steering NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1552 of 3171

FFD-6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

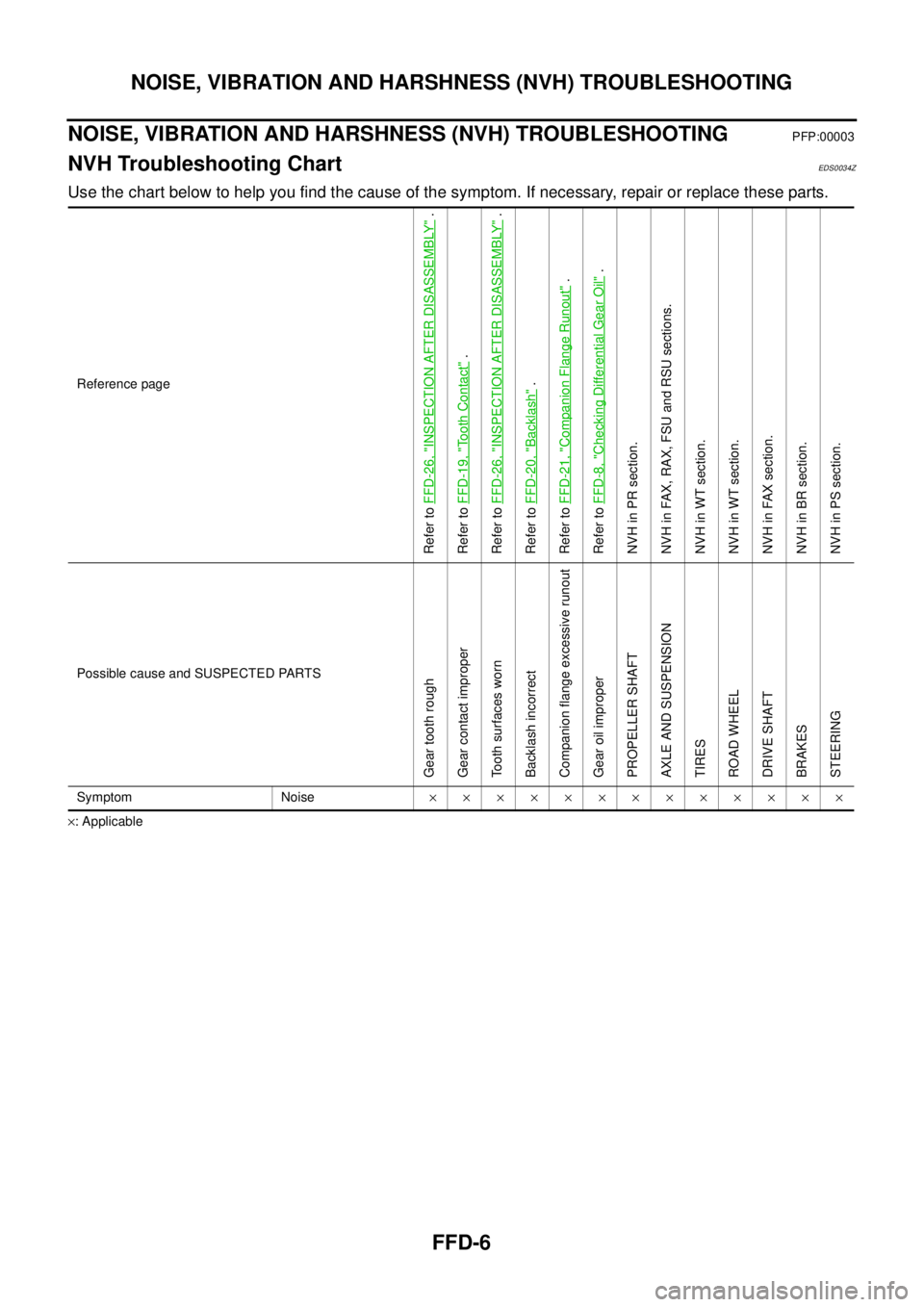

NVH Troubleshooting ChartEDS0034Z

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

Refer toFFD-26, "

INSPECTION AFTER DISASSEMBLY

".

Refer toFFD-19, "

To o t h C o n t a c t

".

Refer toFFD-26, "

INSPECTION AFTER DISASSEMBLY

".

Refer toFFD-20, "

Backlash

".

Refer toFFD-21, "

Companion Flange Runout

".

Refer toFFD-8, "

Checking Differential Gear Oil

".

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise´´´´´´´´´´´´´

Page 1556 of 3171

FFD-10

FRONT OIL SEAL

CAUTION:

Do not pull on the ABS sensor harness.

