differential NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2289 of 3171

MA-14

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

PFP:00000

Fluids and LubricantsELS001JA

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Genuine NISSAN Anti-freeze Coolant (L250) or equivalent in its quality, in order to avoid possible aluminum corrosion within the

engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRON

™III/MER-

CON™ Automatic Transmission Fluid.

*5:Using automatic transmission fluid other than Genuine NISSAN ATF Matic Fluid J will cause deterioration in driveability

and automatic transmission durability, and may damage the automatic transmission, which is not covered by the warranty.

*6: DEXRON™III type ATF can be used.

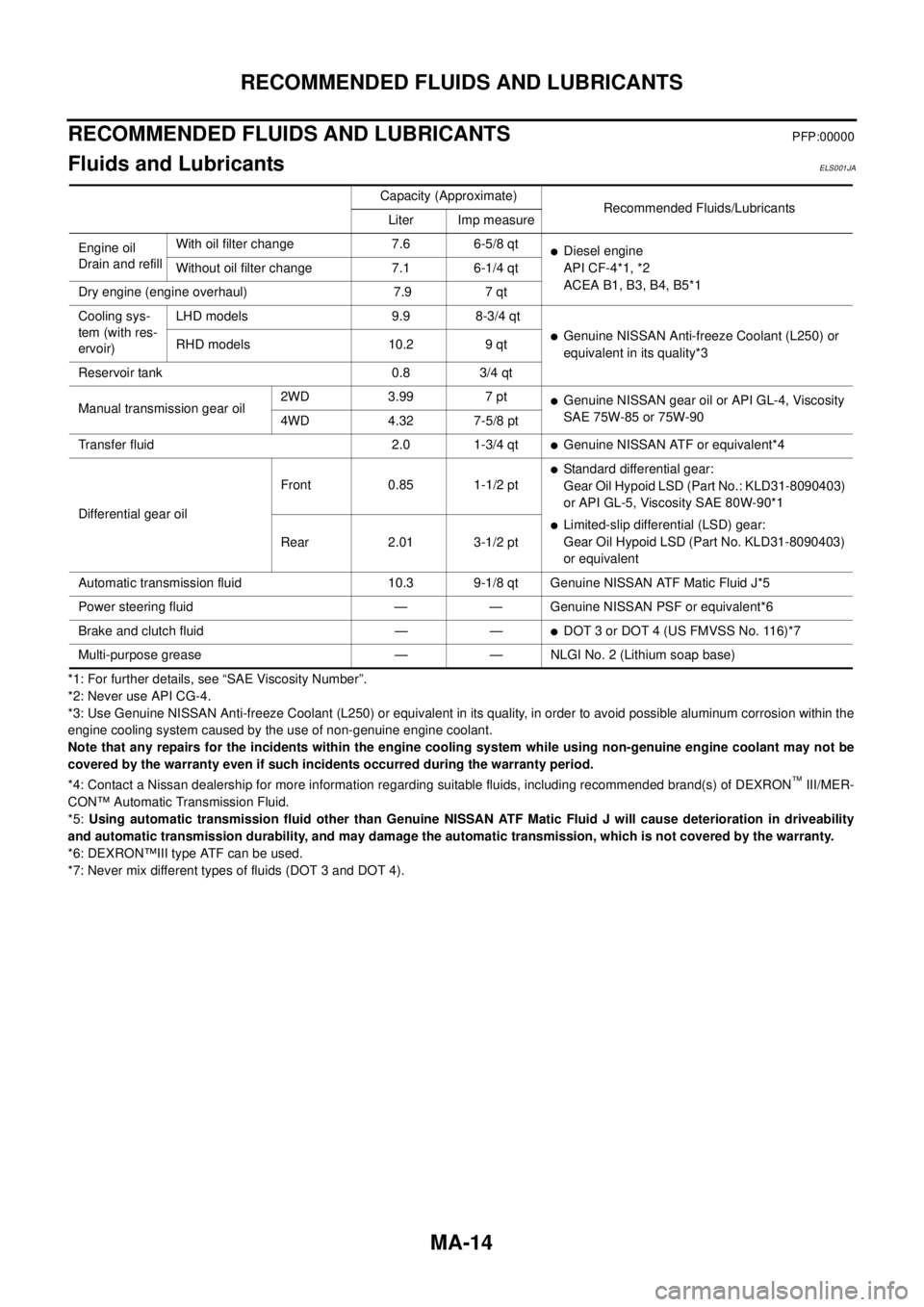

*7: Never mix different types of fluids (DOT 3 and DOT 4).Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil

Drain and refillWith oil filter change 7.6 6-5/8 qt

lDiesel engine

API CF-4*1, *2

ACEA B1, B3, B4, B5*1 Without oil filter change 7.1 6-1/4 qt

Dry engine (engine overhaul) 7.9 7 qt

Cooling sys-

tem (with res-

ervoir)LHD models 9.9 8-3/4 qt

lGenuine NISSAN Anti-freeze Coolant (L250) or

equivalent in its quality*3 RHD models 10.2 9 qt

Reservoir tank 0.8 3/4 qt

Manual transmission gear oil2WD 3.99 7 pt

lGenuine NISSAN gear oil or API GL-4, Viscosity

SAE 75W-85 or 75W-90

4WD 4.32 7-5/8 pt

Transfer fluid 2.0 1-3/4 qt

lGenuine NISSAN ATF or equivalent*4

Differential gear oilFront 0.85 1-1/2 pt

lStandard differential gear:

Gear Oil Hypoid LSD (Part No.: KLD31-8090403)

or API GL-5, Viscosity SAE 80W-90*1

lLimited-slip differential (LSD) gear:

Gear Oil Hypoid LSD (Part No. KLD31-8090403)

or equivalent Rear 2.01 3-1/2 pt

Automatic transmission fluid 10.3 9-1/8 qt Genuine NISSAN ATF Matic Fluid J*5

Power steering fluid — — Genuine NISSAN PSF or equivalent*6

Brake and clutch fluid — —

lDOT 3 or DOT 4 (US FMVSS No. 116)*7

Multi-purpose grease — — NLGI No. 2 (Lithium soap base)

