fuses NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 396 of 3171

ATC-62

TROUBLE DIAGNOSIS

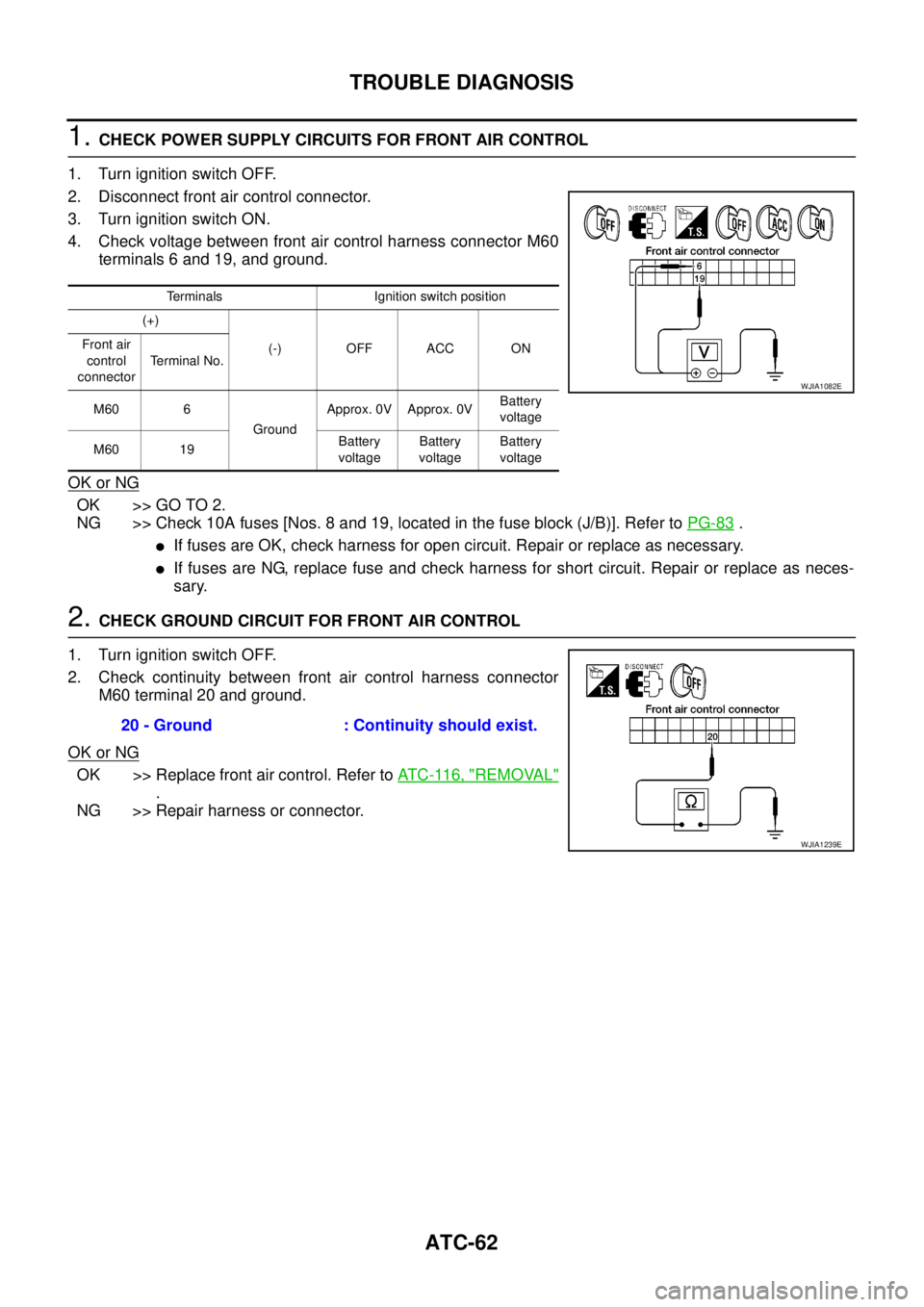

1.CHECK POWER SUPPLY CIRCUITS FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Turn ignition switch ON.

4. Check voltage between front air control harness connector M60

terminals 6 and 19, and ground.

OK or NG

OK >> GO TO 2.

NG >> Check 10A fuses [Nos. 8 and 19, located in the fuse block (J/B)]. Refer toPG-83

.

lIf fuses are OK, check harness for open circuit. Repair or replace as necessary.

lIf fuses are NG, replace fuse and check harness for short circuit. Repair or replace as neces-

sary.

2.CHECK GROUND CIRCUIT FOR FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Check continuity between front air control harness connector

M60 terminal 20 and ground.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> Repair harness or connector.

Terminals Ignition switch position

(+)

(-) OFF ACC ON Front air

control

connectorTerminal No.