6. Support the lower link using a suitable jack.

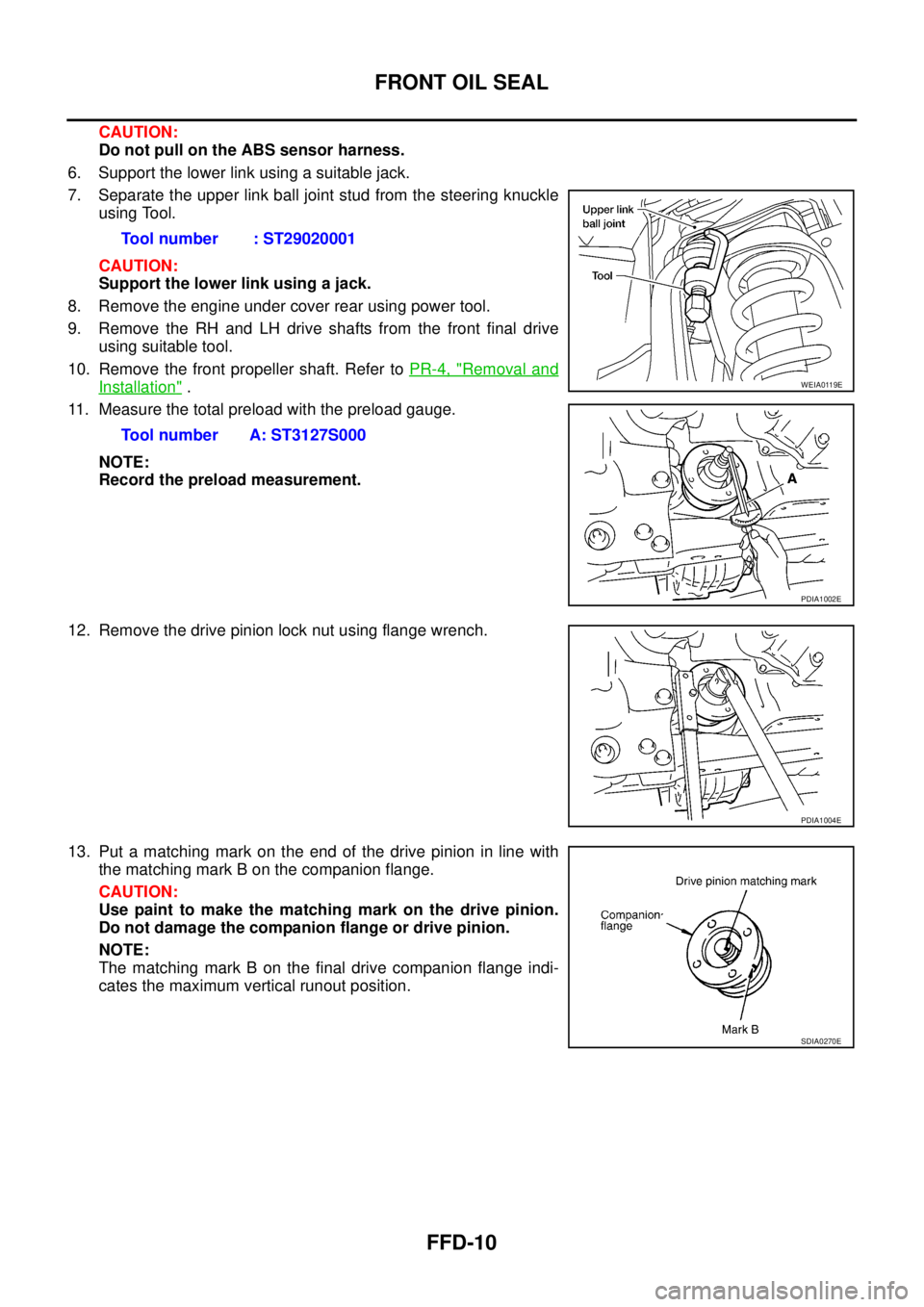

7. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using a jack.

8. Remove the engine under cover rear using power tool.

9. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

10. Remove the front propeller shaft. Refer toPR-4, "

Removal and

Installation".

11. Measure the total preload with the preload gauge.

NOTE:

Record the preload measurement.

12. Remove the drive pinion lock nut using flange wrench.

13. Put a matching mark on the end of the drive pinion in line with

the matching mark B on the companion flange.

CAUTION:

Use paint to make the matching mark on the drive pinion.

Do not damage the companion flange or drive pinion.

NOTE:

The matching mark B on the final drive companion flange indi-

cates the maximum vertical runout position.Tool number : ST29020001

Tool number A: ST3127S000WEIA0119E

PDIA1002E

PDIA1004E

SDIA0270E

Page 1559 of 3171

SIDE OIL SEAL

FFD-13

C

E

F

G

H

I

J

K

L

MA

B

FFD

SIDE OIL SEALPFP:33142

Removal and InstallationEDS00354

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

CAUTION:

Do not pull on the ABS sensor harness.

