differential NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1559 of 3171

SIDE OIL SEAL

FFD-13

C

E

F

G

H

I

J

K

L

MA

B

FFD

SIDE OIL SEALPFP:33142

Removal and InstallationEDS00354

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

CAUTION:

Do not pull on the ABS sensor harness.

4. Support the lower link using a suitable jack.

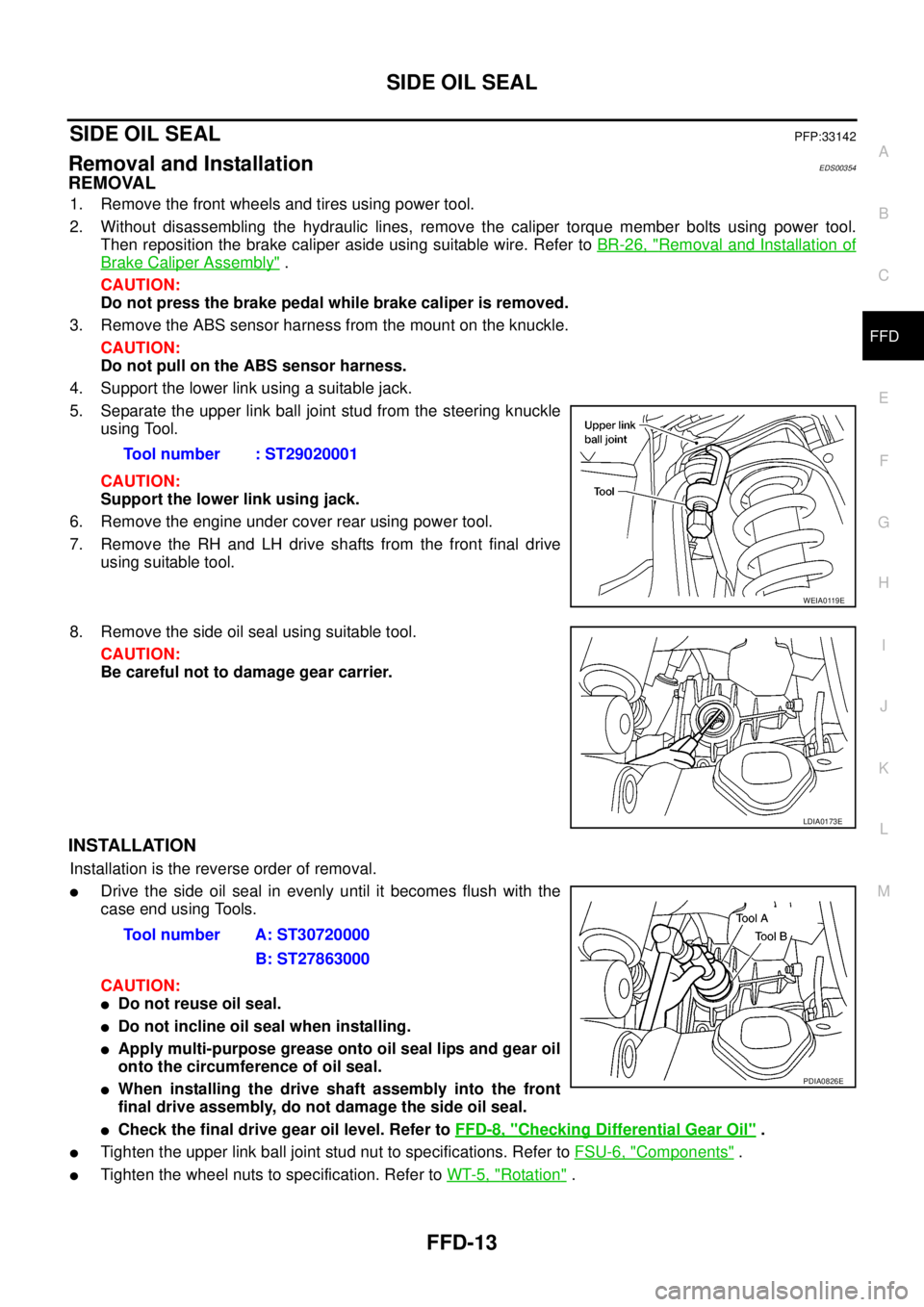

5. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using jack.

