maintain NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 926 of 3171

DI-16

COMBINATION METERS

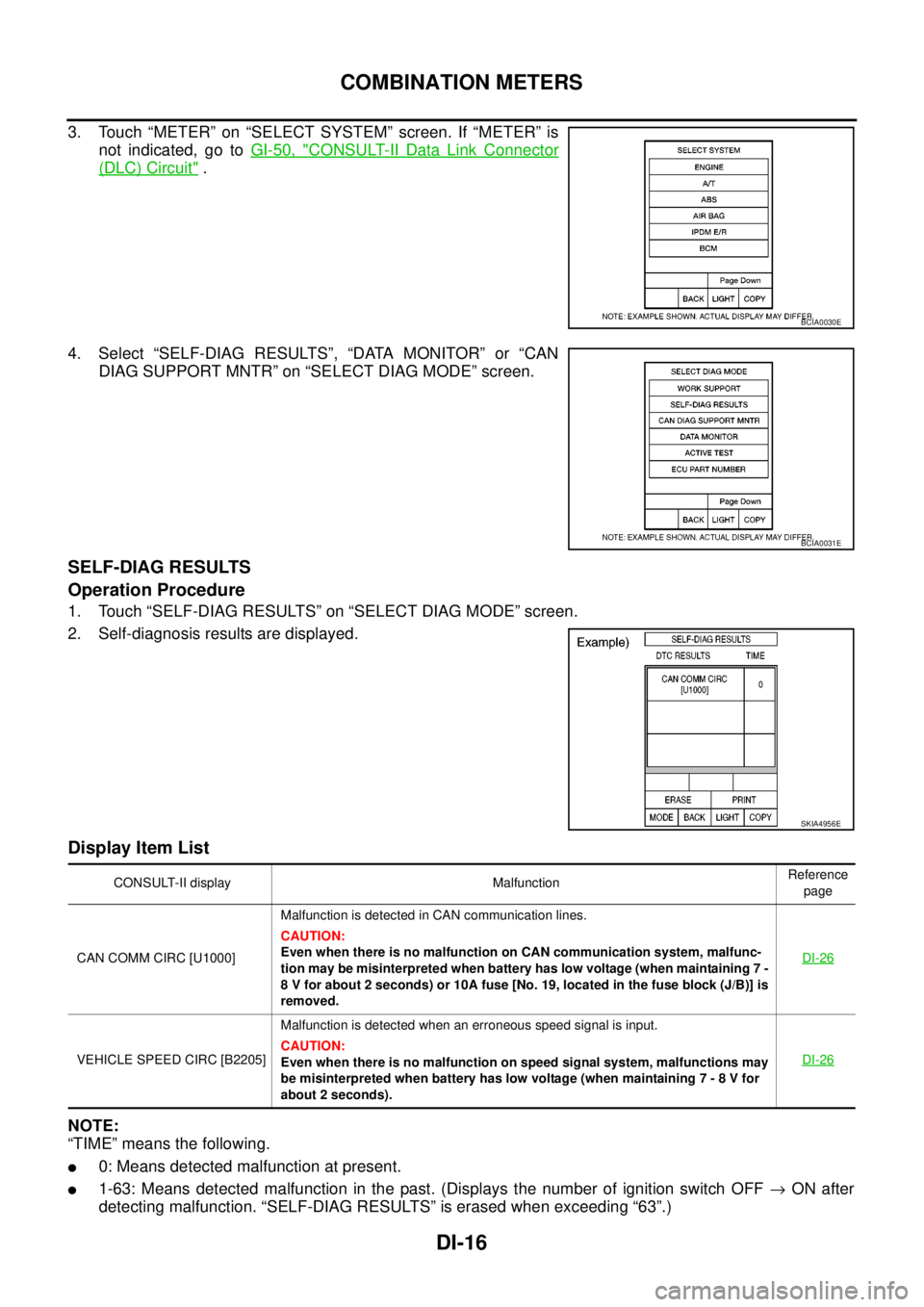

3. Touch “METER” on “SELECT SYSTEM” screen. If “METER” is

not indicated, go toGI-50, "

CONSULT-II Data Link Connector

(DLC) Circuit".

4. Select “SELF-DIAG RESULTS”, “DATA MONITOR” or “CAN

DIAG SUPPORT MNTR” on “SELECT DIAG MODE” screen.

