relay NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 104 of 3171

AT-96

DTC P0615 START SIGNAL CIRCUIT

Data are reference value and are measured between each terminal and ground.

Diagnostic ProcedureECS00FXO

1.CHECK STARTER RELAY

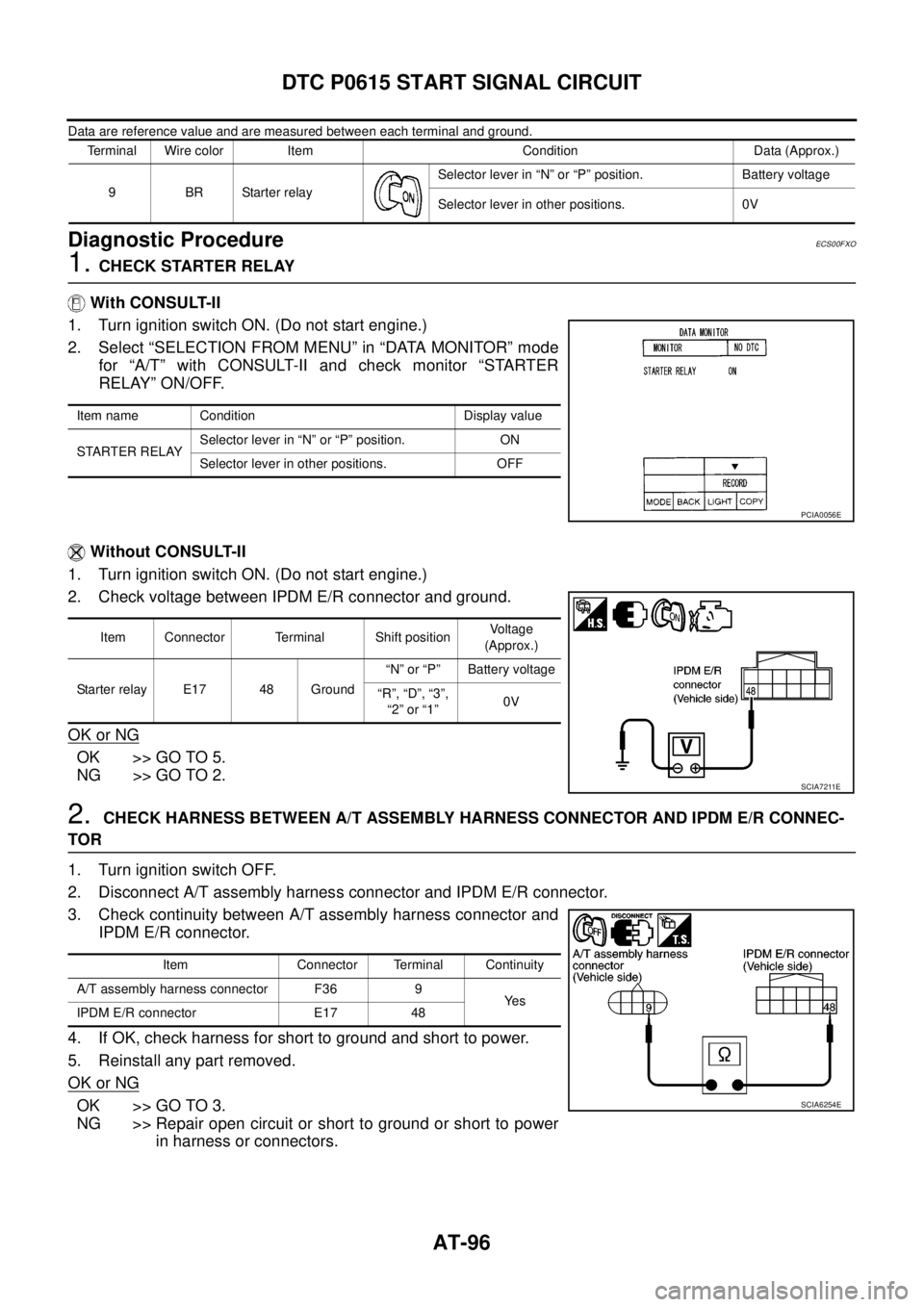

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN A/T ASSEMBLY HARNESS CONNECTOR AND IPDM E/R CONNEC-

TOR

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector and IPDM E/R connector.

