sensor NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1759 of 3171

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

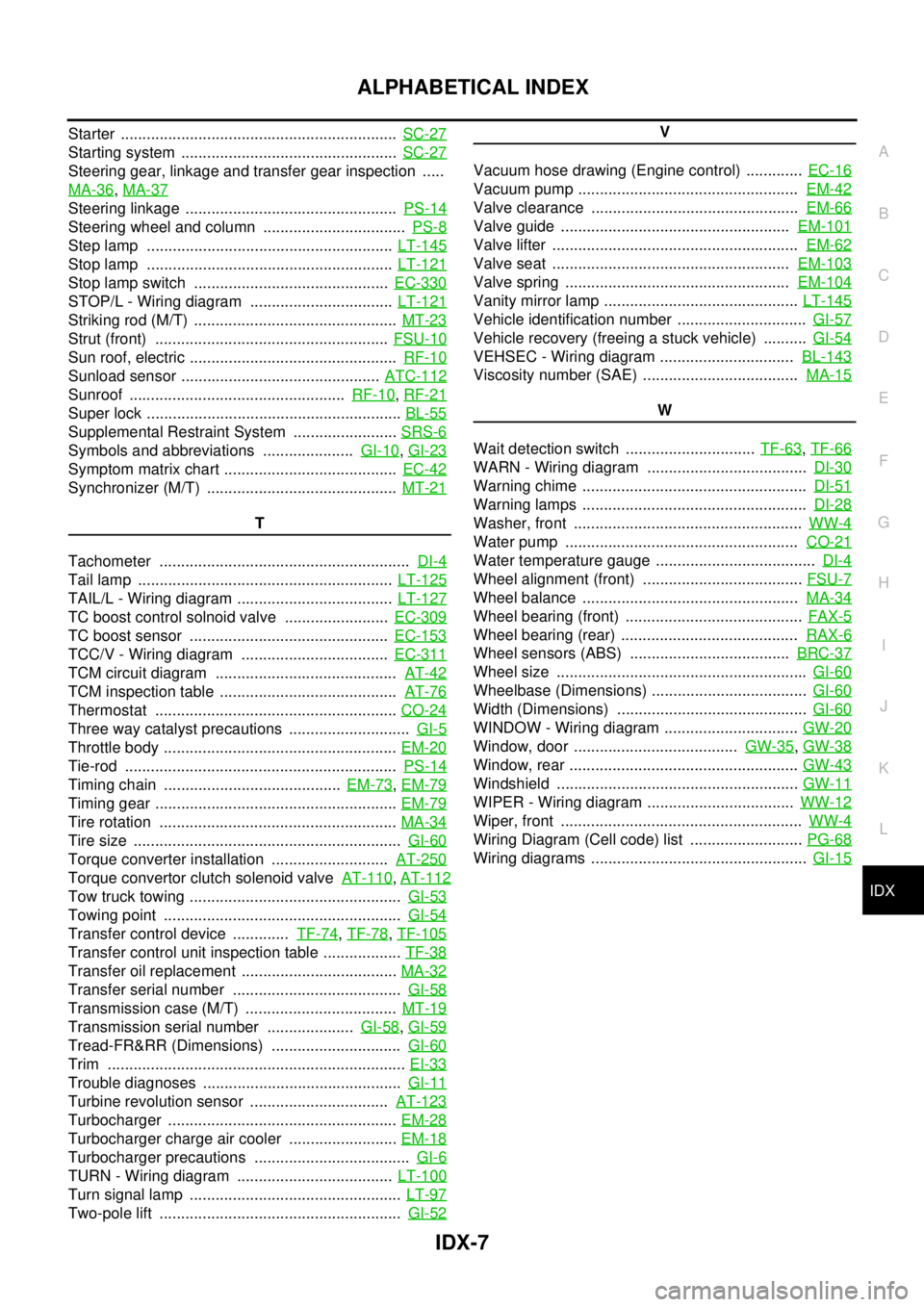

ALPHABETICAL INDEX

Starter ................................................................SC-27

Starting system ..................................................SC-27

Steering gear, linkage and transfer gear inspection .....

