check engine light NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1008 of 3171

EC-28

ON BOARD DIAGNOSTIC (OBD) SYSTEM

lIf the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

lThe following data are cleared when the ECM memory is erased.

–Diagnostic trouble codes

–Freeze frame data

–Fuel pump learning value

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Freeze Frame DataEBS01KCP

The ECM records the driving conditions such as calculated load value, engine coolant temperature, engine

speed, vehicle speed and intake manifold pressure at the moment a malfunction is detected.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II. For

details, seeEC-28, "

Freeze Frame Data".

Only one set of freeze frame data can be stored in the ECM. If freeze frame data is stored in the ECM memory

and another freeze frame data occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Freeze frame data (along with the DTCs) are cleared when the ECM memory is erased. Procedures for clear-

ing the ECM memory are described inEC-27, "

HOW TO ERASE DTC".

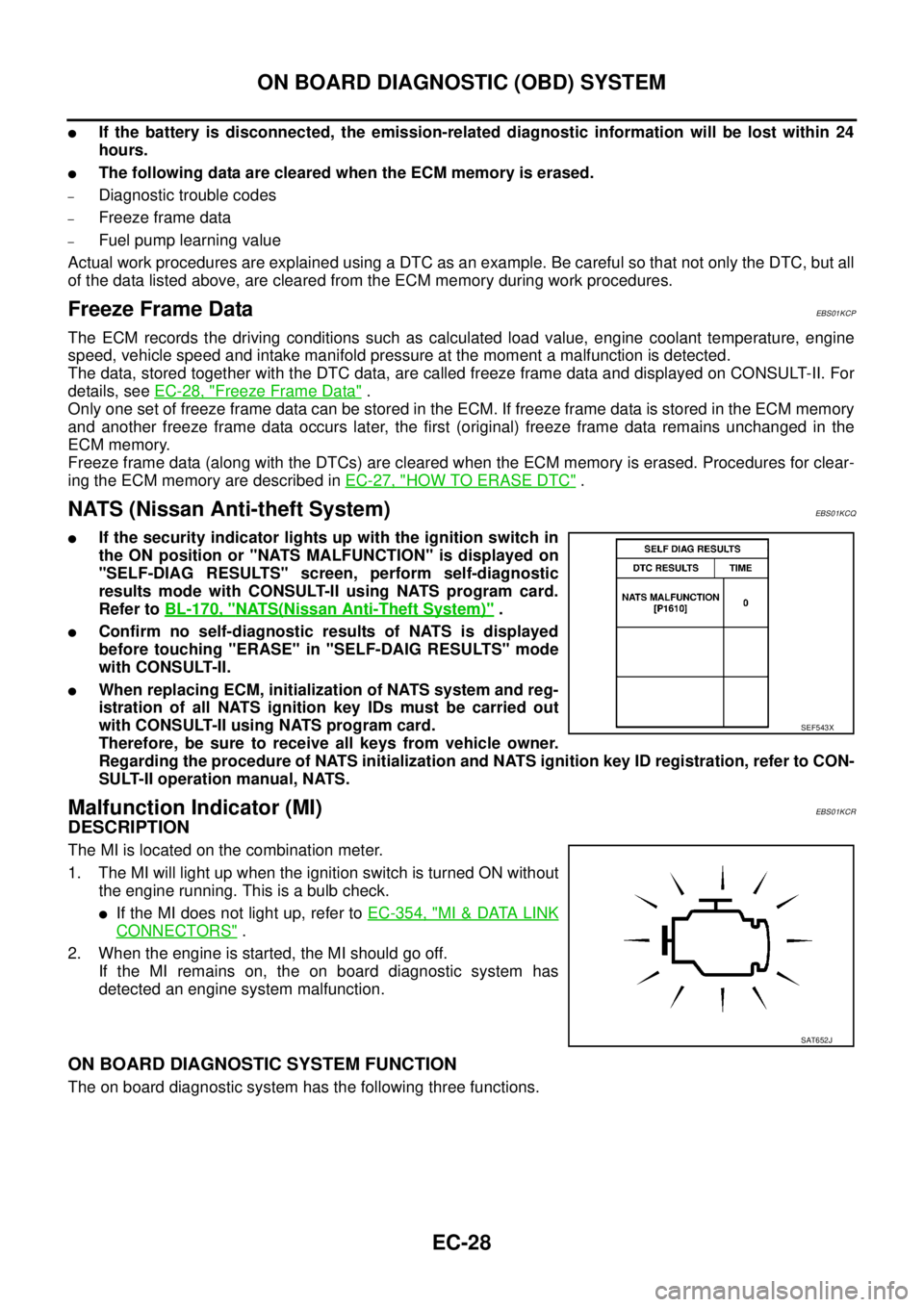

NATS (Nissan Anti-theft System)EBS01KCQ

lIf the security indicator lights up with the ignition switch in

the ON position or "NATS MALFUNCTION" is displayed on

"SELF-DIAG RESULTS" screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer toBL-170, "

NATS(Nissan Anti-Theft System)".

lConfirm no self-diagnostic results of NATS is displayed

before touching "ERASE" in "SELF-DAIG RESULTS" mode

with CONSULT-II.

lWhen replacing ECM, initialization of NATS system and reg-

istration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedure of NATS initialization and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

Malfunction Indicator (MI)EBS01KCR

DESCRIPTION

The MI is located on the combination meter.

