ECU NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 274 of 3171

AT-266

DISASSEMBLY

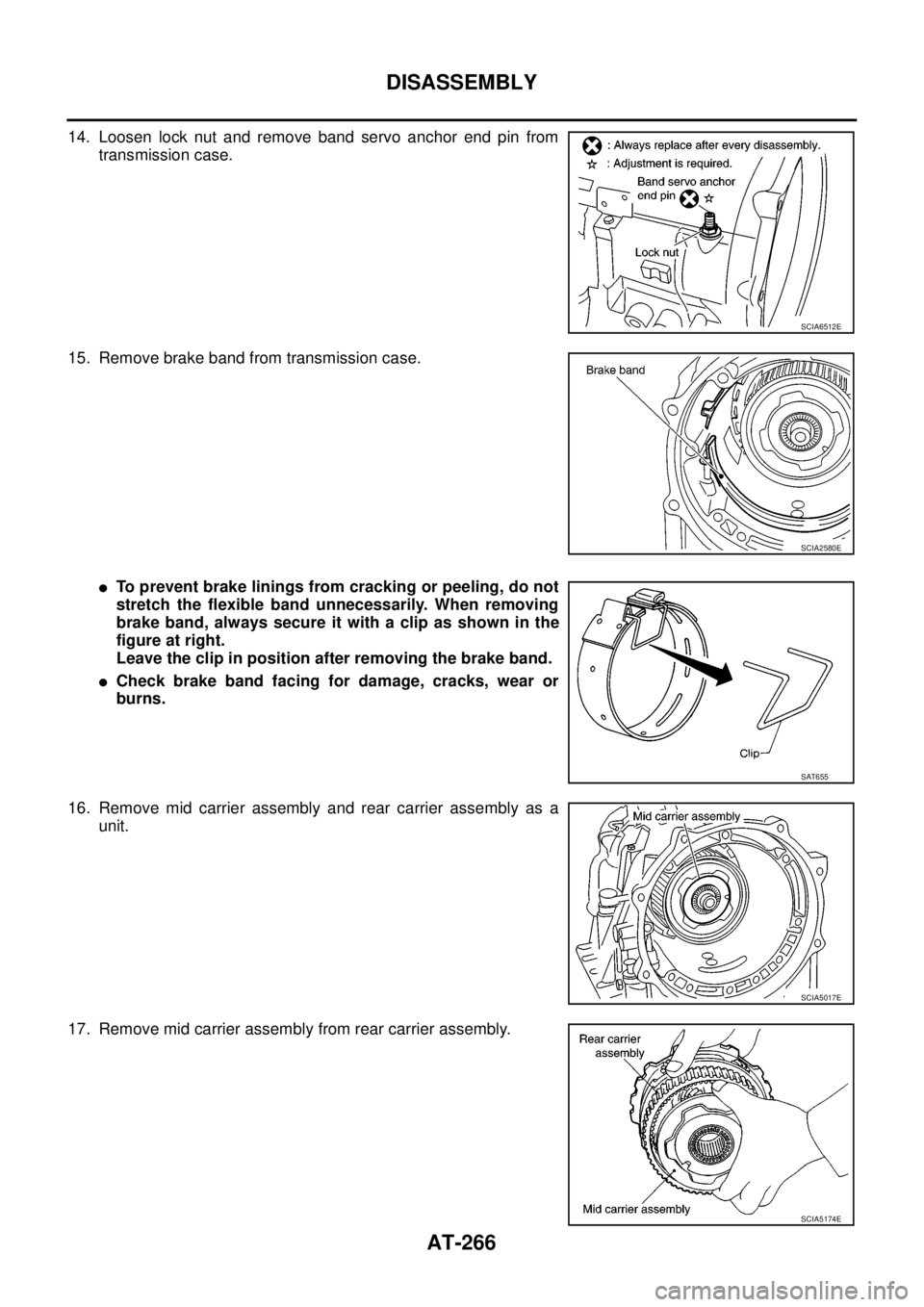

14. Loosen lock nut and remove band servo anchor end pin from

transmission case.

15. Remove brake band from transmission case.

lTo prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

brake band, always secure it with a clip as shown in the

figure at right.

Leave the clip in position after removing the brake band.

lCheck brake band facing for damage, cracks, wear or

burns.

16. Remove mid carrier assembly and rear carrier assembly as a

unit.

