oil type NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 15 of 3171

PRECAUTIONS

AT-7

D

E

F

G

H

I

J

K

L

MA

B

AT

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ECS00IPT

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

PrecautionsECS00IPR

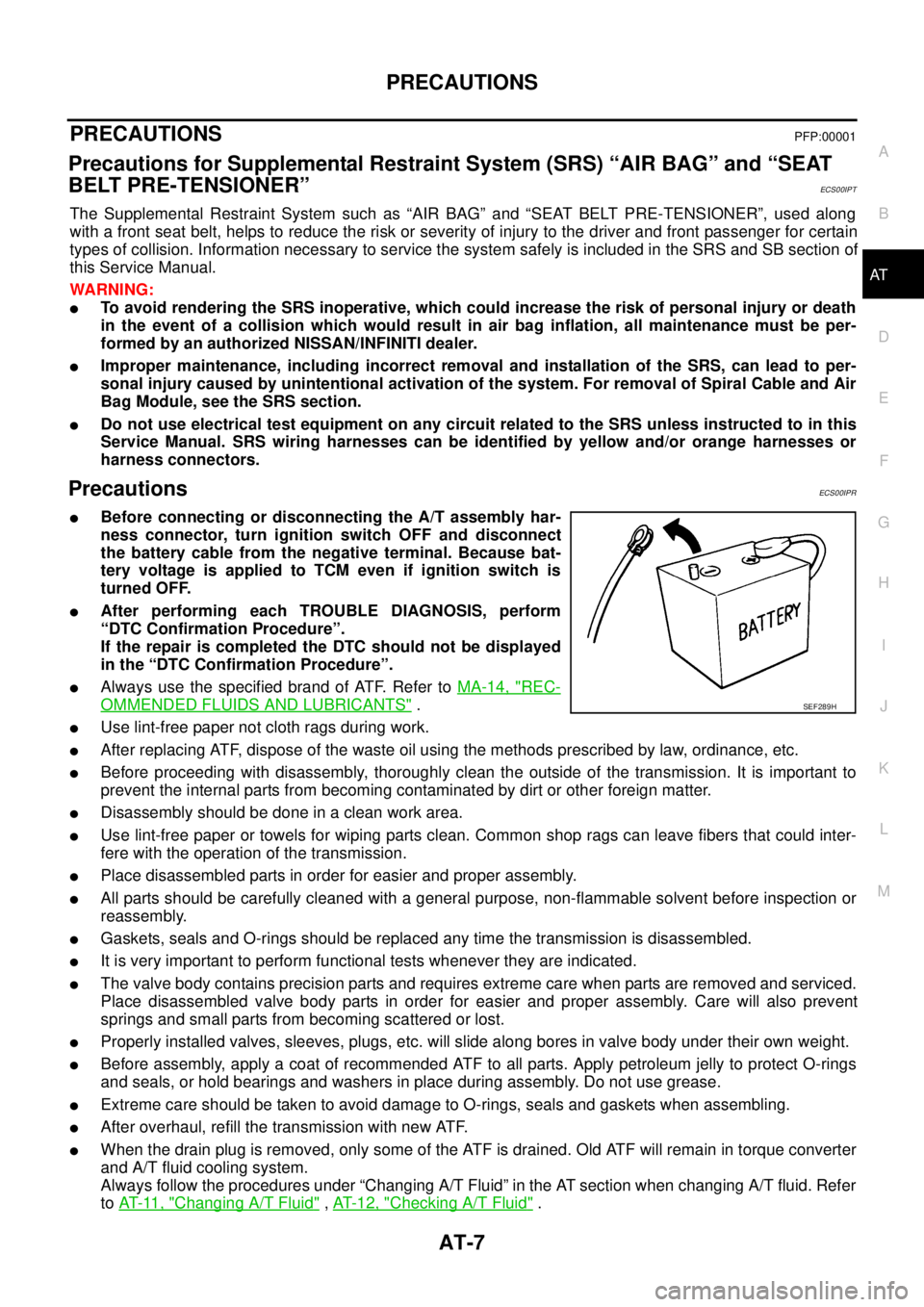

lBefore connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch OFF and disconnect

the battery cable from the negative terminal. Because bat-

tery voltage is applied to TCM even if ignition switch is

turned OFF.

lAfter performing each TROUBLE DIAGNOSIS, perform

“DTC Confirmation Procedure”.

