control unit, tighten bolts to the specified torque.

lAfter the installation, check DIFF LOCK indicator lamp. Refer toRFD-33, "Precautions for Differential

Case Assembly and Differential Lock Control Unit Replacement".

WDIA0254E

Differential lock control unit bolts : 5.1 N·m (0.52 kg-m, 45 in-lb)

Page 2930 of 3171

![NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected](/img/5/57362/w960_57362-2929.png)

TROUBLE DIAGNOSIS

SRS-21

C

D

E

F

G

I

J

K

L

MA

B

SRS

7. Diagnostic code is displayed on "SELF-DIAG [CURRENT]".

If no malfunction is detected on "SELF-DIAG [CURRENT]" even

though malfunction is detected in "SRS Operation Check", refer to

SRS-26, "

DIAGNOSTIC PROCEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)", to diagnose the following cases:

lSelf-diagnostic result "SELF-DIAG [PAST]" (previously stored in

the memory) might not be erased after repair.

lThe SRS system malfunctions intermittently.

CONSULT-II Diagnostic Code Chart ("SELF-DIAG [CURRENT]")

WHIA0151E

SRS701

Diagnostic item ExplanationRepair order

Recheck SRS at each replacement

NO DTC IS DETECTEDWhen malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode.

lLow battery voltage (Less than

9V)lGo toSRS-24, "DIAGNOSTIC PRO-

CEDURE 3".

lSelf-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased

after repair.

lIntermittent malfunction has been

detected in the past.

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)".

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 5".

lNo malfunction is detected. —

DRIVER AIRBAG MODULE

[OPEN]

[B1049] or [B1054]

lDriver air bag module circuit is open (including the spiral

cable).1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the air bag diagnosis sen-

sor unit.

6. Replace the related harness. DRIVER AIRBAG MODULE

[VB-SHORT]

[B1050] or [B1055]

lDriver air bag module circuit is shorted to some power sup-

ply circuit (including the spiral cable).

DRIVER AIRBAG MODULE

[GND-SHORT]

[B1051] or [B1056]

lDriver air bag module circuit is shorted to ground (including

the spiral cable).

DRIVER AIRBAG MODULE

[SHORT]

[B1052] or [B1057]

lDriver air bag module circuits are shorted to each other.