MA-36

,MA-37

Steering linkage .................................................PS-14

Steering wheel and column .................................PS-8

Step lamp .........................................................LT-145

Stop lamp .........................................................LT-121

Stop lamp switch .............................................EC-330

STOP/L - Wiring diagram .................................LT-121

Striking rod (M/T) ...............................................MT-23

Strut (front) ......................................................FSU-10

Sun roof, electric ................................................RF-10

Sunload sensor ..............................................ATC-112

Sunroof ..................................................RF-10,RF-21

Super lock ...........................................................BL-55

Supplemental Restraint System ........................SRS-6

Symbols and abbreviations .....................GI-10,GI-23

Symptom matrix chart ........................................EC-42

Synchronizer (M/T) ............................................MT-21

T

Tachometer ..........................................................DI-4

Tail lamp ...........................................................LT-125

TAIL/L - Wiring diagram ....................................LT-127

TC boost control solnoid valve ........................EC-309

TC boost sensor ..............................................EC-153

TCC/V - Wiring diagram ..................................EC-311

TCM circuit diagram ..........................................AT-42

TCM inspection table .........................................AT-76

Thermostat ........................................................CO-24

Three way catalyst precautions ............................GI-5

Throttle body ......................................................EM-20

Tie-rod ...............................................................PS-14

Timing chain .........................................EM-73,EM-79

Timing gear ........................................................EM-79

Tire rotation .......................................................MA-34

Tire size ..............................................................GI-60

Torque converter installation ...........................AT-250

Torque convertor clutch solenoid valveAT-110,AT-112

Tow truck towing .................................................GI-53

Towing point .......................................................GI-54

Transfer control device .............TF-74,TF-78,TF-105

Transfer control unit inspection table ..................TF-38

Transfer oil replacement ....................................MA-32

Transfer serial number .......................................GI-58

Transmission case (M/T) ...................................MT-19

Transmission serial number ....................GI-58,GI-59

Tread-FR&RR (Dimensions) ..............................GI-60

Trim .....................................................................EI-33

Trouble diagnoses ..............................................GI-11

Turbine revolution sensor ................................AT-123

Turbocharger .....................................................EM-28

Turbocharger charge air cooler .........................EM-18

Turbocharger precautions ....................................GI-6

TURN - Wiring diagram ....................................LT-100

