recommended oil NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2400 of 3171

PRECAUTIONS

MTC-13

C

D

E

F

G

H

I

K

L

MA

B

MTC

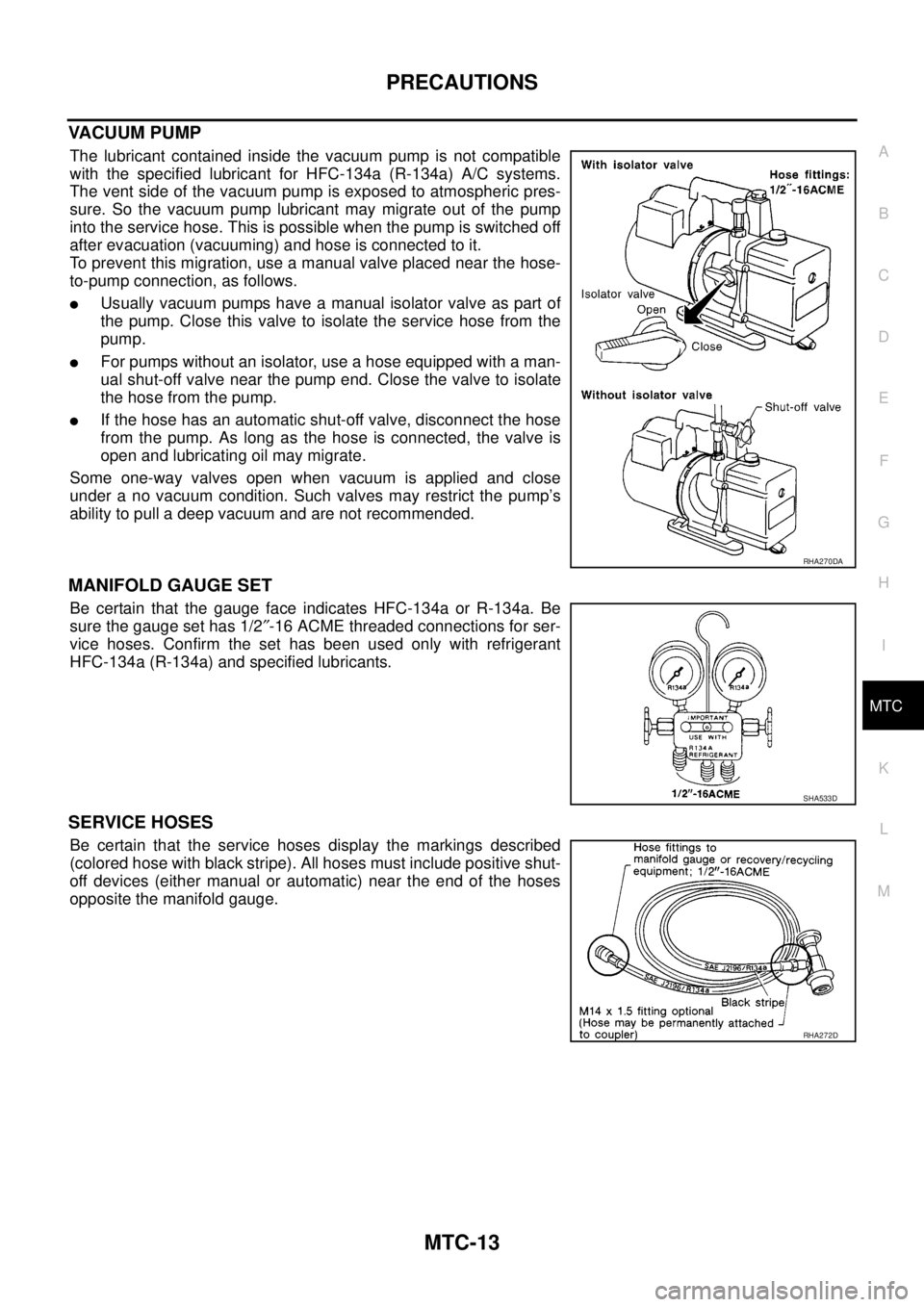

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric pres-

sure. So the vacuum pump lubricant may migrate out of the pump

into the service hose. This is possible when the pump is switched off

after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

lUsually vacuum pumps have a manual isolator valve as part of

the pump. Close this valve to isolate the service hose from the

pump.

lFor pumps without an isolator, use a hose equipped with a man-

ual shut-off valve near the pump end. Close the valve to isolate

the hose from the pump.

lIf the hose has an automatic shut-off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is

open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2²-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

