steering NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1383 of 3171

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONEM

A

EM

ENGINE MECHANICAL

PRECAUTIONS .......................................................... 4

Precautions for Draining Engine Coolant ................. 4

Precautions for Disconnecting Fuel Piping .............. 4

Precautions for Removal and Disassembly ............. 4

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 4

Precautions for Assembly and Installation ............... 4

Parts Requiring Angle Tightening ............................. 4

Precautions For Liquid Gasket ................................. 5

REMOVAL OF LIQUID GASKET .......................... 5

LIQUID GASKET APPLICATION PROCEDURE..... 5

PREPARATION ........................................................... 6

Special Service Tools ............................................... 6

Commercial Service Tools ........................................ 8

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 10

NVH Troubleshooting — Engine Noise .................. 10

Use the Chart Below to Help You Find the Cause

of the Symptom. ...................................................... 11

DRIVE BELTS ........................................................... 12

Checking Drive Belts .............................................. 12

Deflection Adjustment ............................................ 13

POWER STEERING OIL PUMP BELT ............... 13

A/C COMPRESSOR, ALTERNATOR AND

WATER PUMP BELT .......................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

AIR CLEANER AND AIR DUCT ............................... 15

Components ........................................................... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

CHANGING AIR CLEANER FILTER ................... 17

CHARGE AIR COOLER ........................................... 18

Components ........................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19INTAKE MANIFOLD ................................................. 20

Components ........................................................... 20

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 25

CATALYST ................................................................ 26

Components ........................................................... 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 27

