checking oil NISSAN NAVARA 2005 Repair Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2635 of 3171

PS-8

STEERING WHEEL

STEERING WHEEL

PFP:48430

On-Vehicle Inspection and ServiceEGS001LG

CHECKING CONDITION OF INSTALLATION

lCheck installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

lCheck if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

lCheck steering gear assembly mounting bolts and nuts for looseness. Refer toPS-14, "COMPONENT".

CHECKING STEERING WHEEL PLAY

lTurn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

lWhen the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

lMake sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

lPerform neutral position inspection after wheel alignment. Refer toFSU-7, "Front Wheel Alignment".

lSet vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

lLoosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustment if

steering wheel is not in the neutral position.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80°C(122to176°F).]

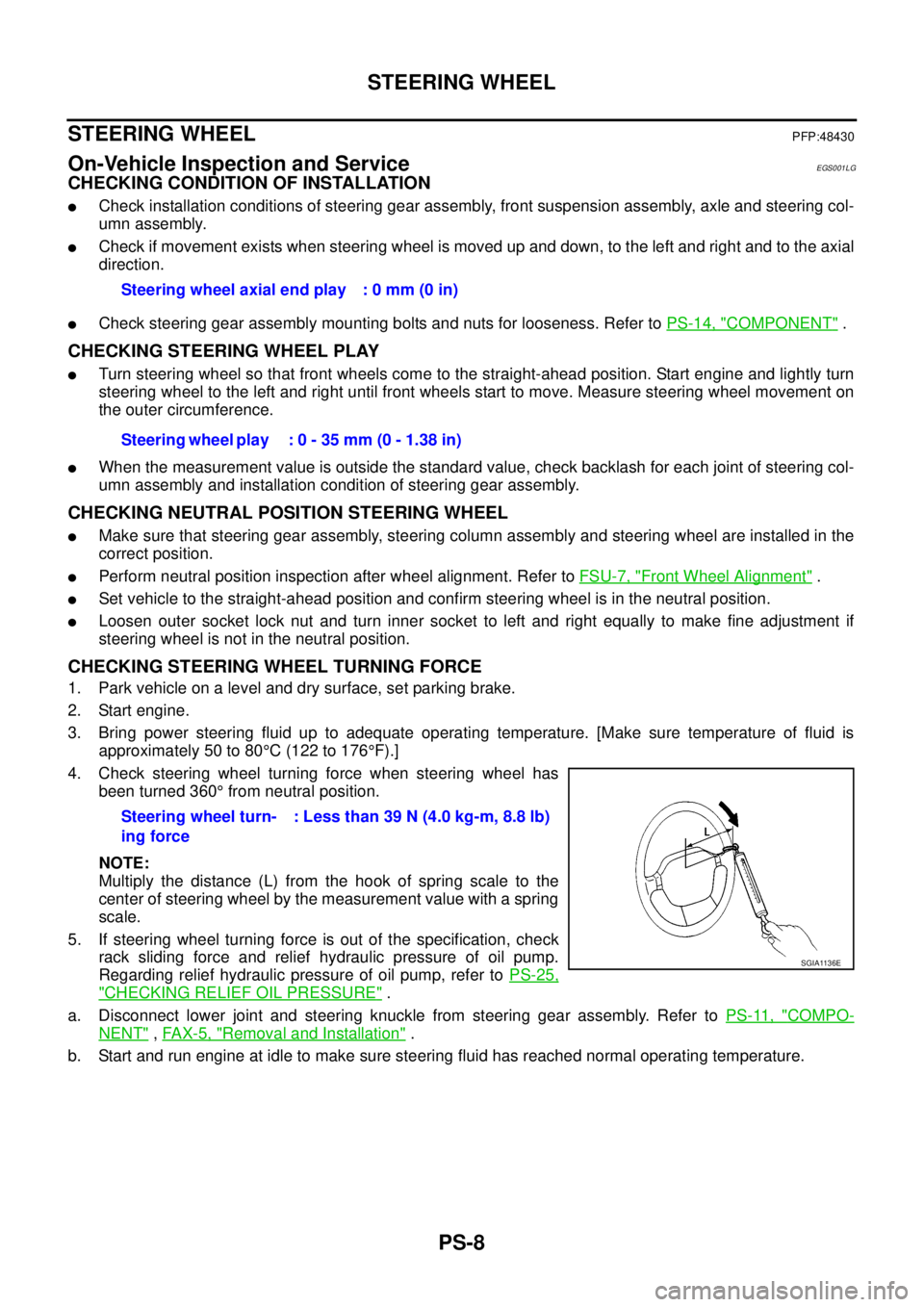

4. Check steering wheel turning force when steering wheel has

been turned 360°from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer toPS-25,

"CHECKING RELIEF OIL PRESSURE".