4. Support the lower link using a suitable jack.

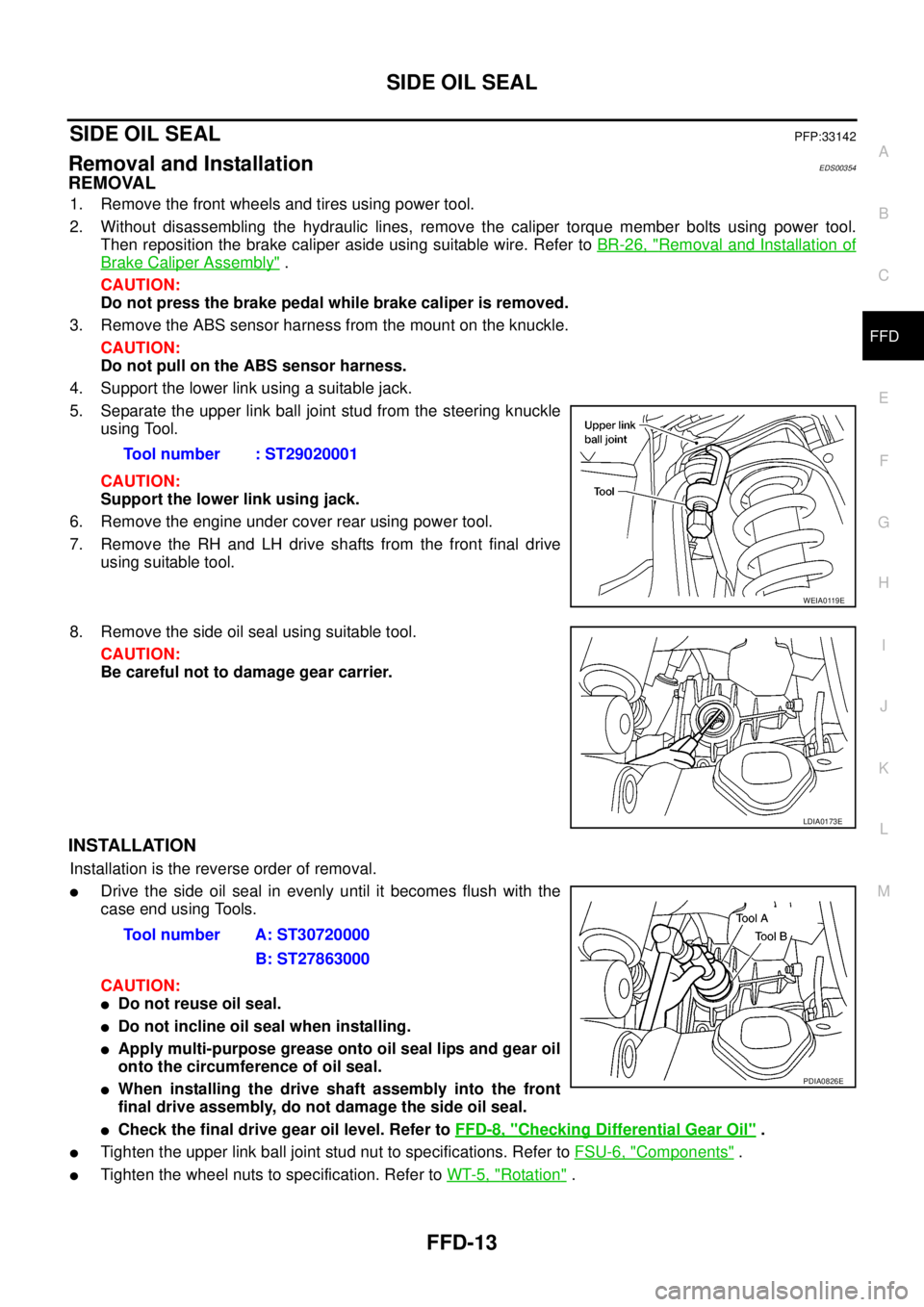

5. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using jack.

6. Remove the engine under cover rear using power tool.

7. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

8. Remove the side oil seal using suitable tool.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Installation is the reverse order of removal.

lDrive the side oil seal in evenly until it becomes flush with the

case end using Tools.

CAUTION:

lDo not reuse oil seal.

lDo not incline oil seal when installing.

lApply multi-purpose grease onto oil seal lips and gear oil

onto the circumference of oil seal.

lWhen installing the drive shaft assembly into the front

final drive assembly, do not damage the side oil seal.

lCheck the final drive gear oil level. Refer toFFD-8, "Checking Differential Gear Oil".

lTighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "Components".

lTighten the wheel nuts to specification. Refer toWT-5, "Rotation". Tool number : ST29020001

WEIA0119E

LDIA0173E

Tool number A: ST30720000

B: ST27863000

PDIA0826E

Page 1562 of 3171

FFD-16

FRONT FINAL DRIVE ASSEMBLY

CAUTION:

Do not pull on the ABS sensor harness.

4. Support the lower link using a suitable jack.

5. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using a jack.

6. Remove the engine under cover rear using power tool.

7. Drain the front final drive fluid. Refer toFFD-8, "

Changing Differ-

ential Gear Oil".

8. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

9. Remove the front crossmember.

10. Disconnect the front propeller shaft from the front final drive. Then reposition the front propeller shaft

aside using suitable wire. Refer toPR-4, "

Removal and Installation".

11. Disconnect the vent hose from the front final drive.

12. Support the front final drive using a suitable jack.

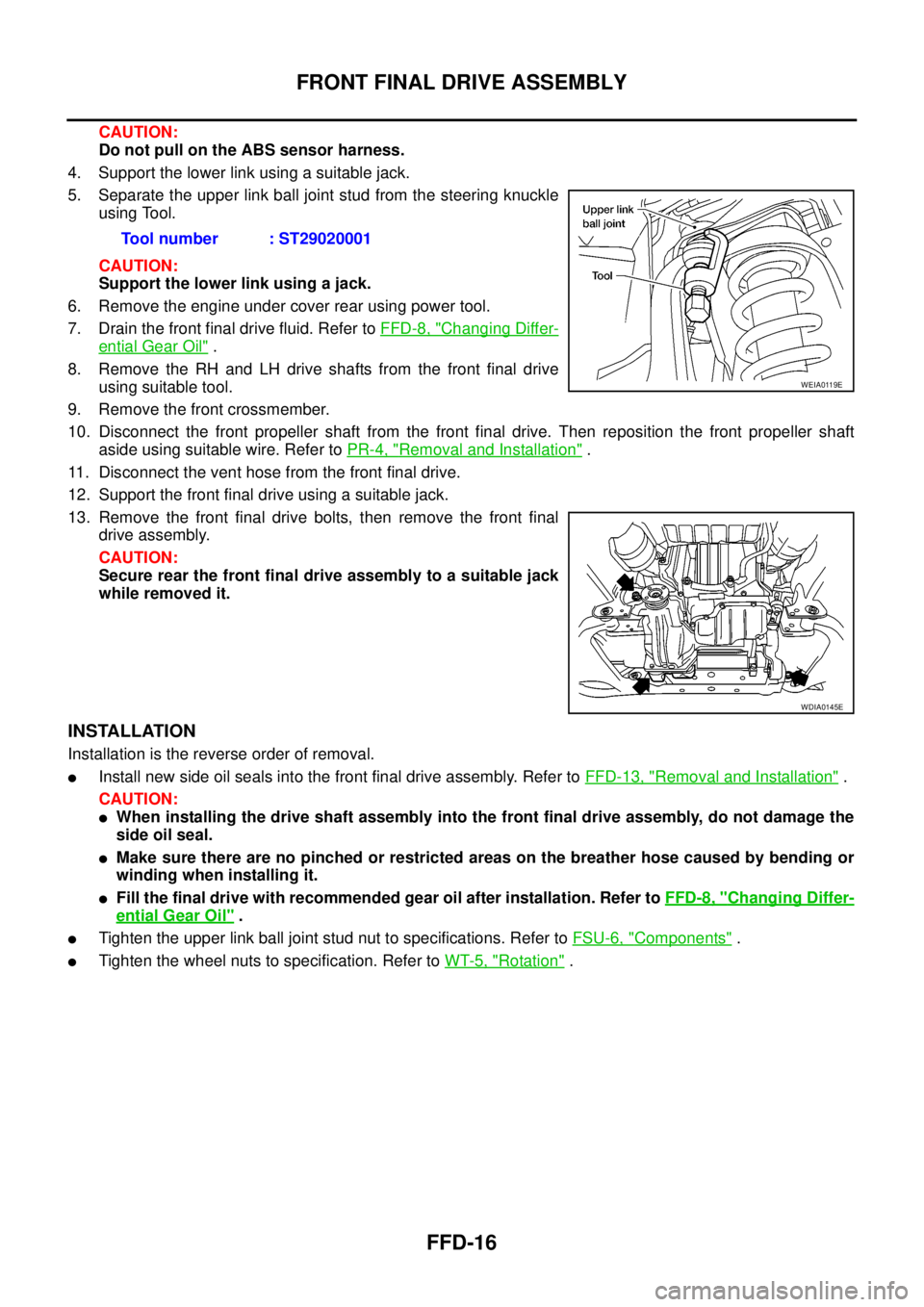

13. Remove the front final drive bolts, then remove the front final

drive assembly.