Turn signal lamp .................................................LT-97

Two-pole lift ........................................................GI-52

V

Vacuum hose drawing (Engine control) .............EC-16

Vacuum pump ...................................................EM-42

Valve clearance ................................................EM-66

Valve guide .....................................................EM-101

Valve lifter .........................................................EM-62

Valve seat .......................................................EM-103

Valve spring ....................................................EM-104

Vanity mirror lamp .............................................LT-145

Vehicle identification number ..............................GI-57

Vehicle recovery (freeing a stuck vehicle) ..........GI-54

VEHSEC - Wiring diagram ...............................BL-143

Viscosity number (SAE) ....................................MA-15

W

Wait detection switch ..............................TF-63

,TF-66

WARN - Wiring diagram .....................................DI-30

Warning chime ....................................................DI-51

Warning lamps ....................................................DI-28

Washer, front .....................................................WW-4

Water pump ......................................................CO-21

Water temperature gauge .....................................DI-4

Wheel alignment (front) .....................................FSU-7

Wheel balance ..................................................MA-34

Wheel bearing (front) .........................................FAX-5

Wheel bearing (rear) .........................................RAX-6

Wheel sensors (ABS) .....................................BRC-37

Wheel size ..........................................................GI-60

Wheelbase (Dimensions) ....................................GI-60

Width (Dimensions) ............................................GI-60

WINDOW - Wiring diagram ...............................GW-20

Window, door ......................................GW-35,GW-38

Window, rear .....................................................GW-43

Windshield ........................................................GW-11

WIPER - Wiring diagram ..................................WW-12

Wiper, front ........................................................WW-4

Wiring Diagram (Cell code) list ..........................PG-68

Wiring diagrams ..................................................GI-15

Page 1761 of 3171

IP-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ8

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ4

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1770 of 3171

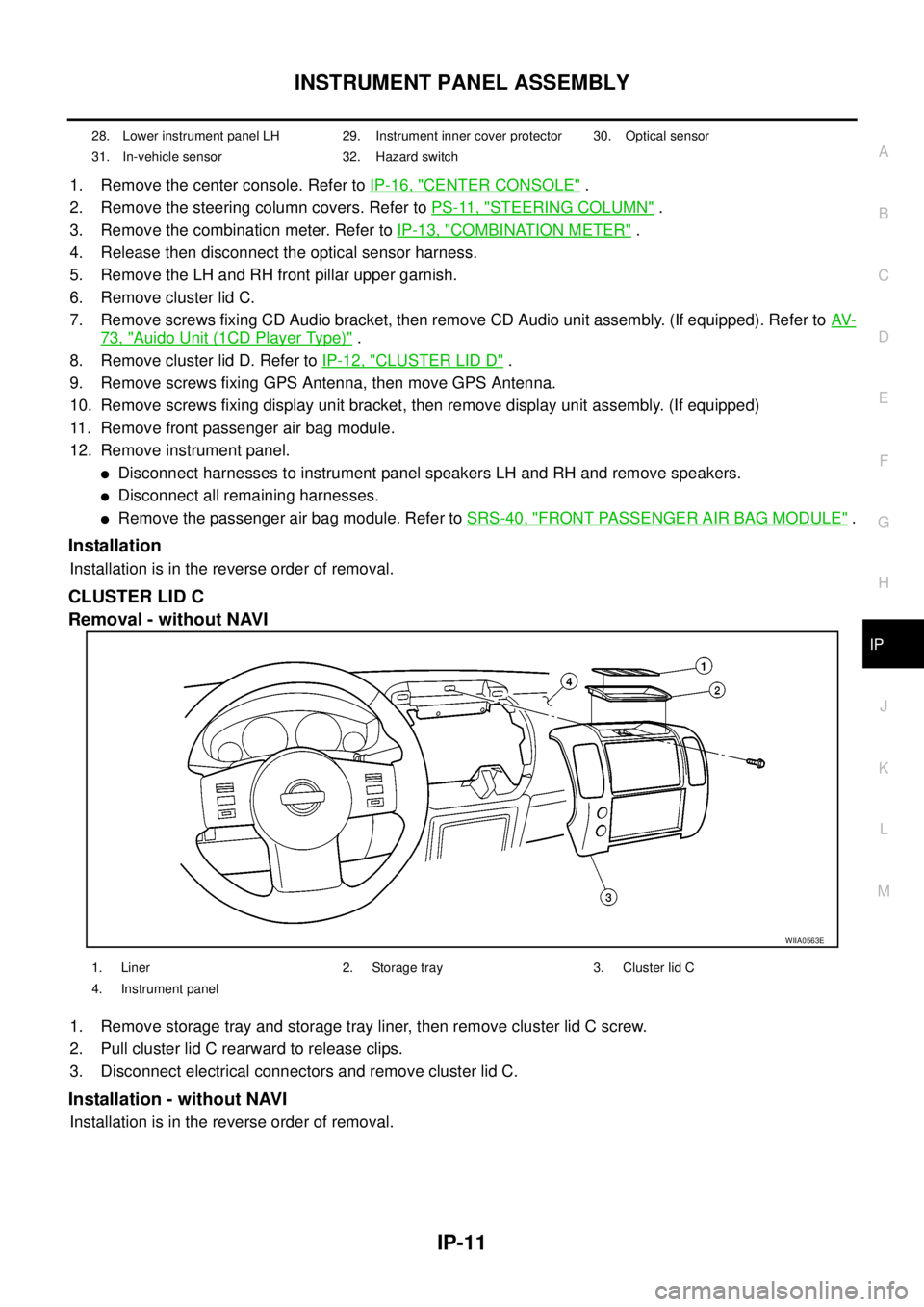

INSTRUMENT PANEL ASSEMBLY

IP-11

C

D

E

F

G

H

J

K

L

MA

B

IP

1. Remove the center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove the steering column covers. Refer toPS-11, "

STEERING COLUMN".

3. Remove the combination meter. Refer toIP-13, "

COMBINATION METER".

4. Release then disconnect the optical sensor harness.

5. Remove the LH and RH front pillar upper garnish.

6. Remove cluster lid C.

7. Remove screws fixing CD Audio bracket, then remove CD Audio unit assembly. (If equipped). Refer toAV-

73, "Auido Unit (1CD Player Type)".

8. Remove cluster lid D. Refer toIP-12, "

CLUSTER LID D".