TURBO CHARGER ................................................... 28

Components ........................................................... 28

Removal and Installation ........................................ 29

REMOVAL ........................................................... 29

INSPECTION AFTER REMOVAL ....................... 30

TROUBLE DIAGNOSIS OF TURBOCHARGER... 32

INSTALLATION ................................................... 33

EXHAUST MANIFOLD ............................................. 34

Components ........................................................... 34

Removal and Installation ........................................ 34

REMOVAL ........................................................... 34

INSPECTION AFTER REMOVAL ....................... 35

INSTALLATION ................................................... 35

INSPECTION AFTER INSTALLATION ................ 35

OIL PAN AND OIL STRAINER ................................. 36

Components ........................................................... 36

Removal and Installation ........................................ 36

REMOVAL ........................................................... 36

INSPECTION AFTER REMOVAL ....................... 38

INSTALLATION ................................................... 38

INSPECTION AFTER INSTALLATION ................ 40

GLOW PLUG ............................................................ 41

Components ........................................................... 41

Removal and Installation ........................................ 41

REMOVAL ........................................................... 41

INSTALLATION ................................................... 41

VACUUM PUMP ........................................................ 42

Page 1394 of 3171

EM-12

DRIVE BELTS

DRIVE BELTS

PFP:02117

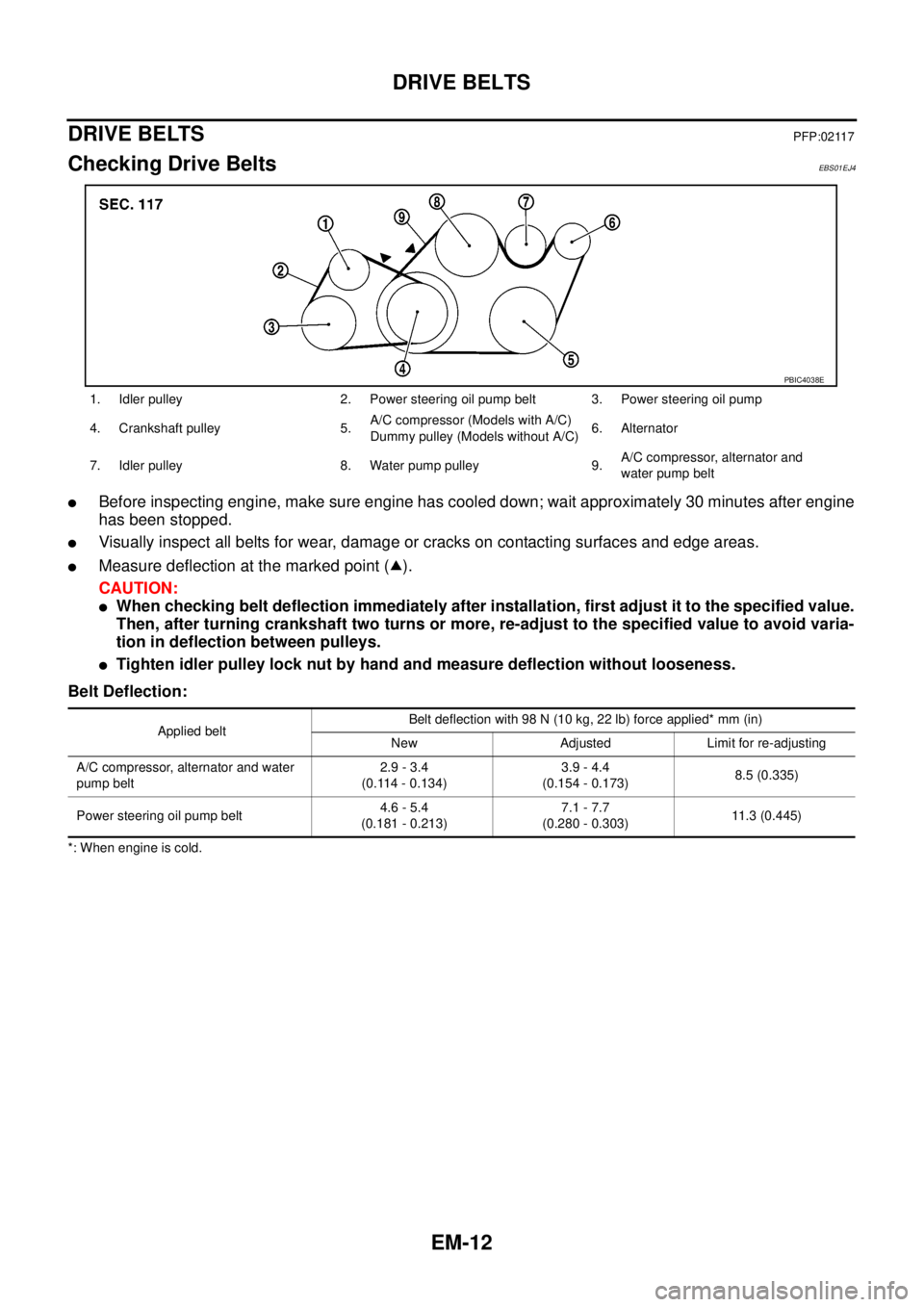

Checking Drive BeltsEBS01EJ4

lBefore inspecting engine, make sure engine has cooled down; wait approximately 30 minutes after engine

has been stopped.

lVisually inspect all belts for wear, damage or cracks on contacting surfaces and edge areas.

lMeasure deflection at the marked point ( ).

CAUTION:

lWhen checking belt deflection immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust to the specified value to avoid varia-

tion in deflection between pulleys.

lTighten idler pulley lock nut by hand and measure deflection without looseness.

Belt Deflection:

*: When engine is cold.1. Idler pulley 2. Power steering oil pump belt 3. Power steering oil pump

4. Crankshaft pulley 5.A/C compressor (Models with A/C)

Dummypulley(ModelswithoutA/C)6. Alternator

7. Idler pulley 8. Water pump pulley 9.A/C compressor, alternator and

water pump belt

PBIC4038E

Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

New Adjusted Limit for re-adjusting

A/C compressor, alternator and water

pump belt2.9 - 3.4

(0.114 - 0.134)3.9 - 4.4

(0.154 - 0.173)8.5 (0.335)

Power steering oil pump belt4.6 - 5.4

(0.181 - 0.213)7.1 - 7.7

(0.280 - 0.303)11.3 (0.445)

