engine oil NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 244 of 3171

AT-236

ON-VEHICLE SERVICE

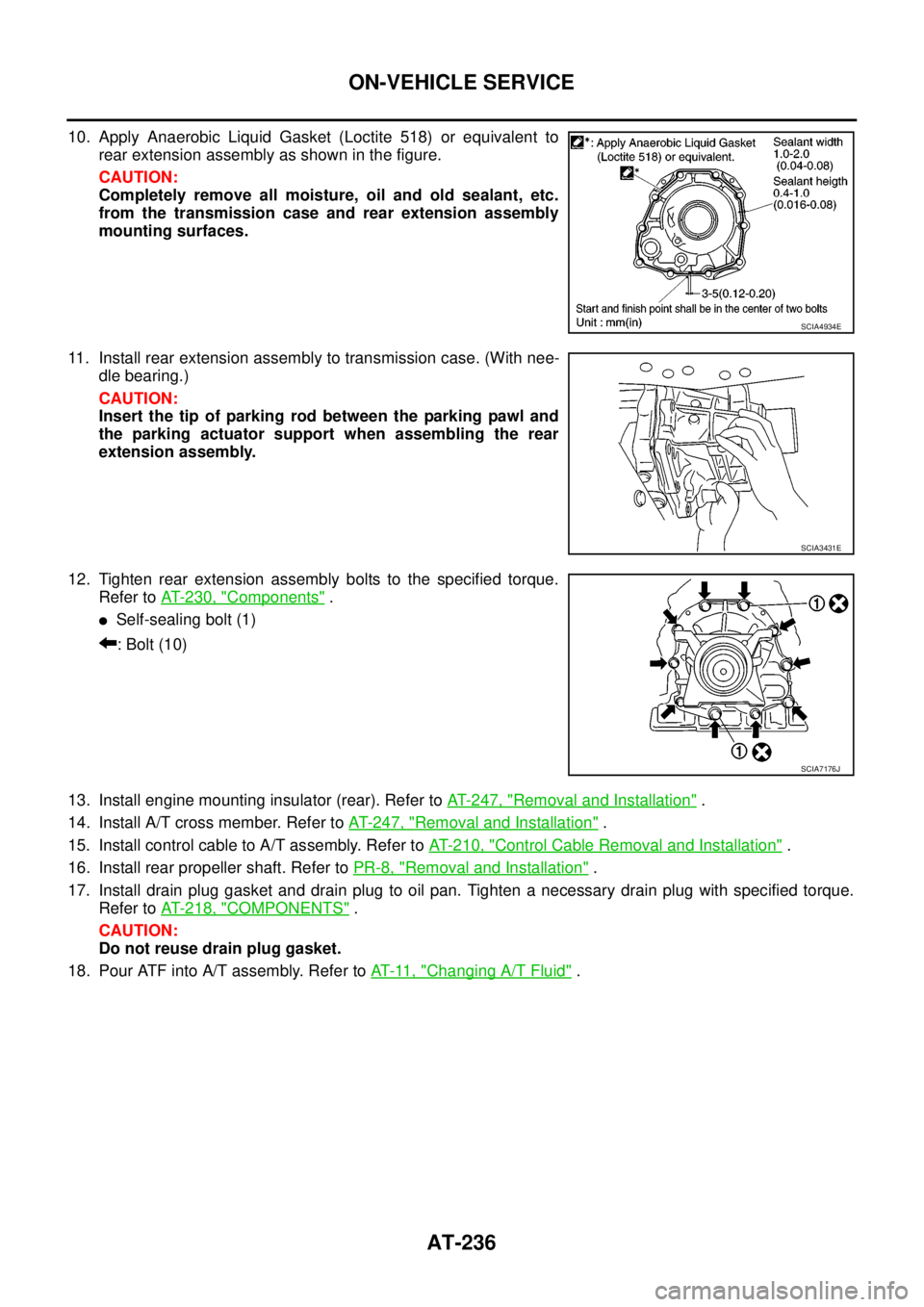

10. Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent to

rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

11. Install rear extension assembly to transmission case. (With nee-

dle bearing.)

CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

12. Tighten rear extension assembly bolts to the specified torque.

Refer toAT- 2 3 0 , "

Components".

lSelf-sealing bolt (1)

:Bolt(10)

13. Install engine mounting insulator (rear). Refer toAT- 2 4 7 , "

Removal and Installation".

14. Install A/T cross member. Refer toAT- 2 4 7 , "

Removal and Installation".

15. Install control cable to A/T assembly. Refer toAT- 2 1 0 , "

Control Cable Removal and Installation".

16. Install rear propeller shaft. Refer toPR-8, "

Removal and Installation".

17. Install drain plug gasket and drain plug to oil pan. Tighten a necessary drain plug with specified torque.

Refer toAT- 2 1 8 , "

COMPONENTS".

CAUTION:

Do not reuse drain plug gasket.

18. Pour ATF into A/T assembly. Refer toAT-11, "

Changing A/T Fluid".

