Coolant leak NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 460 of 3171

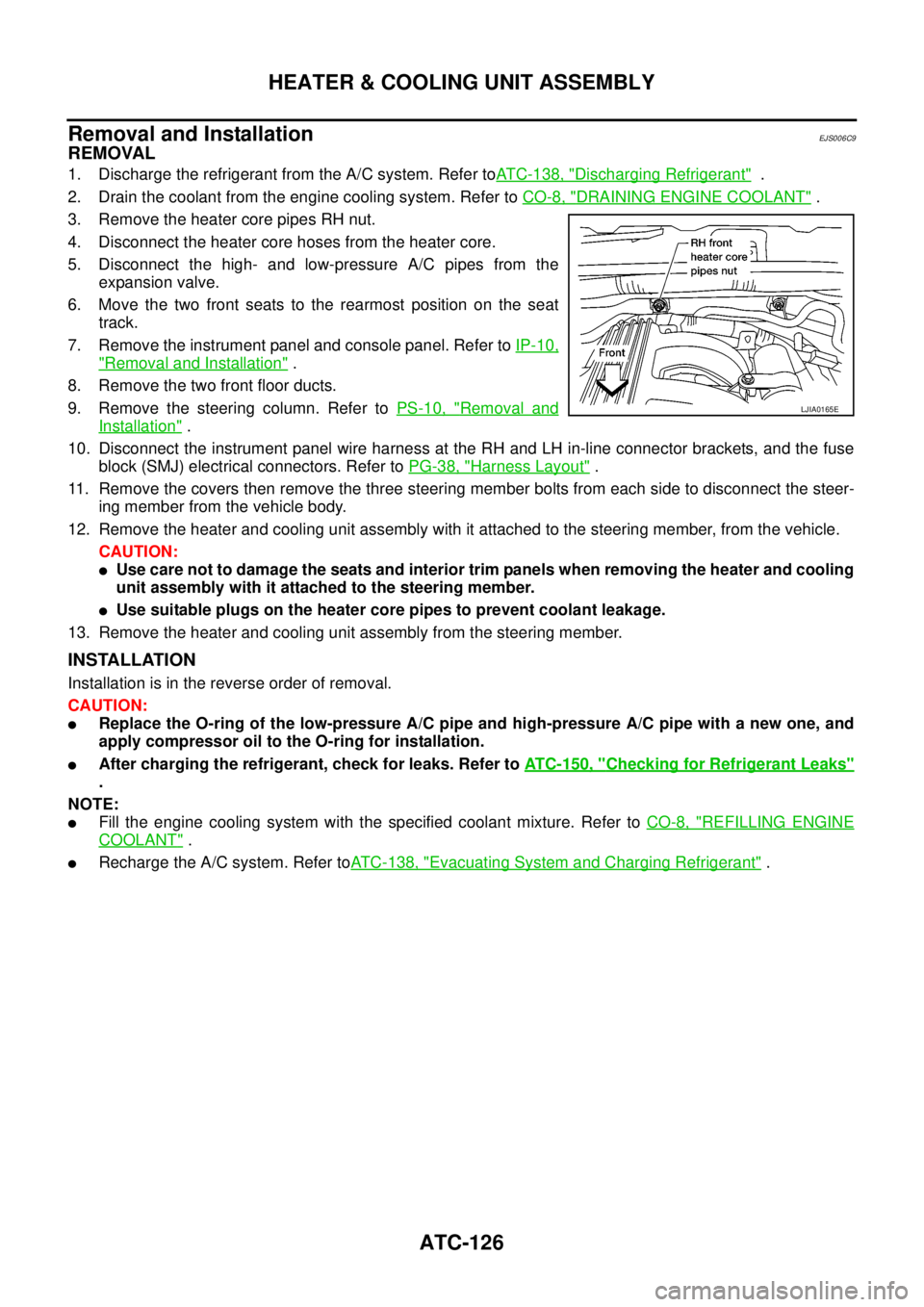

ATC-126

HEATER & COOLING UNIT ASSEMBLY

Removal and Installation

EJS006C9

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toATC-138, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the heater core pipes RH nut.

4. Disconnect the heater core hoses from the heater core.

5. Disconnect the high- and low-pressure A/C pipes from the

expansion valve.

6. Move the two front seats to the rearmost position on the seat

track.

7. Remove the instrument panel and console panel. Refer toIP-10,

"Removal and Installation".

8. Remove the two front floor ducts.

9. Remove the steering column. Refer toPS-10, "

Removal and

Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (SMJ) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Remove the covers then remove the three steering member bolts from each side to disconnect the steer-

ing member from the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

lUse care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

lUse suitable plugs on the heater core pipes to prevent coolant leakage.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure A/C pipe and high-pressure A/C pipe with a new one, and

apply compressor oil to the O-ring for installation.

lAfter charging the refrigerant, check for leaks. Refer toATC-150, "Checking for Refrigerant Leaks"

.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toATC-138, "Evacuating System and Charging Refrigerant".