6. Remove the engine under cover rear using power tool.

7. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

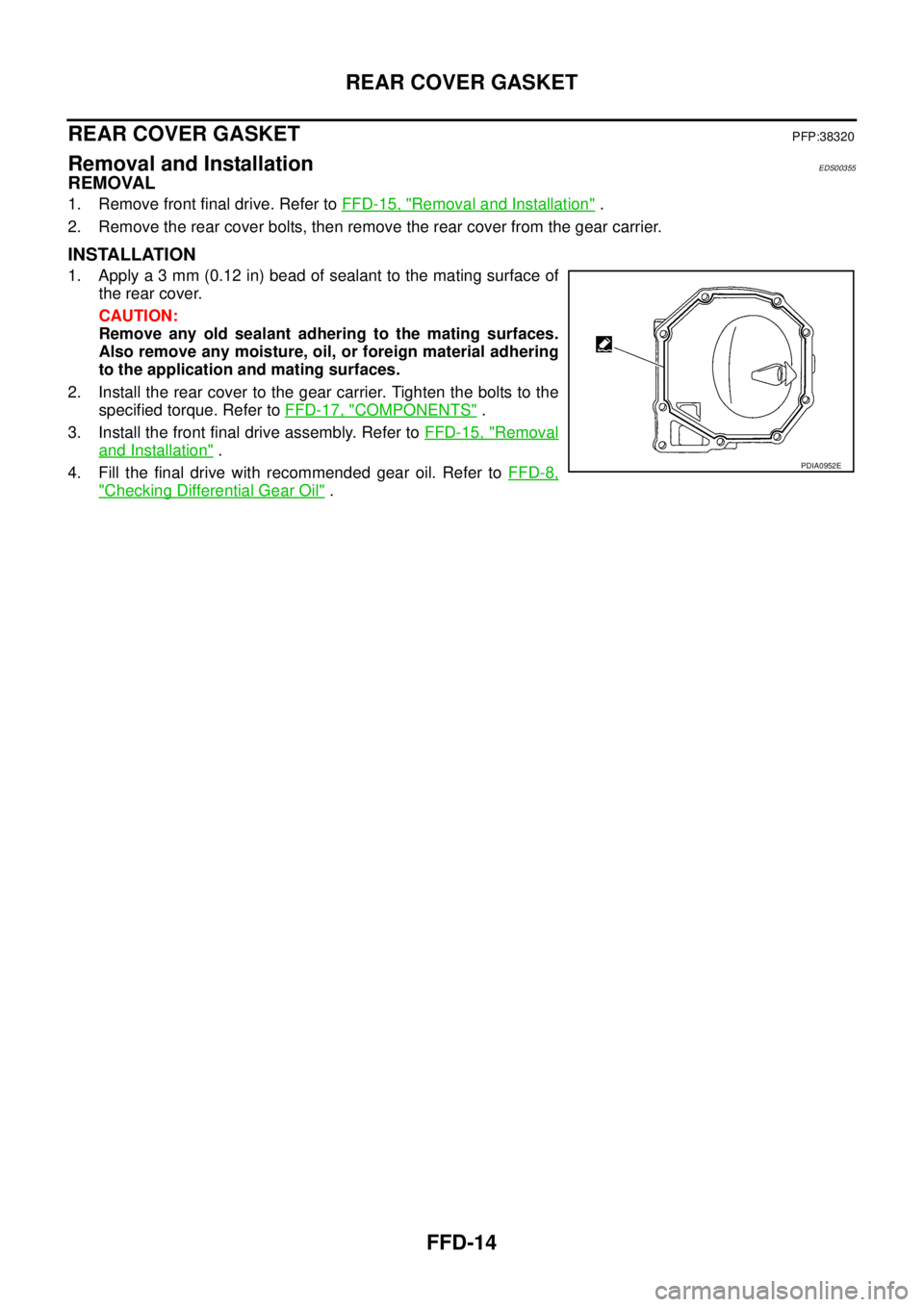

8. Remove the side oil seal using suitable tool.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Installation is the reverse order of removal.

lDrive the side oil seal in evenly until it becomes flush with the

case end using Tools.

CAUTION:

lDo not reuse oil seal.

lDo not incline oil seal when installing.

lApply multi-purpose grease onto oil seal lips and gear oil

onto the circumference of oil seal.

lWhen installing the drive shaft assembly into the front

final drive assembly, do not damage the side oil seal.

lCheck the final drive gear oil level. Refer toFFD-8, "Checking Differential Gear Oil".

lTighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "Components".

lTighten the wheel nuts to specification. Refer toWT-5, "Rotation". Tool number : ST29020001

WEIA0119E

LDIA0173E

Tool number A: ST30720000

B: ST27863000

PDIA0826E

Page 1560 of 3171

FFD-14

REAR COVER GASKET

REAR COVER GASKET

PFP:38320

Removal and InstallationEDS00355

REMOVAL

1. Remove front final drive. Refer toFFD-15, "Removal and Installation".

2. Remove the rear cover bolts, then remove the rear cover from the gear carrier.

INSTALLATION

1. Apply a 3 mm (0.12 in) bead of sealant to the mating surface of

the rear cover.

CAUTION:

Remove any old sealant adhering to the mating surfaces.

Also remove any moisture, oil, or foreign material adhering

to the application and mating surfaces.

2. Install the rear cover to the gear carrier. Tighten the bolts to the

specified torque. Refer toFFD-17, "

COMPONENTS".

3. Install the front final drive assembly. Refer toFFD-15, "

Removal

and Installation".

4. Fill the final drive with recommended gear oil. Refer toFFD-8,

"Checking Differential Gear Oil".