9. Remove screws fixing GPS Antenna, then move GPS Antenna.

10. Remove screws fixing display unit bracket, then remove display unit assembly. (If equipped)

11. Remove front passenger air bag module.

12. Remove instrument panel.

lDisconnect harnesses to instrument panel speakers LH and RH and remove speakers.

lDisconnect all remaining harnesses.

lRemove the passenger air bag module. Refer toSRS-40, "FRONT PASSENGER AIR BAG MODULE".

Installation

Installation is in the reverse order of removal.

CLUSTER LID C

Removal - without NAVI

1. Remove storage tray and storage tray liner, then remove cluster lid C screw.

2. Pull cluster lid C rearward to release clips.

3. Disconnect electrical connectors and remove cluster lid C.

Installation - without NAVI

Installation is in the reverse order of removal.

28. Lower instrument panel LH 29. Instrument inner cover protector 30. Optical sensor

31. In-vehicle sensor 32. Hazard switch

WIIA0563E

1. Liner 2. Storage tray 3. Cluster lid C

4. Instrument panel

Page 1782 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-5

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsEKS00LBH

WHEN A MALFUNCTION IS DETECTED BY CAN CO NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSES WORK FLOW

LAN-5

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsEKS00LBH

WHEN A MALFUNCTION IS DETECTED BY CAN CO](/img/5/57362/w960_57362-1781.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-5

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsEKS00LBH

WHEN A MALFUNCTION IS DETECTED BY CAN COMMUNICATION SYSTEM

lCAN communication line is open. (CAN H, CAN L, or both)

lCAN communication line is shorted. (Ground, between CAN lines, or other harnesses)

lThe areas related to CAN communication of unit is malfunctioning.

WHEN A MALFUNCTION IS DETECTED EXCEPT CAN COMMUNICATION SYSTEM

lRemoval and installation of parts : When the units that perform CAN communication or the sensors

related to CAN communication are removed and installed, malfunction may be detected (or DTC other

than CAN communication may be detected).

lFuse blown out (removed): CAN communication of the unit may be stopped at such time.

lLow voltage : If the voltage decreases because of battery discharge when IGN is ON, malfunction may be

detected by self-diagnosis according to the units.

Page 1812 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

En NISSAN NAVARA 2005 Repair Workshop Manual CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

En](/img/5/57362/w960_57362-1811.png)

CAN COMMUNICATION

LAN-35

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Closed throttle position signal T R

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

Wide open throttle position signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R

OD OFF indicator lamp signal T R

Output shaft revolution signal R T

Turbine revolution signal R T

A/C switch/indicator signal T R

PTC heater signal R T

A/C switch signal R R T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signalTR R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signalTR

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal R T R

Sleep wake up signal T R R

Theft warning horn request signal T R

Trailer lamp signalTR

Turn indicator signal T R

1st position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Overdrive control switch signal R T

Stop lamp switch signal R T

ABS operation signal R T

ABS warning lamp signalRT Signals ECM TCMNAVI

control

unitFront air

controlBCMCombi-

nation

meterABS

actuator

and elec-

tric unit

(control

unit)IPDM

E/R

Page 1819 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow rela NISSAN NAVARA 2005 Repair Workshop Manual LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow rela](/img/5/57362/w960_57362-1818.png)

LAN-42

[CAN]

CAN COMMUNICATION

Engine coolant temperature signal T R R

Engine speed signal T R R R R

Engine status signal T R R

Fuel consumption monitor signalTR

RT

Glow indicator signal T R

Glow relay signal T R

Malfunction indicator signal T R

Wide open throttle position signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R R

OD OFF indicator lamp signal T R

Output shaft revolution signal R T R

Turbine revolution signal R T

A/C switch/indicator signal T R

Differential lock indicator signal T R

Differential lock switch signal T R

PTC heater signal

*RT

A/C switch signal R R T

Buzzer output signal T R

Day time running light request signal R T R R

Door switch signal T R R

Front fog light request signal R T R R

Front wiper request signal T R

High beam request signal T R R

Horn chirp signalTR

Low beam request signal T R

Position light request signal T R R

Rear fog light request signal R T R

Rear window defogger switch signal R T R

Sleepwakeupsignal T R R

Theft warning horn request signal T R

Trailer lamp signal T R

Turn indicator signal T R

1st position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Overdrive control switch signal R T