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer toPS-11, "

COMPO-

NENT",FAX-5, "Removal and Installation".

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature.Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turn-

ing force: Less than 39 N (4.0 kg-m, 8.8 lb)

SGIA1136E

Page 2652 of 3171

POWER STEERING OIL PUMP

PS-25

C

D

E

F

H

I

J

K

L

MA

B

PS

POWER STEERING OIL PUMPPFP:49110

On-Vehicle Inspection and ServiceEGS001LL

CHECKING RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

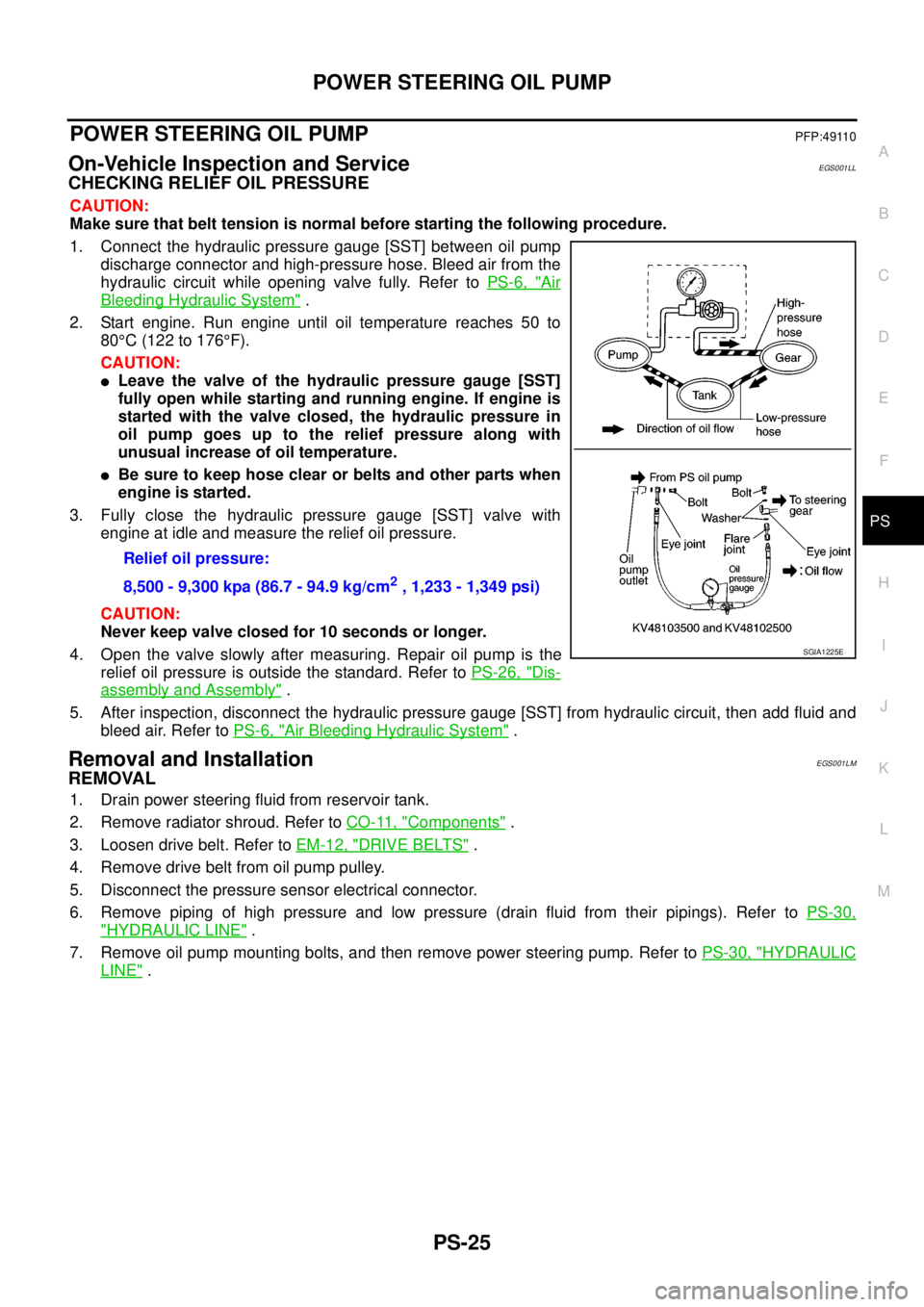

1. Connect the hydraulic pressure gauge [SST] between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer toPS-6, "

Air

Bleeding Hydraulic System".

