brake sensor NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 283 of 3171

DISASSEMBLY

AT-275

D

E

F

G

H

I

J

K

L

MA

B

AT

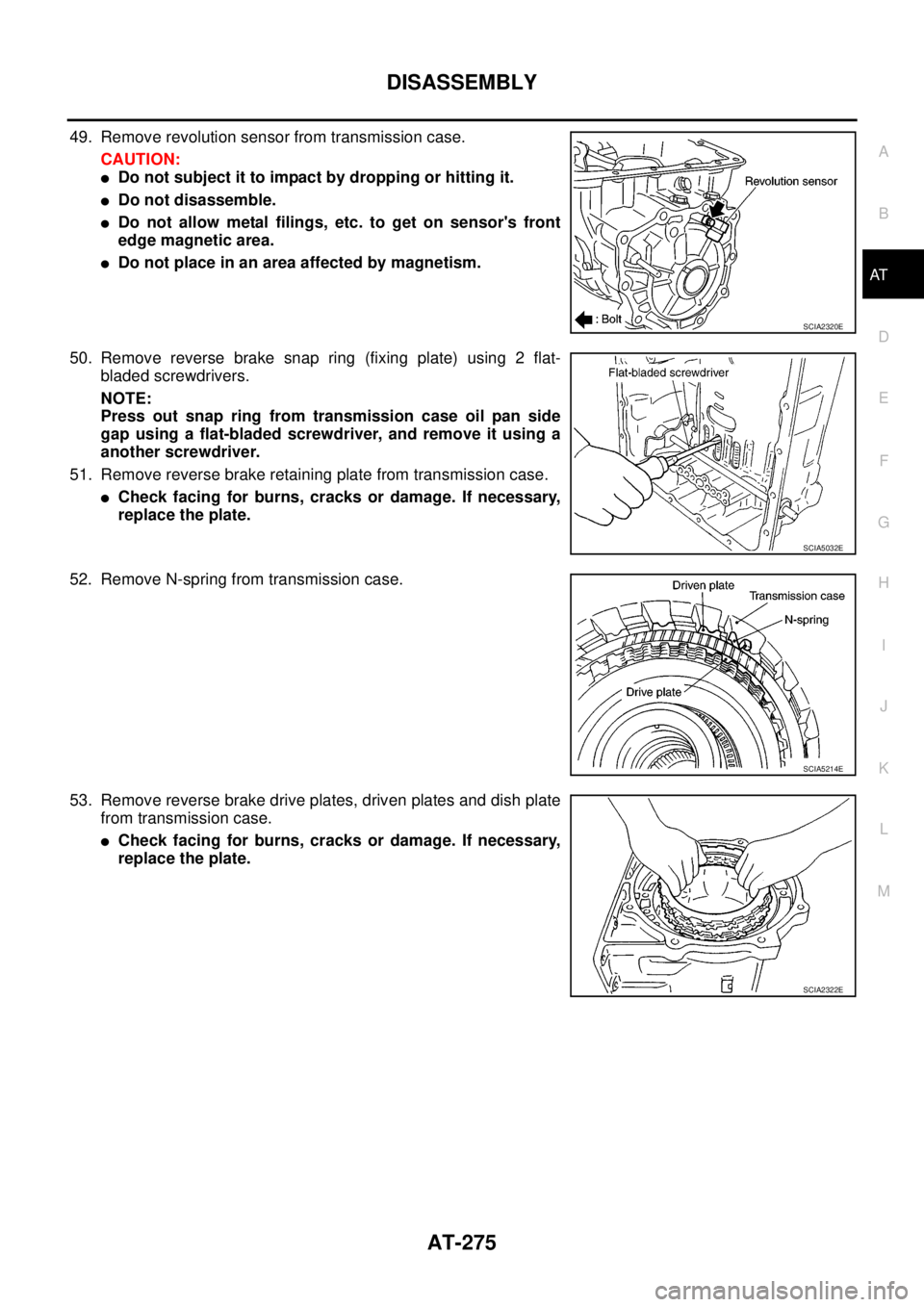

49. Remove revolution sensor from transmission case.

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc. to get on sensor's front

edge magnetic area.

lDo not place in an area affected by magnetism.

50. Remove reverse brake snap ring (fixing plate) using 2 flat-

bladed screwdrivers.

NOTE:

Press out snap ring from transmission case oil pan side

gap using a flat-bladed screwdriver, and remove it using a

another screwdriver.

51. Remove reverse brake retaining plate from transmission case.

lCheck facing for burns, cracks or damage. If necessary,

replace the plate.

52. Remove N-spring from transmission case.

53. Remove reverse brake drive plates, driven plates and dish plate

from transmission case.

lCheck facing for burns, cracks or damage. If necessary,

replace the plate.