Stop lamp switch signal R TSignals ECM TCMNAVI

con-

trol

unitDiffer-

ential

lock

con-

trol

unitFront

air

controlBCMCom-

bina-

tion

meterTrans-

fer

con-

trol

unitABS

actua-

tor and

elec-

tric unit

(con-

trol

unit)IPDM

E/R

Page 2085 of 3171

LT-2

AUTO LIGHT SYSTEM ............................................. 49

Component Parts and Harness Connector Location... 49

System Description ................................................. 49

OUTLINE ............................................................. 49

COMBINATION SWITCH READING FUNCTION... 50

CAN Communication System Description .............. 50

Major Components and Functions .......................... 50

Schematic ............................................................... 51

Wiring Diagram — AUTO/L — ................................ 52

Terminals and Reference Values for BCM .............. 56

Terminals and Reference Values for IPDM E/R ...... 57

How to Proceed With Trouble Diagnosis ................ 57

Preliminary Check .................................................. 58

SETTING CHANGE FUNCTIONS ....................... 58

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 58

CONSULT-II Function (BCM) .................................. 59

CONSULT-II OPERATION ................................... 59

WORK SUPPORT ............................................... 60

DATA MONITOR .................................................. 60

ACTIVE TEST ..................................................... 61

Trouble Diagnosis Chart by Symptom .................... 62

Lighting Switch Inspection ...................................... 62

Light and Rain Sensor System Inspection .............. 63

Removal and Installation of Light and Rain Sensor... 65

REMOVAL ........................................................... 65

INSTALLATION .................................................... 65

HEADLAMP AIMING CONTROL (MANUAL) ........... 66

Schematic ............................................................... 66

Wiring Diagram — H/AIM — ................................... 67

Removal and Installation ........................................ 70

Switch Circuit Inspection ........................................ 70

FRONT FOG LAMP .................................................. 71

Component Parts and Harness Connector Location... 71

System Description ................................................. 71

OUTLINE ............................................................. 71

COMBINATION SWITCH READING FUNCTION... 72

CAN Communication System Description .............. 72

Schematic ............................................................... 73

Wiring Diagram — F/FOG — .................................. 74

Terminals and Reference Values for BCM .............. 77

Terminals and Reference Values for IPDM E/R ...... 77

How to Proceed With Trouble Diagnosis ................ 78

Preliminary Check .................................................. 78

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 78

CONSULT-II Functions (BCM) ................................ 79

CONSULT-II Functions (IPDM E/R) ........................ 79

Front Fog Lamps Do Not Illuminate (Both Sides) ... 80

Front Fog Lamp Does Not Illuminate (One Side) ... 82

Front Fog Lamp Indicator Lamp Does Not Illuminate... 83

Front Fog Lamps Do Not Turn OFF ........................ 84

Aiming Adjustment .................................................. 85

Bulb Replacement .................................................. 86

Removal and Installation of Front Fog Lamp .......... 86

REMOVAL ........................................................... 86

INSTALLATION .................................................... 86

REAR FOG LAMP ..................................................... 87

Component Parts and Harness Connector Location... 87System Description ................................................. 87