SELF-DIAG RESULTS

Operation Procedure

1. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

2. Self-diagnosis results are displayed.

Display Item List

NOTE:

“TIME” means the following.

l0: Means detected malfunction at present.

l1-63: Means detected malfunction in the past. (Displays the number of ignition switch OFF®ON after

detecting malfunction. “SELF-DIAG RESULTS” is erased when exceeding “63”.)

BCIA0030E

BCIA0031E

SKIA4956E

CONSULT-II display MalfunctionReference

page

CAN COMM CIRC [U1000]Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunc-

tion may be misinterpreted when battery has low voltage (when maintaining 7 -

8 V for about 2 seconds) or 10A fuse [No. 19, located in the fuse block (J/B)] is

removed.DI-26

VEHICLE SPEED CIRC [B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunctions may

be misinterpreted when battery has low voltage (when maintaining 7 - 8 V for

about 2 seconds).DI-26

Page 1072 of 3171

EC-92

DTC P0102, P0103 MAF SENSOR

DTC P0102, P0103 MAF SENSOR

PFP:22680

Component DescriptionEBS01KDV

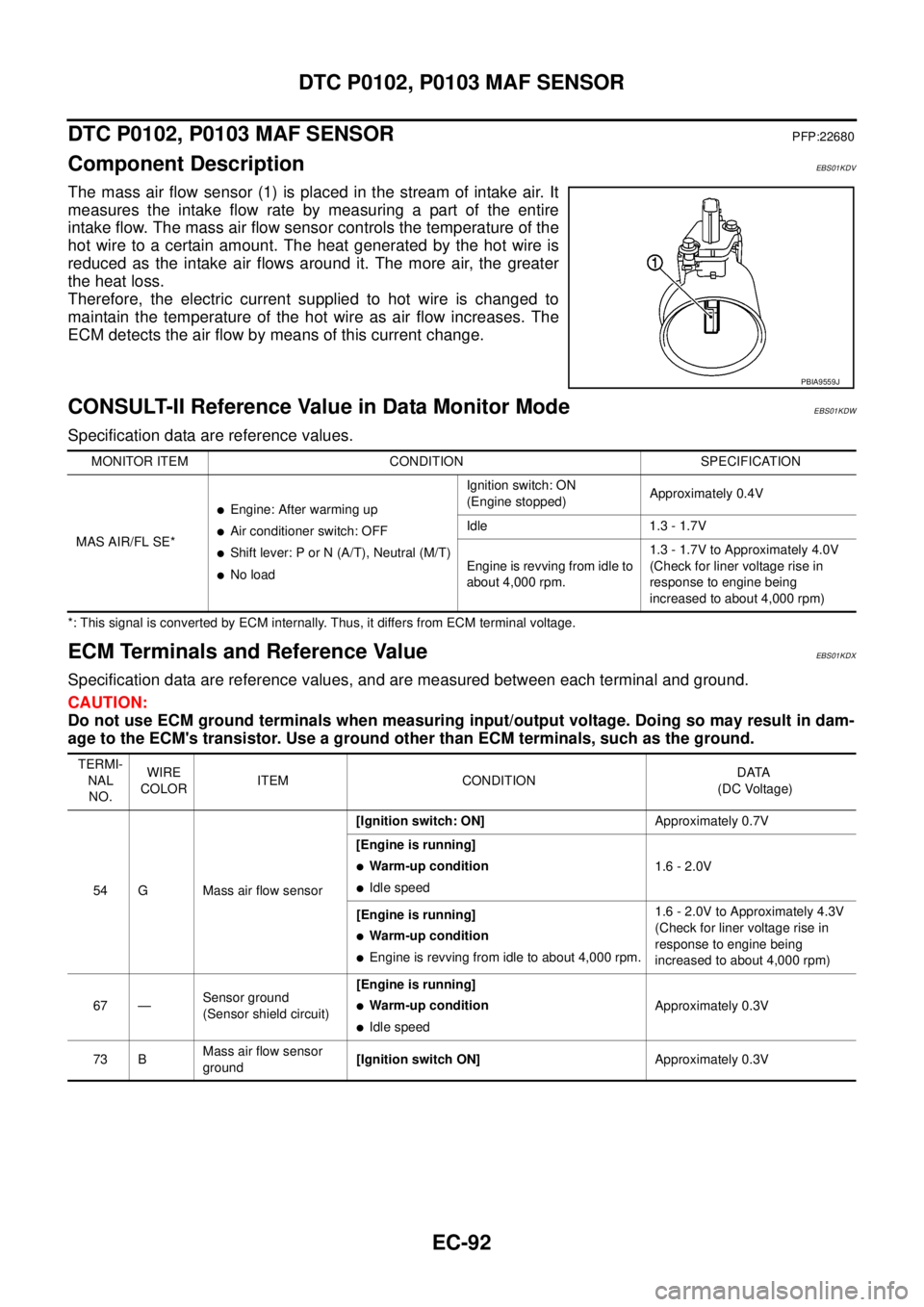

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeEBS01KDW

Specification data are reference values.

*: This signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.

ECM Terminals and Reference ValueEBS01KDX

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIA9559J

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to

about 4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