CAUTION:

Secure rear the front final drive assembly to a suitable jack

while removed it.

INSTALLATION

Installation is the reverse order of removal.

lInstall new side oil seals into the front final drive assembly. Refer toFFD-13, "Removal and Installation".

CAUTION:

lWhen installing the drive shaft assembly into the front final drive assembly, do not damage the

side oil seal.

lMake sure there are no pinched or restricted areas on the breather hose caused by bending or

winding when installing it.

lFill the final drive with recommended gear oil after installation. Refer toFFD-8, "Changing Differ-

ential Gear Oil".

lTighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "Components".

lTighten the wheel nuts to specification. Refer toWT-5, "Rotation". Tool number : ST29020001

WEIA0119E

WDIA0145E

Page 1605 of 3171

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

FSU-5

C

D

F

G

H

I

J

K

L

MA

B

FSU

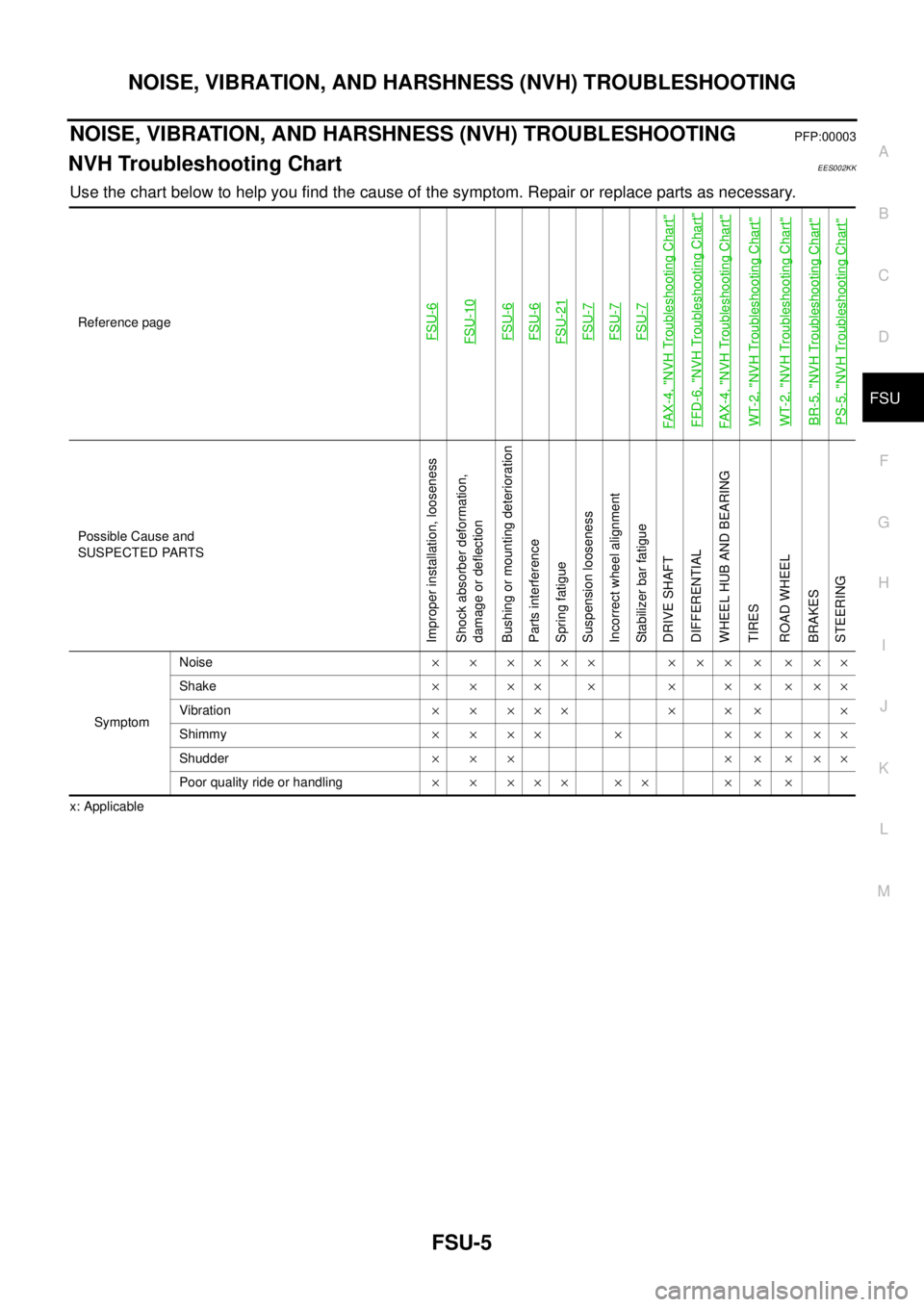

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEES002KK

Use the chart below to help you find the cause of the symptom. Repair or replace parts as necessary.

x: ApplicableReference page

FSU-6FSU-10FSU-6FSU-6FSU-21FSU-7FSU-7FSU-7

FAX-4, "

NVH Troubleshooting Chart

"

FFD-6, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible Cause and

SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

DRIVE SHAFT

DIFFERENTIAL

WHEEL HUB AND BEARING

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomNoise´ ´ ´´´´ ´ ´ ´ ´ ´ ´´