3. Check continuity between A/T assembly harness connector and

IPDM E/R connector.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

Terminal Wire color Item Condition Data (Approx.)

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Item name Condition Display value

STARTER RELAYSelector lever in “N” or “P” position. ON

Selector lever in other positions. OFF

PCIA0056E

Item Connector Terminal Shift positionVoltage

(Approx.)

Starter relay E17 48 Ground“N” or “P” Battery voltage

“R”, “D”, “3”,

“2”or“1”0V

SCIA7211E

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

IPDM E/R connector E17 48

SCIA6254E

Page 105 of 3171

DTC P0615 START SIGNAL CIRCUIT

AT-97

D

E

F

G

H

I

J

K

L

MA

B

AT

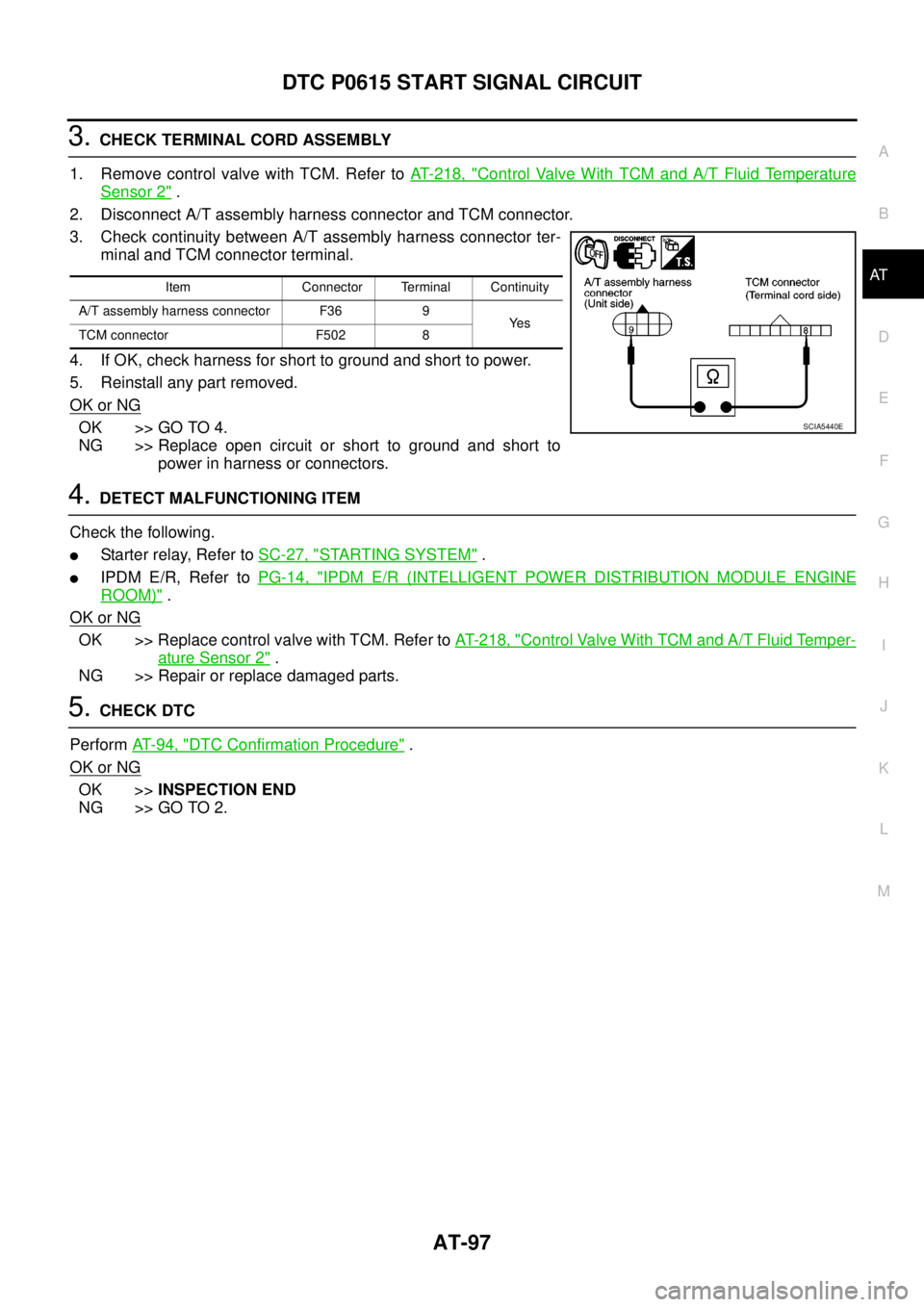

3.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter-

minal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Replace open circuit or short to ground and short to

power in harness or connectors.