1. The MI will light up when the ignition switch is turned ON without

the engine running. This is a bulb check.

lIf the MI does not light up, refer toEC-354, "MI&DATA LINK

CONNECTORS".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF543X

SAT652J

Page 1009 of 3171

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-29

C

D

E

F

G

H

I

J

K

L

MA

EC

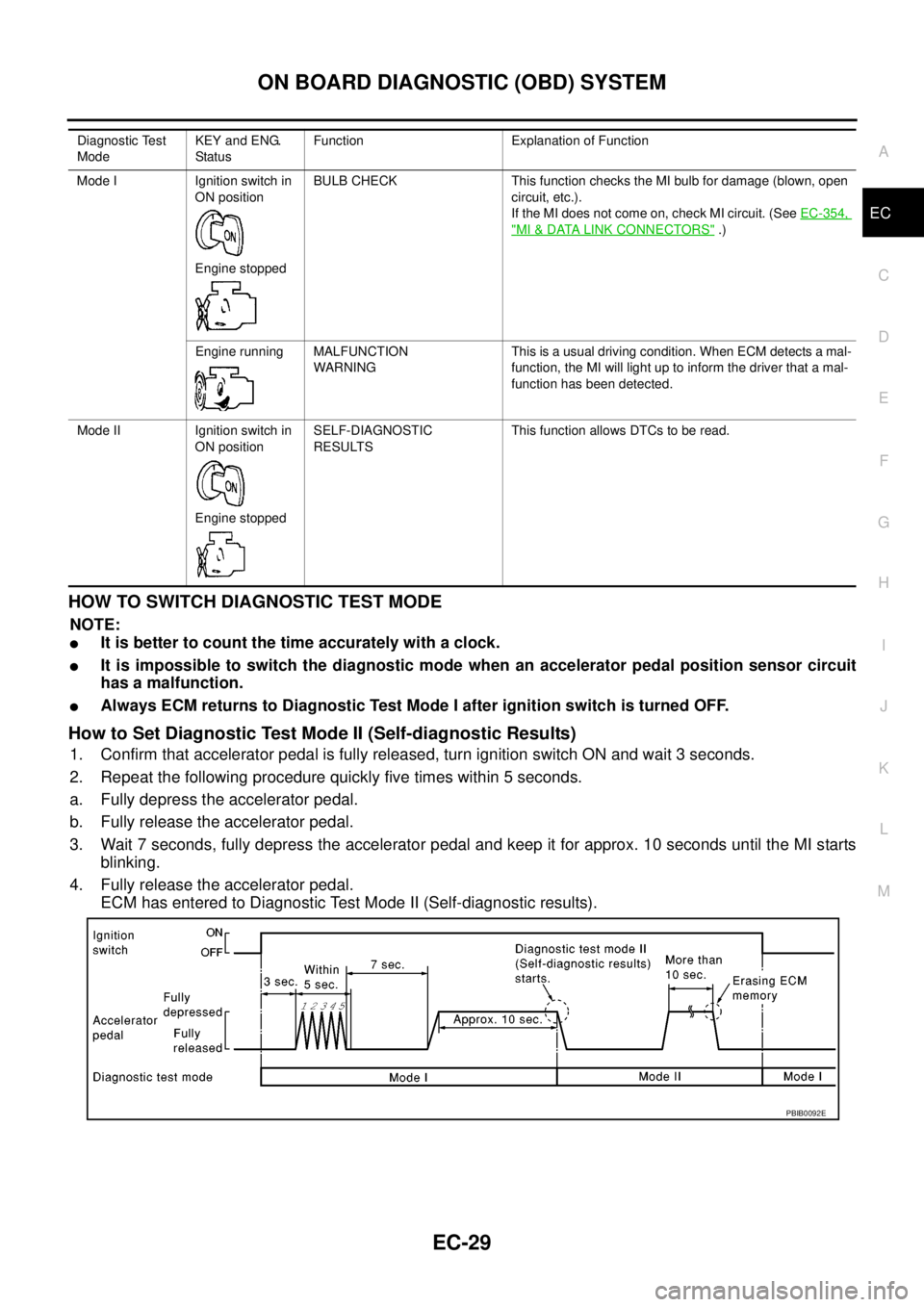

HOWTOSWITCHDIAGNOSTICTESTMODE

NOTE:

lIt is better to count the time accurately with a clock.

lIt is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

lAlways ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MI starts

blinking.

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

Diagnostic Test

ModeKEY and ENG.

