brake pads NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 789 of 3171

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DL

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005SD

lClean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lTo clean or wash all parts of master cylinder, disc brake caliper, wheel cylinder, use new brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

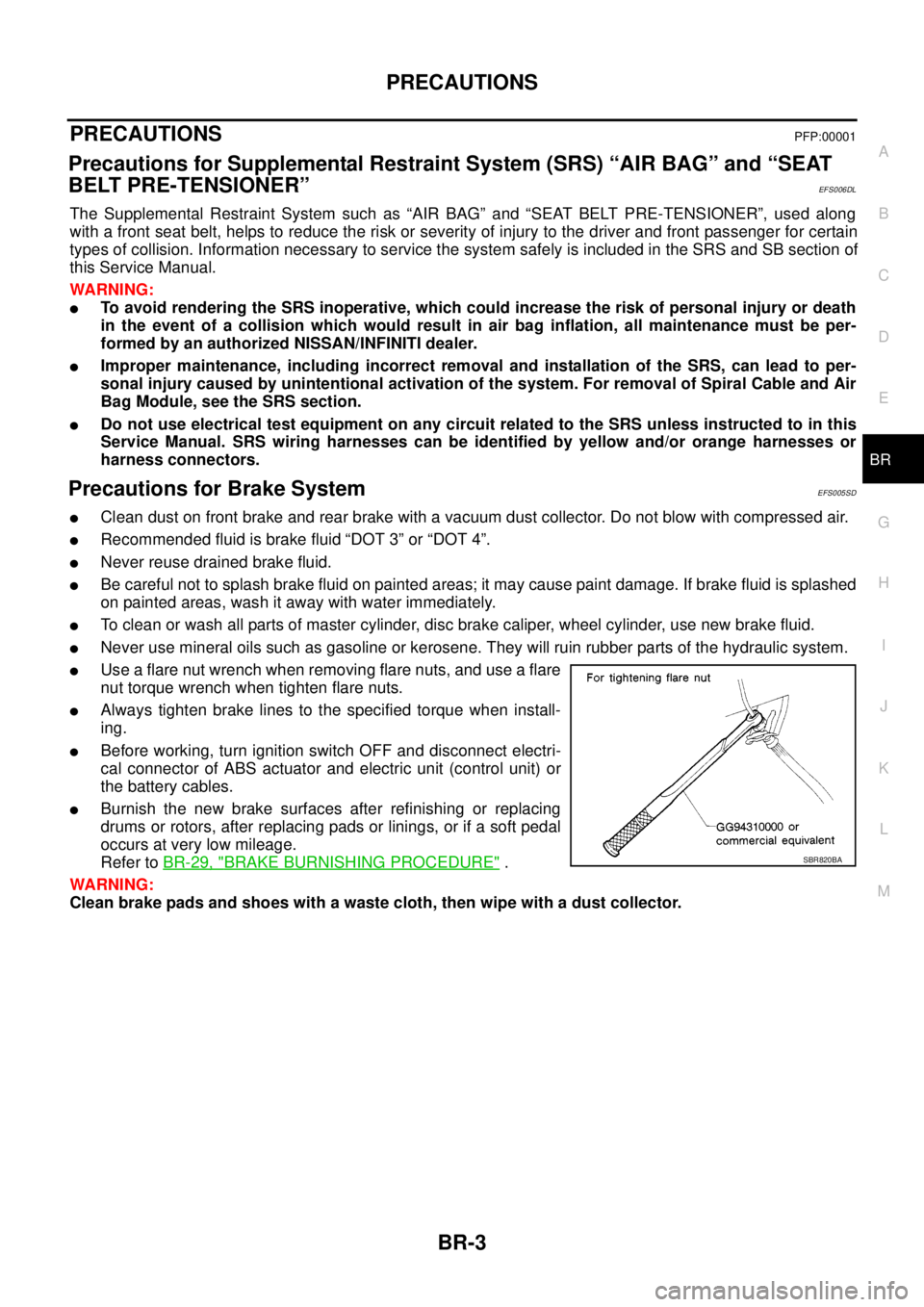

lUse a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lAlways tighten brake lines to the specified torque when install-

ing.

lBefore working, turn ignition switch OFF and disconnect electri-

cal connector of ABS actuator and electric unit (control unit) or

the battery cables.

lBurnish the new brake surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer toBR-29, "

BRAKE BURNISHING PROCEDURE".