54 G Mass air flow sensor[Ignition switch: ON]Approximately 0.7V

[Engine is running]

lWarm-up condition

lIdle speed1.6 - 2.0V

[Engine is running]

lWarm-up condition

lEngine is revving from idle to about 4,000 rpm.1.6 - 2.0V to Approximately 4.3V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

67 —Sensor ground

(Sensor shield circuit)[Engine is running]

lWarm-up condition

lIdle speedApproximately 0.3V

73 BMass air flow sensor

ground[Ignition switch ON]Approximately 0.3V

Page 1165 of 3171

DTC P0502 ASCD VEHICLE SPEED SENSOR

EC-185

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0502 ASCD VEHICLE SPEED SENSORPFP:24810

Component DescriptionEBS01KHL

The ECM receives vehicle speed sensor signal via CAN communication line. It is sent from combination

meter. The ECM uses this signal for ASCD control. Refer toEC-355, "

AUTOMATIC SPEED CONTROL

DEVICE (ASCD)"for ASCD functions.

On Board Diagnosis LogicEBS01KHM

The MI will not light up for this self-diagnosis.

NOTE:

lIf DTC P0502 is displayed with DTC U1000 first perform the trouble diagnosis for DTC U1000. Refer

toEC-79, "

DTC U1000 CAN COMMUNICATION LINE".

lIf DTC P0502 is displayed with DTC P0606, first perform the trouble diagnosis for DTC P0606.

Refer toEC-215, "

DTC P0606 ECM".

DTC Confirmation ProcedureEBS01KHN

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Step 3 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road test

is expected to be easier, it is unnecessary to lift the vehicle.