LJIA0165E

Page 461 of 3171

HEATER CORE

ATC-127

C

D

E

F

G

H

I

K

L

MA

B

AT C

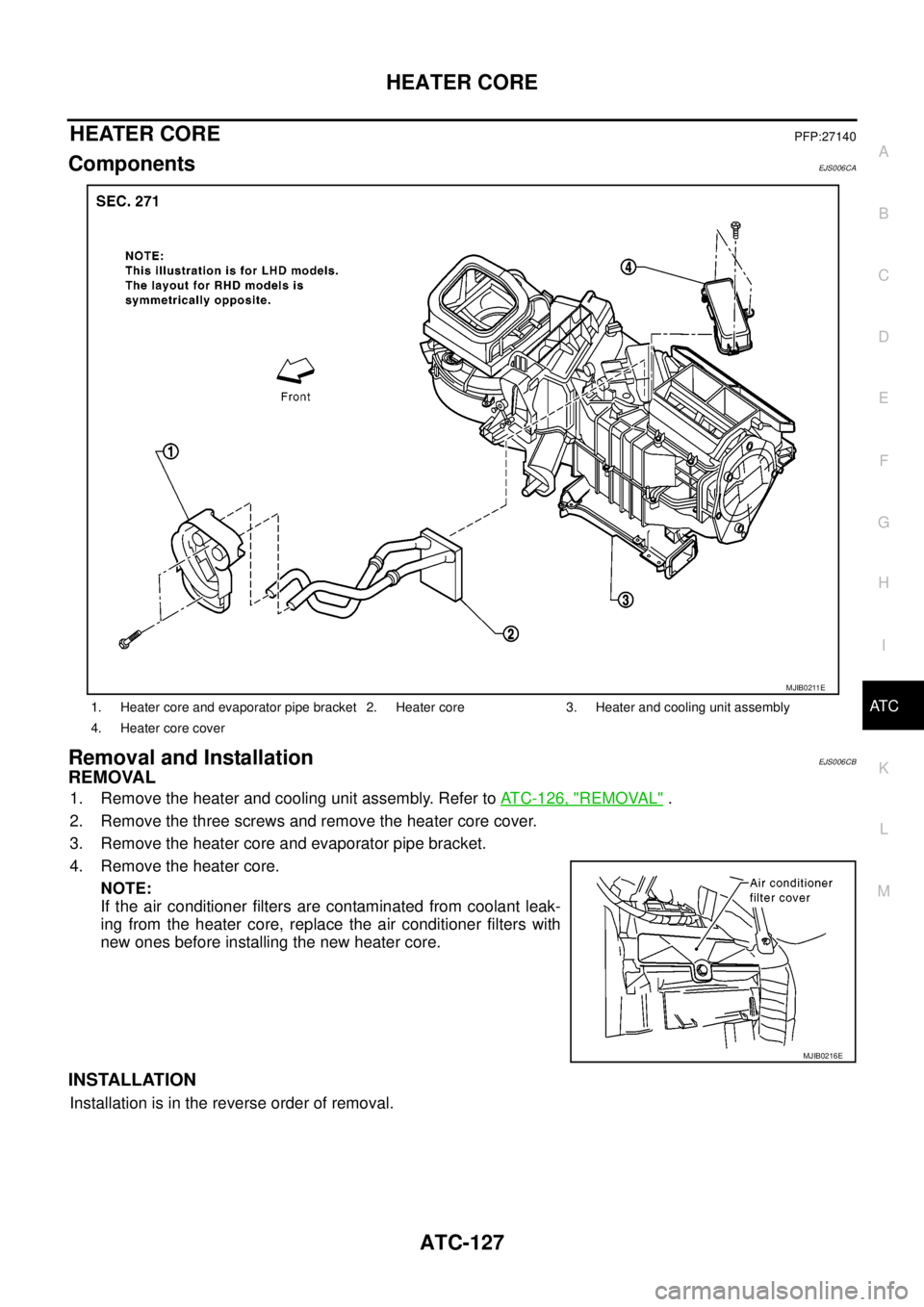

HEATER COREPFP:27140

ComponentsEJS006CA

Removal and InstallationEJS006CB

REMOVAL

1. Remove the heater and cooling unit assembly. Refer toATC-126, "REMOVAL".

2. Remove the three screws and remove the heater core cover.

3. Remove the heater core and evaporator pipe bracket.

4. Remove the heater core.

NOTE:

If the air conditioner filters are contaminated from coolant leak-

ing from the heater core, replace the air conditioner filters with

new ones before installing the new heater core.

INSTALLATION

Installation is in the reverse order of removal.