Page 2290 of 3171

RECOMMENDED FLUIDS AND LUBRICANTS

MA-15

C

D

E

F

G

H

I

J

K

MA

B

MA

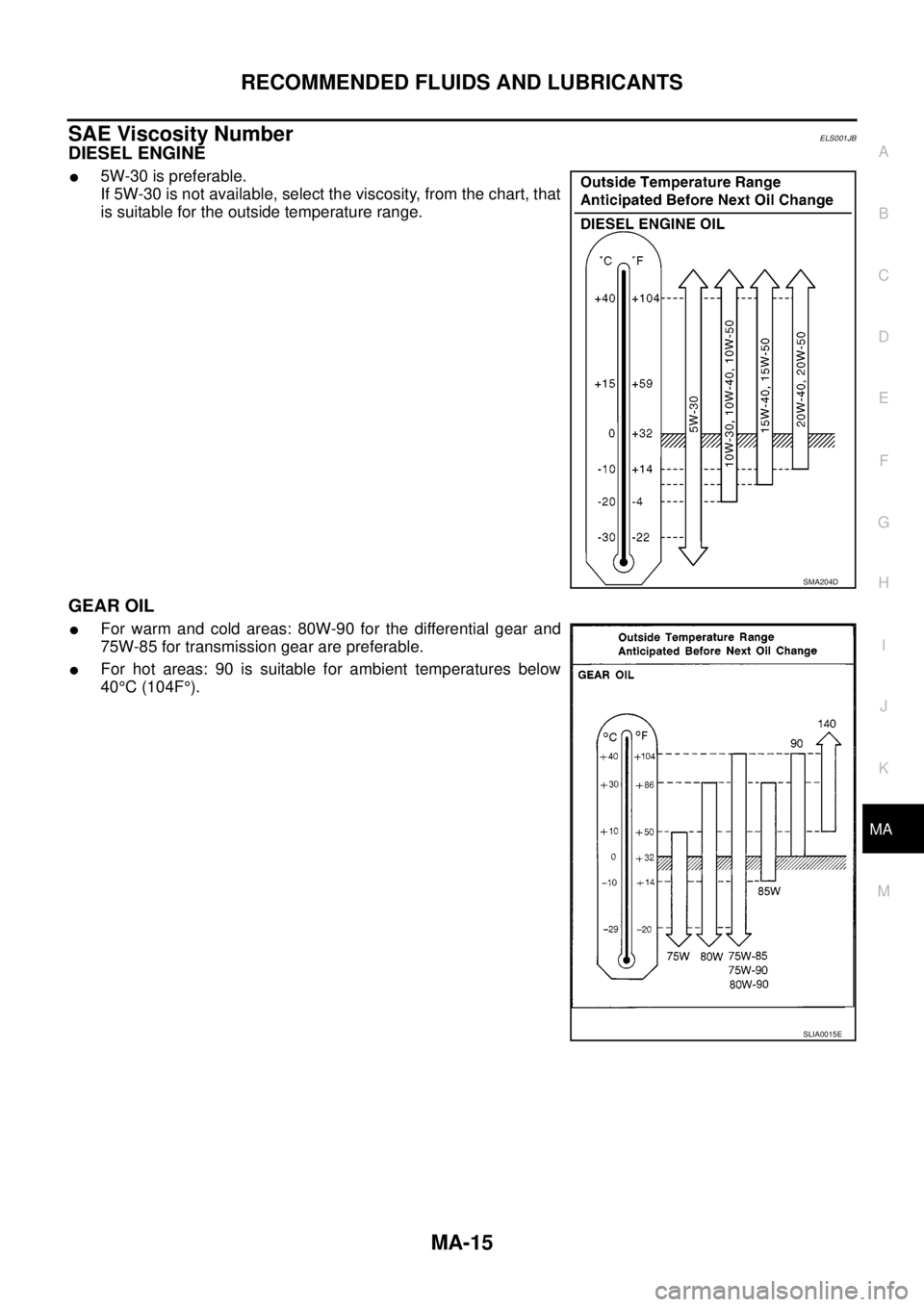

SAE Viscosity NumberELS001JB

DIESEL ENGINE

l5W-30 is preferable.

If 5W-30 is not available, select the viscosity, from the chart, that

is suitable for the outside temperature range.

GEAR OIL

lFor warm and cold areas: 80W-90 for the differential gear and

75W-85 for transmission gear are preferable.

lFor hot areas: 90 is suitable for ambient temperatures below

40°C (104F°).