Page 2937 of 3171

SRS-28

TROUBLE DIAGNOSIS

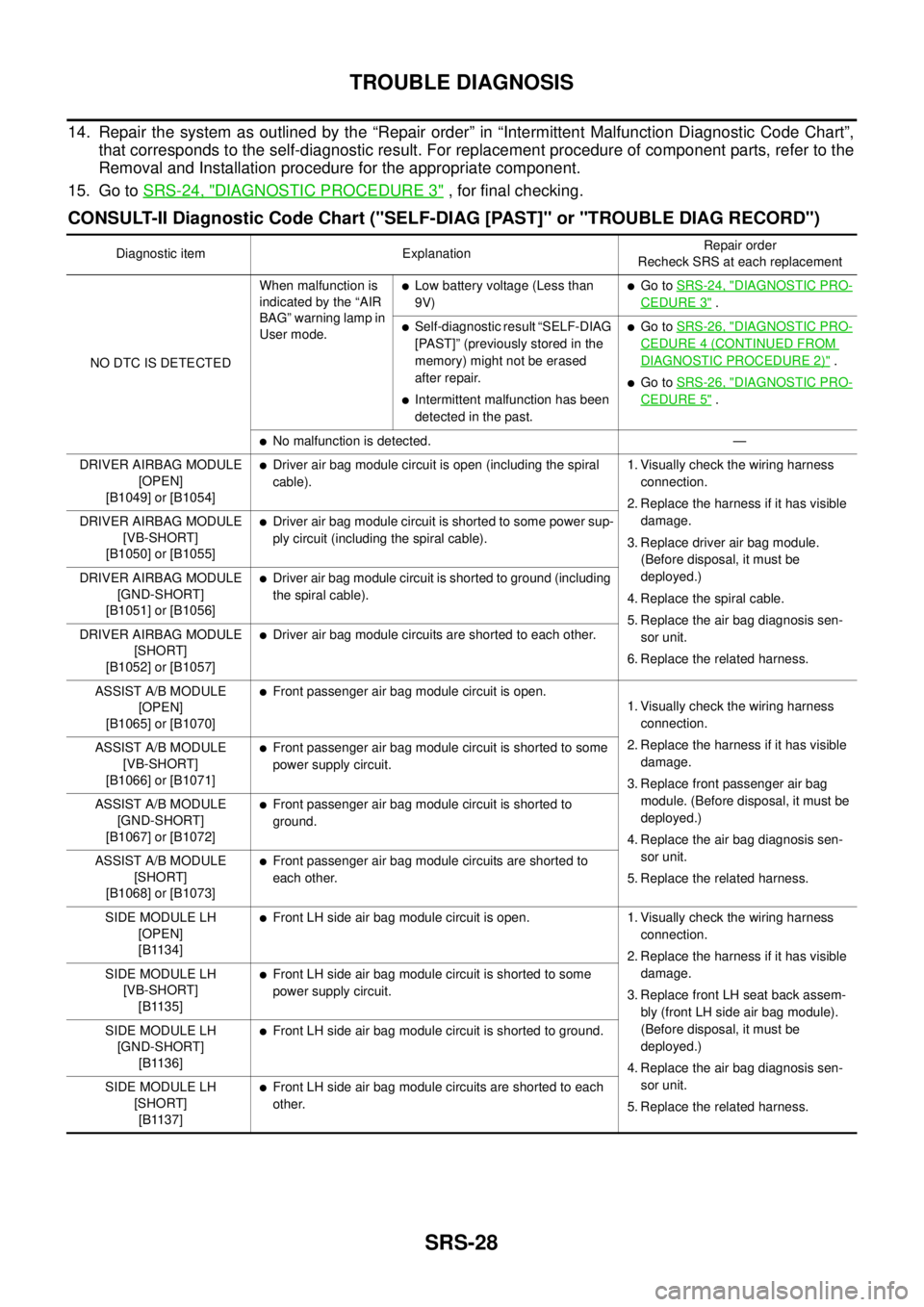

14. Repair the system as outlined by the “Repair order” in “Intermittent Malfunction Diagnostic Code Chart”,

that corresponds to the self-diagnostic result. For replacement procedure of component parts, refer to the

Removal and Installation procedure for the appropriate component.

15. Go toSRS-24, "

DIAGNOSTIC PROCEDURE 3", for final checking.

CONSULT-II Diagnostic Code Chart ("SELF-DIAG [PAST]" or "TROUBLE DIAG RECORD")

Diagnostic item ExplanationRepair order

Recheck SRS at each replacement

NO DTC IS DETECTEDWhen malfunction is

indicated by the “AIR

BAG” warning lamp in

User mode.

lLow battery voltage (Less than

9V)lGo toSRS-24, "DIAGNOSTIC PRO-

CEDURE 3".

lSelf-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased

after repair.

lIntermittent malfunction has been

detected in the past.

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 4 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 2)".

lGo toSRS-26, "DIAGNOSTIC PRO-

CEDURE 5".

lNo malfunction is detected. —

DRIVER AIRBAG MODULE

[OPEN]

[B1049] or [B1054]

lDriver air bag module circuit is open (including the spiral

cable).1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver air bag module.

(Before disposal, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the air bag diagnosis sen-

sor unit.

6. Replace the related harness. DRIVER AIRBAG MODULE

[VB-SHORT]

[B1050] or [B1055]

lDriver air bag module circuit is shorted to some power sup-

ply circuit (including the spiral cable).

DRIVER AIRBAG MODULE

[GND-SHORT]

[B1051] or [B1056]

lDriver air bag module circuit is shorted to ground (including

the spiral cable).

DRIVER AIRBAG MODULE

[SHORT]

[B1052] or [B1057]

lDriver air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[OPEN]

[B1065] or [B1070]

lFront passenger air bag module circuit is open.

1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front passenger air bag

module. (Before disposal, it must be

deployed.)

4. Replace the air bag diagnosis sen-

sor unit.

5. Replace the related harness. ASSIST A/B MODULE

[VB-SHORT]

[B1066] or [B1071]

lFront passenger air bag module circuit is shorted to some

power supply circuit.

ASSIST A/B MODULE

[GND-SHORT]

[B1067] or [B1072]

lFront passenger air bag module circuit is shorted to

ground.

ASSIST A/B MODULE

[SHORT]

[B1068] or [B1073]

lFront passenger air bag module circuits are shorted to

each other.

