relay NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1214 of 3171

EC-234

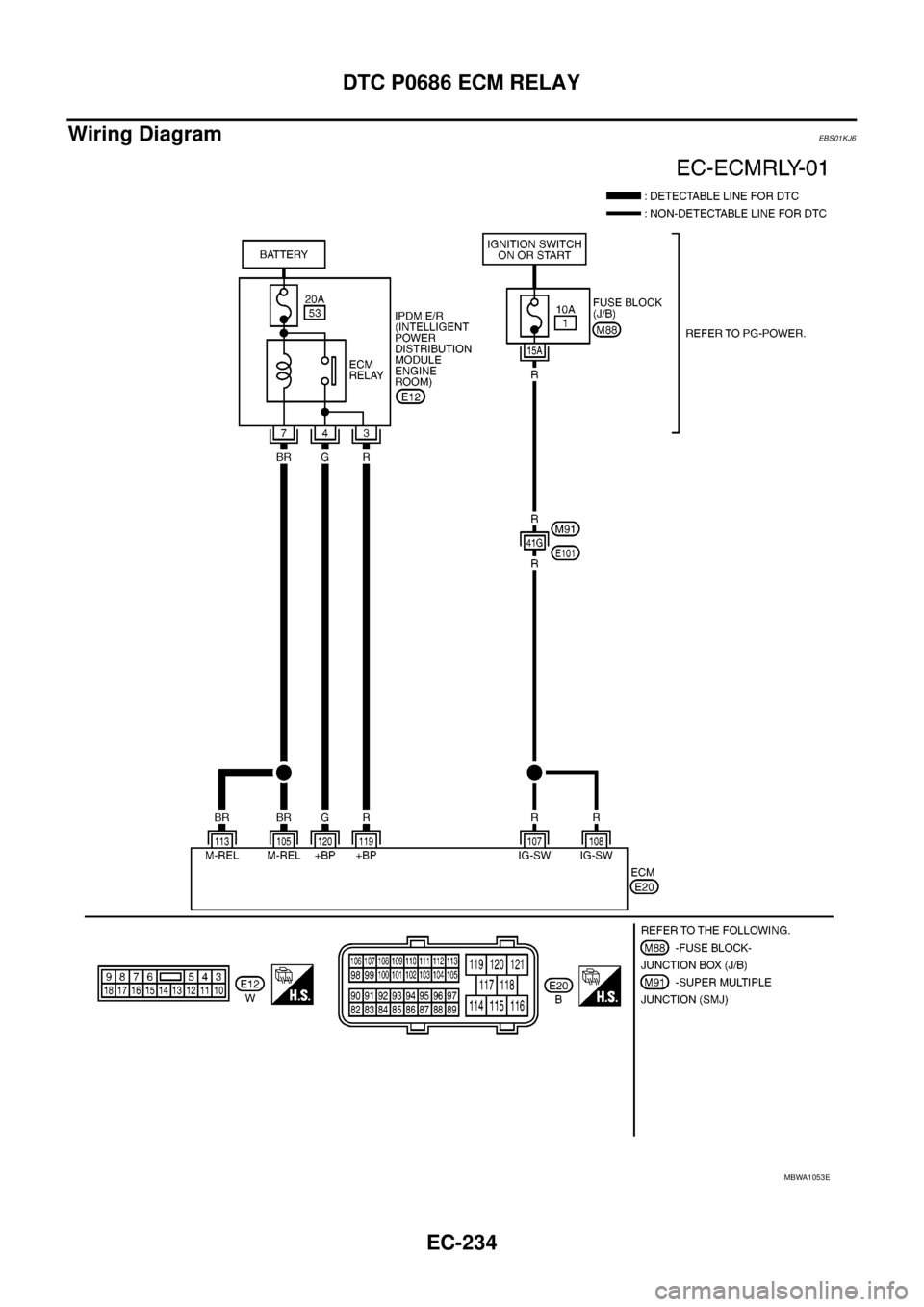

DTC P0686 ECM RELAY

Wiring Diagram

EBS01KJ6

MBWA1053E

Page 1215 of 3171

DTC P0686 ECM RELAY

EC-235

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KJ7

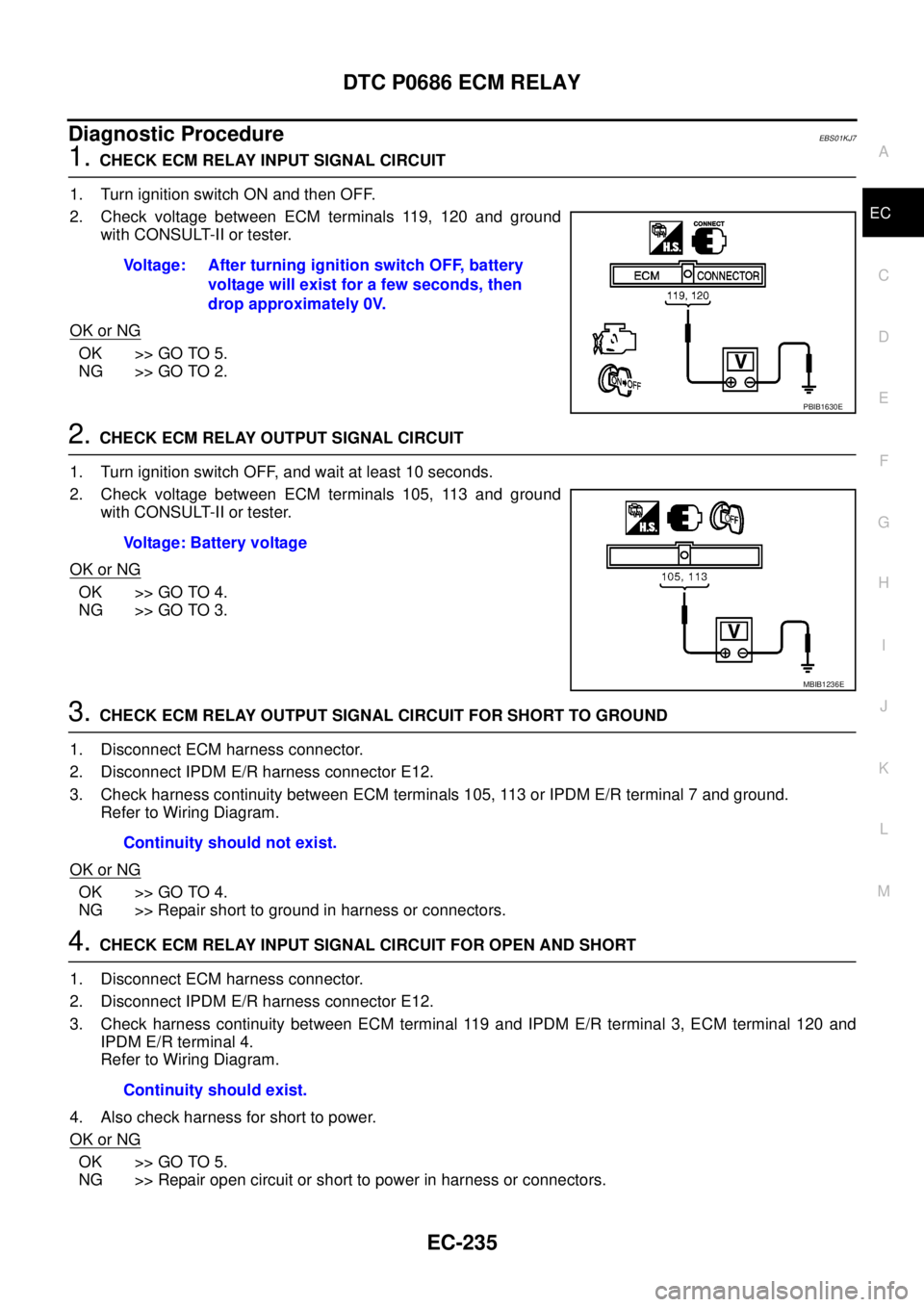

1.CHECK ECM RELAY INPUT SIGNAL CIRCUIT

1. Turn ignition switch ON and then OFF.

2. Check voltage between ECM terminals 119, 120 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK ECM RELAY OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF, and wait at least 10 seconds.

2. Check voltage between ECM terminals 105, 113 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK ECM RELAY OUTPUT SIGNAL CIRCUIT FOR SHORT TO GROUND

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E12.

3. Check harness continuity between ECM terminals 105, 113 or IPDM E/R terminal 7 and ground.

Refer to Wiring Diagram.

OK or NG

OK >> GO TO 4.

NG >> Repair short to ground in harness or connectors.

4.CHECK ECM RELAY INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E12.

3. Check harness continuity between ECM terminal 119 and IPDM E/R terminal 3, ECM terminal 120 and

IPDM E/R terminal 4.

Refer to Wiring Diagram.

4. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to power in harness or connectors.Voltage: After turning ignition switch OFF, battery

voltage will exist for a few seconds, then

drop approximately 0V.

PBIB1630E

Voltage: Battery voltage

MBIB1236E

Continuity should not exist.

Continuity should exist.