SMA204D

SLIA0015E

Page 2307 of 3171

MA-32

CHASSIS AND BODY MAINTENANCE

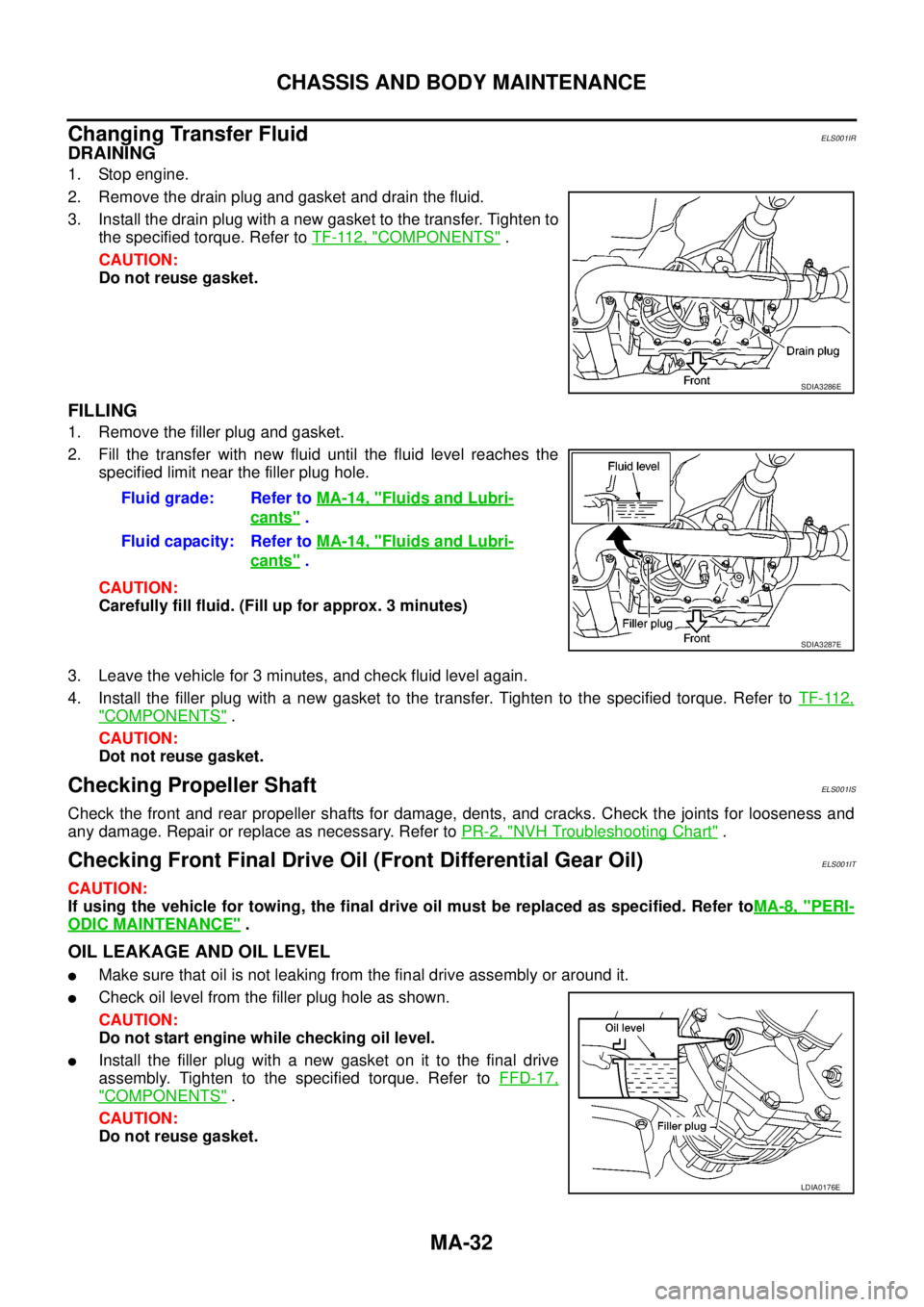

Changing Transfer Fluid

ELS001IR

DRAINING

1. Stop engine.

2. Remove the drain plug and gasket and drain the fluid.

3. Install the drain plug with a new gasket to the transfer. Tighten to

the specified torque. Refer toTF-112, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket.

2. Fill the transfer with new fluid until the fluid level reaches the

specified limit near the filler plug hole.

CAUTION:

Carefully fill fluid. (Fill up for approx. 3 minutes)

3. Leave the vehicle for 3 minutes, and check fluid level again.

4. Install the filler plug with a new gasket to the transfer. Tighten to the specified torque. Refer toTF-112,

"COMPONENTS".

CAUTION:

Dot not reuse gasket.

Checking Propeller ShaftELS001IS

Check the front and rear propeller shafts for damage, dents, and cracks. Check the joints for looseness and

any damage. Repair or replace as necessary. Refer toPR-2, "

NVH Troubleshooting Chart".

Checking Front Final Drive Oil (Front Differential Gear Oil)ELS001IT

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from the final drive assembly or around it.

lCheck oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

lInstall the filler plug with a new gasket on it to the final drive

assembly. Tighten to the specified torque. Refer toFFD-17,

"COMPONENTS".

CAUTION:

Do not reuse gasket.

SDIA3286E

Fluid grade: Refer toMA-14, "Fluids and Lubri-

cants".

Fluid capacity: Refer toMA-14, "

Fluids and Lubri-

cants".

SDIA3287E

LDIA0176E

Page 2308 of 3171

CHASSIS AND BODY MAINTENANCE

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

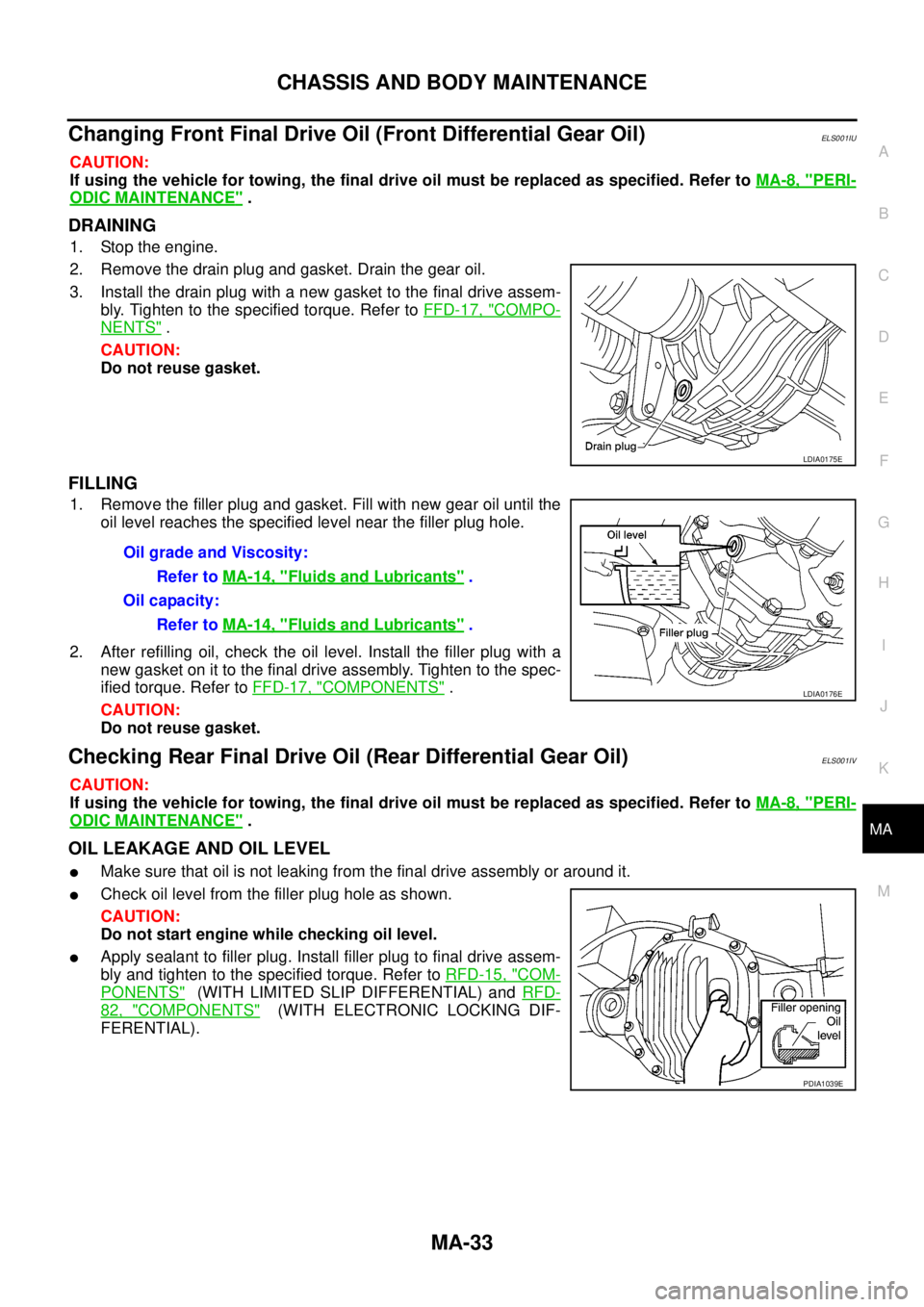

Changing Front Final Drive Oil (Front Differential Gear Oil)ELS001IU

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Install the drain plug with a new gasket to the final drive assem-

bly. Tighten to the specified torque. Refer toFFD-17, "

COMPO-

NENTS".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket. Fill with new gear oil until the

oil level reaches the specified level near the filler plug hole.