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.SBR820BA

Page 791 of 3171

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

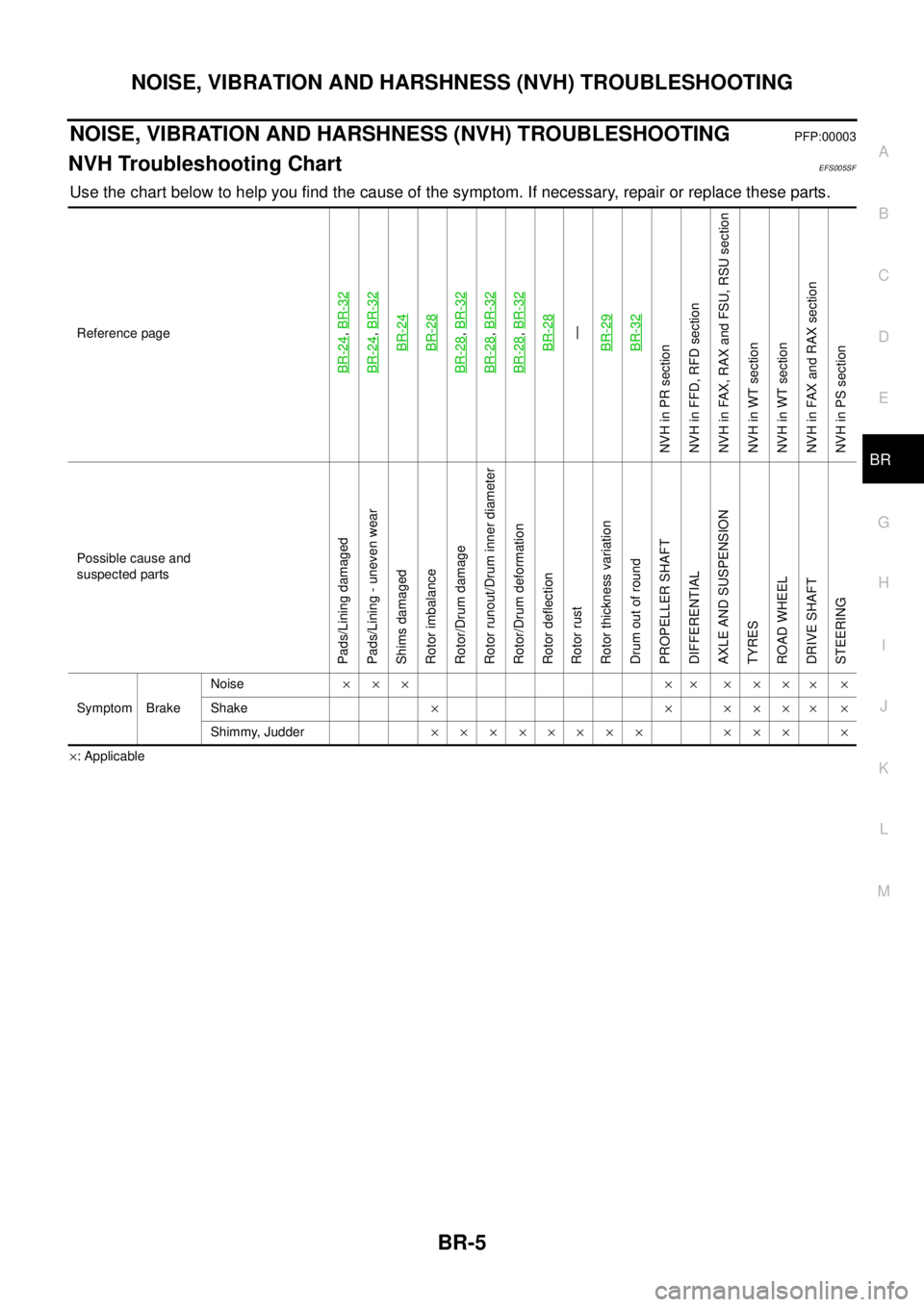

NVH Troubleshooting ChartEFS005SF

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: Applicable Reference page

BR-24

,BR-32

BR-24

,BR-32BR-24BR-28

BR-28

,BR-32

BR-28

,BR-32

BR-28

,BR-32BR-28—

BR-29BR-32

NVHinPRsection

NVH in FFD, RFD section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX and RAX section

NVH in PS section

Possible cause and

suspected parts

Pads/Lining damaged

Pads/Lining - uneven wear

Shims damaged

Rotor imbalance

Rotor/Drum damage

Rotor runout/Drum inner diameter

Rotor/Drum deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TYRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BrakeNoise´´´ ´´ ´´´

´´

Shake´´´´´

´´

Shimmy, Judder´´´´´´´´ ´´´ ´

Page 811 of 3171

FRONT DISC BRAKE

BR-25

C

D

E

G

H

I

J

K

L

MA

B

BR

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air- borne

particles or other materials.

CAUTION:

lWhile removing cylinder body, do not depress brake pedal because piston will pop out.

lIt is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

lDo not damage piston boot.

lIf any shim is subject to serious corrosion, replace it with a new one.

lAlways replace shim as a set when replacing brake pad.

lKeep rotor out of brake fluid.

Removal and Installation of Brake PadEFS005T0

REMOVAL

1. Remove tyre from vehicle.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire. Remove pad assembly and pad retainer from torque member.

CAUTION:

When removing the pad retainer from the torque member, lift it in the direction indicated by the

arrow in the figure so that it does not deform.

INSTALLATION

1. Install inner shim to inner pad, and outer shim to outer pad.

2. Install pad retainers and pad assembly to torque member.

3. Press in piston until pads can be installed, and then install cylin-

der body to torque member.

CAUTION:

lWhen installing pad retainer, attach it firmly so that it

does not flat up higher than torque member, as shown in

the figure.

lIn the case of replacing pad with new one, check a brake

fluid level in the reservoir tank because brake fluid

returns to master cylinder reservoir tank when pressing

piston in.

4. Install lower sliding pin bolt and tighten to the specified torque. Refer toBR-24, "

Components".

5. Check front disc brake for drag.

6. Install tyre to vehicle.

: Brake fluid

Refer to GI section for symbol marks except in the above.

PFIA0273E

Page 812 of 3171

BR-26

FRONT DISC BRAKE

Removal and Installation of Brake Caliper Assembly

EFS005T1

REMOVAL

1. Remove tyre from vehicle.

2. Fasten disc rotor using wheel nut.

CAUTION:

Align the matching marks of disc rotor and wheel hub, which were marked at the time of removal

when reusing disc rotor.

3. Drain brake fluid. Refer toBR-10, "

Drain and Refill".