Page 1395 of 3171

DRIVE BELTS

EM-13

C

D

E

F

G

H

I

J

K

L

MA

EM

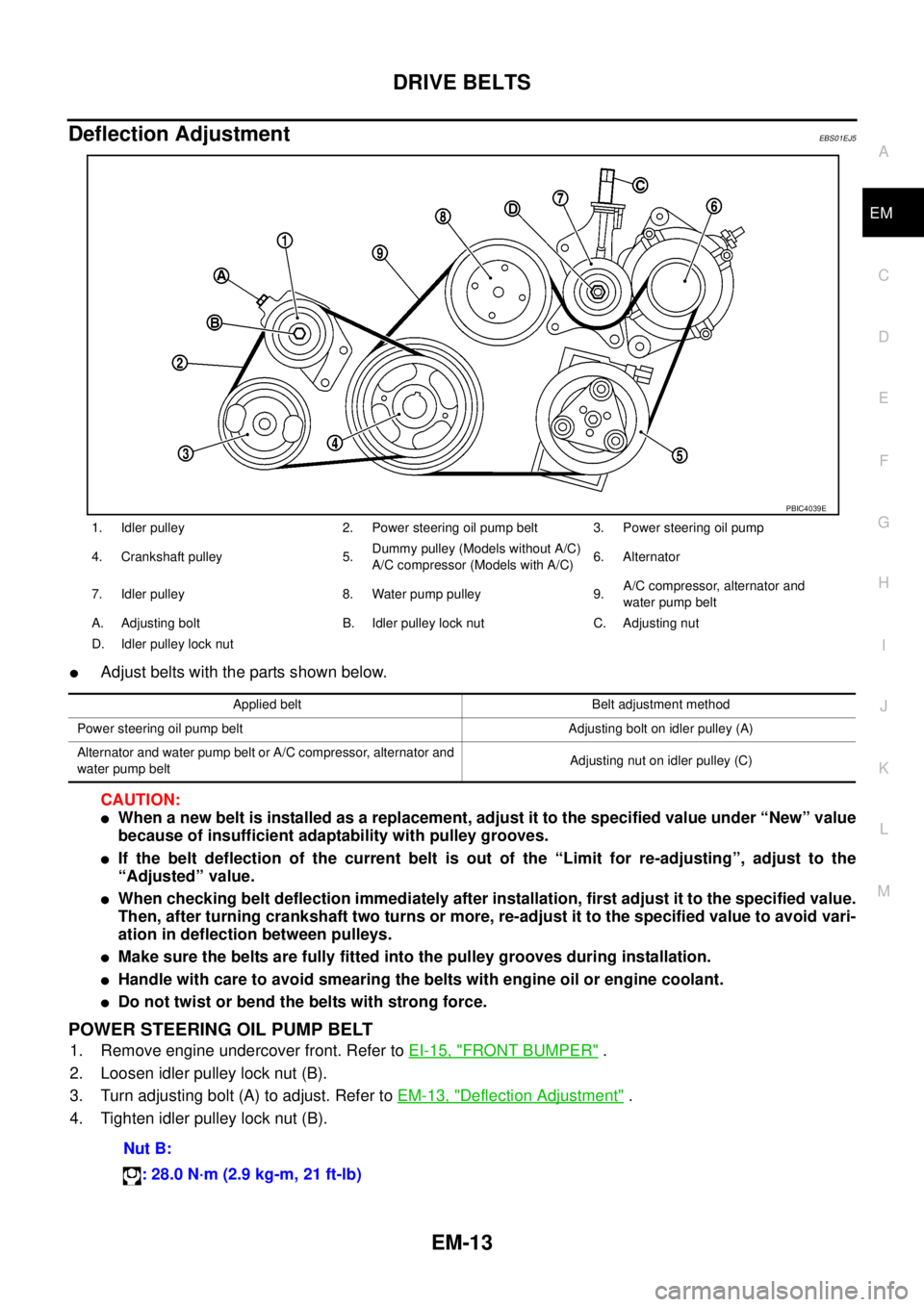

Deflection AdjustmentEBS01EJ5

lAdjust belts with the parts shown below.

CAUTION:

lWhen a new belt is installed as a replacement, adjust it to the specified value under “New” value

because of insufficient adaptability with pulley grooves.

lIf the belt deflection of the current belt is out of the “Limit for re-adjusting”, adjust to the

“Adjusted” value.

lWhen checking belt deflection immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust it to the specified value to avoid vari-

ation in deflection between pulleys.

lMake sure the belts are fully fitted into the pulley grooves during installation.

lHandle with care to avoid smearing the belts with engine oil or engine coolant.

lDo not twist or bend the belts with strong force.

POWER STEERING OIL PUMP BELT

1. Remove engine undercover front. Refer toEI-15, "FRONT BUMPER".

2. Loosen idler pulley lock nut (B).

3. Turn adjusting bolt (A) to adjust. Refer toEM-13, "

Deflection Adjustment".

4. Tighten idler pulley lock nut (B).

1. Idler pulley 2. Power steering oil pump belt 3. Power steering oil pump

4. Crankshaft pulley 5.Dummy pulley (Models without A/C)

A/C compressor (Models with A/C)6. Alternator

7. Idler pulley 8. Water pump pulley 9.A/C compressor, alternator and

water pump belt

A. Adjusting bolt B. Idler pulley lock nut C. Adjusting nut

D. Idler pulley lock nut

PBIC4039E

Applied belt Belt adjustment method

Power steering oil pump belt Adjusting bolt on idler pulley (A)

Alternator and water pump belt or A/C compressor, alternator and

water pump beltAdjusting nut on idler pulley (C)

Nut B:

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

Page 1396 of 3171

EM-14

DRIVE BELTS

A/C COMPRESSOR, ALTERNATOR AND WATER PUMP BELT

1. Loosen idler pulley lock nut (D).

2. Turn adjusting nut (C) to adjust. Refer toEM-13, "

Deflection Adjustment".