If the repair is completed the DTC should not be displayed

in the “DTC Confirmation Procedure”.

lAlways use the specified brand of ATF. Refer toMA-14, "REC-

OMMENDED FLUIDS AND LUBRICANTS".

lUse lint-free paper not cloth rags during work.

lAfter replacing ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

lBefore proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

lDisassembly should be done in a clean work area.

lUse lint-free paper or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

lPlace disassembled parts in order for easier and proper assembly.

lAll parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

lGaskets, seals and O-rings should be replaced any time the transmission is disassembled.

lIt is very important to perform functional tests whenever they are indicated.

lThe valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from becoming scattered or lost.

lProperly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

lBefore assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

lExtreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

lAfter overhaul, refill the transmission with new ATF.

lWhen the drain plug is removed, only some of the ATF is drained. Old ATF will remain in torque converter

and A/T fluid cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer

toAT-11, "

Changing A/T Fluid",AT-12, "Checking A/T Fluid".

SEF289H

Page 338 of 3171

ATC-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EJS006AK

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Working with HFC-134a (R-134a)EJS006AL

WARNING:

lCFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed and compressor

malfunction is likely occur.

lUse only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

lThe specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

ble to minimize the entry of moisture into system.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refriger-

ant. If accidental system discharge occurs, ventilate work area before resuming service. Addi-

tional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

–Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

Contaminated RefrigerantEJS006AM

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

lExplain to the customer that environmental regulations prohibit the release of contaminated refrigerant

into the atmosphere.

lExplain that recovery of the contaminated refrigerant could damage your service equipment and refriger-

ant supply.

lSuggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

lIf you choose to perform the repair, recover the refrigerant using onlydedicated equipment and contain-

ers. Do not recover contaminated refrigerant into your existing service equipment.If your facility

does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for avail-

able service. This refrigerant must be disposed of in accordance with all federal and local regulations. In

addition, replacement of all refrigerant system components on the vehicle is recommended.

Page 350 of 3171

ATC-16

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEJS006AT

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tools and EquipmentEJS006AU

Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or

its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/lubri-

cant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor malfunction will result.