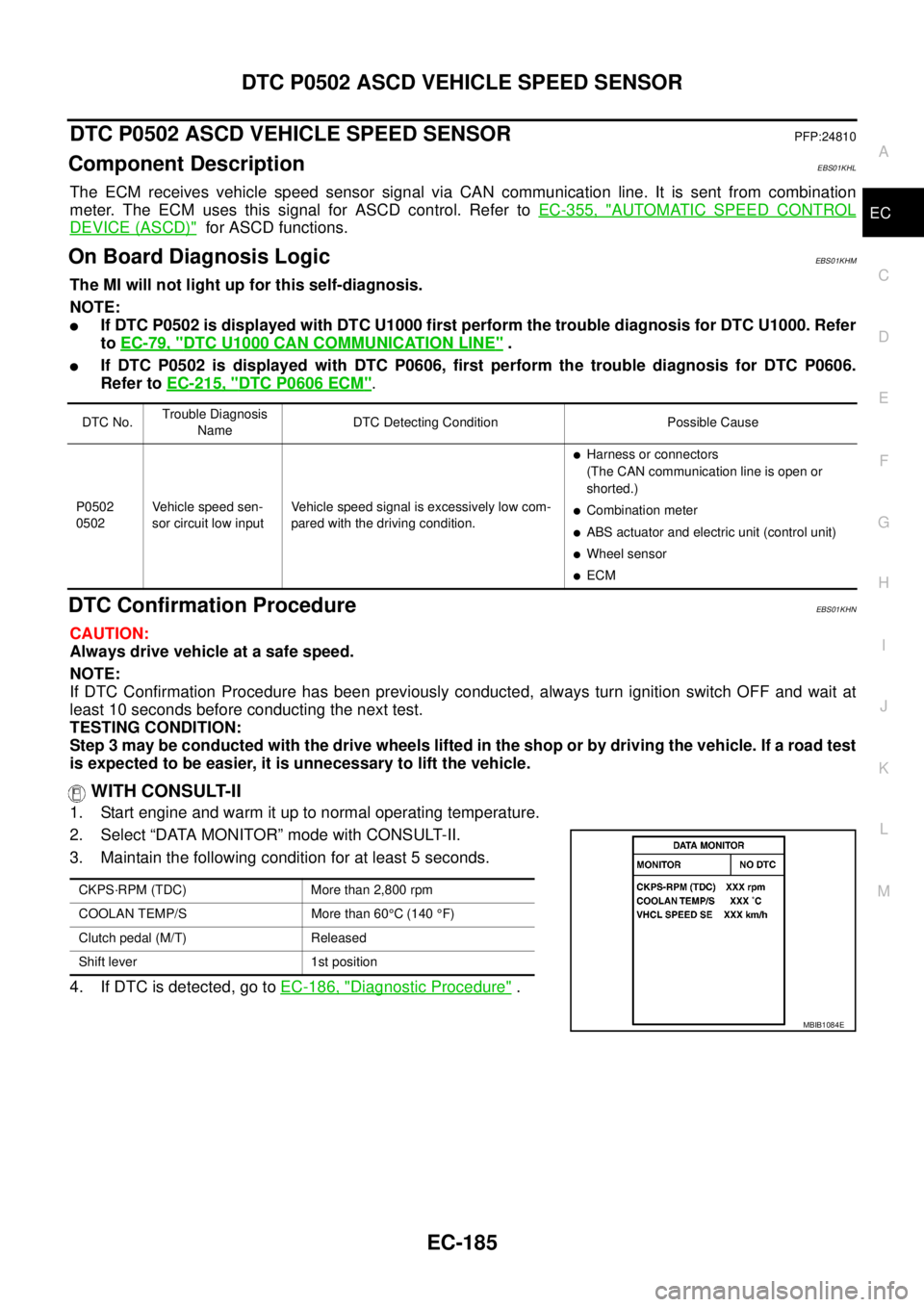

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Maintain the following condition for at least 5 seconds.

4. If DTC is detected, go toEC-186, "

Diagnostic Procedure".

DTC No.Trouble Diagnosis

NameDTC Detecting Condition Possible Cause

P0502

0502Vehicle speed sen-

sor circuit low inputVehicle speed signal is excessively low com-

pared with the driving condition.

lHarness or connectors

(The CAN communication line is open or

shorted.)

lCombination meter

lABS actuator and electric unit (control unit)

lWheel sensor

lECM

CKPS·RPM (TDC) More than 2,800 rpm

COOLAN TEMP/S More than 60°C (140°F)

Clutch pedal (M/T) Released

Shift lever 1st position

MBIB1084E

Page 1166 of 3171

EC-186

DTC P0502 ASCD VEHICLE SPEED SENSOR

WITHOUT CONSULT-II

TESTING CONDITION:

Step 2 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road test

is expected to be easier, it is unnecessary to lift the vehicle.

1. Start engine and warm it up to normal operating temperature.

2. Maintain the following condition for at least 5 seconds.

3. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

4. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

5. If DTC is detected, go toEC-188, "

Diagnostic Procedure".

Diagnostic ProcedureEBS01KHO

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Refer toBRC-8, "

TROUBLE DIAGNOSIS".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK COMBINATION METER

Check combination meter function.

Refer toDI-4, "

COMBINATION METERS".