PDIA0952E

Page 1563 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-17

C

E

F

G

H

I

J

K

L

MA

B

FFD

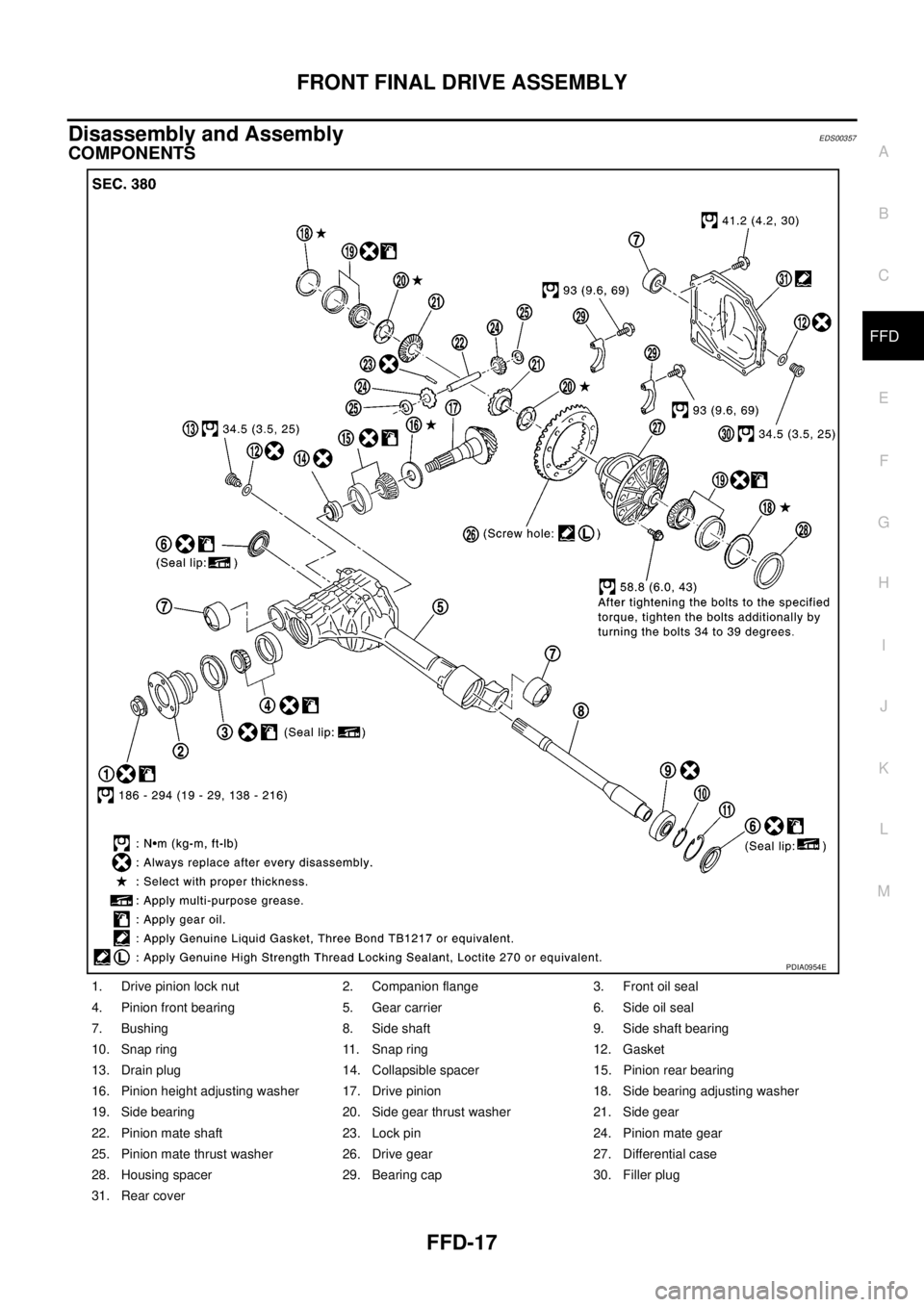

Disassembly and AssemblyEDS00357

COMPONENTS

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Pinion front bearing 5. Gear carrier 6. Side oil seal

7. Bushing 8. Side shaft 9. Side shaft bearing

10. Snap ring 11. Snap ring 12. Gasket

13. Drain plug 14. Collapsible spacer 15. Pinion rear bearing

16. Pinion height adjusting washer 17. Drive pinion 18. Side bearing adjusting washer

19. Side bearing 20. Side gear thrust washer 21. Side gear

22. Pinion mate shaft 23. Lock pin 24. Pinion mate gear

25. Pinion mate thrust washer 26. Drive gear 27. Differential case

28. Housing spacer 29. Bearing cap 30. Filler plug

31. Rear cover

PDIA0954E

Page 1564 of 3171

FFD-18

FRONT FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

lBefore inspection and adjustment, drain gear oil.

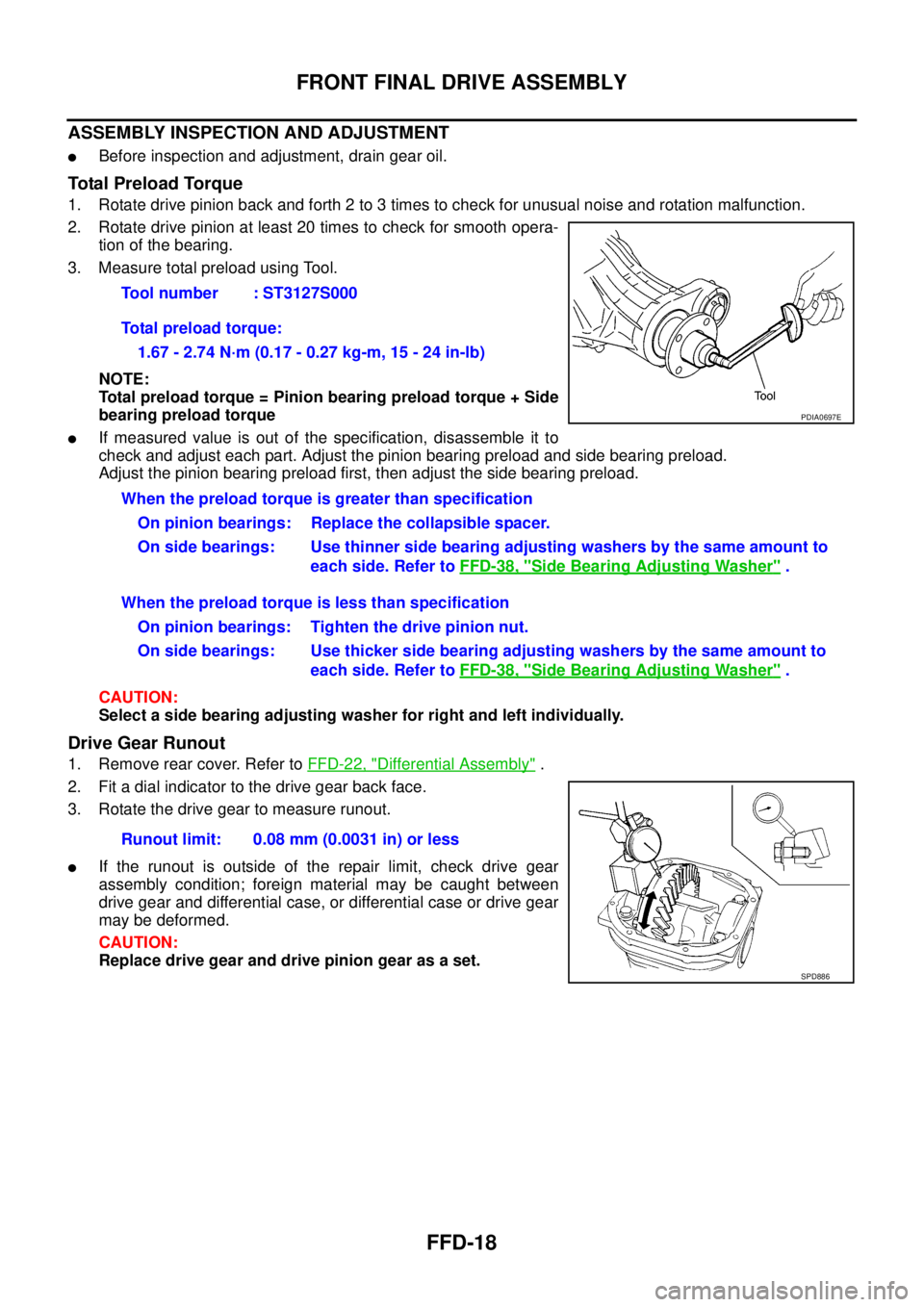

Total Preload Torque

1. Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

2. Rotate drive pinion at least 20 times to check for smooth opera-

tion of the bearing.