17. Remove mid carrier assembly from rear carrier assembly.

SCIA6512E

SCIA2580E

SAT655

SCIA5017E

SCIA5174E

Page 311 of 3171

ASSEMBLY

AT-303

D

E

F

G

H

I

J

K

L

MA

B

AT

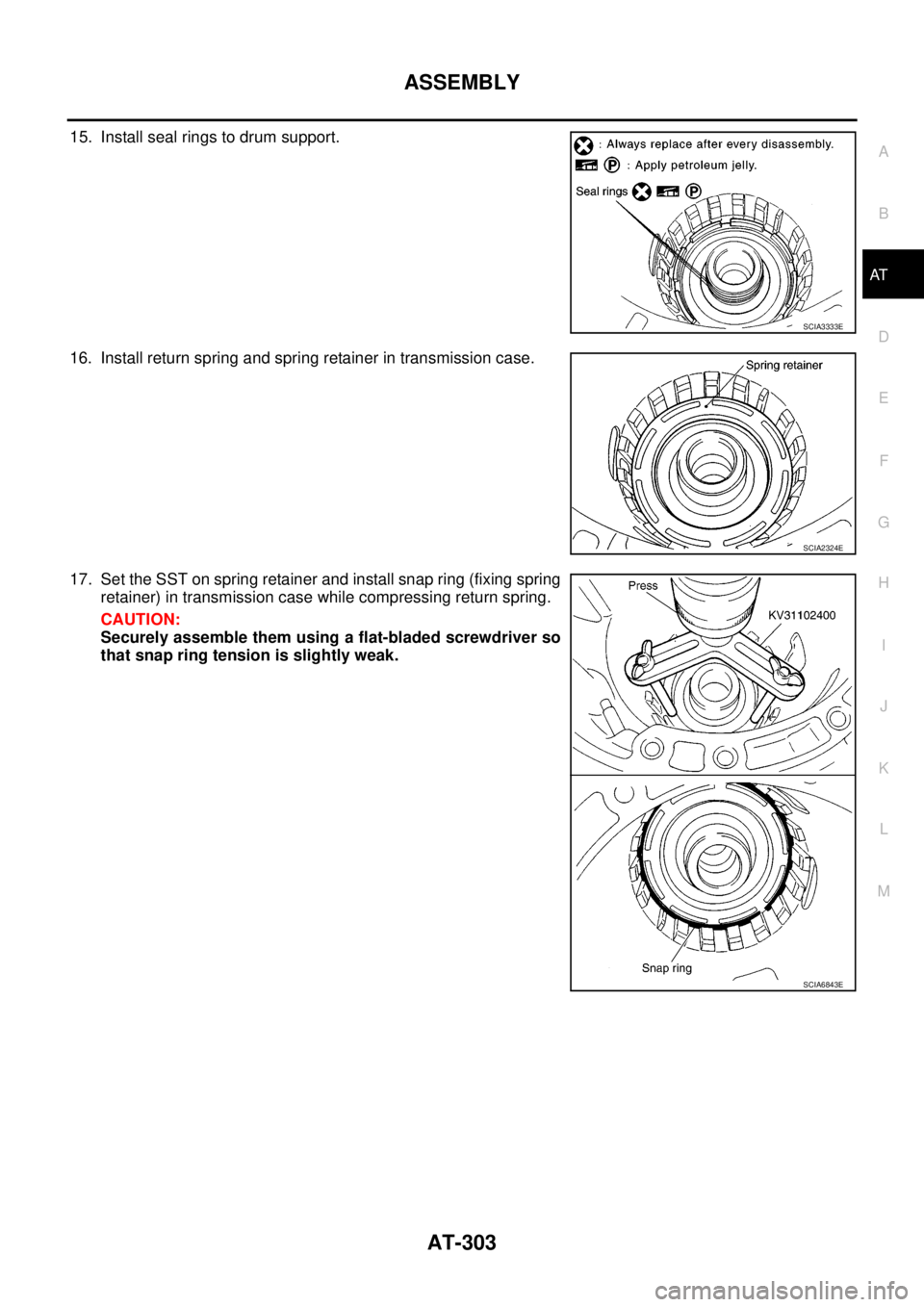

15. Install seal rings to drum support.

16. Install return spring and spring retainer in transmission case.

17. Set the SST on spring retainer and install snap ring (fixing spring

retainer) in transmission case while compressing return spring.

CAUTION:

Securely assemble them using a flat-bladed screwdriver so

that snap ring tension is slightly weak.

