sensor NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1337 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-357

C

D

E

F

G

H

I

J

K

L

MA

EC

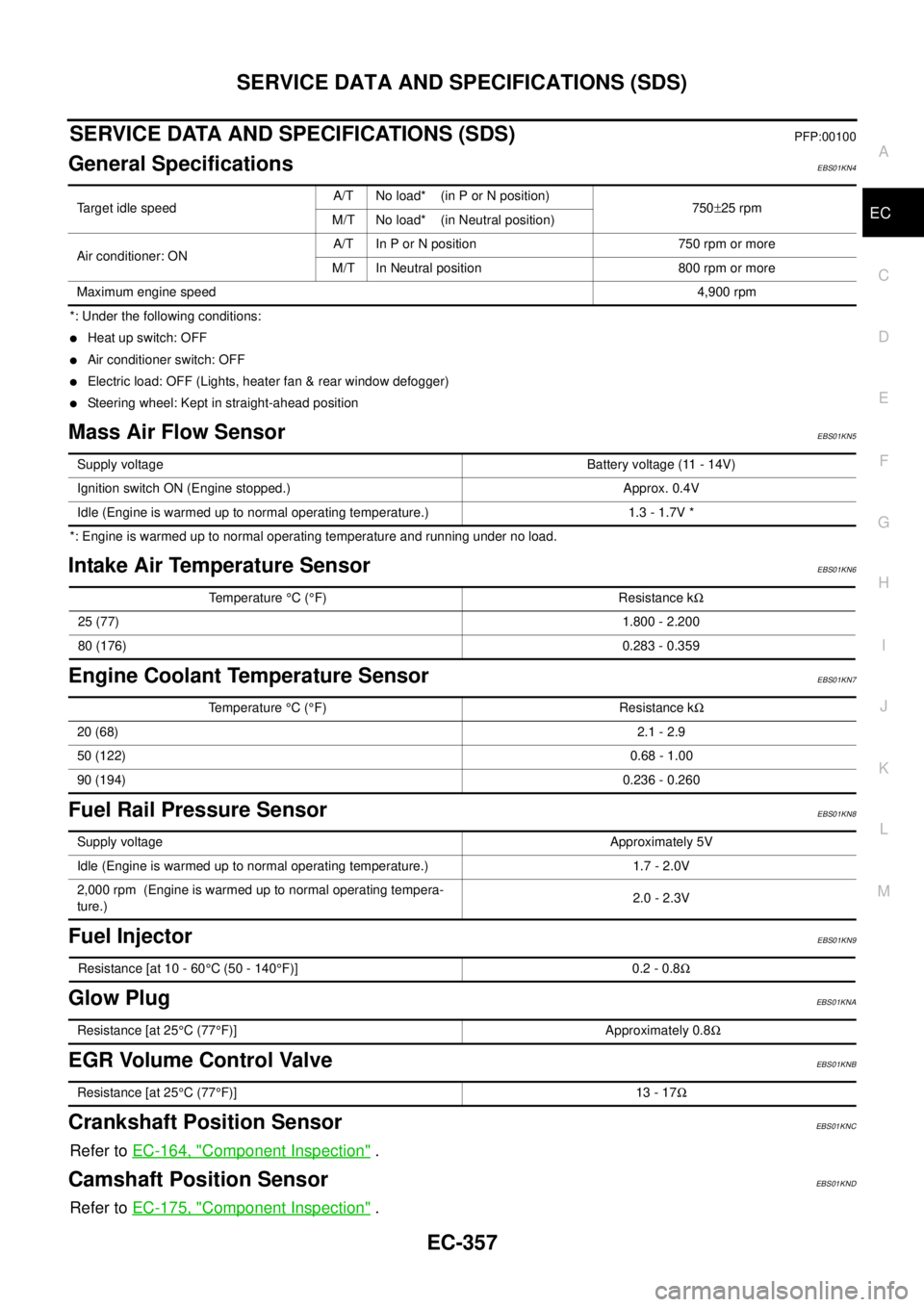

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

General SpecificationsEBS01KN4

*: Under the following conditions:

lHeat up switch: OFF

lAir conditioner switch: OFF

lElectric load: OFF (Lights, heater fan & rear window defogger)

lSteering wheel: Kept in straight-ahead position

Mass Air Flow SensorEBS01KN5

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorEBS01KN6

Engine Coolant Temperature SensorEBS01KN7

Fuel Rail Pressure SensorEBS01KN8

Fuel InjectorEBS01KN9

Glow PlugEBS01KNA

EGR Volume Control ValveEBS01KNB

Crankshaft Position SensorEBS01KNC

Refer toEC-164, "Component Inspection".

Camshaft Position SensorEBS01KND

Refer toEC-175, "Component Inspection".