2. After refilling oil, check the oil level. Install the filler plug with a

new gasket on it to the final drive assembly. Tighten to the spec-

ified torque. Refer toFFD-17, "

COMPONENTS".

CAUTION:

Do not reuse gasket.

Checking Rear Final Drive Oil (Rear Differential Gear Oil)ELS001IV

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

OIL LEAKAGE AND OIL LEVEL

lMake sure that oil is not leaking from the final drive assembly or around it.

lCheck oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

lApply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-15, "

COM-

PONENTS"(WITH LIMITED SLIP DIFFERENTIAL) andRFD-

82, "COMPONENTS"(WITH ELECTRONIC LOCKING DIF-

FERENTIAL).

LDIA0175E

OilgradeandViscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Refer toMA-14, "

Fluids and Lubricants".

LDIA0176E

PDIA1039E

Page 2309 of 3171

MA-34

CHASSIS AND BODY MAINTENANCE

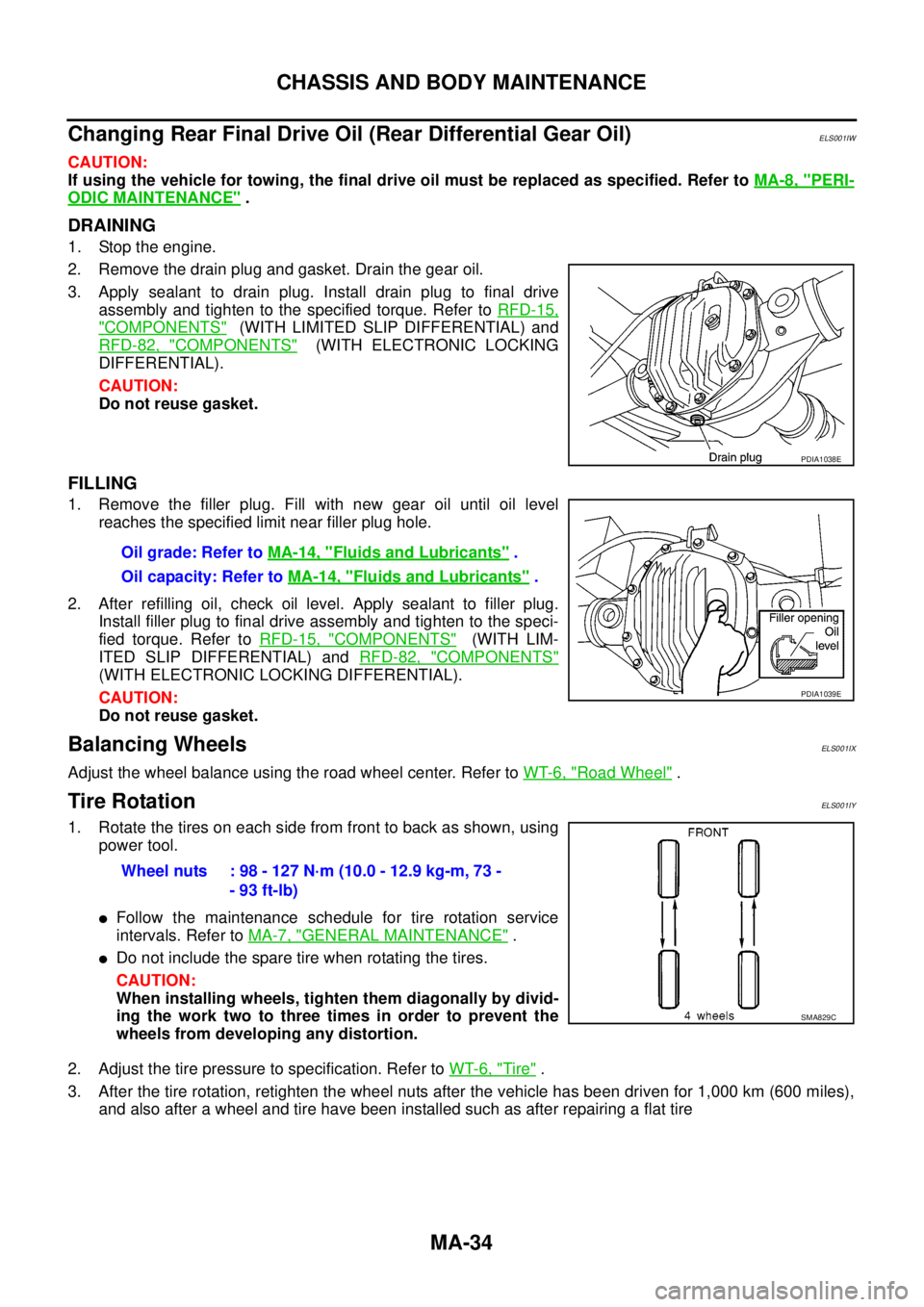

Changing Rear Final Drive Oil (Rear Differential Gear Oil)

ELS001IW

CAUTION:

If using the vehicle for towing, the final drive oil must be replaced as specified. Refer toMA-8, "

PERI-

ODIC MAINTENANCE".

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket. Drain the gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS"(WITH LIMITED SLIP DIFFERENTIAL) and

RFD-82, "

COMPONENTS"(WITH ELECTRONIC LOCKING

DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug. Fill with new gear oil until oil level

reaches the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS"(WITH LIM-

ITED SLIP DIFFERENTIAL) andRFD-82, "

COMPONENTS"

(WITH ELECTRONIC LOCKING DIFFERENTIAL).

CAUTION:

Do not reuse gasket.

