radiator NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2295 of 3171

MA-20

ENGINE MAINTENANCE

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

lIf water drain plug on cylinder block is removed, close and tighten it. Refer toEM-110, "CYLIN-

DER BLOCK".

2. Make sure that each hose clamp has been firmly tightened.

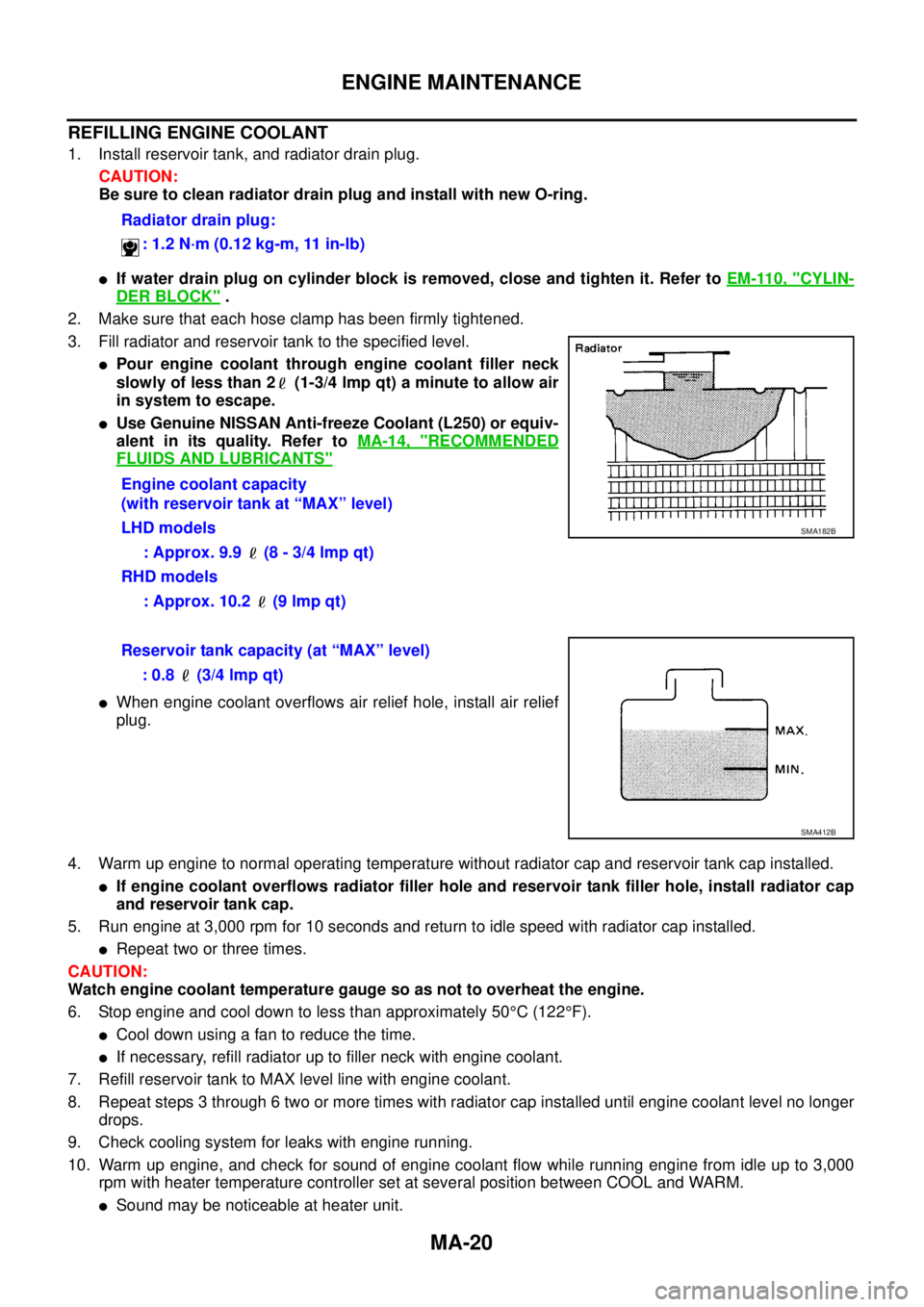

3. Fill radiator and reservoir tank to the specified level.

lPour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

lUse Genuine NISSAN Anti-freeze Coolant (L250) or equiv-

alent in its quality. Refer toMA-14, "

RECOMMENDED

FLUIDS AND LUBRICANTS"

lWhen engine coolant overflows air relief hole, install air relief

plug.

4. Warm up engine to normal operating temperature without radiator cap and reservoir tank cap installed.

lIf engine coolant overflows radiator filler hole and reservoir tank filler hole, install radiator cap

and reservoir tank cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed with radiator cap installed.

lRepeat two or three times.