3. Measure total preload using Tool.

NOTE:

Total preload torque = Pinion bearing preload torque + Side

bearing preload torque

lIf measured value is out of the specification, disassemble it to

check and adjust each part. Adjust the pinion bearing preload and side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

CAUTION:

Select a side bearing adjusting washer for right and left individually.

Drive Gear Runout

1. Remove rear cover. Refer toFFD-22, "Differential Assembly".

2. Fit a dial indicator to the drive gear back face.

3. Rotate the drive gear to measure runout.

lIf the runout is outside of the repair limit, check drive gear

assembly condition; foreign material may be caught between

drive gear and differential case, or differential case or drive gear

may be deformed.

CAUTION:

Replace drive gear and drive pinion gear as a set.Tool number : ST3127S000

Total preload torque:

1.67 - 2.74 N·m (0.17 - 0.27 kg-m, 15 - 24 in-lb)

PDIA0697E

When the preload torque is greater than specification

On pinion bearings: Replace the collapsible spacer.

On side bearings: Use thinner side bearing adjusting washers by the same amount to

each side. Refer toFFD-38, "

Side Bearing Adjusting Washer".

When the preload torque is less than specification

On pinion bearings: Tighten the drive pinion nut.

On side bearings: Use thicker side bearing adjusting washers by the same amount to

each side. Refer toFFD-38, "

Side Bearing Adjusting Washer".

Runout limit: 0.08 mm (0.0031 in) or less

SPD886

Page 1565 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-19

C

E

F

G

H

I

J

K

L

MA

B

FFD

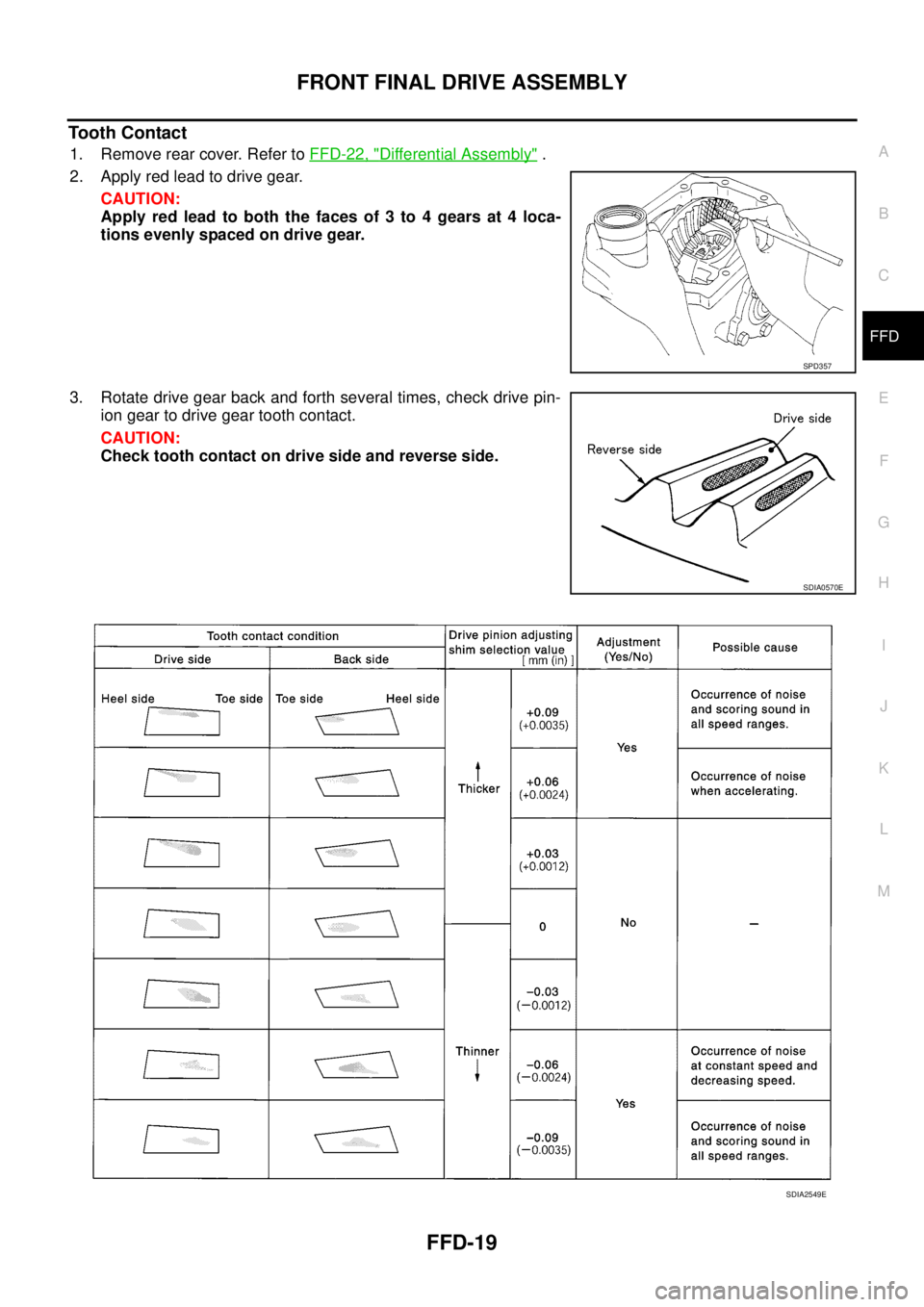

Tooth Contact

1. Remove rear cover. Refer toFFD-22, "Differential Assembly".

2. Apply red lead to drive gear.

CAUTION:

Applyredleadtoboththefacesof3to4gearsat4loca-

tions evenly spaced on drive gear.

3. Rotate drive gear back and forth several times, check drive pin-

iongeartodrivegeartoothcontact.

CAUTION:

Check tooth contact on drive side and reverse side.