SCIA3333E

SCIA2324E

SCIA6843E

Page 327 of 3171

ASSEMBLY

AT-319

D

E

F

G

H

I

J

K

L

MA

B

AT

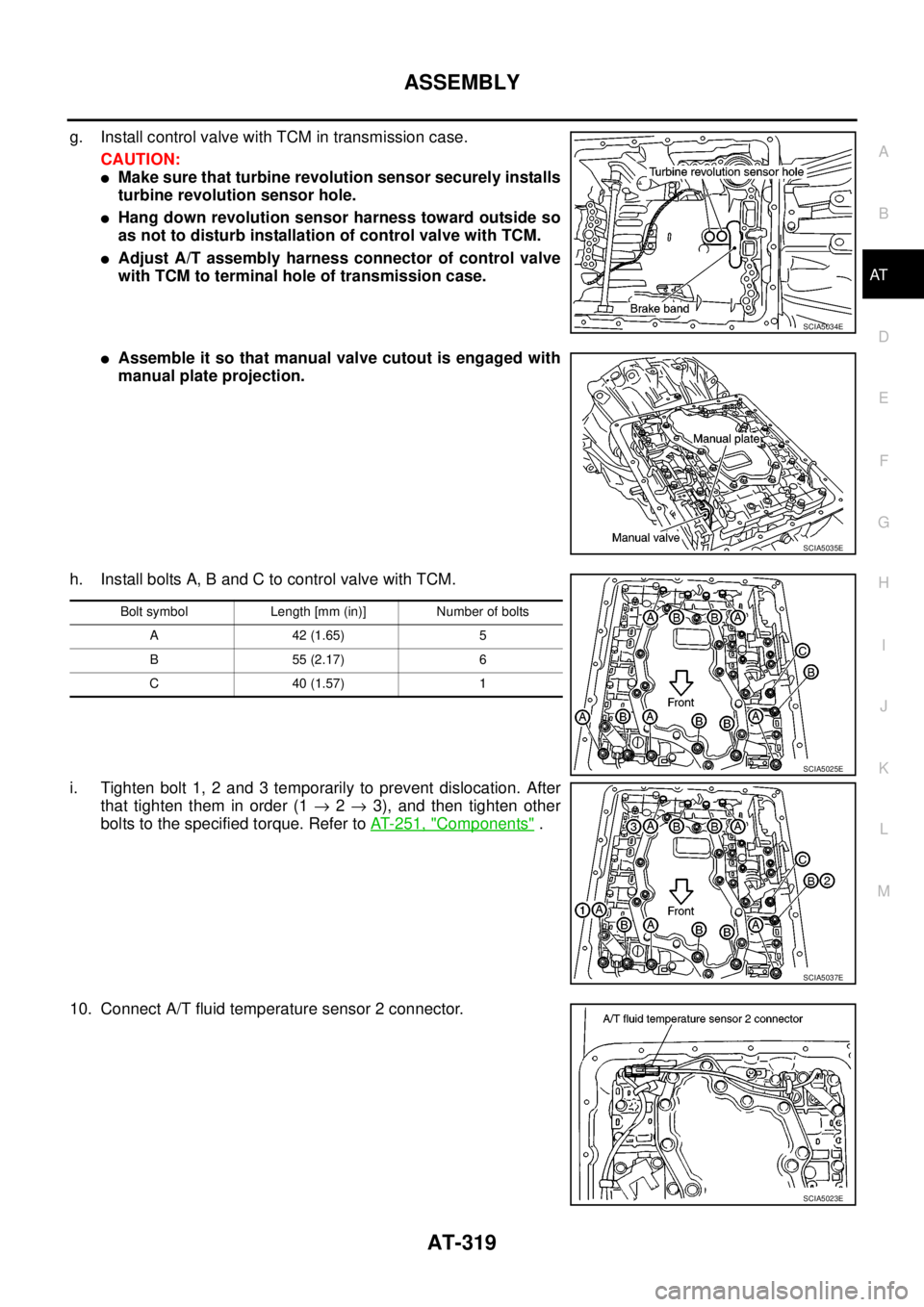

g. Install control valve with TCM in transmission case.

CAUTION:

lMake sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

lHang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

lAdjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

lAssemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts A, B and C to control valve with TCM.

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After

that tighten them in order (1®2®3), and then tighten other

bolts to the specified torque. Refer toAT- 2 5 1 , "

Components".