M60 6

GroundApprox. 0V Approx. 0VBattery

voltage

M60 19Battery

voltageBattery

voltageBattery

voltage

WJIA1082E

20 - Ground : Continuity should exist.

WJIA1239E

Page 417 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK B NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK B](/img/5/57362/w960_57362-416.png)

TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK BOX".

OK or NG

OK >> GO TO 2.

NG >> GO TO 10.

2.CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect blower motor connector.

3. Turn ignition switch ON.

4. Turn the blower control dial to select any mode except off.

5. Check voltage between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> GO TO 12.

NG >> GO TO 3.

3.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect blower motor relay.

3. Check voltage between blower motor relay harness connector

E28 terminals 3 and 6 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK BLOWER MOTOR RELAY

Refer toAT C - 8 6 , "

Blower Motor Relay".

OK or NG

OK >> GO TO 5.

NG >> Replace blower motor relay.

5.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect blower motor relay connector and blower motor con-

nector.

3. Check continuity between blower motor relay harness connector

E28 terminals 5 and 7 and blower motor harness connector M94

terminal 2.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.Fuses are good.

2 - Ground : Battery voltage.

MJIB0065E

3, 6 - Ground : Battery voltage.

MJIB0066E

5, 7 - 2 : Continuity should exist.

MJIB0067E

Page 419 of 3171

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

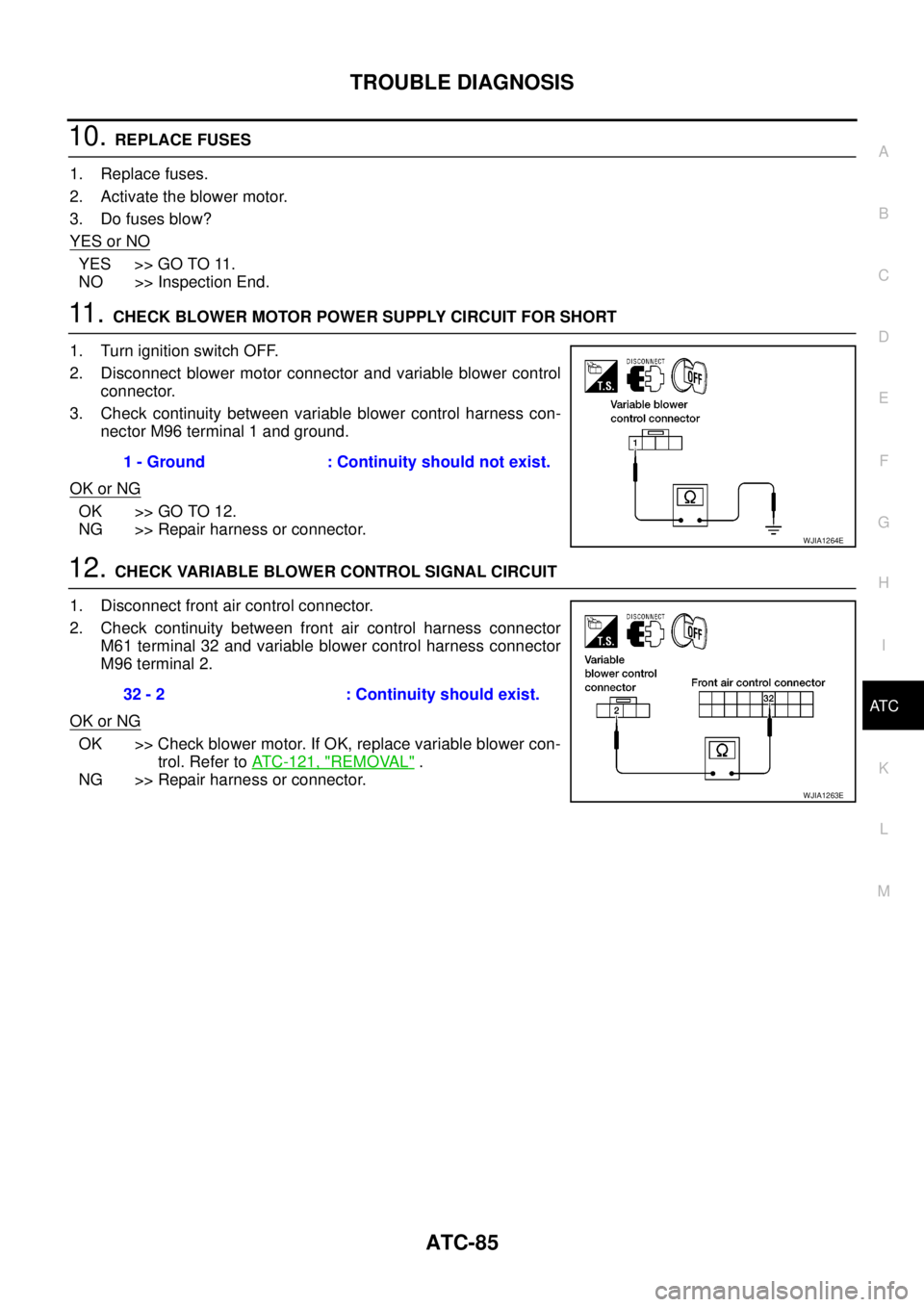

10.REPLACE FUSES

1. Replace fuses.

2. Activate the blower motor.

3. Do fuses blow?

YES or NO

YES >> GO TO 11.