RHA270DA

SHA533D

RHA272D

Page 2633 of 3171

PS-6

POWER STEERING FLUID

POWER STEERING FLUID

PFP:KLF20

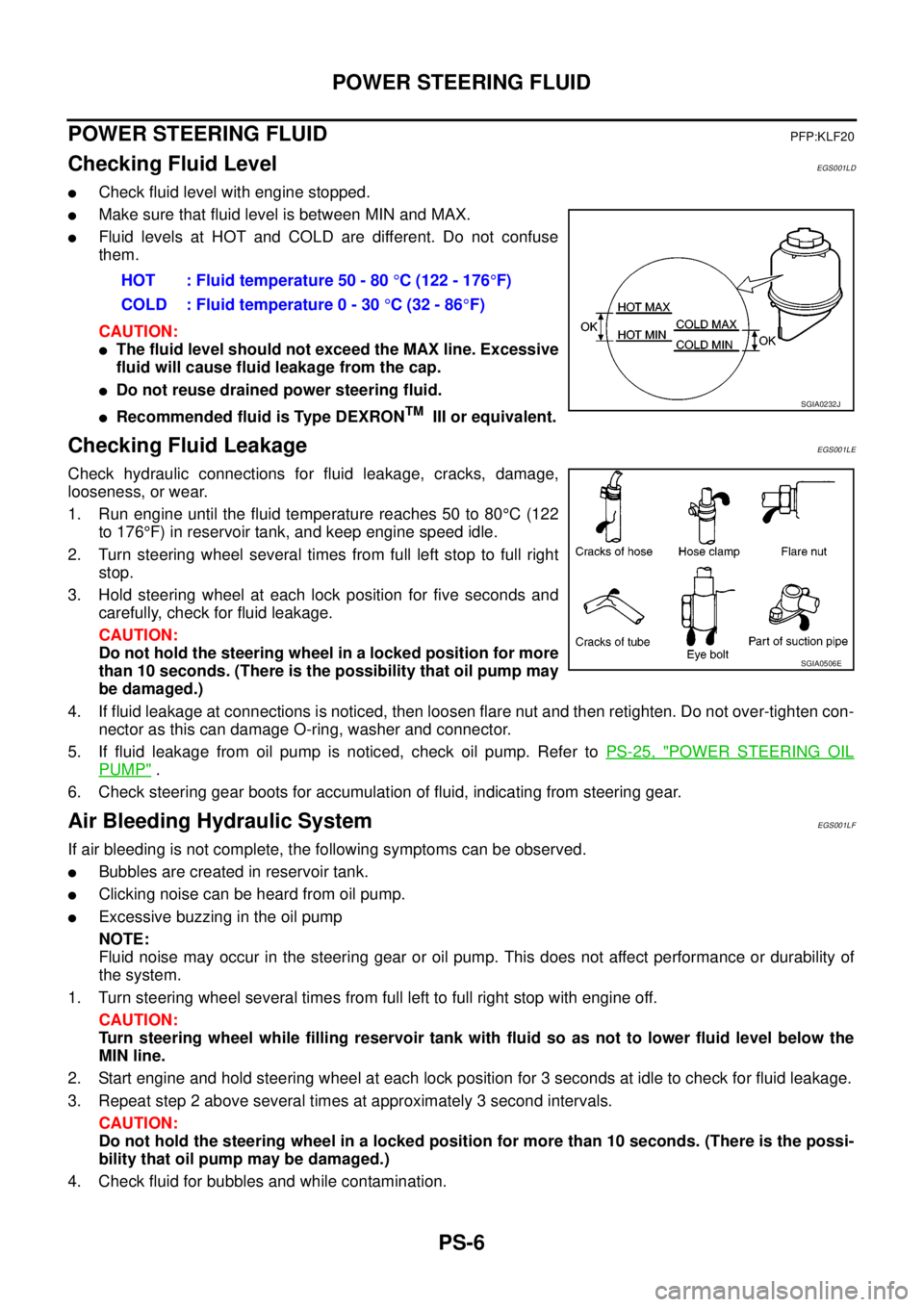

Checking Fluid LevelEGS001LD

lCheck fluid level with engine stopped.

lMake sure that fluid level is between MIN and MAX.

lFluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

lThe fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

lDo not reuse drained power steering fluid.

lRecommended fluid is Type DEXRONTMIII or equivalent.

Checking Fluid LeakageEGS001LE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80°C(122

to 176°F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over-tighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer toPS-25, "

POWER STEERING OIL

PUMP".

6. Check steering gear boots for accumulation of fluid, indicating from steering gear.

Air Bleeding Hydraulic SystemEGS001LF

If air bleeding is not complete, the following symptoms can be observed.

lBubbles are created in reservoir tank.

lClicking noise can be heard from oil pump.

lExcessive buzzing in the oil pump

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80°C (122 - 176°F)

COLD : Fluid temperature 0 - 30°C(32-86°F)