SPD357

SDIA0570E

SDIA2549E

Page 1566 of 3171

FFD-20

FRONT FINAL DRIVE ASSEMBLY

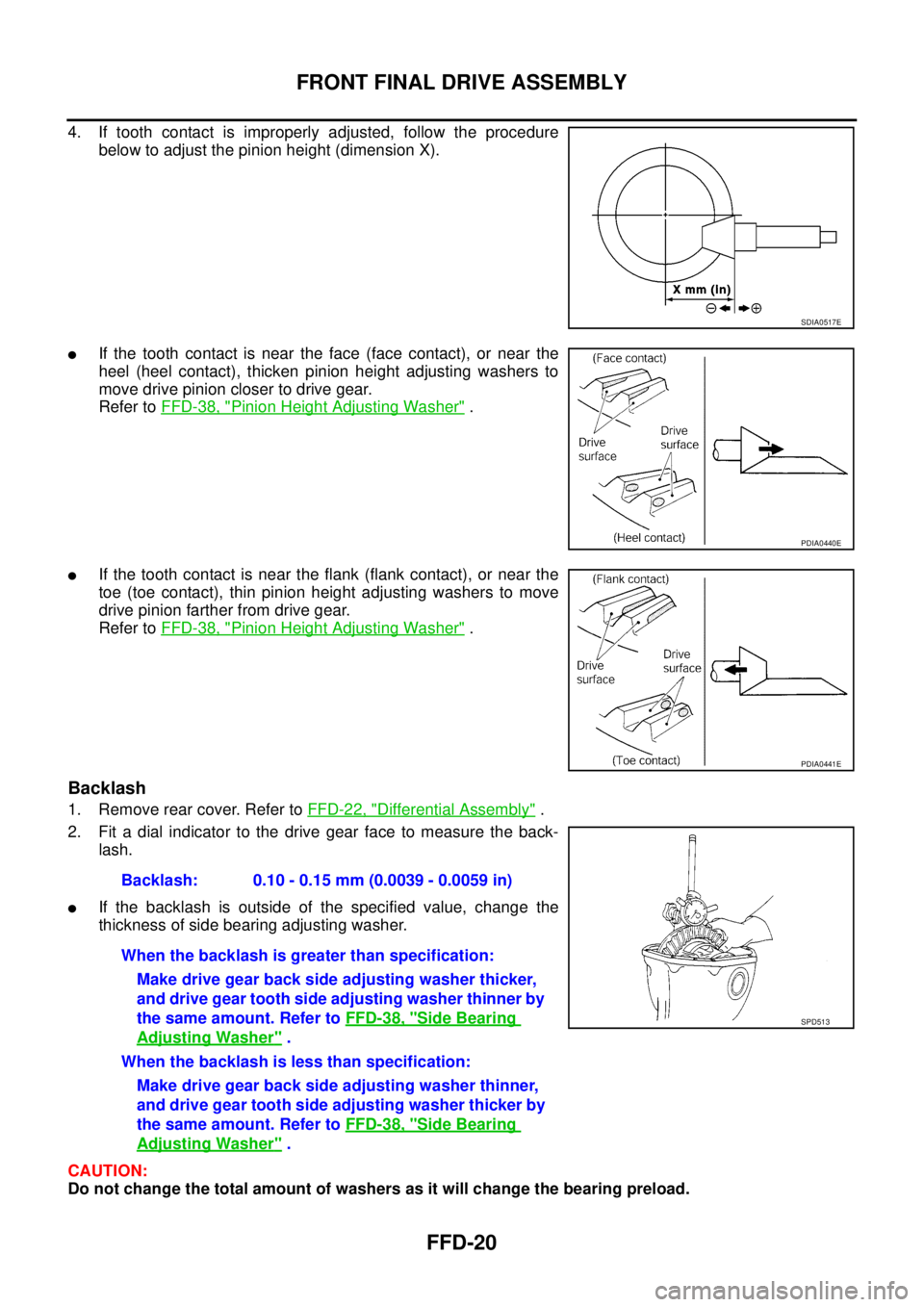

4. If tooth contact is improperly adjusted, follow the procedure

below to adjust the pinion height (dimension X).

lIf the tooth contact is near the face (face contact), or near the

heel (heel contact), thicken pinion height adjusting washers to

move drive pinion closer to drive gear.

Refer toFFD-38, "

Pinion Height Adjusting Washer".

lIf the tooth contact is near the flank (flank contact), or near the

toe (toe contact), thin pinion height adjusting washers to move

drive pinion farther from drive gear.

Refer toFFD-38, "

Pinion Height Adjusting Washer".

Backlash

1. Remove rear cover. Refer toFFD-22, "Differential Assembly".

2. Fit a dial indicator to the drive gear face to measure the back-

lash.

lIf the backlash is outside of the specified value, change the

thickness of side bearing adjusting washer.

CAUTION:

Do not change the total amount of washers as it will change the bearing preload.

SDIA0517E

PDIA0440E

PDIA0441E

Backlash: 0.10 - 0.15 mm (0.0039 - 0.0059 in)

When the backlash is greater than specification:

Make drive gear back side adjusting washer thicker,

and drive gear tooth side adjusting washer thinner by

the same amount. Refer toFFD-38, "

Side Bearing

Adjusting Washer".

When the backlash is less than specification:

Make drive gear back side adjusting washer thinner,

and drive gear tooth side adjusting washer thicker by

the same amount. Refer toFFD-38, "

Side Bearing

Adjusting Washer".