3. Tighten lock nut (D).

Removal and InstallationEBS01EJ6

REMOVAL

1. Loosen each belt. Refer toEM-13, "Deflection Adjustment".

2. Remove power steering oil pump belt. Refer toEM-13, "

POWER STEERING OIL PUMP BELT".

3. Remove A/C compressor, alternator and water pump belt. Refer toEM-14, "

A/C COMPRESSOR, ALTER-

NATOR AND WATER PUMP BELT".

INSTALLATION

1. Install each belt on pulley in the reverse order of removal.

2. Adjust belt deflection. Refer toEM-13, "

Deflection Adjustment".

3. Tighten nuts provided for adjustment to the specified torque.

4. Make sure again that each belt deflection is as specified.Nut D:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)

Page 1419 of 3171

OIL PAN AND OIL STRAINER

EM-37

C

D

E

F

G

H

I

J

K

L

MA

EM

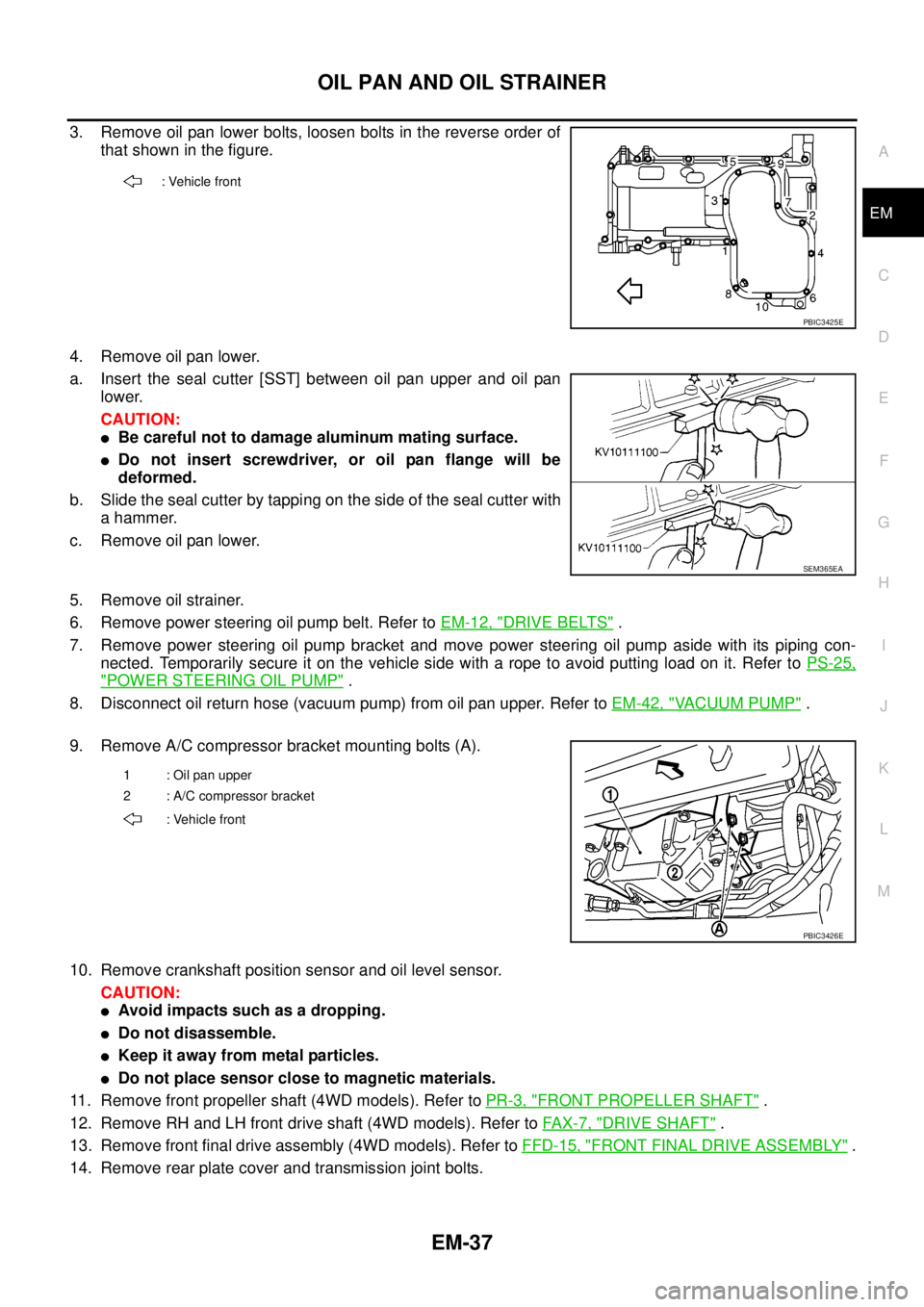

3. Remove oil pan lower bolts, loosen bolts in the reverse order of

that shown in the figure.