1. Heater core and evaporator pipe bracket 2. Heater core 3. Heater and cooling unit assembly

4. Heater core cover

MJIB0211E

MJIB0216E

Page 885 of 3171

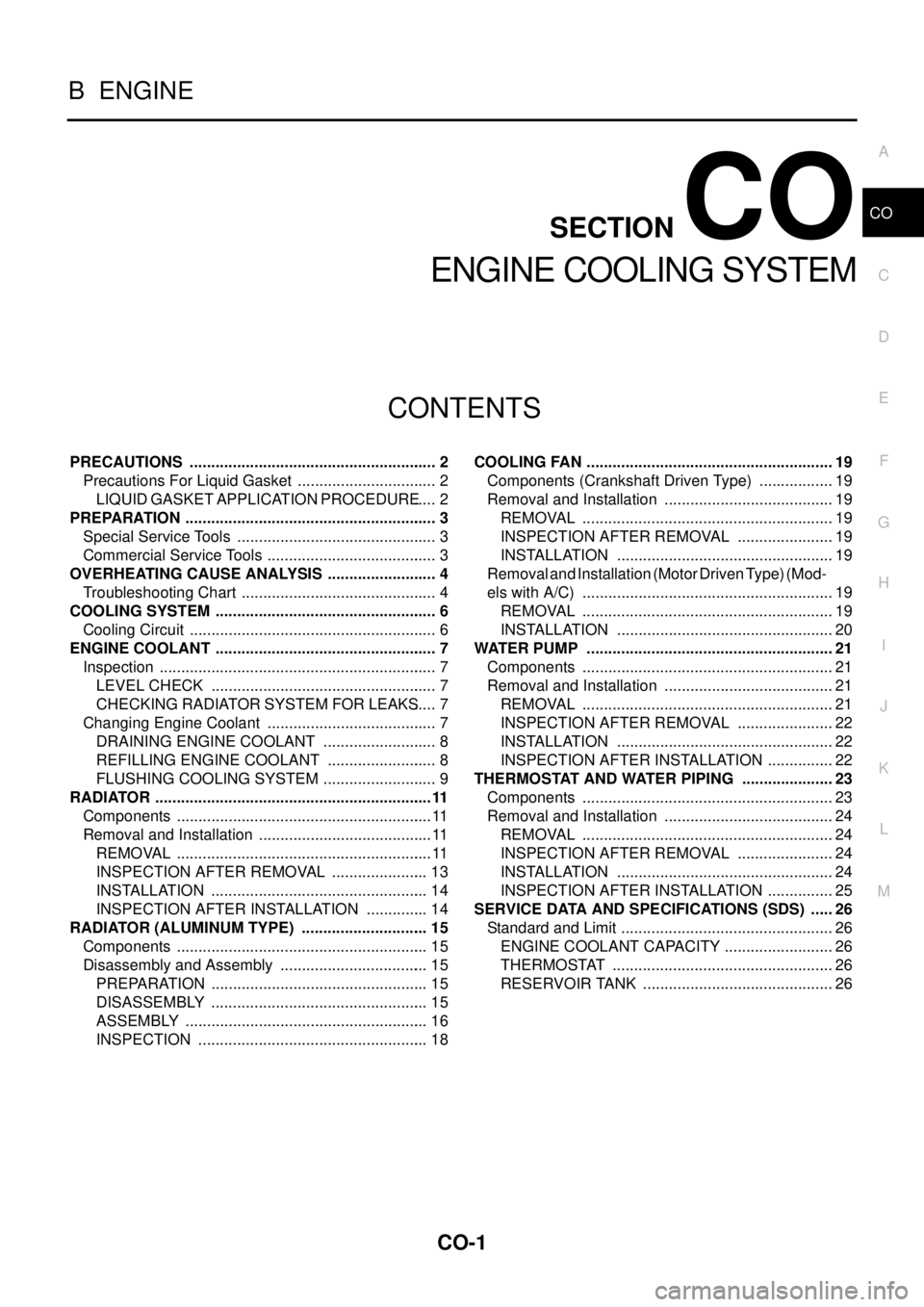

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONCO

A

CO

ENGINE COOLING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions For Liquid Gasket ................................. 2

LIQUID GASKET APPLICATION PROCEDURE..... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

OVERHEATING CAUSE ANALYSIS .......................... 4

Troubleshooting Chart .............................................. 4

COOLING SYSTEM .................................................... 6

Cooling Circuit .......................................................... 6

ENGINE COOLANT .................................................... 7

Inspection ................................................................. 7

LEVEL CHECK ..................................................... 7

CHECKING RADIATOR SYSTEM FOR LEAKS..... 7

Changing Engine Coolant ........................................ 7

DRAINING ENGINE COOLANT ........................... 8

REFILLING ENGINE COOLANT .......................... 8

FLUSHING COOLING SYSTEM ........................... 9

RADIATOR .................................................................11

Components ............................................................ 11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 13

INSTALLATION ................................................... 14

INSPECTION AFTER INSTALLATION ............... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Components ........................................................... 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18COOLING FAN .......................................................... 19

Components (Crankshaft Driven Type) .................. 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

Removal and Installation (Motor Driven Type) (Mod-

els with A/C) ........................................................... 19

REMOVAL ........................................................... 19

INSTALLATION ................................................... 20

WATER PUMP .......................................................... 21

Components ........................................................... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

THERMOSTAT AND WATER PIPING ...................... 23

Components ........................................................... 23

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSPECTION AFTER REMOVAL ....................... 24