Page 1216 of 3171

EC-236

DTC P0686 ECM RELAY

5.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

Page 1275 of 3171

GLOW CONTROL SYSTEM

EC-295

C

D

E

F

G

H

I

J

K

L

MA

EC

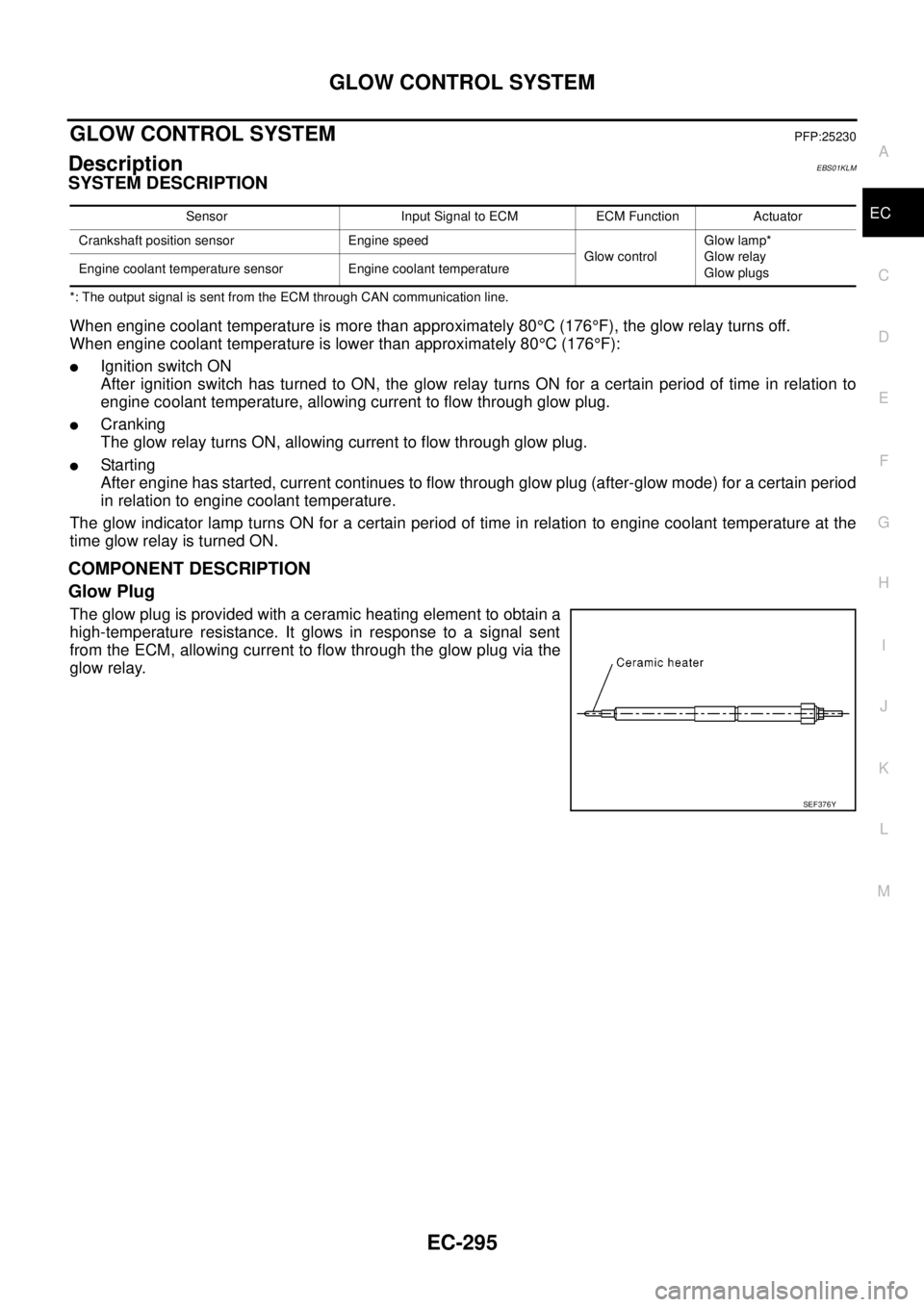

GLOW CONTROL SYSTEMPFP:25230

DescriptionEBS01KLM

SYSTEM DESCRIPTION

*: The output signal is sent from the ECM through CAN communication line.

When engine coolant temperature is more than approximately 80°C(176°F), the glow relay turns off.

When engine coolant temperature is lower than approximately 80°C(176°F):

lIgnition switch ON

After ignition switch has turned to ON, the glow relay turns ON for a certain period of time in relation to

engine coolant temperature, allowing current to flow through glow plug.

lCranking

The glow relay turns ON, allowing current to flow through glow plug.

lSta rti ng

After engine has started, current continues to flow through glow plug (after-glow mode) for a certain period

in relation to engine coolant temperature.

The glow indicator lamp turns ON for a certain period of time in relation to engine coolant temperature at the

time glow relay is turned ON.

COMPONENT DESCRIPTION

Glow Plug

The glow plug is provided with a ceramic heating element to obtain a

high-temperature resistance. It glows in response to a signal sent

from the ECM, allowing current to flow through the glow plug via the

glow relay.

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor Engine speed

Glow controlGlow lamp*

Glow relay

Glow plugs Engine coolant temperature sensor Engine coolant temperature

SEF376Y

Page 1279 of 3171

GLOW CONTROL SYSTEM

EC-299

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK DTC

Check that DTC U1000 is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses for DTC U1000, refer toEC-79, "DTC U1000 CAN COMMUNICATION

LINE".

No >> GO TO 6.

6.CHECK COMBINATON METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 1 4 .

No >> Check combination meter circuit. Refer toDI-4, "

COMBINATION METERS".