4.DETECT MALFUNCTIONING ITEM

Check the following.

lStarter relay, Refer toSC-27, "STARTING SYSTEM".

lIPDM E/R, Refer toPG-14, "IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)".

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

5.CHECK DTC

PerformAT-94, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

TCM connector F502 8

SCIA5440E

Page 185 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-177

D

E

F

G

H

I

J

K

L

MA

B

AT

Data are reference value and are measured between each terminal and ground.

OD OFF Indicator Lamp Does Not Come OnECS00G2B

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OD OFF INDICATOR LAMP CIRCUIT

Check combination meter. Refer toDI-4, "

COMBINATION METERS".

OK or NG

OK >> GO TO 3

NG >> Repair or replace damaged parts.

3.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in “P” or “N” PositionECS00G2C

SYMPTOM:

lEngine cannot be started with selector lever in “P” or “N” position.

lEngine can be started with selector lever in “R”, “D”, “3”, “2” or “1” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Do the self-diagnosis results indicate PNP switch?

YES >> Check malfunctioning system. Refer toAT-99, "DTC P0705 PARK/NEUTRAL POSITION

SWITCH".

NO >> GO TO 2.

TerminalWire

colorItem Condition Data (Approx.)

3 L CAN-H – –

4GRK-line (CONSULT-

II signal)The terminal is connected to the data link connector for CONSULT-II. –

7LGBack-up lamp

relaySelector lever in “R” position. 0V

Selector lever in other positions. Battery voltage

8 P CAN-L – –

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Page 354 of 3171

ATC-20

REFRIGERATION SYSTEM

REFRIGERATION SYSTEM

PFP:KA990

Refrigerant CycleEJS006AW

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator is

controlled by an externally equalized expansion valve, located inside the evaporator case.

FREEZE PROTECTION

Under usual operating conditions, when the A/C is switched ON, the compressor runs continuously, and the

evaporator pressure, and therefore, temperature is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionEJS006AX

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2,17.4psi).