10. Connect A/T fluid temperature sensor 2 connector.

SCIA5034E

SCIA5035E

Bolt symbol Length [mm (in)] Number of bolts

A42(1.65) 5

B55(2.17) 6

C40(1.57) 1

SCIA5025E

SCIA5037E

SCIA5023E

Page 328 of 3171

AT-320

ASSEMBLY

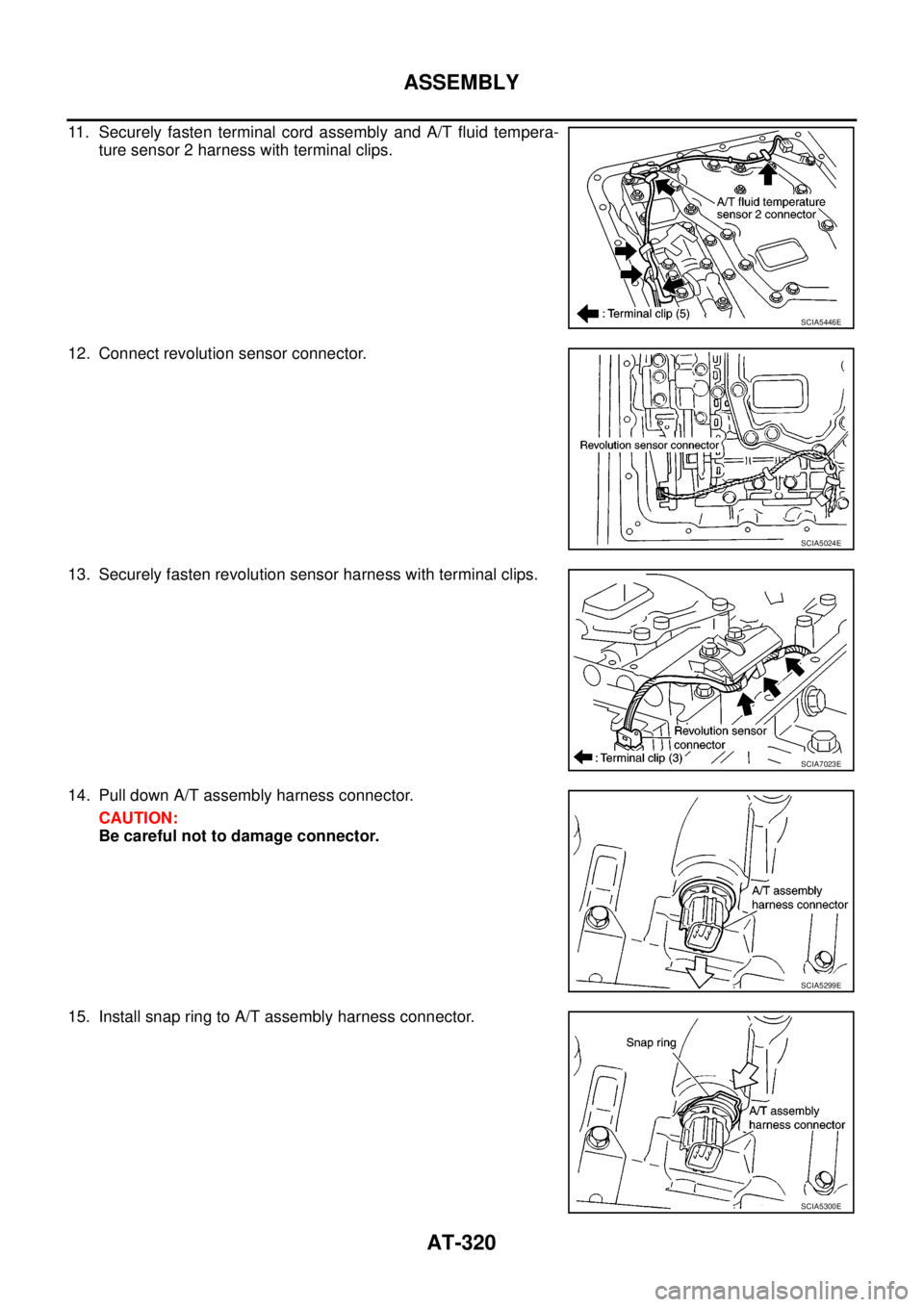

11. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

12. Connect revolution sensor connector.

13. Securely fasten revolution sensor harness with terminal clips.

14. Pull down A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

15. Install snap ring to A/T assembly harness connector.

SCIA5446E

SCIA5024E

SCIA7023E

SCIA5299E

SCIA5300E

Page 341 of 3171

PRECAUTIONS

ATC-7

C

D

E

F

G

H

I

K

L

MA

B

AT C

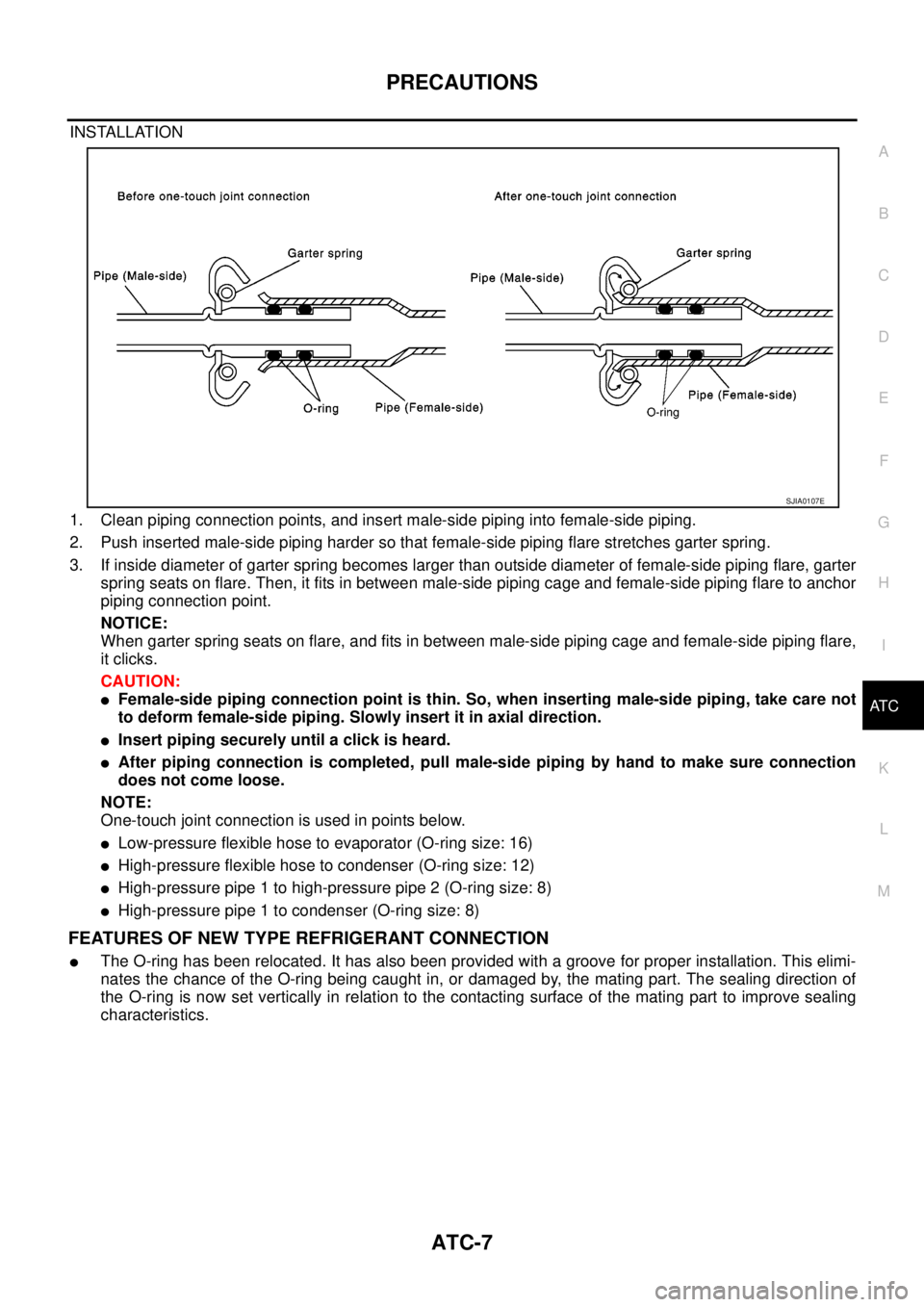

INSTALLATION

1. Clean piping connection points, and insert male-side piping into female-side piping.

2. Push inserted male-side piping harder so that female-side piping flare stretches garter spring.

3. If inside diameter of garter spring becomes larger than outside diameter of female-side piping flare, garter

spring seats on flare. Then, it fits in between male-side piping cage and female-side piping flare to anchor

piping connection point.

NOTICE:

When garter spring seats on flare, and fits in between male-side piping cage and female-side piping flare,

it clicks.