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

6. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

8. Repeat steps 3 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.Radiator drain plug:

: 1.2 N·m (0.12 kg-m, 11 in-lb)

Engine coolant capacity

(with reservoir tank at “MAX” level)

LHD models

: Approx. 9.9 (8 - 3/4 lmp qt)

RHD models

: Approx. 10.2 (9 lmp qt)

SMA182B

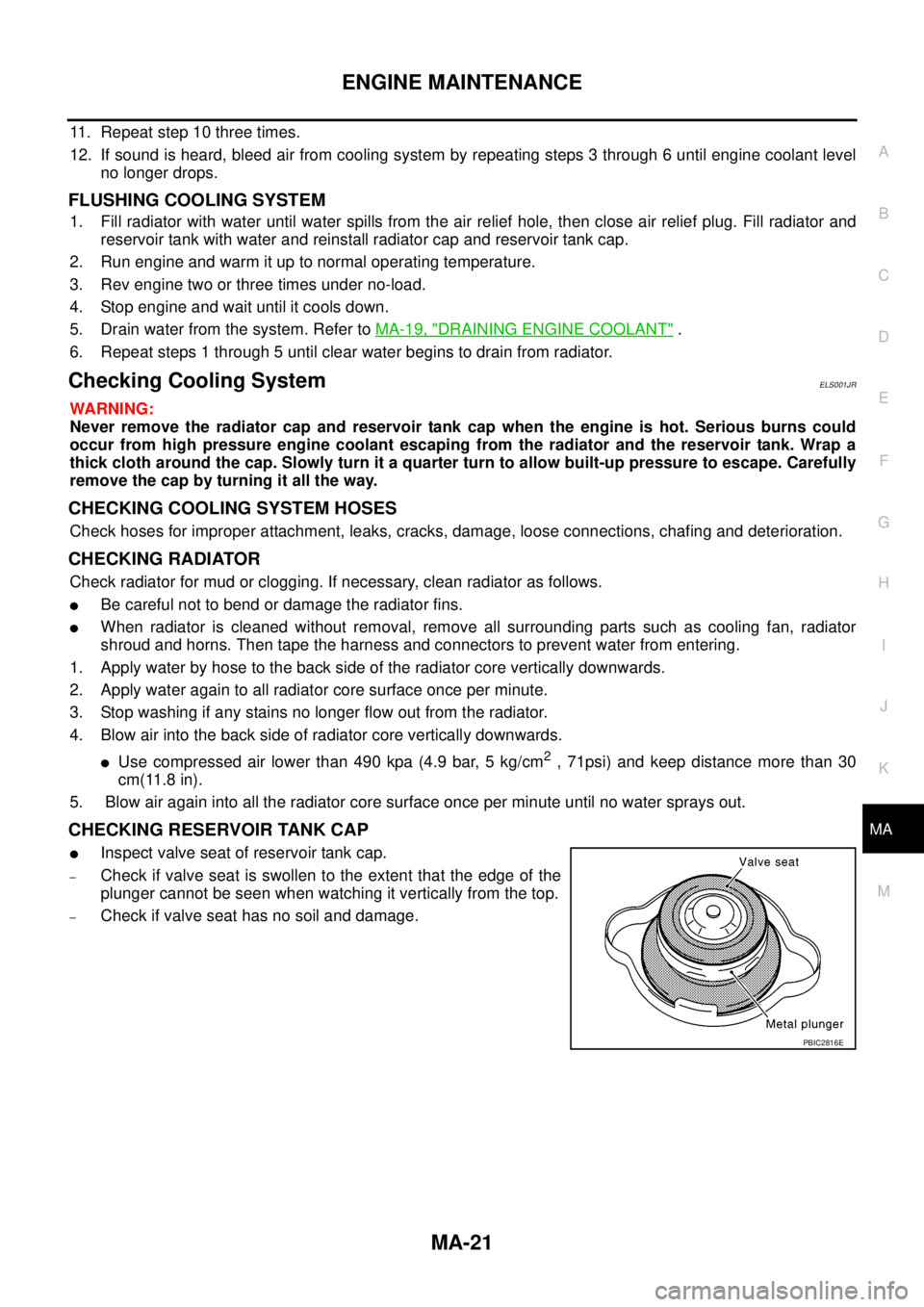

Reservoir tank capacity (at “MAX” level)

: 0.8 (3/4 lmp qt)

SMA412B

Page 2296 of 3171

ENGINE MAINTENANCE

MA-21

C

D

E

F

G

H

I

J

K

MA

B

MA

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toMA-19, "

DRAINING ENGINE COOLANT".