SGIA0232J

SGIA0506E

Page 2647 of 3171

PS-20

POWER STEERING GEAR AND LINKAGE

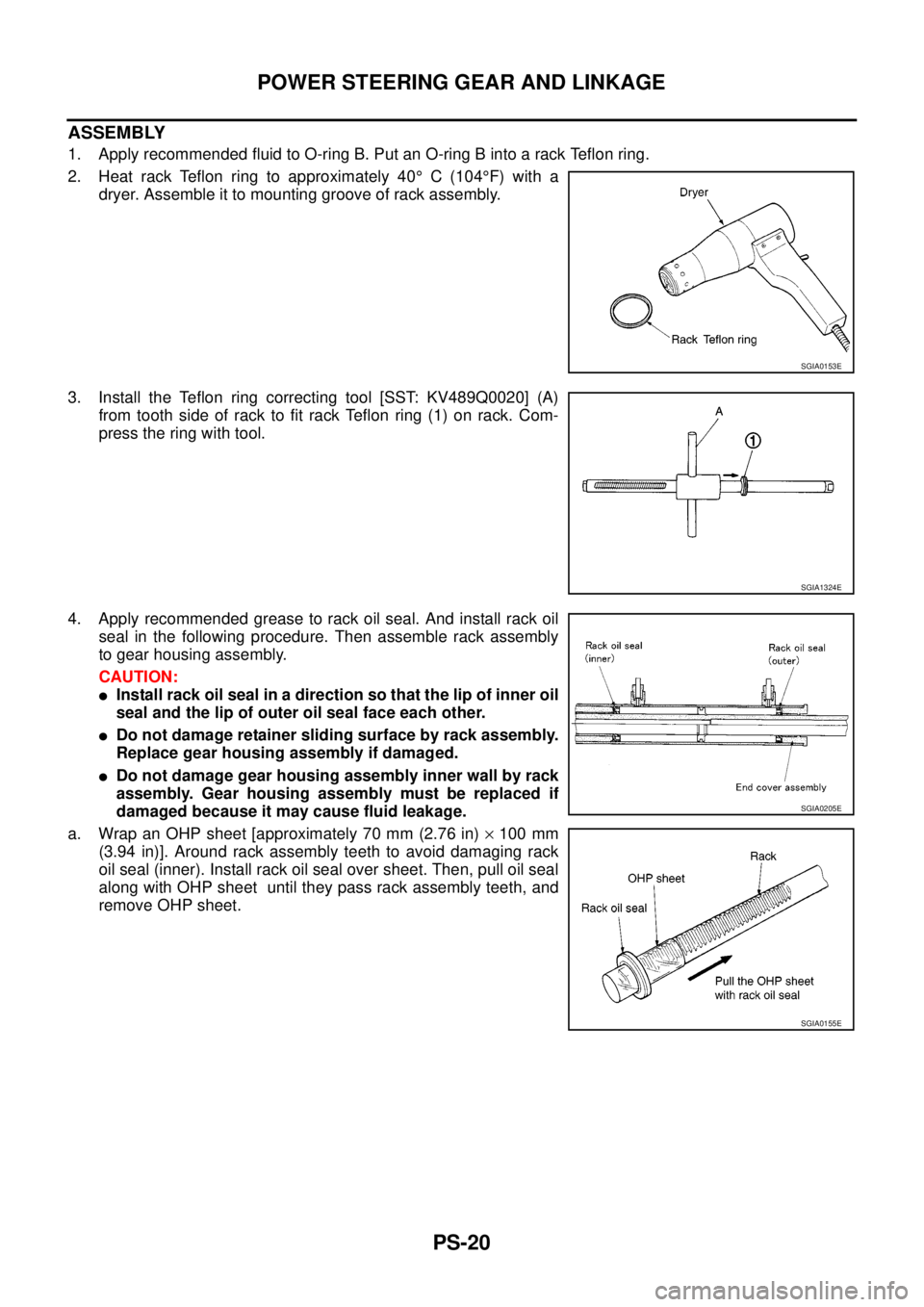

ASSEMBLY

1. Apply recommended fluid to O-ring B. Put an O-ring B into a rack Teflon ring.

2. Heat rack Teflon ring to approximately 40°C(104°F) with a

dryer. Assemble it to mounting groove of rack assembly.

3. Install the Teflon ring correcting tool [SST: KV489Q0020] (A)

from tooth side of rack to fit rack Teflon ring (1) on rack. Com-

press the ring with tool.

4. Apply recommended grease to rack oil seal. And install rack oil

seal in the following procedure. Then assemble rack assembly

to gear housing assembly.

CAUTION:

lInstall rack oil seal in a direction so that the lip of inner oil

seal and the lip of outer oil seal face each other.

lDo not damage retainer sliding surface by rack assembly.

Replace gear housing assembly if damaged.

lDo not damage gear housing assembly inner wall by rack

assembly. Gear housing assembly must be replaced if

damaged because it may cause fluid leakage.

a. Wrap an OHP sheet [approximately 70 mm (2.76 in)´100 mm

(3.94 in)]. Around rack assembly teeth to avoid damaging rack

oil seal (inner). Install rack oil seal over sheet. Then, pull oil seal

along with OHP sheet until they pass rack assembly teeth, and

remove OHP sheet.