SIDE MODULE LH

[OPEN]

[B1134]

lFront LH side air bag module circuit is open. 1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace front LH seat back assem-

bly (front LH side air bag module).

(Before disposal, it must be

deployed.)

4. Replace the air bag diagnosis sen-

sor unit.

5. Replace the related harness. SIDE MODULE LH

[VB-SHORT]

[B1135]

lFront LH side air bag module circuit is shorted to some

power supply circuit.

SIDE MODULE LH

[GND-SHORT]

[B1136]

lFront LH side air bag module circuit is shorted to ground.

SIDE MODULE LH

[SHORT]

[B1137]

lFront LH side air bag module circuits are shorted to each

other.

Page 2949 of 3171

SRS-40

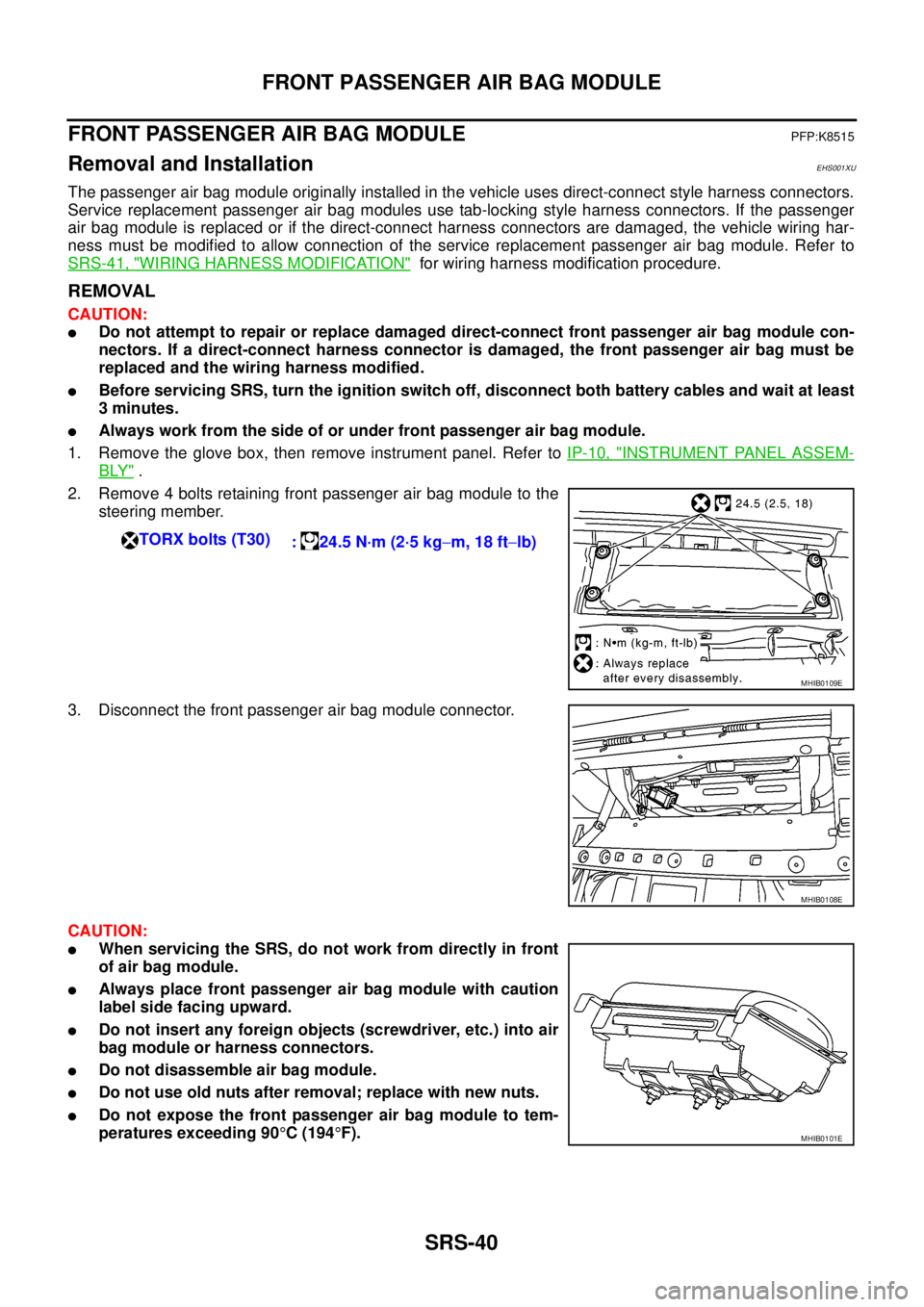

FRONT PASSENGER AIR BAG MODULE

FRONT PASSENGER AIR BAG MODULE

PFP:K8515

Removal and InstallationEHS001XU

The passenger air bag module originally installed in the vehicle uses direct-connect style harness connectors.