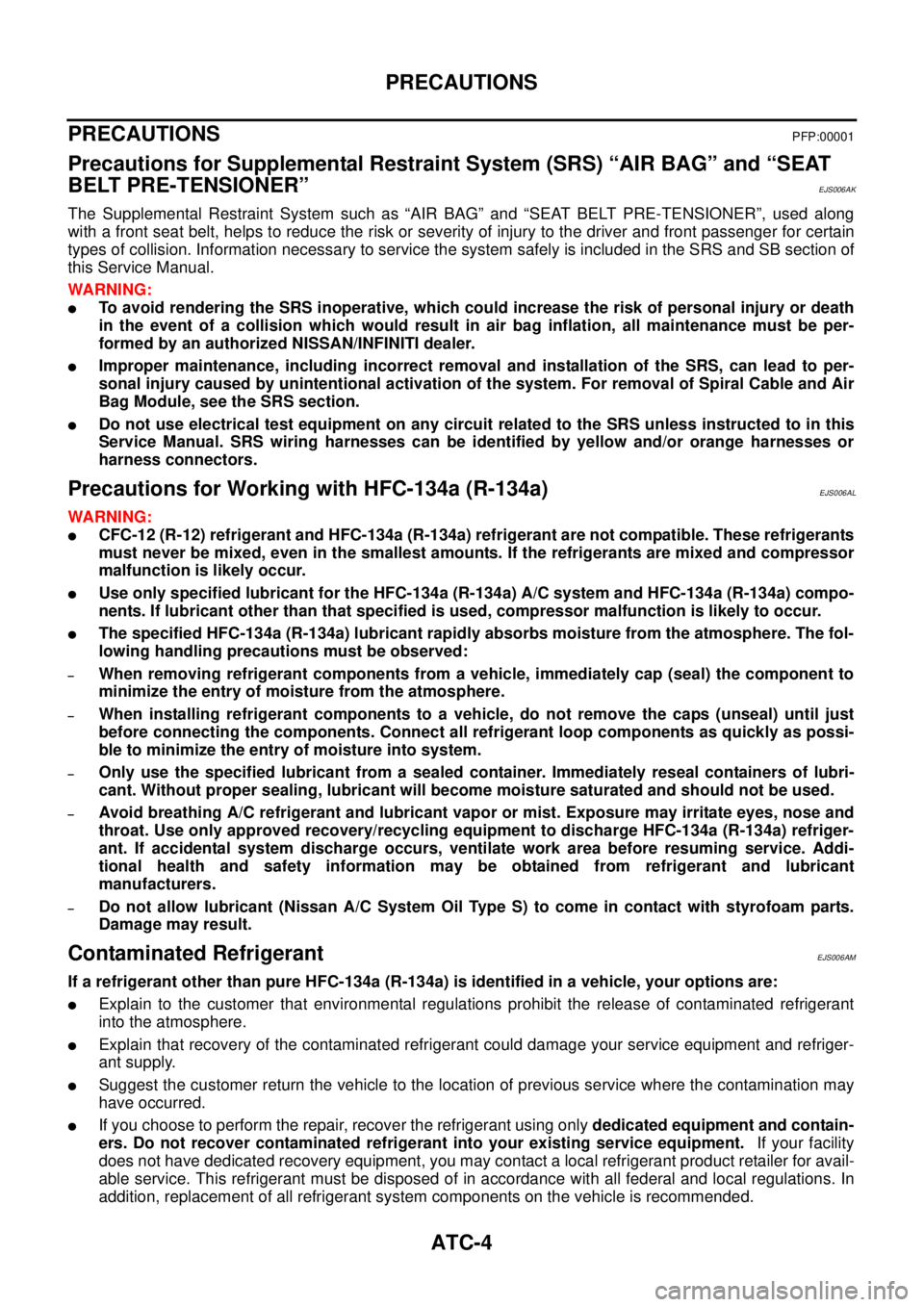

Tool number

Tool nameDescription

KV99106200

Pulley installerInstalling pulley

KV99233130

Pulley pullerRemoving pulley

S-NT235

LHA172

Tool number

Tool nameDescription

HFC-134a (R-134a) refrigerantContainer color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

lLarge container 1/2²-16 ACME

KLH00-PAGS0

Nissan A/C System Oil Type S

(DH-PS)Type: Polyalkylene glycol oil (PAG),

type S (DH-PS)

Application: HFC-134a (R-134a)

wobble (swash) plate compressors

(Nissan only)

Lubricity: 40 m (1.4 Imp fl oz.)

S-NT196

S-NT197

Page 789 of 3171

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DL

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005SD

lClean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lTo clean or wash all parts of master cylinder, disc brake caliper, wheel cylinder, use new brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