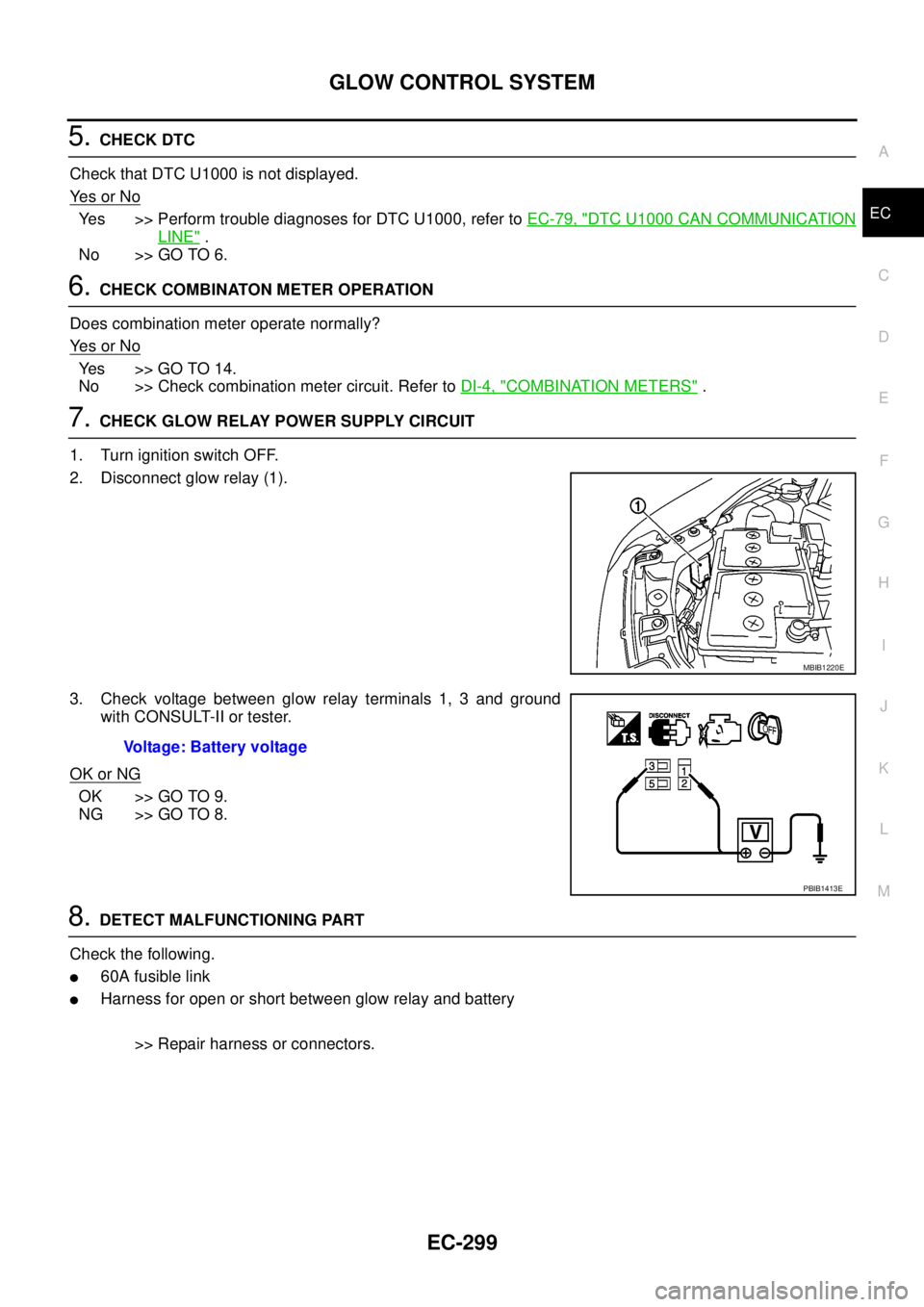

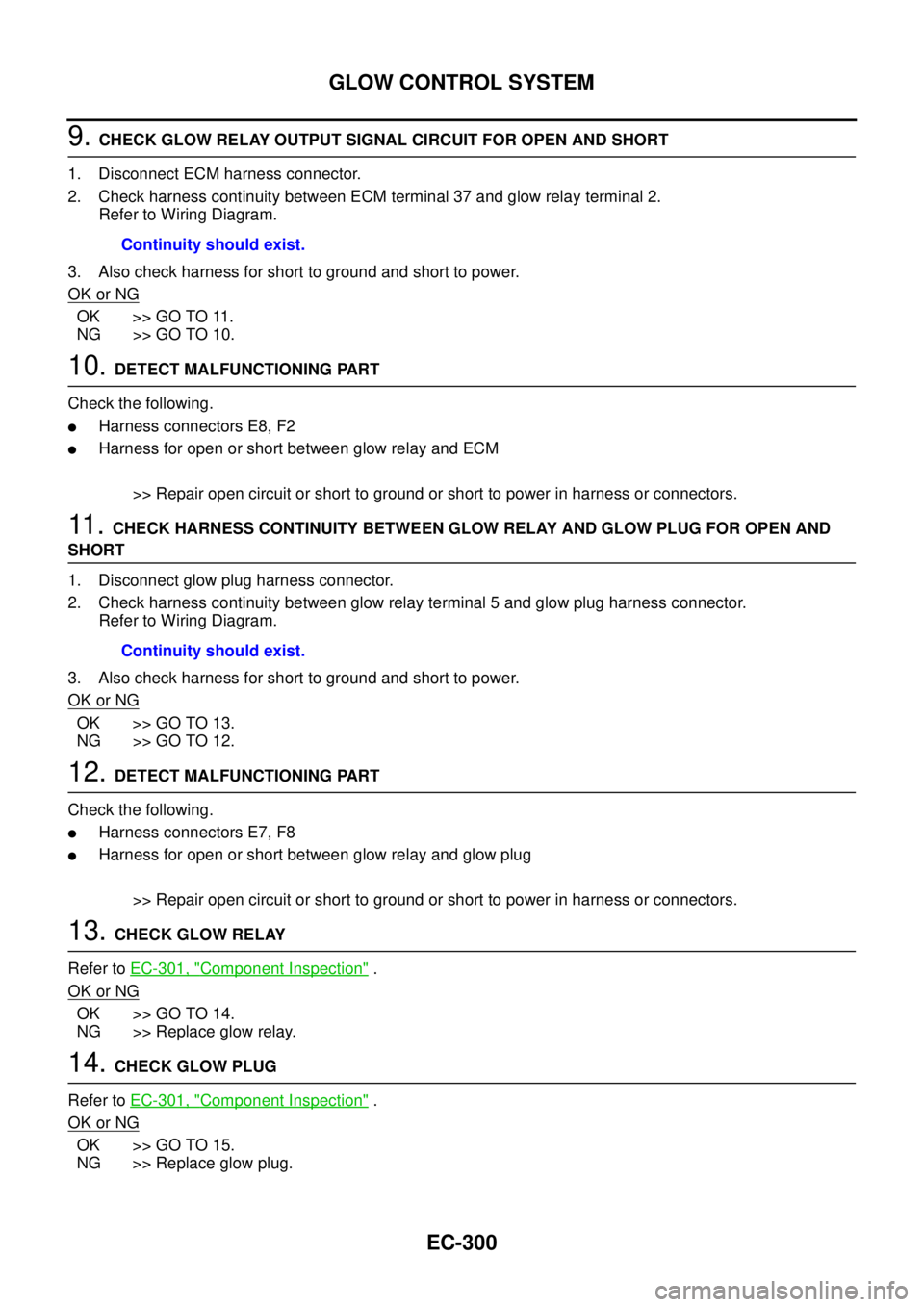

7.CHECK GLOW RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect glow relay (1).

3. Check voltage between glow relay terminals 1, 3 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

l60A fusible link

lHarness for open or short between glow relay and battery

>> Repair harness or connectors.

MBIB1220E

Voltage: Battery voltage

PBIB1413E

Page 1280 of 3171

EC-300

GLOW CONTROL SYSTEM

9.CHECK GLOW RELAY OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 37 and glow relay terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E8, F2

lHarness for open or short between glow relay and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK HARNESS CONTINUITY BETWEEN GLOW RELAY AND GLOW PLUG FOR OPEN AND

SHORT

1. Disconnect glow plug harness connector.

2. Check harness continuity between glow relay terminal 5 and glow plug harness connector.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12.DETECT MALFUNCTIONING PART

Check the following.

lHarness connectors E7, F8

lHarness for open or short between glow relay and glow plug

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.CHECK GLOW RELAY

Refer toEC-301, "

Component Inspection".

OK or NG

OK >> GO TO 14.

NG >> Replace glow relay.

14.CHECK GLOW PLUG

Refer toEC-301, "

Component Inspection".

OK or NG

OK >> GO TO 15.

NG >> Replace glow plug.Continuity should exist.

Continuity should exist.