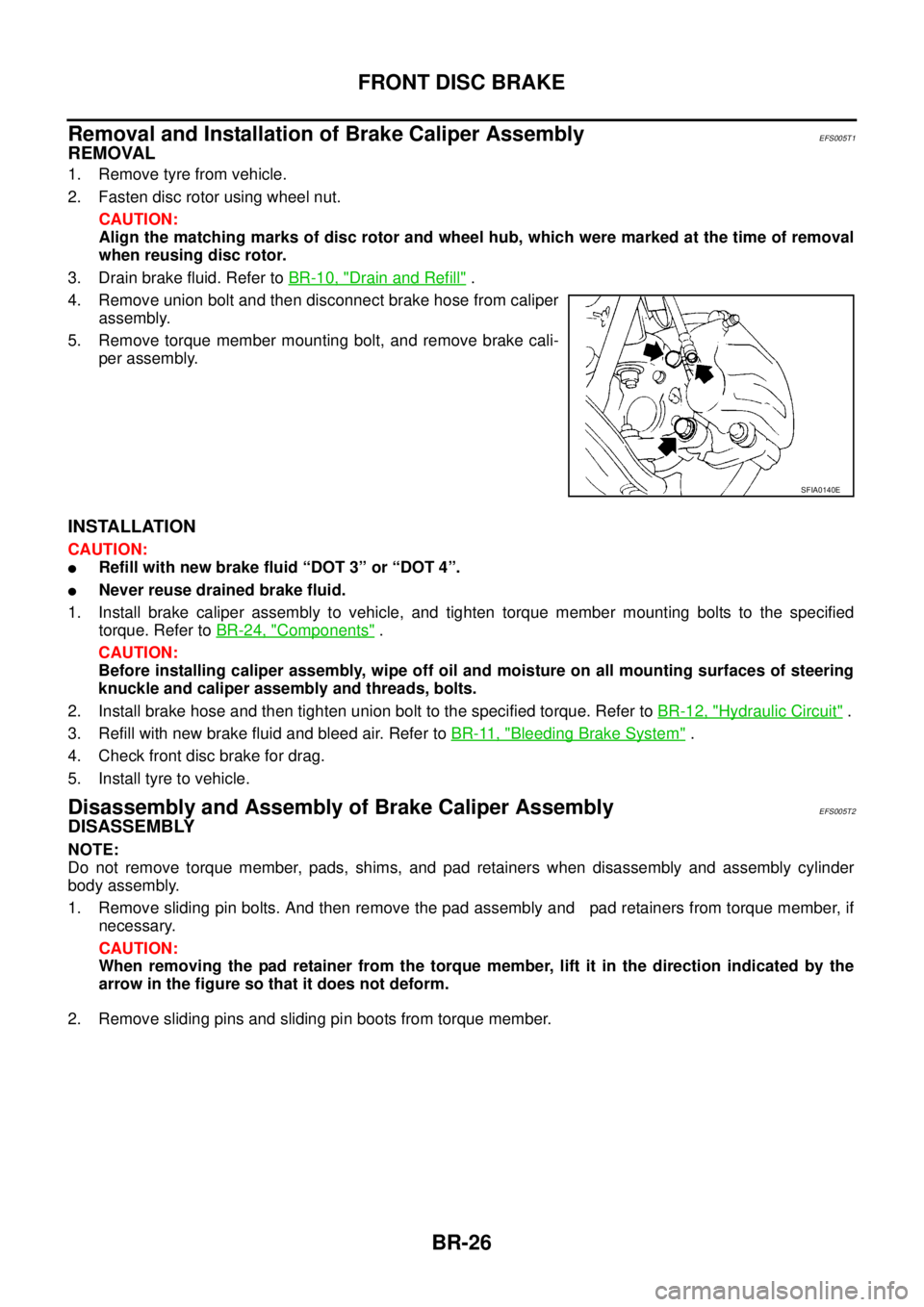

4. Remove union bolt and then disconnect brake hose from caliper

assembly.

5. Remove torque member mounting bolt, and remove brake cali-

per assembly.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Install brake caliper assembly to vehicle, and tighten torque member mounting bolts to the specified

torque. Refer toBR-24, "

Components".

CAUTION:

Before installing caliper assembly, wipe off oil and moisture on all mounting surfaces of steering

knuckle and caliper assembly and threads, bolts.

2. Install brake hose and then tighten union bolt to the specified torque. Refer toBR-12, "

Hydraulic Circuit".

3. Refill with new brake fluid and bleed air. Refer toBR-11, "

Bleeding Brake System".

4. Check front disc brake for drag.

5. Install tyre to vehicle.

Disassembly and Assembly of Brake Caliper AssemblyEFS005T2

DISASSEMBLY

NOTE:

Do not remove torque member, pads, shims, and pad retainers when disassembly and assembly cylinder

body assembly.

1. Remove sliding pin bolts. And then remove the pad assembly and pad retainers from torque member, if

necessary.

CAUTION:

When removing the pad retainer from the torque member, lift it in the direction indicated by the

arrow in the figure so that it does not deform.