4. Remove oil pan lower.

a. Insert the seal cutter [SST] between oil pan upper and oil pan

lower.

CAUTION:

lBe careful not to damage aluminum mating surface.

lDo not insert screwdriver, or oil pan flange will be

deformed.

b. Slide the seal cutter by tapping on the side of the seal cutter with

a hammer.

c. Remove oil pan lower.

5. Remove oil strainer.

6. Remove power steering oil pump belt. Refer toEM-12, "

DRIVE BELTS".

7. Remove power steering oil pump bracket and move power steering oil pump aside with its piping con-

nected. Temporarily secure it on the vehicle side with a rope to avoid putting load on it. Refer toPS-25,

"POWER STEERING OIL PUMP".

8. Disconnect oil return hose (vacuum pump) from oil pan upper. Refer toEM-42, "

VACUUM PUMP".

9. Remove A/C compressor bracket mounting bolts (A).

10. Remove crankshaft position sensor and oil level sensor.

CAUTION:

lAvoid impacts such as a dropping.

lDo not disassemble.

lKeep it away from metal particles.

lDo not place sensor close to magnetic materials.

11. Remove front propeller shaft (4WD models). Refer toPR-3, "

FRONT PROPELLER SHAFT".

12. Remove RH and LH front drive shaft (4WD models). Refer toFAX-7, "

DRIVE SHAFT".

13. Remove front final drive assembly (4WD models). Refer toFFD-15, "

FRONT FINAL DRIVE ASSEMBLY".