SPD513

Page 1568 of 3171

FFD-22

FRONT FINAL DRIVE ASSEMBLY

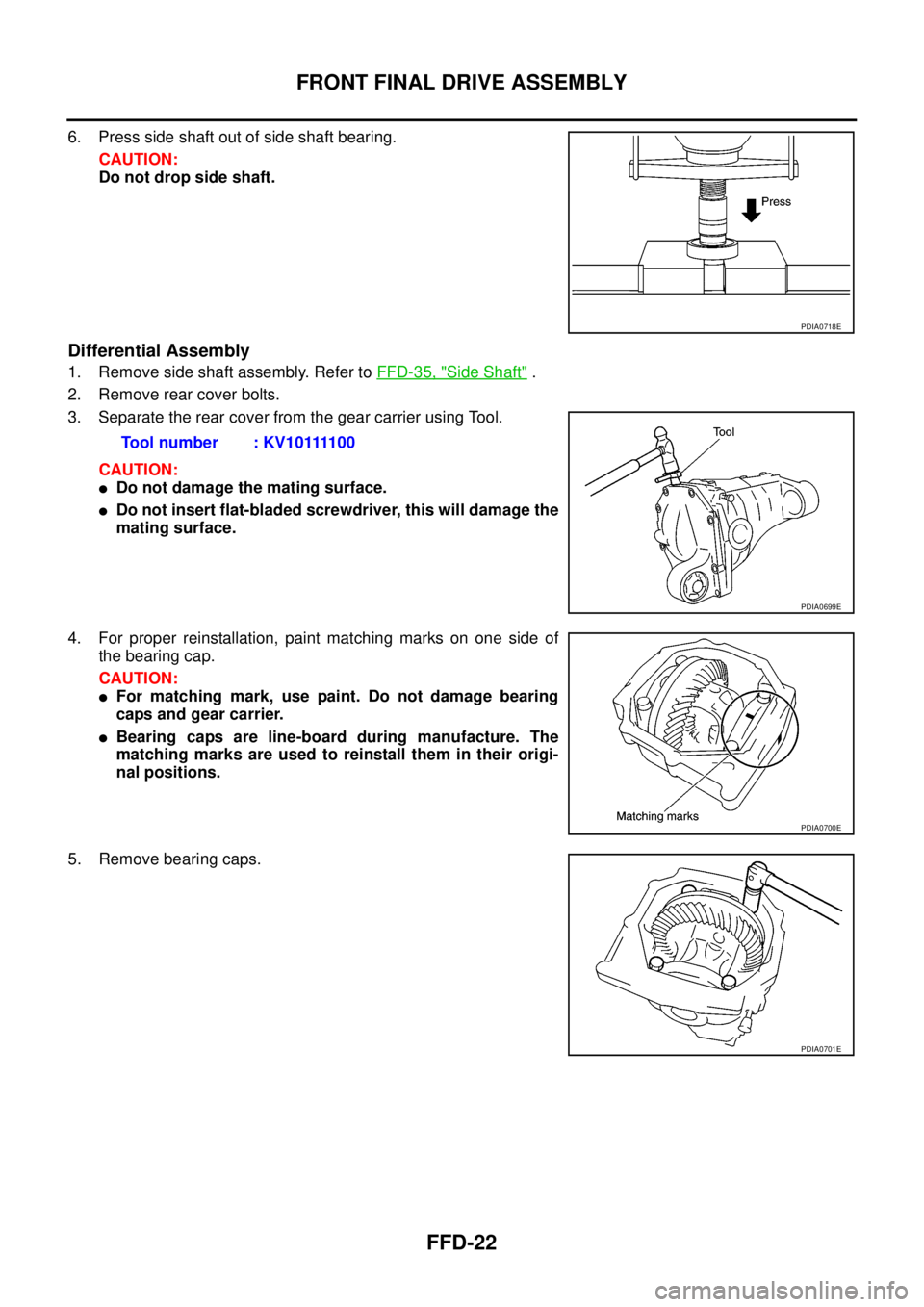

6. Press side shaft out of side shaft bearing.

CAUTION:

Do not drop side shaft.

Differential Assembly

1. Remove side shaft assembly. Refer toFFD-35, "Side Shaft".

2. Remove rear cover bolts.

3. Separate the rear cover from the gear carrier using Tool.

CAUTION:

lDo not damage the mating surface.

lDo not insert flat-bladed screwdriver, this will damage the

mating surface.

4. For proper reinstallation, paint matching marks on one side of

the bearing cap.

CAUTION:

lFor matching mark, use paint. Do not damage bearing

caps and gear carrier.

lBearing caps are line-board during manufacture. The

matching marks are used to reinstall them in their origi-

nal positions.