Statu sFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (SeeEC-354,

"MI&DATA LINK CONNECTORS".)

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When ECM detects a mal-

function, the MI will light up to inform the driver that a mal-

function has been detected.

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs to be read.

PBIB0092E

Page 1018 of 3171

EC-38

TROUBLE DIAGNOSIS

Basic Inspection

EBS01KCV

Precaution:

Perform Basic Inspection without electrical or mechanical loads applied;

lHeadlamp switch is OFF.

lOn vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

lAir conditioner switch is OFF.

lHeater fan switch is OFF.

lRear defogger switch is OFF.

lHeat up switch is OFF.

lSteering wheel is in the straight-ahead position, etc.

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related incident.

2. Check the current need for scheduled maintenance, especially for fuel filter and air cleaner filter. Refer to

MA-8, "

PERIODIC MAINTENANCE".

3. Open engine hood and check the following:

–Harness connectors for improper connections

–Vacuum hoses for splits, kinks, or improper connections

–Wiring for improper connections, pinches, or cuts

4. Start engine and warm it up to the normal operating tempera-

ture.

>> GO TO 2.

2.PREPARATION FOR CHECKING IDLE SPEED

With CONSULT-II

Connect CONSULT-II to the data link connector.

Without CONSULT-II

Install diesel tacho tester to the vehicle.

>> GO TO 3.

SEF142I

Page 1047 of 3171

TROUBLE DIAGNOSIS

EC-67

C

D

E

F

G

H

I

J

K

L

MA

EC

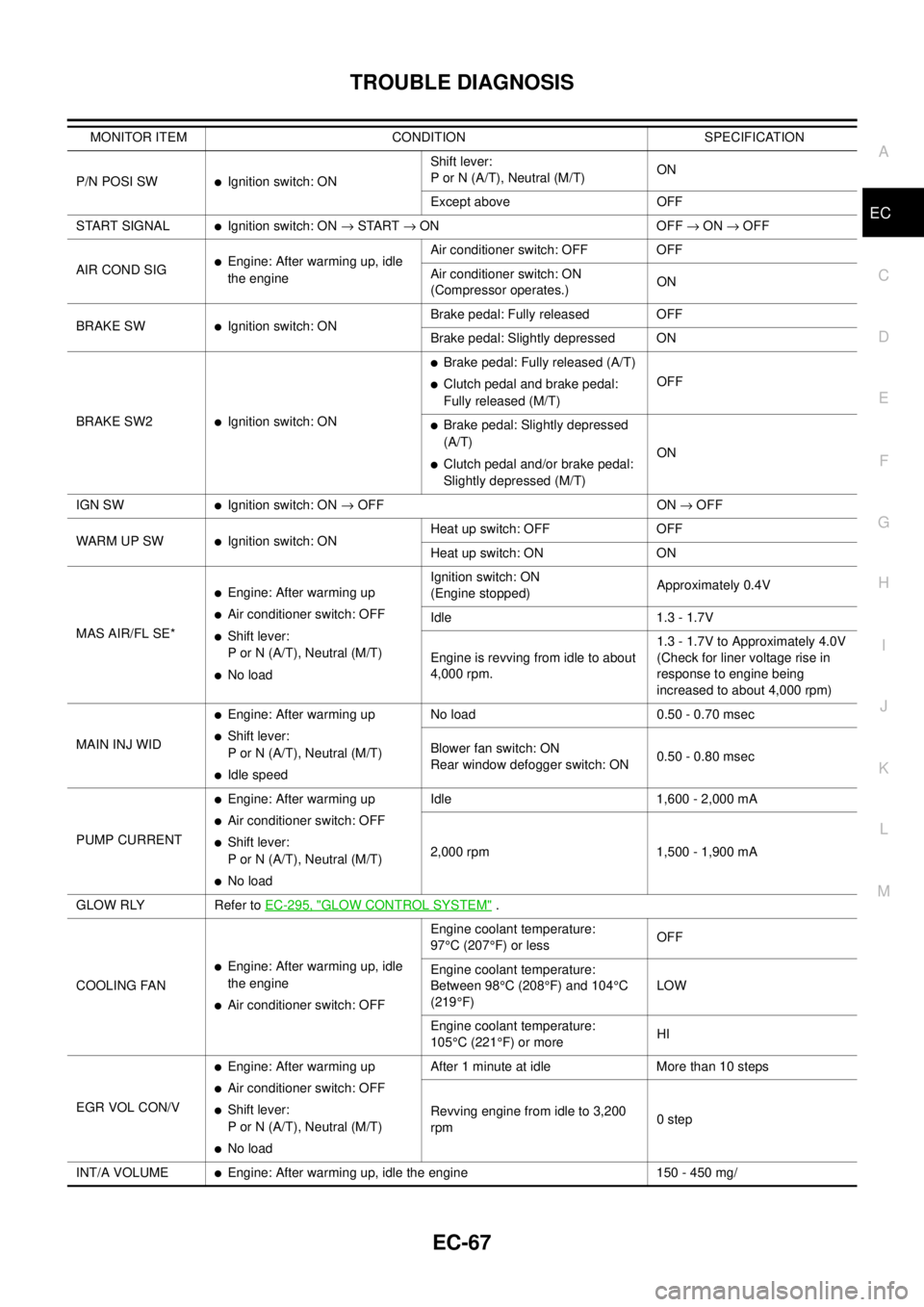

P/N POSI SWlIgnition switch: ONShift lever:

P or N (A/T), Neutral (M/T)ON

Except above OFF

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

AIRCONDSIG

lEngine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed

(A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

IGN SW

lIgnition switch: ON®OFF ON®OFF

WARM UP SW

lIgnition switch: ONHeat up switch: OFF OFF

Heat up switch: ON ON

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to about

4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

MAIN INJ WID

lEngine: After warming up

lShift lever:

P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

PUMP CURRENT

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 1,600 - 2,000 mA

2,000 rpm 1,500 - 1,900 mA

GLOW RLY Refer toEC-295, "

GLOW CONTROL SYSTEM".

COOLING FAN

lEngine: After warming up, idle

the engine

lAir conditioner switch: OFFEngine coolant temperature:

97°C (207°F) or lessOFF

Engine coolant temperature:

Between 98°C(208°F) and 104°C

(219°F)LOW

Engine coolant temperature:

105°C(221°F) or moreHI

EGR VOL CON/V

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadAfter 1 minute at idle More than 10 steps

Revving engine from idle to 3,200

rpm0step

INT/A VOLUME

lEngine: After warming up, idle the engine 150 - 450 mg/ MONITOR ITEM CONDITION SPECIFICATION

Page 1062 of 3171

EC-82

DTC P0016 CKP - CMP CORRELATION

DTC P0016 CKP - CMP CORRELATION

PFP:10328

On Board Diagnosis LogicEBS01KDF

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0016 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

DTC Confirmation ProcedureEBS01KDG

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 5 seconds.

4. If DTC is detected, go toEC-82, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 5 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-82, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KDH

1.CHECK CAMSHAFT POSITION SENSOR

Refer toEC-175, "

Component Inspection".

OK or NG

OK >> GO TO 2.

NG >> Replace camshaft position sensor.

2.CHECK SPROCKET

Visually check for chipping signal plate gear tooth.

OK or NG

OK >> GO TO 3.

NG >> Remove debris and clean the signal plate or replace sprocket.

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

P0016

0016Crankshaft position -

camshaft position cor-

relationThe correlation between crankshaft position sen-

sor signal and camshaft position sensor signal is

out of the normal range.

lCamshaft position sensor

lCrankshaft position sensor

lTiming chain

lSignal plate

SEF817Y

Page 1128 of 3171

EC-148

DTC P0234 TC SYSTEM

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicEBS01KG4

The MI will not light up for this self-diagnosis.

NOTE:

If DTC P0234 is displayed with DTC P0652 or P0653, first perform the trouble diagnosis for DTC P0652

or P0653. Refer toEC-227, "

DTC P0652, P0653 SENSOR POWER SUPPLY".