14. Remove rear plate cover and transmission joint bolts.

: Vehicle front

PBIC3425E

SEM365EA

1 : Oil pan upper

2 : A/C compressor bracket

: Vehicle front

PBIC3426E

Page 1447 of 3171

CAMSHAFT

EM-65

C

D

E

F

G

H

I

J

K

L

MA

EM

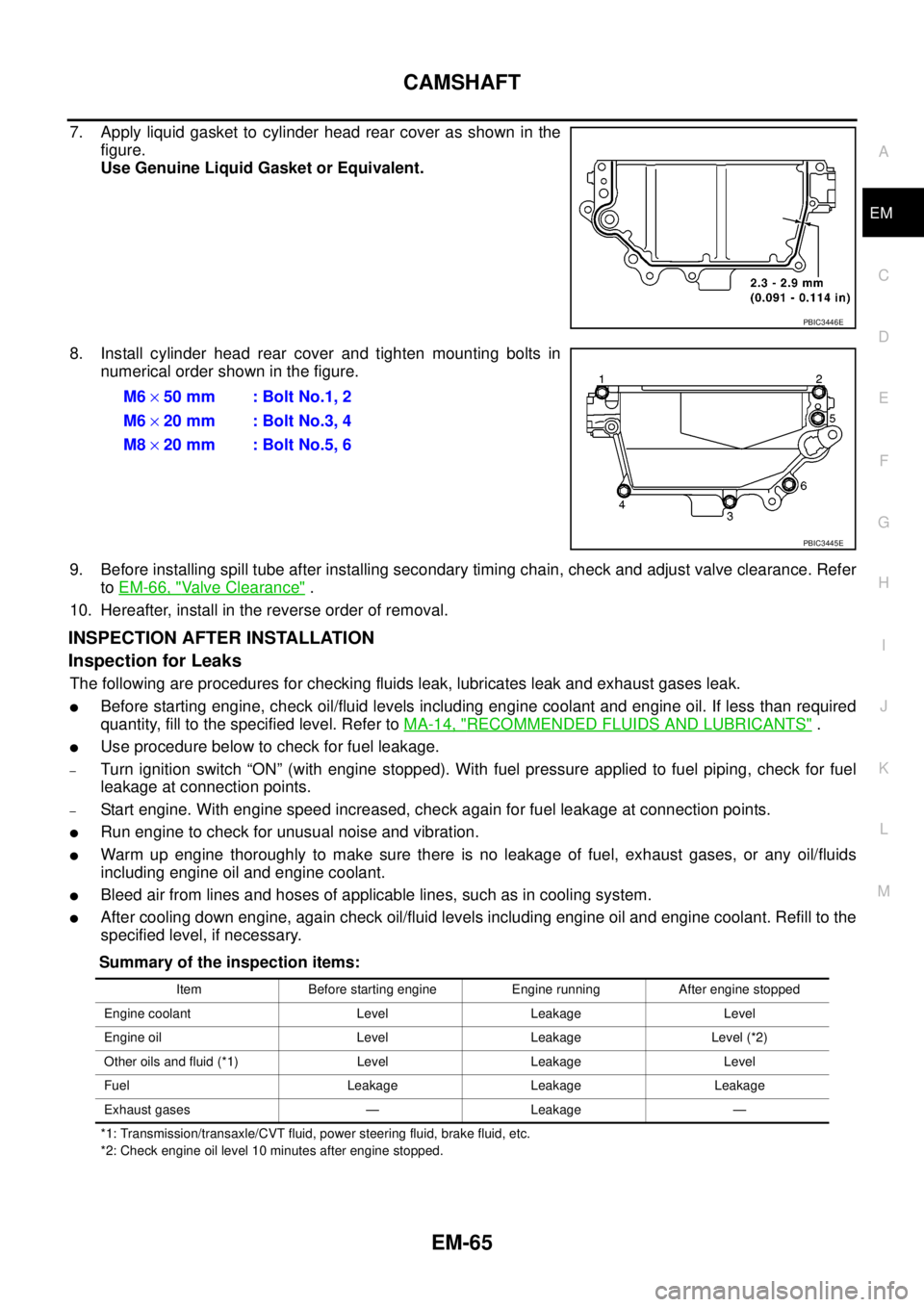

7. Apply liquid gasket to cylinder head rear cover as shown in the

figure.

Use Genuine Liquid Gasket or Equivalent.

8. Install cylinder head rear cover and tighten mounting bolts in

numerical order shown in the figure.

9. Before installing spill tube after installing secondary timing chain, check and adjust valve clearance. Refer

toEM-66, "

Valve Clearance".

10. Hereafter, install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.

PBIC3446E

M6´50 mm : Bolt No.1, 2

M6´20 mm : Bolt No.3, 4

M8´20 mm : Bolt No.5, 6

PBIC3445E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1460 of 3171

EM-78

SECONDARY TIMING CHAIN

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1462 of 3171

EM-80

PRIMARY TIMING CHAIN

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E69

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals or other sliding parts, lubricate contacting

surfaces with new engine oil.

REMOVAL

1. Remove power steering oil pump and power steering oil pump bracket. Refer toPS-25, "POWER STEER-

ING OIL PUMP".

2. Remove idler pulleys.

3. Remove rocker cover. Refer toEM-56, "

ROCKER COVER".

4. Remove oil pan (upper and lower). Refer toEM-36, "

OIL PAN AND OIL STRAINER".

5. Remove fuel injector. Refer toEM-44, "

INJECTION TUBE AND FUEL INJECTOR".

6. Remove secondary timing chain and associated parts. Refer toEM-73, "

SECONDARY TIMING CHAIN".

7. When removing rear chain case, remove camshaft sprockets. Refer toEM-59, "

CAMSHAFT".