>>INSPECTION END

Engine speed More than 2,800 rpm

Clutch pedal (M/T) Released

Shift lever 1st position

Page 1219 of 3171

DTC P1268 - P1271 FUEL INJECTOR

EC-239

C

D

E

F

G

H

I

J

K

L

MA

EC

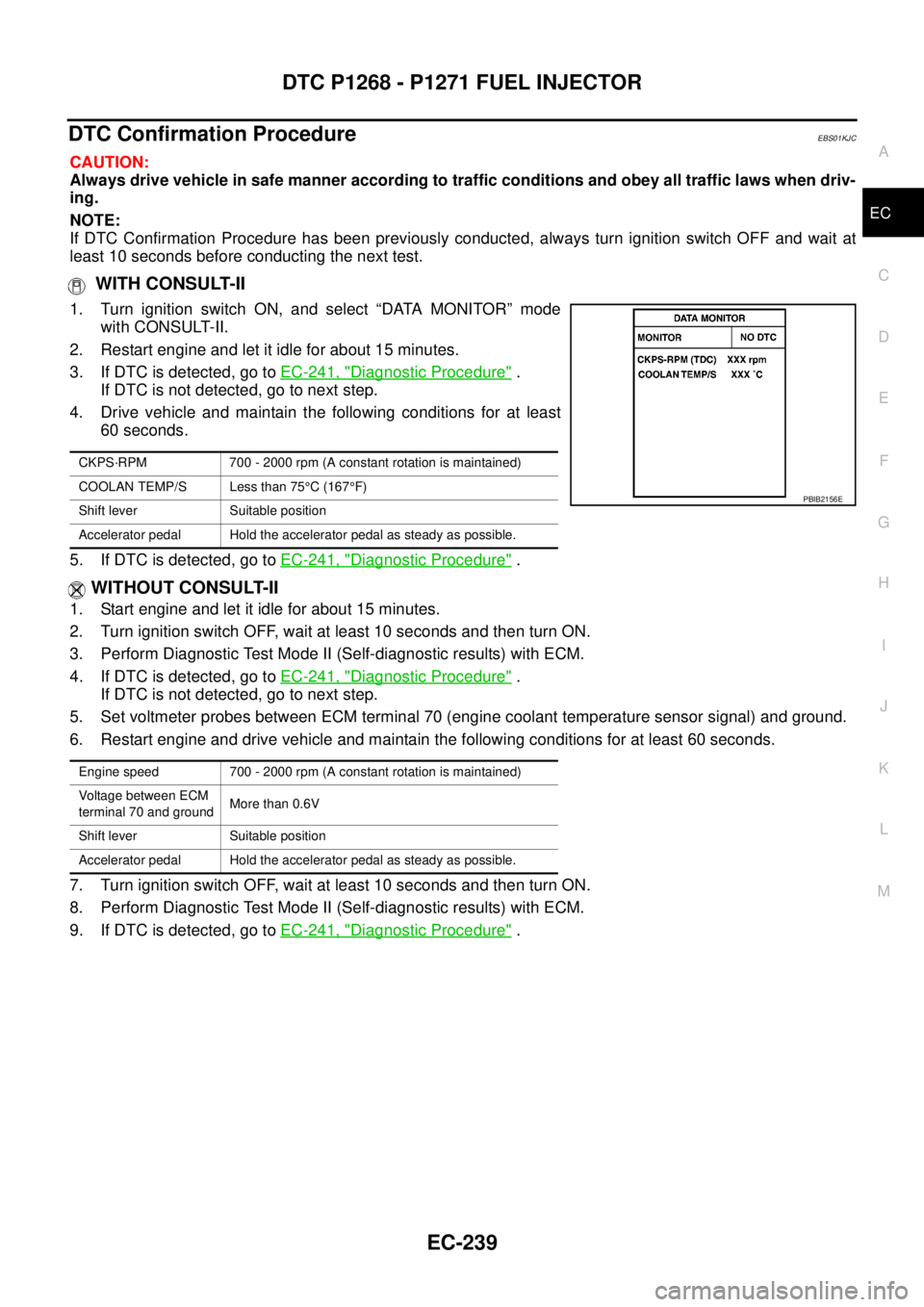

DTC Confirmation ProcedureEBS01KJC

CAUTION:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws when driv-

ing.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON, and select “DATA MONITOR” mode

with CONSULT-II.

2. Restart engine and let it idle for about 15 minutes.

3. If DTC is detected, go toEC-241, "

Diagnostic Procedure".

If DTC is not detected, go to next step.

4. Drive vehicle and maintain the following conditions for at least

60 seconds.

5. If DTC is detected, go toEC-241, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine and let it idle for about 15 minutes.

2. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

3. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

4. If DTC is detected, go toEC-241, "

Diagnostic Procedure".

If DTC is not detected, go to next step.

5. Set voltmeter probes between ECM terminal 70 (engine coolant temperature sensor signal) and ground.

6. Restart engine and drive vehicle and maintain the following conditions for at least 60 seconds.

7. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

8. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

9. If DTC is detected, go toEC-241, "

Diagnostic Procedure".

CKPS·RPM 700 - 2000 rpm (A constant rotation is maintained)

COOLAN TEMP/S Less than 75°C (167°F)

Shift lever Suitable position

Accelerator pedal Hold the accelerator pedal as steady as possible.