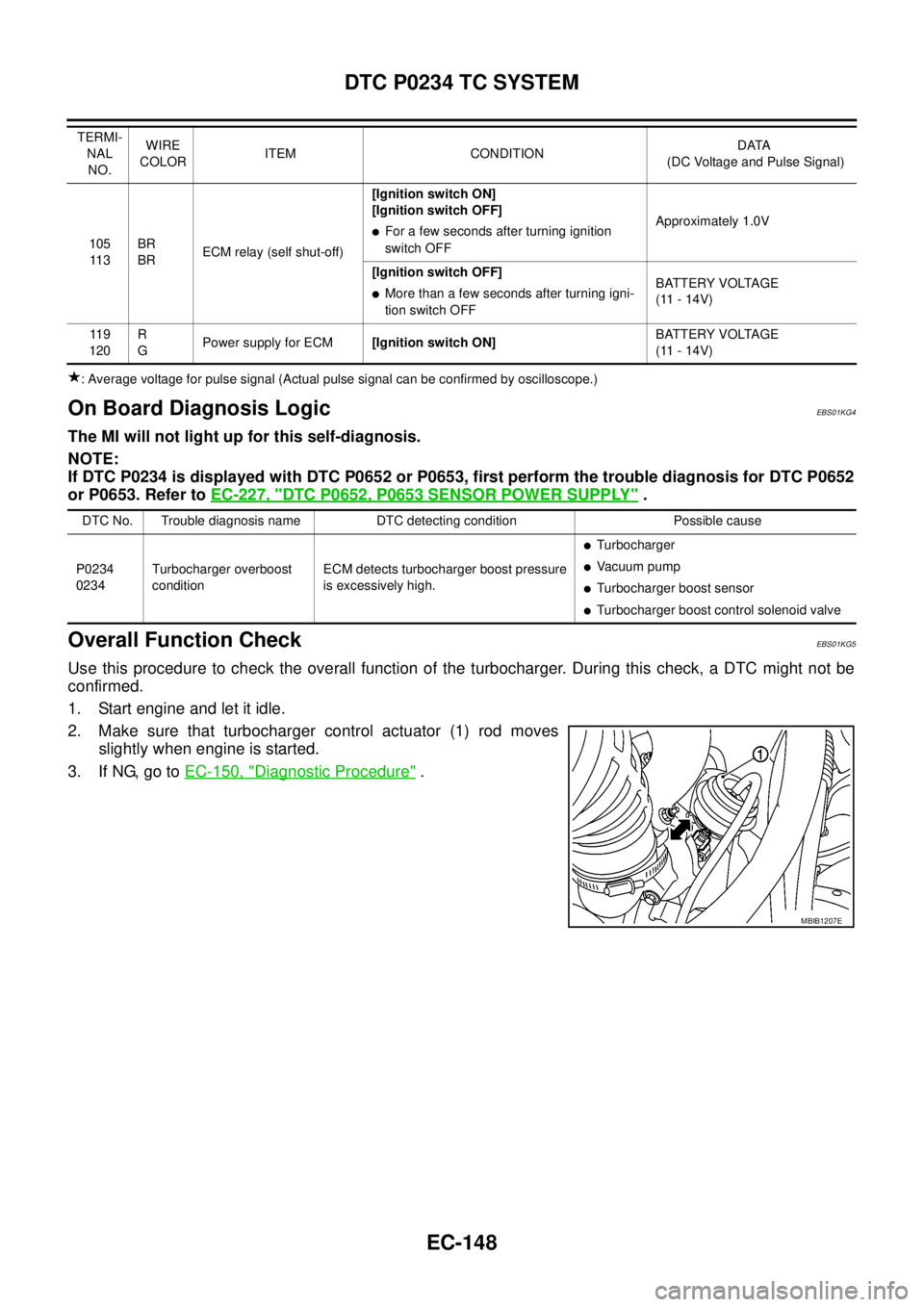

Overall Function CheckEBS01KG5

Use this procedure to check the overall function of the turbocharger. During this check, a DTC might not be

confirmed.

1. Start engine and let it idle.

2. Make sure that turbocharger control actuator (1) rod moves

slightly when engine is started.

3. If NG, go toEC-150, "

Diagnostic Procedure".

105

11 3BR

BRECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V) TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0234

0234Turbocharger overboost

conditionECM detects turbocharger boost pressure

is excessively high.

lTurbocharger

lVa c u u m p u m p

lTurbocharger boost sensor

lTurbocharger boost control solenoid valve

MBIB1207E

Page 1183 of 3171

DTC P0563 BATTERY VOLTAGE

EC-203

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0563 BATTERY VOLTAGEPFP:24410

On Board Diagnosis LogicEBS01KI1

The MI will not light up for this self-diagnosis.

DTC Confirmation ProcedureEBS01KI2

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 35 seconds.

4. If DTC is detected, go toEC-203, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for at least 35 seconds.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-203, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KI3

1.INSPECTION START

Are jumper cables connected for the jump starting?

Ye s o r N o

Ye s > > G O T O 3 .

No >> GO TO 2.

2.CHECK BATTERY AND ALTERNATOR

Check that the proper type of battery and type of alternator are installed.

Refer to,SC-5, "

BATTERY"andSC-14, "CHARGING SYSTEM".

OK or NG

OK >> GO TO 5.

NG >> Replace with the proper one.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0563

0563Battery voltage highAn excessively high voltage from the battery is

sent to ECM.