NO >> Inspection End.

11 .CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect blower motor connector and variable blower control

connector.

3. Check continuity between variable blower control harness con-

nector M96 terminal 1 and ground.

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT

1. Disconnect front air control connector.

2. Check continuity between front air control harness connector

M61 terminal 32 and variable blower control harness connector

M96 terminal 2.

OK or NG

OK >> Check blower motor. If OK, replace variable blower con-

trol. Refer toATC-121, "

REMOVAL".

NG >> Repair harness or connector.1 - Ground : Continuity should not exist.

WJIA1264E

32 - 2 : Continuity should exist.

WJIA1263E

Page 1185 of 3171

DTC P0563 BATTERY VOLTAGE

EC-205

C

D

E

F

G

H

I

J

K

L

MA

EC

7.CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

lWiring harness and harness connectors for burn

lFuses for short

OK or NG

OK >>INSPECTION END

NG >> Repair or replace malfunctioning part.

Page 2096 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-13

C

D

E

F

G

H

I

J

L

MA

B

LT

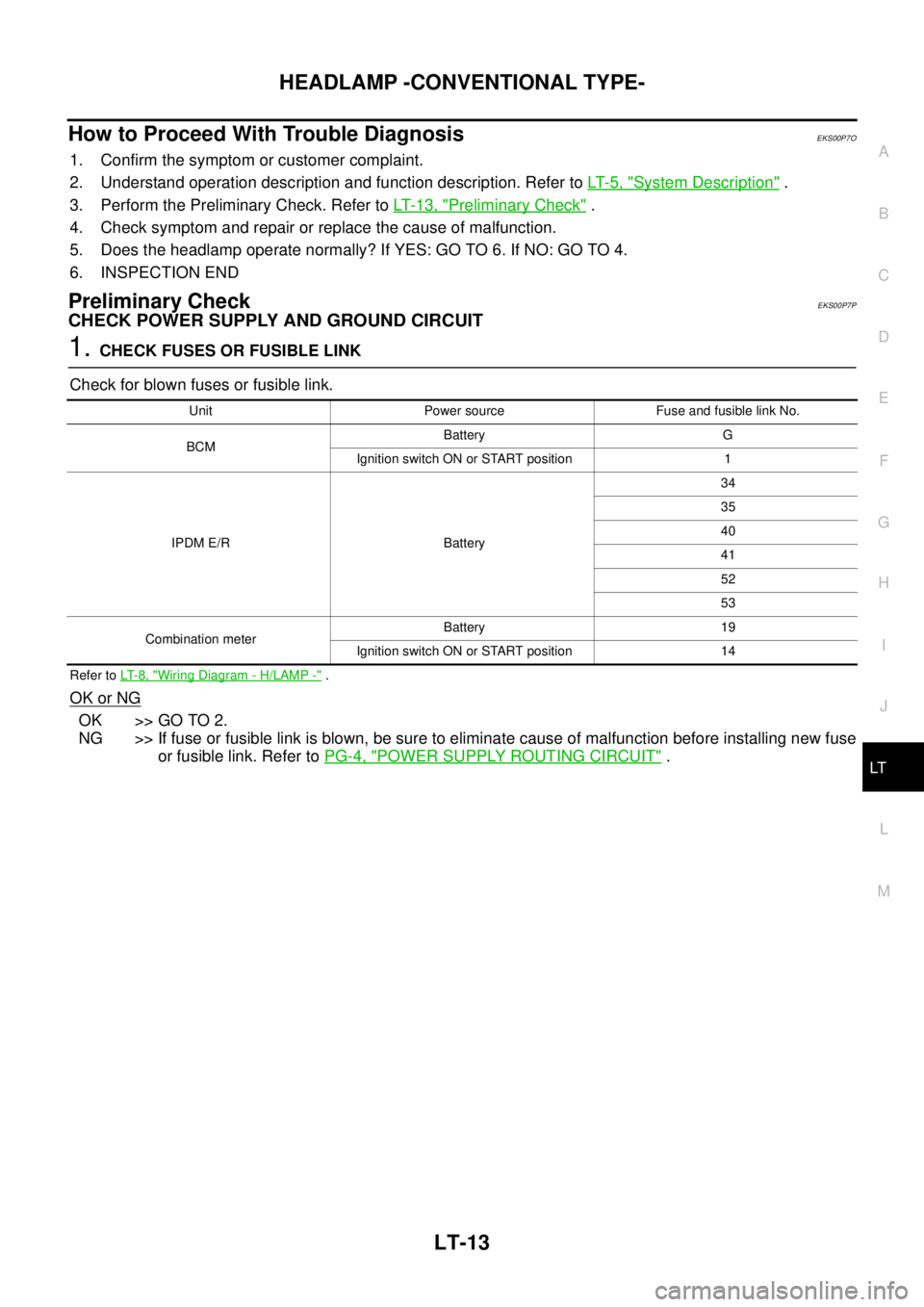

How to Proceed With Trouble DiagnosisEKS00P7O

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT- 5 , "

System Description".

3. Perform the Preliminary Check. Refer toLT-13, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the headlamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P7P

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT- 8 , "Wiring Diagram - H/LAMP -".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/R Battery34

35

40

41

52

53

Combination meterBattery 19

Ignition switch ON or START position 14

Page 2123 of 3171

LT-40

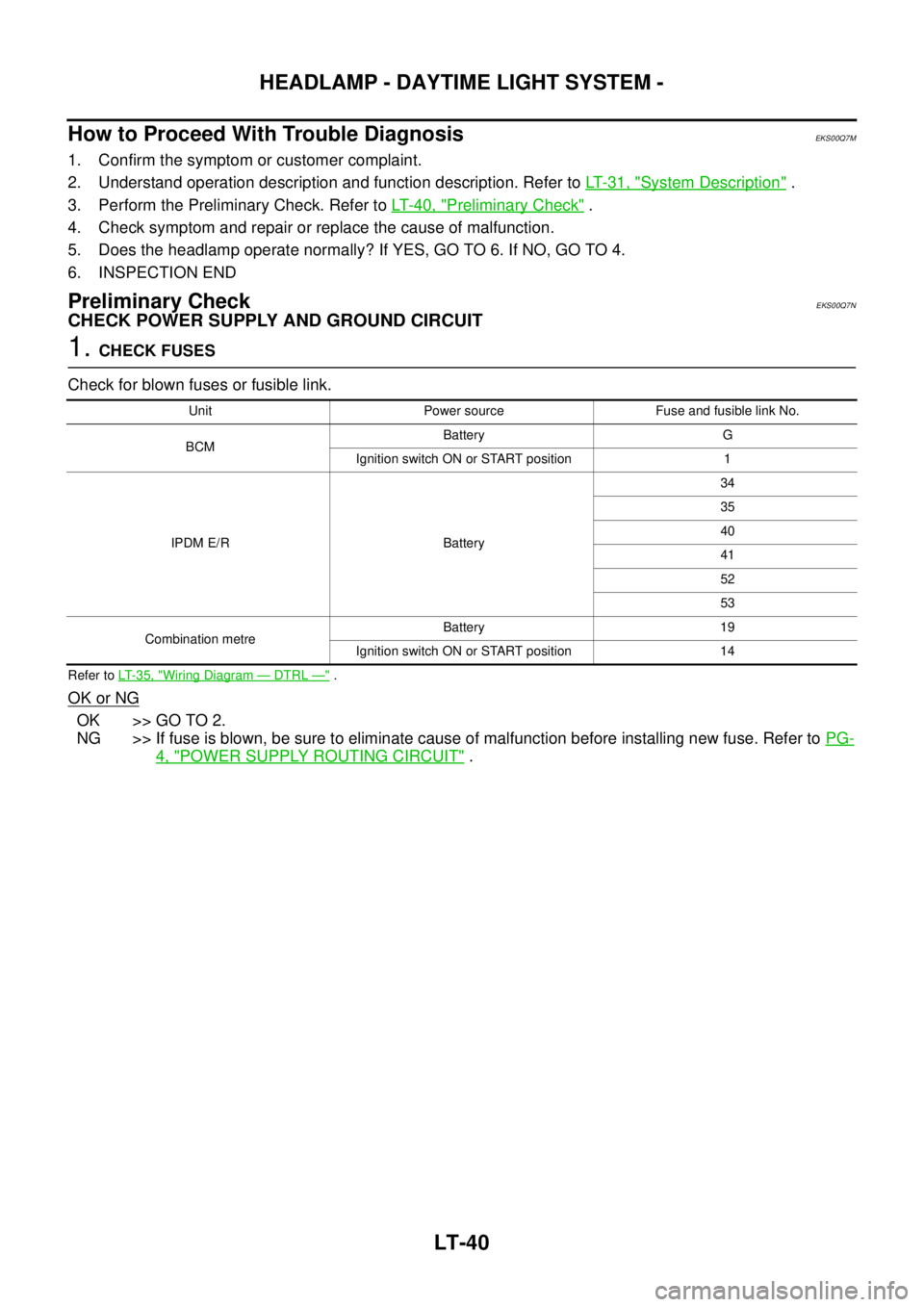

HEADLAMP - DAYTIME LIGHT SYSTEM -

How to Proceed With Trouble Diagnosis

EKS00Q7M

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT-31, "

System Description".