SCIA4934E

SCIA3431E

SCIA7176J

Page 460 of 3171

ATC-126

HEATER & COOLING UNIT ASSEMBLY

Removal and Installation

EJS006C9

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toATC-138, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

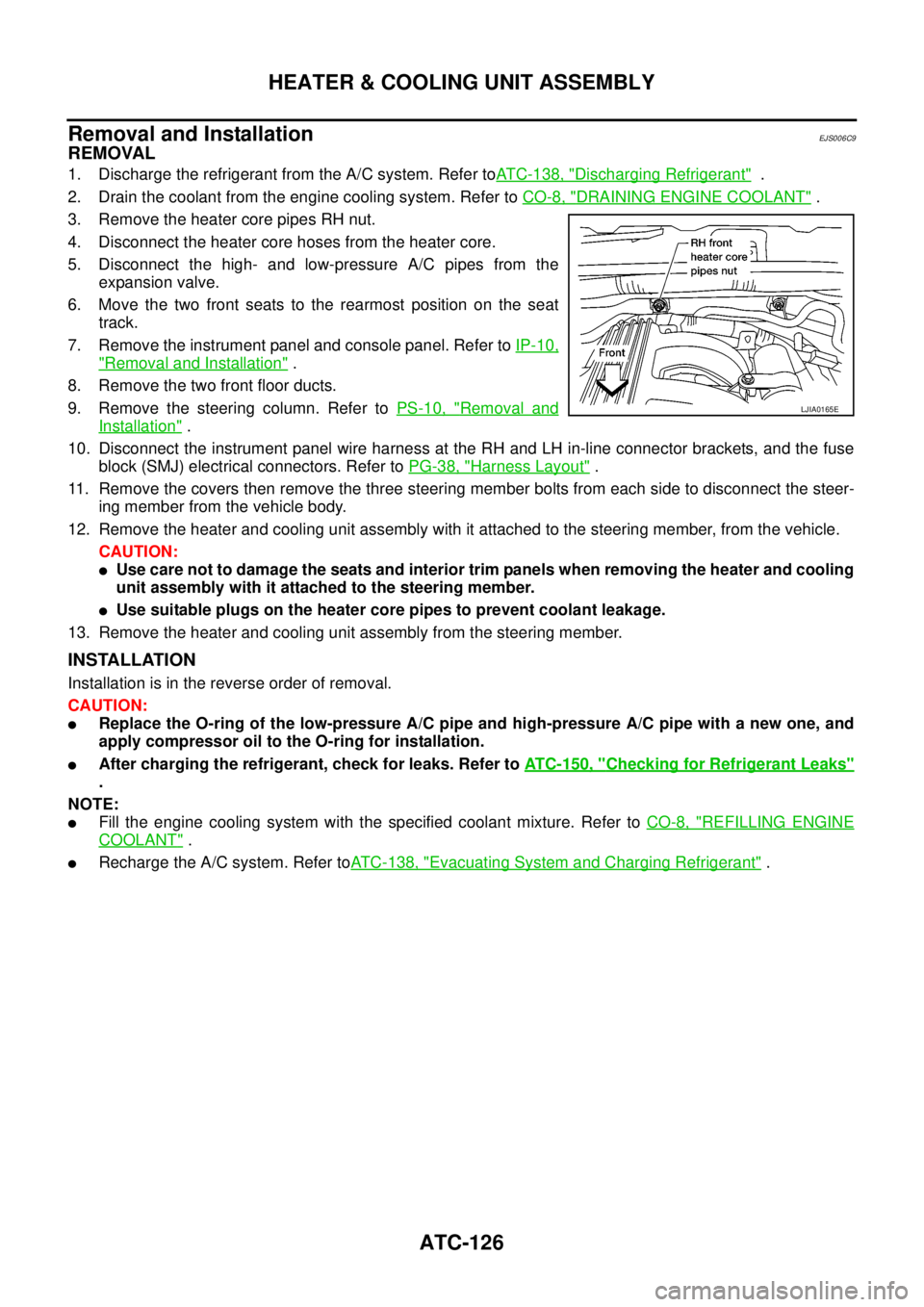

3. Remove the heater core pipes RH nut.

4. Disconnect the heater core hoses from the heater core.

5. Disconnect the high- and low-pressure A/C pipes from the

expansion valve.

6. Move the two front seats to the rearmost position on the seat

track.

7. Remove the instrument panel and console panel. Refer toIP-10,

"Removal and Installation".

8. Remove the two front floor ducts.

9. Remove the steering column. Refer toPS-10, "

Removal and

Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (SMJ) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Remove the covers then remove the three steering member bolts from each side to disconnect the steer-

ing member from the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

lUse care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

lUse suitable plugs on the heater core pipes to prevent coolant leakage.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure A/C pipe and high-pressure A/C pipe with a new one, and

apply compressor oil to the O-ring for installation.

lAfter charging the refrigerant, check for leaks. Refer toATC-150, "Checking for Refrigerant Leaks"

.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toATC-138, "Evacuating System and Charging Refrigerant".