lBattery

lBattery terminal

lAlternator

lIncorrect jump starting

SEF817Y

Page 1292 of 3171

EC-312

TC BOOST CONTROL SOLENOID VALVE

Diagnostic Procedure

EBS01KM2

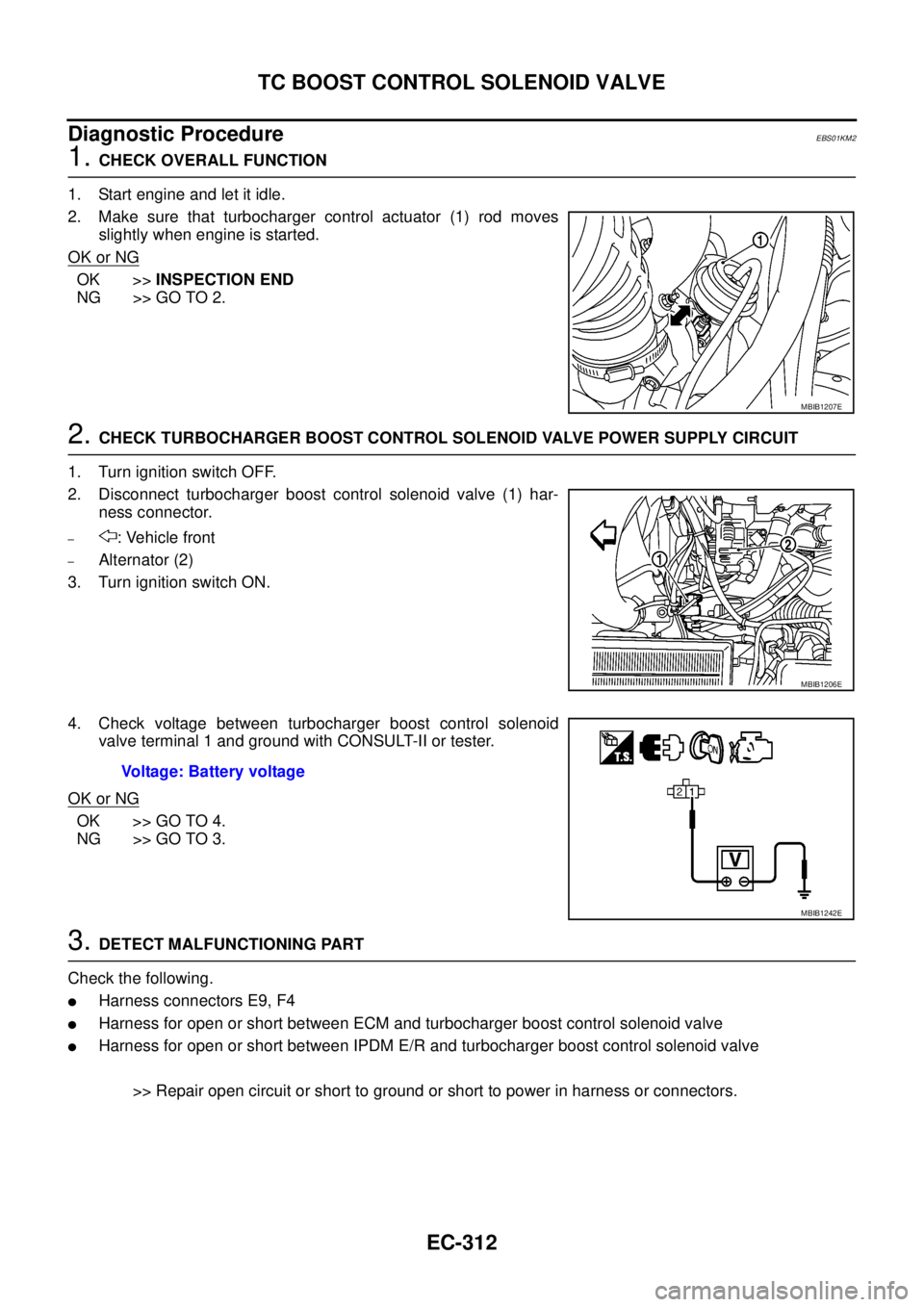

1.CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that turbocharger control actuator (1) rod moves

slightly when engine is started.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect turbocharger boost control solenoid valve (1) har-

ness connector.

–: Vehicle front

–Alternator (2)

3. Turn ignition switch ON.

4. Check voltage between turbocharger boost control solenoid

valve terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E9, F4

lHarness for open or short between ECM and turbocharger boost control solenoid valve

lHarness for open or short between IPDM E/R and turbocharger boost control solenoid valve

>> Repair open circuit or short to ground or short to power in harness or connectors.