Shake´´´´ ´ ´ ´´´´´

Vibration´ ´ ´´´ ´ ´ ´ ´

Shimmy´´´´ ´ ´´´´´

Shudder´´´ ´´´´´

Poor quality ride or handling´ ´ ´´´ ´´ ´ ´ ´

Page 1606 of 3171

FSU-6

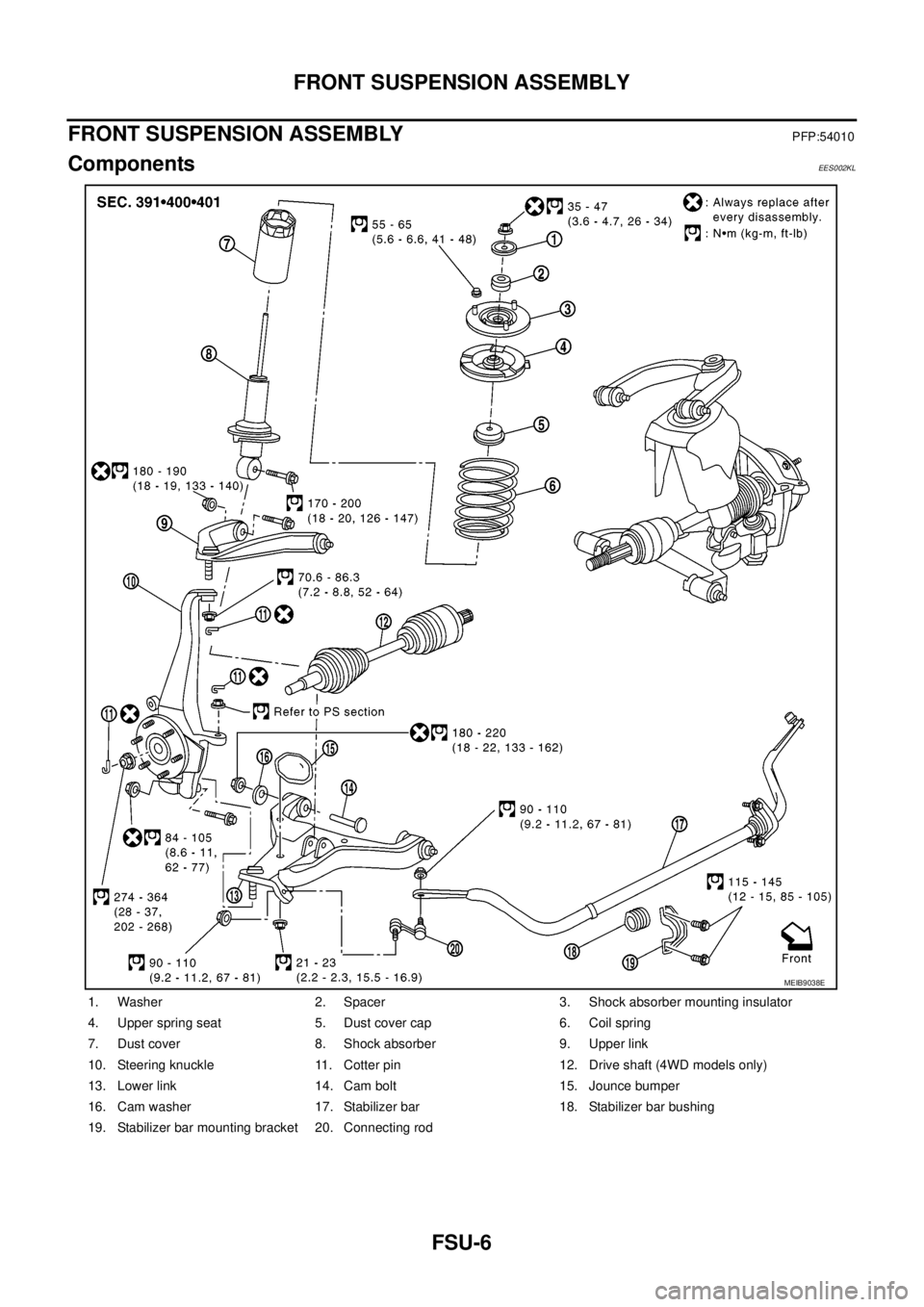

FRONT SUSPENSION ASSEMBLY

FRONT SUSPENSION ASSEMBLY

PFP:54010

ComponentsEES002KL

1. Washer 2. Spacer 3. Shock absorber mounting insulator

4. Upper spring seat 5. Dust cover cap 6. Coil spring

7. Dust cover 8. Shock absorber 9. Upper link

10. Steering knuckle 11. Cotter pin 12. Drive shaft (4WD models only)

13. Lower link 14. Cam bolt 15. Jounce bumper

16. Cam washer 17. Stabilizer bar 18. Stabilizer bar bushing

19. Stabilizer bar mounting bracket 20. Connecting rod

MEIB9038E

Page 1609 of 3171

ON-VEHICLE SERVICE

FSU-9

C

D

F

G

H

I

J

K

L

MA

B

FSU

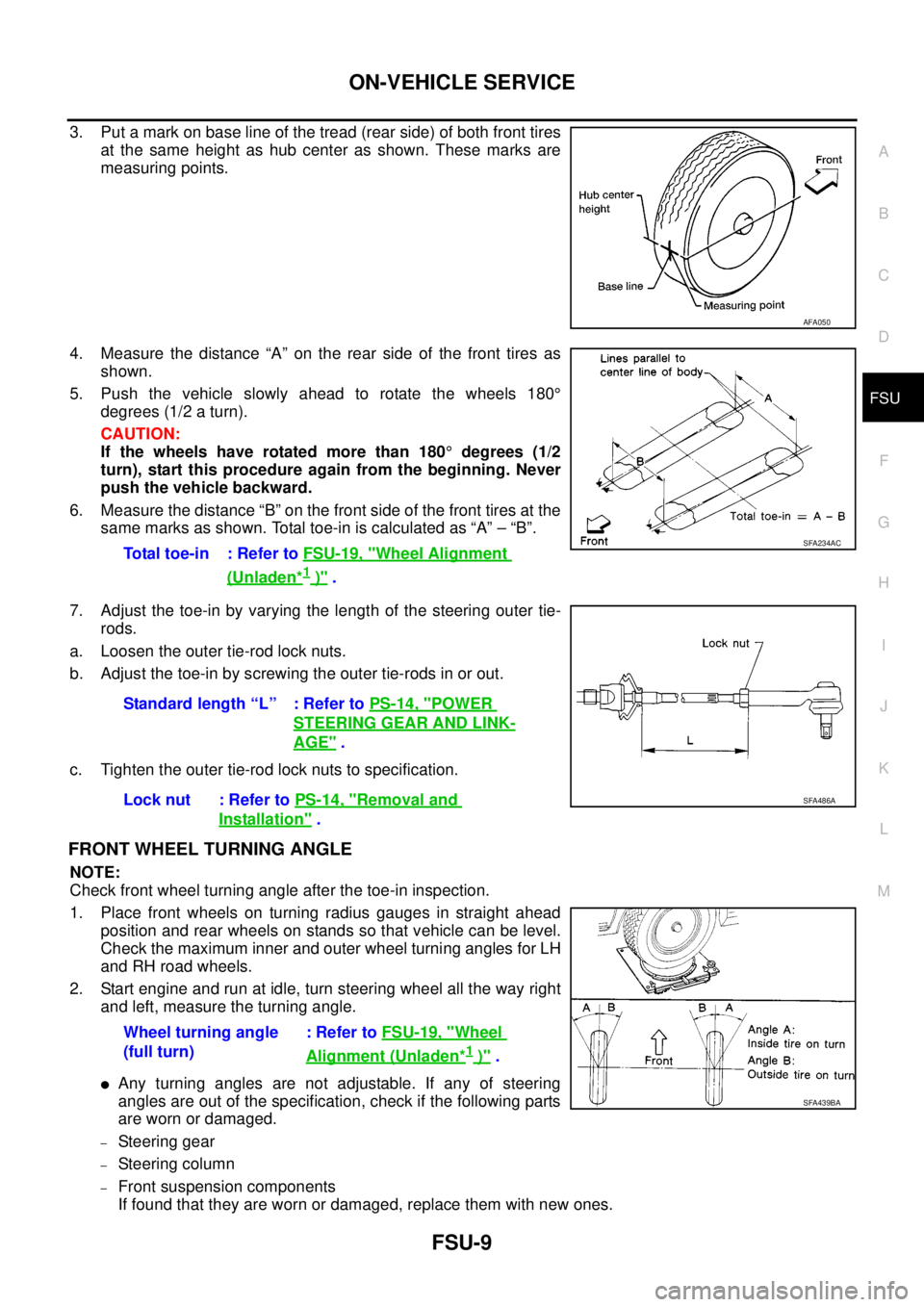

3. Put a mark on base line of the tread (rear side) of both front tires

at the same height as hub center as shown. These marks are

measuring points.

4. Measure the distance “A” on the rear side of the front tires as

shown.

5. Push the vehicle slowly ahead to rotate the wheels 180°

degrees (1/2 a turn).

CAUTION:

If the wheels have rotated more than 180°degrees (1/2

turn), start this procedure again from the beginning. Never

push the vehicle backward.