3. Perform the Preliminary Check. Refer toLT-40, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the headlamp operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00Q7N

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES

Check for blown fuses or fusible link.

Refer toLT-35, "Wiring Diagram—DTRL—".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/R Battery34

35

40

41

52

53

Combination metreBattery 19

Ignition switch ON or START position 14

Page 2141 of 3171

LT-58

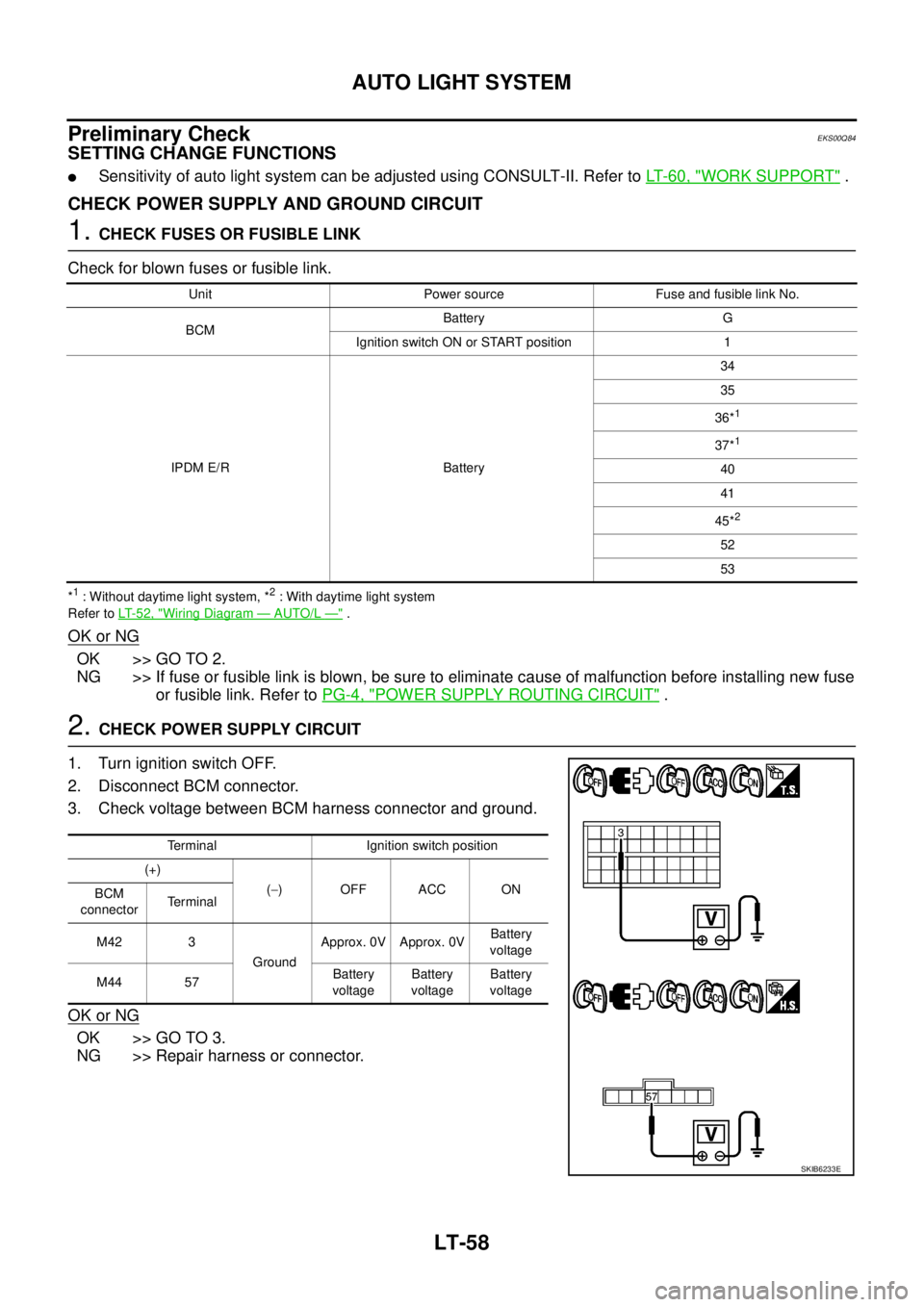

AUTO LIGHT SYSTEM

Preliminary Check

EKS00Q84

SETTING CHANGE FUNCTIONS

lSensitivity of auto light system can be adjusted using CONSULT-II. Refer toLT-60, "WORK SUPPORT".