CAUTION:

lFemale-side piping connection point is thin. So, when inserting male-side piping, take care not

to deform female-side piping. Slowly insert it in axial direction.

lInsert piping securely until a click is heard.

lAfter piping connection is completed, pull male-side piping by hand to make sure connection

does not come loose.

NOTE:

One-touch joint connection is used in points below.

lLow-pressure flexible hose to evaporator (O-ring size: 16)

lHigh-pressure flexible hose to condenser (O-ring size: 12)

lHigh-pressure pipe 1 to high-pressure pipe 2 (O-ring size: 8)

lHigh-pressure pipe 1 to condenser (O-ring size: 8)

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

lThe O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of

the O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing

characteristics.

SJIA0107E

Page 367 of 3171

TROUBLE DIAGNOSIS

ATC-33

C

D

E

F

G

H

I

K

L

MA

B

AT C

TROUBLE DIAGNOSISPFP:00004

CONSULT-II Function (BCM)EJS006B8

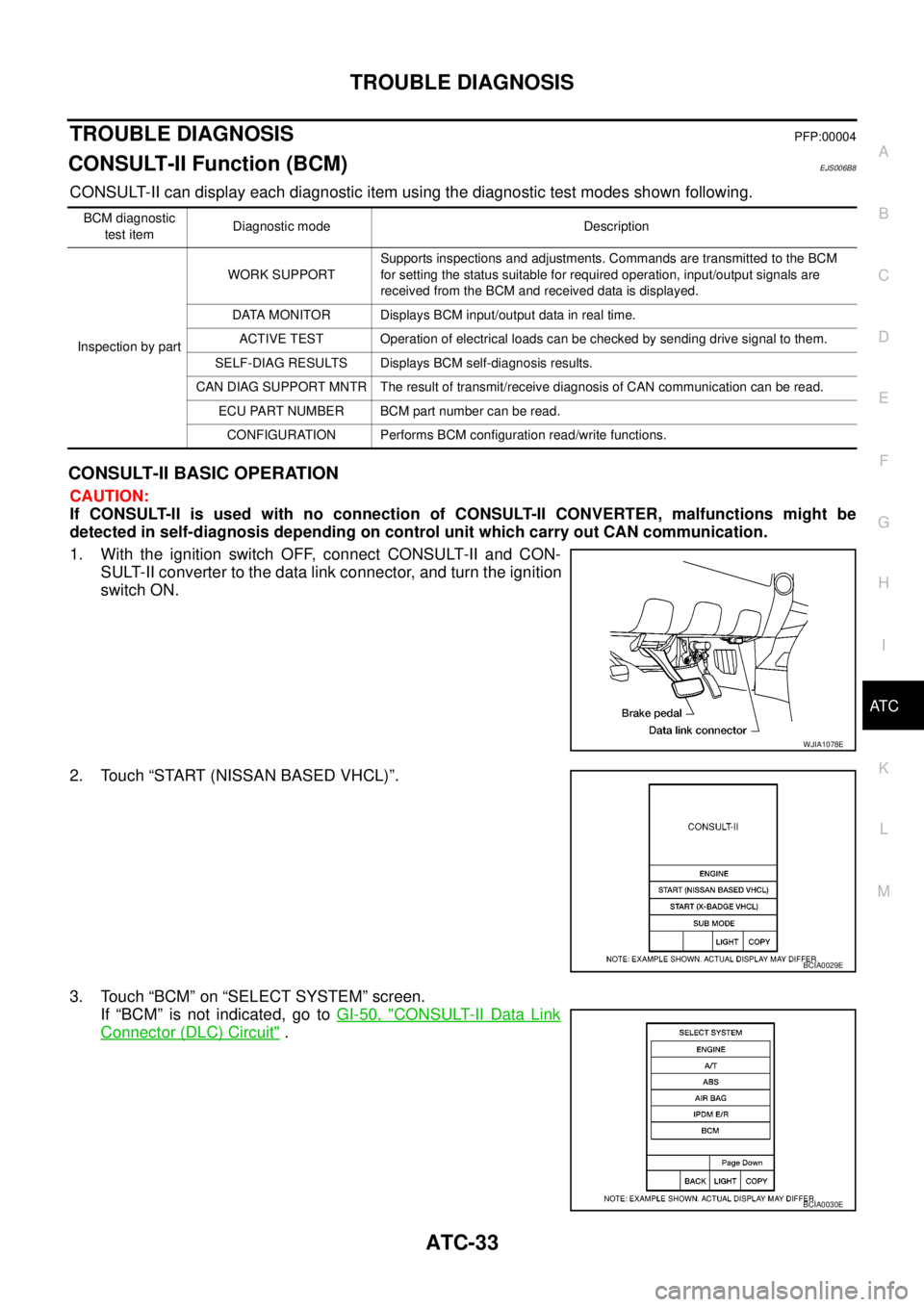

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II converter to the data link connector, and turn the ignition

switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, go toGI-50, "

CONSULT-II Data Link

Connector (DLC) Circuit".