SGIA0153E

SGIA1324E

SGIA0205E

SGIA0155E

Page 2648 of 3171

POWER STEERING GEAR AND LINKAGE

PS-21

C

D

E

F

H

I

J

K

L

MA

B

PS

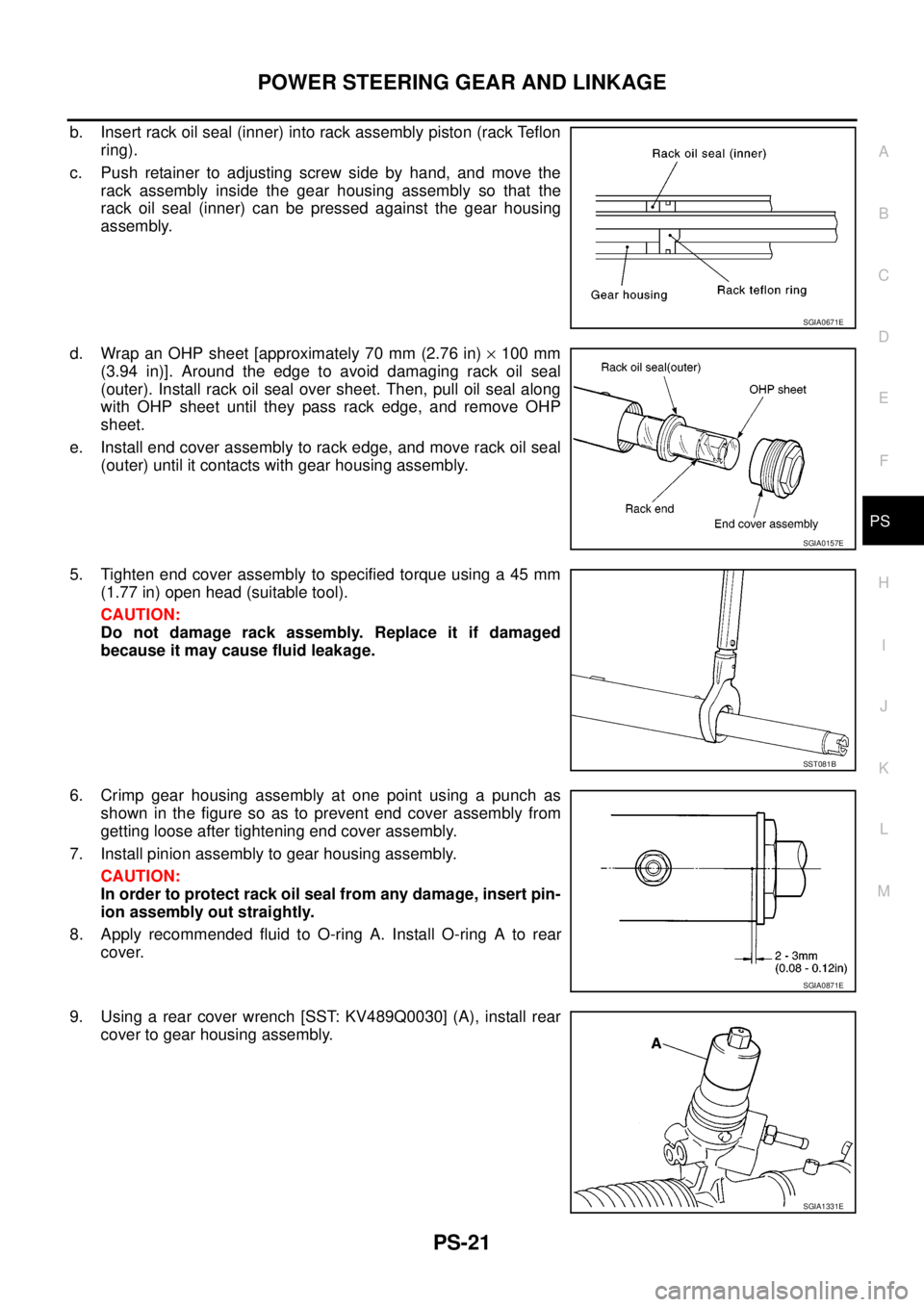

b. Insert rack oil seal (inner) into rack assembly piston (rack Teflon

ring).

c. Push retainer to adjusting screw side by hand, and move the

rack assembly inside the gear housing assembly so that the

rack oil seal (inner) can be pressed against the gear housing

assembly.

d. Wrap an OHP sheet [approximately 70 mm (2.76 in)´100 mm

(3.94 in)]. Around the edge to avoid damaging rack oil seal

(outer). Install rack oil seal over sheet. Then, pull oil seal along

with OHP sheet until they pass rack edge, and remove OHP

sheet.

e. Install end cover assembly to rack edge, and move rack oil seal

(outer) until it contacts with gear housing assembly.

5. Tighten end cover assembly to specified torque using a 45 mm

(1.77 in) open head (suitable tool).

CAUTION:

Do not damage rack assembly. Replace it if damaged

because it may cause fluid leakage.

6. Crimp gear housing assembly at one point using a punch as

shown in the figure so as to prevent end cover assembly from

getting loose after tightening end cover assembly.

7. Install pinion assembly to gear housing assembly.

CAUTION:

In order to protect rack oil seal from any damage, insert pin-

ion assembly out straightly.

