center console NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1377 of 3171

FLOOR TRIM

EI-39

C

D

E

F

G

H

J

K

L

MA

B

EI

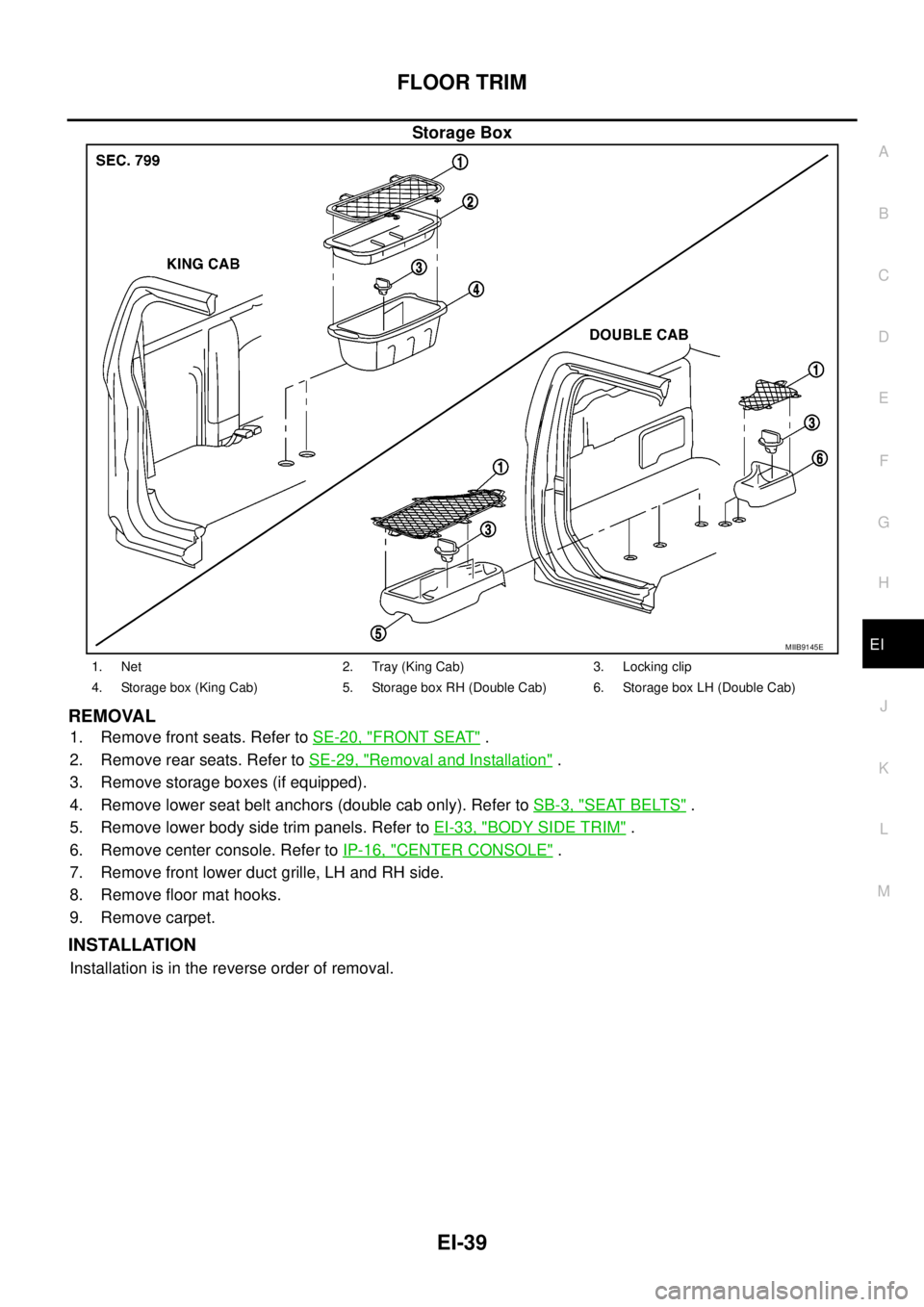

Storage Box

REMOVAL

1. Remove front seats. Refer toSE-20, "FRONT SEAT".

2. Remove rear seats. Refer toSE-29, "

Removal and Installation".

3. Remove storage boxes (if equipped).

4. Remove lower seat belt anchors (double cab only). Refer toSB-3, "

SEAT BELTS".

5. Remove lower body side trim panels. Refer toEI-33, "

BODY SIDE TRIM".

6. Remove center console. Refer toIP-16, "

CENTER CONSOLE".

7. Remove front lower duct grille, LH and RH side.

8. Remove floor mat hooks.

9. Remove carpet.

INSTALLATION

Installation is in the reverse order of removal.