Page 1281 of 3171

GLOW CONTROL SYSTEM

EC-301

C

D

E

F

G

H

I

J

K

L

MA

EC

15.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

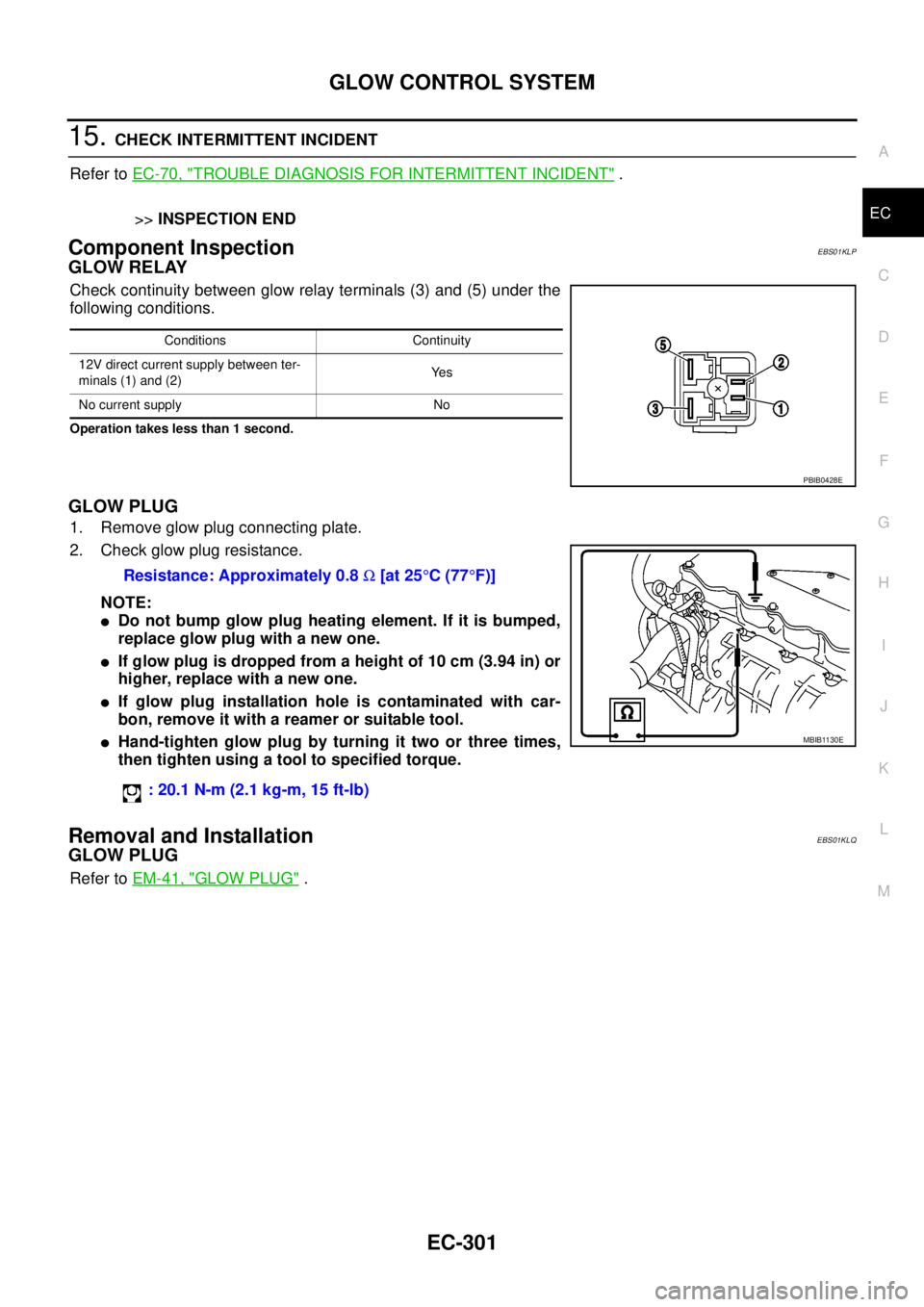

Component InspectionEBS01KLP

GLOW RELAY

Check continuity between glow relay terminals (3) and (5) under the

following conditions.

Operation takes less than 1 second.

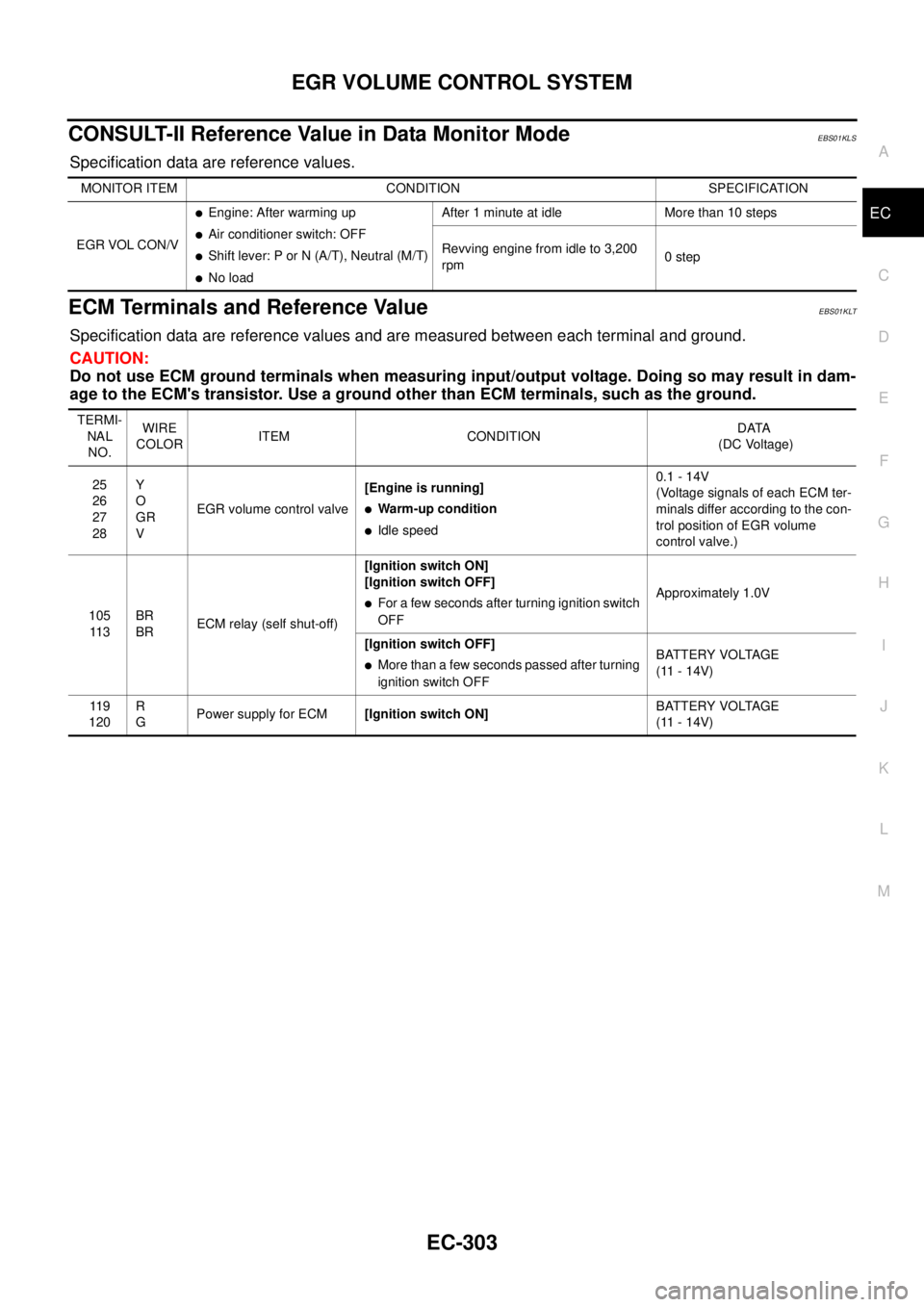

GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

NOTE:

lDo not bump glow plug heating element. If it is bumped,

replace glow plug with a new one.

lIf glow plug is dropped from a height of 10 cm (3.94 in) or

higher, replace with a new one.

lIf glow plug installation hole is contaminated with car-

bon, remove it with a reamer or suitable tool.

lHand-tighten glow plug by turning it two or three times,

then tighten using a tool to specified torque.