8. Apply recommended fluid to O-ring A. Install O-ring A to rear

cover.

9. Using a rear cover wrench [SST: KV489Q0030] (A), install rear

cover to gear housing assembly.

SGIA0671E

SGIA0157E

SST081B

SGIA0871E

SGIA1331E

Page 2655 of 3171

PS-28

POWER STEERING OIL PUMP

Flow Control Valve Inspection

Check flow control valve and spring for damage. Replace if there are.

ASSEMBLY

NOTE:

Secureoilpumpinaviseifnecessary.

CAUTION:

Use copper plates when securing in a vise.

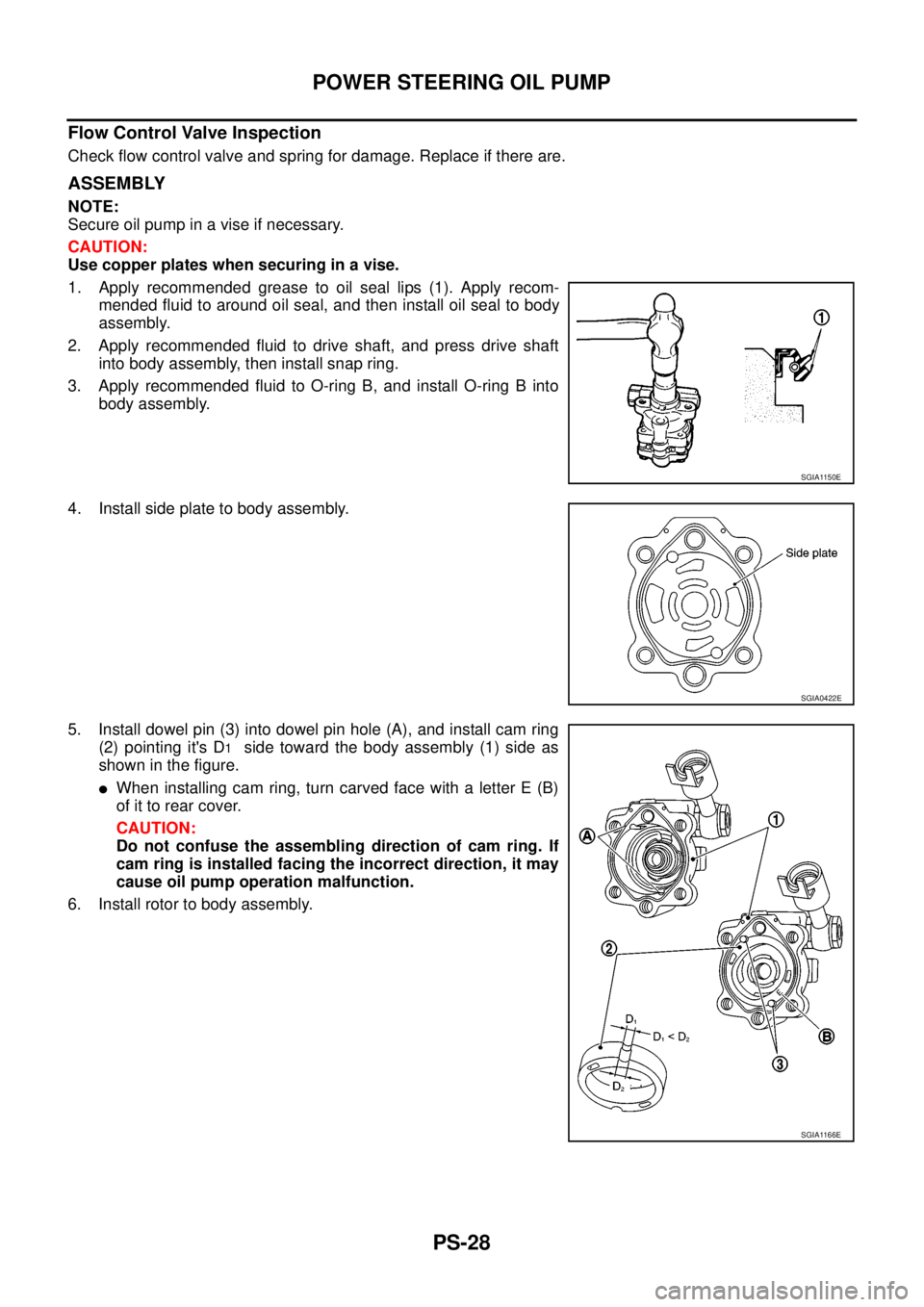

1. Apply recommended grease to oil seal lips (1). Apply recom-

mended fluid to around oil seal, and then install oil seal to body

assembly.

2. Apply recommended fluid to drive shaft, and press drive shaft

into body assembly, then install snap ring.

3. Apply recommended fluid to O-ring B, and install O-ring B into

body assembly.

4. Install side plate to body assembly.

5. Install dowel pin (3) into dowel pin hole (A), and install cam ring

(2) pointing it's D

1side toward the body assembly (1) side as

showninthefigure.

lWhen installing cam ring, turn carved face with a letter E (B)

of it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing the incorrect direction, it may

cause oil pump operation malfunction.