MIIB9145E

1. Net 2. Tray (King Cab) 3. Locking clip

4. Storage box (King Cab) 5. Storage box RH (Double Cab) 6. Storage box LH (Double Cab)

Page 1379 of 3171

HEADLINING

EI-41

C

D

E

F

G

H

J

K

L

MA

B

EI

REMOVAL

CAUTION:

Disconnect both the positive and negative battery terminals in advance.

1. Remove body side trim panels. Refer toEI-33, "

BODY SIDE TRIM".

2. Remove rear trim. Refer toEI-36, "

REAR".

3. Remove sun visor assemblies, both LH and RH.

4. Remove sun visor holders LH and RH.

5. Remove roof console (if equipped).

lDisconnect harness.

6. Remove room lamp.

lDisconnect harness.

7. Remove microphone assembly (if equiped).

8. Remove inside mirror finisher, and inside mirror harness finisher (if equipped). Refer toGW-46, "

Removal

and Installation".

lDisconnect harness, then release it, from headlining.

9. Remove striker covers (King Cab only).

10. Remove assist grips.

11. Remove headlining.

NOTE:

Use an assistant to steady the headlining while lowering from roof.

lRemove clips from center of headlining (if equipped).

12. Remove assist grip brackets from roof.

INSTALLATION

CAUTION:

Use only Nissan available process to fix harness with Headlining.

Installation is in the reverse order of removal.