5. Remove bearing caps.

PDIA0718E

Tool number : KV10111100

PDIA0699E

PDIA0700E

PDIA0701E

Page 1569 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-23

C

E

F

G

H

I

J

K

L

MA

B

FFD

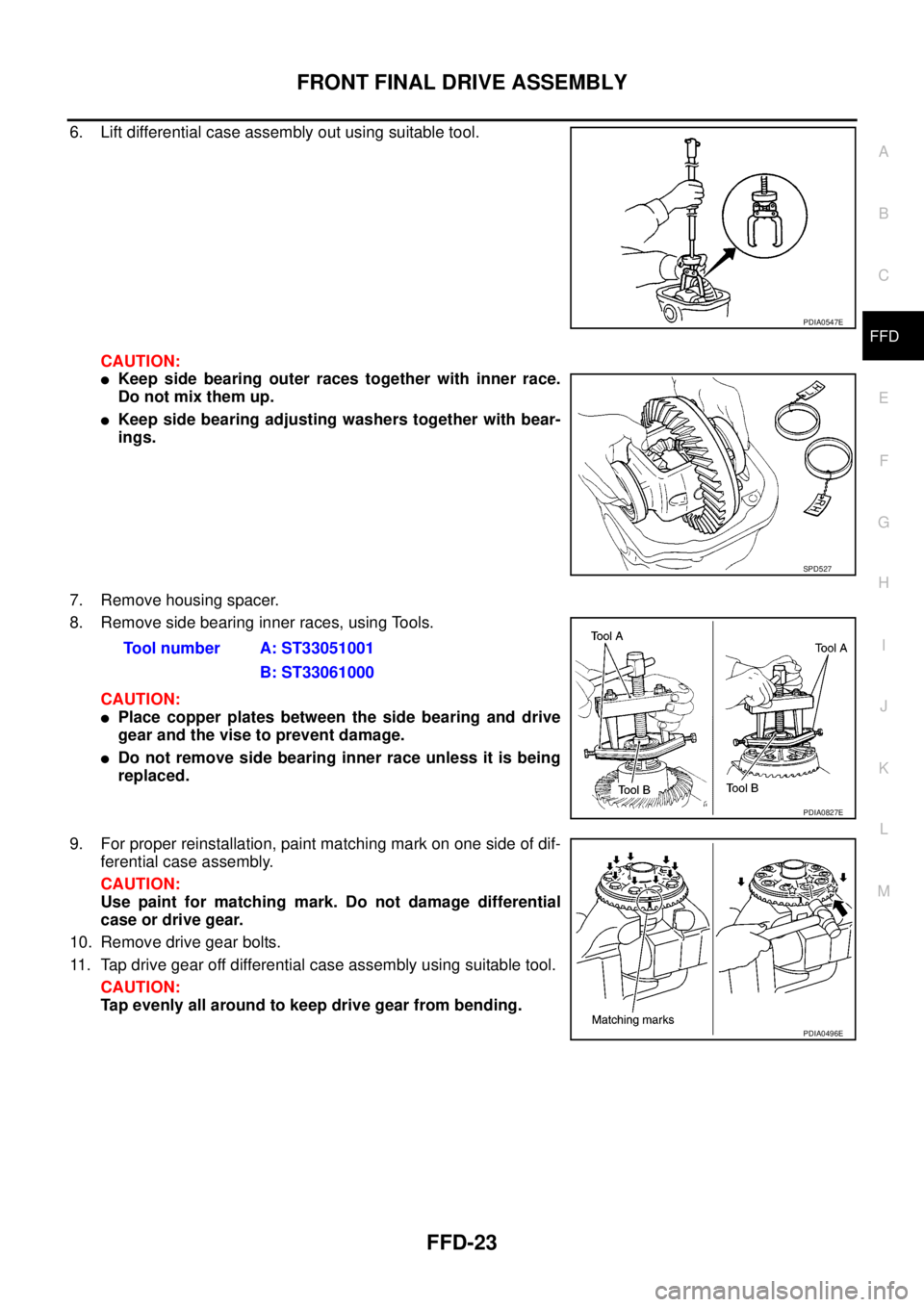

6. Lift differential case assembly out using suitable tool.

CAUTION:

lKeep side bearing outer races together with inner race.

Do not mix them up.

lKeep side bearing adjusting washers together with bear-

ings.

7. Remove housing spacer.

8. Remove side bearing inner races, using Tools.

CAUTION:

lPlace copper plates between the side bearing and drive

gear and the vise to prevent damage.

lDo not remove side bearing inner race unless it is being

replaced.

9. For proper reinstallation, paint matching mark on one side of dif-

ferential case assembly.

CAUTION:

Use paint for matching mark. Do not damage differential

case or drive gear.

10. Remove drive gear bolts.

11. Tap drive gear off differential case assembly using suitable tool.

CAUTION:

Tap evenly all around to keep drive gear from bending.

PDIA0547E

SPD527

Tool number A: ST33051001

B: ST33061000

PDIA0827E

PDIA0496E

Page 1570 of 3171

FFD-24

FRONT FINAL DRIVE ASSEMBLY

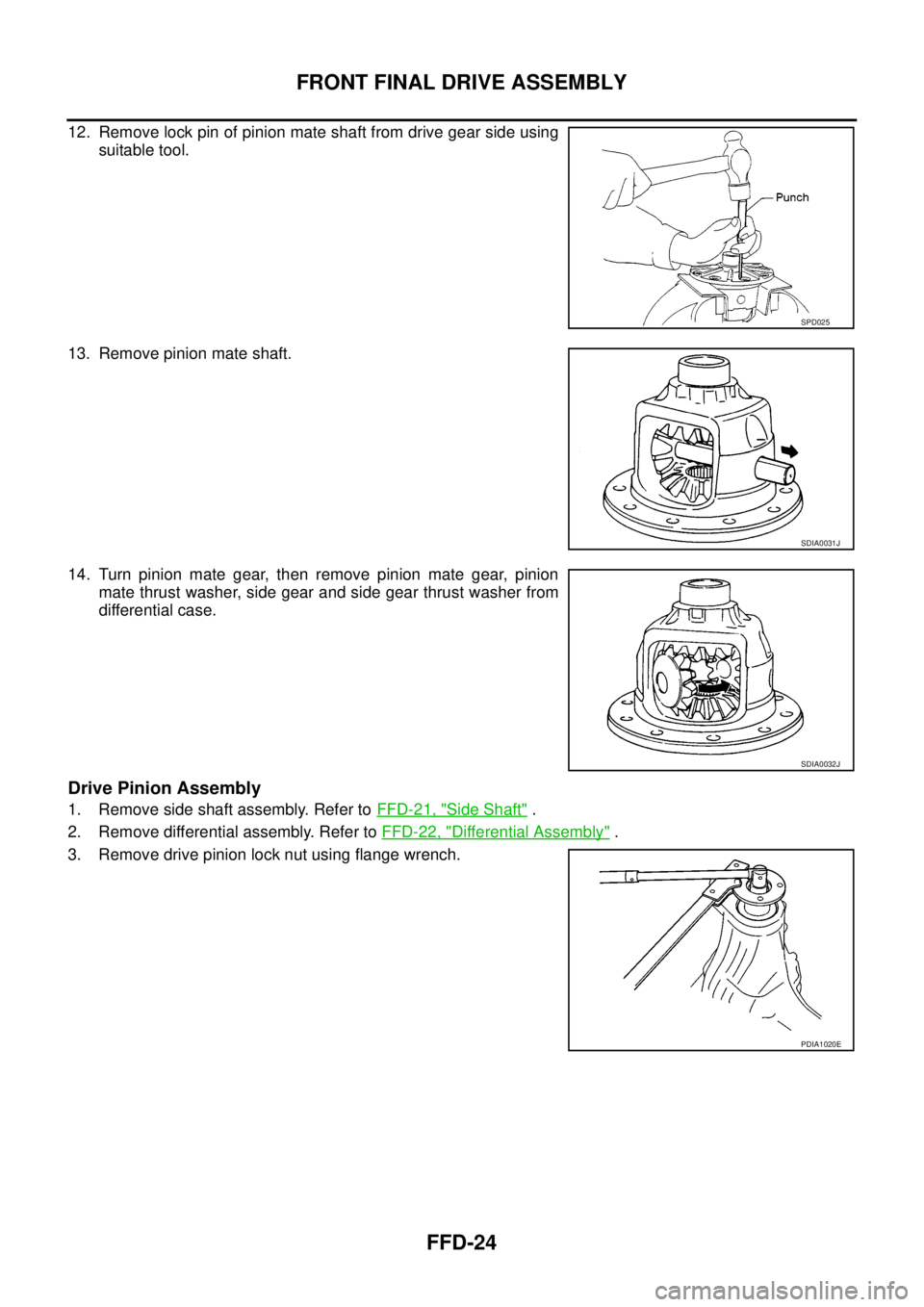

12. Remove lock pin of pinion mate shaft from drive gear side using

suitable tool.