2. Start engine. Run engine until oil temperature reaches 50 to

80°C(122to176°F).

CAUTION:

lLeave the valve of the hydraulic pressure gauge [SST]

fully open while starting and running engine. If engine is

started with the valve closed, the hydraulic pressure in

oil pump goes up to the relief pressure along with

unusual increase of oil temperature.

lBe sure to keep hose clear or belts and other parts when

engineisstarted.

3. Fully close the hydraulic pressure gauge [SST] valve with

engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump is the

relief oil pressure is outside the standard. Refer toPS-26, "

Dis-

assembly and Assembly".

5. After inspection, disconnect the hydraulic pressure gauge [SST] from hydraulic circuit, then add fluid and

bleed air. Refer toPS-6, "

Air Bleeding Hydraulic System".

Removal and InstallationEGS001LM

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove radiator shroud. Refer toCO-11, "

Components".

3. Loosen drive belt. Refer toEM-12, "

DRIVE BELTS".

4. Remove drive belt from oil pump pulley.

5. Disconnect the pressure sensor electrical connector.

6. Remove piping of high pressure and low pressure (drain fluid from their pipings). Refer toPS-30,

"HYDRAULIC LINE".

7. Remove oil pump mounting bolts, and then remove power steering pump. Refer toPS-30, "

HYDRAULIC

LINE". Relief oil pressure:

8,500 - 9,300 kpa (86.7 - 94.9 kg/cm

2, 1,233 - 1,349 psi)

SGIA1225E

Page 2704 of 3171

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONRFD

A

B

RFD

REAR FINAL DRIVE

WITH LIMITED SLIP DIFFERENTIAL

PRECAUTIONS .......................................................... 3

Limited Slip Differential (LSD) Performance Judge-

ment ......................................................................... 3

METHOD FOR TROUBLESHOOTING ................. 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

CARRIER COVER .................................................... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

REAR FINAL DRIVE ASSEMBLY ............................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Disassembly and Assembly ................................... 15

COMPONENTS .................................................. 15

ASSEMBLY INSPECTION AND ADJUSTMENT... 16

DISASSEMBLY ................................................... 19

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTION ADJUSTING WASHERS ............... 23

ASSEMBLY ......................................................... 24SERVICE DATA AND SPECIFICATIONS (SDS) ...... 31

General Specifications ............................................ 31

Inspection and Adjustment ..................................... 31

PRELOAD TORQUE ........................................... 31

BACKLASH ......................................................... 31

COMPANION FLANGE RUNOUT ....................... 31

SELECTIVE PARTS ............................................ 32

WITH ELECTRONIC LOCKING DIFFEREN-

TIAL

PRECAUTIONS ........................................................ 33

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................. 33

Precautions for Differential Case Assembly and Dif-

ferential Lock Control Unit Replacement ................ 33

CHECK DIFF LOCK INDICATOR LAMP ............. 33

METHOD FOR ADJUSTMENT ........................... 34

Precautions ............................................................. 34

Service Notice or Precaution .................................. 35

Wiring Diagrams and Trouble Diagnosis ................ 35

PREPARATION ......................................................... 36

Special Service Tools ............................................. 36

Commercial Service Tools ...................................... 37

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 39

NVH Troubleshooting Chart ................................... 39

DIFFERENTIAL GEAR OIL ...................................... 40

Changing Differential Gear Oil ................................ 40

DRAINING ........................................................... 40

FILLING ............................................................... 40

Checking Differential Gear Oil ................................ 40

OIL LEAKAGE AND OIL LEVEL ......................... 40

DIFFERENTIAL LOCK SYSTEM .............................. 41

Cross-sectional View .............................................. 41

Differential Lock Operation ..................................... 42

System Description ................................................. 42

DIFFERENTIAL LOCK SOLENOID .................... 42

DIFFERENTIAL LOCK POSITION SWITCH ....... 42

Page 2706 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec NISSAN NAVARA 2005 Repair Manual PDF PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspec](/img/5/57362/w960_57362-2705.png)

PRECAUTIONS

RFD-3

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH LIMITED SLIP DIFFERENTIAL]PRECAUTIONSPFP:00001

Limited Slip Differential (LSD) Performance JudgementEDS003IG

lInspection is required when detecting any noise or malfunction while driving or turning. Improper condition

of oil or differential case assembly is suspected. Refer toRFD-3, "

METHOD FOR TROUBLESHOOTING"

.

METHOD FOR TROUBLESHOOTING

1. Check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differential

Gear Oil".

2. Changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

3. Start engine. Drive for 10 min.

4. Again changing differential gear oil. Refer toRFD-9, "

Changing Differential Gear Oil".

5. Start engine. Drive for 10 min. Check if any noise or improper oil condition is detected.

lIf OK, check differential gear oil level and differential gear oil leakage. Refer toRFD-9, "Checking Differ-

ential Gear Oil".

lIf NG, replace differential case assembly after checking each part of final drive. Refer toRFD-15, "Dis-

assembly and Assembly".

Service Notice or PrecautionsEDS0038Z

lCheck for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts when applied.

lOverhaul should be done in a clean work area, it is preferable to work in dust proof area.

lBefore disassembly completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

lCheck appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

lGaskets, seals and O-rings should be replaced any time the unit is disassembled.

lIn principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

lClean and flush the parts sufficiently and blow-dry them.

lBe careful not to damage sliding surfaces and mating surfaces.

lWhen applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

lAlways use shop paper for cleaning the inside of components.

lAvoid using cotton gloves or shop rags to prevent entering of lint.

lDuring assembly, observe the specified tightening torque, and apply new differential gear oil, petroleum

jelly, or multi-purpose grease as specified.

Page 2710 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooti NISSAN NAVARA 2005 Repair Manual PDF NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooti](/img/5/57362/w960_57362-2709.png)

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEDS00392

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

RFD-22, "

INSPECTION AFTER DISASSEMBLY

"

RFD-16, "

Tooth Contact

"

RFD-22, "

INSPECTION AFTER DISASSEMBLY

"

RFD-17, "

Backlash

"

RFD-18, "

Companion Flange Runout

"

RFD-9, "

Checking Differential Gear Oil

"

PR-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

",RSU-3, "

NVH Troubleshooting Chart

"

WT-2, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

AXLE SHAFT

BRAKES

STEERING

Symptom Noise´´´´´´´´´´´´´

Page 2712 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain p NISSAN NAVARA 2005 Repair Manual PDF DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain p](/img/5/57362/w960_57362-2711.png)

DIFFERENTIAL GEAR OIL

RFD-9

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilEDS00394

DRAINING

1. Stop engine.

2. Remove drain plug and drain gear oil.

3. Apply sealant to drain plug. Install drain plug to final drive

assembly and tighten to the specified torque. Refer toRFD-15,

"COMPONENTS".

FILLING

1. Remove filler plug. Fill with new gear oil until oil level reaches

the specified limit near filler plug hole.

2. After refilling oil, check oil level. Apply sealant to filler plug.

Install filler plug to final drive assembly and tighten to the speci-

fied torque. Refer toRFD-15, "

COMPONENTS".

Checking Differential Gear OilEDS00395

OIL LEAKAGE AND OIL LEVEL

1. Make sure that gear oil is not leaking from final drive assembly or around it.

2. Check oil level from filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

3. Apply sealant to filler plug. Install filler plug to final drive assem-

bly and tighten to the specified torque. Refer toRFD-15, "

COM-

PONENTS".

PDIA1038E

OilgradeandViscosity:

Refer toMA-14, "

Fluids and Lubricants".

Oil capacity:

Approx. 2.01 (3-1/2pt)

PDIA1039E

PDIA1039E

Page 2715 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF RFD-12

[WITH LIMITED SLIP DIFFERENTIAL]

FRONT OIL SEAL

4. Rotate the drive pinion using Tool. Rotating torque should be

equaltothereadingrecordedinstep4aboveduringremoval

plus an additional 0.56 N·m NISSAN NAVARA 2005 Repair Manual PDF RFD-12

[WITH LIMITED SLIP DIFFERENTIAL]

FRONT OIL SEAL

4. Rotate the drive pinion using Tool. Rotating torque should be

equaltothereadingrecordedinstep4aboveduringremoval

plus an additional 0.56 N·m](/img/5/57362/w960_57362-2714.png)

RFD-12

[WITH LIMITED SLIP DIFFERENTIAL]

FRONT OIL SEAL

4. Rotate the drive pinion using Tool. Rotating torque should be

equaltothereadingrecordedinstep4aboveduringremoval

plus an additional 0.56 N·m (5 in-lb).

5. If the rotating torque is low, continue to tighten the drive pinion

lock nut in 6.8 N·m (5 ft-lb) increments without overtightening.

Refer toRFD-15, "

COMPONENTS". Tighten until proper rotat-

ing torque is achieved.