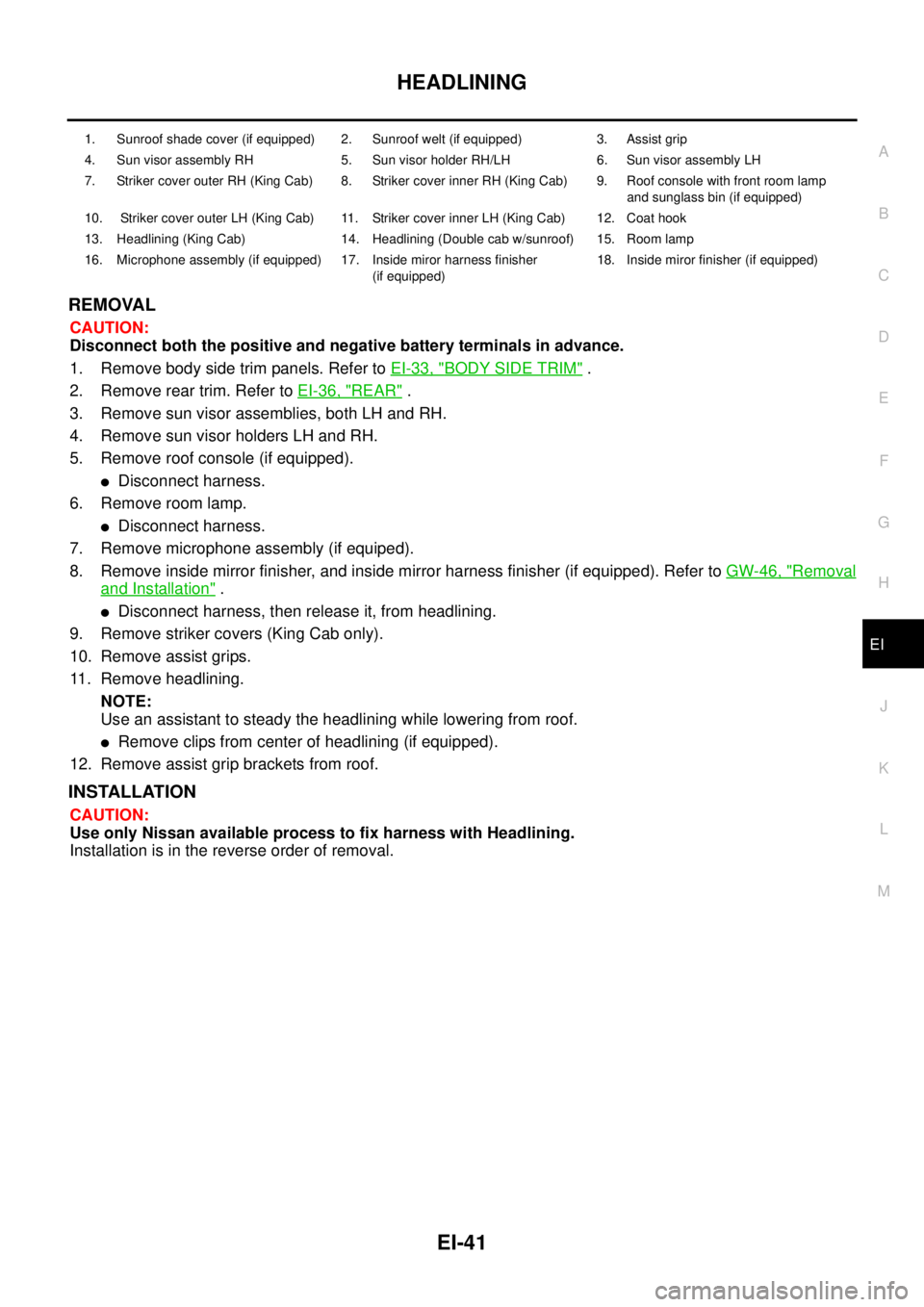

1. Sunroof shade cover (if equipped) 2. Sunroof welt (if equipped) 3. Assist grip

4. Sun visor assembly RH 5. Sun visor holder RH/LH 6. Sun visor assembly LH

7. Striker cover outer RH (King Cab) 8. Striker cover inner RH (King Cab) 9. Roof console with front room lamp

and sunglass bin (if equipped)

10. Striker cover outer LH (King Cab) 11. Striker cover inner LH (King Cab) 12. Coat hook

13. Headlining (King Cab) 14. Headlining (Double cab w/sunroof) 15. Room lamp

16. Microphone assembly (if equipped) 17. Inside miror harness finisher

(if equipped)18. Inside miror finisher (if equipped)

Page 1687 of 3171

GW-1

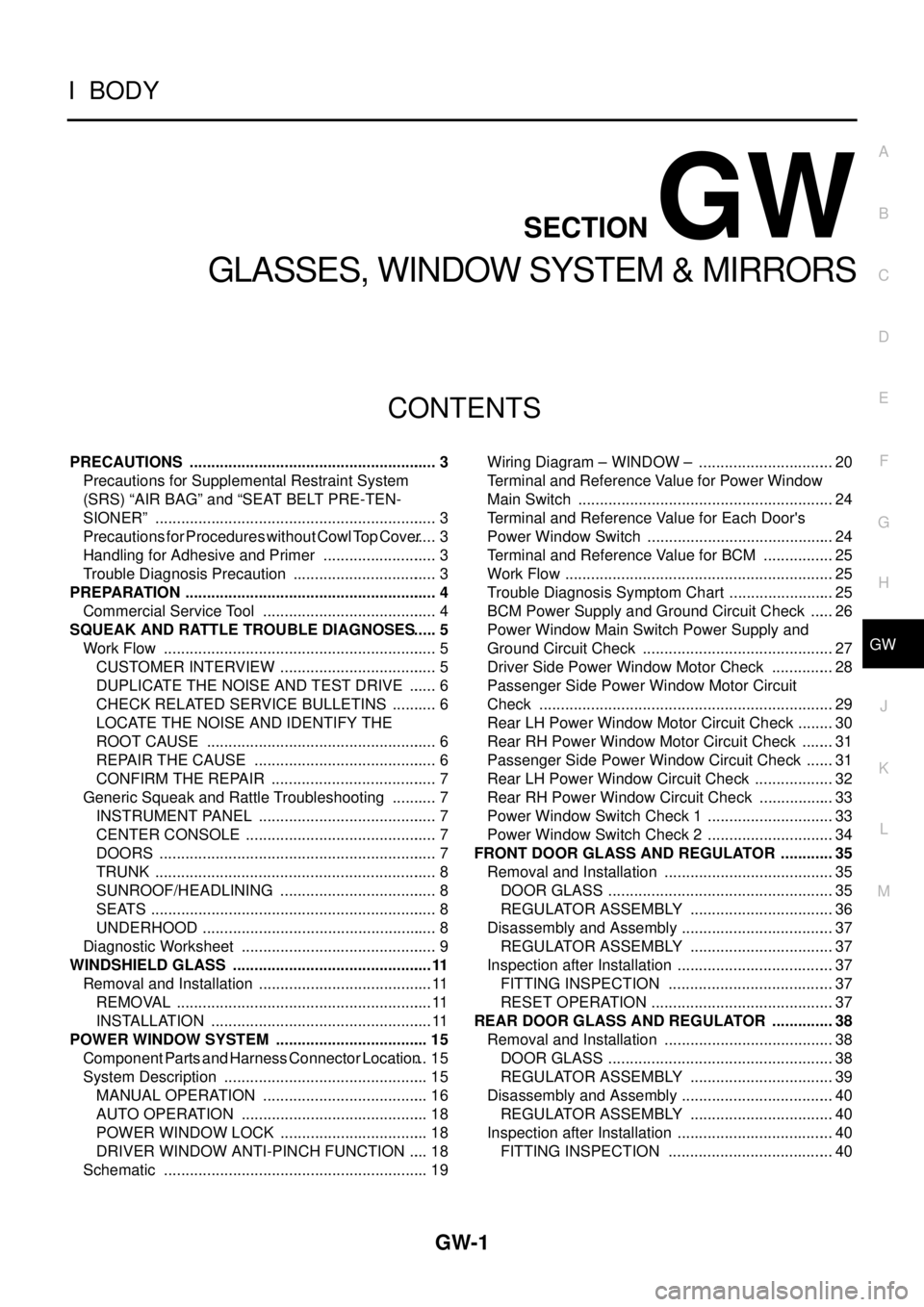

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONGW

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover..... 3

Handling for Adhesive and Primer ........................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tool ......................................... 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POWER WINDOW SYSTEM .................................... 15