6. Install rotor to body assembly.

SGIA1150E

SGIA0422E

SGIA1166E

Page 2656 of 3171

POWER STEERING OIL PUMP

PS-29

C

D

E

F

H

I

J

K

L

MA

B

PS

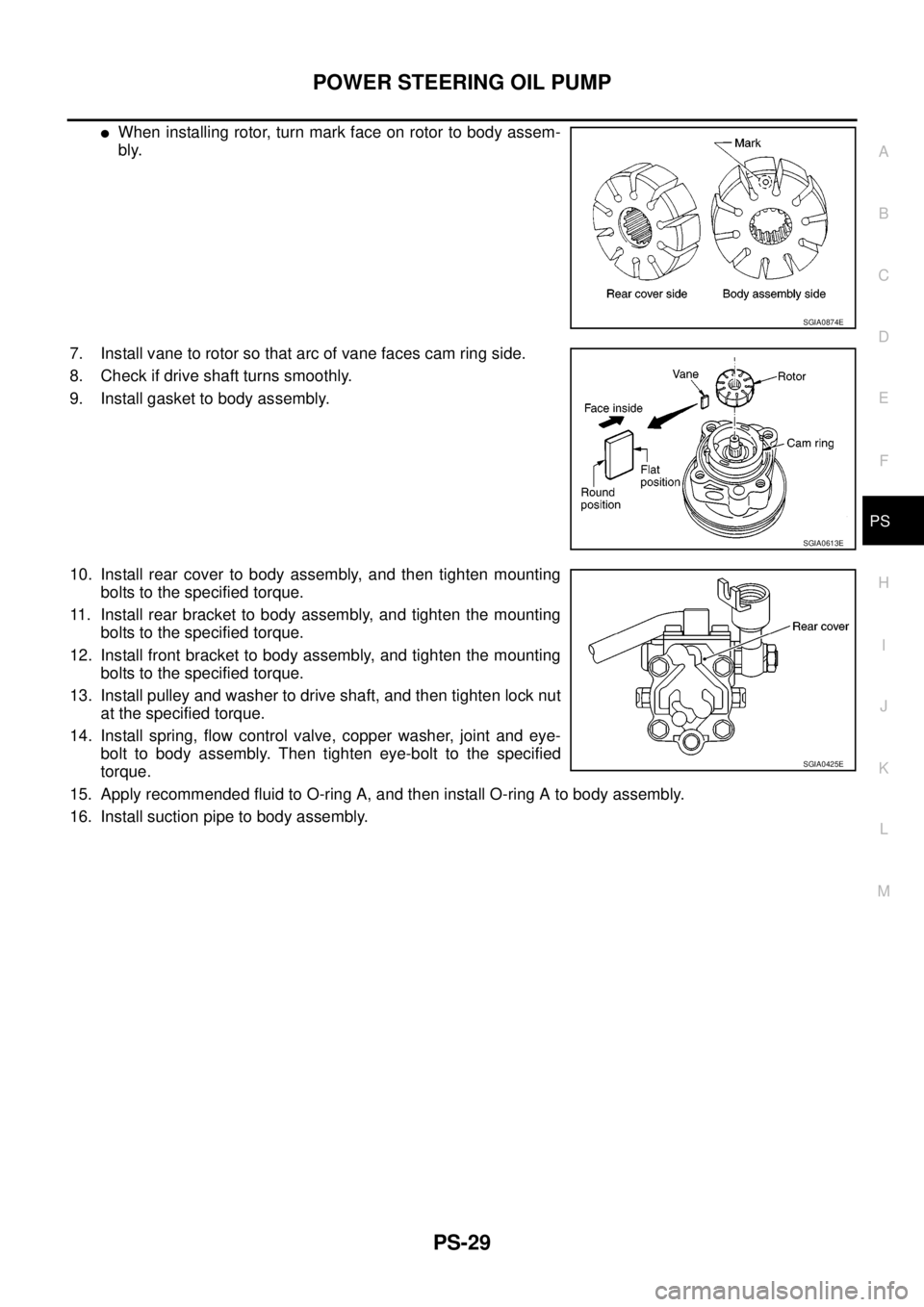

lWhen installing rotor, turn mark face on rotor to body assem-

bly.

7. Install vane to rotor so that arc of vane faces cam ring side.

8. Check if drive shaft turns smoothly.

9. Install gasket to body assembly.

10. Install rear cover to body assembly, and then tighten mounting

bolts to the specified torque.

11. Install rear bracket to body assembly, and tighten the mounting

bolts to the specified torque.

12. Install front bracket to body assembly, and tighten the mounting

bolts to the specified torque.

13. Install pulley and washer to drive shaft, and then tighten lock nut

at the specified torque.

14. Install spring, flow control valve, copper washer, joint and eye-

bolt to body assembly. Then tighten eye-bolt to the specified

torque.