6. Measure the distance “B” on the front side of the front tires at the

same marks as shown. Total toe-in is calculated as “A” – “B”.

7. Adjust the toe-in by varying the length of the steering outer tie-

rods.

a. Loosen the outer tie-rod lock nuts.

b. Adjust the toe-in by screwing the outer tie-rods in or out.

c. Tighten the outer tie-rod lock nuts to specification.

FRONT WHEEL TURNING ANGLE

NOTE:

Check front wheel turning angle after the toe-in inspection.

1. Place front wheels on turning radius gauges in straight ahead

position and rear wheels on stands so that vehicle can be level.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

2. Start engine and run at idle, turn steering wheel all the way right

and left, measure the turning angle.

lAny turning angles are not adjustable. If any of steering

angles are out of the specification, check if the following parts

are worn or damaged.

–Steering gear

–Steering column

–Front suspension components

If found that they are worn or damaged, replace them with new ones.

AFA050

Total toe-in : Refer toFSU-19, "Wheel Alignment

(Unladen*1)".

SFA234AC

Standard length “L” : Refer toPS-14, "POWER

STEERING GEAR AND LINK-

AGE".

Lock nut : Refer toPS-14, "

Removal and

Installation".

SFA486A

Wheel turning angle

(full turn):RefertoFSU-19, "Wheel

Alignment (Unladen*1)".