2. Remove sliding pins and sliding pin boots from torque member.

SFIA0140E

Page 815 of 3171

FRONT DISC BRAKE

BR-29

C

D

E

G

H

I

J

K

L

MA

B

BR

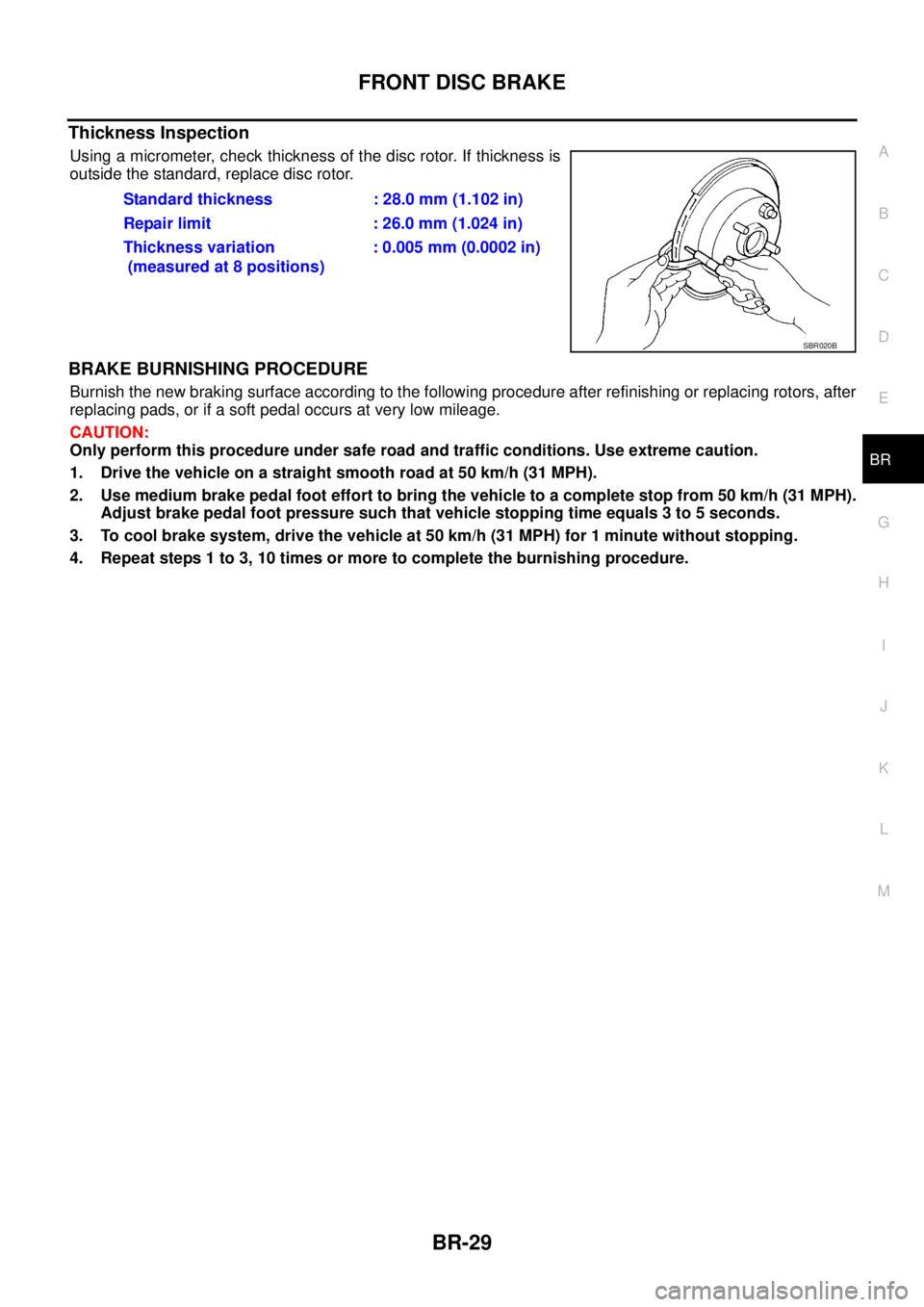

Thickness Inspection

Using a micrometer, check thickness of the disc rotor. If thickness is

outside the standard, replace disc rotor.

BRAKE BURNISHING PROCEDURE

Burnish the new braking surface according to the following procedure after refinishing or replacing rotors, after

replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH).

Adjust brake pedal foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.Standard thickness : 28.0 mm (1.102 in)

Repairlimit :26.0mm(1.024in)

Thickness variation

(measured at 8 positions): 0.005 mm (0.0002 in)