Target idle speedA/T No load* (in P or N position)

750±25 rpm

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position 750 rpm or more

M/T In Neutral position 800 rpm or more

Maximum engine speed4,900 rpm

Supply voltageBattery voltage (11 - 14V)

Ignition switch ON (Engine stopped.) Approx. 0.4V

Idle (Engine is warmed up to normal operating temperature.) 1.3 - 1.7V *

Temperature°C(°F) Resistance kW

25 (77)1.800 - 2.200

80 (176)0.283 - 0.359

Temperature°C(°F) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Supply voltageApproximately 5V

Idle (Engine is warmed up to normal operating temperature.) 1.7 - 2.0V

2,000 rpm (Engine is warmed up to normal operating tempera-

ture.)2.0 - 2.3V

Resistance [at 10 - 60°C (50 - 140°F)] 0.2 - 0.8W

Resistance [at 25°C(77°F)] Approximately 0.8W

Resistance [at 25°C(77°F)] 13 - 17W

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1373 of 3171

BODY SIDE TRIM

EI-35

C

D

E

F

G

H

J

K

L

MA

B

EI

2. Remove front kick plate from center pillar lower finisher.

3. Remove front kick plate from dash side from lower dash side finisher.

4. Remove lower dash side finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR LOWER FINISHER

Removal

1. Remove front and rear door welts.

2. Remove seat belt anchor. Refer toSB-3, "

SEAT BELTS".

lOn RH side, remove the cover and disconnect seat belt tension sensor.

3. Remove front and rear kick plates. Refer toEI-35, "

KICK PLATES".

4. Remove center pillar lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER PILLAR UPPER FINISHER

Removal

1. Remove front and rear door welts.

2. Remove seat belt shoulder anchor and D-ring. Refer toSB-3, "

SEAT BELTS".

3. Remove front and rear kick plates. Refer toEI-35, "

KICK PLATES".

4. Remove center pillar lower finisher.

5. Remove assist grip.

6. Remove center pillar upper finisher.

Installation

Installation is in the reverse order of removal.

FRONT PILLAR UPPER FINISHER

Removal

1. Remove front pillar lower finisher. Refer toEI-35, "FRONT PILLAR LOWER FINISHER".

2. Remove the front pillar assist grip.

3. Remove the front pillar upper finisher bolt.

4. Remove the front pillar upper finisher.

Installation

Installation is in the reverse order of removal.

FRONT PILLAR LOWER FINISHER

Removal

1. Remove front door welt and kick plate.

2. Remove the front pillar lower finisher.

Installation

Installation is in the reverse order of removal.

KICK PLATES

Removal

Release clips and remove front and/or rear kick plates.

Installation

Installation is in the reverse order of removal.