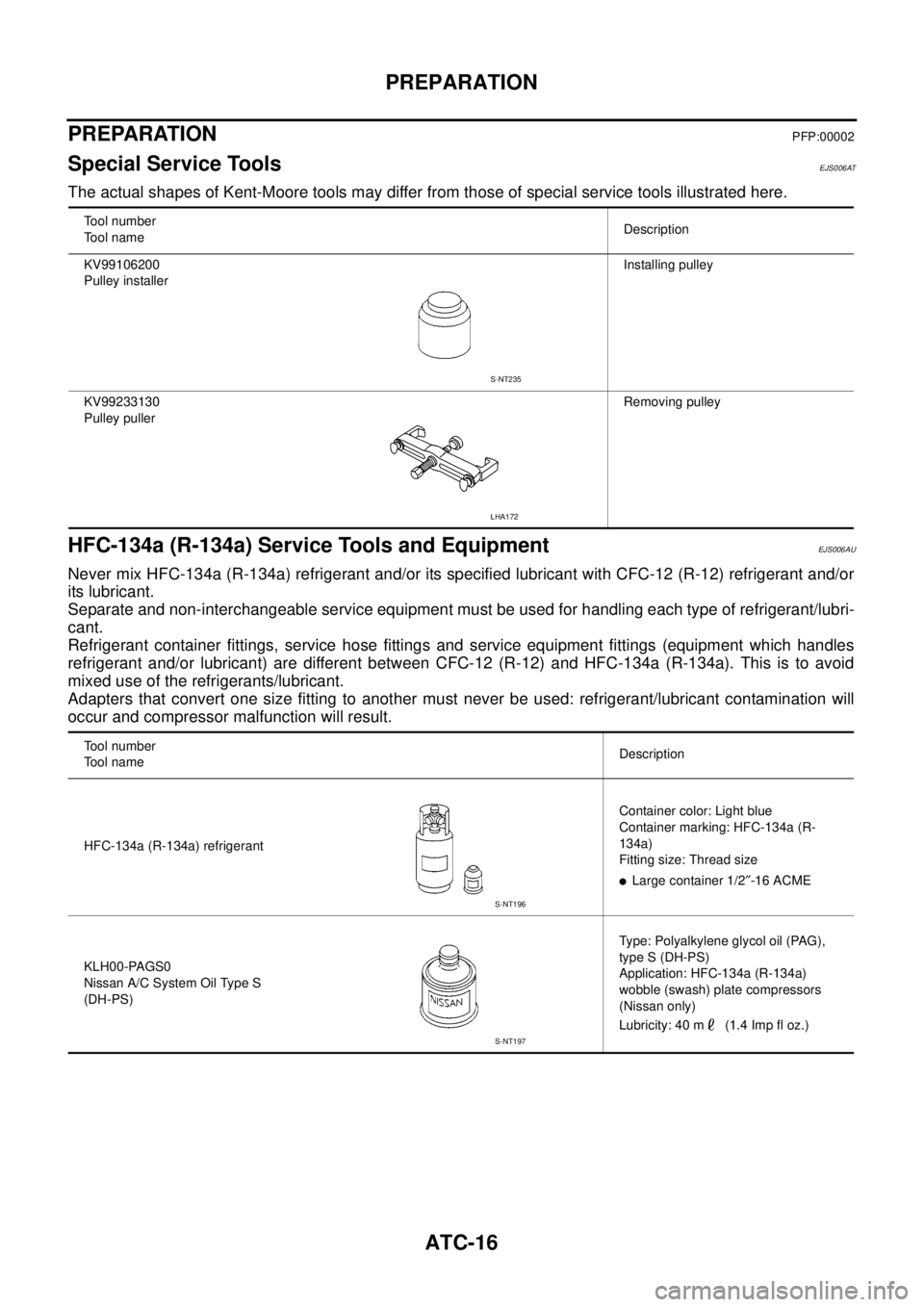

lUse a flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lAlways tighten brake lines to the specified torque when install-

ing.

lBefore working, turn ignition switch OFF and disconnect electri-

cal connector of ABS actuator and electric unit (control unit) or

the battery cables.

lBurnish the new brake surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer toBR-29, "

BRAKE BURNISHING PROCEDURE".

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.SBR820BA

Page 825 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplement](/img/5/57362/w960_57362-824.png)

PRECAUTIONS

BRC-3

[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

[ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS006DM

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Brake SystemEFS005TG

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.If brake fluid is splashed, wipe it off and flush area

with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing flare nuts, and use a flare

nut torque wrench when tighten flare nuts.

lBrake system is an important safety part.If a brake fluid leak is

detected, always disassemble the affected part.If a malfunction

is detected, replace part with new one.

lBefore working, turn ignition switch OFF and disconnect con-

nector of ABS actuator and electric unit (control unit) or the bat-

tery cables.

lWhen installing brake tube and hose, be sure to torque.

WARNING:

Clean brake pads and shoes with a waster cloth, then wipe with

a dust collector.