13. Removepinionmateshaft.

14. Turn pinion mate gear, then remove pinion mate gear, pinion

mate thrust washer, side gear and side gear thrust washer from

differential case.

Drive Pinion Assembly

1. Remove side shaft assembly. Refer toFFD-21, "Side Shaft".

2. Remove differential assembly. Refer toFFD-22, "

Differential Assembly".

3. Remove drive pinion lock nut using flange wrench.

SPD025

SDIA0031J

SDIA0032J

PDIA1020E

Page 1572 of 3171

FFD-26

FRONT FINAL DRIVE ASSEMBLY

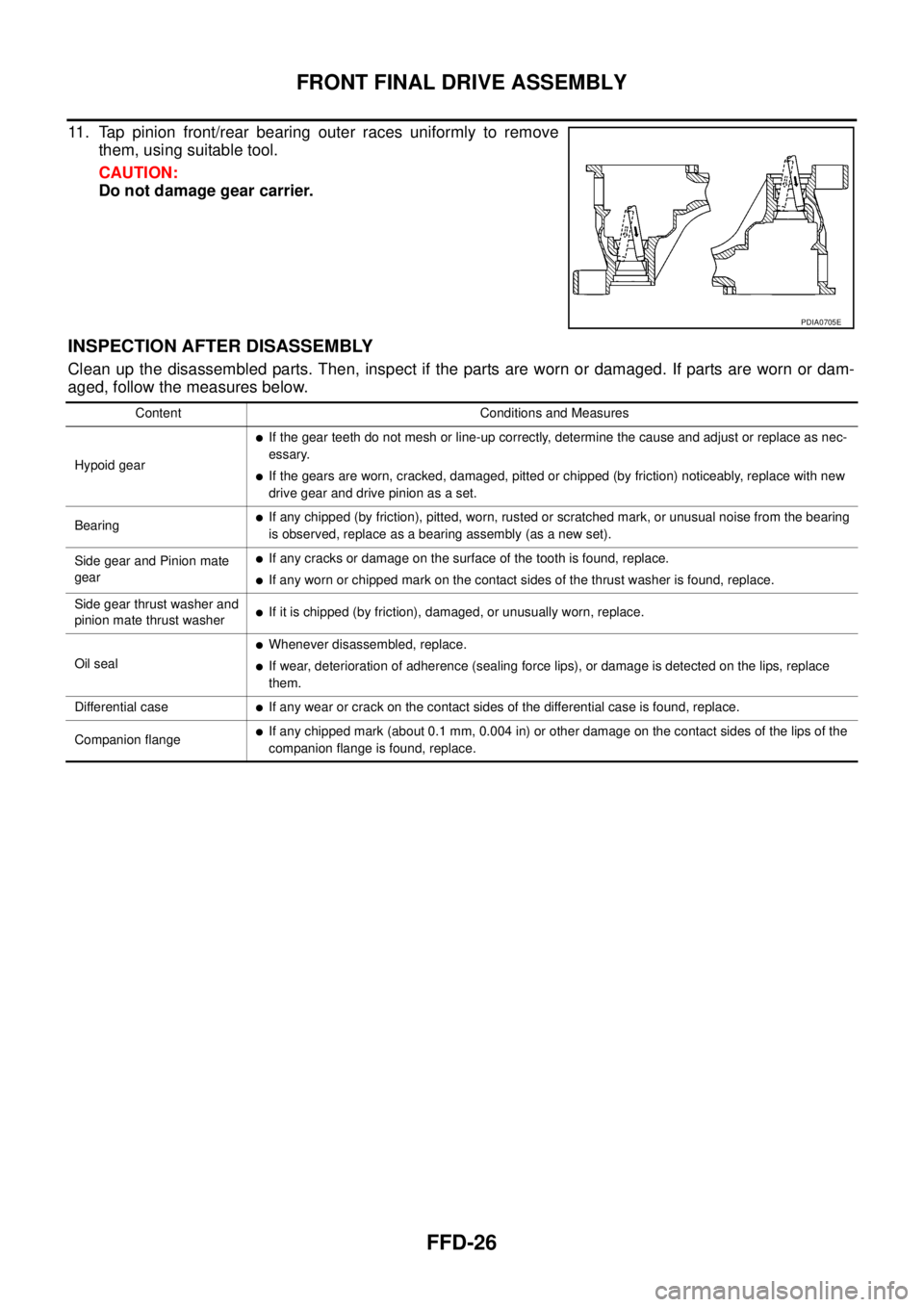

11. Tap pinion front/rear bearing outer races uniformly to remove

them, using suitable tool.

CAUTION:

Do not damage gear carrier.

INSPECTION AFTER DISASSEMBLY

Clean up the disassembled parts. Then, inspect if the parts are worn or damaged. If parts are worn or dam-

aged, follow the measures below.

PDIA0705E

Content Conditions and Measures

Hypoid gear

lIf the gear teeth do not mesh or line-up correctly, determine the cause and adjust or replace as nec-

essary.

lIf the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new

drive gear and drive pinion as a set.

Bearing

lIf any chipped (by friction), pitted, worn, rusted or scratched mark, or unusual noise from the bearing

is observed, replace as a bearing assembly (as a new set).

Side gear and Pinion mate

gear

lIf any cracks or damage on the surface of the tooth is found, replace.

lIf any worn or chipped mark on the contact sides of the thrust washer is found, replace.

Side gear thrust washer and

pinion mate thrust washer

lIf it is chipped (by friction), damaged, or unusually worn, replace.

Oil seal

lWhenever disassembled, replace.

lIf wear, deterioration of adherence (sealing force lips), or damage is detected on the lips, replace

them.

Differential case

lIf any wear or crack on the contact sides of the differential case is found, replace.

Companion flange

lIf any chipped mark (about 0.1 mm, 0.004 in) or other damage on the contact sides of the lips of the

companion flange is found, replace.