LJIA0165E

Page 476 of 3171

ATC-142

REFRIGERANT LINES

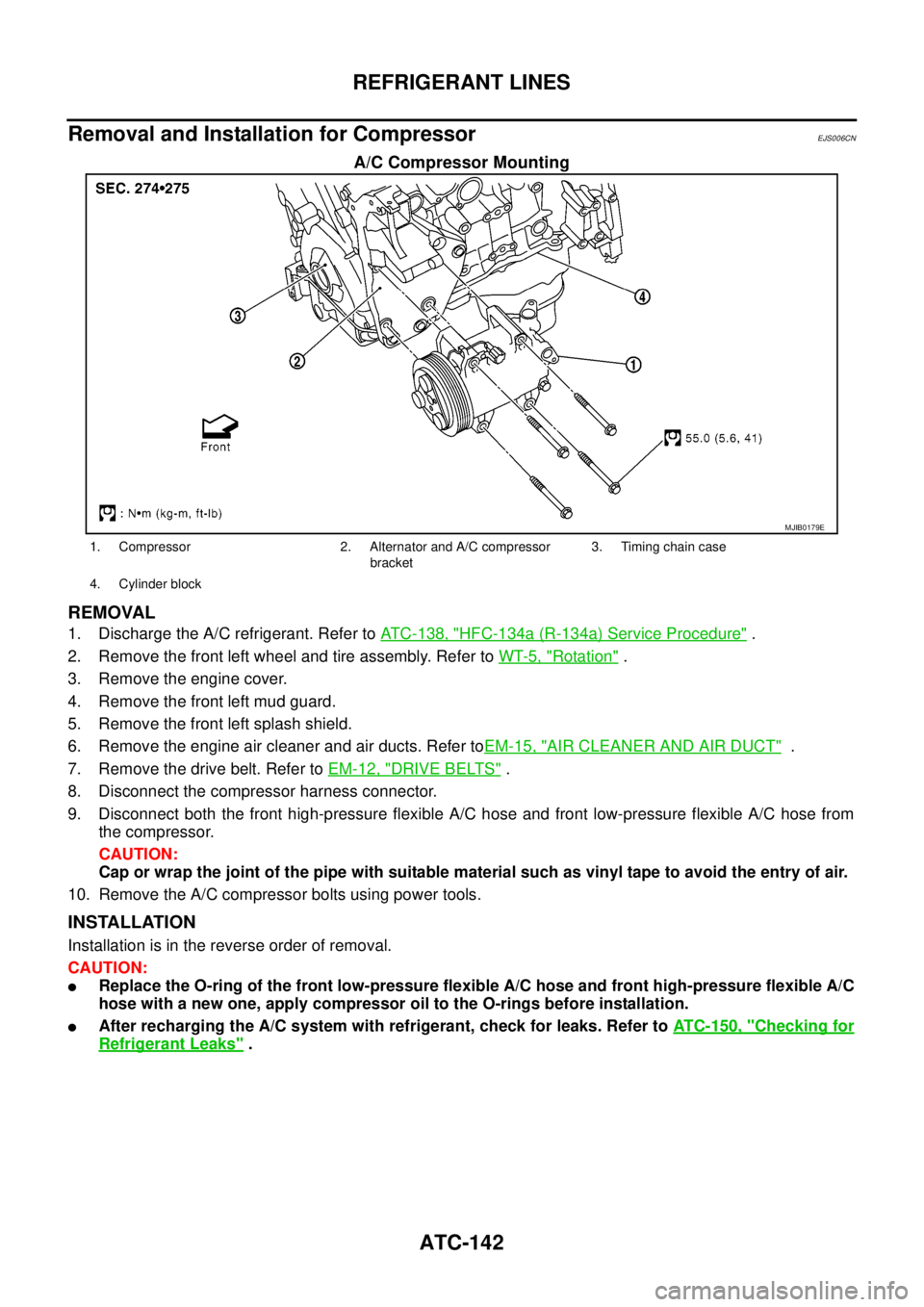

Removal and Installation for Compressor

EJS006CN

A/C Compressor Mounting

REMOVAL

1. Discharge the A/C refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the front left wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine cover.

4. Remove the front left mud guard.

5. Remove the front left splash shield.

6. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

7. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

8. Disconnect the compressor harness connector.

9. Disconnect both the front high-pressure flexible A/C hose and front low-pressure flexible A/C hose from

the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

10. Remove the A/C compressor bolts using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the front low-pressure flexible A/C hose and front high-pressure flexible A/C

hose with a new one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks. Refer toATC-150, "Checking for

Refrigerant Leaks".