Precautions for Brake ControlEFS005TH

lJust after starting vehicle after ignition switch ON, brake pedal may vibrate or motor operating noise may

be heard from engine room. This is a normal status of operation check.

lStopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel,

or snow-covered (fresh, deep snow) roads.

lWhen an error is indicated by ABS or another warning lamp, collect all necessary information from cus-

tomer (what symptoms are present under what conditions) and check for simple causes before starting

diagnostic servicing. Besides electrical system inspection, check brake booster operation, brake fluid

level, and fluid leaks.

lIf tyre size and type are used in an improper combination, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, ABS function

may have a malfunction or error.

lIf aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR820BA

Page 903 of 3171

COOLING FAN

CO-19

C

D

E

F

G

H

I

J

K

L

MA

CO

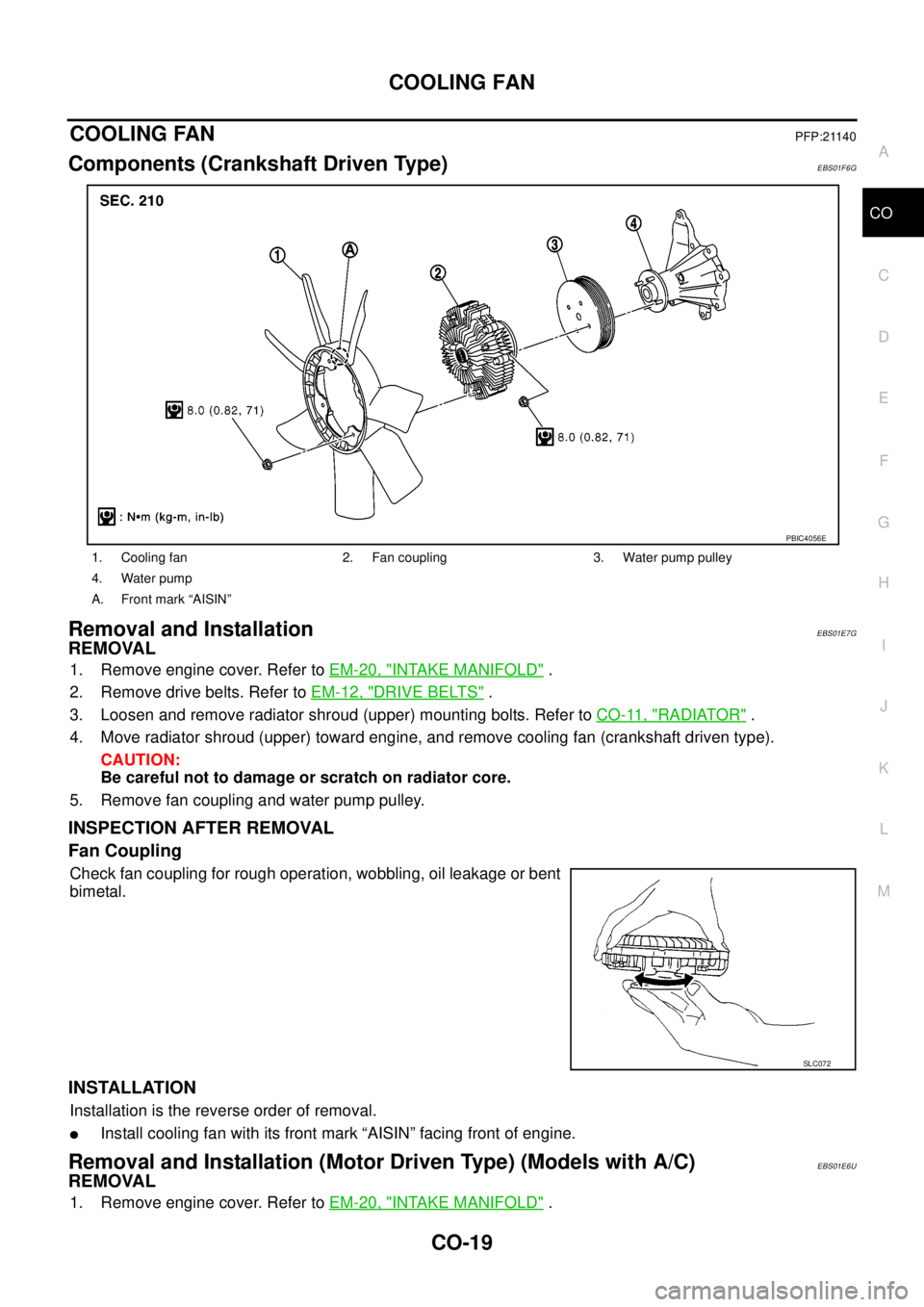

COOLING FANPFP:21140

Components (Crankshaft Driven Type)EBS01F6G

Removal and InstallationEBS01E7G

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

2. Remove drive belts. Refer toEM-12, "

DRIVE BELTS".

3. Loosen and remove radiator shroud (upper) mounting bolts. Refer toCO-11, "

RADIATOR".

4. Move radiator shroud (upper) toward engine, and remove cooling fan (crankshaft driven type).

CAUTION:

Be careful not to damage or scratch on radiator core.

5. Remove fan coupling and water pump pulley.

INSPECTION AFTER REMOVAL

Fan Coupling

Check fan coupling for rough operation, wobbling, oil leakage or bent

bimetal.

INSTALLATION

Installation is the reverse order of removal.

lInstall cooling fan with its front mark “AISIN” facing front of engine.