Balancing WheelsELS001IX

Adjust the wheel balance using the road wheel center. Refer toWT-6, "Road Wheel".

Tire RotationELS001IY

1. Rotate the tires on each side from front to back as shown, using

power tool.

lFollow the maintenance schedule for tire rotation service

intervals. Refer toMA-7, "

GENERAL MAINTENANCE".

lDo not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by divid-

ing the work two to three times in order to prevent the

wheels from developing any distortion.

2. Adjust the tire pressure to specification. Refer toWT-6, "

Tire".

3. After the tire rotation, retighten the wheel nuts after the vehicle has been driven for 1,000 km (600 miles),

and also after a wheel and tire have been installed such as after repairing a flat tire

PDIA1038E

Oil grade: Refer toMA-14, "Fluids and Lubricants".

Oil capacity: Refer toMA-14, "

Fluids and Lubricants".

PDIA1039E

Wheel nuts : 98 - 127 N·m (10.0 - 12.9 kg-m, 73 -

- 93 ft-lb)

SMA829C

Page 2617 of 3171

PR-2

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

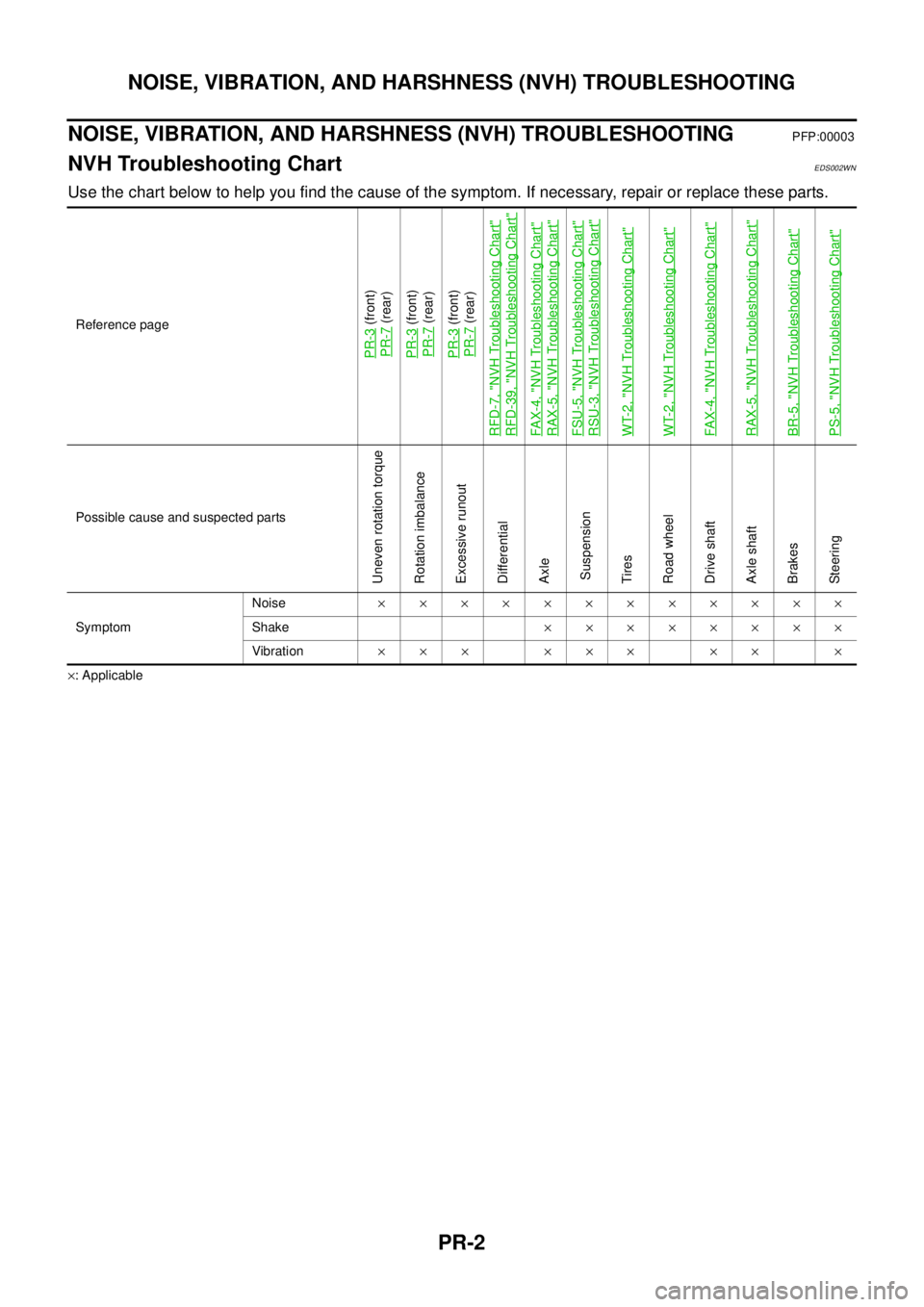

NVH Troubleshooting ChartEDS002WN

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PR-3

(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

PR-3(front)

PR-7(rear)

RFD-7, "

NVH Troubleshooting Chart

"