Page 1397 of 3171

AIR CLEANER AND AIR DUCT

EM-15

C

D

E

F

G

H

I

J

K

L

MA

EM

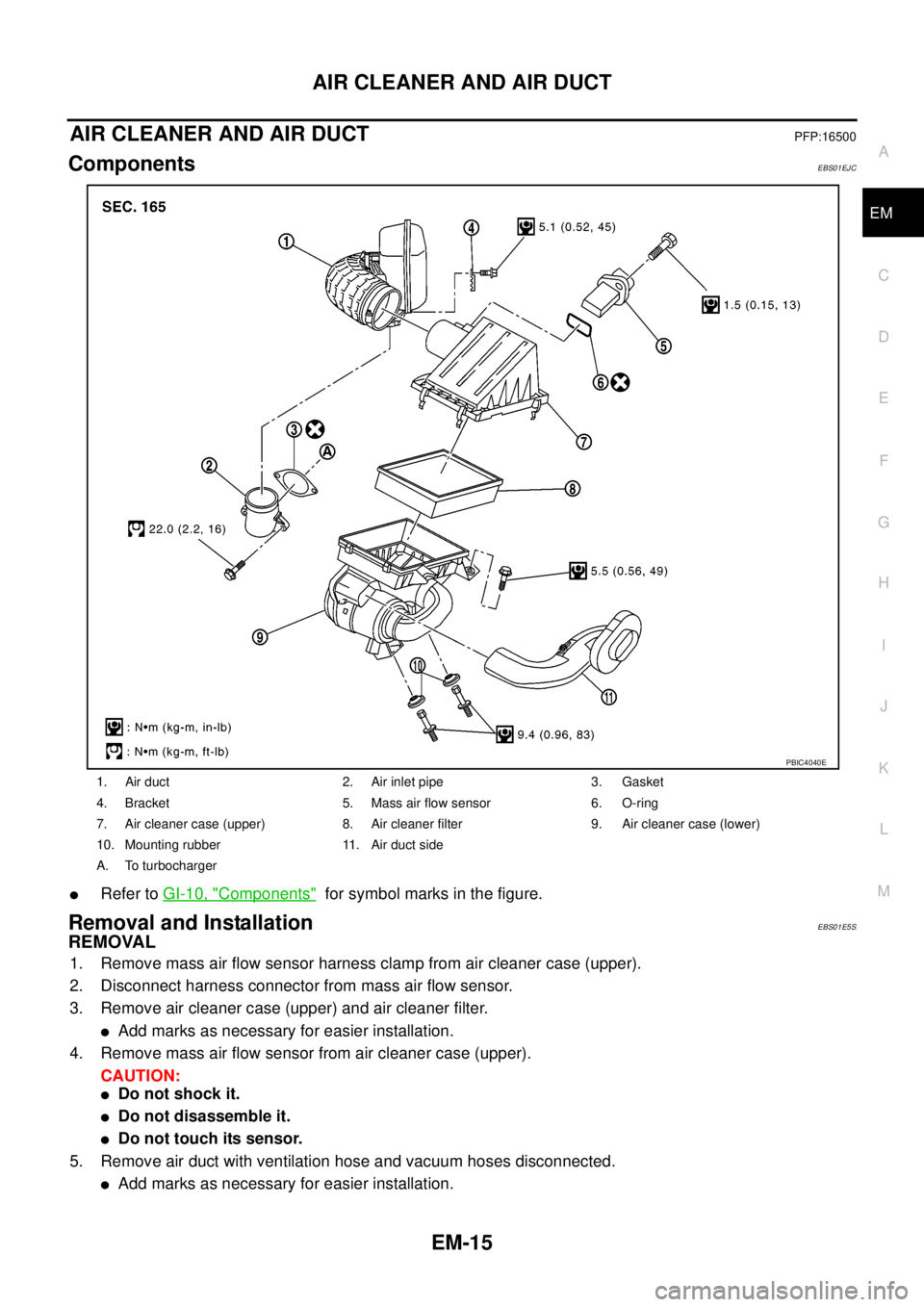

AIR CLEANER AND AIR DUCTPFP:16500

ComponentsEBS01EJC

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E5S

REMOVAL

1. Remove mass air flow sensor harness clamp from air cleaner case (upper).

2. Disconnect harness connector from mass air flow sensor.

3. Remove air cleaner case (upper) and air cleaner filter.

lAdd marks as necessary for easier installation.

4. Remove mass air flow sensor from air cleaner case (upper).

CAUTION:

lDo not shock it.

lDo not disassemble it.

lDo not touch its sensor.

5. Remove air duct with ventilation hose and vacuum hoses disconnected.

lAdd marks as necessary for easier installation.

1. Air duct 2. Air inlet pipe 3. Gasket

4. Bracket 5. Mass air flow sensor 6. O-ring

7. Air cleaner case (upper) 8. Air cleaner filter 9. Air cleaner case (lower)

10. Mounting rubber 11. Air duct side

A. To turbocharger

PBIC4040E

Page 1399 of 3171

AIR CLEANER AND AIR DUCT

EM-17

C

D

E

F

G

H

I

J

K

L

MA

EM

CHANGING AIR CLEANER FILTER

Removal

1. Remove mass air flow sensor harness clamp from air cleaner case (upper).

2. Disconnect harness connector from mass air flow sensor.

3. Unfasten clips and lift up air cleaner case (upper).

4. Remove air cleaner filter.

Installation

Installation is the reverse order of removal.