SCIA2320E

SCIA5032E

SCIA5214E

SCIA2322E

Page 313 of 3171

ASSEMBLY

AT-305

D

E

F

G

H

I

J

K

L

MA

B

AT

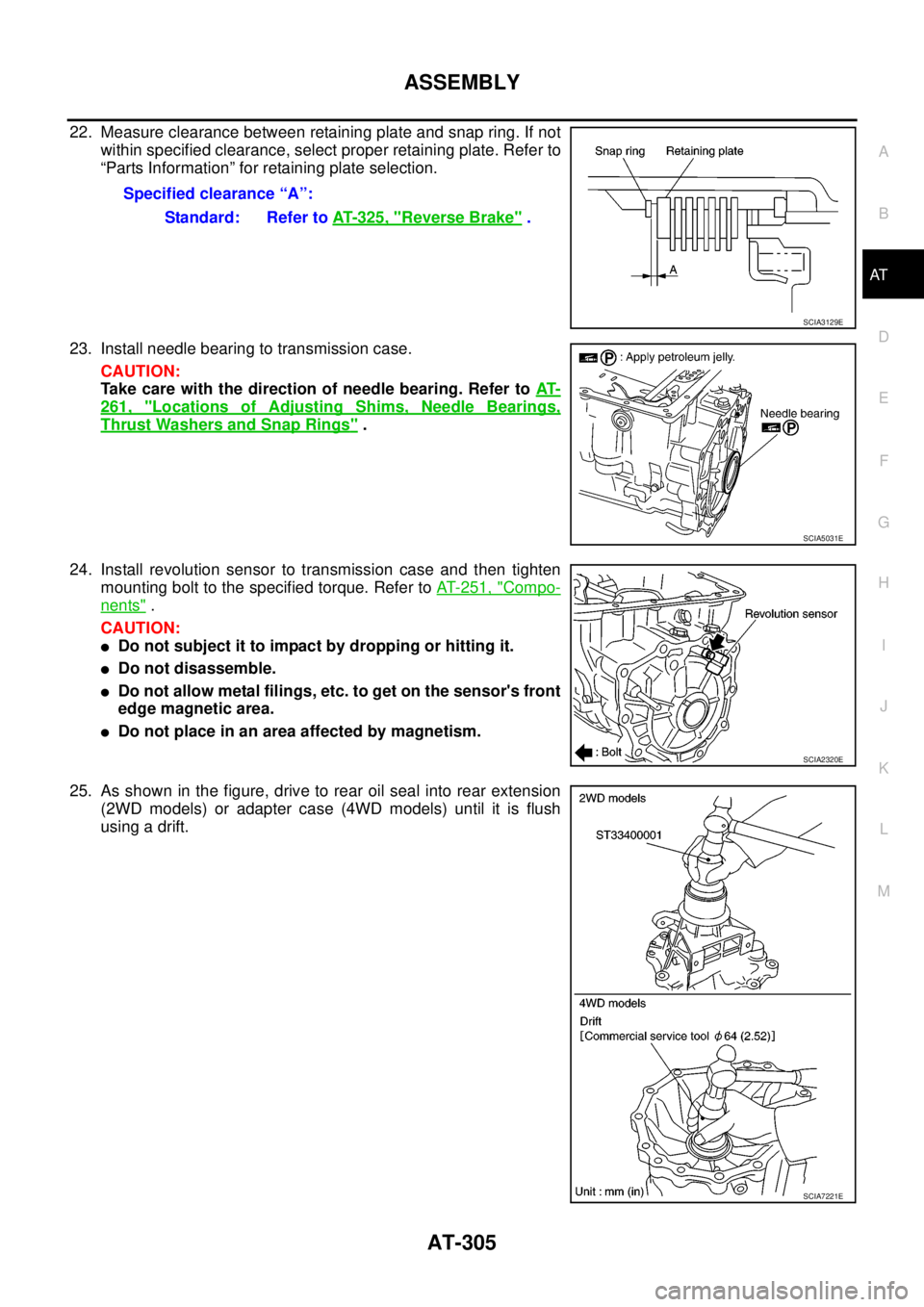

22. Measure clearance between retaining plate and snap ring. If not

within specified clearance, select proper retaining plate. Refer to

“Parts Information” for retaining plate selection.

23. Install needle bearing to transmission case.

CAUTION:

Take care with the direction of needle bearing. Refer toAT-

261, "Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

24. Install revolution sensor to transmission case and then tighten

mounting bolt to the specified torque. Refer toAT- 2 5 1 , "

Compo-

nents".

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

lDo not place in an area affected by magnetism.

25. As shown in the figure, drive to rear oil seal into rear extension

(2WD models) or adapter case (4WD models) until it is flush

usingadrift.Specified clearance “A”:

Standard: Refer toAT- 3 2 5 , "

Reverse Brake".