Component Parts and Harness Connector Location... 15

System Description ................................................ 15

MANUAL OPERATION ....................................... 16

AUTO OPERATION ............................................ 18

POWER WINDOW LOCK ................................... 18

DRIVER WINDOW ANTI-PINCH FUNCTION ..... 18

Schematic .............................................................. 19Wiring Diagram – WINDOW – ................................ 20

Terminal and Reference Value for Power Window

Main Switch ............................................................ 24

Terminal and Reference Value for Each Door's

Power Window Switch ............................................ 24

Terminal and Reference Value for BCM ................. 25

Work Flow ............................................................... 25

Trouble Diagnosis Symptom Chart ......................... 25

BCM Power Supply and Ground Circuit Check ...... 26

Power Window Main Switch Power Supply and

Ground Circuit Check ............................................. 27

Driver Side Power Window Motor Check ............... 28

Passenger Side Power Window Motor Circuit

Check ..................................................................... 29

Rear LH Power Window Motor Circuit Check ......... 30

Rear RH Power Window Motor Circuit Check ........ 31

Passenger Side Power Window Circuit Check ....... 31

Rear LH Power Window Circuit Check ................... 32

Rear RH Power Window Circuit Check .................. 33

Power Window Switch Check 1 .............................. 33

Power Window Switch Check 2 .............................. 34

FRONT DOOR GLASS AND REGULATOR ............. 35

Removal and Installation ........................................ 35

DOOR GLASS ..................................................... 35

REGULATOR ASSEMBLY .................................. 36

Disassembly and Assembly .................................... 37

REGULATOR ASSEMBLY .................................. 37

Inspection after Installation ..................................... 37

FITTING INSPECTION ....................................... 37

RESET OPERATION ........................................... 37

REAR DOOR GLASS AND REGULATOR ............... 38

Removal and Installation ........................................ 38

DOOR GLASS ..................................................... 38

REGULATOR ASSEMBLY .................................. 39

Disassembly and Assembly .................................... 40

REGULATOR ASSEMBLY .................................. 40

Inspection after Installation ..................................... 40

FITTING INSPECTION ....................................... 40

Page 1693 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

GW-7

C

D

E

F

G

H

J

K

L

MA

B

GW

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15´25 mm (0.59´0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Usetoeliminatemovement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00C03

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you

will not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

Page 1760 of 3171

IP-1

INSTRUMENT PANEL

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONIP

A

B

IP

INSTRUMENT PANEL

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for SRS “AIR BAG” and “SEAT BELT

PRE-TENSIONER” Service ..................................... 2

PREPARATION ........................................................... 3

Commercial Service Tools ........................................ 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 5

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6TRUNK .................................................................. 6

SUNROOF/HEADLINING ..................................... 7

OVERHEAD CONSOLE (FRONT AND REAR)..... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet ............................................... 8

INSTRUMENT PANEL ASSEMBLY ......................... 10

Removal and Installation ........................................ 10

INSTRUMENT PANEL ........................................ 10

CLUSTER LID C ................................................. 11

CLUSTER LID D ................................................. 12

LOWER INSTRUMENT PANEL LH ..................... 13

COMBINATION METER ...................................... 13

A/T CONTROL FINISHER (A/T) .......................... 14

CONSOLE BOOT M/T ........................................ 14

LOWER INSTRUMENT PANEL RH AND GLOVE

BOX ..................................................................... 15

CENTER CONSOLE ........................................... 16

Disassembly and Assembly .................................... 17

CENTER CONSOLE ........................................... 17

Page 1765 of 3171

IP-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Generic Squeak and Rattle Troubleshooting

EIS00DYX

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

Page 1770 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-11

C

D

E

F

G

H

J

K

L

MA

B

IP

1. Remove the center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove the steering column covers. Refer toPS-11, "

STEERING COLUMN".

3. Remove the combination meter. Refer toIP-13, "

COMBINATION METER".

4. Release then disconnect the optical sensor harness.

5. Remove the LH and RH front pillar upper garnish.

6. Remove cluster lid C.

7. Remove screws fixing CD Audio bracket, then remove CD Audio unit assembly. (If equipped). Refer toAV-

73, "Auido Unit (1CD Player Type)".

8. Remove cluster lid D. Refer toIP-12, "

CLUSTER LID D".