MBIB1207E

MBIB1206E

Voltage: Battery voltage

MBIB1242E

Page 1468 of 3171

EM-86

PRIMARY TIMING CHAIN

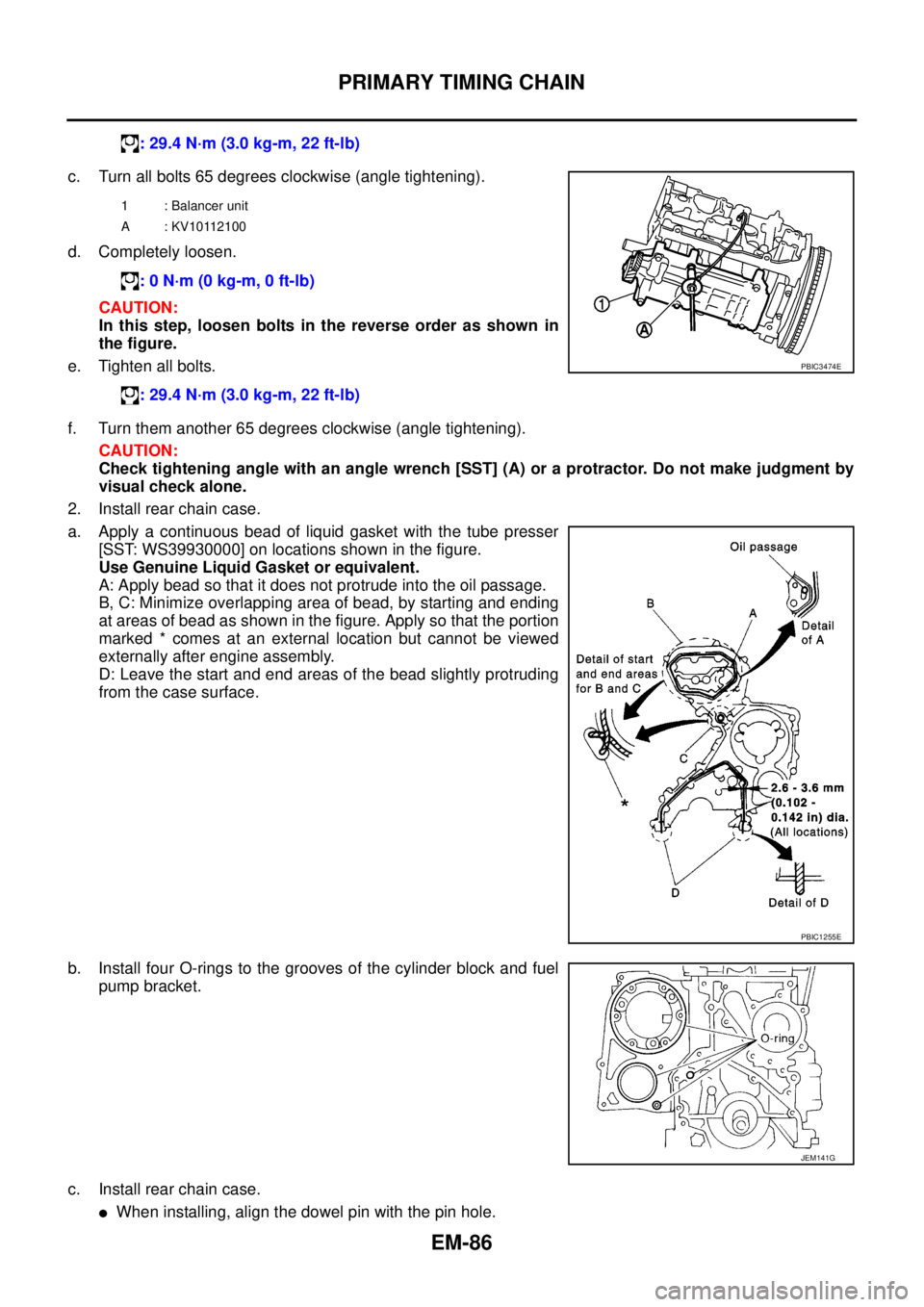

c. Turn all bolts 65 degrees clockwise (angle tightening).

d. Completely loosen.

CAUTION:

In this step, loosen bolts in the reverse order as shown in

the figure.

e. Tighten all bolts.

f. Turn them another 65 degrees clockwise (angle tightening).

CAUTION:

Check tightening angle with an angle wrench [SST] (A) or a protractor. Do not make judgment by

visual check alone.

2. Install rear chain case.

a. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000] on locations shown in the figure.

Use Genuine Liquid Gasket or equivalent.

A: Apply bead so that it does not protrude into the oil passage.

B, C: Minimize overlapping area of bead, by starting and ending

at areas of bead as shown in the figure. Apply so that the portion

marked * comes at an external location but cannot be viewed

externally after engine assembly.

D: Leave the start and end areas of the bead slightly protruding

from the case surface.

b. Install four O-rings to the grooves of the cylinder block and fuel

pump bracket.

c. Install rear chain case.

lWhen installing, align the dowel pin with the pin hole.: 29.4 N·m (3.0 kg-m, 22 ft-lb)

1 : Balancer unit

A : KV10112100

: 0 N·m (0 kg-m, 0 ft-lb)

: 29.4 N·m (3.0 kg-m, 22 ft-lb)