SCIA3129E

SCIA5031E

SCIA2320E

SCIA7221E

Page 325 of 3171

ASSEMBLY

AT-317

D

E

F

G

H

I

J

K

L

MA

B

AT

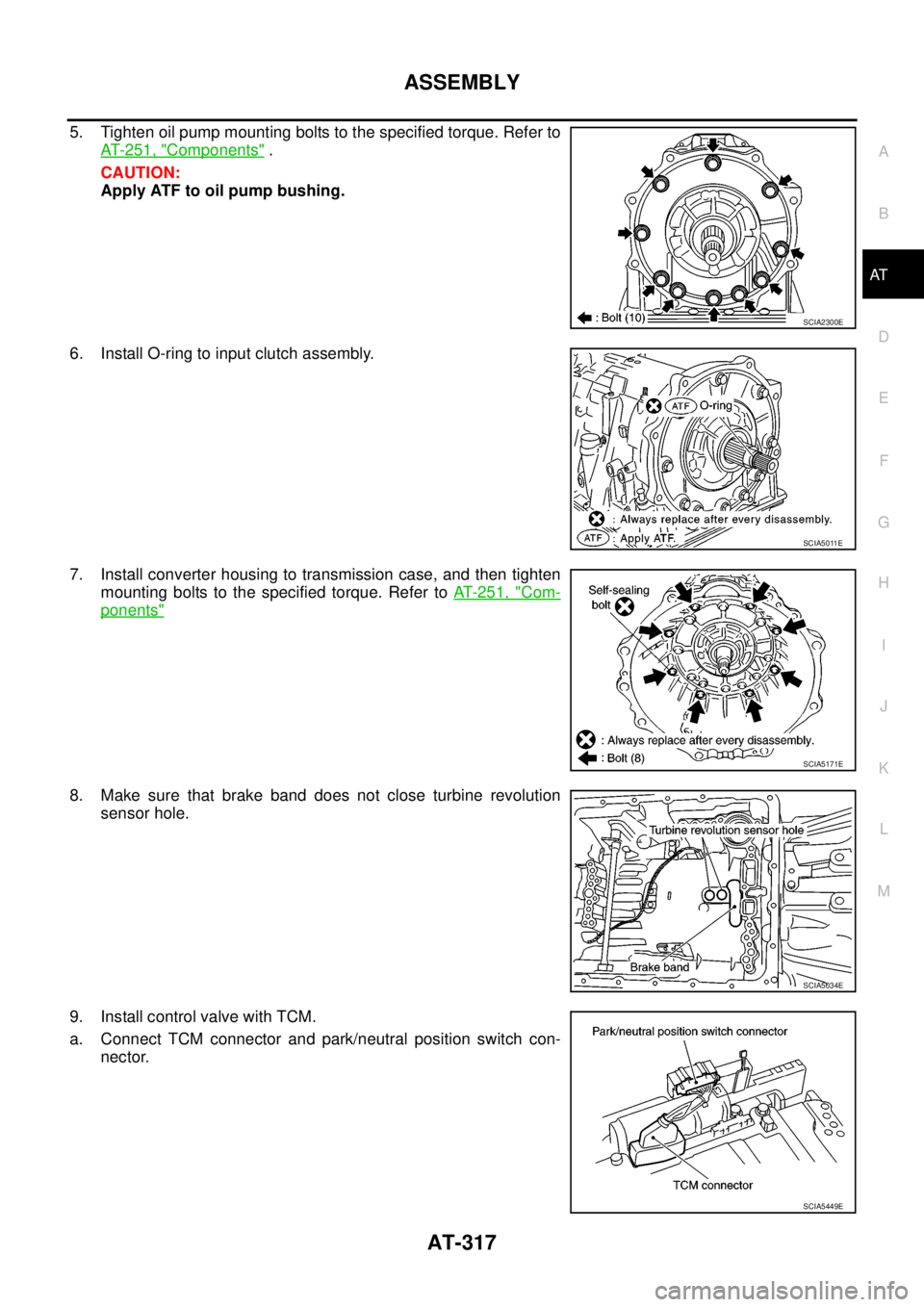

5. Tighten oil pump mounting bolts to the specified torque. Refer to

AT- 2 5 1 , "

Components".

CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly.

7. Install converter housing to transmission case, and then tighten

mounting bolts to the specified torque. Refer toAT- 2 5 1 , "

Com-

ponents"

8. Make sure that brake band does not close turbine revolution

sensor hole.

9. Install control valve with TCM.

a. Connect TCM connector and park/neutral position switch con-

nector.