Removal and Installation (Motor Driven Type) (Models with A/C)EBS01E6U

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

1. Cooling fan 2. Fan coupling 3. Water pump pulley

4. Water pump

A. Front mark “AISIN”

PBIC4056E

SLC072

Page 991 of 3171

PRECAUTIONS

EC-11

C

D

E

F

G

H

I

J

K

L

MA

EC

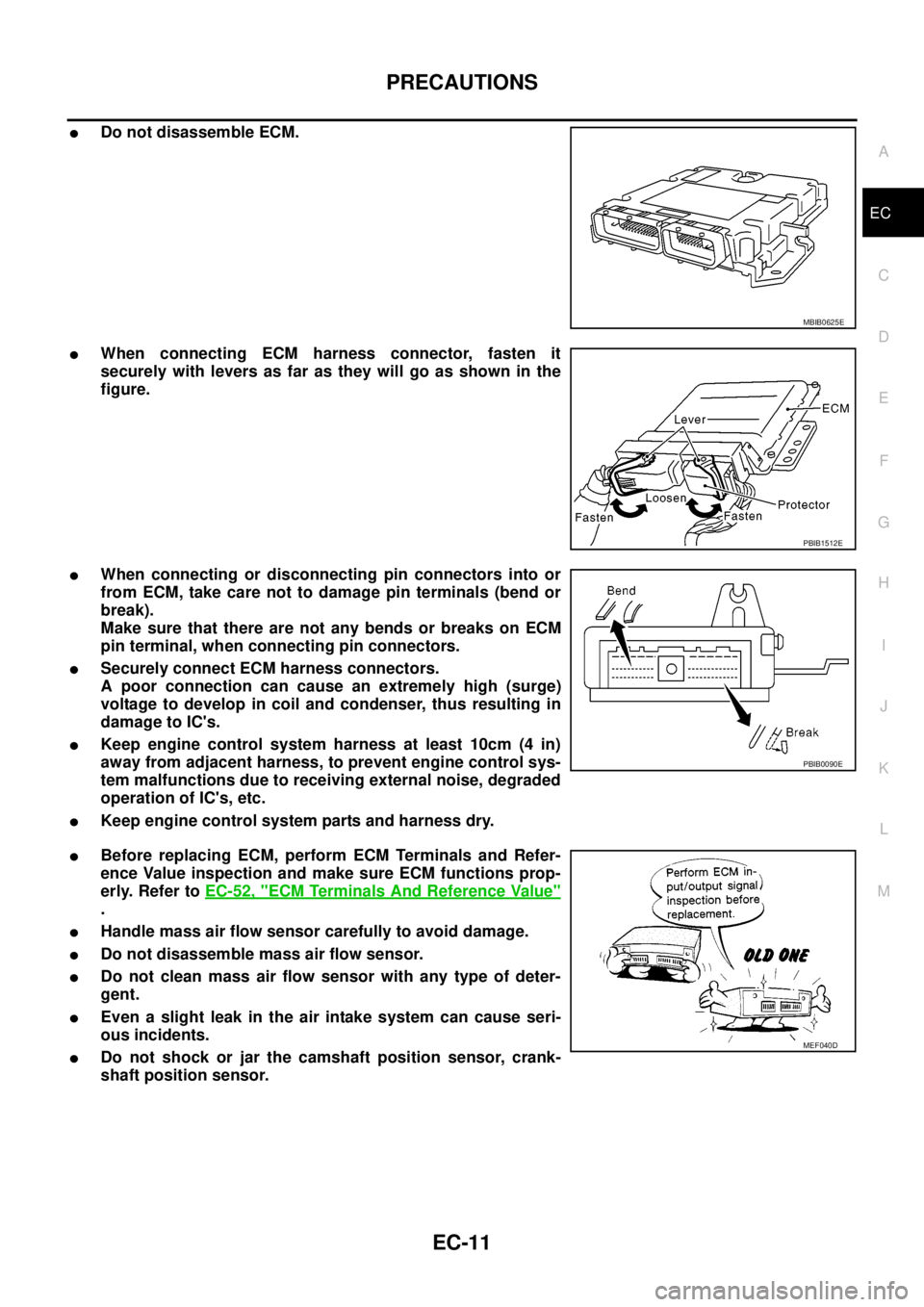

lDo not disassemble ECM.

lWhen connecting ECM harness connector, fasten it

securely with levers as far as they will go as shown in the

figure.

lWhen connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

lSecurely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in coil and condenser, thus resulting in

damage to IC's.

lKeep engine control system harness at least 10cm (4 in)

away from adjacent harness, to prevent engine control sys-

tem malfunctions due to receiving external noise, degraded

operation of IC's, etc.

lKeep engine control system parts and harness dry.

lBefore replacing ECM, perform ECM Terminals and Refer-

ence Value inspection and make sure ECM functions prop-

erly. Refer toEC-52, "

ECM Terminals And Reference Value"

.

lHandle mass air flow sensor carefully to avoid damage.

lDo not disassemble mass air flow sensor.

lDo not clean mass air flow sensor with any type of deter-

gent.

lEven a slight leak in the air intake system can cause seri-

ous incidents.

lDo not shock or jar the camshaft position sensor, crank-

shaft position sensor.