OUTLINE ............................................................. 87

COMBINATION SWITCH READING FUNCTION... 88

CAN Communication System Description .............. 88

CAN Communication Unit ....................................... 88

Wiring Diagram — R/FOG — .................................. 89

Terminals and Reference Values for BCM .............. 91

How to Proceed With Trouble Diagnosis ................ 91

Preliminary Check ................................................... 92

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................... 92

CONSULT-II Functions (BCM) ................................ 93

Rear Fog Lamp Does Not Operate ......................... 93

Rear Fog Lamp Indicator Lamp Does Not Illuminate... 95

Rear Fog Lamp Does Not Turn OFF ....................... 96

Bulb Replacement ................................................... 96

Removal and Installation ......................................... 96

TURN SIGNAL AND HAZARD WARNING LAMPS... 97

Component Parts and Harness Connector Location... 97

System Description ................................................. 97

OUTLINE ............................................................. 97

TURN SIGNAL OPERATION ............................... 97

HAZARD LAMP OPERATION ............................. 98

REMOTE KEYLESS ENTRY SYSTEM OPERA-

TION .................................................................... 99

COMBINATION SWITCH READING FUNCTION... 99

CAN Communication System Description .............. 99

Wiring Diagram — TURN — .................................100

Terminals and Reference Values for BCM ............102

How to Proceed With Trouble Diagnosis ..............103

Preliminary Check .................................................103

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................103

CONSULT-II Function (BCM) ................................105

CONSULT-II OPERATION .................................105

DATA MONITOR ................................................106

ACTIVE TEST ....................................................106

Turn Signal Lamp Does Not Operate ....................107

Hazard Warning Lamp Does Not Operate But Turn

Signal Lamps Operate ..........................................109

Turn Signal Indicator Lamp Does Not Operate .....110

Bulb Replacement (Front Turn Signal Lamp) ........ 111

Bulb Replacement (Rear Turn Signal Lamp) ........ 111

Bulb Replacement (Side Turn Signal Lamp) ......... 111

Removal and Installation of Front Turn Signal Lamp. 111

Removal and Installation of Rear Turn Signal Lamp. 111

Removal and Installation of Side Turn Signal Lamp. 111

REMOVAL .......................................................... 111