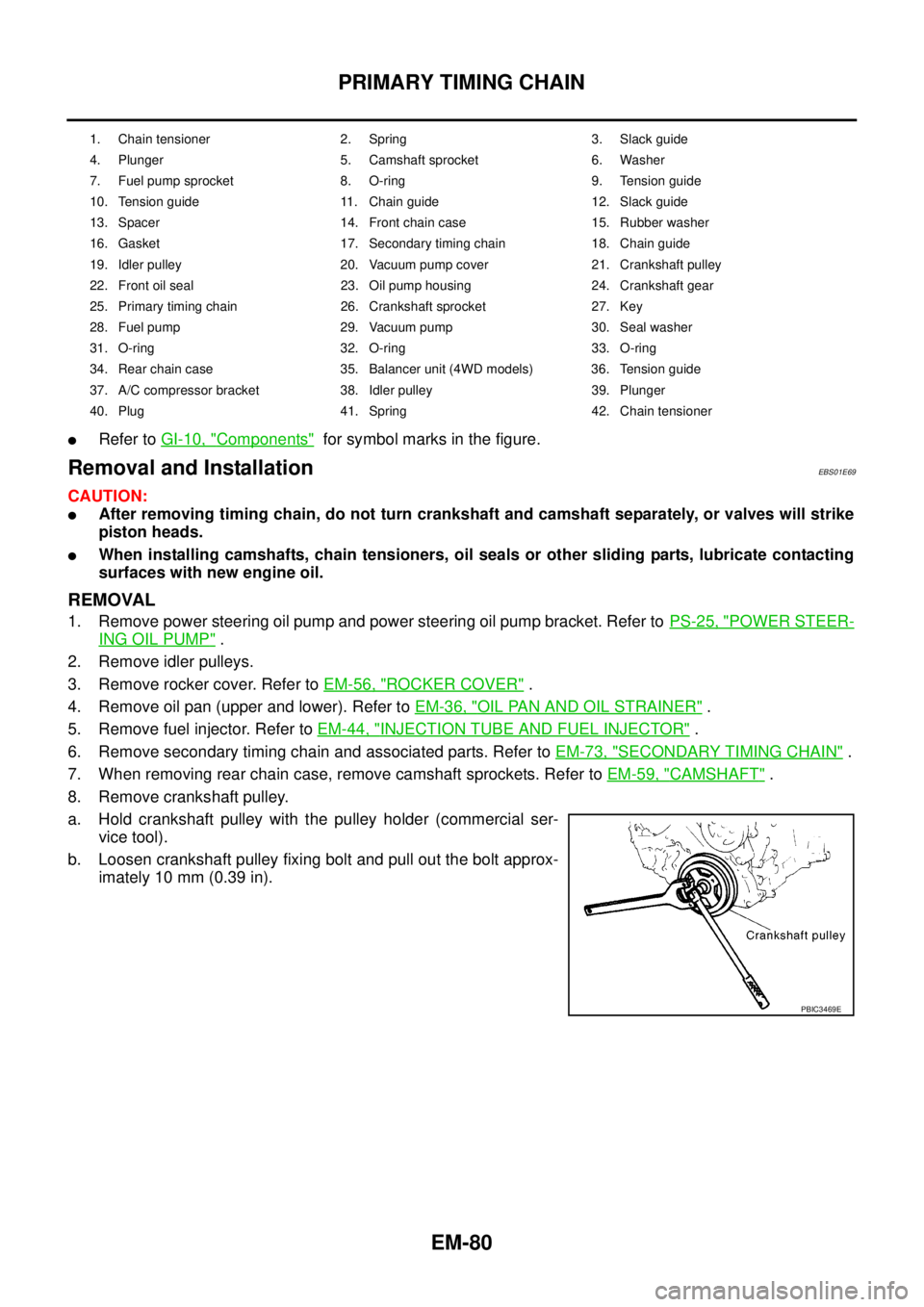

8. Remove crankshaft pulley.

a. Hold crankshaft pulley with the pulley holder (commercial ser-

vice tool).

b. Loosen crankshaft pulley fixing bolt and pull out the bolt approx-

imately 10 mm (0.39 in).