Page 361 of 3171

AIR CONDITIONER CONTROL

ATC-27

C

D

E

F

G

H

I

K

L

MA

B

AT C

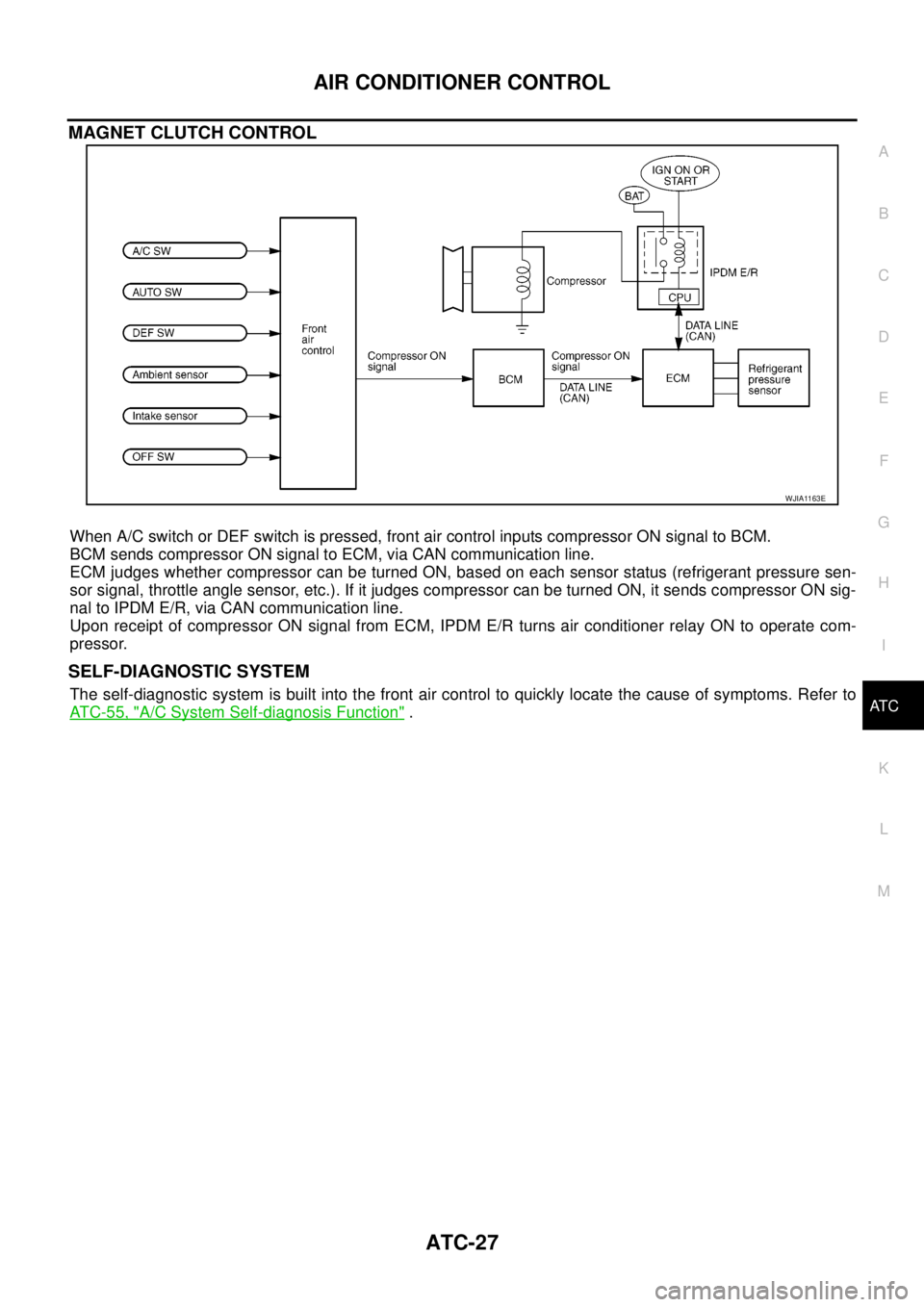

MAGNET CLUTCH CONTROL

When A/C switch or DEF switch is pressed, front air control inputs compressor ON signal to BCM.

BCM sends compressor ON signal to ECM, via CAN communication line.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sen-

sor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON sig-

nal to IPDM E/R, via CAN communication line.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

SELF-DIAGNOSTIC SYSTEM

The self-diagnostic system is built into the front air control to quickly locate the cause of symptoms. Refer to

AT C - 5 5 , "

A/C System Self-diagnosis Function".