SCIA2300E

SCIA5011E

SCIA5171E

SCIA5034E

SCIA5449E

Page 333 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-325

D

E

F

G

H

I

J

K

L

MA

B

AT

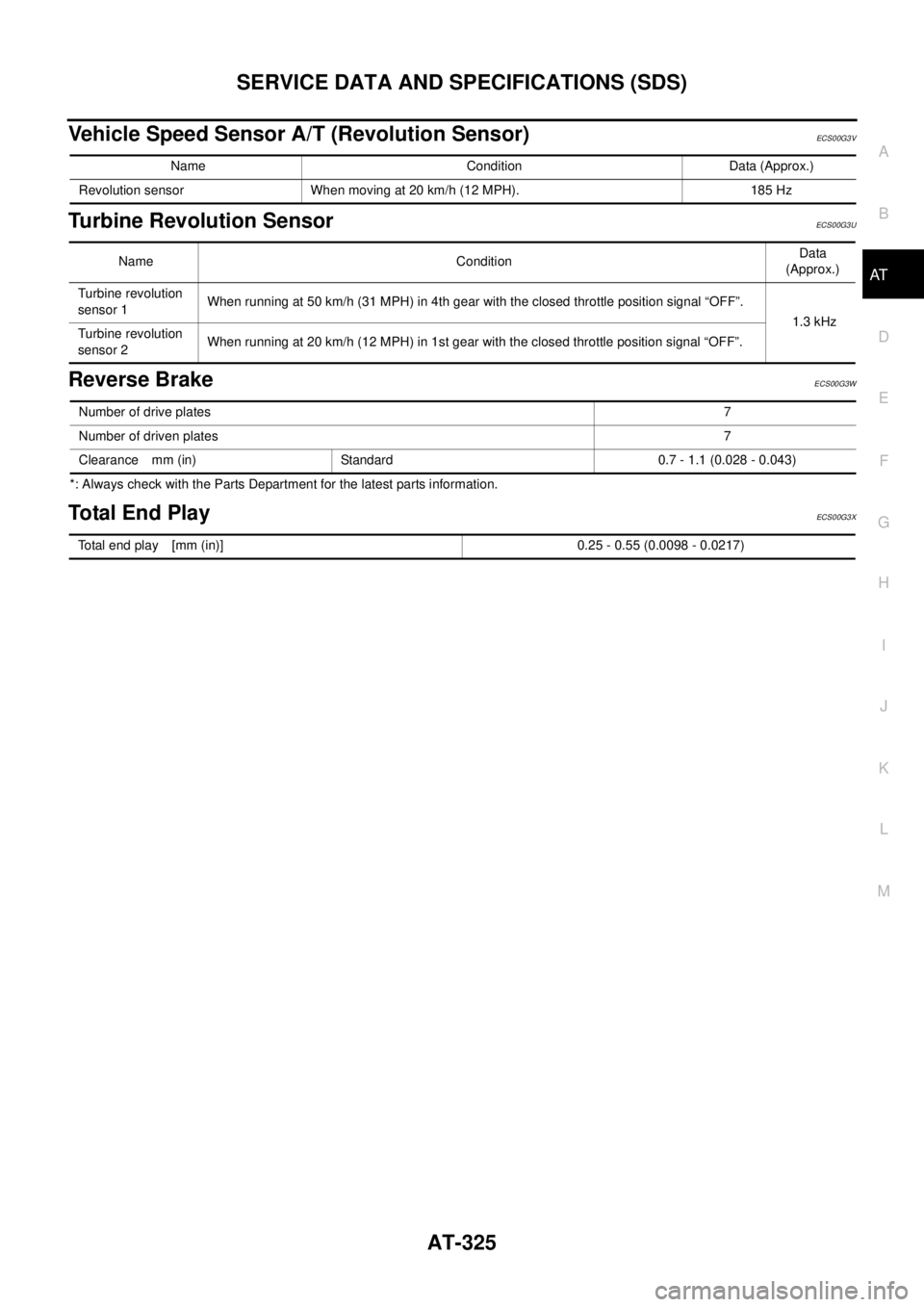

Vehicle Speed Sensor A/T (Revolution Sensor)ECS00G3V

Turbine Revolution SensorECS00G3U

Reverse BrakeECS00G3W

*: Always check with the Parts Department for the latest parts information.

To ta l E n d P l a yECS00G3X

Name Condition Data (Approx.)

Revolution sensor When moving at 20 km/h (12 MPH). 185 Hz

Name ConditionData

(Approx.)

Turbine revolution

sensor 1When running at 50 km/h (31 MPH) in 4th gear with the closed throttle position signal “OFF”.

1.3 kHz

Turbine revolution

sensor 2When running at 20 km/h (12 MPH) in 1st gear with the closed throttle position signal “OFF”.

Number of drive plates7

Number of driven plates7

Clearance mm (in) Standard 0.7 - 1.1 (0.028 - 0.043)

Total end play [mm (in)] 0.25 - 0.55 (0.0098 - 0.0217)