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

Checking Cooling SystemELS001JR

WARNING:

Never remove the radiator cap and reservoir tank cap when the engine is hot. Serious burns could

occur from high pressure engine coolant escaping from the radiator and the reservoir tank. Wrap a

thick cloth around the cap. Slowly turn it a quarter turn to allow built-up pressure to escape. Carefully

remove the cap by turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, loose connections, chafing and deterioration.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

lBe careful not to bend or damage the radiator fins.

lWhen radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downwards.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core vertically downwards.

lUse compressed air lower than 490 kpa (4.9 bar, 5 kg/cm2, 71psi) and keep distance more than 30

cm(11.8 in).

5. Blow air again into all the radiator core surface once per minute until no water sprays out.

CHECKING RESERVOIR TANK CAP

lInspect valve seat of reservoir tank cap.

–Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

–Check if valve seat has no soil and damage.

PBIC2816E

Page 2297 of 3171

MA-22

ENGINE MAINTENANCE

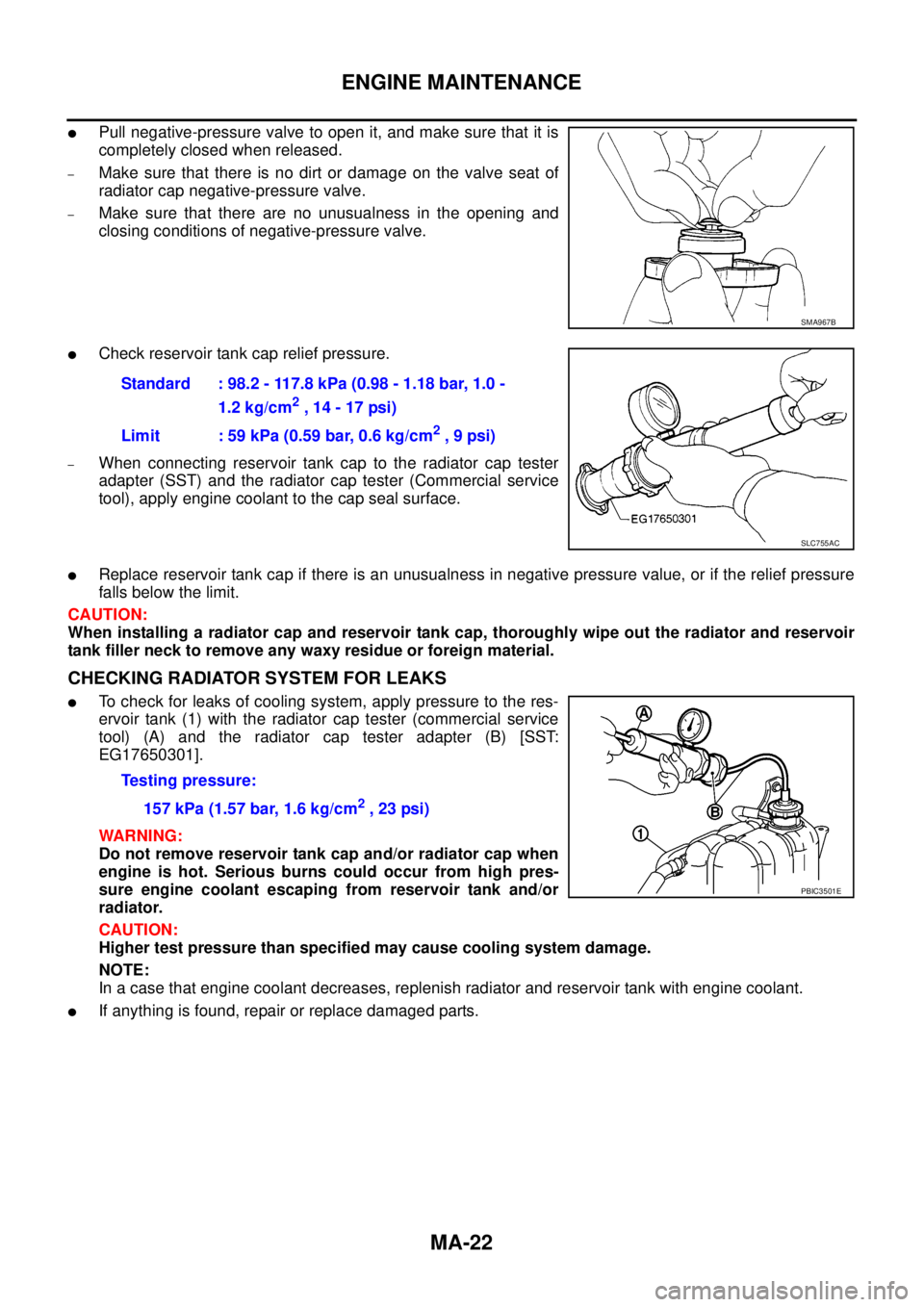

lPull negative-pressure valve to open it, and make sure that it is

completely closed when released.