Page 1400 of 3171

EM-18

CHARGE AIR COOLER

CHARGE AIR COOLER

PFP:14461

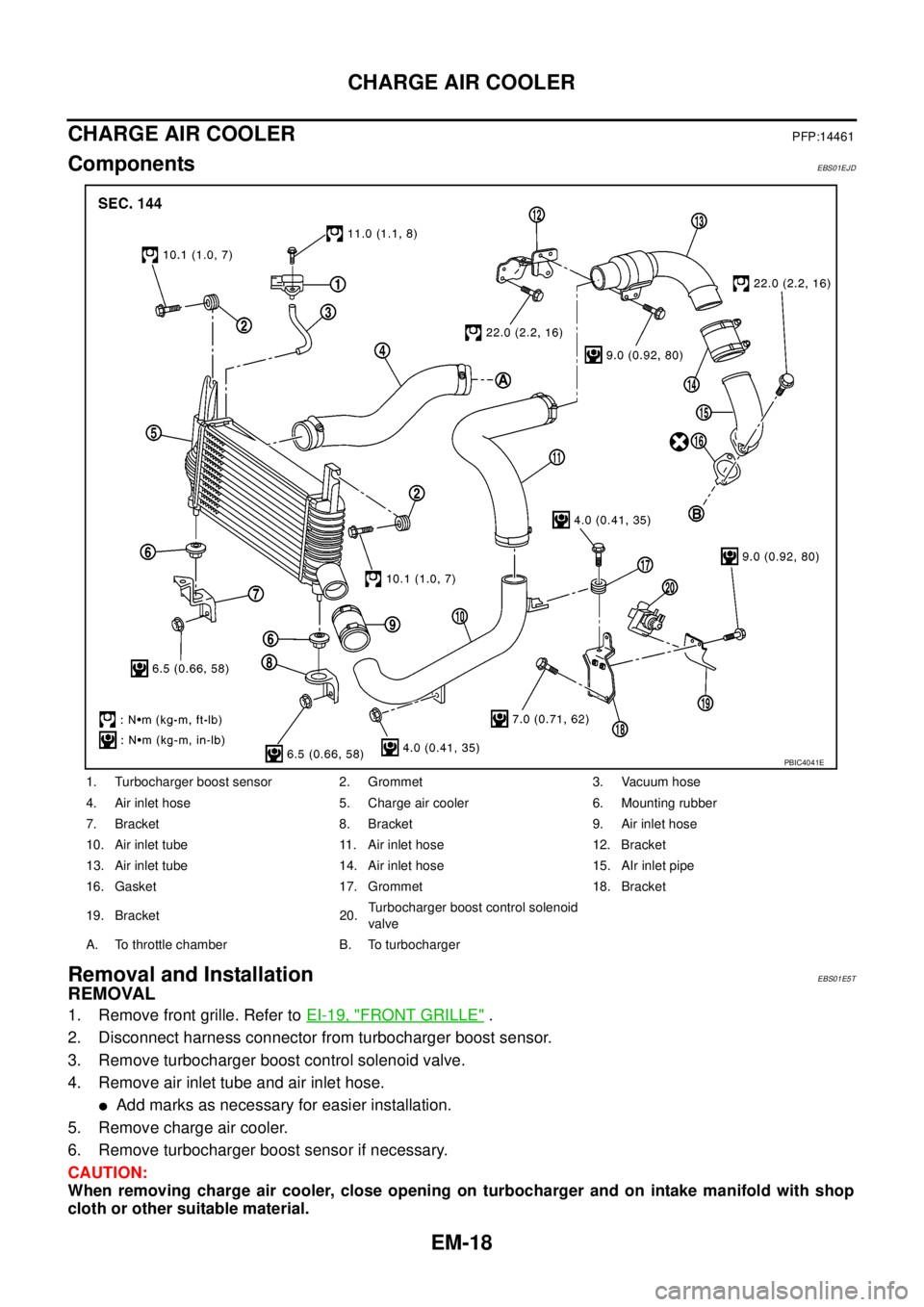

ComponentsEBS01EJD

Removal and InstallationEBS01E5T

REMOVAL

1. Remove front grille. Refer toEI-19, "FRONT GRILLE".

2. Disconnect harness connector from turbocharger boost sensor.

3. Remove turbocharger boost control solenoid valve.

4. Remove air inlet tube and air inlet hose.

lAdd marks as necessary for easier installation.

5. Remove charge air cooler.

6. Remove turbocharger boost sensor if necessary.

CAUTION:

When removing charge air cooler, close opening on turbocharger and on intake manifold with shop

cloth or other suitable material.