9. Remove screws fixing GPS Antenna, then move GPS Antenna.

10. Remove screws fixing display unit bracket, then remove display unit assembly. (If equipped)

11. Remove front passenger air bag module.

12. Remove instrument panel.

lDisconnect harnesses to instrument panel speakers LH and RH and remove speakers.

lDisconnect all remaining harnesses.

lRemove the passenger air bag module. Refer toSRS-40, "FRONT PASSENGER AIR BAG MODULE".

Installation

Installation is in the reverse order of removal.

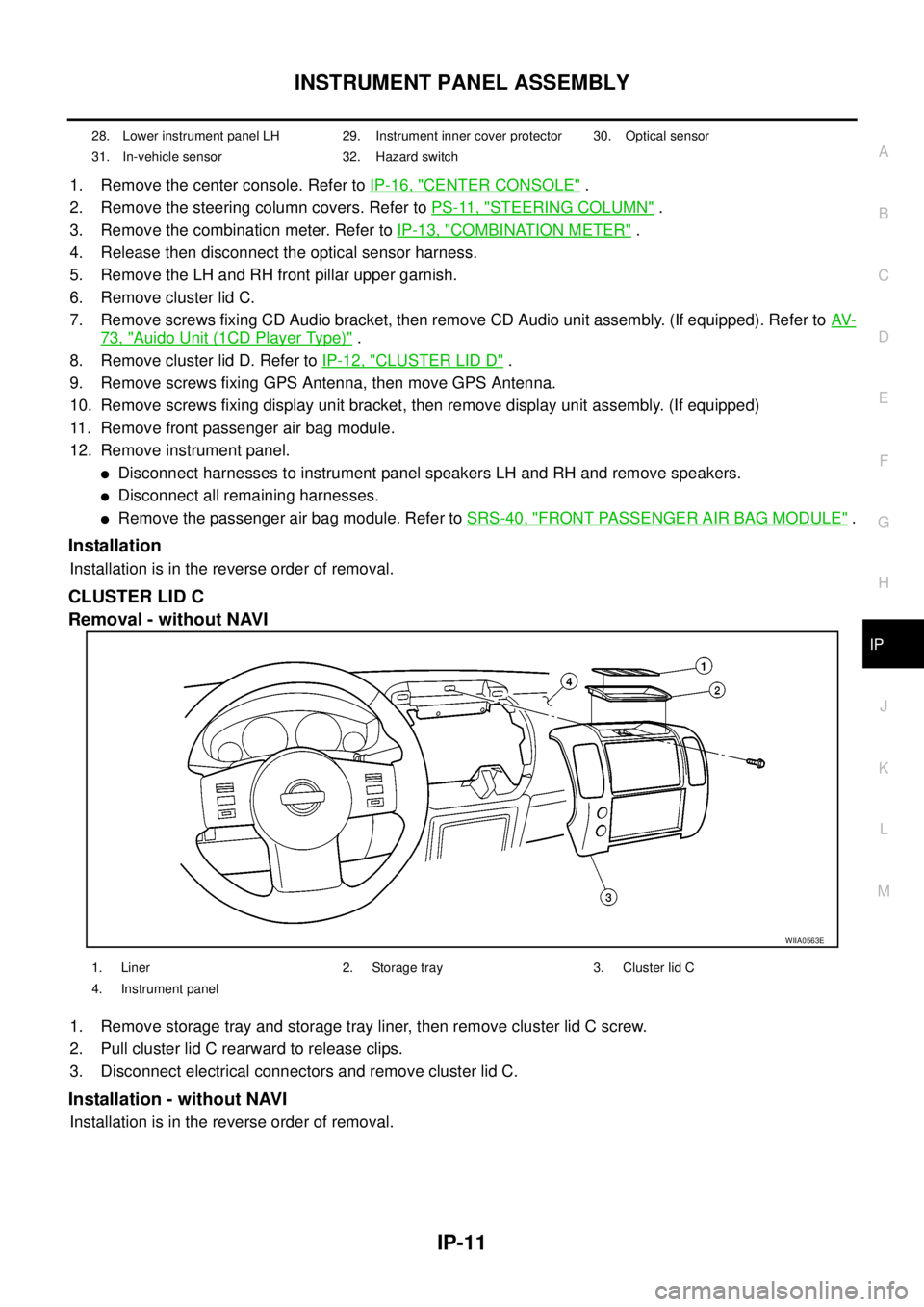

CLUSTER LID C

Removal - without NAVI

1. Remove storage tray and storage tray liner, then remove cluster lid C screw.

2. Pull cluster lid C rearward to release clips.

3. Disconnect electrical connectors and remove cluster lid C.

Installation - without NAVI

Installation is in the reverse order of removal.