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

ENGINE COOLANT CAPACITY .......................... 26

THERMOSTAT .................................................... 26

RESERVOIR TANK ............................................. 26

Page 888 of 3171

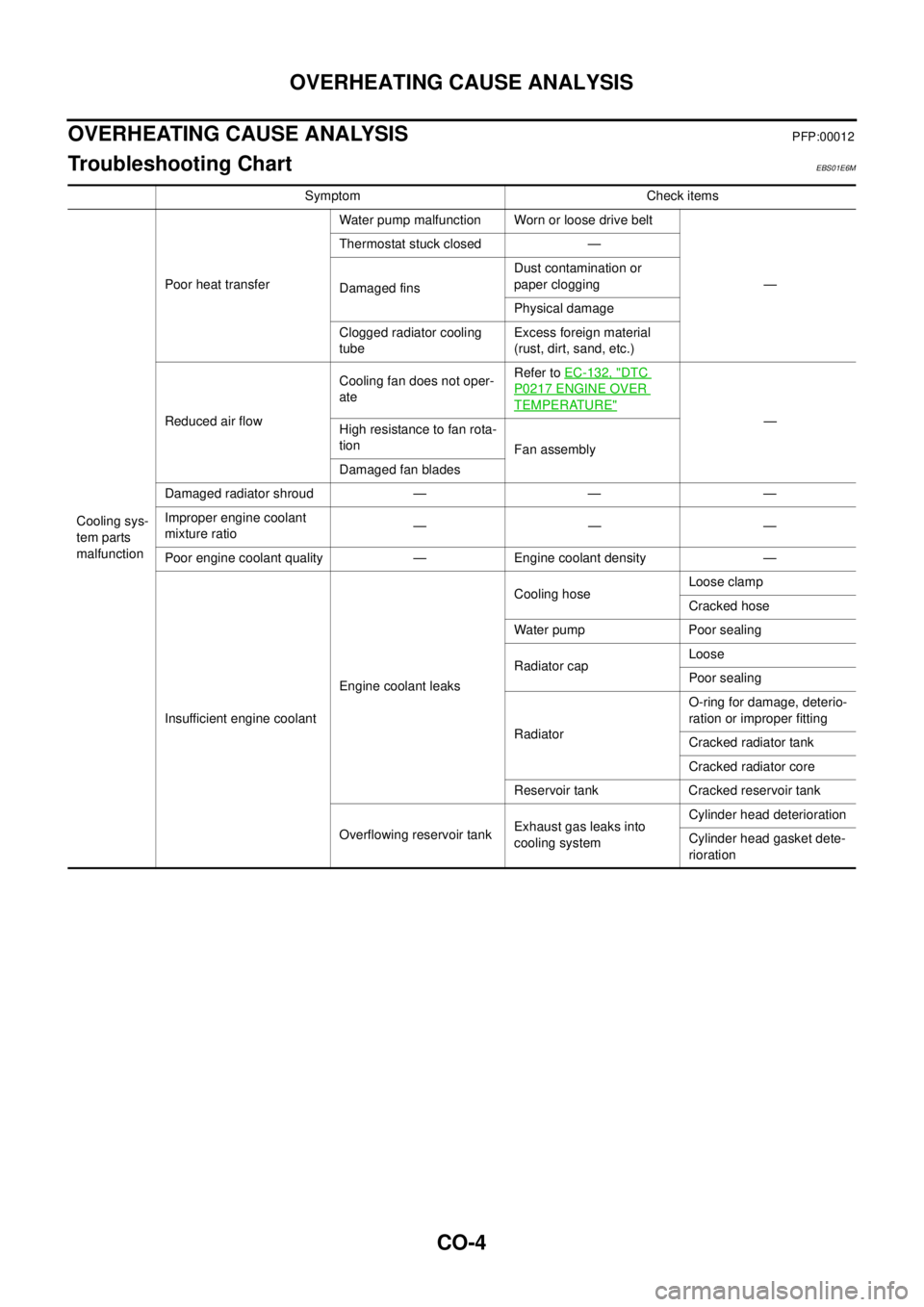

CO-4

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

PFP:00012

Troubleshooting ChartEBS01E6M

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ateRefer toEC-132, "

DTC

P0217 ENGINE OVER

TEMPERATURE"

—

Highresistancetofanrota-

tion

Fan assembly

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio—— —

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 891 of 3171

ENGINE COOLANT

CO-7

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS01E6P

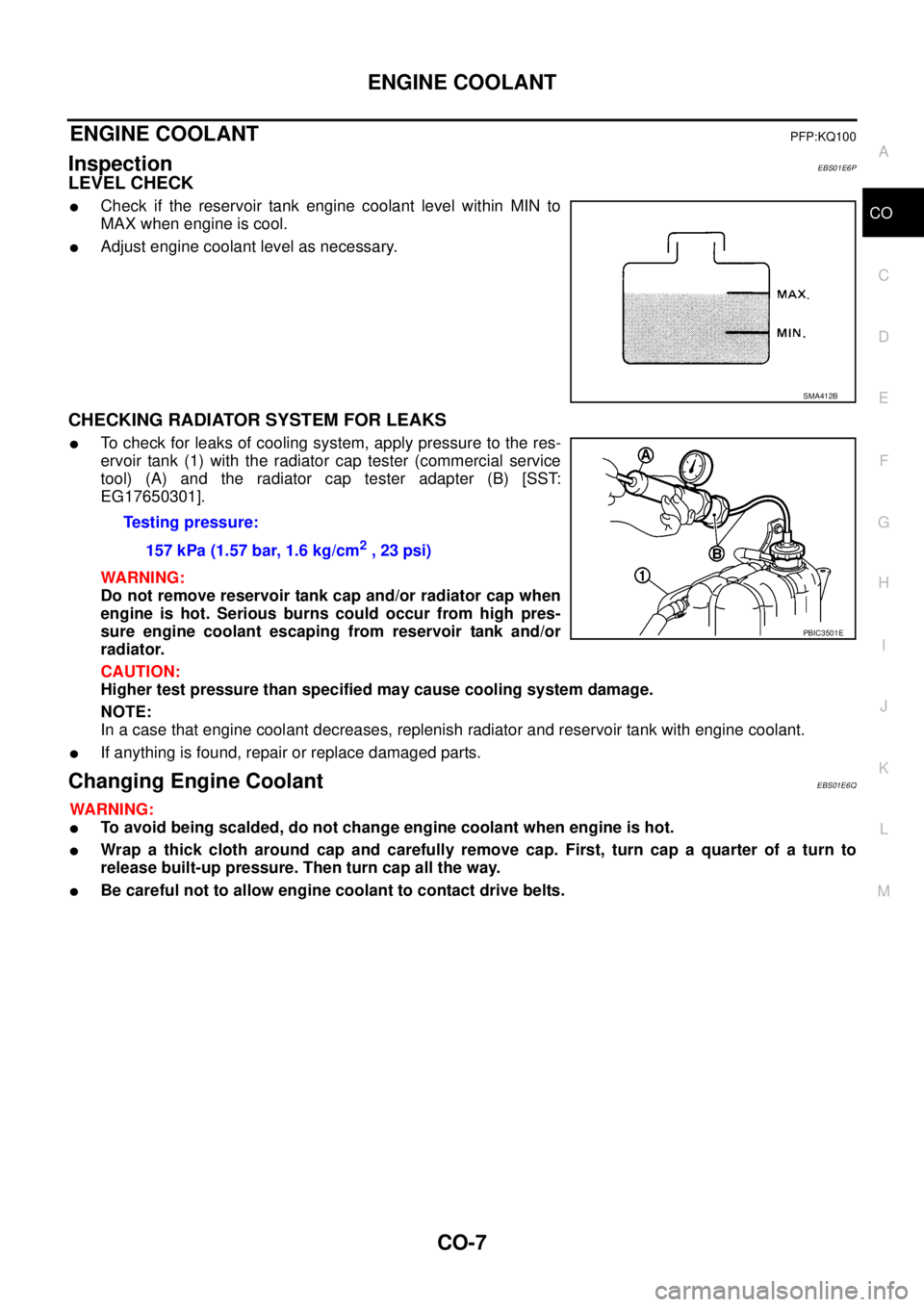

LEVEL CHECK

lCheck if the reservoir tank engine coolant level within MIN to

MAX when engine is cool.

lAdjust engine coolant level as necessary.