PBIC3474E

PBIC1255E

JEM141G

Page 1514 of 3171

EM-132

CYLINDER BLOCK

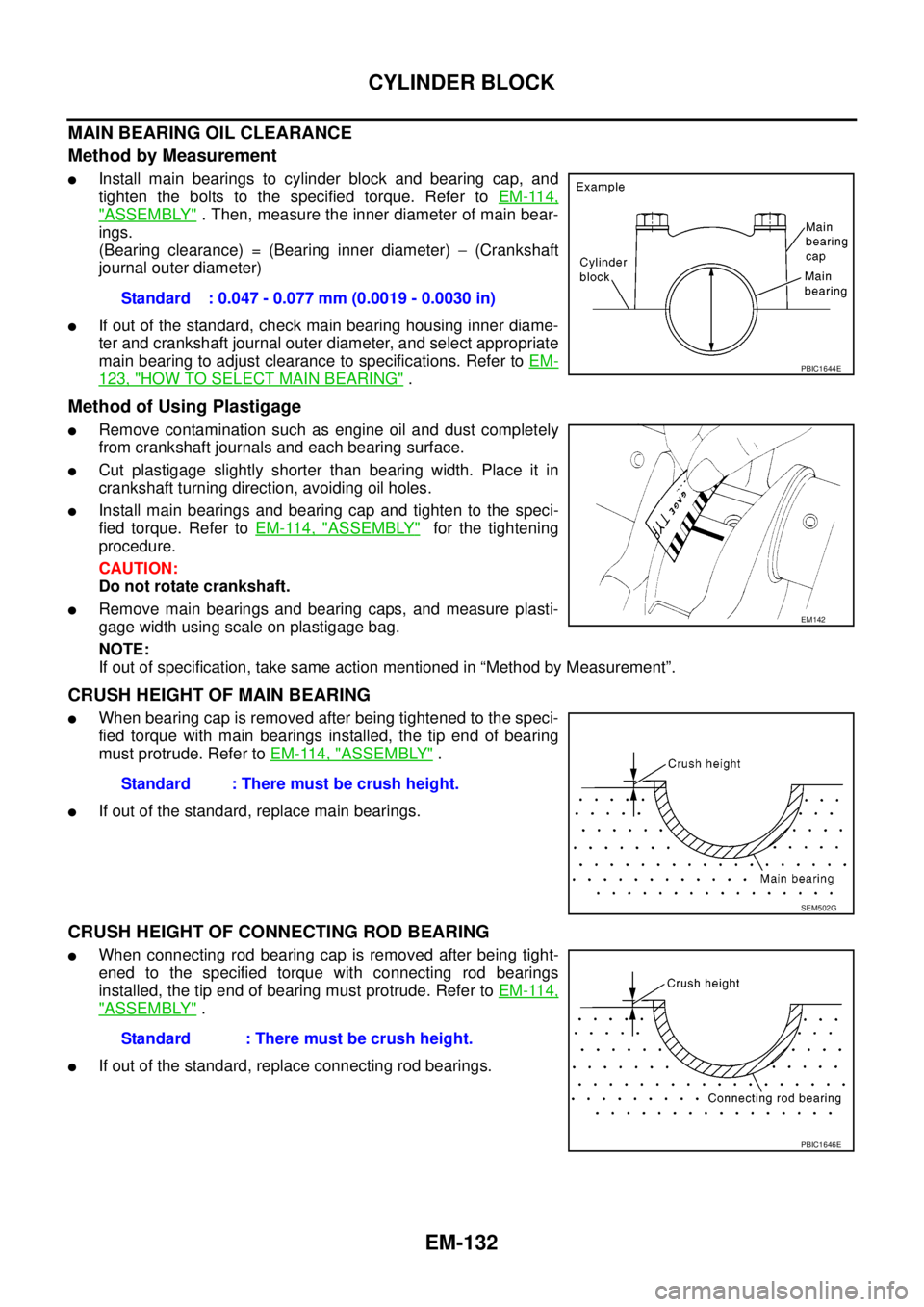

MAIN BEARING OIL CLEARANCE

Method by Measurement

lInstall main bearings to cylinder block and bearing cap, and

tighten the bolts to the specified torque. Refer toEM-114,

"ASSEMBLY". Then, measure the inner diameter of main bear-

ings.

(Bearing clearance) = (Bearing inner diameter)-(Crankshaft

journal outer diameter)

lIf out of the standard, check main bearing housing inner diame-

ter and crankshaft journal outer diameter, and select appropriate

main bearing to adjust clearance to specifications. Refer toEM-

123, "HOW TO SELECT MAIN BEARING".

Method of Using Plastigage

lRemove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surface.

lCut plastigage slightly shorter than bearing width. Place it in

crankshaft turning direction, avoiding oil holes.

lInstall main bearings and bearing cap and tighten to the speci-

fied torque. Refer toEM-114, "

ASSEMBLY"for the tightening

procedure.

CAUTION:

Do not rotate crankshaft.

lRemove main bearings and bearing caps, and measure plasti-

gage width using scale on plastigage bag.

NOTE:

If out of specification, take same action mentioned in “Method by Measurement”.

CRUSH HEIGHT OF MAIN BEARING

lWhen bearing cap is removed after being tightened to the speci-

fied torque with main bearings installed, the tip end of bearing

must protrude. Refer toEM-114, "

ASSEMBLY".

lIf out of the standard, replace main bearings.

CRUSH HEIGHT OF CONNECTING ROD BEARING

lWhen connecting rod bearing cap is removed after being tight-

ened to the specified torque with connecting rod bearings

installed, the tip end of bearing must protrude. Refer toEM-114,

"ASSEMBLY".

lIf out of the standard, replace connecting rod bearings.Standard : 0.047 - 0.077 mm (0.0019 - 0.0030 in)

PBIC1644E

EM142

Standard : There must be crush height.

SEM502G

Standard : There must be crush height.

PBIC1646E