INSTALLATION .................................................. 111

LIGHTING AND TURN SIGNAL SWITCH ..............112

Removal and Installation .......................................112

REMOVAL ..........................................................112

INSTALLATION ..................................................112

HAZARD SWITCH ...................................................113

Removal and Installation .......................................113

REMOVAL ..........................................................113

INSTALLATION ..................................................113

COMBINATION SWITCH ........................................114

Wiring Diagram — COMBSW — ..........................114

Page 2132 of 3171

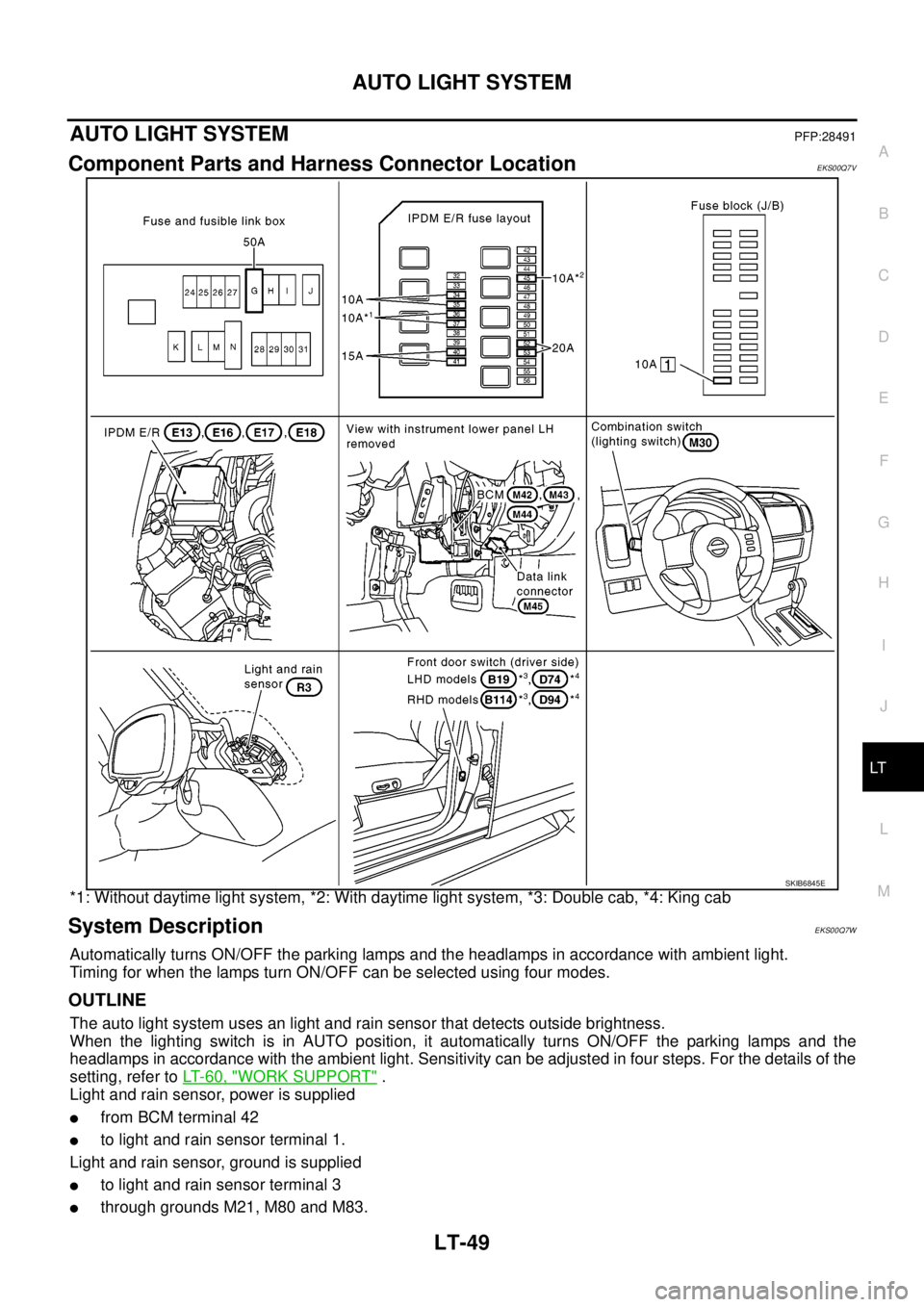

AUTO LIGHT SYSTEM

LT-49

C

D

E

F

G

H

I

J

L

MA

B

LT

AUTO LIGHT SYSTEMPFP:28491

Component Parts and Harness Connector LocationEKS00Q7V

*1: Without daytime light system, *2: With daytime light system, *3: Double cab, *4: King cab

System DescriptionEKS00Q7W

Automatically turns ON/OFF the parking lamps and the headlamps in accordance with ambient light.

Timing for when the lamps turn ON/OFF can be selected using four modes.

OUTLINE

The auto light system uses an light and rain sensor that detects outside brightness.

When the lighting switch is in AUTO position, it automatically turns ON/OFF the parking lamps and the

headlamps in accordance with the ambient light. Sensitivity can be adjusted in four steps. For the details of the

setting, refer toLT-60, "

WORK SUPPORT".

Light and rain sensor, power is supplied

lfrom BCM terminal 42

lto light and rain sensor terminal 1.

Light and rain sensor, ground is supplied

lto light and rain sensor terminal 3

lthrough grounds M21, M80 and M83.

SKIB6845E

Page 2133 of 3171

LT-50

AUTO LIGHT SYSTEM

When ignition switch is turned to ON position and when outside brightness is darker than prescribed level,

input is supplied

lto BCM terminal 24

lfrom light and rain sensor terminal 2.

The headlamps will then illuminate. For a description of headlamp operation, refer toLT-49, "

System Descrip-

tion".

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00Q7X

Refer toLAN-23, "CAN COMMUNICATION".

Major Components and FunctionsEKS00Q7Y

Components Functions

BCM

lTurns ON/OFF circuits of tail light and headlamp according to signals from light and rain sensor, lighting switch

(AUTO), driver door switch, passenger door switch, rear door switches, back door switch, glass hatch opener

switch and ignition switch (ON, OFF).

Light and rain

sensor

lConverts outside brightness (lux) to voltage, and sends it to BCM. (Detects lightness of 50 to 1,300 lux.)