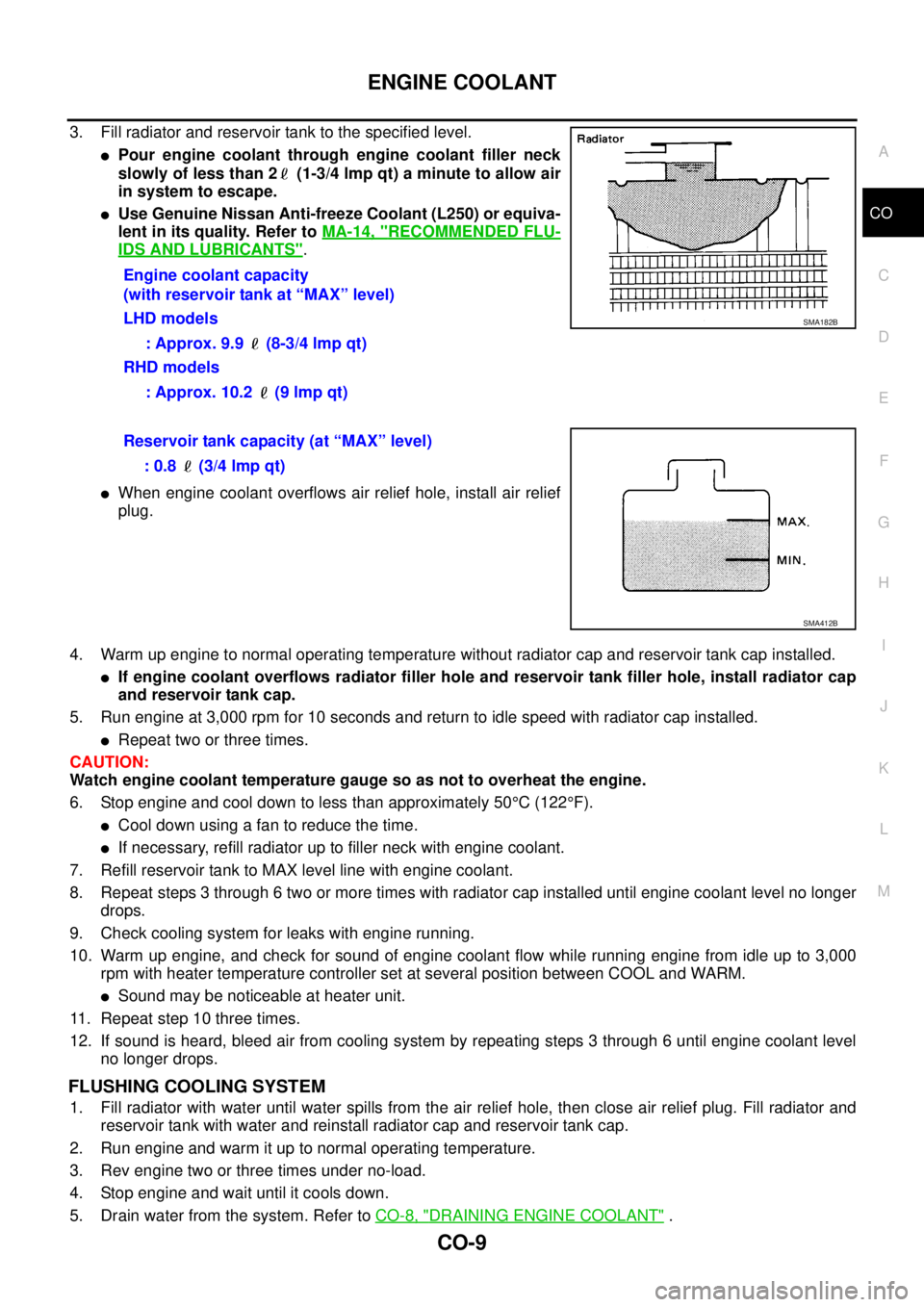

CHECKING RADIATOR SYSTEM FOR LEAKS

lTo check for leaks of cooling system, apply pressure to the res-

ervoir tank (1) with the radiator cap tester (commercial service

tool) (A) and the radiator cap tester adapter (B) [SST:

EG17650301].

WARNING:

Do not remove reservoir tank cap and/or radiator cap when

engine is hot. Serious burns could occur from high pres-

sure engine coolant escaping from reservoir tank and/or

radiator.

CAUTION:

Higher test pressure than specified may cause cooling system damage.

NOTE:

In a case that engine coolant decreases, replenish radiator and reservoir tank with engine coolant.

lIf anything is found, repair or replace damaged parts.

Changing Engine CoolantEBS01E6Q

WARNING:

lTo avoid being scalded, do not change engine coolant when engine is hot.

lWrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to

release built-up pressure. Then turn cap all the way.

lBe careful not to allow engine coolant to contact drive belts.