–Makesurethatthereisnodirtordamageonthevalveseatof

radiator cap negative-pressure valve.

–Make sure that there are no unusualness in the opening and

closing conditions of negative-pressure valve.

lCheck reservoir tank cap relief pressure.

–When connecting reservoir tank cap to the radiator cap tester

adapter (SST) and the radiator cap tester (Commercial service

tool), apply engine coolant to the cap seal surface.

lReplace reservoir tank cap if there is an unusualness in negative pressure value, or if the relief pressure

falls below the limit.

CAUTION:

When installing a radiator cap and reservoir tank cap, thoroughly wipe out the radiator and reservoir

tank filler neck to remove any waxy residue or foreign material.

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

SMA967B

Standard : 98.2 - 117.8 kPa (0.98 - 1.18 bar, 1.0 -

1.2 kg/cm

2,14-17psi)

Limit : 59 kPa (0.59 bar, 0.6 kg/cm

2,9psi)

SLC755AC

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 2305 of 3171

MA-30

CHASSIS AND BODY MAINTENANCE

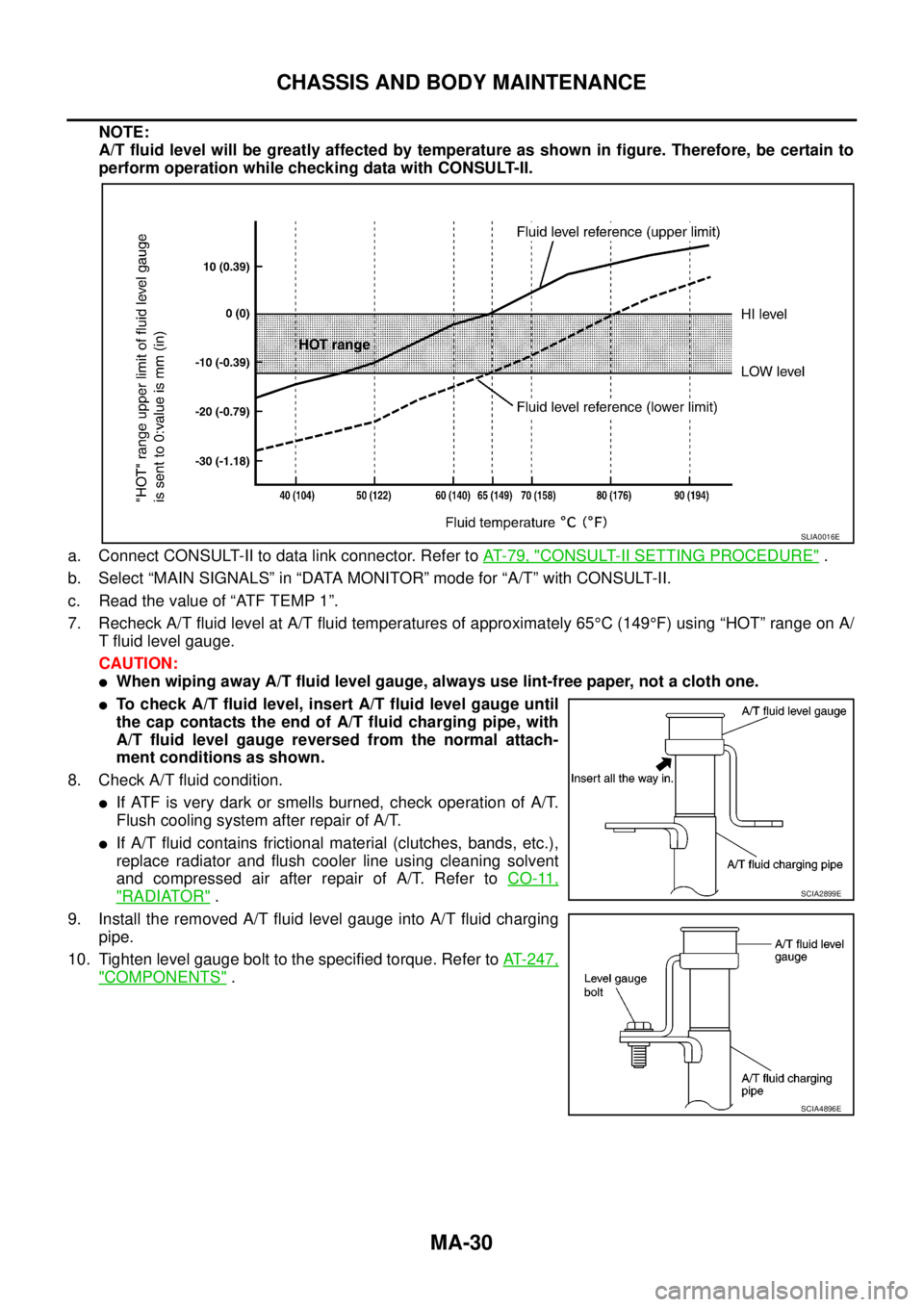

NOTE:

A/T fluid level will be greatly affected by temperature as shown in figure. Therefore, be certain to

perform operation while checking data with CONSULT-II.

a. Connect CONSULT-II to data link connector. Refer toAT-79, "

CONSULT-II SETTING PROCEDURE".

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

c. Readthevalueof“ATFTEMP1”.

7. Recheck A/T fluid level at A/T fluid temperatures of approximately 65°C(149°F)using“HOT”rangeonA/

T fluid level gauge.

CAUTION:

lWhen wiping away A/T fluid level gauge, always use lint-free paper, not a cloth one.

lTo check A/T fluid level, insert A/T fluid level gauge until

the cap contacts the end of A/T fluid charging pipe, with

A/T fluid level gauge reversed from the normal attach-

ment conditions as shown.

8. Check A/T fluid condition.

lIf ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-11,

"RADIATOR".

9. Install the removed A/T fluid level gauge into A/T fluid charging

pipe.

10. Tighten level gauge bolt to the specified torque. Refer toAT-247,

"COMPONENTS".

SLIA0016E

SCIA2899E

SCIA4896E

Page 2514 of 3171

REFRIGERANT LINES

MTC-127

C

D

E

F

G

H

I

K

L

MA

B

MTC

CAUTION:

lReplace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure PipeEJS005HH

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the cowl top and the cowl top extension. Refer toEI-20, "

COWL TOP".

3. Remove the low-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

lAfter charging refrigerant, check for leaks.