BCM diagnostic

test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are

received from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

WJIA1078E

BCIA0029E

BCIA0030E

Page 450 of 3171

ATC-116

CONTROL UNIT

CONTROL UNIT

PFP:27500

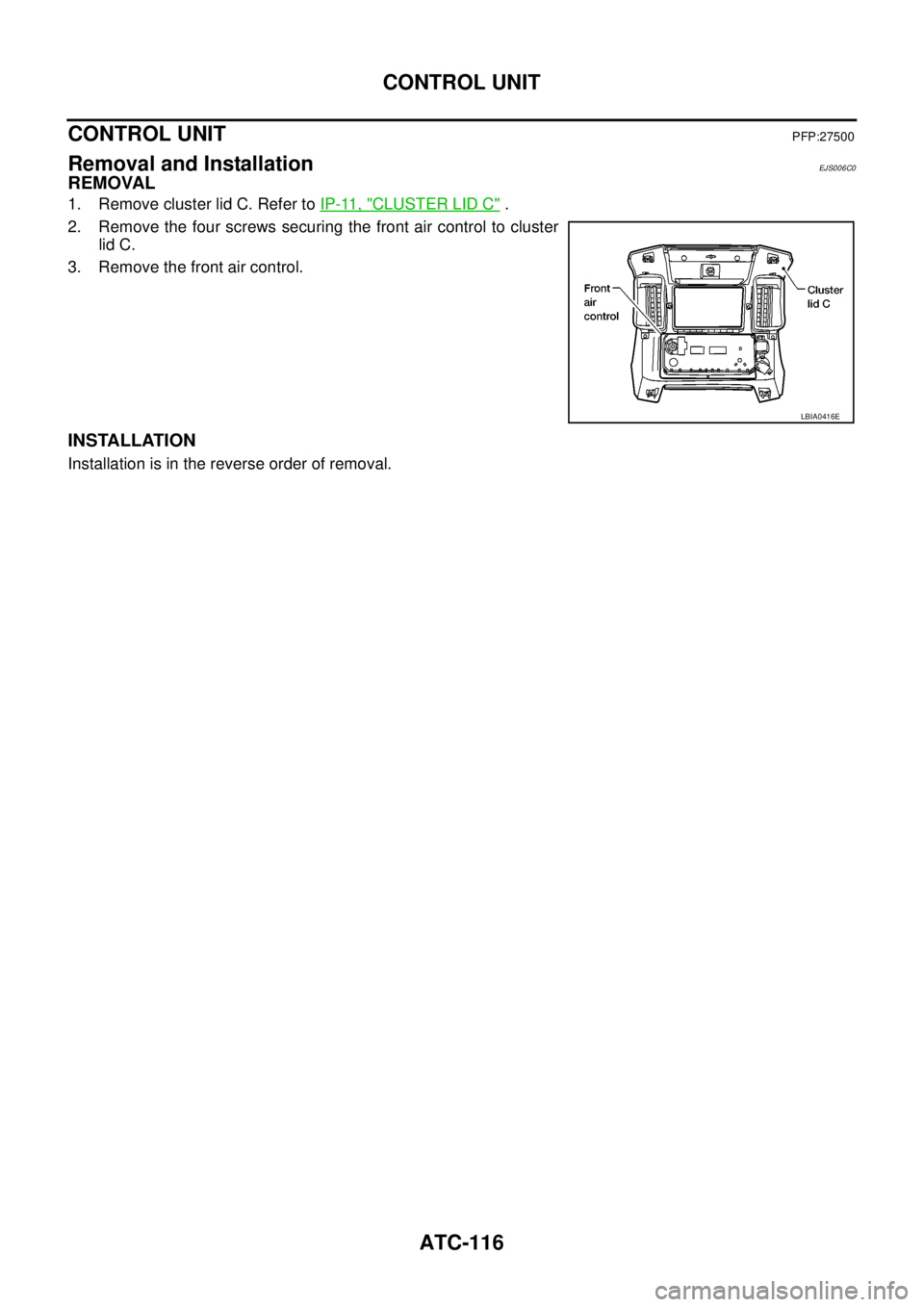

Removal and InstallationEJS006C0

REMOVAL

1. Remove cluster lid C. Refer toIP-11, "CLUSTER LID C".

2. Remove the four screws securing the front air control to cluster

lid C.

3. Remove the front air control.

INSTALLATION

Installation is in the reverse order of removal.