15. Apply recommended fluid to O-ring A, and then install O-ring A to body assembly.

16. Install suction pipe to body assembly.

SGIA0874E

SGIA0613E

SGIA0425E

Page 3091 of 3171

TF-124

TRANSFER ASSEMBLY

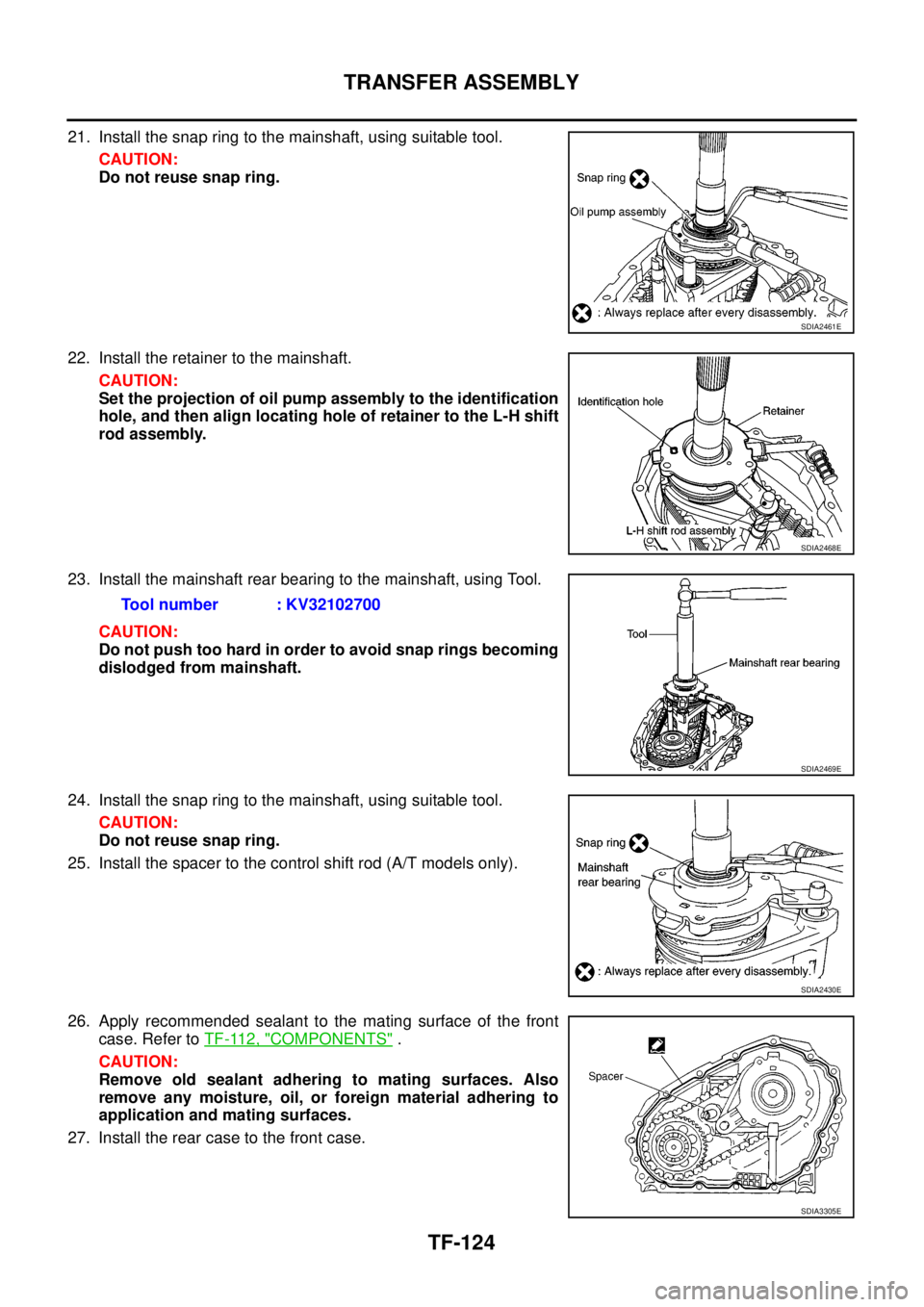

21. Install the snap ring to the mainshaft, using suitable tool.

CAUTION:

Do not reuse snap ring.

22. Install the retainer to the mainshaft.

CAUTION:

Set the projection of oil pump assembly to the identification

hole, and then align locating hole of retainer to the L-H shift

rod assembly.

23. Install the mainshaft rear bearing to the mainshaft, using Tool.

CAUTION:

Do not push too hard in order to avoid snap rings becoming

dislodged from mainshaft.

24. Install the snap ring to the mainshaft, using suitable tool.

CAUTION:

Do not reuse snap ring.

25. Install the spacer to the control shift rod (A/T models only).

26. Apply recommended sealant to the mating surface of the front

case. Refer toTF-112, "

COMPONENTS".

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mating surfaces.