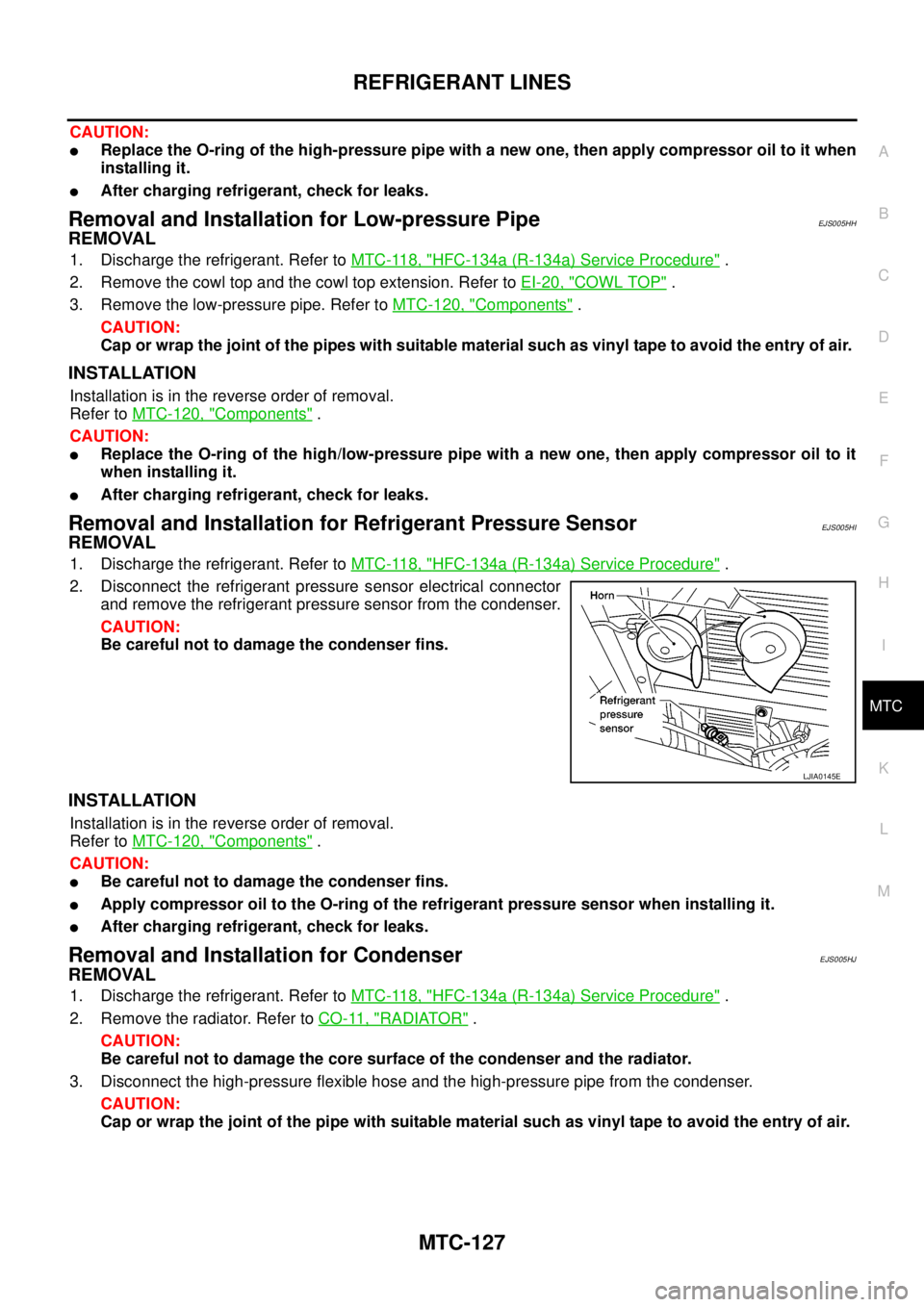

Removal and Installation for Refrigerant Pressure SensorEJS005HI

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressure sensor electrical connector

and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lBe careful not to damage the condenser fins.

lApply compressor oil to the O-ring of the refrigerant pressure sensor when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for CondenserEJS005HJ

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer toCO-11, "

RADIATOR".

CAUTION:

Be careful not to damage the core surface of the condenser and the radiator.