RFD-39, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

FA X -4 , "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive runout

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Axle shaft

Brakes

Steering

SymptomNoise´´´´´´´´´´´´

Shake´´´´´´´´

Vibration´´´ ´´´ ´´ ´

Page 2632 of 3171

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

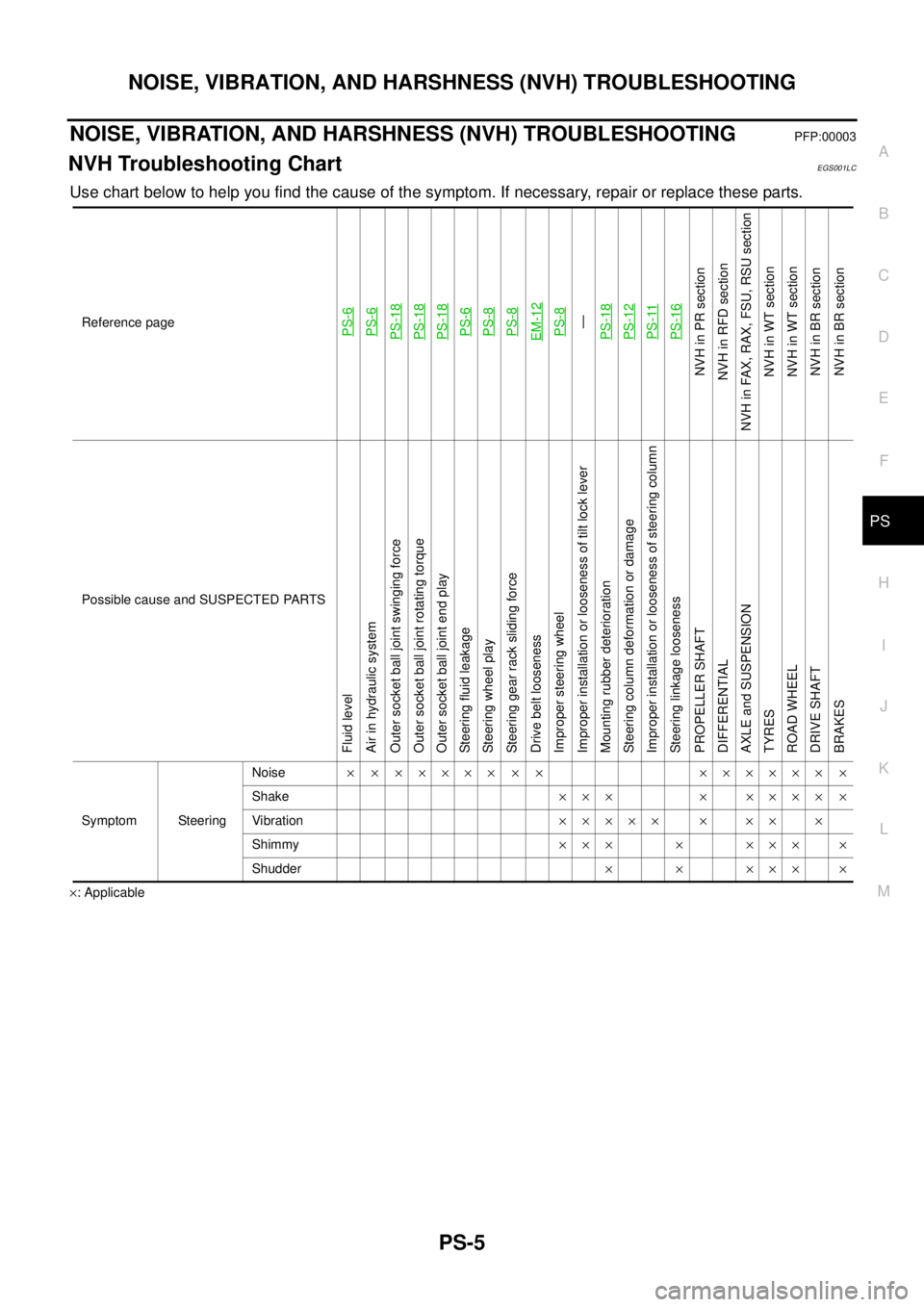

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEGS001LC

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PS-6PS-6PS-18PS-18PS-18PS-6PS-8PS-8EM-12PS-8—

PS-18PS-12PS-11PS-16

NVHinPRsection

NVH in RFD section

NVH in FAX, RAX, FSU, RSU section

NVH in WT section

NVH in WT section

NVHinBRsection

NVHinBRsection

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TYRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom SteeringNoise´ ´ ´´´´´ ´ ´ ´´´´´´ ´

Shake´´´ ´ ´´´´ ´

Vibration´´´´´ ´ ´´ ´

Shimmy´´´ ´ ´´´ ´

Shudder´ ´ ´´´ ´

Page 2672 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a NISSAN NAVARA 2005 Repair Repair Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a](/img/5/57362/w960_57362-2671.png)

AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

Axle Shaft Retainer

lCheck for deformation and cracks. Replace if necessary.

Rear Axle Case

lCheck the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

When installing pay attention to following points:

lInstall a new shaft guide and a new oil seal into the rear axle case.

CAUTION:

lDo not reuse the axle oil seal. The axle oil seal must be replaced every time the axle shaft assem-

bly is removed from the axle shaft housing.

lWhen installing oil seals, apply multi-purpsose grease to oil seal lips.

lInstall four new lock nuts to secure the axle shaft assembly to the rear axle case, and tighten lock nuts to

the specified torque. Refer toRAX-7, "

Removal and Installation".

lReinstall the rear brake drum. Refer toBR-31, "Removal and Installation of Drum Brake Assembly".

lAdjust the differential gear oil level.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 without LD.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 with LD.

lReinstall the wheel. Refer toWT-5, "Rotation".

DISASSEMBLY

1. Remove the ABS sensor rotor. Refer toBRC-39, "SENSOR ROTOR".

2. Remove the snap ring from the axle shaft using a suitable snap ring pliers.

3. Secure the axle shaft in a suitable vise as shown, and use a

brass hammer to remove studs (4) from the axle shaft retainer.

CAUTION:

lMount the axle shaft using a soft jaw vise to avoid dam-

aging the axle shaft retainer.