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 479 of 3171

REFRIGERANT LINES

ATC-145

C

D

E

F

G

H

I

K

L

MA

B

AT C

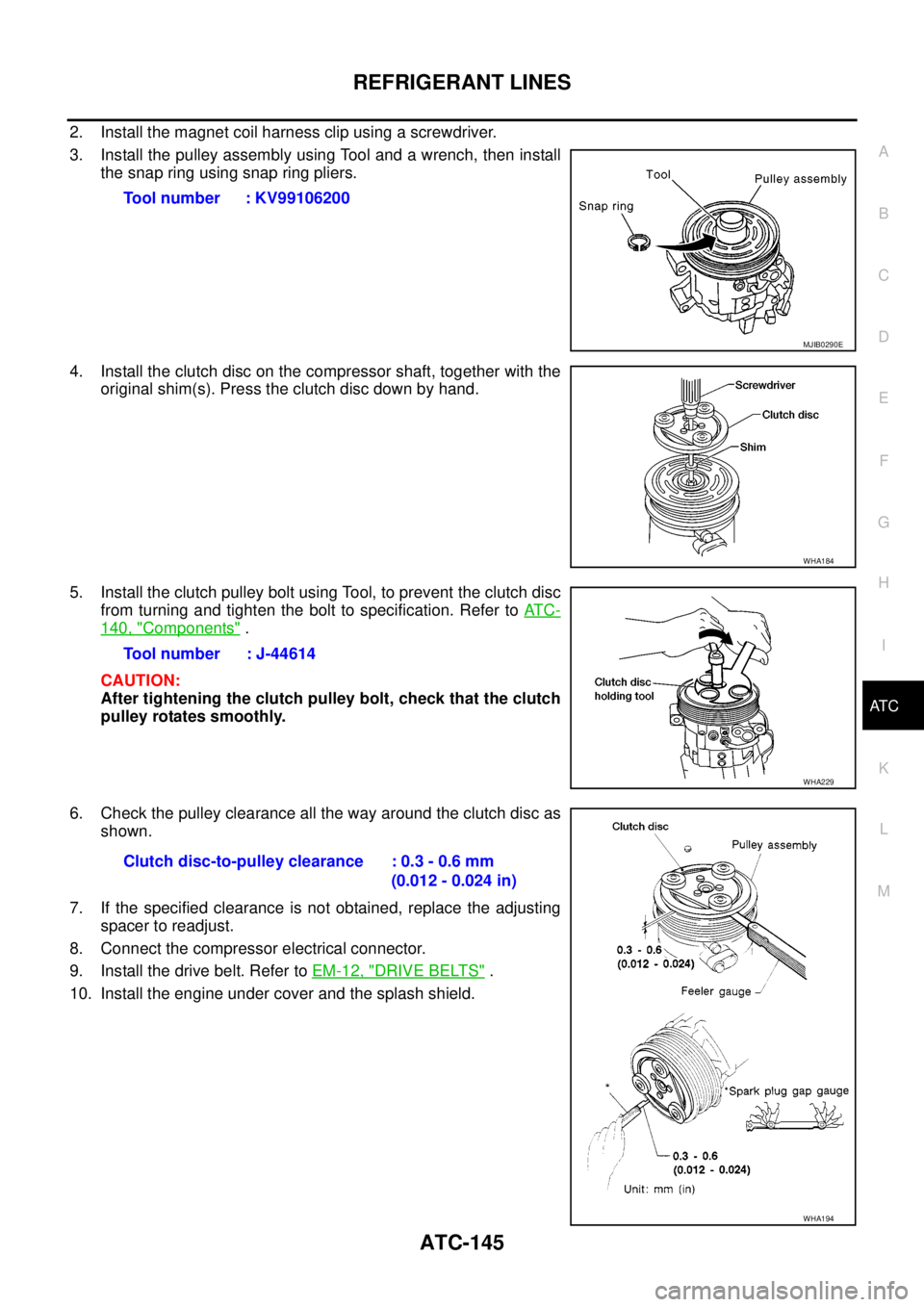

2. Install the magnet coil harness clip using a screwdriver.

3. Install the pulley assembly using Tool and a wrench, then install

the snap ring using snap ring pliers.

4. Install the clutch disc on the compressor shaft, together with the

original shim(s). Press the clutch disc down by hand.

5. Install the clutch pulley bolt using Tool, to prevent the clutch disc

from turning and tighten the bolt to specification. Refer toAT C -

140, "Components".

CAUTION:

After tightening the clutch pulley bolt, check that the clutch

pulley rotates smoothly.

6. Check the pulley clearance all the way around the clutch disc as

shown.

7. If the specified clearance is not obtained, replace the adjusting

spacer to readjust.

8. Connect the compressor electrical connector.

9. Install the drive belt. Refer toEM-12, "

DRIVE BELTS".

10. Install the engine under cover and the splash shield.Tool number : KV99106200

MJIB0290E

WHA184

Tool number : J-44614

WHA229

Clutch disc-to-pulley clearance : 0.3 - 0.6 mm

(0.012 - 0.024 in)

WHA194

Page 485 of 3171

REFRIGERANT LINES

ATC-151

C

D

E

F

G

H

I

K

L

MA

B

AT C

Dye InjectionEJS006D3

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool [SST: J-41459].