LBIA0416E

Page 462 of 3171

ATC-128

HEATER PUMP

HEATER PUMP

PFP:92264

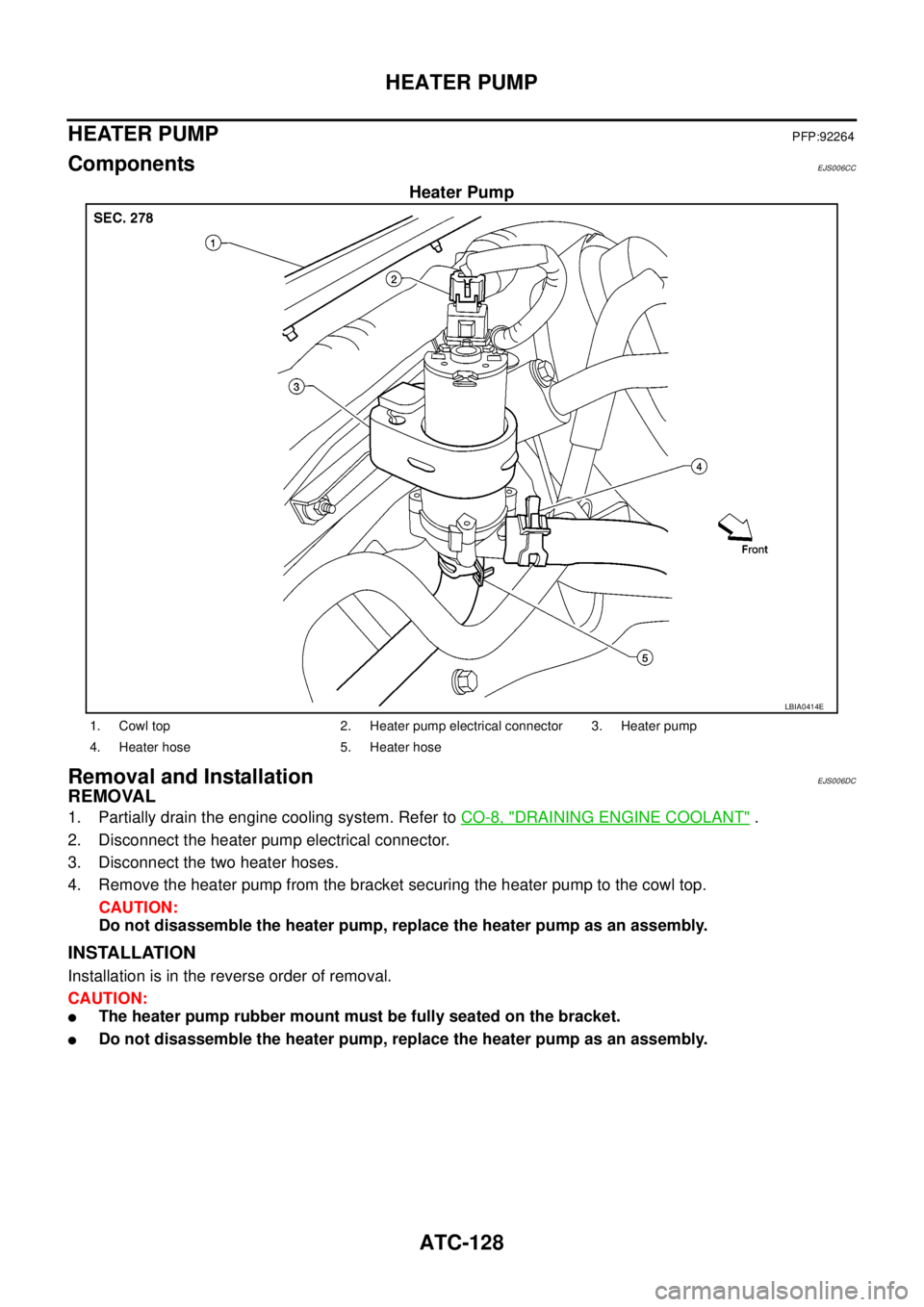

ComponentsEJS006CC

Heater Pump

Removal and InstallationEJS006DC

REMOVAL

1. Partially drain the engine cooling system. Refer toCO-8, "DRAINING ENGINE COOLANT".

2. Disconnect the heater pump electrical connector.

3. Disconnect the two heater hoses.

4. Remove the heater pump from the bracket securing the heater pump to the cowl top.

CAUTION:

Do not disassemble the heater pump, replace the heater pump as an assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lThe heater pump rubber mount must be fully seated on the bracket.

lDo not disassemble the heater pump, replace the heater pump as an assembly.