1. Turbocharger boost sensor 2. Grommet 3. Vacuum hose

4. Air inlet hose 5. Charge air cooler 6. Mounting rubber

7. Bracket 8. Bracket 9. Air inlet hose

10. Air inlet tube 11. Air inlet hose 12. Bracket

13. Air inlet tube 14. Air inlet hose 15. AIr inlet pipe

16. Gasket 17. Grommet 18. Bracket

19. Bracket 20.Turbocharger boost control solenoid

valve

A. To throttle chamber B. To turbocharger

PBIC4041E

Page 1418 of 3171

EM-36

OIL PAN AND OIL STRAINER

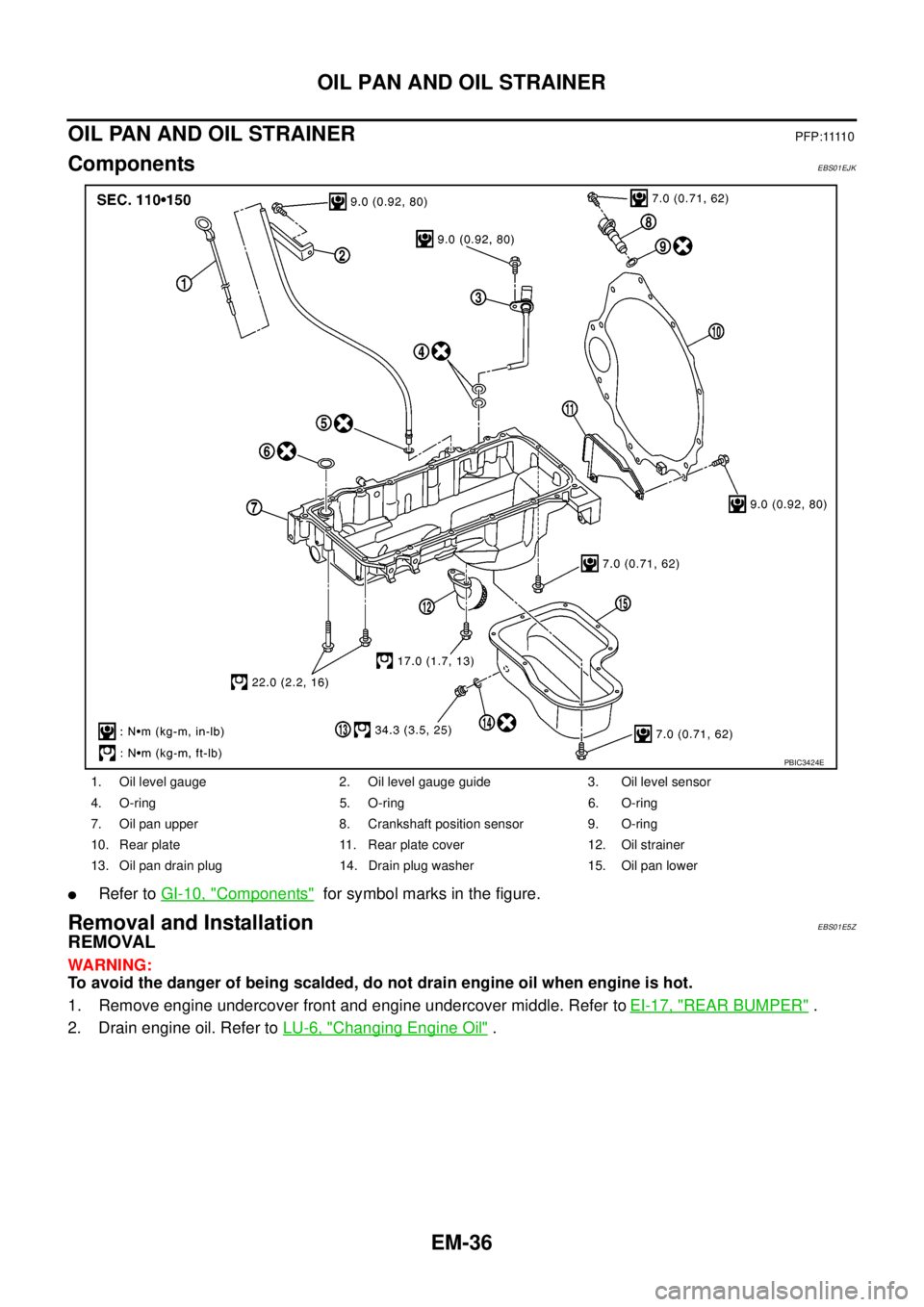

OIL PAN AND OIL STRAINER

P F P : 1111 0

ComponentsEBS01EJK

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E5Z

REMOVAL

WARNING:

To avoid the danger of being scalded, do not drain engine oil when engine is hot.

1. Remove engine undercover front and engine undercover middle. Refer toEI-17, "

REAR BUMPER".

2. Drain engine oil. Refer toLU-6, "

Changing Engine Oil".