SFA439BA

Page 1610 of 3171

FSU-10

COIL SPRING AND SHOCK ABSORBER

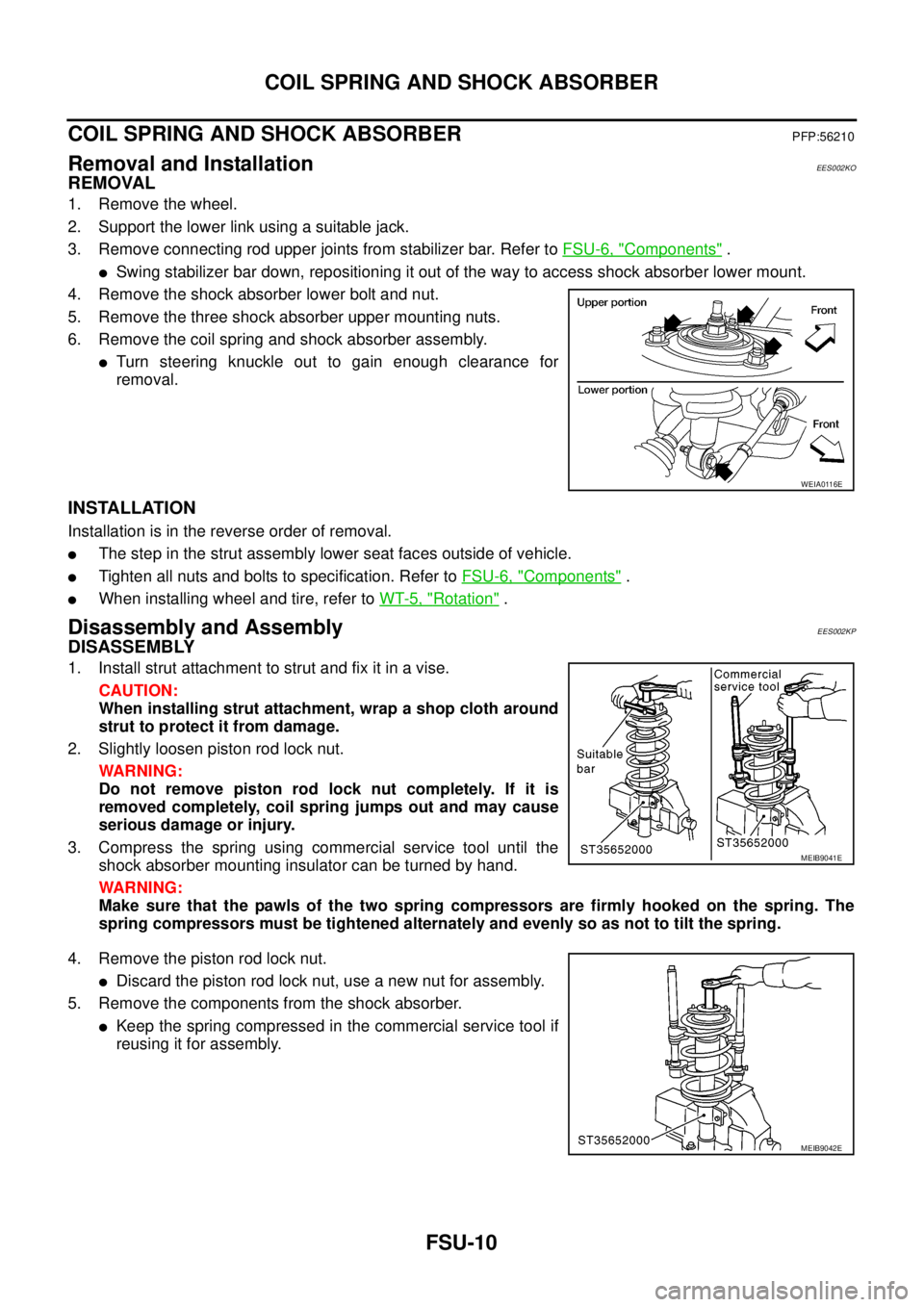

COIL SPRING AND SHOCK ABSORBER

PFP:56210

Removal and InstallationEES002KO

REMOVAL

1. Remove the wheel.

2. Support the lower link using a suitable jack.

3. Remove connecting rod upper joints from stabilizer bar. Refer toFSU-6, "

Components".

lSwing stabilizer bar down, repositioning it out of the way to access shock absorber lower mount.

4. Remove the shock absorber lower bolt and nut.

5. Remove the three shock absorber upper mounting nuts.

6. Remove the coil spring and shock absorber assembly.

lTurn steering knuckle out to gain enough clearance for

removal.

INSTALLATION

Installation is in the reverse order of removal.

lThe step in the strut assembly lower seat faces outside of vehicle.

lTighten all nuts and bolts to specification. Refer toFSU-6, "Components".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

Disassembly and AssemblyEES002KP

DISASSEMBLY

1. Install strut attachment to strut and fix it in a vise.

CAUTION:

When installing strut attachment, wrap a shop cloth around

strut to protect it from damage.

2. Slightly loosen piston rod lock nut.

WARNING:

Do not remove piston rod lock nut completely. If it is

removed completely, coil spring jumps out and may cause

serious damage or injury.

3. Compress the spring using commercial service tool until the

shock absorber mounting insulator can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are firmly hooked on the spring. The

spring compressors must be tightened alternately and evenly so as not to tilt the spring.

4. Remove the piston rod lock nut.

lDiscard the piston rod lock nut, use a new nut for assembly.

5. Remove the components from the shock absorber.

lKeep the spring compressed in the commercial service tool if

reusing it for assembly.