Removal and InstallationEBS01KLQ

GLOW PLUG

Refer toEM-41, "GLOW PLUG".

Conditions Continuity

12V direct current supply between ter-

minals (1) and (2)Ye s

No current supply No

PBIB0428E

Resistance: Approximately 0.8W[at 25°C(77°F)]

: 20.1 N-m (2.1 kg-m, 15 ft-lb)

MBIB1130E

Page 1283 of 3171

EGR VOLUME CONTROL SYSTEM

EC-303

C

D

E

F

G

H

I

J

K

L

MA

EC

CONSULT-II Reference Value in Data Monitor ModeEBS01KLS

Specification data are reference values.

ECM Terminals and Reference ValueEBS01KLT

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MONITOR ITEM CONDITION SPECIFICATION

EGR VOL CON/V

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadAfter 1 minute at idle More than 10 steps

Revving engine from idle to 3,200

rpm0step

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

25

26

27

28Y

O

GR

VEGR volume control valve[Engine is running]

lWarm-up condition

lIdle speed0.1 - 14V

(Voltage signals of each ECM ter-

minals differ according to the con-

trol position of EGR volume

control valve.)

105

11 3BR

BRECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]

lFor a few seconds after turning ignition switch

OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds passed after turning

ignition switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

Page 1290 of 3171

EC-310

TC BOOST CONTROL SOLENOID VALVE

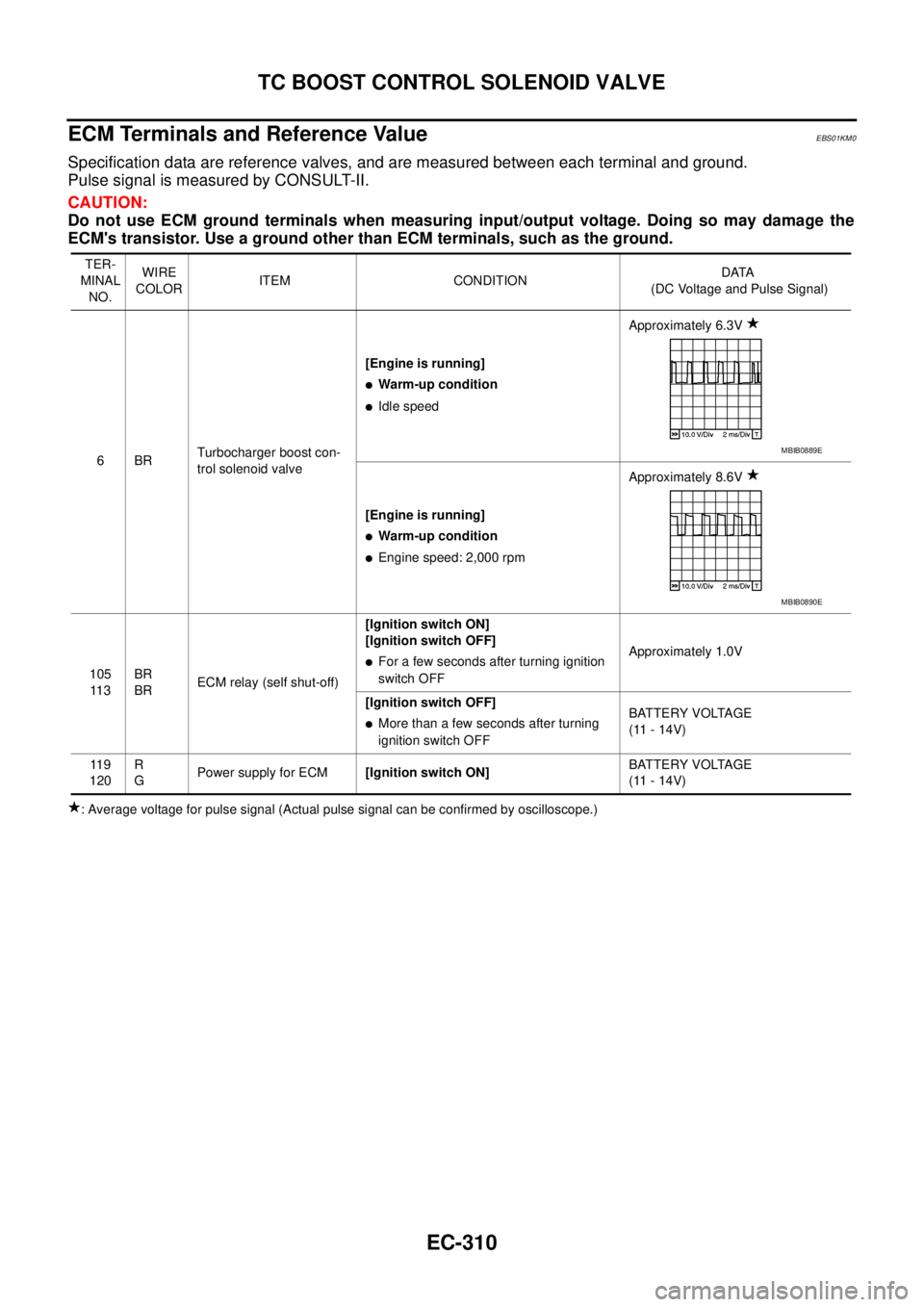

ECM Terminals and Reference Value

EBS01KM0

Specification data are reference valves, and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