Service replacement passenger air bag modules use tab-locking style harness connectors. If the passenger

air bag module is replaced or if the direct-connect harness connectors are damaged, the vehicle wiring har-

ness must be modified to allow connection of the service replacement passenger air bag module. Refer to

SRS-41, "

WIRING HARNESS MODIFICATION"for wiring harness modification procedure.

REMOVAL

CAUTION:

lDo not attempt to repair or replace damaged direct-connect front passenger air bag module con-

nectors. If a direct-connect harness connector is damaged, the front passenger air bag must be

replaced and the wiring harness modified.

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

lAlways work from the side of or under front passenger air bag module.

1. Remove the glove box, then remove instrument panel. Refer toIP-10, "

INSTRUMENT PANEL ASSEM-

BLY".

2. Remove 4 bolts retaining front passenger air bag module to the

steering member.

3. Disconnect the front passenger air bag module connector.

CAUTION:

lWhen servicing the SRS, do not work from directly in front

of air bag module.

lAlways place front passenger air bag module with caution

label side facing upward.

lDo not insert any foreign objects (screwdriver, etc.) into air

bag module or harness connectors.

lDo not disassemble air bag module.

lDo not use old nuts after removal; replace with new nuts.

lDo not expose the front passenger air bag module to tem-

peratures exceeding 90°C(194°F). TORX bolts (T30)

: 24.5 N·m (2·5 kg-m, 18 ft-lb)

MHIB0109E

MHIB0108E

MHIB0101E

Page 2951 of 3171

SRS-42

FRONT PASSENGER AIR BAG MODULE

lBefore servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least

3 minutes.

lAlways work from the side of or under front passenger air bag module.

lAfter the work is completed, perform self-diagnosis to check that no malfunction is detected.

Refer toSRS-18, "

SRS Operation Check".

1. Locate the yellow and orange direct-connect passenger air bag module harness connectors.

2. Use wire cutters to cut back both previously used direct-connect passenger air bag module harness con-

nectors from the vehicle wiring harness approximately 50 mm (1.9 in) from the connectors.

3. Remove approximately 150 mm (5.9 in) of the vehicle harness covering from the cut end.

4. Slide a piece of dual-wall heat shrink tubing (provided in the pas-

senger air bag service kit) onto each wire of the previously used

vehicle wiring harness.

5. Fold each wire back and insert into the end of the heat shrink

tubing so that the end of the wire is approximately centered in

the heat shrink tubing.

6. Use a heat gun to shrink the heat shrink tubing and seal the wire.

7. Use electrical tape to secure the modified circuits to the outside of the wiring harness.

8. Locate the front passenger air bag service replacement connec-

tor that is taped back to the main harness. Unwrap the tape to

access the yellow service replacement connector and remove

the dust cover from the connector.