WJIA1163E

Page 388 of 3171

ATC-54

TROUBLE DIAGNOSIS

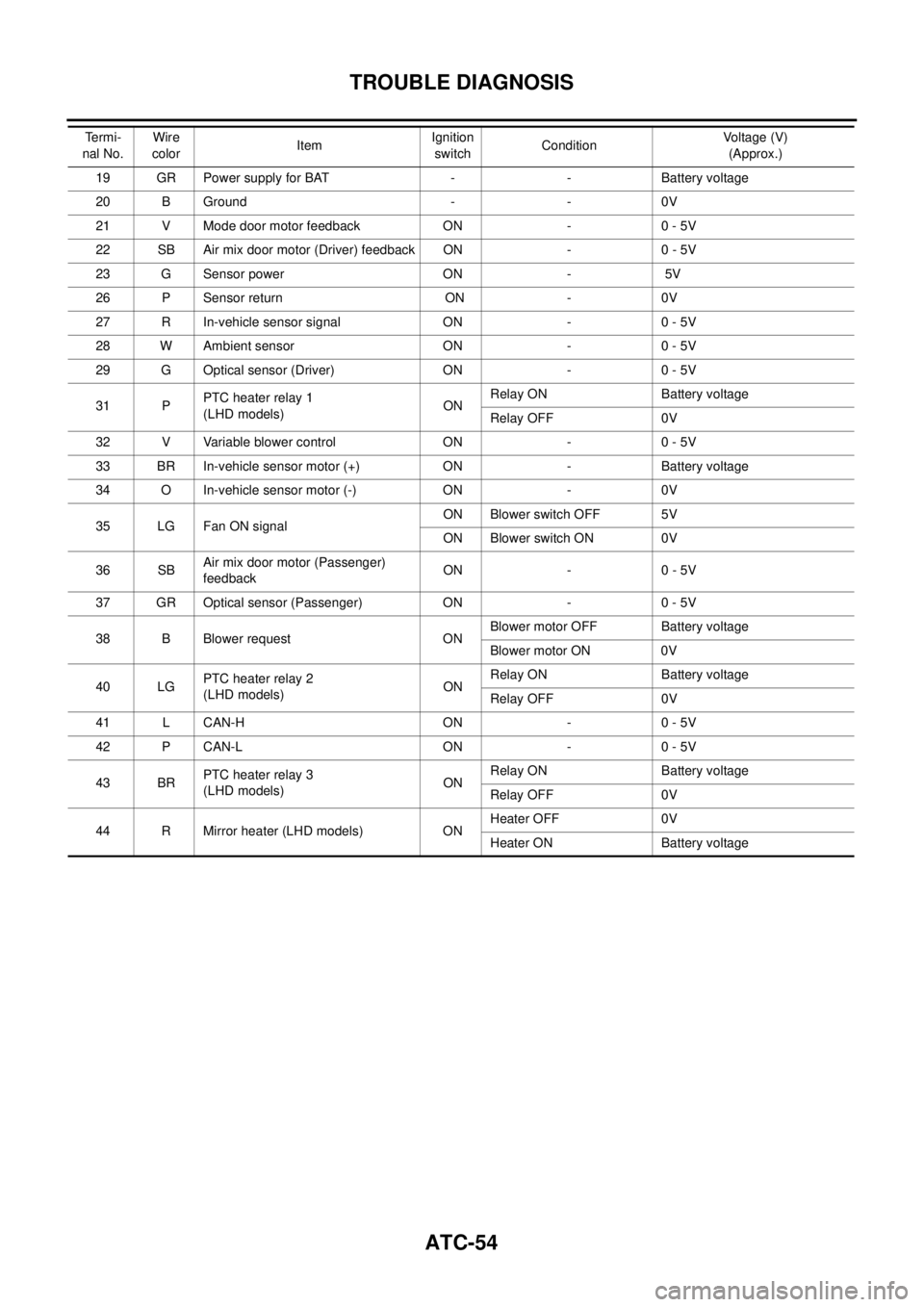

19 GR Power supply for BAT - - Battery voltage

20 B Ground - - 0V

21 V Mode door motor feedback ON - 0 - 5V

22 SB Air mix door motor (Driver) feedback ON - 0 - 5V

23 G Sensor power ON - 5V

26 P Sensor return ON - 0V

27 R In-vehicle sensor signal ON - 0 - 5V

28 W Ambient sensor ON - 0 - 5V

29 G Optical sensor (Driver) ON - 0 - 5V

31 PPTC heater relay 1

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

32 V Variable blower control ON - 0 - 5V

33 BR In-vehicle sensor motor (+) ON - Battery voltage

34 O In-vehicle sensor motor (-) ON - 0V

35 LG Fan ON signalON Blower switch OFF 5V

ON Blower switch ON 0V

36 SBAir mix door motor (Passenger)

feedbackON - 0 - 5V

37 GR Optical sensor (Passenger) ON - 0 - 5V

38 B Blower request ONBlower motor OFF Battery voltage

Blower motor ON 0V

40 LGPTC heater relay 2

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

41 L CAN-H ON - 0 - 5V

42 P CAN-L ON - 0 - 5V

43 BRPTC heater relay 3

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

44 R Mirror heater (LHD models) ONHeater OFF 0V

Heater ON Battery voltage Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

Page 417 of 3171

![NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK B NISSAN NAVARA 2005 Repair User Guide TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK B](/img/5/57362/w960_57362-416.png)

TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

1.CHECK FUSES

Check 15A fuses [No. 24 and 27, (located in the fuse and fusible link box)]. For fuse layout, refer toPG-84,

"FUSE AND FUSIBLE LINK BOX".

OK or NG

OK >> GO TO 2.

NG >> GO TO 10.

2.CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect blower motor connector.