SMA412B

Testing pressure:

157 kPa (1.57 bar, 1.6 kg/cm

2,23psi)

PBIC3501E

Page 893 of 3171

ENGINE COOLANT

CO-9

C

D

E

F

G

H

I

J

K

L

MA

CO

3. Fill radiator and reservoir tank to the specified level.

lPour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

lUse Genuine Nissan Anti-freeze Coolant (L250) or equiva-

lent in its quality. Refer toMA-14, "

RECOMMENDED FLU-

IDS AND LUBRICANTS".

lWhen engine coolant overflows air relief hole, install air relief

plug.

4. Warm up engine to normal operating temperature without radiator cap and reservoir tank cap installed.

lIf engine coolant overflows radiator filler hole and reservoir tank filler hole, install radiator cap

and reservoir tank cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed with radiator cap installed.

lRepeat two or three times.

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

6. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with engine coolant.

7. Refill reservoir tank to MAX level line with engine coolant.

8. Repeat steps 3 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. Repeat step 10 three times.

12. If sound is heard, bleed air from cooling system by repeating steps 3 through 6 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer toCO-8, "

DRAINING ENGINE COOLANT". Engine coolant capacity

(with reservoir tank at “MAX” level)

LHD models

: Approx. 9.9 (8-3/4 lmp qt)

RHD models

: Approx. 10.2 (9 lmp qt)

SMA182B

Reservoir tank capacity (at “MAX” level)

: 0.8 (3/4 lmp qt)

SMA412B

Page 896 of 3171

CO-12

RADIATOR

3. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

4. Remove air inlet hoses between engine to charge air cooler. Refer toEM-18, "

CHARGE AIR COOLER".

5. Disconnect radiator hose (upper and lower) and reservoir tank hose.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

6. Remove reservoir tank.

7. Remove cooling fans (crankshaft driven type and motor driven type) and radiator shrouds (upper and

lower). Refer toCO-19, "

COOLING FAN".

8. Disconnect A/T fluid cooler hoses. (A/T models)

lInstall blind plug to avoid leakage of A/T fluid.

9. Remove radiator mounting brackets.

10. Remove the two A/C condenser bolts. (models with A/C)

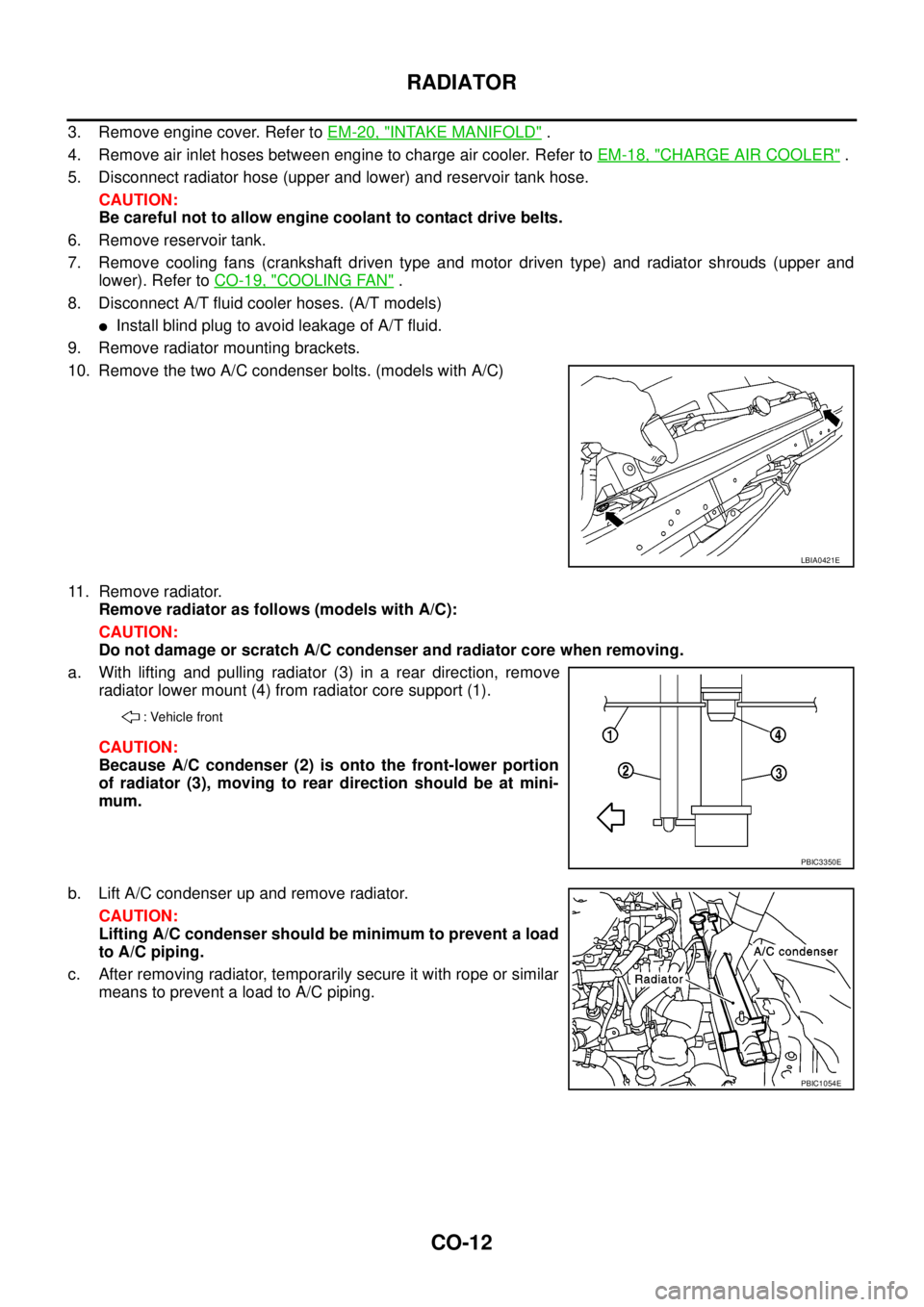

11. Remove radiator.

Remove radiator as follows (models with A/C):

CAUTION:

Do not damage or scratch A/C condenser and radiator core when removing.

a. With lifting and pulling radiator (3) in a rear direction, remove

radiator lower mount (4) from radiator core support (1).