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

*1: Without daytime light system, *2: With daytime light system

Refer toLT-52, "

Wiring Diagram—AUTO/L—".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/R Battery34

35

36*

1

37*1

40

41

45*

2

52

53

Terminal Ignition switch position

(+)

(-)OFFACCON

BCM

connectorTerminal

M42 3

GroundApprox. 0V Approx. 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

Page 2161 of 3171

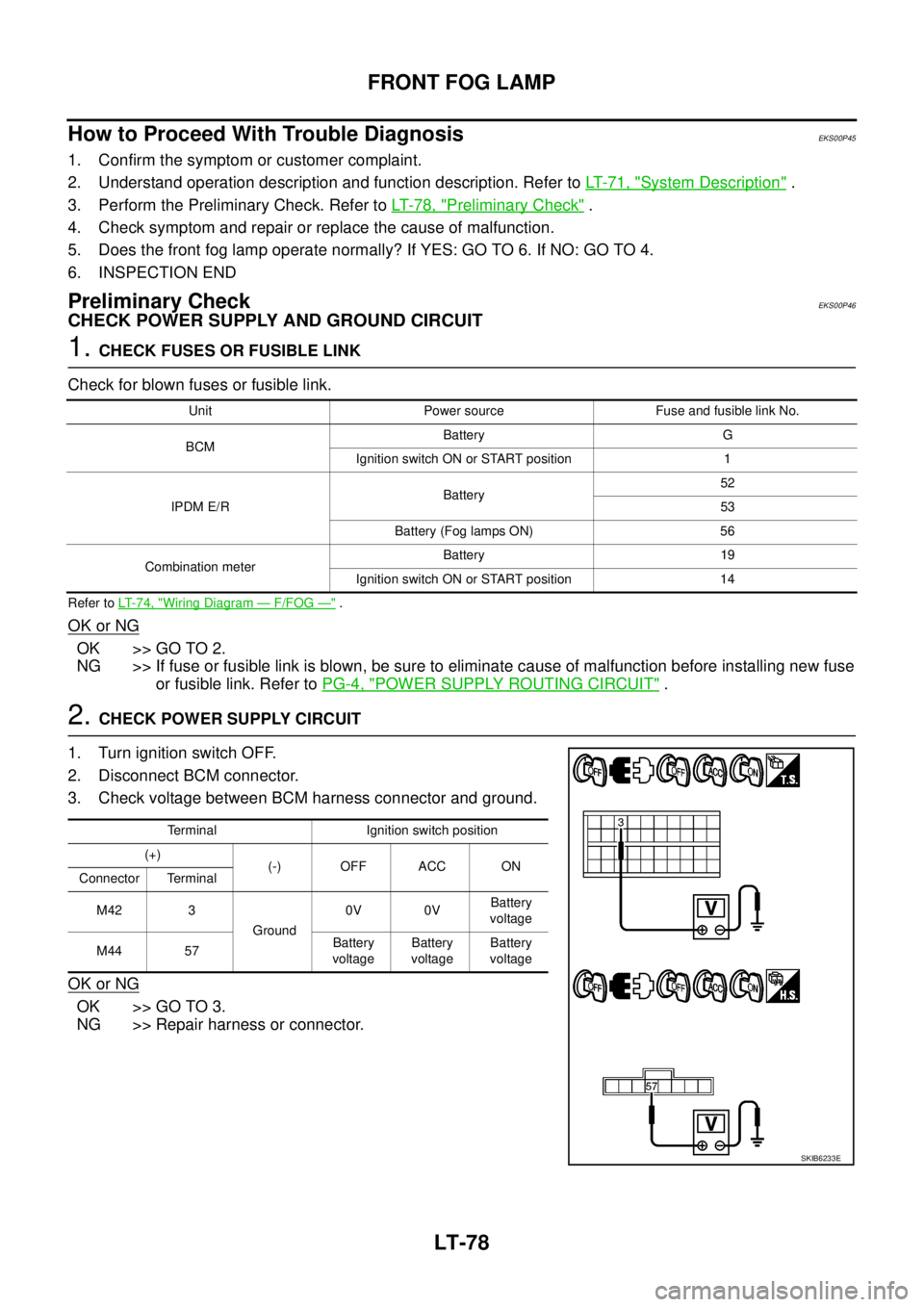

LT-78

FRONT FOG LAMP

How to Proceed With Trouble Diagnosis

EKS00P45

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT-71, "

System Description".