3. Turn ignition switch ON.

4. Turn the blower control dial to select any mode except off.

5. Check voltage between blower motor harness connector M94

terminal 2 and ground.

OK or NG

OK >> GO TO 12.

NG >> GO TO 3.

3.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect blower motor relay.

3. Check voltage between blower motor relay harness connector

E28 terminals 3 and 6 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK BLOWER MOTOR RELAY

Refer toAT C - 8 6 , "

Blower Motor Relay".

OK or NG

OK >> GO TO 5.

NG >> Replace blower motor relay.

5.CHECK BLOWER MOTOR RELAY (SWITCH SIDE) CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect blower motor relay connector and blower motor con-

nector.

3. Check continuity between blower motor relay harness connector

E28 terminals 5 and 7 and blower motor harness connector M94

terminal 2.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.Fuses are good.

2 - Ground : Battery voltage.

MJIB0065E

3, 6 - Ground : Battery voltage.

MJIB0066E

5, 7 - 2 : Continuity should exist.

MJIB0067E

Page 418 of 3171

ATC-84

TROUBLE DIAGNOSIS

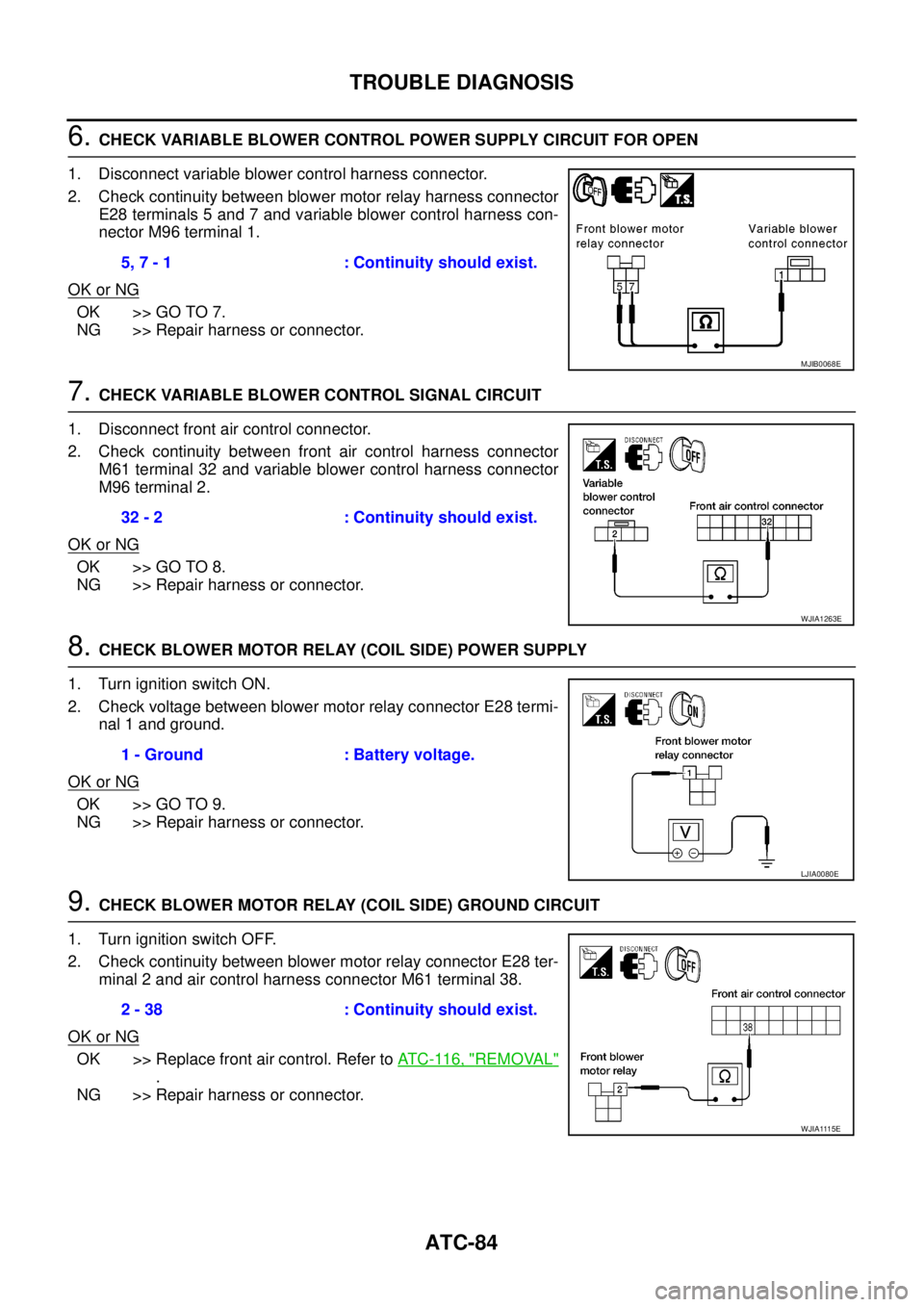

6.CHECK VARIABLE BLOWER CONTROL POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect variable blower control harness connector.

2. Check continuity between blower motor relay harness connector

E28 terminals 5 and 7 and variable blower control harness con-

nector M96 terminal 1.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT

1. Disconnect front air control connector.

2. Check continuity between front air control harness connector

M61 terminal 32 and variable blower control harness connector

M96 terminal 2.

OK or NG

OK >> GO TO 8.

NG >> Repair harness or connector.

8.CHECK BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between blower motor relay connector E28 termi-

nal 1 and ground.

OK or NG

OK >> GO TO 9.

NG >> Repair harness or connector.

9.CHECK BLOWER MOTOR RELAY (COIL SIDE) GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between blower motor relay connector E28 ter-

minal 2 and air control harness connector M61 terminal 38.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> Repair harness or connector.5, 7 - 1 : Continuity should exist.

MJIB0068E

32 - 2 : Continuity should exist.

WJIA1263E

1 - Ground : Battery voltage.

LJIA0080E

2 - 38 : Continuity should exist.