1. Oil level gauge 2. Oil level gauge guide 3. Oil level sensor

4. O-ring 5. O-ring 6. O-ring

7. Oil pan upper 8. Crankshaft position sensor 9. O-ring

10. Rear plate 11. Rear plate cover 12. Oil strainer

13. Oil pan drain plug 14. Drain plug washer 15. Oil pan lower

PBIC3424E

Page 1419 of 3171

OIL PAN AND OIL STRAINER

EM-37

C

D

E

F

G

H

I

J

K

L

MA

EM

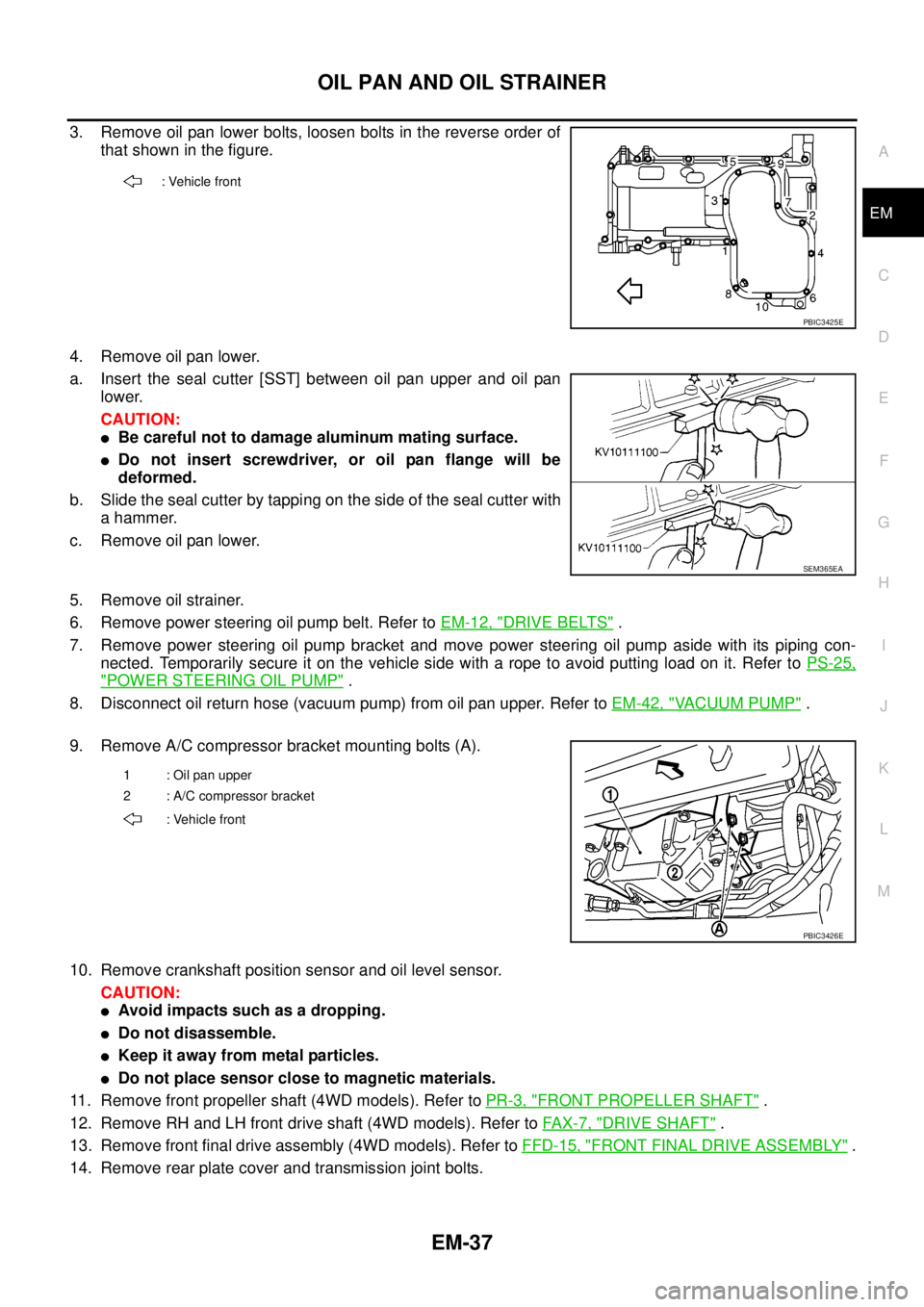

3. Remove oil pan lower bolts, loosen bolts in the reverse order of

that shown in the figure.

4. Remove oil pan lower.

a. Insert the seal cutter [SST] between oil pan upper and oil pan

lower.

CAUTION:

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be

deformed.

b. Slide the seal cutter by tapping on the side of the seal cutter with

a hammer.

c. Remove oil pan lower.

5. Remove oil strainer.

6. Remove power steering oil pump belt. Refer toEM-12, "

DRIVE BELTS".

7. Remove power steering oil pump bracket and move power steering oil pump aside with its piping con-

nected. Temporarily secure it on the vehicle side with a rope to avoid putting load on it. Refer toPS-25,

"POWER STEERING OIL PUMP".

8. Disconnect oil return hose (vacuum pump) from oil pan upper. Refer toEM-42, "

VACUUM PUMP".

9. Remove A/C compressor bracket mounting bolts (A).

10. Remove crankshaft position sensor and oil level sensor.

CAUTION:

lAvoid impacts such as a dropping.

lDo not disassemble.

lKeep it away from metal particles.

lDo not place sensor close to magnetic materials.

11. Remove front propeller shaft (4WD models). Refer toPR-3, "

FRONT PROPELLER SHAFT".

12. Remove RH and LH front drive shaft (4WD models). Refer toFAX-7, "

DRIVE SHAFT".

13. Remove front final drive assembly (4WD models). Refer toFFD-15, "

FRONT FINAL DRIVE ASSEMBLY".