3. Connect the injector tool to the A/C Low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

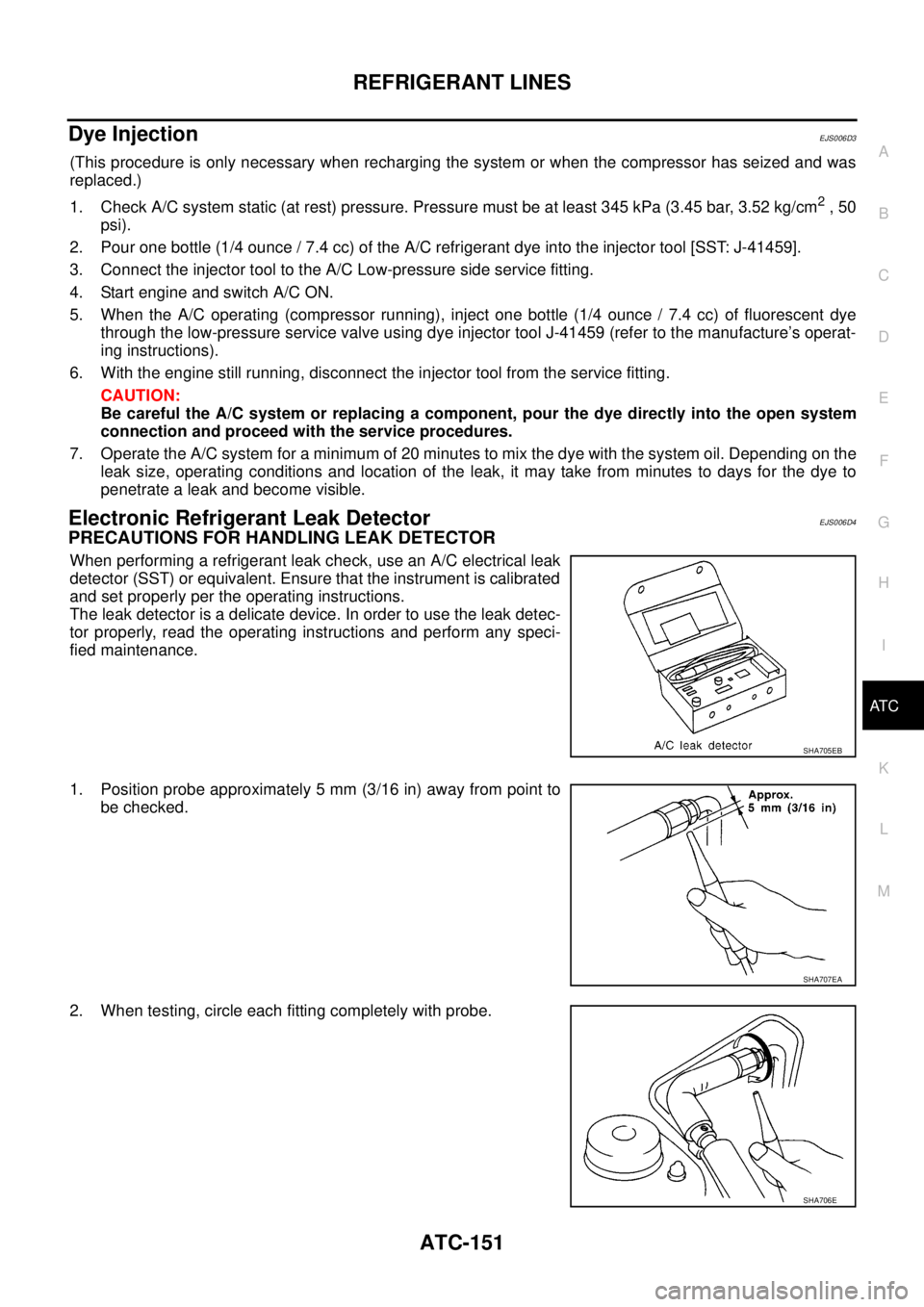

Electronic Refrigerant Leak DetectorEJS006D4

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

2. When testing, circle each fitting completely with probe.

SHA705EB

SHA707EA

SHA706E

Page 602 of 3171

BL-18

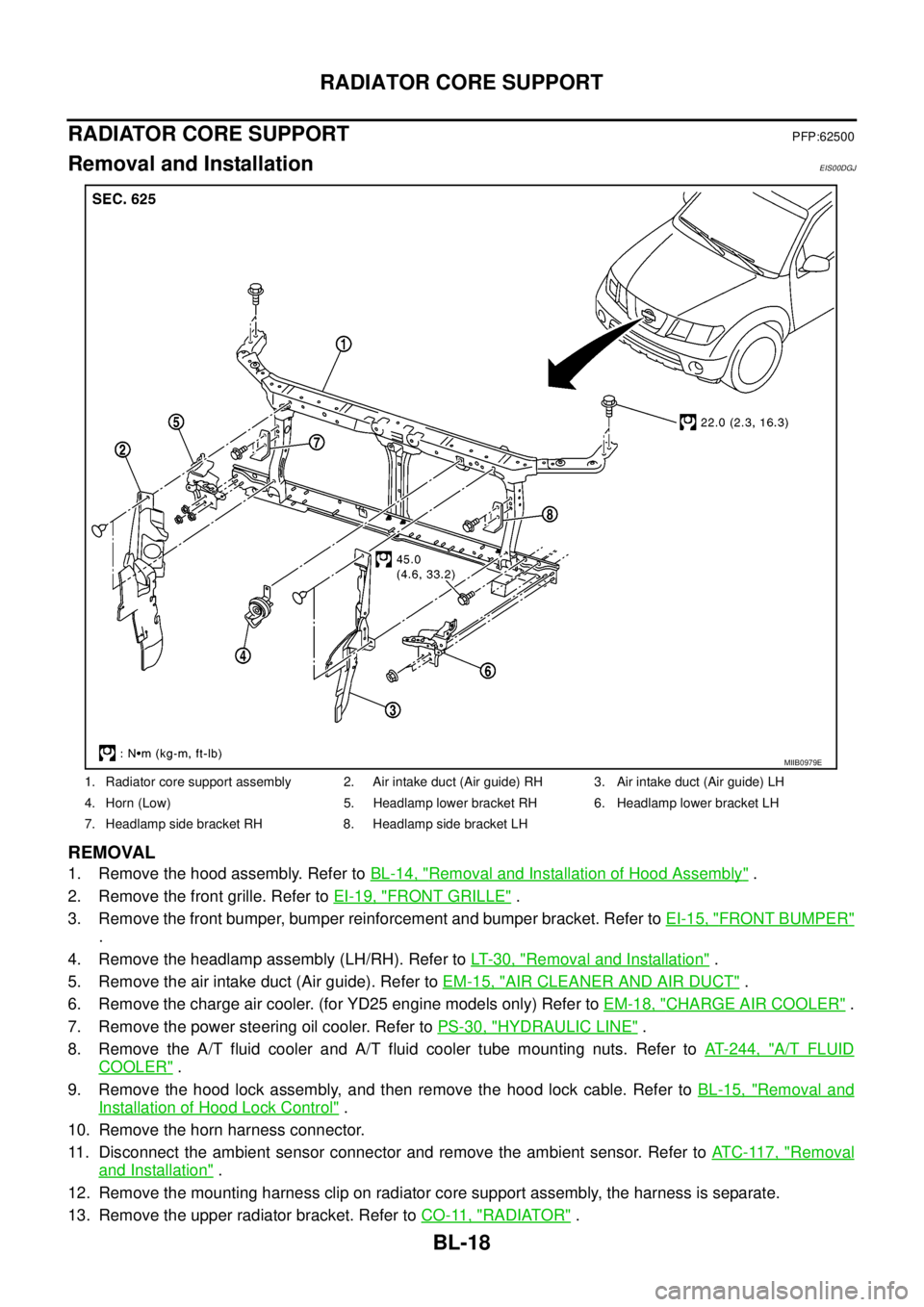

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

PFP:62500

Removal and InstallationEIS00DGJ

REMOVAL

1. Remove the hood assembly. Refer toBL-14, "Removal and Installation of Hood Assembly".

2. Remove the front grille. Refer toEI-19, "

FRONT GRILLE".