3. Perform the Preliminary Check. Refer toLT-78, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the front fog lamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P46

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT-74, "Wiring Diagram—F/FOG—".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

IPDM E/RBattery52

53

Battery (Fog lamps ON) 56

Combination meterBattery 19

Ignition switch ON or START position 14

Terminal Ignition switch position

(+)

(-) OFF ACC ON

Connector Terminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

Page 2175 of 3171

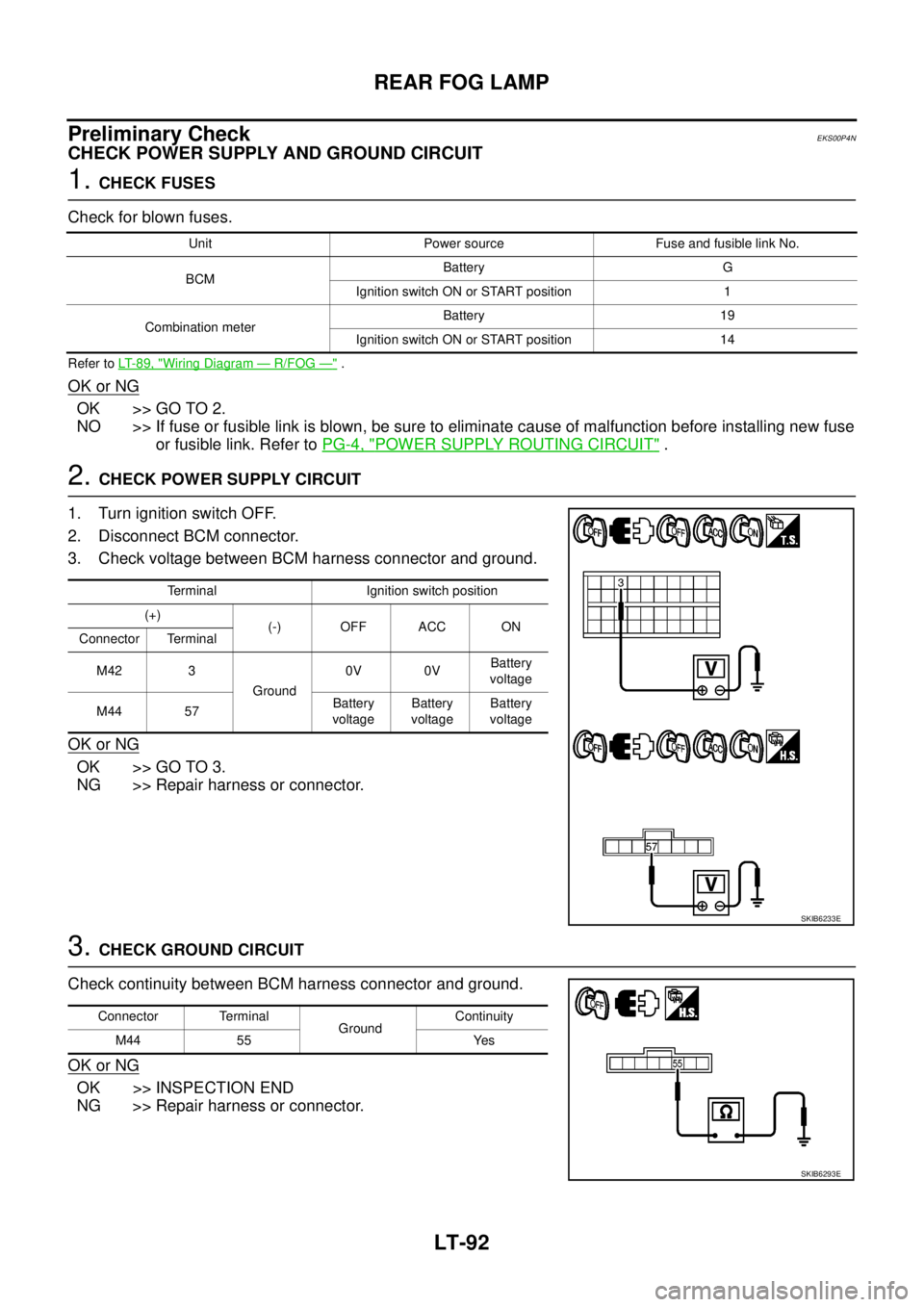

LT-92

REAR FOG LAMP

Preliminary Check

EKS00P4N

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES

Check for blown fuses.

Refer toLT-89, "Wiring Diagram—R/FOG—".

OK or NG

OK >> GO TO 2.

NO >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

Combination meterBattery 19

Ignition switch ON or START position 14

Terminal Ignition switch position

(+)

(-) OFF ACC ON

Connector Terminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E

Connector Terminal

GroundContinuity

M44 55 Yes

SKIB6293E

Page 2186 of 3171

TURN SIGNAL AND HAZARD WARNING LAMPS

LT-103

C

D

E

F

G

H

I

J

L

MA

B

LT

How to Proceed With Trouble DiagnosisEKS00P8A

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT-97, "

System Description".