14. Remove rear plate cover and transmission joint bolts.

: Vehicle front

PBIC3425E

SEM365EA

1 : Oil pan upper

2 : A/C compressor bracket

: Vehicle front

PBIC3426E

Page 1441 of 3171

CAMSHAFT

EM-59

C

D

E

F

G

H

I

J

K

L

MA

EM

CAMSHAFTPFP:13001

ComponentsEBS01EK5

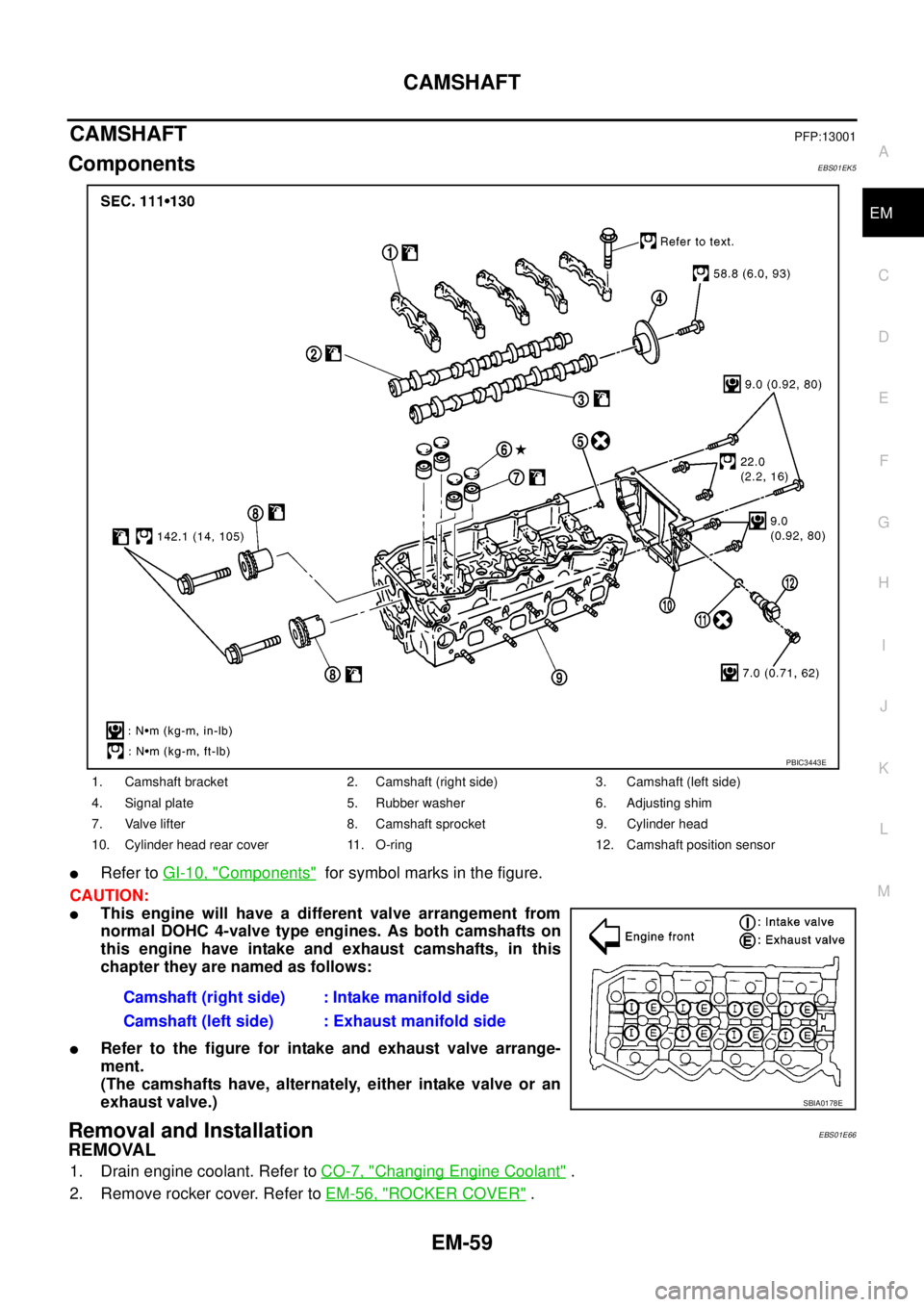

lRefer toGI-10, "Components"for symbol marks in the figure.

CAUTION:

lThis engine will have a different valve arrangement from

normal DOHC 4-valve type engines. As both camshafts on

this engine have intake and exhaust camshafts, in this

chapter they are named as follows:

lRefer to the figure for intake and exhaust valve arrange-

ment.

(The camshafts have, alternately, either intake valve or an

exhaust valve.)

Removal and InstallationEBS01E66

REMOVAL

1. Drain engine coolant. Refer toCO-7, "Changing Engine Coolant".

2. Remove rocker cover. Refer toEM-56, "

ROCKER COVER".