28. Lower instrument panel LH 29. Instrument inner cover protector 30. Optical sensor

31. In-vehicle sensor 32. Hazard switch

WIIA0563E

1. Liner 2. Storage tray 3. Cluster lid C

4. Instrument panel

Page 1771 of 3171

IP-12

INSTRUMENT PANEL ASSEMBLY

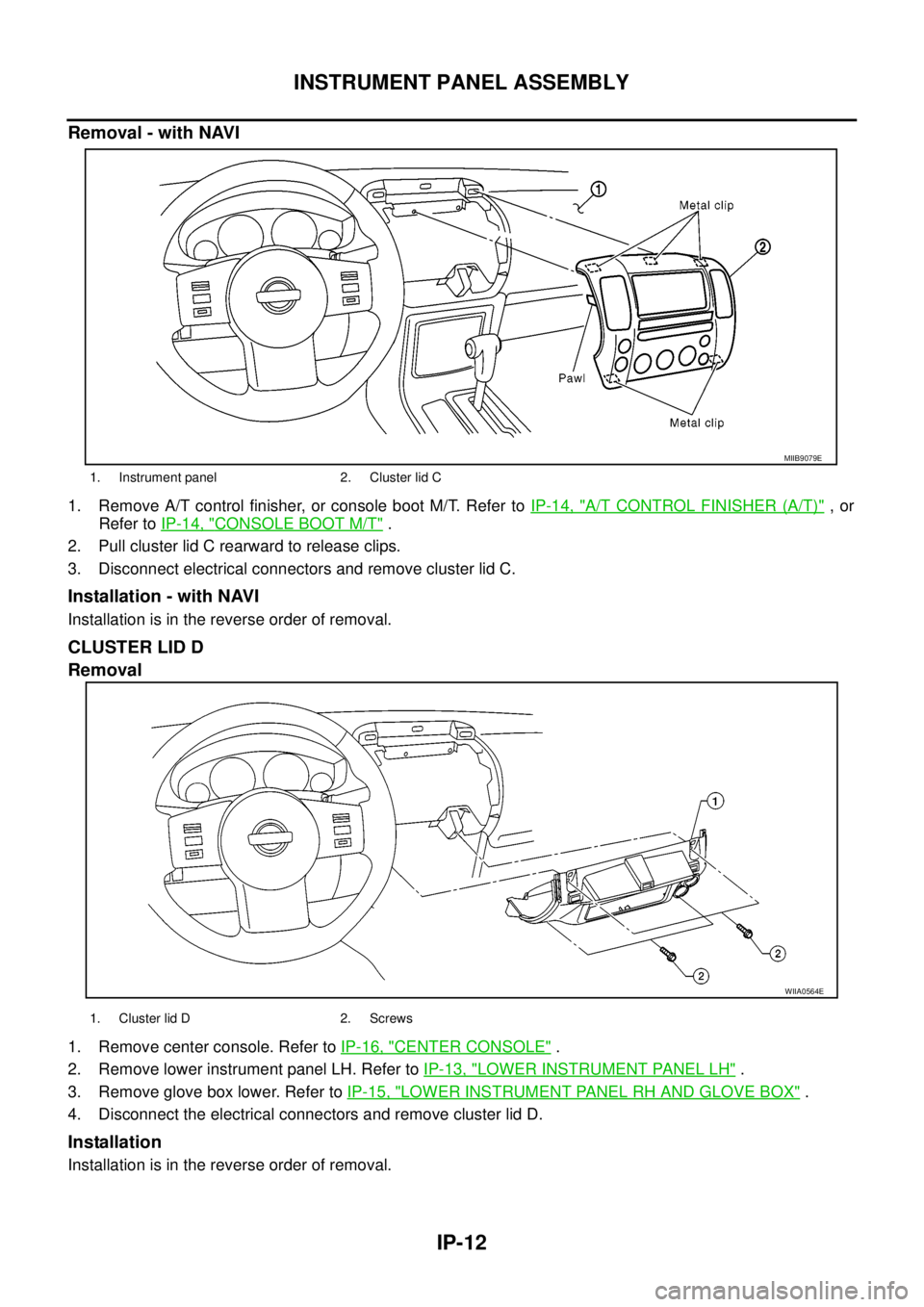

Removal - with NAVI

1. Remove A/T control finisher, or console boot M/T. Refer toIP-14, "A/T CONTROL FINISHER (A/T)",or

Refer toIP-14, "

CONSOLE BOOT M/T".

2. Pull cluster lid C rearward to release clips.

3. Disconnect electrical connectors and remove cluster lid C.

Installation - with NAVI

Installation is in the reverse order of removal.

CLUSTER LID D

Removal

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove lower instrument panel LH. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH".

3. Remove glove box lower. Refer toIP-15, "

LOWER INSTRUMENT PANEL RH AND GLOVE BOX".