MDIB9051E

Page 2704 of 3171

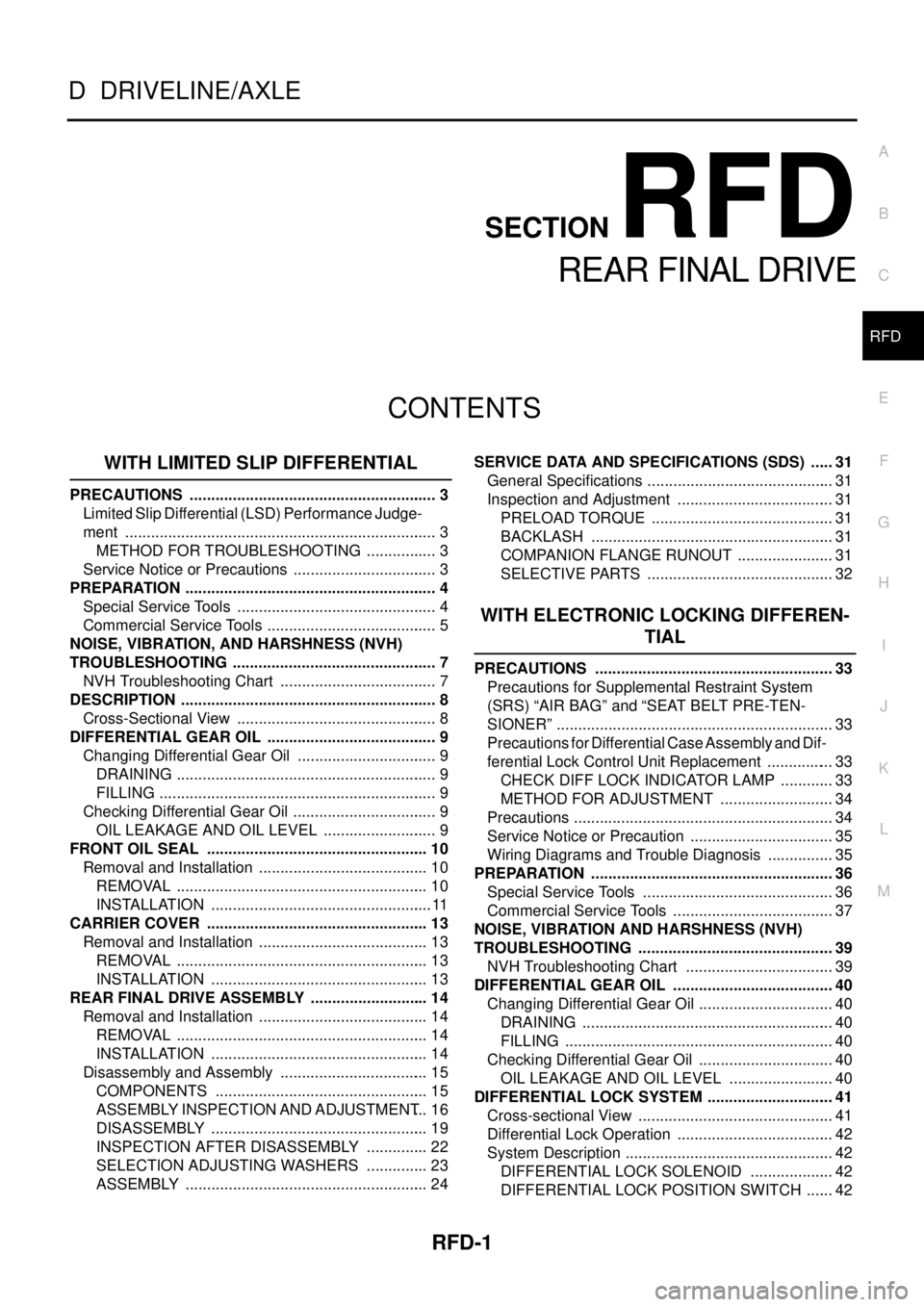

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONRFD

A

B

RFD

REAR FINAL DRIVE

WITH LIMITED SLIP DIFFERENTIAL

PRECAUTIONS .......................................................... 3

Limited Slip Differential (LSD) Performance Judge-

ment ......................................................................... 3

METHOD FOR TROUBLESHOOTING ................. 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

CARRIER COVER .................................................... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

REAR FINAL DRIVE ASSEMBLY ............................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Disassembly and Assembly ................................... 15

COMPONENTS .................................................. 15

ASSEMBLY INSPECTION AND ADJUSTMENT... 16

DISASSEMBLY ................................................... 19

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTION ADJUSTING WASHERS ............... 23