WEIA0116E

MEIB9041E

MEIB9042E

Page 1613 of 3171

UPPER LINK

FSU-13

C

D

F

G

H

I

J

K

L

MA

B

FSU

UPPER LINKPFP:54524

Removal and InstallationEES002KR

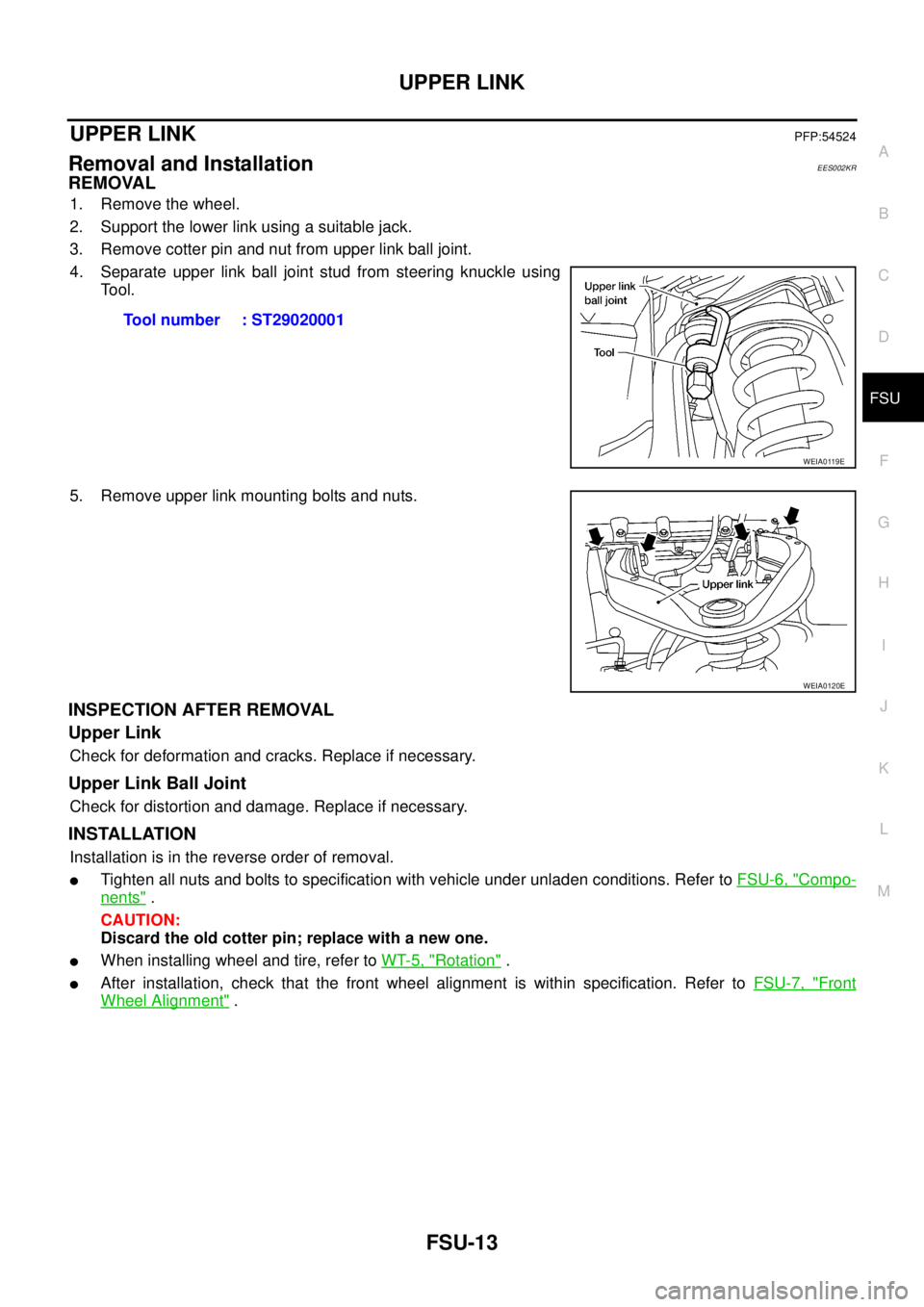

REMOVAL

1. Remove the wheel.

2. Support the lower link using a suitable jack.

3. Remove cotter pin and nut from upper link ball joint.

4. Separate upper link ball joint stud from steering knuckle using

Tool.

5. Remove upper link mounting bolts and nuts.

INSPECTION AFTER REMOVAL

Upper Link

Check for deformation and cracks. Replace if necessary.

Upper Link Ball Joint

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lTighten all nuts and bolts to specification with vehicle under unladen conditions. Refer toFSU-6, "Compo-

nents".

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within specification. Refer toFSU-7, "Front

Wheel Alignment". Tool number : ST29020001

WEIA0119E

WEIA0120E

Page 1614 of 3171

FSU-14

LOWER LINK

LOWER LINK

PFP:55020

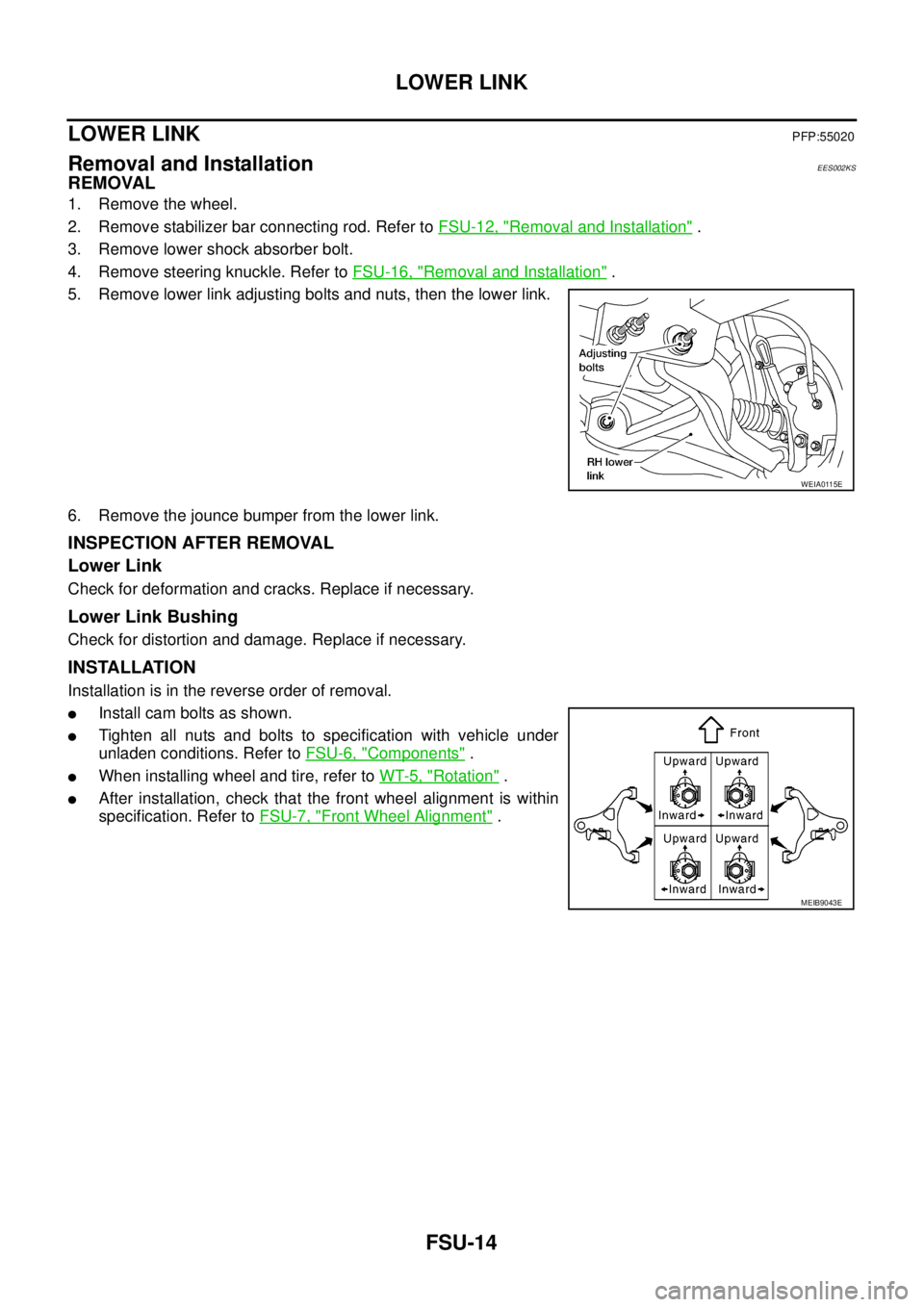

Removal and InstallationEES002KS

REMOVAL

1. Remove the wheel.

2. Remove stabilizer bar connecting rod. Refer toFSU-12, "

Removal and Installation".

3. Remove lower shock absorber bolt.

4. Remove steering knuckle. Refer toFSU-16, "

Removal and Installation".

5. Remove lower link adjusting bolts and nuts, then the lower link.

6. Remove the jounce bumper from the lower link.

INSPECTION AFTER REMOVAL

Lower Link

Check for deformation and cracks. Replace if necessary.

Lower Link Bushing

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lInstall cam bolts as shown.

lTighten all nuts and bolts to specification with vehicle under

unladen conditions. Refer toFSU-6, "

Components".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within

specification. Refer toFSU-7, "

Front Wheel Alignment".

WEIA0115E

MEIB9043E