3. Disconnect the high-pressure flexible hose and the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

LJIA0145E

Page 2652 of 3171

POWER STEERING OIL PUMP

PS-25

C

D

E

F

H

I

J

K

L

MA

B

PS

POWER STEERING OIL PUMPPFP:49110

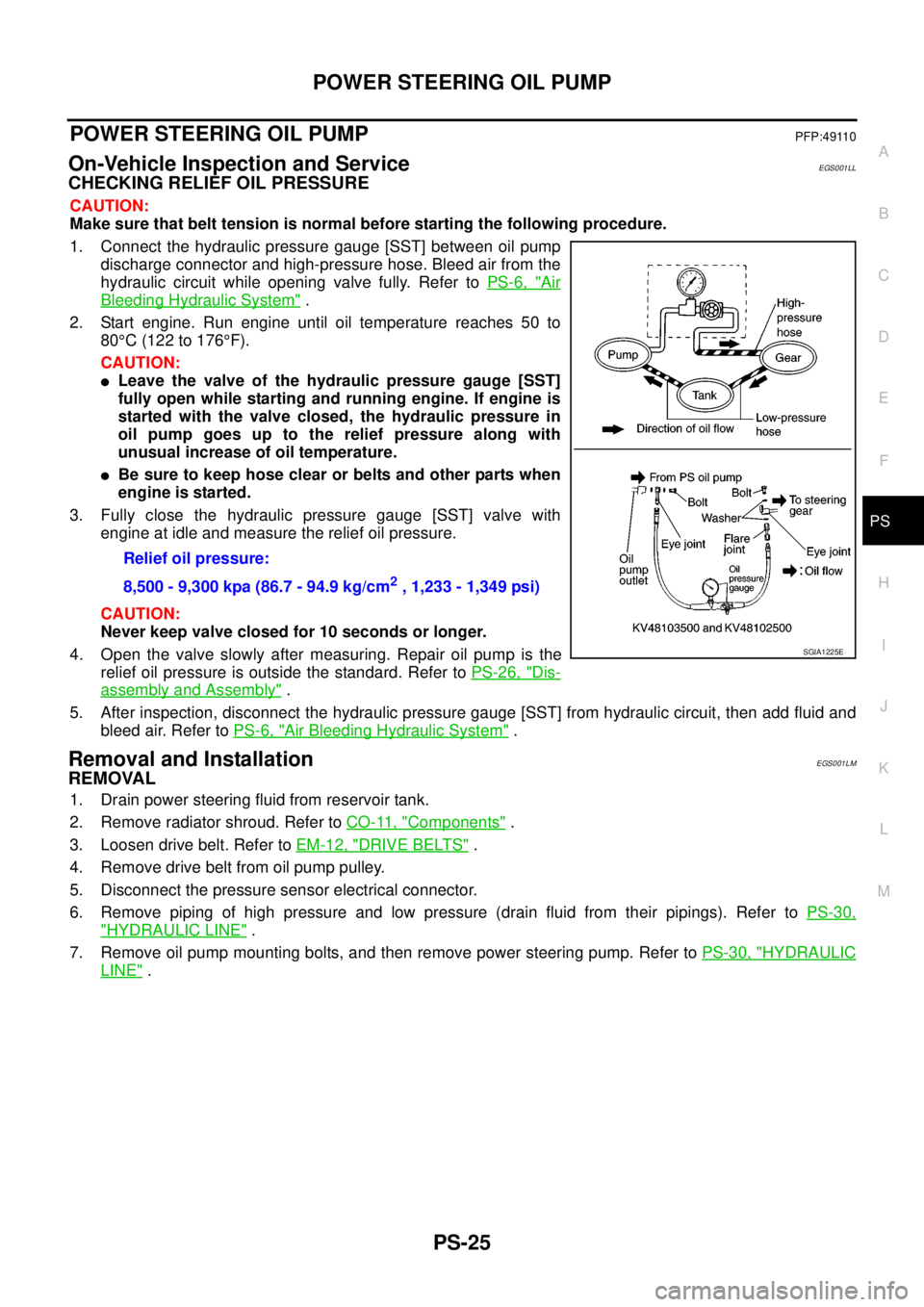

On-Vehicle Inspection and ServiceEGS001LL

CHECKING RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

1. Connect the hydraulic pressure gauge [SST] between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer toPS-6, "

Air

Bleeding Hydraulic System".

2. Start engine. Run engine until oil temperature reaches 50 to

80°C(122to176°F).

CAUTION:

lLeave the valve of the hydraulic pressure gauge [SST]

fully open while starting and running engine. If engine is

started with the valve closed, the hydraulic pressure in

oil pump goes up to the relief pressure along with

unusual increase of oil temperature.

lBe sure to keep hose clear or belts and other parts when

engineisstarted.

3. Fully close the hydraulic pressure gauge [SST] valve with

engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump is the

relief oil pressure is outside the standard. Refer toPS-26, "

Dis-

assembly and Assembly".

5. After inspection, disconnect the hydraulic pressure gauge [SST] from hydraulic circuit, then add fluid and

bleed air. Refer toPS-6, "

Air Bleeding Hydraulic System".

Removal and InstallationEGS001LM

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove radiator shroud. Refer toCO-11, "

Components".