3. Remove the front bumper, bumper reinforcement and bumper bracket. Refer toEI-15, "

FRONT BUMPER"

.

4. Remove the headlamp assembly (LH/RH). Refer toLT-30, "

Removal and Installation".

5. Remove the air intake duct (Air guide). Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

6. Remove the charge air cooler. (for YD25 engine models only) Refer toEM-18, "

CHARGE AIR COOLER".

7. Remove the power steering oil cooler. Refer toPS-30, "

HYDRAULIC LINE".

8. Remove the A/T fluid cooler and A/T fluid cooler tube mounting nuts. Refer toAT- 2 4 4 , "

A/T FLUID

COOLER".

9. Remove the hood lock assembly, and then remove the hood lock cable. Refer toBL-15, "

Removal and

Installation of Hood Lock Control".

10. Remove the horn harness connector.

11. Disconnect the ambient sensor connector and remove the ambient sensor. Refer toAT C - 11 7 , "

Removal

and Installation".

12. Remove the mounting harness clip on radiator core support assembly, the harness is separate.

13. Remove the upper radiator bracket. Refer toCO-11, "

RADIATOR".

1. Radiator core support assembly 2. Air intake duct (Air guide) RH 3. Air intake duct (Air guide) LH

4. Horn (Low) 5. Headlamp lower bracket RH 6. Headlamp lower bracket LH

7. Headlamp side bracket RH 8. Headlamp side bracket LH

MIIB0979E

Page 809 of 3171

VACUUM LINES

BR-23

C

D

E

G

H

I

J

K

L

MA

B

BR

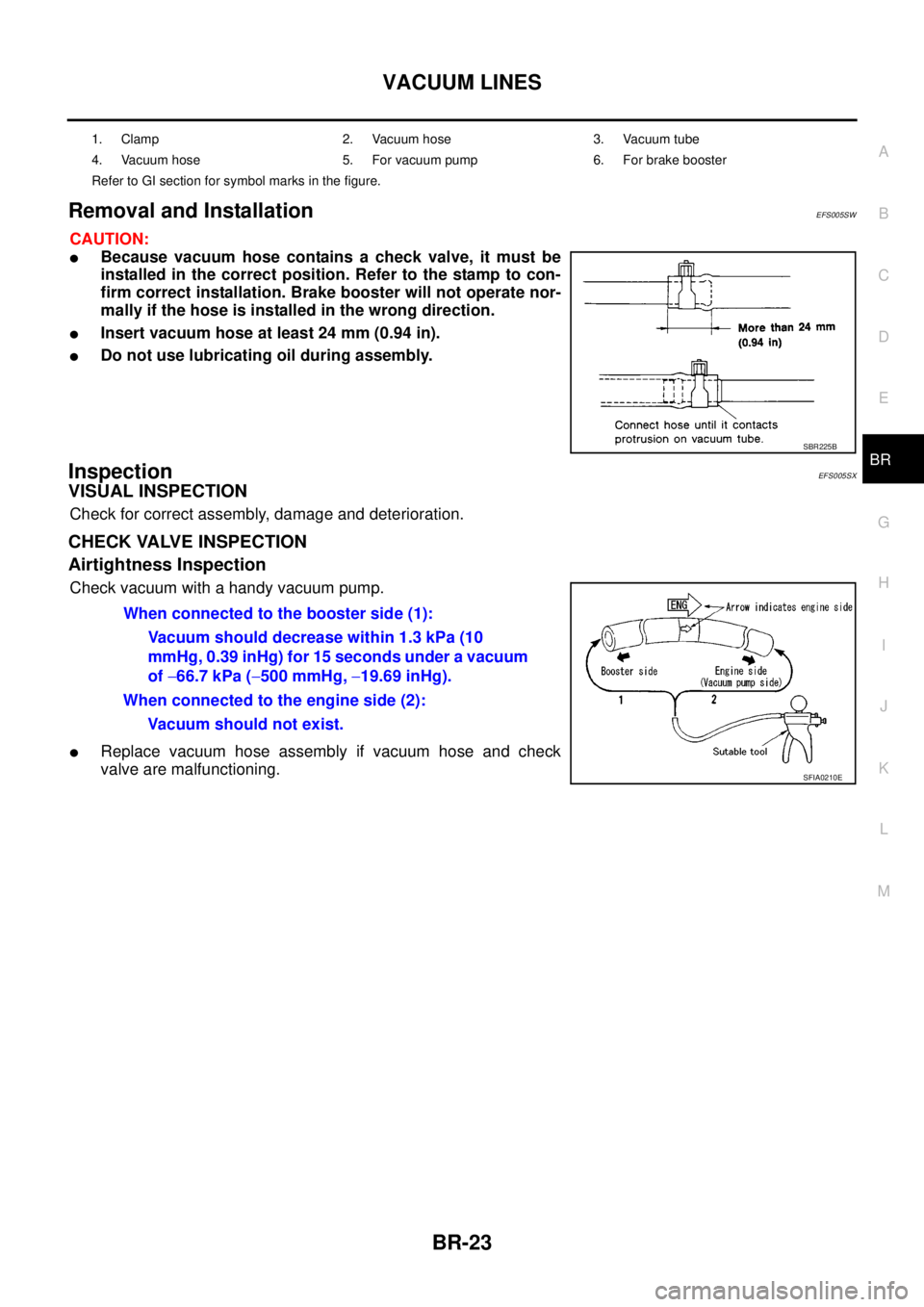

Removal and InstallationEFS005SW

CAUTION:

lBecause vacuum hose contains a check valve, it must be

installed in the correct position. Refer to the stamp to con-

firm correct installation. Brake booster will not operate nor-

mally if the hose is installed in the wrong direction.