WJIA1115E

Page 420 of 3171

ATC-86

TROUBLE DIAGNOSIS

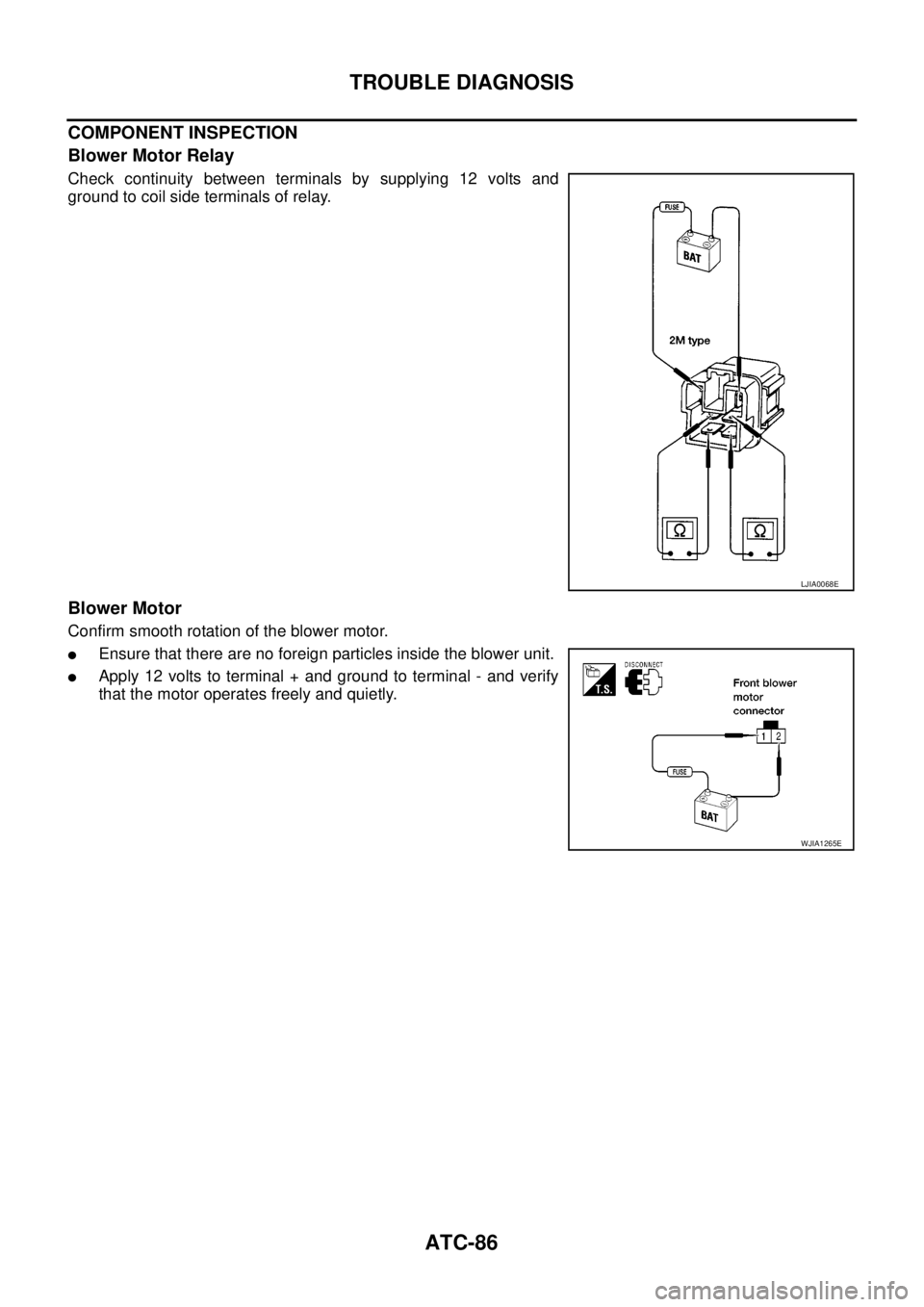

COMPONENT INSPECTION

Blower Motor Relay

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Blower Motor

Confirm smooth rotation of the blower motor.

lEnsure that there are no foreign particles inside the blower unit.

lApply 12 volts to terminal + and ground to terminal - and verify

that the motor operates freely and quietly.

LJIA0068E

WJIA1265E

Page 725 of 3171

THEFT WARNING SYSTEM

BL-141

C

D

E

F

G

H

J

K

L

MA

B

BL

2. A door is unlocked without using the keyfob.

3. Disconnect and connecting the battery connector before canceling armed phase.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

lthrough 10A fuse [No.19, located in the fuse block (J/B)]

lto combination meter (security indicator lamp) terminal 3

lthrough 50A fusible link (letterG, located in the fuse and fusible link box)

lto BCM terminal 57

lthrough 10A fuse [No. 21, located in the fuse block (J/B)]

lto BCM terminal 41

lthrough 15A fuse (No. 30, located in the fuse and fusible link box)

lto horn relay terminal 2

lthrough 20A fuse (No. 52, located in the IPDM E/R)

lthrough 20A fuse (No. 53, located in the IPDM E/R),

lto IPDM E/R internal CPU.

With the ignition switch in the ACC or ON position, power is supplied

lthrough 10A fuse [No. 4, located in the fuse block (J/B)]

lto BCM terminal 4.

Ground is supplied

lto BCM terminal 55