Page 801 of 3171

LOAD SENSING VALVE

BR-15

C

D

E

G

H

I

J

K

L

MA

B

BR

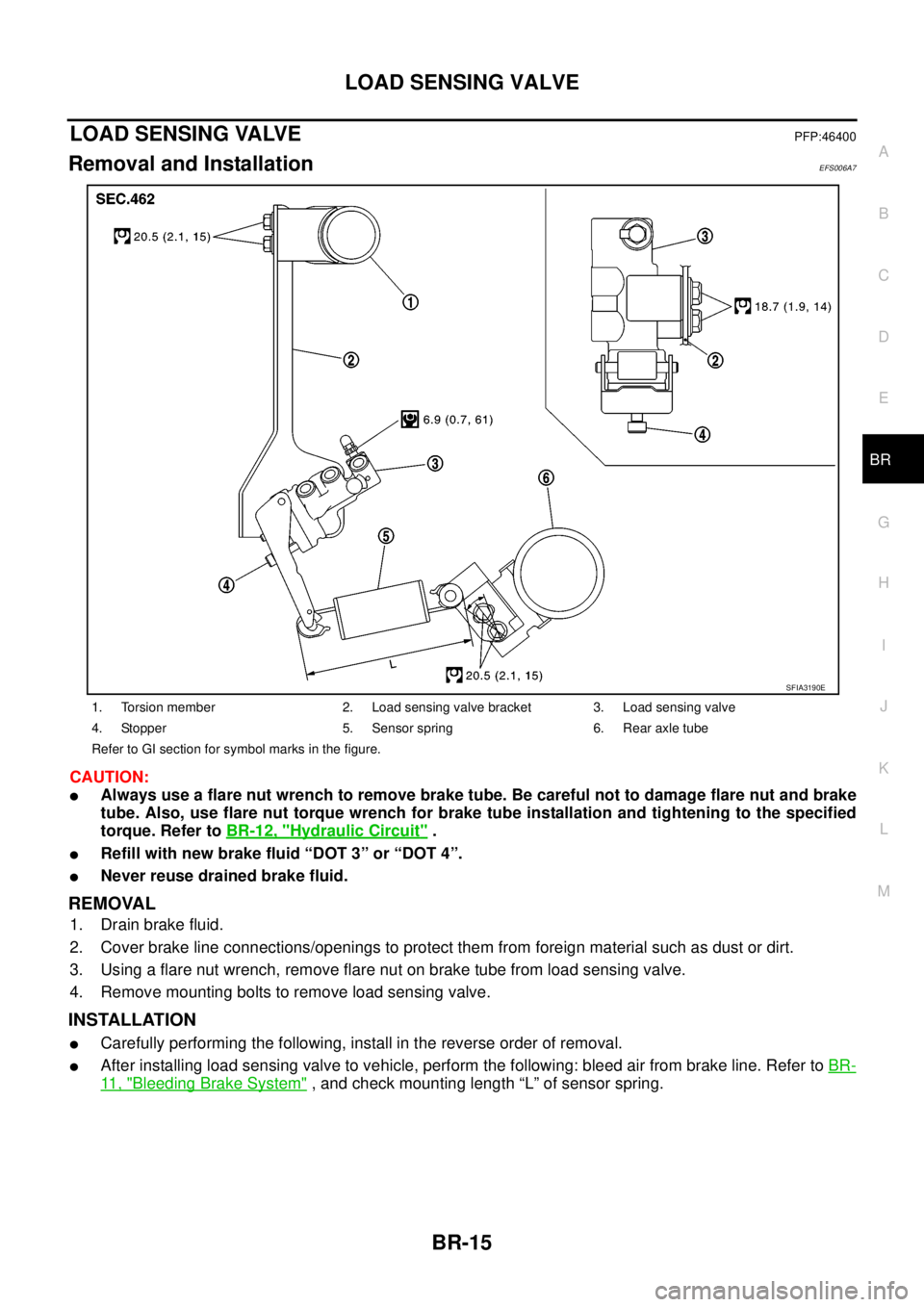

LOAD SENSING VALVEPFP:46400

Removal and InstallationEFS006A7

CAUTION:

lAlways use a flare nut wrench to remove brake tube. Be careful not to damage flare nut and brake

tube. Also, use flare nut torque wrench for brake tube installation and tightening to the specified

torque. Refer toBR-12, "

Hydraulic Circuit".

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

REMOVAL

1. Drain brake fluid.

2. Cover brake line connections/openings to protect them from foreign material such as dust or dirt.

3. Using a flare nut wrench, remove flare nut on brake tube from load sensing valve.

4. Remove mounting bolts to remove load sensing valve.

INSTALLATION

lCarefully performing the following, install in the reverse order of removal.

lAfter installing load sensing valve to vehicle, perform the following: bleed air from brake line. Refer toBR-

11 , "Bleeding Brake System", and check mounting length “L” of sensor spring.

1. Torsion member 2. Load sensing valve bracket 3. Load sensing valve

4. Stopper 5. Sensor spring 6. Rear axle tube

Refer to GI section for symbol marks in the figure.