lInsert vacuum hose at least 24 mm (0.94 in).

lDo not use lubricating oil during assembly.

InspectionEFS005SX

VISUAL INSPECTION

Check for correct assembly, damage and deterioration.

CHECK VALVE INSPECTION

Airtightness Inspection

Check vacuum with a handy vacuum pump.

lReplace vacuum hose assembly if vacuum hose and check

valve are malfunctioning.

1. Clamp 2. Vacuum hose 3. Vacuum tube

4. Vacuum hose 5. For vacuum pump 6. For brake booster

Refer to GI section for symbol marks in the figure.

SBR225B

When connected to the booster side (1):

Vacuum should decrease within 1.3 kPa (10

mmHg, 0.39 inHg) for 15 seconds under a vacuum

of-66.7 kPa (-500 mmHg,-19.69 inHg).

When connected to the engine side (2):

Vacuum should not exist.

SFIA0210E

Page 825 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement NISSAN NAVARA 2005 Repair Owners Guide PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement](/img/5/57362/w960_57362-824.png)

PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005TG

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.If brake fluid is splashed, wipe it off and flush area

with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lBrake system is an important safety part.If a brake fluid leak is

detected, always disassemble the affected part.If a malfunction

is detected, replace part with new one.

lBefore working, turn ignition switch OFF and disconnect con-

nector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

lWhen installing brake tube and hose, be sure to torque.

WARNING:

Clean brake pads and shoes with a waster cloth, then wipe with

a dust collector.

Precautions for Brake ControlEFS005TH

lJust after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of operation check.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

lWhen an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leaks.