CAUTION:

Because A/C condenser (2) is onto the front-lower portion

of radiator (3), moving to rear direction should be at mini-

mum.

b. Lift A/C condenser up and remove radiator.

CAUTION:

Lifting A/C condenser should be minimum to prevent a load

to A/C piping.

c. After removing radiator, temporarily secure it with rope or similar

means to prevent a load to A/C piping.

LBIA0421E

: Vehicle front

PBIC3350E

PBIC1054E

Page 898 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and t NISSAN NAVARA 2005 Repair Workshop Manual CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and t](/img/5/57362/w960_57362-897.png)

CO-14

RADIATOR

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and the radia-

tor cap tester (commercial service tool). Refer toCO-7, "

CHECKING RADIATOR SYSTEM FOR LEAKS".

lStart and warm up engine. Visually check if there is no leaks of engine coolant.

Page 905 of 3171

WATER PUMP

CO-21

C

D

E

F

G

H

I

J

K

L

MA

CO

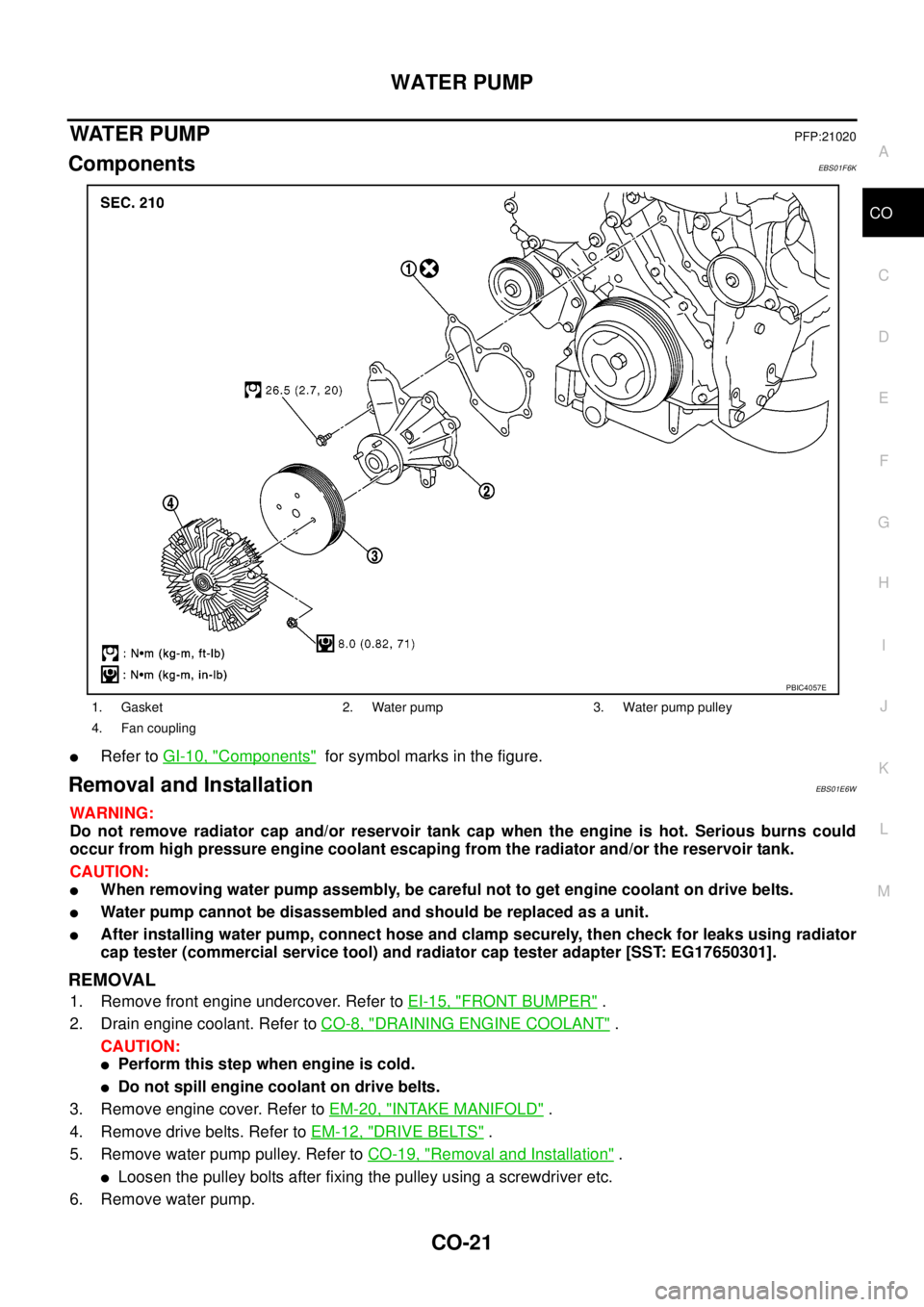

WAT E R P U MPPFP:21020

ComponentsEBS01F6K

lRefer toGI-10, "Components"for symbol marks in the figure.

Removal and InstallationEBS01E6W

WARNING:

Do not remove radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

occur from high pressure engine coolant escaping from the radiator and/or the reservoir tank.

CAUTION:

lWhen removing water pump assembly, be careful not to get engine coolant on drive belts.

lWater pump cannot be disassembled and should be replaced as a unit.

lAfter installing water pump, connect hose and clamp securely, then check for leaks using radiator

cap tester (commercial service tool) and radiator cap tester adapter [SST: EG17650301].