CAUTION:

lDo not loosen the drive pinion lock nut to decrease drive

pinion rear bearing rotating torque.

lDo not exceed specified rotating preload torque. If preload torque or rotating torque is exceeded

a new collapsible spacer must be installed.

lDo not exceed maximum tightening torque. If maximum tightening torque is reached prior to

reaching the required rotating torque, the collapsible spacer may have been damaged. Replace

the collapsible spacer.

6. Check the gear oil level. Refer toRFD-9, "

Checking Differential Gear Oil".

7. Install the remaining components in the reverse order of removal.Tool number : ST3127S000

PDIA0309E

Page 2716 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF CARRIER COVER

RFD-13

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CARRIER COVERPFP:38351

Removal and InstallationEDS00397

REMOVAL

1. Remove the drain plug and drain the gear oil. Refer NISSAN NAVARA 2005 Repair Manual PDF CARRIER COVER

RFD-13

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CARRIER COVERPFP:38351

Removal and InstallationEDS00397

REMOVAL

1. Remove the drain plug and drain the gear oil. Refer](/img/5/57362/w960_57362-2715.png)

CARRIER COVER

RFD-13

[WITH LIMITED SLIP DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

CARRIER COVERPFP:38351

Removal and InstallationEDS00397

REMOVAL

1. Remove the drain plug and drain the gear oil. Refer toRFD-9, "DRAINING".

2. Disconnect the rear cable (LH) from the carrier cover. Refer toPB-3, "

Components".

3. Remove bracket from the axle housing.

4. Remove the carrier cover bolts. Then separate carrier cover

from the axle housing using Tool.

CAUTION:

lBe careful not to damage the mating surface.

lDo not insert flat-bladed screwdriver, this will damage the

mating surface.

INSTALLATION

1. Apply sealant to mating surface of carrier cover. Refer toRFD-

15, "COMPONENTS".

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

2. Install carrier cover and bracket on axle housing. Then tighten

carrier cover bolts to the specified torque. Refer toRFD-15,

"COMPONENTS".

3. Connect the rear cable (LH) to the carrier cover and tighten to

the specified torque. Refer toPB-3, "

Components".

4. Fill with new gear oil until oil level reaches the specified limit

near filler plug hole. Refer toRFD-9, "

Checking Differential Gear

Oil".

PDIA1066E

Tool number : KV10111100

PDIA1041E

PDIA1042E

PDIA1066E

Page 2717 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova NISSAN NAVARA 2005 Repair Manual PDF RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova](/img/5/57362/w960_57362-2716.png)

RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-9, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

Page 2719 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF RFD-16

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

lBefore inspection and adjustment, drain gear oil.

Total Preload Torque

1. Rotate drive pinion back NISSAN NAVARA 2005 Repair Manual PDF RFD-16

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

lBefore inspection and adjustment, drain gear oil.

Total Preload Torque

1. Rotate drive pinion back](/img/5/57362/w960_57362-2718.png)

RFD-16

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

lBefore inspection and adjustment, drain gear oil.

Total Preload Torque

1. Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

2. Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

3. Turn drive pinion in both directions several times to set bearing

rollers.

4. Measure total preload with preload gauge.

NOTE:

Total preload torque = Pinion bearing preload torque + Side bearing preload torque

lIf measured value is out of the specification, disassemble it to check and adjust each part. Adjust pinion

bearing preload and side bearing preload.

Adjust pinion bearing preload first, then adjust side bearing preload.

Tooth Contact

Checking gear tooth contact pattern is necessary to verify correct relationship between drive gear and drive

pinion. Gears which are not positioned in proper arrangement may be noisy and/or have a short life. Check

gear tooth contact pattern to obtain the best contact for low noise and long life.

1. Remove carrier cover. Refer toRFD-13, "

Removal and Installation".

2. Thoroughly clean drive gear and drive pinion teeth.

3. Apply red lead to drive gear.

CAUTION:

Apply red lead to both the faces of 3 to 4 gears at 4 loca-

tions evenly spaced on drive gear.Tool number : ST3127S000

To ta l p r e l o a d

Gear ratio 3.357 Type:

2.38 - 4.46 N·m (0.25 - 0.45 kg-m, 21- 39 in-lb)

Gear ratio 3.538 Type:

2.34 - 4.34 N·m (0.24 - 0.44 kg-m, 21- 38 in-lb)

Gear ratio 3.692 Type:

2.32 - 4.34 N·m (0.24 - 0.44 kg-m, 21 - 38 in-lb)

When the preload torque is greater than specification

On pinion bearings: Replace collapsible spacer.

On side bearings: Loosen side bearing adjuster.

When the preload torque is less than specification

On pinion bearings: Tighten drive pinion lock nut.

On side bearings: Tighten side bearing adjuster.

PDIA0309E

PDIA0321E