lIf tyre size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

lIf aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 869 of 3171

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

CL-5

D

E

F

G

H

I

J

K

L

MA

B

CL

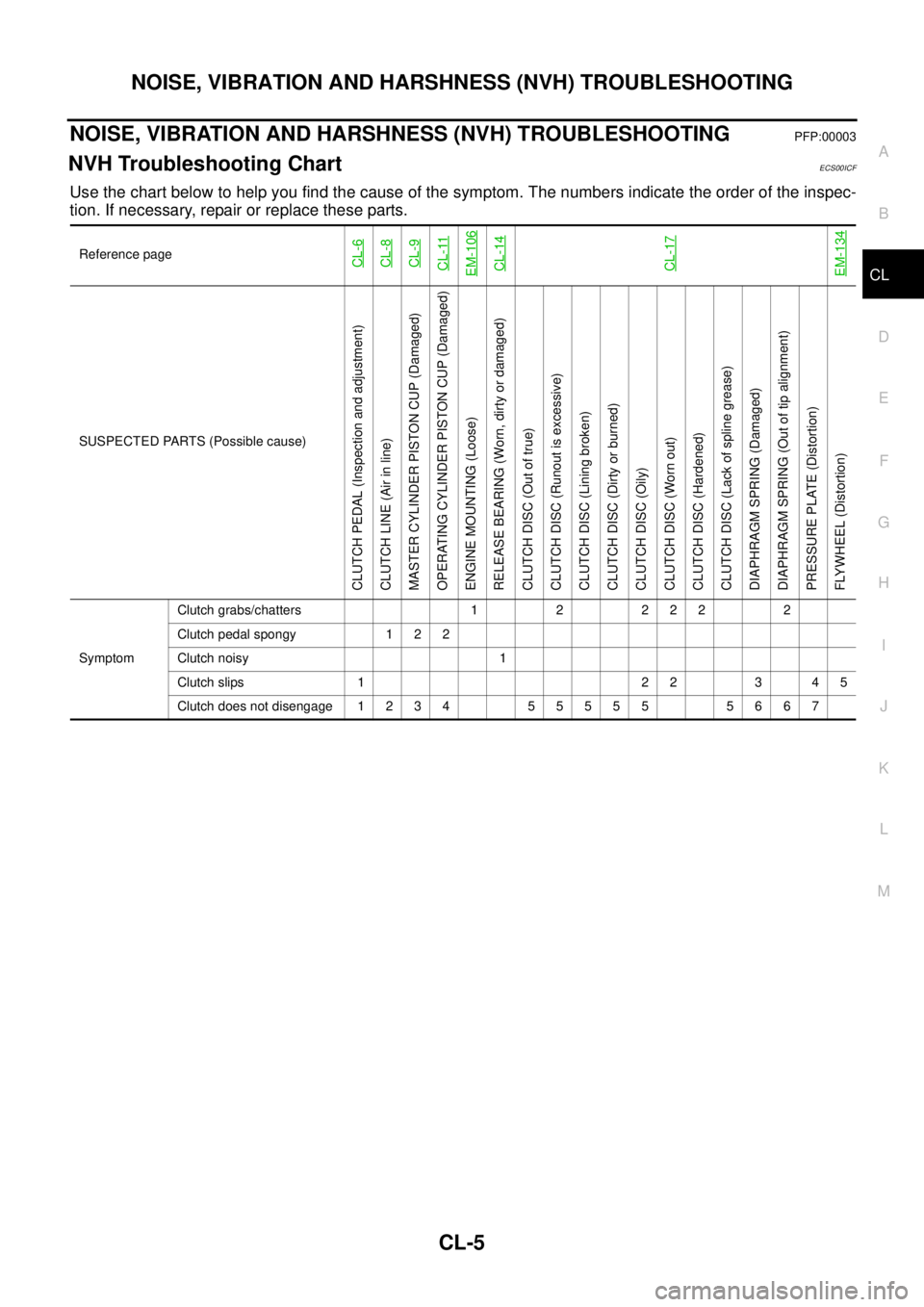

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartECS00ICF

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageCL-6CL-8CL-9CL-11EM-106CL-14CL-17EM-134

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

Page 886 of 3171

CO-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions For Liquid GasketEBS01E6J

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket application surface and the mating surface.

lRemove liquid gasket completely from the liquid gasket application surface, mounting bolts, and bolt

holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating

use) to remove adhering moisture, grease and foreign materials.

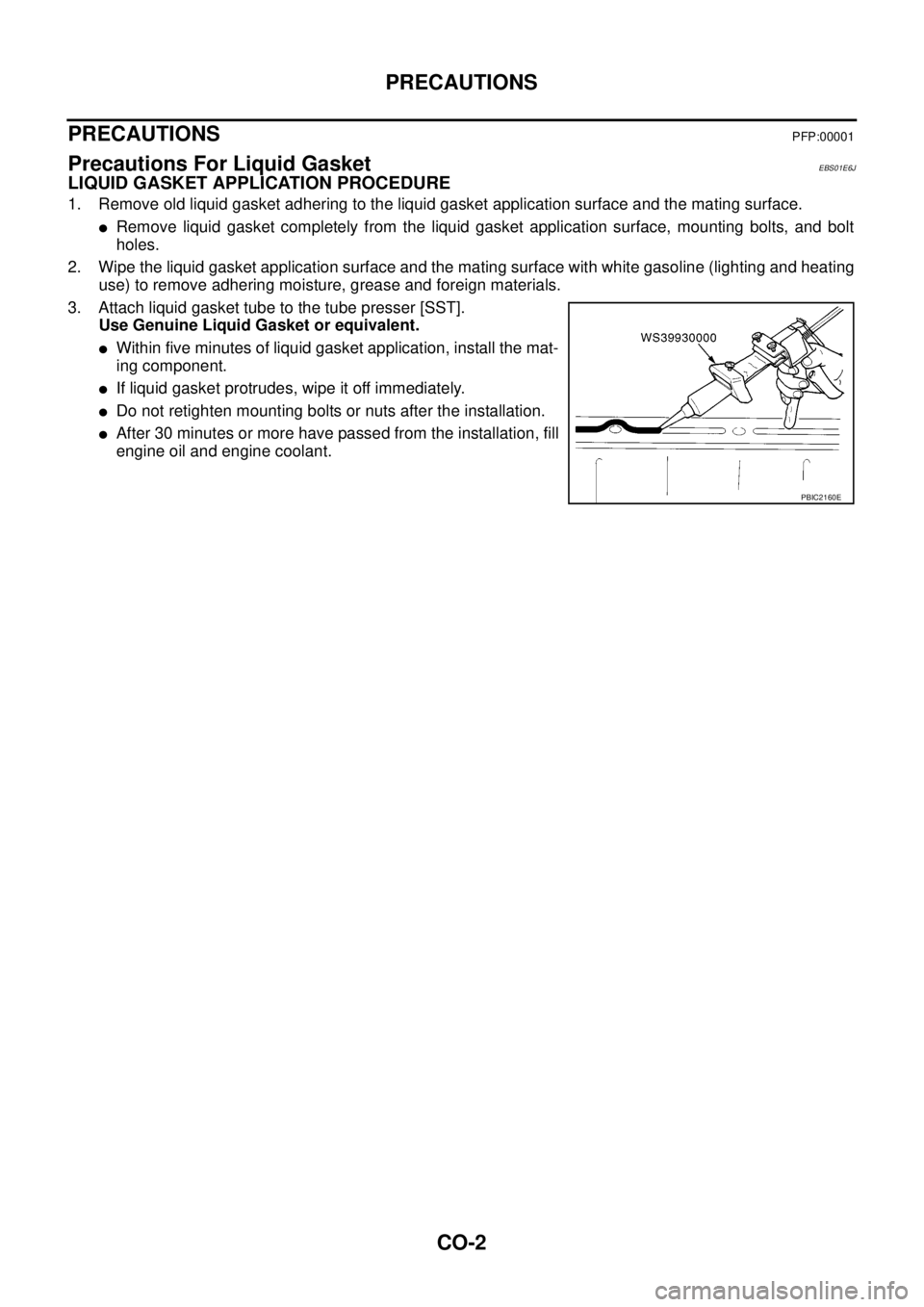

3. Attach liquid gasket tube to the tube presser [SST].

Use Genuine Liquid Gasket or equivalent.

lWithin five minutes of liquid gasket application, install the mat-

ing component.

lIf liquid gasket protrudes, wipe it off immediately.

lDo not retighten mounting bolts or nuts after the installation.

lAfter 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

PBIC2160E