27. Install the rear case to the front case.

SDIA2461E

SDIA2468E

Tool number : KV32102700

SDIA2469E

SDIA2430E

SDIA3305E

Page 3093 of 3171

TF-126

TRANSFER ASSEMBLY

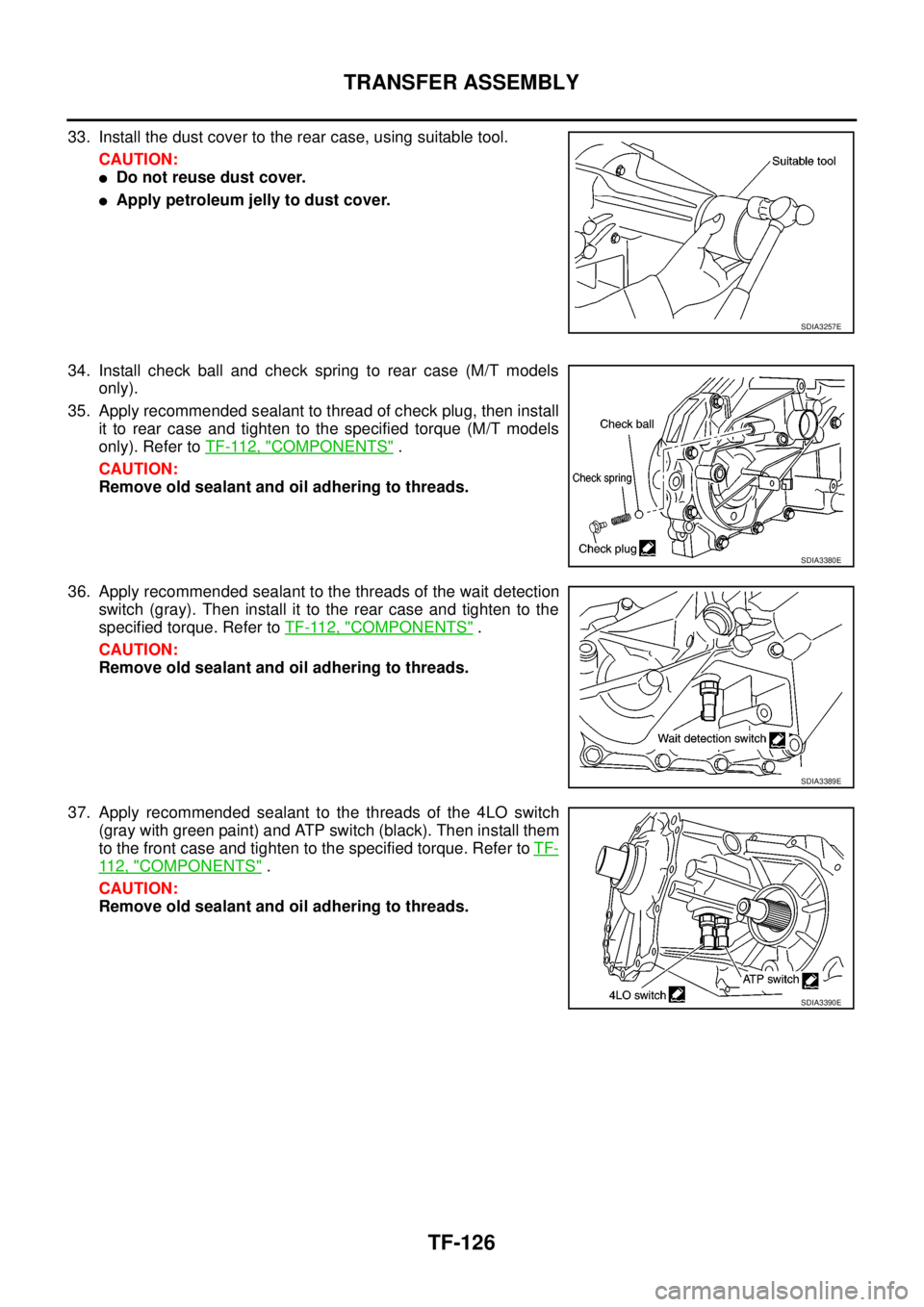

33. Install the dust cover to the rear case, using suitable tool.

CAUTION:

lDo not reuse dust cover.

lApply petroleum jelly to dust cover.

34. Install check ball and check spring to rear case (M/T models

only).

35. Apply recommended sealant to thread of check plug, then install

it to rear case and tighten to the specified torque (M/T models

only). Refer toTF-112, "

COMPONENTS".

CAUTION:

Remove old sealant and oil adhering to threads.

36. Apply recommended sealant to the threads of the wait detection

switch(gray).Theninstallittotherearcaseandtightentothe

specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Remove old sealant and oil adhering to threads.

37. Apply recommended sealant to the threads of the 4LO switch

(gray with green paint) and ATP switch (black). Then install them

to the front case and tighten to the specified torque. Refer toTF-

11 2 , "COMPONENTS".

CAUTION:

Remove old sealant and oil adhering to threads.

SDIA3257E

SDIA3380E

SDIA3389E

SDIA3390E