lthrough body grounds M21, M80 and M83

lto IPDM E/R terminals 38 and 59

lthrough body ground E21, E41 and E61.

INITIAL CONDITION TO ACTIVATE THE SYSTEM

The operation of the theft warning system is controlled by the engine hood and doors.

To activate the theft warning system, BCM must receive signals indicating the doors are closed and locked.

When a door is open, BCM terminal 12, 14, 15 or 16 receives a ground signal from each door switch.

When the engine hood is open, IPDM E/R terminal 41 receives a ground signal

THEFT WARNING SYSTEM ALARM OPERATION

The vehicle security system is triggered by

lopening a door

lopening the hood

ldetecting battery disconnect/connection.

The vehicle security system will be triggered once the system is in armed phase,

when BCM receives a ground signal at terminals 12, 14, 15, 16 (door switch) or IPDM E/R receives a ground

signal at terminal 41 (hood switch).

When the vehicle security system is triggered, siren control unit or horn is activate.

The alarm automatically turns off after 30 seconds, but will reactivate if the vehicle is tampered with again.

THEFT WARNING SYSTEM DEACTIVATION

To deactivate the theft warning system, a door must be unlocked with keyfob.

When the BCM receives either one of these signals or unlock signal from keyfob the theft warning system is

deactivated. (Disarmed phase)

CAN Communication System DescriptionEIS00DBY

Refer toLAN-23, "CAN COMMUNICATION".