4. Disconnect the electrical connectors and remove cluster lid D.

Installation

Installation is in the reverse order of removal.

1. Instrument panel 2. Cluster lid C

MIIB9079E

WIIA0564E

1. Cluster lid D 2. Screws

Page 1775 of 3171

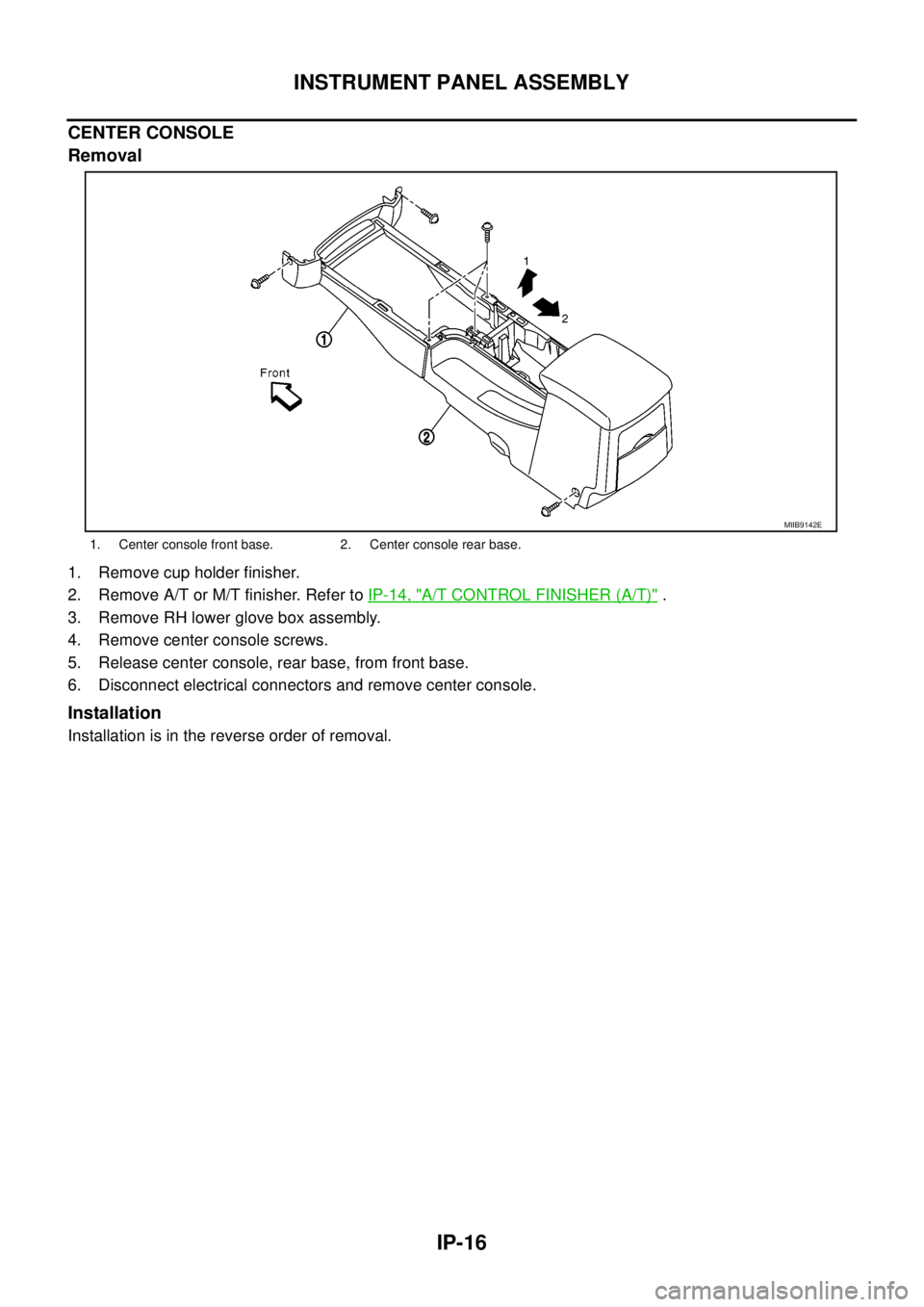

IP-16

INSTRUMENT PANEL ASSEMBLY

CENTER CONSOLE

Removal

1. Remove cup holder finisher.

2. Remove A/T or M/T finisher. Refer toIP-14, "

A/T CONTROL FINISHER (A/T)".

3. Remove RH lower glove box assembly.

4. Remove center console screws.

5. Release center console, rear base, from front base.

6. Disconnect electrical connectors and remove center console.

Installation

Installation is in the reverse order of removal.