REMOVAL

1. Remove front engine undercover. Refer toEI-15, "FRONT BUMPER".

2. Drain engine coolant. Refer toCO-8, "

DRAINING ENGINE COOLANT".

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

3. Remove engine cover. Refer toEM-20, "

INTAKE MANIFOLD".

4. Remove drive belts. Refer toEM-12, "

DRIVE BELTS".

5. Remove water pump pulley. Refer toCO-19, "

Removal and Installation".

lLoosen the pulley bolts after fixing the pulley using a screwdriver etc.

6. Remove water pump.

1. Gasket 2. Water pump 3. Water pump pulley

4. Fan coupling

PBIC4057E

Page 906 of 3171

CO-22

WATER PUMP

lEngine coolant will leak from cylinder block, so have a receptacle ready below.

CAUTION:

lHandle the water pump vane so that it does not contact any other parts.

lWater pump cannot be disassembled and should be replaced as a unit.

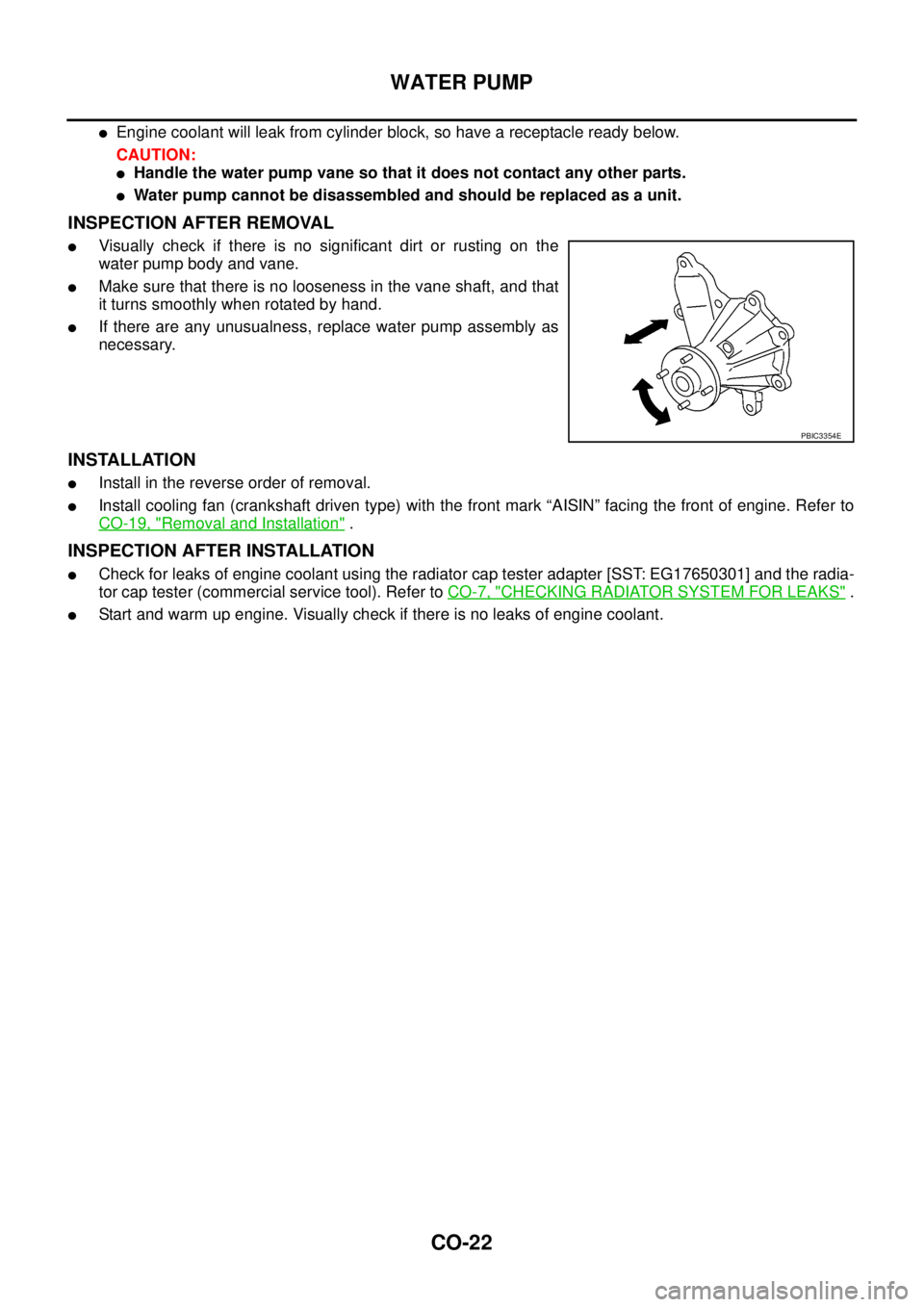

INSPECTION AFTER REMOVAL

lVisually check if there is no significant dirt or rusting on the

water pump body and vane.

lMake sure that there is no looseness in the vane shaft, and that

it turns smoothly when rotated by hand.

lIf there are any unusualness, replace water pump assembly as

necessary.

INSTALLATION

lInstall in the reverse order of removal.

lInstall cooling fan (crankshaft driven type) with the front mark “AISIN” facing the front of engine. Refer to

CO-19, "

Removal and Installation".

INSPECTION AFTER INSTALLATION

lCheck for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301] and the radia-

tor cap tester (commercial service tool). Refer toCO-7, "

CHECKING RADIATOR SYSTEM FOR LEAKS".

lStart and warm up engine. Visually check if there is no leaks of engine coolant.

PBIC3354E