SBR020B

Page 821 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-35

C

D

E

G

H

I

J

K

L

MA

B

BR

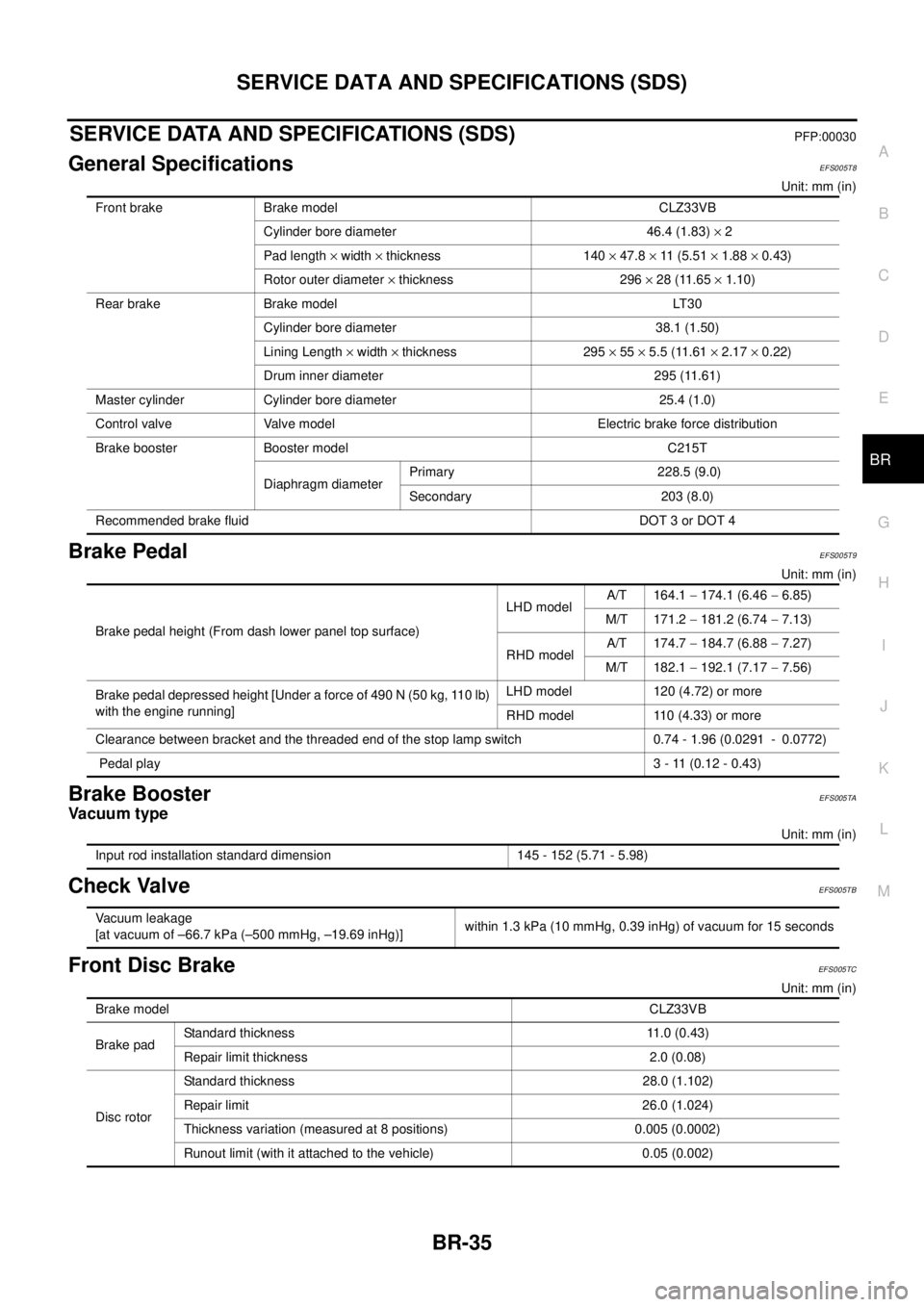

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEFS005T8

Unit: mm (in)

Brake PedalEFS005T9

Unit: mm (in)

Brake BoosterEFS005TA

Va c u u m t y p e

Unit: mm (in)

Check ValveEFS005TB

Front Disc BrakeEFS005TC

Unit: mm (in) Front brake Brake model CLZ33VB

Cylinder bore diameter 46.4 (1.83)´2

Pad length´width´thickness 140´47.8´11 ( 5 . 5 1´1.88´0.43)

Rotor outer diameter´thickness 296´28 (11.65´1.10)

Rear brake Brake model LT30

Cylinder bore diameter 38.1 (1.50)

Lining Length´width´thickness 295´55´5.5 (11.61´2.17´0.22)

Drum inner diameter 295 (11.61)

Master cylinder Cylinder bore diameter 25.4 (1.0)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameterPrimary 228.5 (9.0)

Secondary 203 (8.0)

Recommended brake fluid DOT 3 or DOT 4

Brake pedal height (From dash lower panel top surface)LHD modelA/T 164.1-174.1 (6.46-6.85)

M/T 171.2-181.2 (6.74-7.13)

RHD modelA/T 174.7-184.7 (6.88-7.27)

M/T 182.1-192.1 (7.17-7.56)

Brake pedal depressed height [Under a force of 490 N (50 kg, 110 lb)

with the engine running]LHD model 120 (4.72) or more

RHD model 110 (4.33) or more

Clearance between bracket and the threaded end of the stop lamp switch 0.74 - 1.96 (0.0291 - 0.0772)

Pedal play3-11(0.12-0.43)

Input rod installation standard dimension 145 - 152 (5.71 - 5.98)

Vacuum leakage

[at vacuum of –66.7 kPa (–500 mmHg, –19.69 inHg)]within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake modelCLZ33VB

Brake padStandard thickness 11.0 (0.43)

Repair limit thickness 2.0 (0.08)

Disc rotorStandard thickness 28.0 (1.102)

Repair limit 26.0 (1.024)

Thickness variation (measured at 8 positions) 0.005 (0.0002)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Page 823 of 3171