1. Chain tensioner 2. Spring 3. Slack guide

4. Plunger 5. Camshaft sprocket 6. Washer

7. Fuel pump sprocket 8. O-ring 9. Tension guide

10. Tension guide 11. Chain guide 12. Slack guide

13. Spacer 14. Front chain case 15. Rubber washer

16. Gasket 17. Secondary timing chain 18. Chain guide

19. Idler pulley 20. Vacuum pump cover 21. Crankshaft pulley

22. Front oil seal 23. Oil pump housing 24. Crankshaft gear

25. Primary timing chain 26. Crankshaft sprocket 27. Key

28. Fuel pump 29. Vacuum pump 30. Seal washer

31. O-ring 32. O-ring 33. O-ring

34. Rear chain case 35. Balancer unit (4WD models) 36. Tension guide

37. A/C compressor bracket 38. Idler pulley 39. Plunger

40. Plug 41. Spring 42. Chain tensioner

PBIC3469E

Page 1469 of 3171

PRIMARY TIMING CHAIN

EM-87

C

D

E

F

G

H

I

J

K

L

MA

EM

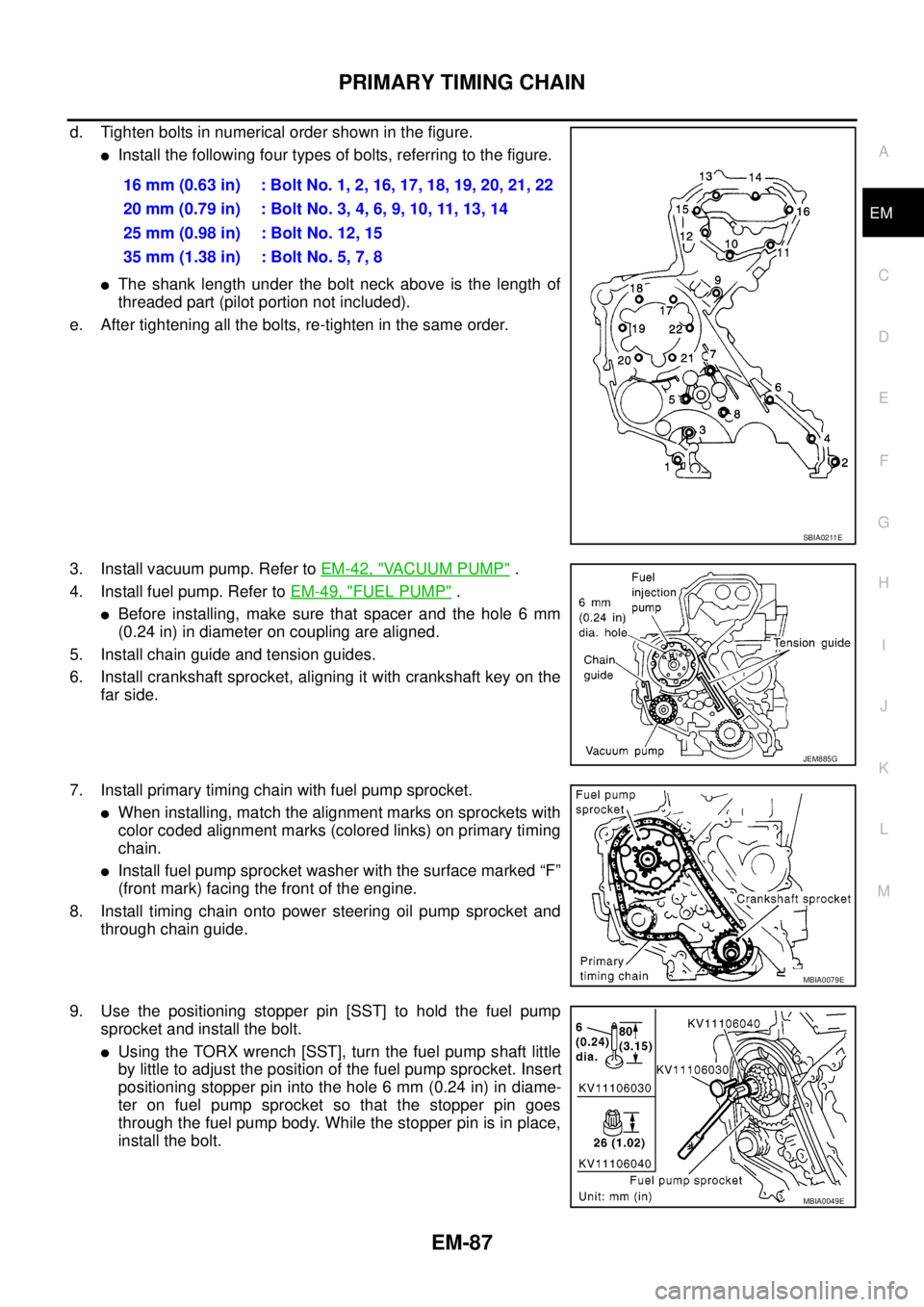

d. Tighten bolts in numerical order shown in the figure.

lInstall the following four types of bolts, referring to the figure.

lThe shank length under the bolt neck above is the length of

threaded part (pilot portion not included).

e. After tightening all the bolts, re-tighten in the same order.

3. Install vacuum pump. Refer toEM-42, "

VACUUM PUMP".

4. Install fuel pump. Refer toEM-49, "

FUEL PUMP".

lBefore installing, make sure that spacer and the hole 6 mm

(0.24 in) in diameter on coupling are aligned.

5. Install chain guide and tension guides.

6. Install crankshaft sprocket, aligning it with crankshaft key on the

far side.

7. Install primary timing chain with fuel pump sprocket.

lWhen installing, match the alignment marks on sprockets with

color coded alignment marks (colored links) on primary timing

chain.

lInstall fuel pump sprocket washer with the surface marked “F”

(front mark) facing the front of the engine.

8. Install timing chain onto power steering oil pump sprocket and

through chain guide.

9. Use the positioning stopper pin [SST] to hold the fuel pump

sprocket and install the bolt.

lUsing the TORX wrench [SST], turn the fuel pump shaft little

by little to adjust the position of the fuel pump sprocket. Insert

positioning stopper pin into the hole 6 mm (0.24 in) in diame-

ter on fuel pump sprocket so that the stopper pin goes

through the fuel pump body. While the stopper pin is in place,

install the bolt.16 mm (0.63 in) : Bolt No. 1, 2, 16, 17, 18, 19, 20, 21, 22

20mm(0.79in) :BoltNo.3,4,6,9,10,11,13,14

25 mm (0.98 in) : Bolt No. 12, 15

35 mm (1.38 in) : Bolt No. 5, 7, 8

SBIA0211E

JEM885G

MBIA0079E

MBIA0049E