1. Camshaft bracket 2. Camshaft (right side) 3. Camshaft (left side)

4. Signal plate 5. Rubber washer 6. Adjusting shim

7. Valve lifter 8. Camshaft sprocket 9. Cylinder head

10. Cylinder head rear cover 11. O-ring 12. Camshaft position sensor

Camshaft (right side) : Intake manifold side

Camshaft (left side) : Exhaust manifold side

PBIC3443E

SBIA0178E

Page 1442 of 3171

EM-60

CAMSHAFT

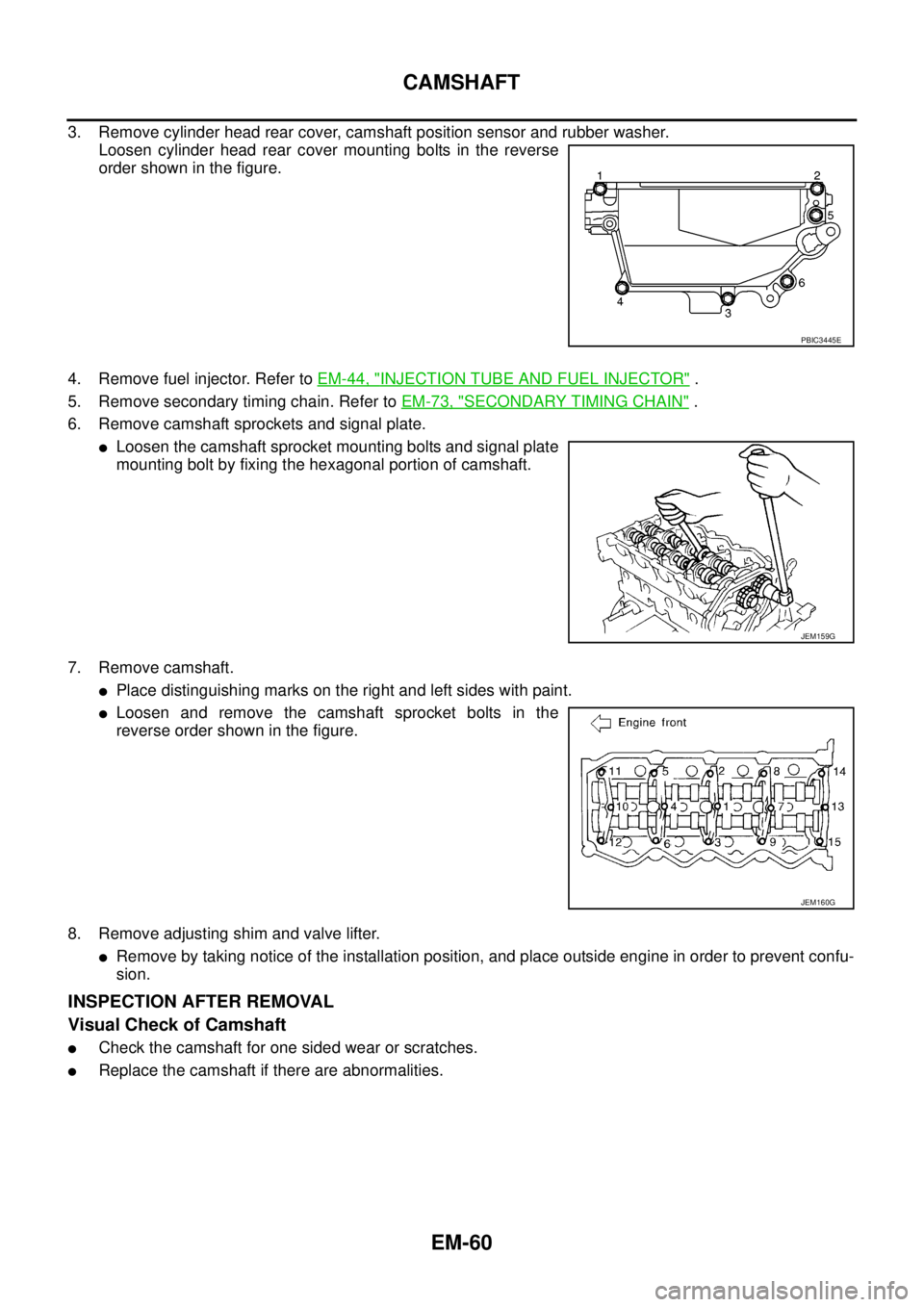

3. Remove cylinder head rear cover, camshaft position sensor and rubber washer.

Loosen cylinder head rear cover mounting bolts in the reverse

order shown in the figure.

4. Remove fuel injector. Refer toEM-44, "

INJECTION TUBE AND FUEL INJECTOR".

5. Remove secondary timing chain. Refer toEM-73, "

SECONDARY TIMING CHAIN".

6. Remove camshaft sprockets and signal plate.

lLoosen the camshaft sprocket mounting bolts and signal plate

mounting bolt by fixing the hexagonal portion of camshaft.

7. Remove camshaft.

lPlace distinguishing marks on the right and left sides with paint.

lLoosen and remove the camshaft sprocket bolts in the

reverse order shown in the figure.

8. Remove adjusting shim and valve lifter.

lRemove by taking notice of the installation position, and place outside engine in order to prevent confu-

sion.

INSPECTION AFTER REMOVAL

Visual Check of Camshaft

lCheck the camshaft for one sided wear or scratches.

lReplace the camshaft if there are abnormalities.

PBIC3445E

JEM159G

JEM160G