PBIB2156E

Engine speed 700 - 2000 rpm (A constant rotation is maintained)

Voltage between ECM

terminal 70 and groundMore than 0.6V

Shift lever Suitable position

Accelerator pedal Hold the accelerator pedal as steady as possible.

Page 1625 of 3171

PRECAUTIONS

GI-3

C

D

E

F

G

H

I

J

K

L

MB

GI

PRECAUTIONSPFP:00001

DescriptionEAS001GG

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EAS001GH

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for NATS (NISSAN ANTI-THEFT SYSTEM)EAS001GI

NATS will immobilize the engine if someone tries to start it without the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS registered.

The security indicator is located on the instrument panel. The indicator blinks when the immobilizer system is

functioning.

Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

lWhen NATS detects trouble, the security indicator lamp lights up while ignition switch is in "ON" position.

This lighting up indicates that the anti-theft is not functioning, so prompt service is required.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), CONSULT-II hardware and CONSULT-II NATS software is necessary.

Regarding the procedures of NATS initialization and NATS ignition key ID registration, refer to CONSULT-

II operation manual, NATS.

Therefore, CONSULT-II NATS software (program card and operation manual) must be kept strictly con-

fidential to maintain the integrity of the anti-theft function.

lWhen servicing NATS (trouble diagnoses, system initialization and additional registration of other NATS

ignition key IDs), it may be necessary to re-register original key identification. Therefore, be sure to

receive all keys from vehicle owner. A maximum of four or five key IDs can be registered into NATS.

lWhen failing to start the engine first time using the key of NATS, start as follows.

1. Leave the ignition key in "ON" position for approximately 5 seconds.

2. Turn ignition key to "OFF" or "LOCK" position and wait approximately 5 seconds.

3. Repeat step 1 and 2 again.

4. Restart the engine while keeping the key separate from any others on key-chain.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectEAS001HY

NOTE:

lThis Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT

SYSTEM).

lRemove and install all control units after disconnecting both battery cables with the ignition knob in the

²LOCK²position.

lAlways use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

Page 1628 of 3171

GI-6

PRECAUTIONS

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission control devices and systems, and could

also affect the warranty coverage validity.

DIESEL ENGINE

Diesel fuel of at least 50 cetane.

If two types of diesel fuel are available, use summer or winter fuel properly according to the following temper-

ature conditions.

lAbove –7°C(20°F) ... Summer type diesel fuel.

lBelow –7°C(20°F) ... Winter type diesel fuel.

CAUTION:

lDo not use home heating oil, gasoline or other alternate fuels in your diesel engine. The use of

those can cause engine damage.

lDo not use summer fuel at temperatures below –7°C(20°F). The cold temperatures will cause wax

to form in the fuel. As a result, it may prevent the engine from running smoothly.

lDo not add gasoline or other alternate fuels to diesel fuel.

Precautions for Multiport Fuel Injection System or Engine Control SystemEAS001GN

lBefore connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

lBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

lBe careful not to jar components such as ECM and mass air

flow sensor.

Precautions for Turbocharger (If Equipped)EAS001GO

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean sup-

ply of oil flowing through the turbocharger and to follow all required

maintenance instructions and operating procedures.

lAlways use the recommended oil. Follow the instructions for

proper time to change the oil and proper oil level.

lAvoid accelerating engine to a high rpm immediately after start-

ing.

lIf engine had been operating at high rpm for an extended period

of time, let it idle for a few minutes prior to shutting if off.

Precautions for HosesEAS001GP

HOSE REMOVAL AND INSTALLATION

lTo prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

SGI787

SGI292

SMA019D

Page 2411 of 3171

MTC-24

LUBRICANT

LUBRICANT

PFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS005FV

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS)

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

test condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F).]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