SFIA3190E

Page 802 of 3171

BR-16

LOAD SENSING VALVE

Inspection

EFS006A8

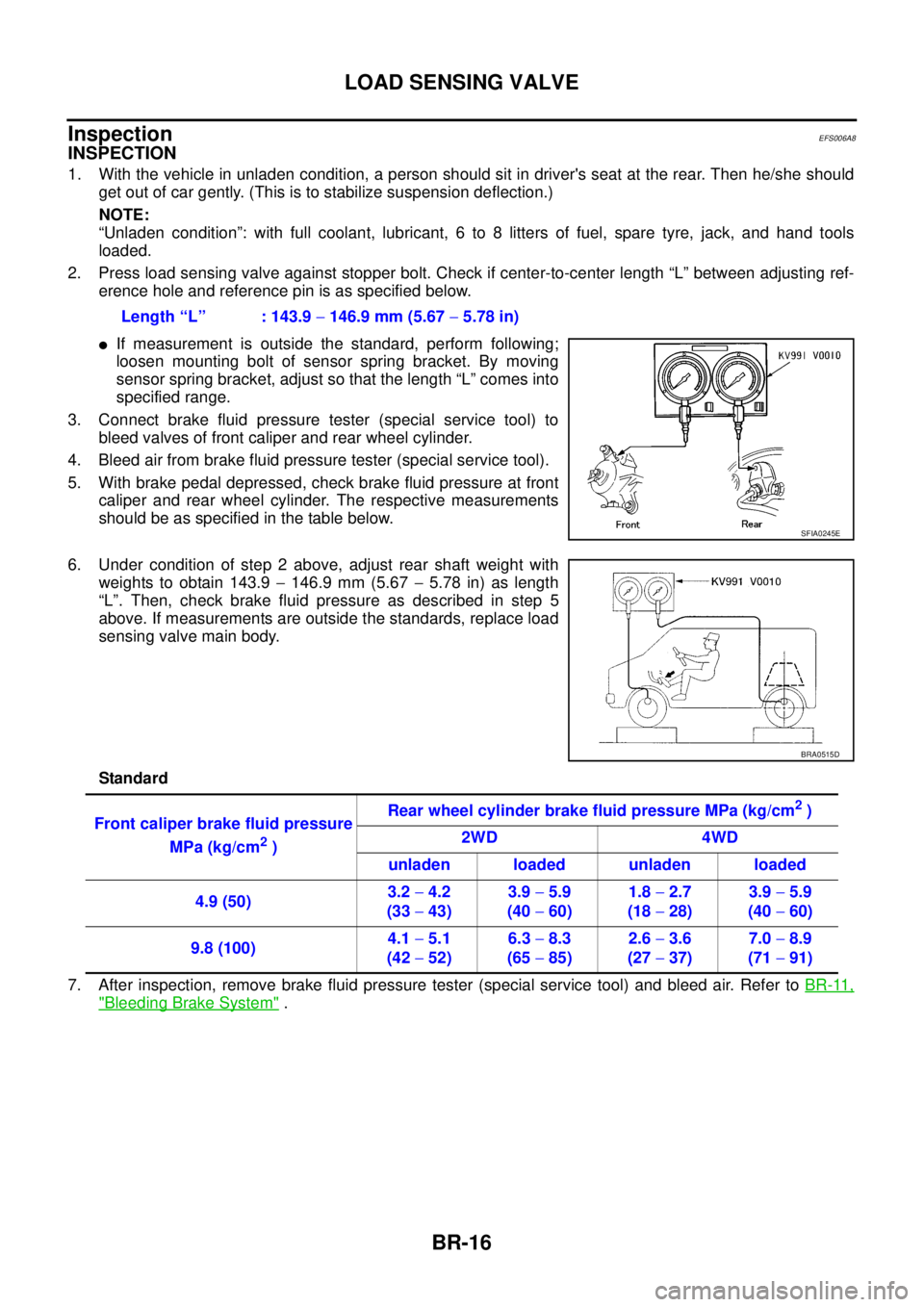

INSPECTION

1. With the vehicle in unladen condition, a person should sit in driver's seat at the rear. Then he/she should

get out of car gently. (This is to stabilize suspension deflection.)

NOTE:

“Unladen condition”: with full coolant, lubricant, 6 to 8 litters of fuel, spare tyre, jack, and hand tools

loaded.

2. Press load sensing valve against stopper bolt. Check if center-to-center length “L” between adjusting ref-

erence hole and reference pin is as specified below.

lIf measurement is outside the standard, perform following;

loosen mounting bolt of sensor spring bracket. By moving

sensor spring bracket, adjust so that the length “L” comes into

specified range.

3. Connect brake fluid pressure tester (special service tool) to

bleed valves of front caliper and rear wheel cylinder.

4. Bleed air from brake fluid pressure tester (special service tool).

5. With brake pedal depressed, check brake fluid pressure at front

caliper and rear wheel cylinder. The respective measurements

should be as specified in the table below.

6. Under condition of step 2 above, adjust rear shaft weight with

weights to obtain 143.9-146.9 mm (5.67-5.78 in) as length

“L”. Then, check brake fluid pressure as described in step 5

above. If measurements are outside the standards, replace load

sensing valve main body.

Standard

7. After inspection, remove brake fluid pressure tester (special service tool) and bleed air. Refer toBR-11,

"Bleeding Brake System". Length “L” : 143.9-146.9 mm (5.67-5.78 in)

SFIA0245E

BRA0515D

Front caliper brake fluid pressure

MPa (kg/cm

2)Rear wheel cylinder brake fluid pressure MPa (kg/cm

2)

2WD 4WD

unladen loaded unladen loaded

4.9 (50)3.2-4.2

(33-43)3.9-5.9

(40-60)1.8-2.7

(18-28)3.9-5.9

(40-60)

9.8 (100)4.1-5.1

(42-52)6.3-8.3

(65-85)2.6-3.6

(27-37)7.0-8.9

(71-91)