3. Perform preliminary check. Refer toLT- 1 0 3 , "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Do turn signal and hazard warning lamps operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Preliminary CheckEKS00P8B

CHECK POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSES OR FUSIBLE LINK

Check for blown fuses or fusible link.

Refer toLT-100, "Wiring Diagram—TURN—".

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer toPG-4, "

POWER SUPPLY ROUTING CIRCUIT".

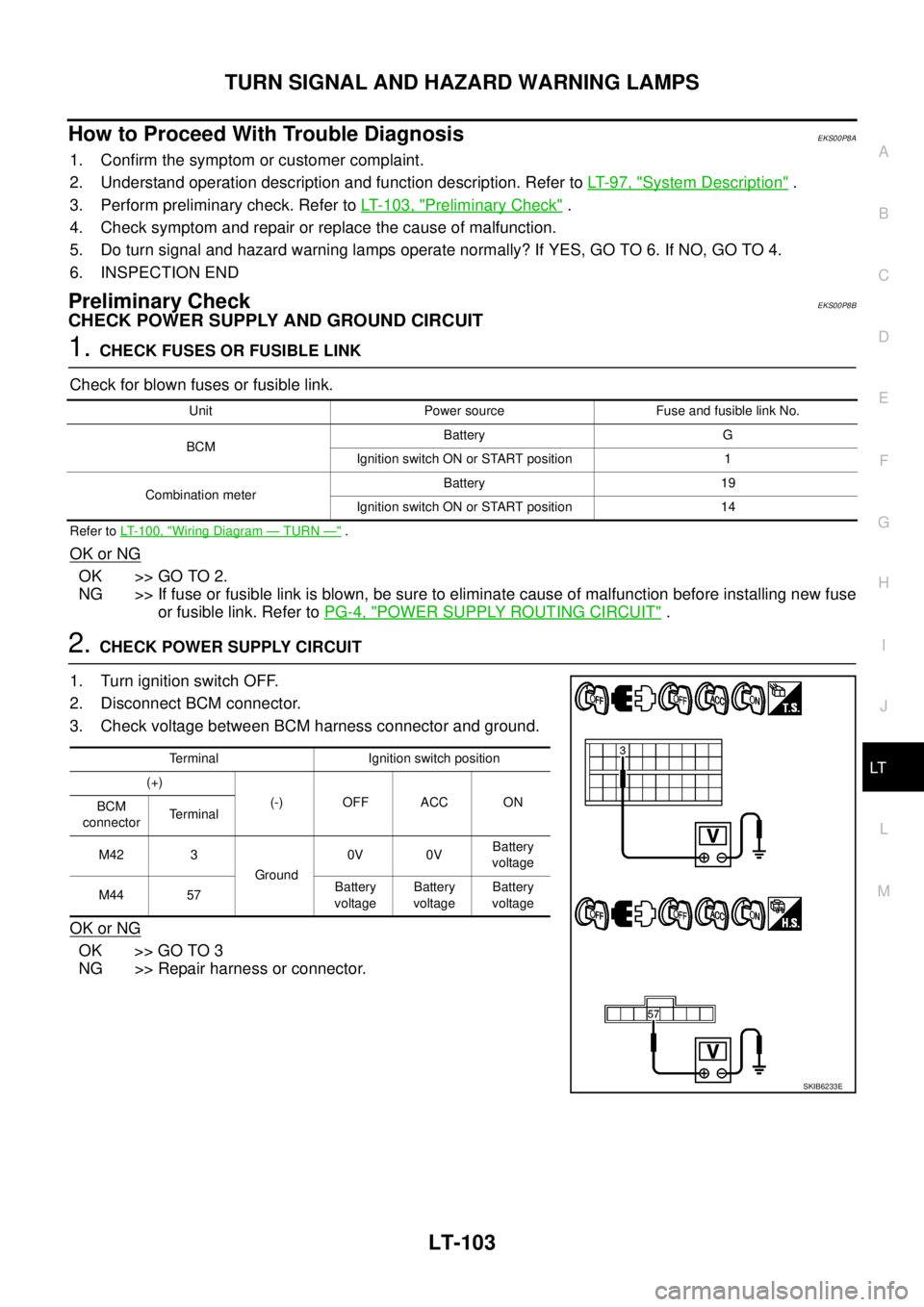

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM harness connector and ground.

OK or NG

OK >> GO TO 3

NG >> Repair harness or connector.

Unit Power source Fuse and fusible link No.

BCMBattery G

Ignition switch ON or START position 1

Combination meterBattery 19

Ignition switch ON or START position 14

Terminal Ignition switch position

(+)

(-) OFF ACC ON

BCM

connectorTerminal

M42 3

Ground0V 0VBattery

voltage

M44 57Battery

voltageBattery

voltageBattery

voltage

SKIB6233E