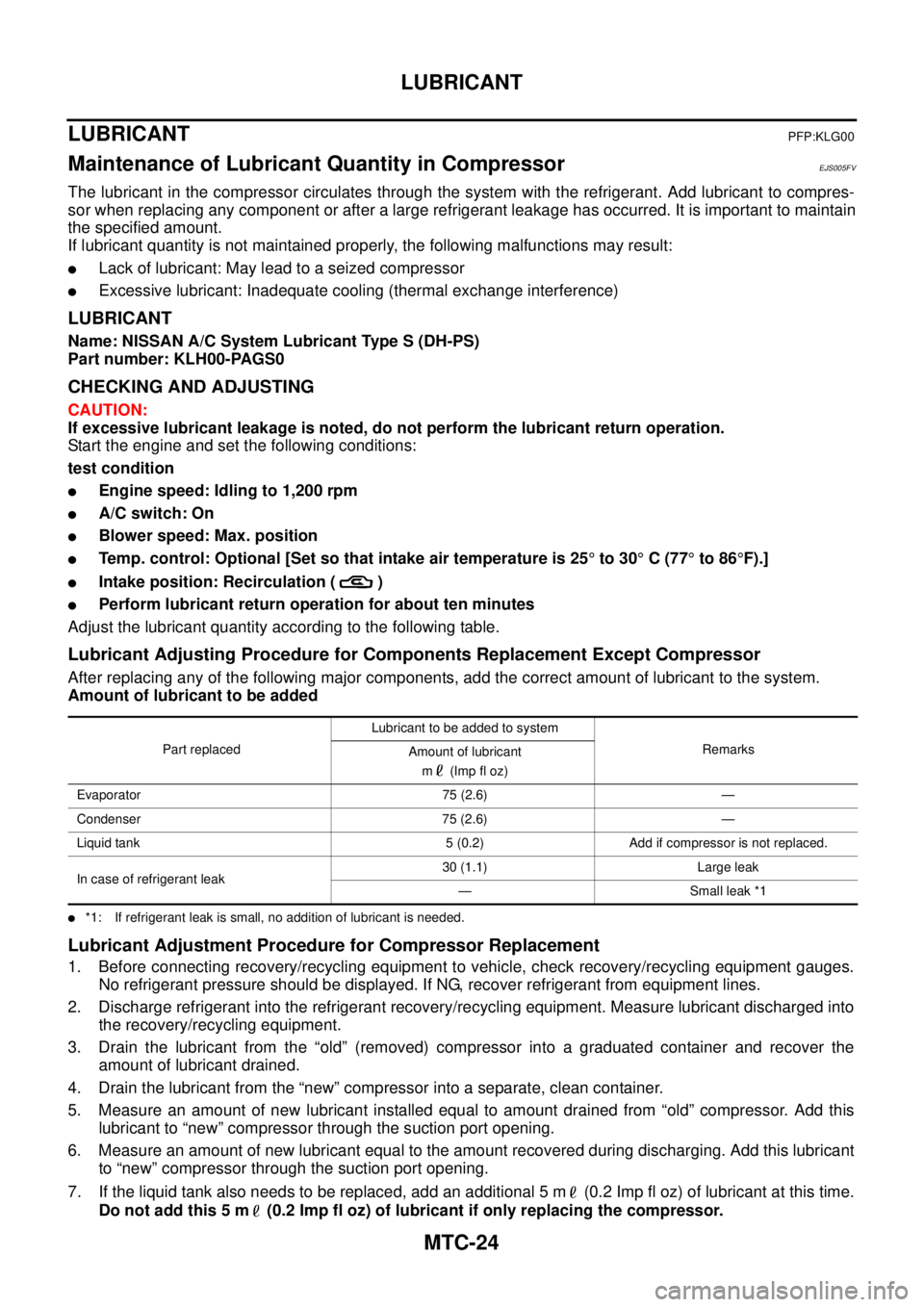

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

3. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

4. Drain the lubricant from the “new” compressor into a separate, clean container.

5. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

6. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

7. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 2916 of 3171

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-7

C

D

E

F

G

I

J

K

L

MA

B

SRS

Front Seat Belt Pre-Tensioner with Load LimiterEHS001XB

The seat belt pre-tensioner system with load limiter is installed for

both the driver's seat and the front passenger's seat. It operates

simultaneously with the SRS air bag system in the event of a frontal

collision with an impact exceeding a specified level.

When the frontal collision with an impact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioner. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the

load limiter permits the specified extension of the seat belt by the

twisting of the ELR shaft, and a relaxation of the chest-area seat belt

web tension while maintaining force.

Front Side Air BagEHS001XC

Front side air bag modules are built into the front seatback assemblies.

Vehicles with side air bags are equipped with labels as shown.

Side Curtain Air BagEHS001XD

Side curtain air bag modules are located above the vehicle headlining.

Vehicles with side curtain air bags are equipped with labels as

shown.

WHIA0225E

WHIA0008E

WHIA0041E