Page 810 of 3171

BR-24

FRONT DISC BRAKE

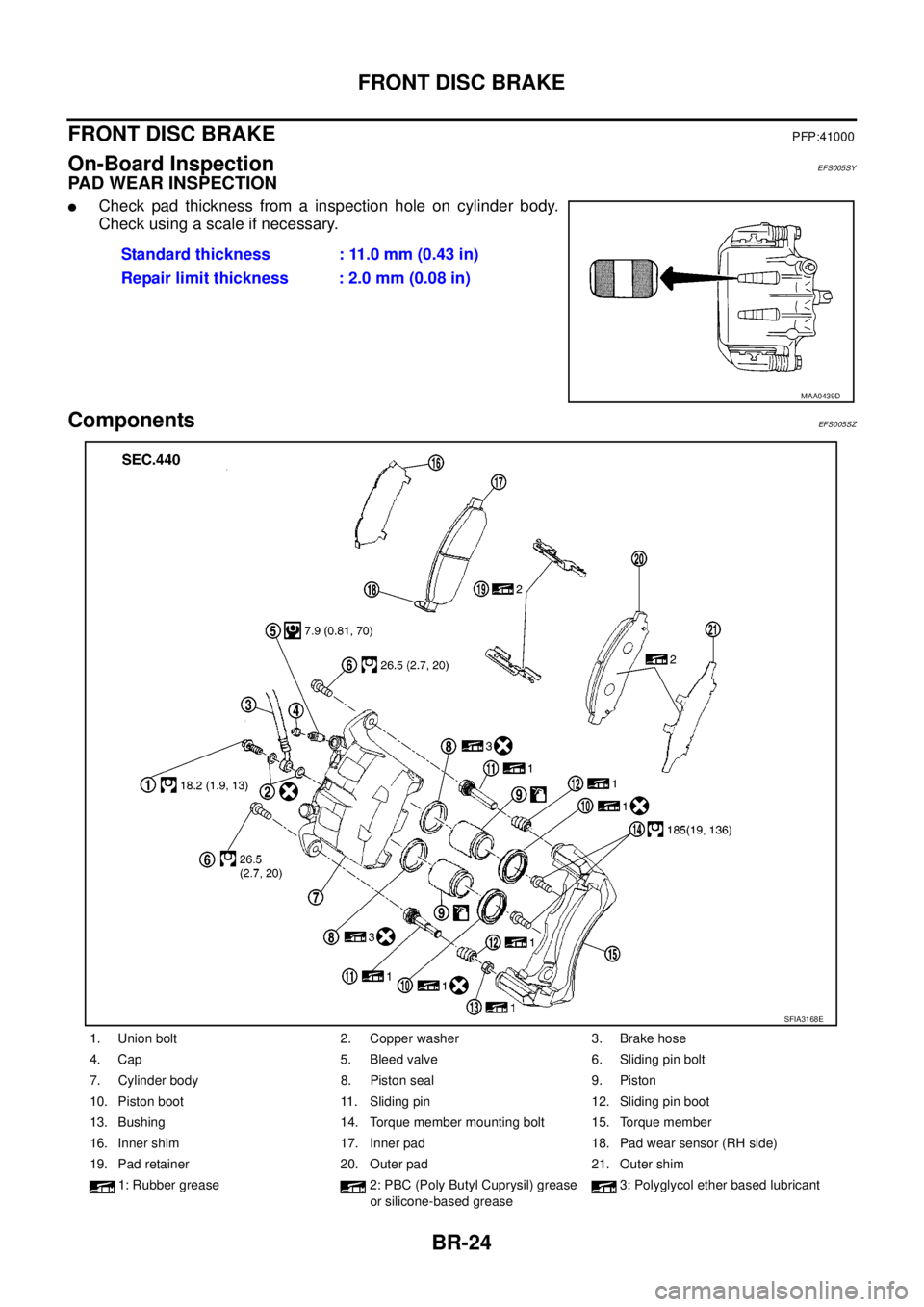

FRONT DISC BRAKE

PFP:41000

On-Board InspectionEFS005SY

PAD WEAR INSPECTION

lCheck pad thickness from a inspection hole on cylinder body.

Check using a scale if necessary.

ComponentsEFS005SZ

Standard thickness : 11.0 mm (0.43 in)

Repair limit thickness : 2.0 mm (0.08 in)

MAA0439D

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Sliding pin 12. Sliding pin boot

13. Bushing 14. Torque member mounting bolt 15. Torque member

16. Inner shim 17. Inner pad 18. Pad wear sensor (RH side)

19. Pad retainer 20. Outer pad 21. Outer shim

1: Rubber grease 2: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease3: Polyglycol ether based lubricant

SFIA3168E

Page 823 of 3171

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONBRC

A

B

BRC

BRAKE CONTROL SYSTEM

ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 3

PREPARATION ........................................................... 4

Special Service Tools (SST) ..................................... 4

SYSTEM DESCRIPTION ............................................ 5

System Diagram ....................................................... 5

Functions .................................................................. 5

Operation That Is Not “System Error” ...................... 5

Fail-Safe Function .................................................... 5

ABS, EBD SYSTEM .............................................. 5

Hydraulic Circuit Diagram ........................................ 6

CAN COMMUNICATION ............................................ 7

System Description .................................................. 7

TROUBLE DIAGNOSIS .............................................. 8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ....................................................... 8

INTRODUCTION ................................................... 8

DIAGNOSIS FLOWCHART .................................. 9

ASKING COMPLAINTS ...................................... 10

EXAMPLE OF DIAGNOSIS SHEET ................... 10

Component Parts Location ...................................... 11

Schematic — ABS — ............................................. 12

Wiring Diagram — ABS — ..................................... 13

CONSULT- II Functions .......................................... 17

CONSULT-II MAIN FUNCTION ........................... 17

CONSULT-II BASIC OPERATION PROCEDURE

... 17

Self-Diagnosis ........................................................ 18

OPERATION PROCEDURE ............................... 18

ERASE MEMORY ............................................... 18

DISPLAY ITEM LIST ........................................... 18

Data Monitor ........................................................... 20

OPERATION PROCEDURE ............................... 20

DISPLAY ITEM LIST ........................................... 20Active Test .............................................................. 21