3. Loosen drive belt. Refer toEM-12, "

DRIVE BELTS".

4. Remove drive belt from oil pump pulley.

5. Disconnect the pressure sensor electrical connector.

6. Remove piping of high pressure and low pressure (drain fluid from their pipings). Refer toPS-30,

"HYDRAULIC LINE".

7. Remove oil pump mounting bolts, and then remove power steering pump. Refer toPS-30, "

HYDRAULIC

LINE". Relief oil pressure:

8,500 - 9,300 kpa (86.7 - 94.9 kg/cm

2, 1,233 - 1,349 psi)

SGIA1225E

Page 2684 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

RF-7

C

D

E

F

G

H

J

K

L

MA

B

RF

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2807 of 3171

RSU-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

PrecautionsEES002JD

lWhen installing rubber parts, final tightening must be carried out under unladen condition* with

tires on ground.

*Fuel, radiator coolant, and engine oil are full. Spare tire, jack, hand tools, and mats are in their

designated positions. Oil will shorten the life of rubber bushings, so wipe off any spilled oil imme-

diately.

lLock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled,

do not apply any additional lubrication.

Page 2815 of 3171

RSU-10

LEAF SPRING

8. Tighten the rear spring shackle nuts, rear leaf spring front nut,

and shock absorber nuts to specification.

lWhen installing the components with rubber bushings, the

final nut tightening must be carried out under unladen* condi-

tions with the tires on level ground.

* (Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.)