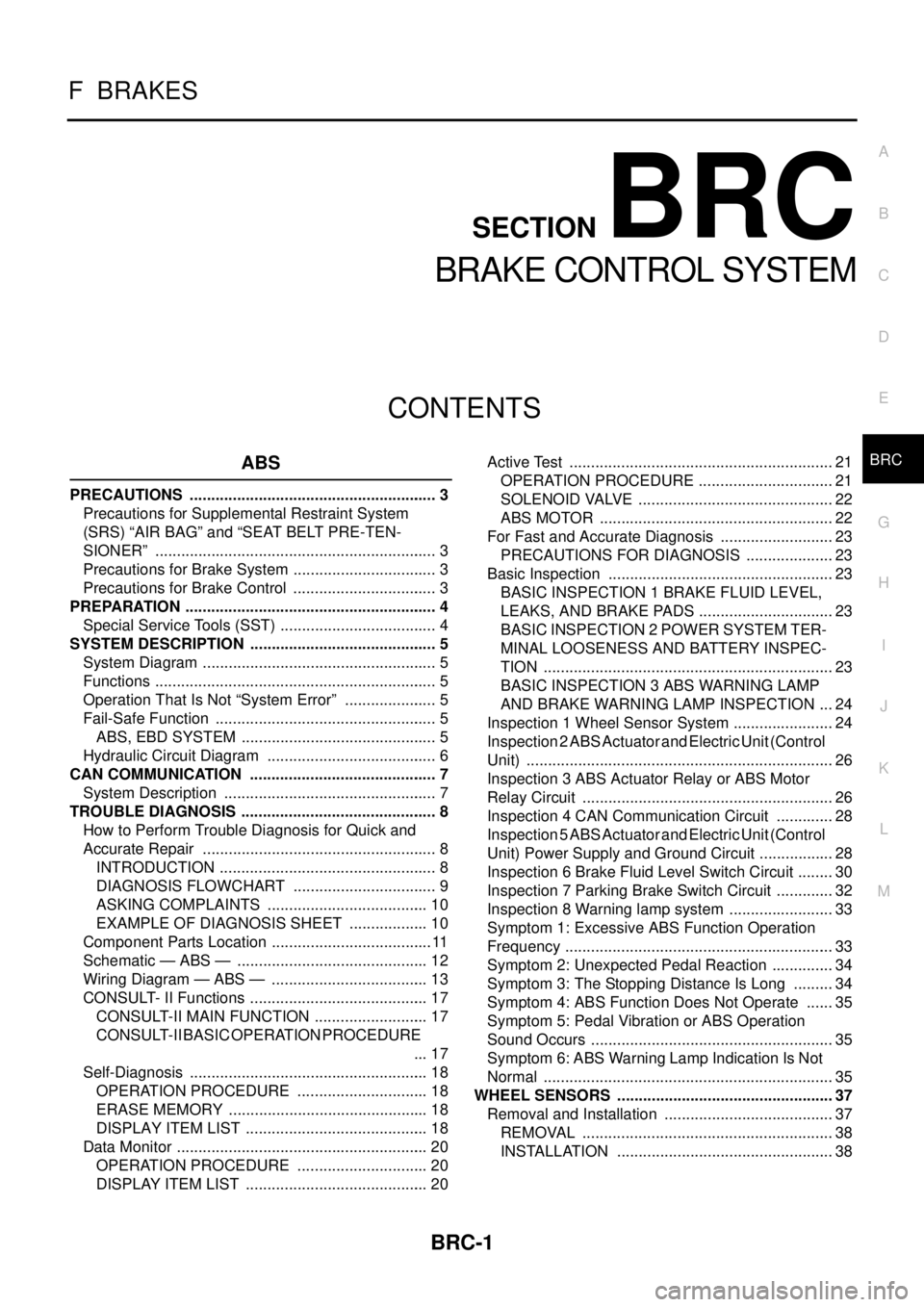

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTIONBRC

A

B

BRC

BRAKE CONTROL SYSTEM

ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 3

PREPARATION ........................................................... 4

Special Service Tools (SST) ..................................... 4

SYSTEM DESCRIPTION ............................................ 5

System Diagram ....................................................... 5

Functions .................................................................. 5

Operation That Is Not “System Error” ...................... 5

Fail-Safe Function .................................................... 5

ABS, EBD SYSTEM .............................................. 5

Hydraulic Circuit Diagram ........................................ 6

CAN COMMUNICATION ............................................ 7

System Description .................................................. 7

TROUBLE DIAGNOSIS .............................................. 8

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ....................................................... 8

INTRODUCTION ................................................... 8

DIAGNOSIS FLOWCHART .................................. 9

ASKING COMPLAINTS ...................................... 10

EXAMPLE OF DIAGNOSIS SHEET ................... 10

Component Parts Location ...................................... 11

Schematic — ABS — ............................................. 12

Wiring Diagram — ABS — ..................................... 13

CONSULT- II Functions .......................................... 17

CONSULT-II MAIN FUNCTION ........................... 17

CONSULT-II BASIC OPERATION PROCEDURE

... 17

Self-Diagnosis ........................................................ 18

OPERATION PROCEDURE ............................... 18

ERASE MEMORY ............................................... 18

DISPLAY ITEM LIST ........................................... 18

Data Monitor ........................................................... 20

OPERATION PROCEDURE ............................... 20

DISPLAY ITEM LIST ........................................... 20Active Test .............................................................. 21

OPERATION PROCEDURE ................................ 21

SOLENOID VALVE .............................................. 22

ABS MOTOR ....................................................... 22

For Fast and Accurate Diagnosis ........................... 23

PRECAUTIONS FOR DIAGNOSIS ..................... 23

Basic Inspection ..................................................... 23

BASIC INSPECTION 1 BRAKE FLUID LEVEL,

LEAKS, AND BRAKE PADS ................................ 23

BASIC INSPECTION 2 POWER SYSTEM TER-

MINAL LOOSENESS AND BATTERY INSPEC-

TION .................................................................... 23

BASIC INSPECTION 3 ABS WARNING LAMP

AND BRAKE WARNING LAMP INSPECTION .... 24

Inspection 1 Wheel Sensor System ........................ 24

Inspection 2 ABS Actuator and Electric Unit (Control

Unit) ........................................................................ 26