ASSEMBLY ......................................................... 24SERVICE DATA AND SPECIFICATIONS (SDS) ...... 31

General Specifications ............................................ 31

Inspection and Adjustment ..................................... 31

PRELOAD TORQUE ........................................... 31

BACKLASH ......................................................... 31

COMPANION FLANGE RUNOUT ....................... 31

SELECTIVE PARTS ............................................ 32

WITH ELECTRONIC LOCKING DIFFEREN-

TIAL

PRECAUTIONS ........................................................ 33

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................. 33

Precautions for Differential Case Assembly and Dif-

ferential Lock Control Unit Replacement ................ 33

CHECK DIFF LOCK INDICATOR LAMP ............. 33

METHOD FOR ADJUSTMENT ........................... 34

Precautions ............................................................. 34

Service Notice or Precaution .................................. 35

Wiring Diagrams and Trouble Diagnosis ................ 35

PREPARATION ......................................................... 36

Special Service Tools ............................................. 36

Commercial Service Tools ...................................... 37

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 39

NVH Troubleshooting Chart ................................... 39

DIFFERENTIAL GEAR OIL ...................................... 40

Changing Differential Gear Oil ................................ 40

DRAINING ........................................................... 40

FILLING ............................................................... 40

Checking Differential Gear Oil ................................ 40

OIL LEAKAGE AND OIL LEVEL ......................... 40

DIFFERENTIAL LOCK SYSTEM .............................. 41

Cross-sectional View .............................................. 41

Differential Lock Operation ..................................... 42

System Description ................................................. 42

DIFFERENTIAL LOCK SOLENOID .................... 42

DIFFERENTIAL LOCK POSITION SWITCH ....... 42

Page 2705 of 3171

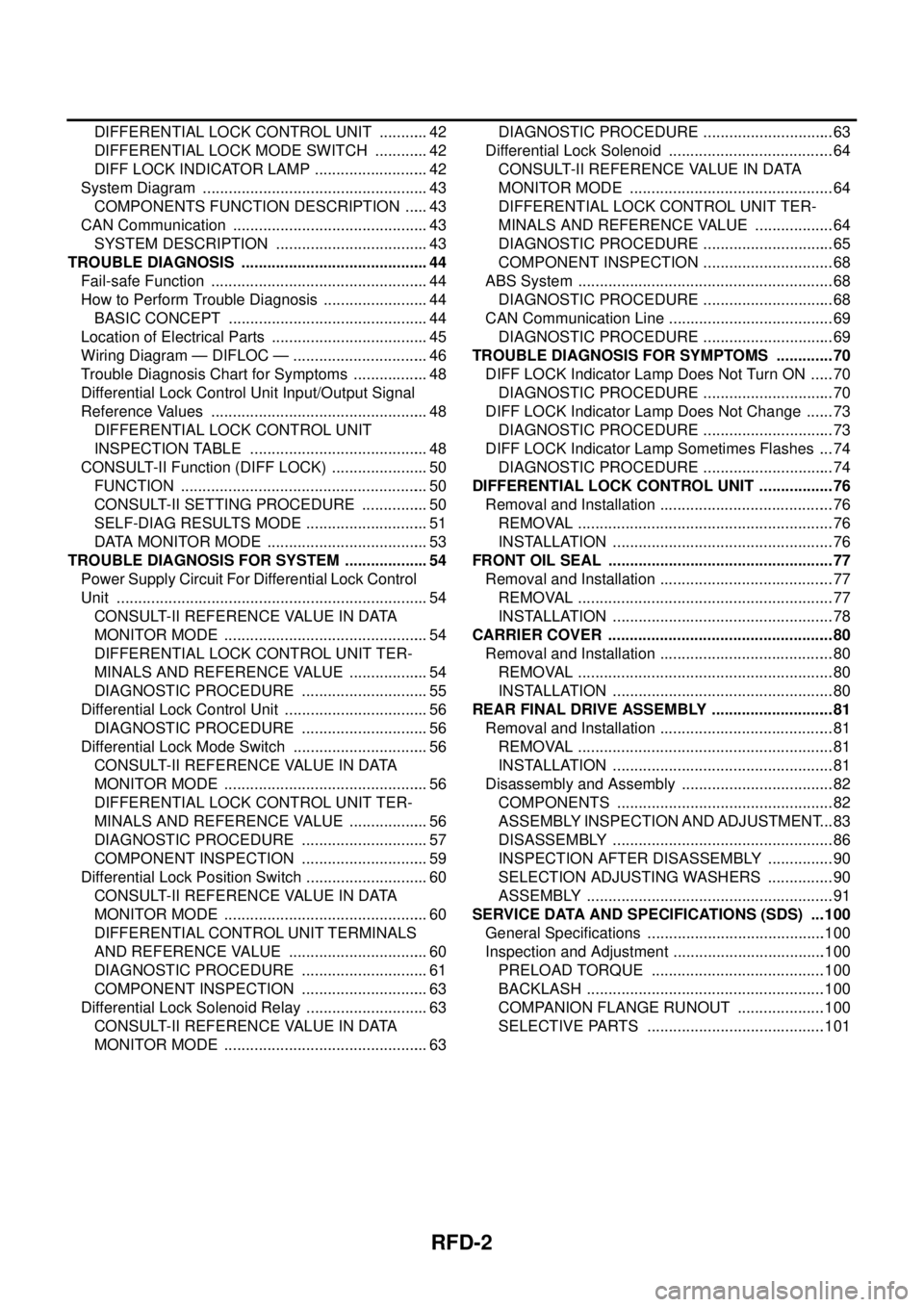

RFD-2

DIFFERENTIAL LOCK CONTROL UNIT ............ 42

DIFFERENTIAL LOCK MODE SWITCH ............. 42

DIFF LOCK INDICATOR LAMP ........................... 42

System Diagram ..................................................... 43

COMPONENTS FUNCTION DESCRIPTION ...... 43

CAN Communication .............................................. 43

SYSTEM DESCRIPTION .................................... 43

TROUBLE DIAGNOSIS ............................................ 44

Fail-safe Function ................................................... 44

How to Perform Trouble Diagnosis ......................... 44

BASIC CONCEPT ............................................... 44

Location of Electrical Parts ..................................... 45

Wiring Diagram — DIFLOC — ................................ 46

Trouble Diagnosis Chart for Symptoms .................. 48

Differential Lock Control Unit Input/Output Signal

Reference Values ................................................... 48

DIFFERENTIAL LOCK CONTROL UNIT

INSPECTION TABLE .......................................... 48

CONSULT-II Function (DIFF LOCK) ....................... 50

FUNCTION .......................................................... 50

CONSULT-II SETTING PROCEDURE ................ 50

SELF-DIAG RESULTS MODE ............................. 51

DATA MONITOR MODE ...................................... 53

TROUBLE DIAGNOSIS FOR SYSTEM .................... 54

Power Supply Circuit For Differential Lock Control

Unit ......................................................................... 54

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 54

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 54

DIAGNOSTIC PROCEDURE .............................. 55

Differential Lock Control Unit .................................. 56

DIAGNOSTIC PROCEDURE .............................. 56

Differential Lock Mode Switch ................................ 56

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 56

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 56

DIAGNOSTIC PROCEDURE .............................. 57

COMPONENT INSPECTION .............................. 59

Differential Lock Position Switch ............................. 60

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 60

DIFFERENTIAL CONTROL UNIT TERMINALS

AND REFERENCE VALUE ................................. 60

DIAGNOSTIC PROCEDURE .............................. 61

COMPONENT INSPECTION .............................. 63

Differential Lock Solenoid Relay ............................. 63

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 63DIAGNOSTIC PROCEDURE ............................... 63

Differential Lock Solenoid ....................................... 64

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 64

DIFFERENTIAL LOCK CONTROL UNIT TER-

MINALS AND REFERENCE VALUE ................... 64

DIAGNOSTIC PROCEDURE ............................... 65

COMPONENT INSPECTION ............................... 68

ABS System ............................................................ 68

DIAGNOSTIC PROCEDURE ............................... 68

CAN Communication Line ....................................... 69

DIAGNOSTIC PROCEDURE ............................... 69

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 70

DIFF LOCK Indicator Lamp Does Not Turn ON ...... 70

DIAGNOSTIC PROCEDURE ............................... 70

DIFF LOCK Indicator Lamp Does Not Change ....... 73

DIAGNOSTIC PROCEDURE ............................... 73

DIFF LOCK Indicator Lamp Sometimes Flashes .... 74

DIAGNOSTIC PROCEDURE ............................... 74

DIFFERENTIAL LOCK CONTROL UNIT .................. 76

Removal and Installation ......................................... 76

REMOVAL ............................................................ 76

INSTALLATION .................................................... 76

FRONT OIL SEAL ..................................................... 77

Removal and Installation ......................................... 77

REMOVAL ............................................................ 77

INSTALLATION .................................................... 78

CARRIER COVER ..................................................... 80

Removal and Installation ......................................... 80

REMOVAL ............................................................ 80

INSTALLATION .................................................... 80

REAR FINAL DRIVE ASSEMBLY ............................. 81

Removal and Installation ......................................... 81

REMOVAL ............................................................ 81

INSTALLATION .................................................... 81

Disassembly and Assembly .................................... 82

COMPONENTS ................................................... 82

ASSEMBLY INSPECTION AND ADJUSTMENT...83

DISASSEMBLY .................................................... 86

INSPECTION AFTER DISASSEMBLY ................ 90

SELECTION ADJUSTING WASHERS ................ 90

ASSEMBLY .......................................................... 91

SERVICE DATA AND SPECIFICATIONS (SDS) ....100

General Specifications ..........................................100

Inspection and Adjustment ....................................100

PRELOAD TORQUE .........................................100

BACKLASH ........................................................100

COMPANION FLANGE RUNOUT .....................100

SELECTIVE PARTS ..........................................101