LHIA0017E

WHIA0062E

MHIB0108E

Page 3067 of 3171

TF-100

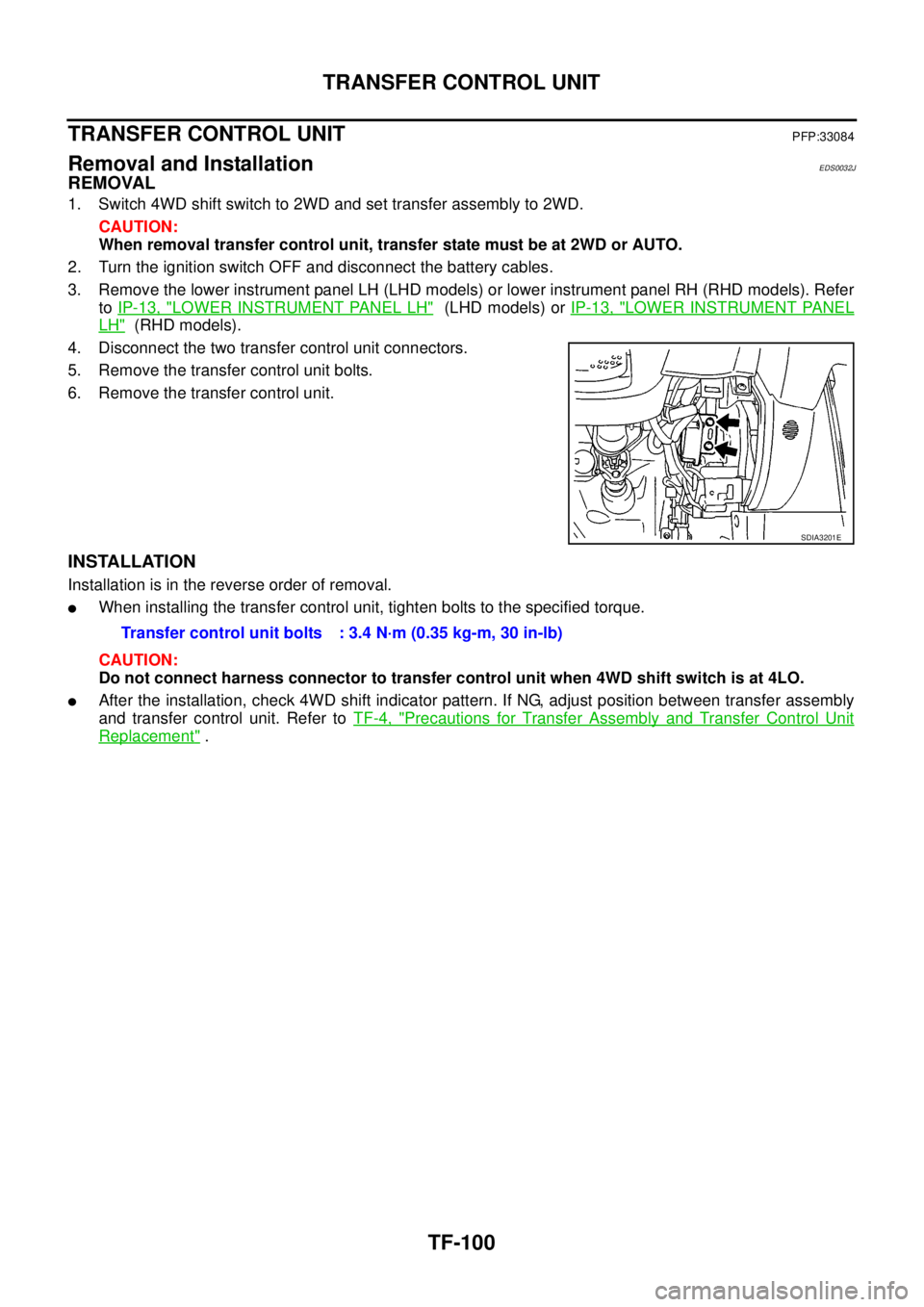

TRANSFER CONTROL UNIT

TRANSFER CONTROL UNIT

PFP:33084

Removal and InstallationEDS0032J

REMOVAL

1. Switch 4WD shift switch to 2WD and set transfer assembly to 2WD.

CAUTION:

When removal transfer control unit, transfer state must be at 2WD or AUTO.

2. Turn the ignition switch OFF and disconnect the battery cables.

3. Remove the lower instrument panel LH (LHD models) or lower instrument panel RH (RHD models). Refer

toIP-13, "

LOWER INSTRUMENT PANEL LH"(LHD models) orIP-13, "LOWER INSTRUMENT PANEL

LH"(RHD models).

4. Disconnect the two transfer control unit connectors.

5. Remove the transfer control unit bolts.

6. Remove the transfer control unit.

INSTALLATION

Installation is in the reverse order of removal.

lWhen installing the transfer control unit, tighten bolts to the specified torque.

CAUTION:

Do not connect harness connector to transfer control unit when 4WD shift switch is at 4LO.

lAfter the installation, check 4WD shift indicator pattern. If NG, adjust position between transfer assembly

and transfer control unit. Refer toTF-4, "

Precautions for Transfer Assembly and Transfer Control Unit

Replacement".

SDIA3201E

Transfer control unit bolts : 3.4 N·m (0.35 kg-m, 30 in-lb)