Inspection 3 ABS Actuator Relay or ABS Motor

Relay Circuit ........................................................... 26

Inspection 4 CAN Communication Circuit .............. 28

Inspection 5 ABS Actuator and Electric Unit (Control

Unit) Power Supply and Ground Circuit .................. 28

Inspection 6 Brake Fluid Level Switch Circuit ......... 30

Inspection 7 Parking Brake Switch Circuit .............. 32

Inspection 8 Warning lamp system ......................... 33

Symptom 1: Excessive ABS Function Operation

Frequency ............................................................... 33

Symptom 2: Unexpected Pedal Reaction ............... 34

Symptom 3: The Stopping Distance Is Long .......... 34

Symptom 4: ABS Function Does Not Operate ....... 35

Symptom 5: Pedal Vibration or ABS Operation

Sound Occurs ......................................................... 35

Symptom 6: ABS Warning Lamp Indication Is Not

Normal .................................................................... 35

WHEEL SENSORS ................................................... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 38

INSTALLATION ................................................... 38

Page 825 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement](/img/5/57362/w960_57362-824.png)

PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005TG

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.If brake fluid is splashed, wipe it off and flush area

with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lBrake system is an important safety part.If a brake fluid leak is

detected, always disassemble the affected part.If a malfunction

is detected, replace part with new one.

lBefore working, turn ignition switch OFF and disconnect con-

nector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

lWhen installing brake tube and hose, be sure to torque.

WARNING:

Clean brake pads and shoes with a waster cloth, then wipe with

a dust collector.

Precautions for Brake ControlEFS005TH

lJust after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of operation check.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

lWhen an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leaks.

lIf tyre size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

lIf aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 845 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONS NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONS](/img/5/57362/w960_57362-844.png)

TROUBLE DIAGNOSIS

BRC-23

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

For Fast and Accurate DiagnosisEFS005TX

PRECAUTIONS FOR DIAGNOSIS

lBefore performing diagnosis, always read precautions. Refer toBRC-17, "CONSULT- II Functions".

lAfter diagnosis is finished, be sure to erase memory. Refer toBRC-18, "ERASE MEMORY".

lWhen checking continuity and voltage between units, be sure to check for disconnection, looseness,

bend, or collapse of connector terminals. If any malfunction is found, repair or replace connector termi-

nals.

lFor intermittent symptoms, possible cause is malfunction in harness, harness connector, or terminals.

Move harness, harness connector, and terminals to check for poor connections.

lIf a circuit tester is used for check, be careful not to forcibly extend any connector terminal.

lABS system electrically controls brake operation and engine output. Following symptoms may be caused

by normal operations:

Basic InspectionEFS005TY

BASIC INSPECTION 1 BRAKE FLUID LEVEL, LEAKS, AND BRAKE PADS

1. Check fluid level in the brake reservoir tank. If fluid level is low, refill brake fluid.

2. Check brake tube and around ABS actuator and electric unit (control unit) for leaks. If leakage or seepage

is found, check the following items.

lIf ABS actuator and electric unit (control unit) connection is loose, tighten brake tube to the specified

torque and re-conduct the leak inspection to make sure there are no leakage.

lIf there is damage to the connection flare nut or ABS actuator and electric unit (control unit) screw,

replace the damaged part and re-conduct the leak inspection to make sure there are no leakage.

lIf there is leakage or seepage at any location other than ABS actuator and electric unit (control unit)

connection, wipe away leakage or seepage with clean cloth. Then inspect again and confirm than there

is on leakage.

lIf there is leakage from ABS actuator and electric unit (control unit), wipe away leakage or seepage with

clean cloth. Then inspect again. If there is leakage or seepage, replace ABS actuator and electric unit

(control unit).

CAUTION:

ABS actuator and electric unit (control unit) body cannot be disassembled.

3. Check brake pad degree of wear. Refer toBR-24, "

PAD WEAR INSPECTION"in “Front Disc Brake” and

BR-32, "

Lining Thickness Inspection"in “Rear Drum Brake”.

BASIC INSPECTION 2 POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

Make sure battery positive cable, negative cable and ground connection are not loose. In addition, check the

battery voltage to make sure it has not dropped and alternator is normal.

Symptom Symptom description Result

Motor operation noiseThis is noise of motor inside ABS actuator and electric unit (control unit). Slight

noise may occur during ABS operation.

Normal

Just after engine starts, motor operating noise may be heard. This is a normal

status of the system operation check.

System operation check noiseWhen engine starts, slight “click” noise may be heard from engine compart-

ment. This is normal and is part of system operation check.Normal

ABS operation

(Longer stopping distance)When driving on roads with a low coefficient of friction, such as snowy roads