SRA754

Page 2816 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

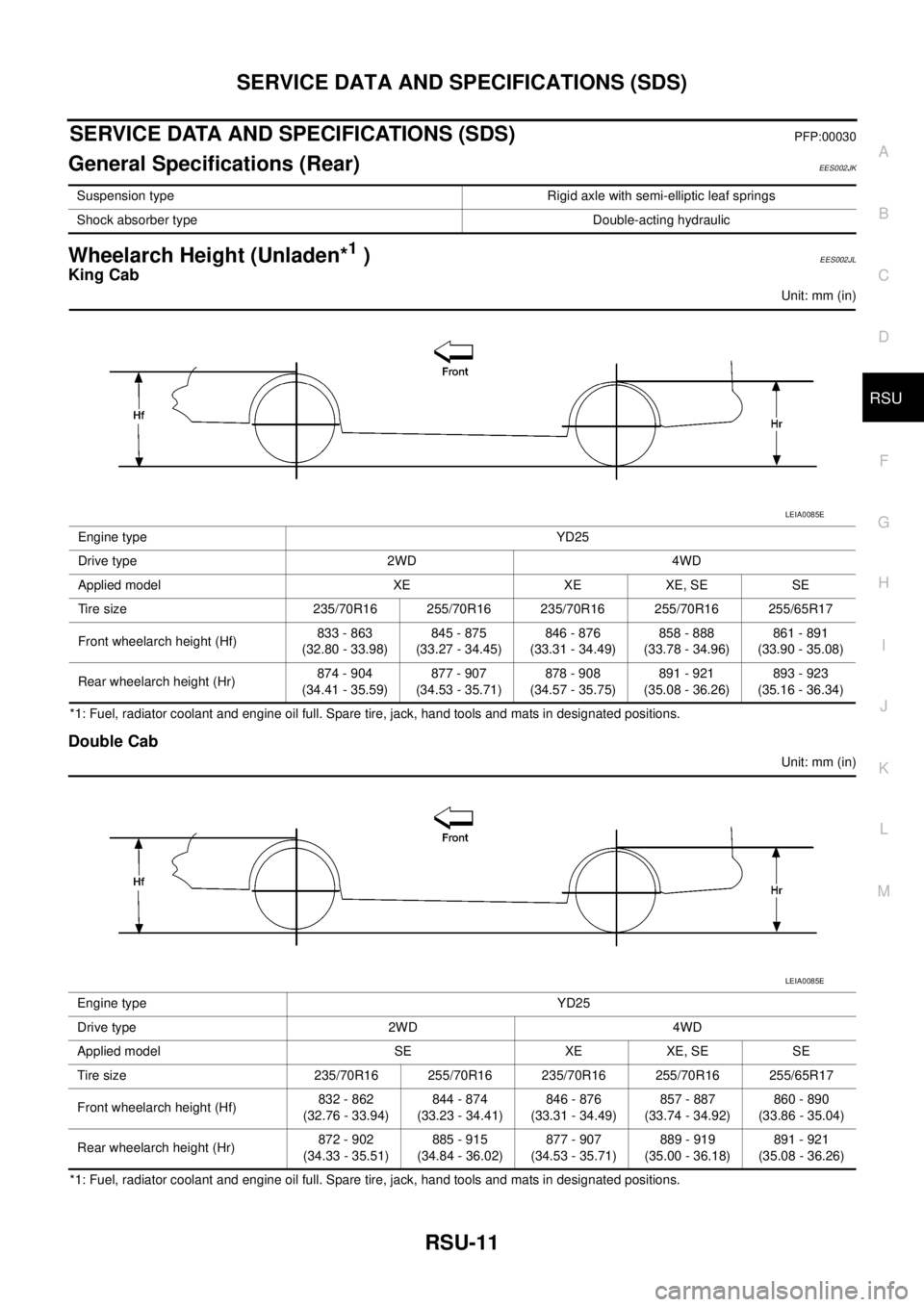

General Specifications (Rear)EES002JK

Wheelarch Height (Unladen*1)EES002JL

King Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

Double Cab

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Suspension type Rigid axle with semi-elliptic leaf springs

Shock absorber type Double-acting hydraulic

Engine type YD25

Drive type 2WD 4WD

Applied model XE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)833 - 863

(32.80 - 33.98)845 - 875

(33.27 - 34.45)846 - 876

(33.31 - 34.49)858 - 888

(33.78 - 34.96)861 - 891

(33.90 - 35.08)

Rear wheelarch height (Hr)874 - 904

(34.41 - 35.59)877 - 907

(34.53 - 35.71)878 - 908

(34.57 - 35.75)891 - 921

(35.08 - 36.26)893 - 923

(35.16 - 36.34)

LEIA0085E

Engine type YD25

Drive type 2WD 4WD

Applied model SE XE XE, SE SE

Tire size 235/70R16 255/70R16 235/70R16 255/70R16 255/65R17

Front wheelarch height (Hf)832 - 862

(32.76 - 33.94)844 - 874

(33.23 - 34.41)846 - 876

(33.31 - 34.49)857 - 887

(33.74 - 34.92)860 - 890

(33.86 - 35.04)

Rear wheelarch height (Hr)872 - 902

(34.33 - 35.51)885 - 915

(34.84 - 36.02)877 - 907

(34.53 - 35.71)889 - 919

(35.00 - 36.18)891 - 921

(35.08 - 36.26)

LEIA0085E