6BRTurbocharger boost con-

trol solenoid valve[Engine is running]

lWarm-up condition

lIdle speedApproximately 6.3V

[Engine is running]

lWarm-up condition

lEngine speed: 2,000 rpmApproximately 8.6V

105

11 3BR

BRECM relay (self shut-off)[Ignition switch ON]

[Ignition switch OFF]

lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning

ignition switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

MBIB0889E

MBIB0890E

Page 1294 of 3171

EC-314

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

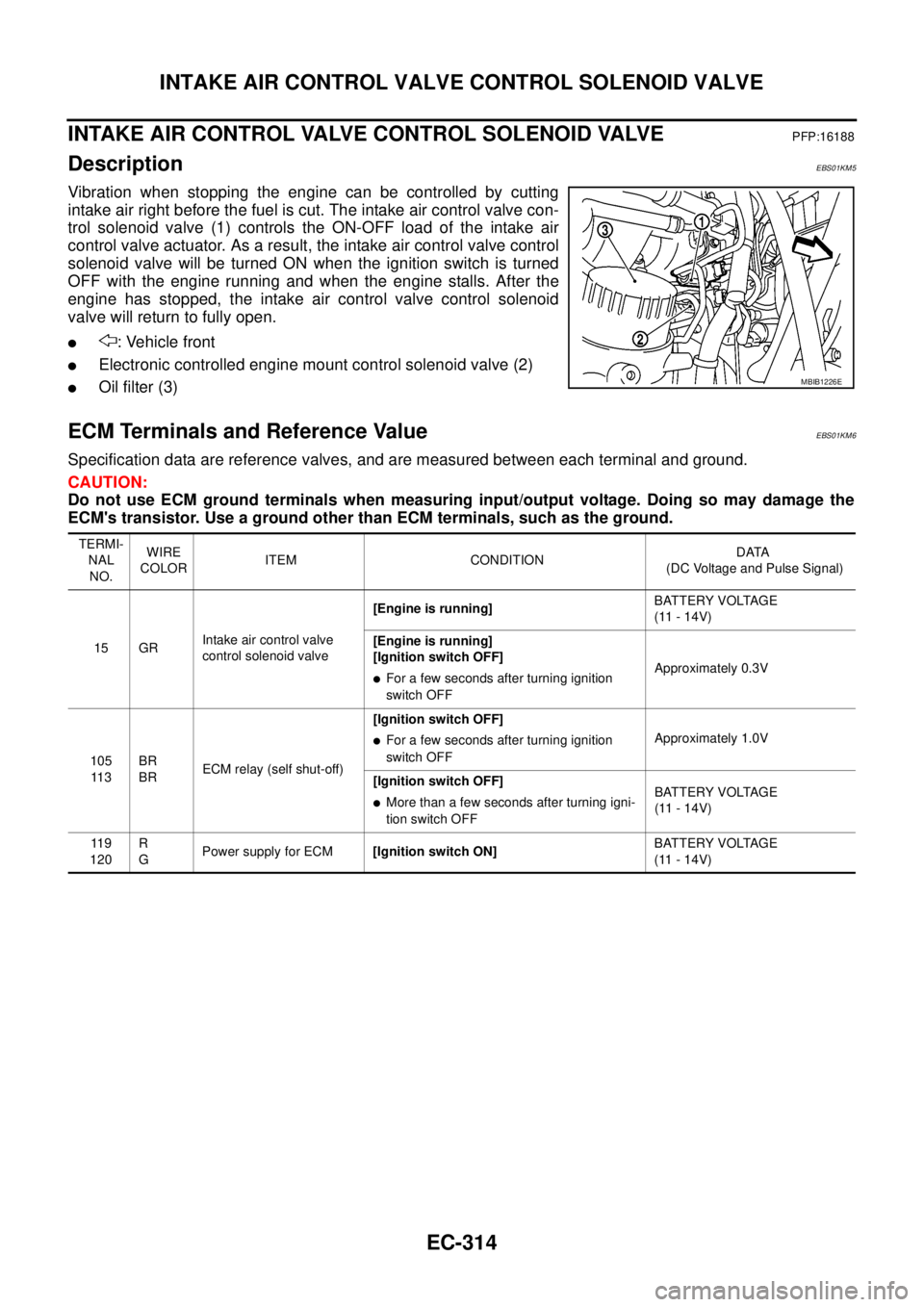

INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

PFP:16188

DescriptionEBS01KM5

Vibration when stopping the engine can be controlled by cutting

intake air right before the fuel is cut. The intake air control valve con-

trol solenoid valve (1) controls the ON-OFF load of the intake air

control valve actuator. As a result, the intake air control valve control

solenoid valve will be turned ON when the ignition switch is turned

OFF with the engine running and when the engine stalls. After the

engine has stopped, the intake air control valve control solenoid

valve will return to fully open.

l: Vehicle front

lElectronic controlled engine mount control solenoid valve (2)

lOil filter (3)

ECM Terminals and Reference ValueEBS01KM6

Specification data are reference valves, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

MBIB1226E

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse Signal)

15 GRIntake air control valve

control solenoid valve[Engine is running]BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

[Ignition switch OFF]

lFor a few seconds after turning ignition

switch OFFApproximately 0.3V

105

11 3BR

BRECM relay (self shut-off)[Ignition switch OFF]

lFor a few seconds after turning ignition

switch OFFApproximately 1.0V

[Ignition switch OFF]

lMore than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120R

GPower supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)