1. Center console front base. 2. Center console rear base.

MIIB9142E

Page 1776 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-17

C

D

E

F

G

H

J

K

L

MA

B

IP

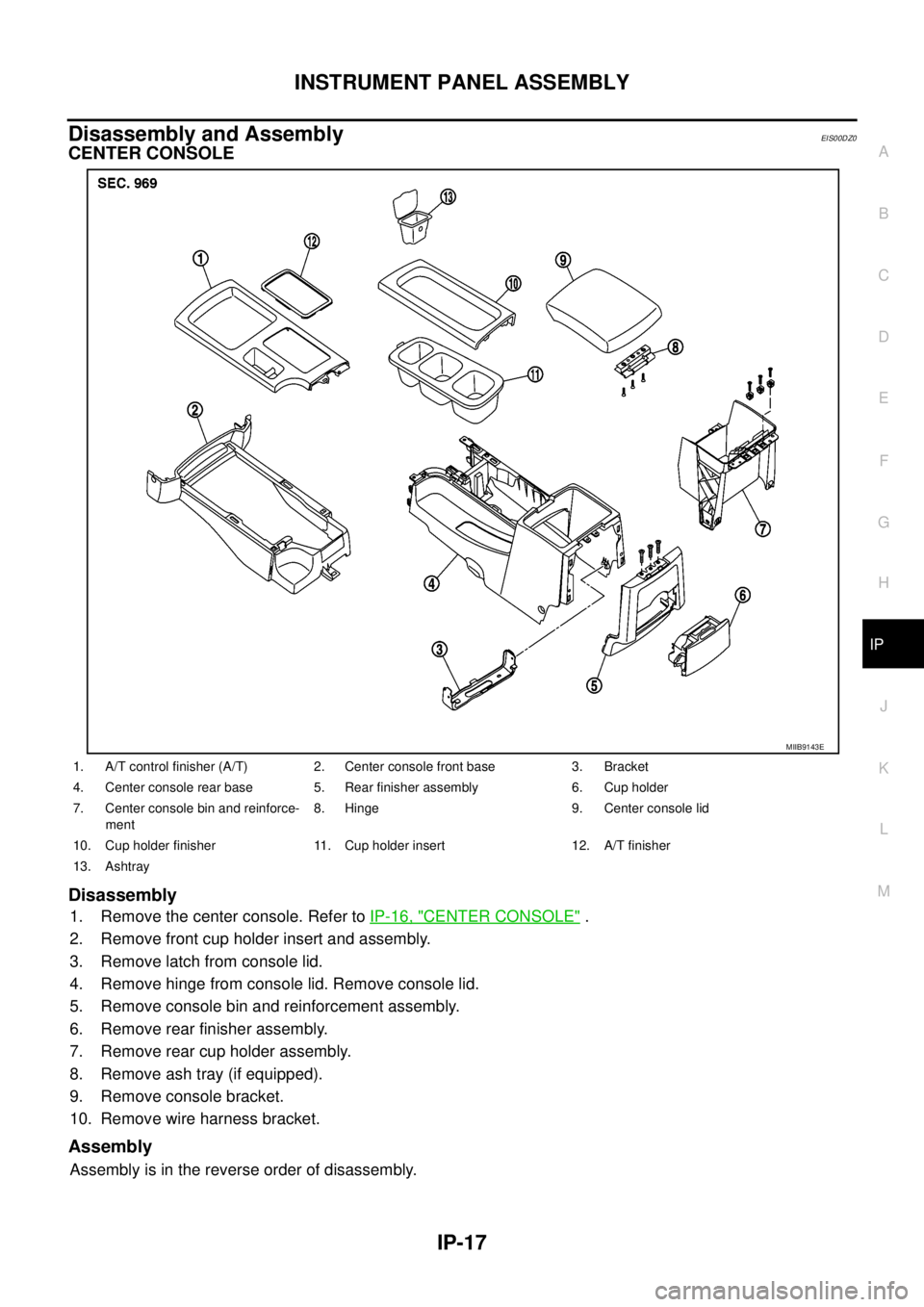

Disassembly and AssemblyEIS00DZ0

CENTER CONSOLE

Disassembly

1. Remove the center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove front cup holder insert and assembly.

3. Remove latch from console lid.

4. Remove hinge from console lid. Remove console lid.

5. Remove console bin and reinforcement assembly.

6. Remove rear finisher assembly.

7. Remove rear cup holder assembly.

8. Remove ash tray (if equipped).

9. Remove console bracket.

10. Remove wire harness bracket.

Assembly

Assembly is in the reverse order of disassembly.

MIIB9143E

1. A/T control finisher (A/T) 2. Center console front base 3. Bracket

4. Center console rear base 5. Rear finisher assembly 6. Cup holder

7. Center console bin and reinforce-

ment8. Hinge 9. Center console lid

10. Cup holder finisher 11. Cup holder insert 12. A/T finisher

13. Ashtray