OPERATION PROCEDURE ................................ 21

SOLENOID VALVE .............................................. 22

ABS MOTOR ....................................................... 22

For Fast and Accurate Diagnosis ........................... 23

PRECAUTIONS FOR DIAGNOSIS ..................... 23

Basic Inspection ..................................................... 23

BASIC INSPECTION 1 BRAKE FLUID LEVEL,

LEAKS, AND BRAKE PADS ................................ 23

BASIC INSPECTION 2 POWER SYSTEM TER-

MINAL LOOSENESS AND BATTERY INSPEC-

TION .................................................................... 23

BASIC INSPECTION 3 ABS WARNING LAMP

AND BRAKE WARNING LAMP INSPECTION .... 24

Inspection 1 Wheel Sensor System ........................ 24

Inspection 2 ABS Actuator and Electric Unit (Control

Unit) ........................................................................ 26

Inspection 3 ABS Actuator Relay or ABS Motor

Relay Circuit ........................................................... 26

Inspection 4 CAN Communication Circuit .............. 28

Inspection 5 ABS Actuator and Electric Unit (Control

Unit) Power Supply and Ground Circuit .................. 28

Inspection 6 Brake Fluid Level Switch Circuit ......... 30

Inspection 7 Parking Brake Switch Circuit .............. 32

Inspection 8 Warning lamp system ......................... 33

Symptom 1: Excessive ABS Function Operation

Frequency ............................................................... 33

Symptom 2: Unexpected Pedal Reaction ............... 34

Symptom 3: The Stopping Distance Is Long .......... 34

Symptom 4: ABS Function Does Not Operate ....... 35

Symptom 5: Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 35

Symptom 6: ABS Warning Lamp Indication Is Not

Normal .................................................................... 35

WHEEL SENSORS ................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Page 826 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST NISSAN NAVARA 2005 Repair Repair Manual BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST](/img/5/57362/w960_57362-825.png)

BRC-4

[ABS]

PREPARATION

PREPARATION

PFP:00002

Special Service Tools (SST)EFS005TI

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

a:10 mm (0.39 in)Installing brake tube and hose

ST30720000

Drift

a: 77 mm (0.03 in) dia.

b: 55 mm (2.17 in) dia.

Installation rear sensor rotor ST27863000

Drift

a: 75 mm (2.95 in) dia.

b: 62 mm (2.44 in) dia.

KV40104710

Drift

a: 76 mm (2.99 in) dia.

b: 68.5 mm (2.697 in) dia.

NT406

ZZA0701D

ZZA0832D

ZZA0832D

Page 840 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch O NISSAN NAVARA 2005 Repair Repair Manual BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch O](/img/5/57362/w960_57362-839.png)

BRC-18

[ABS]

TROUBLE DIAGNOSIS

Self-Diagnosis

EFS005TU

OPERATION PROCEDURE

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping vehicle, with engine running, touch “START (NISSAN BASED VHCL)”, “ABS”, “SELF-DIAG

RESULTS” in order on CONSULT-II screen.

CAUTION:

If “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turn on the

ignition switch, “ABS” might not be displayed in the “SELECT SYSTEM” screen. In this case,

repeat the operation from step 1.

6. The self-diagnostic results are displayed. (Touch “PRINT” to print out self-diagnostic results, If necessary.)

lCheck ABS warning lamp if “NO FAILURE” is displayed.

7. Perform the appropriate inspection from display item list, and repair or replace the malfunctioning compo-

nent. Refer toBRC-18, "

Display Item List".

8. Start engine and drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

When the wheel sensor malfunctions, after inspecting the wheel sensor system, the ABS warning

lamp and brake warning lamp will not turn off even when the system is normal unless the vehicle

is driving at 30 km/h (19MPH) or more for approximately 1 minute.

ERASE MEMORY

1. Turn ignition switch OFF.

2. Start engine and touch “START (NISSAN BASED VHCL)”, “ABS”, “SELF-DIAG RESULTS”, “ERASE

MEMORY” in order on CONSULT-II screen to erase the error memory.

If “ABS” is not indicated, go toGI-50, "

CONSULT-II Data Link Connector (DLC) Circuit".

CAUTION:

If the error memory is not erased, re-perform the operation from step 4.

3. Perform self-diagnosis again, and make sure that diagnostic memory is erased.

4. Drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute as the final inspection, and make

sure that the ABS warning lamp turn off.

DISPLAY ITEM LIST

Self-diagnostic item Malfunction detecting condition Check system

RR RH SENSOR-1 Circuit of rear RH wheel sensor is open.

BRC-24, "

Inspection 1

Wheel Sensor System"

(Note 1) RR LH SENSOR-1 Circuit of rear LH wheel sensor is open.

FR RH SENSOR-1 Circuit of front RH wheel sensor is open.

FR LH SENSOR-1 Circuit of front LH wheel sensor is open.

RR RH SENSOR-2When the circuit in the rear RH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

RR LH SENSOR-2When the circuit in the rear LH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR RH SENSOR-2When the circuit in the front RH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.

FR LH SENSOR-2When the circuit in the front LH wheel sensor is short-circuited. Or

when the sensor power voltage is outside the standard. When the

distance between the wheel sensor and sensor rotor is too large

and the sensor pulse cannot be recognized by the control unit.