or gravel roads, the stopping distance is sometimes longer for vehicles

equipped with ABS. Therefore, when driving on such roads, drive at a suffi-

ciently reduced speed to be safe.Normal

Page 2284 of 3171

PERIODIC MAINTENANCE

MA-9

C

D

E

F

G

H

I

J

K

MA

B

MA

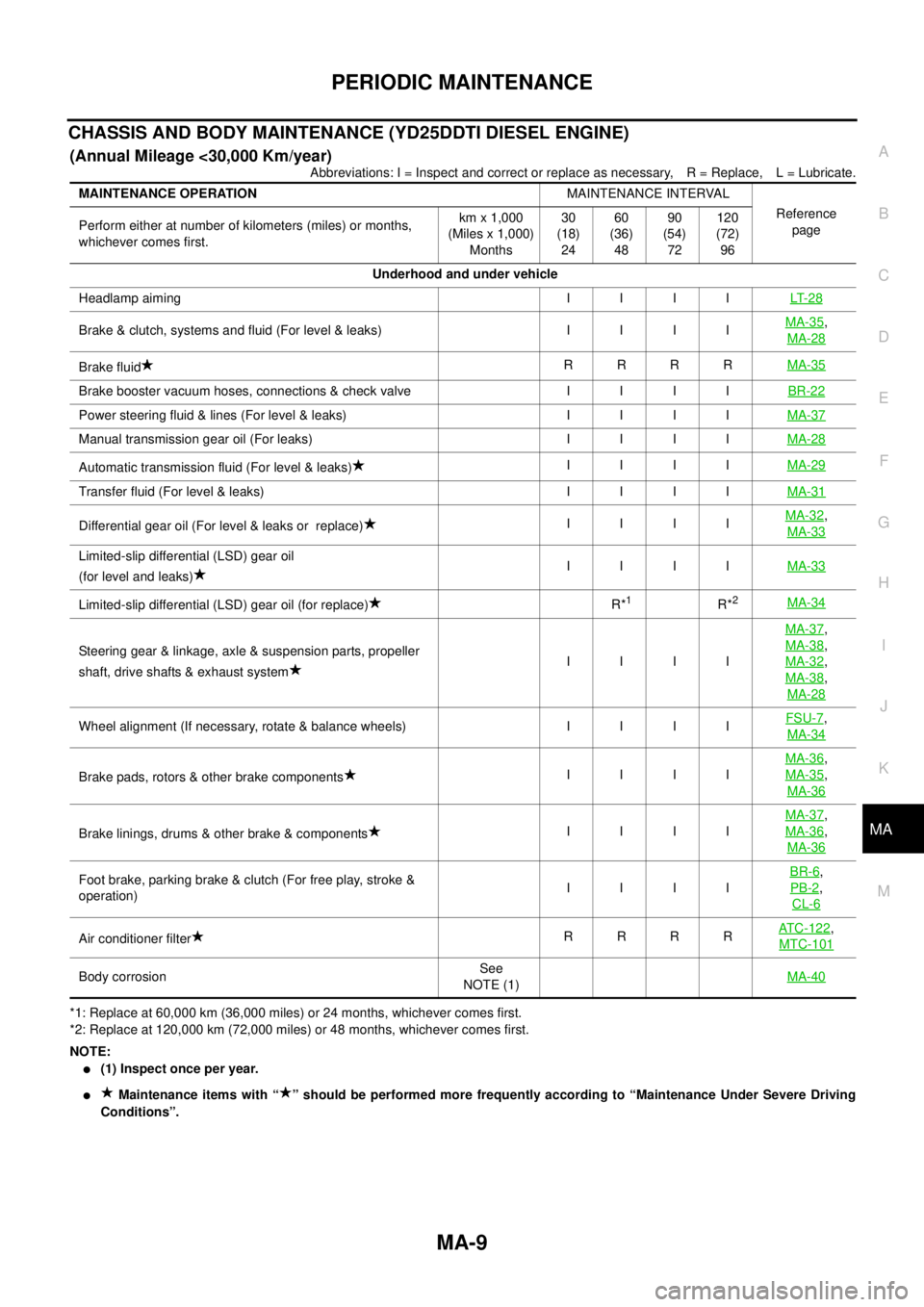

CHASSIS AND BODY MAINTENANCE (YD25DDTI DIESEL ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

*1: Replace at 60,000 km (36,000 miles) or 24 months, whichever comes first.

*2: Replace at 120,000 km (72,000 miles) or 48 months, whichever comes first.

NOTE:

l(1) Inspect once per year.

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”. MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers (miles) or months,

whichever comes first.km x 1,000

(Miles x 1,000)

Months30

(18)

2460

(36)

4890

(54)

72120

(72)

96

Underhood and under vehicle

Headlampaiming IIIILT- 2 8

Brake&clutch,systemsandfluid(Forlevel&leaks) IIIIMA-35,

MA-28

Brake fluidRRRRMA-35

Brakeboostervacuumhoses,connections&checkvalve IIIIBR-22

Powersteeringfluid&lines(Forlevel&leaks) IIIIMA-37

Manual transmission gear oil (For leaks)IIIIMA-28

Automatic transmission fluid (For level & leaks)IIIIMA-29

Transferfluid(Forlevel&leaks) IIIIMA-31

Differential gear oil (For level & leaks or replace)IIIIMA-32,

MA-33

Limited-slip differential (LSD) gear oil

(for level and leaks)IIIIMA-33

Limited-slip differential (LSD) gear oil (for replace)R*1R*2MA-34

Steering gear & linkage, axle & suspension parts, propeller

shaft, drive shafts & exhaust systemIIIIMA-37

,

MA-38

,

MA-32

,

MA-38

,

MA-28

Wheelalignment(Ifnecessary,rotate&balancewheels) IIIIFSU-7,

MA-34

Brake pads, rotors & other brake componentsIIIIMA-36

,

MA-35

,

MA-36

Brake linings, drums & other brake & componentsIIIIMA-37

,

MA-36

,

MA-36

Foot brake, parking brake & clutch (For free play, stroke &

operation)IIIIBR-6,

PB-2

,

CL-6

Air conditioner filterRRRRATC-122,

MTC-101

Body corrosionSee

NOTE (1)MA-40