LBIA0414E

1. Cowl top 2. Heater pump electrical connector 3. Heater pump

4. Heater hose 5. Heater hose

Page 486 of 3171

ATC-152

REFRIGERANT LINES

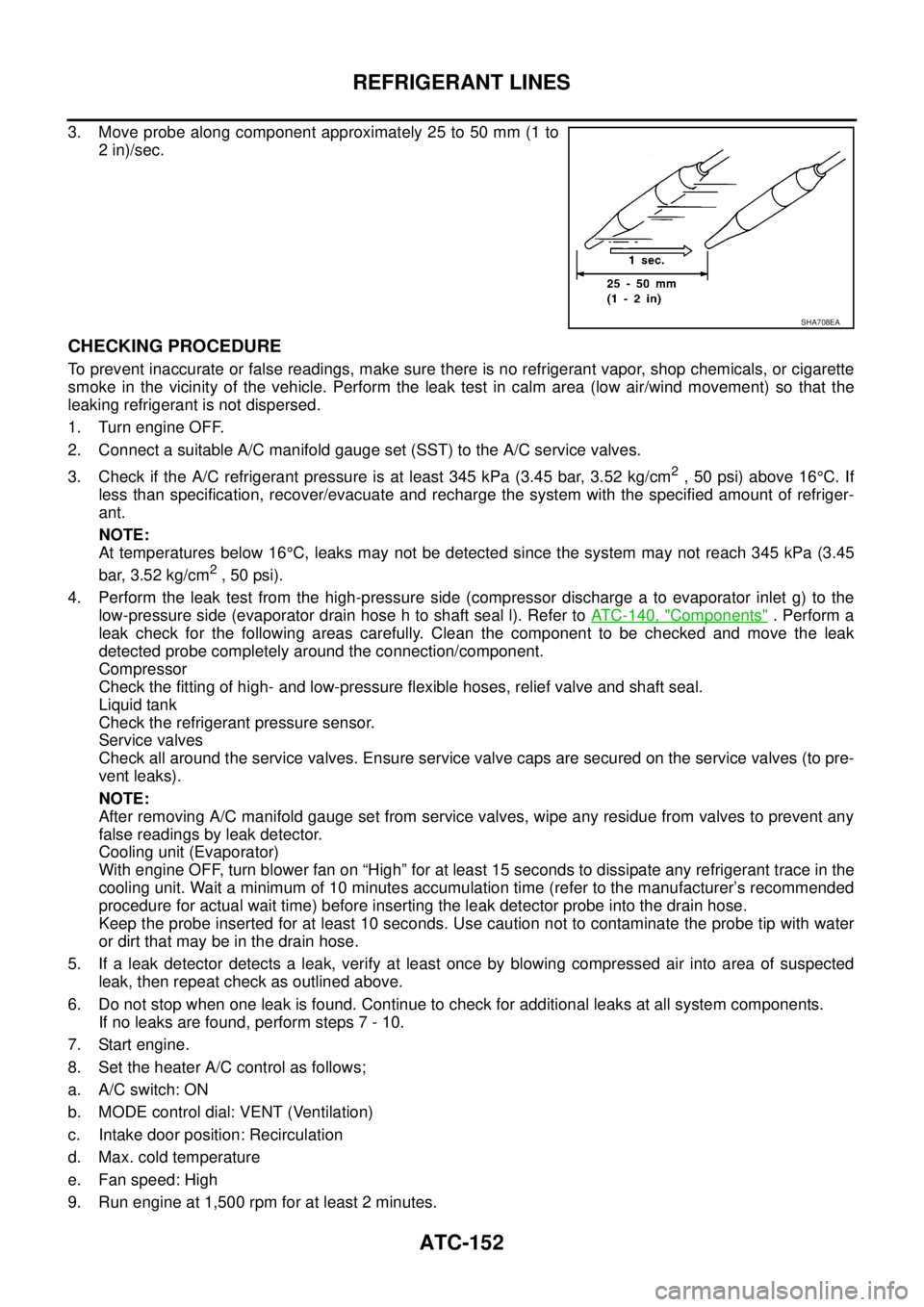

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50psi)above16°C. If

less than specification, recover/evacuate and recharge the system with the specified amount of refriger-

ant.

NOTE:

At temperatures below 16°C, leaks may not be detected since the system may not reach 345 kPa (3.45

bar, 3.52 kg/cm

2,50psi).

4. Perform the leak test from the high-pressure side (compressor discharge a to evaporator inlet g) to the

low-pressure side (evaporator drain hose h to shaft seal l). Refer toATC-140, "

Components". Perform a

leak check for the following areas carefully. Clean the component to be checked and move the leak

detected probe completely around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. MODE control dial: VENT (Ventilation)

c. Intake door position: Recirculation

d. Max. cold temperature

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

SHA708EA

Page 489 of 3171

AV-1

AUDIO-VISUAL SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONAV

A

B

AV

AUDIO-VISUAL SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Wiring Diagrams and Trouble Diagnosis .................. 3

SYSTEM DESCRIPTION ............................................ 4

System Functions ..................................................... 4

AUDIO ................................................................... 4

NATS AUDIO LINK (WITHOUT NAVIGATION

SYSTEM) .............................................................. 4

VEHICLE INFORMATION SYSTEM ..................... 5

NAVIGATION SYSTEM ......................................... 5

HANDS-FREE PHONE ......................................... 7

Component Description ............................................ 8

AUDIO UNIT ......................................................... 8

NAVI CONTROL UNIT .......................................... 8

GPS ANTENNA .................................................... 9

DISPLAY UNIT ...................................................... 9

AV SWITCH .......................................................... 9

Component Parts Location ..................................... 10

Location Of Antenna .............................................. 10

Schematic — AUDIO — / With 1CD Player Type... 12

Wiring Diagram — AUDIO — / With 1CD Player Type

... 13

Schematic — AUDIO — / With 6CD Player Type... 16

Wiring Diagram — AUDIO — / With 6CD Player Type

... 17

Schematic — NAVI — ............................................ 20

Wiring Diagram — NAVI — .................................... 21

Schematic — NAVI — / COMM .............................. 28

Wiring Diagram — NAVI — / COMM ...................... 29

Wiring Diagram — TELEPHONE (PRE WIRE) —

/ Without NAVI ........................................................ 32

CAN Communication .............................................. 33

SYSTEM DESCRIPTION .................................... 33

TERMINALS AND REFERENCE VALUE FOR CON-

TROL UNIT ............................................................... 34

Audio Unit (1CD Player Type) ................................ 34

Audio Unit (6CD Player Type) Without NAVI .......... 35Audio Unit (With NAVI) ........................................... 37

NAVI Control Unit ................................................... 38

Display Unit ............................................................ 41

DIAGNOSIS SYSTEM ............................................... 44

Navigation System Diagnosis Function .................. 44

On Bord Self-Diagnosis Function ........................... 44

DESCRIPTION .................................................... 44

DIAGNOSIS ITEM ............................................... 44

OPERATION PROCEDURE ................................ 45

Self Diagnosis Mode ............................................... 46

ERROR DETECTION RANGE OF SELF-DIAG-

NOSIS MODE ..................................................... 47

DIAGNOSIS RESULTS ....................................... 47

Confirmation/Adjustment Mode .............................. 48

SCREEN TROUBLE DIAGNOSIS ...................... 49

VEHICLE SIGNALS ............................................ 49

SPEAKER TEST ................................................. 50

NAVIGATION ....................................................... 50

ERROR HISTORY ............................................... 51

VEHICLE CAN DIAGNOSIS ............................... 53

AV COMM DIAGNOSIS ....................................... 54

HANDSFREE PHONE ........................................ 54

BLUETOOTH ....................................................... 54

DELETE UNIT CONNECTION LOG ................... 55

CONSULT-II Functions ........................................... 56

CONSULT-II FUNCTIONS ................................... 56

CONSULT-II BASIC OPERATION PROCEDURE

... 56

SELF-DIAG RESULTS ........................................ 56

DATA MONITOR ................................................. 58

AV COMM MONITOR .......................................... 59

ECU PART NUMBER .......................................... 60

TROUBLE DIAGNOSIS ............................................ 61

Navigation System .................................................. 61

RGB Image ............................................................. 61

Voice Activated Control System ............................. 62

Steering Wheel Switch ............................................ 63

Component Parts Inspection .................................. 63

STEERING WHEEL SWITCH UNIT INSPEC-