Page 2139 of 3171

LT-56

AUTO LIGHT SYSTEM

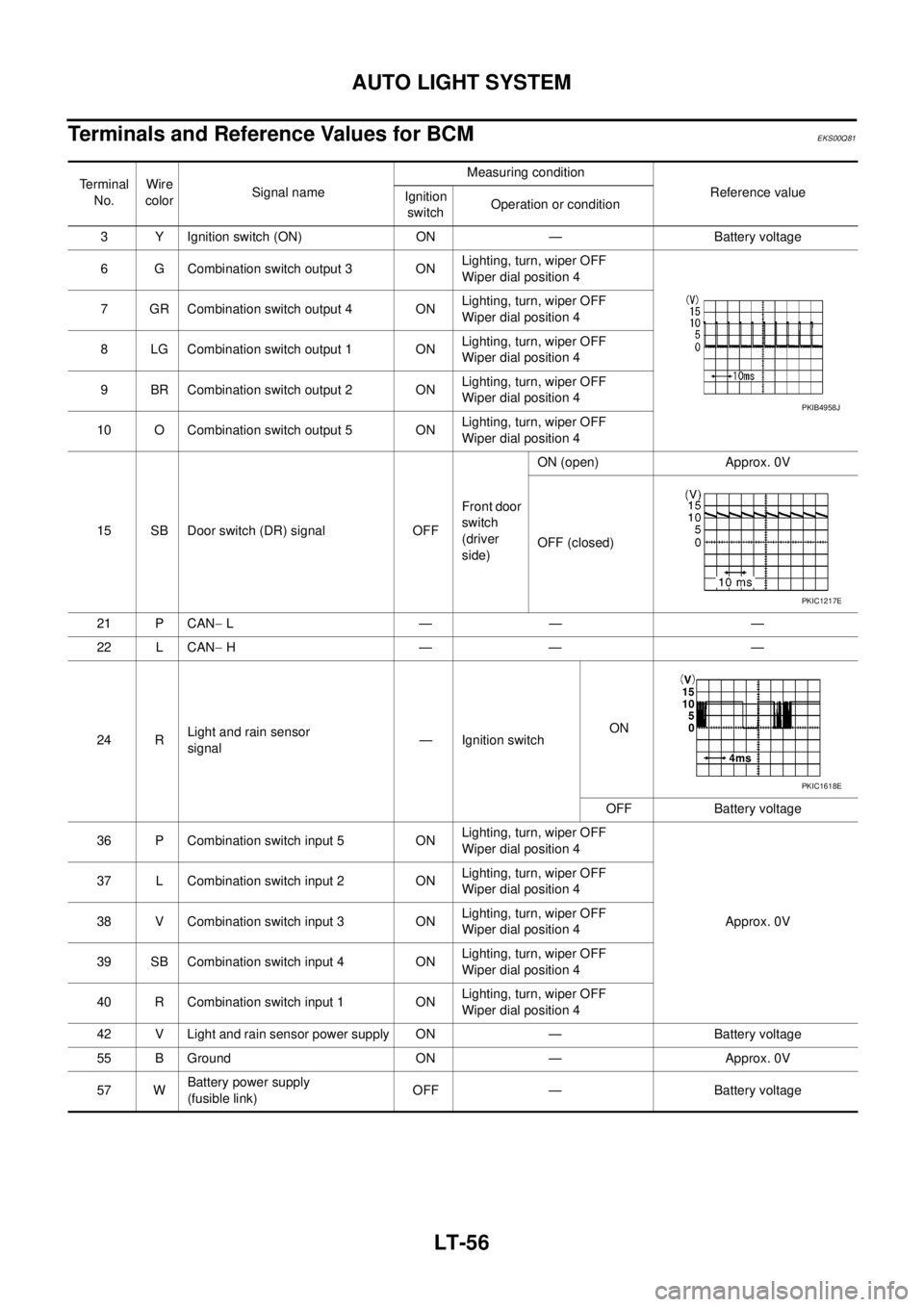

Terminals and Reference Values for BCM

EKS00Q81

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

3 Y Ignition switch (ON) ON — Battery voltage

6 G Combination switch output 3 ONLighting, turn, wiper OFF

Wiper dial position 4

7 GR Combination switch output 4 ONLighting, turn, wiper OFF

Wiper dial position 4

8 LG Combination switch output 1 ONLighting, turn, wiper OFF

Wiper dial position 4

9 BR Combination switch output 2 ONLighting, turn, wiper OFF

Wiper dial position 4

10 O Combination switch output 5 ONLighting, turn, wiper OFF

Wiper dial position 4

15 SB Door switch (DR) signal OFFFront door

switch

(driver

side)ON (open) Approx. 0V

OFF (closed)

21 P CAN-L—— —

22 L CAN-H—— —

24 RLight and rain sensor

signal— Ignition switchON

OFF Battery voltage

36 P Combination switch input 5 ONLighting, turn, wiper OFF

Wiper dial position 4

Approx. 0V 37 L Combination switch input 2 ONLighting, turn, wiper OFF

Wiper dial position 4

38 V Combination switch input 3 ONLighting, turn, wiper OFF

Wiper dial position 4

39 SB Combination switch input 4 ONLighting, turn, wiper OFF

Wiper dial position 4

40 R Combination switch input 1 ONLighting, turn, wiper OFF

Wiper dial position 4

42 V Light and rain sensor power supply ON — Battery voltage

55 B Ground ON — Approx. 0V

57 WBattery power supply

(fusible link)OFF — Battery voltage

PKIB4958J

PKIC1217E

PKIC1618E