MBIB0625E

PBIB1512E

PBIB0090E

MEF040D

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1393 of 3171

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-11

C

D

E

F

G

H

I

J

K

L

MA

EM

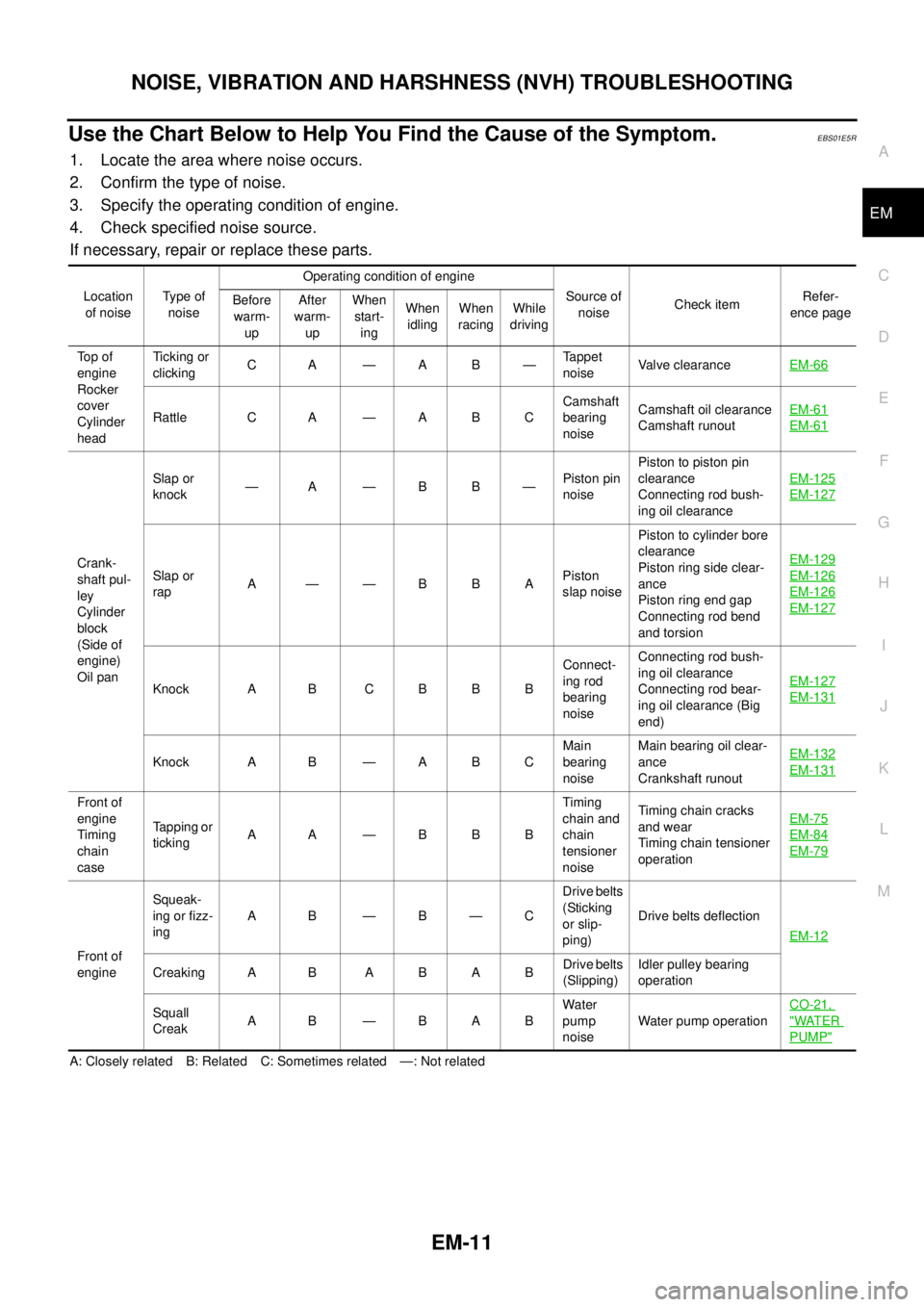

Use the Chart Below to Help You Find the Cause of the Symptom.EBS01E5R

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCA—AB—Tappet

noiseValve clearanceEM-66

Rattle C A — A B CCamshaft

bearing

noiseCamshaft oil clearance

Camshaft runoutEM-61EM-61

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—BB—Piston pin

noisePiston to piston pin

clearance

Connecting rod bush-

ing oil clearanceEM-125

EM-127

Slap or

rapA ——BBAPiston

slap noisePiston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-129EM-126

EM-126

EM-127

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bush-

ing oil clearance

Connecting rod bear-

ing oil clearance (Big

end)EM-127EM-131

Knock A B — A B CMain

bearing

noiseMain bearing oil clear-

ance

Crankshaft runoutEM-132EM-131

Front of

engine

Timing

chain

caseTapping or

tickingA A —BBBTiming

chain and

chain

tensioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-75

EM-84

EM-79

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)Drive belts deflection

EM-12

CreakingA B ABABDrive belts

(Slipping)Idler pulley bearing

operation

Squall

CreakA B —BABWater

pump

noiseWater pump operationCO-21,

"WATER

PUMP"

Page 1455 of 3171

SECONDARY TIMING CHAIN

EM-73

C

D

E

F

G

H

I

J

K

L

MA

EM

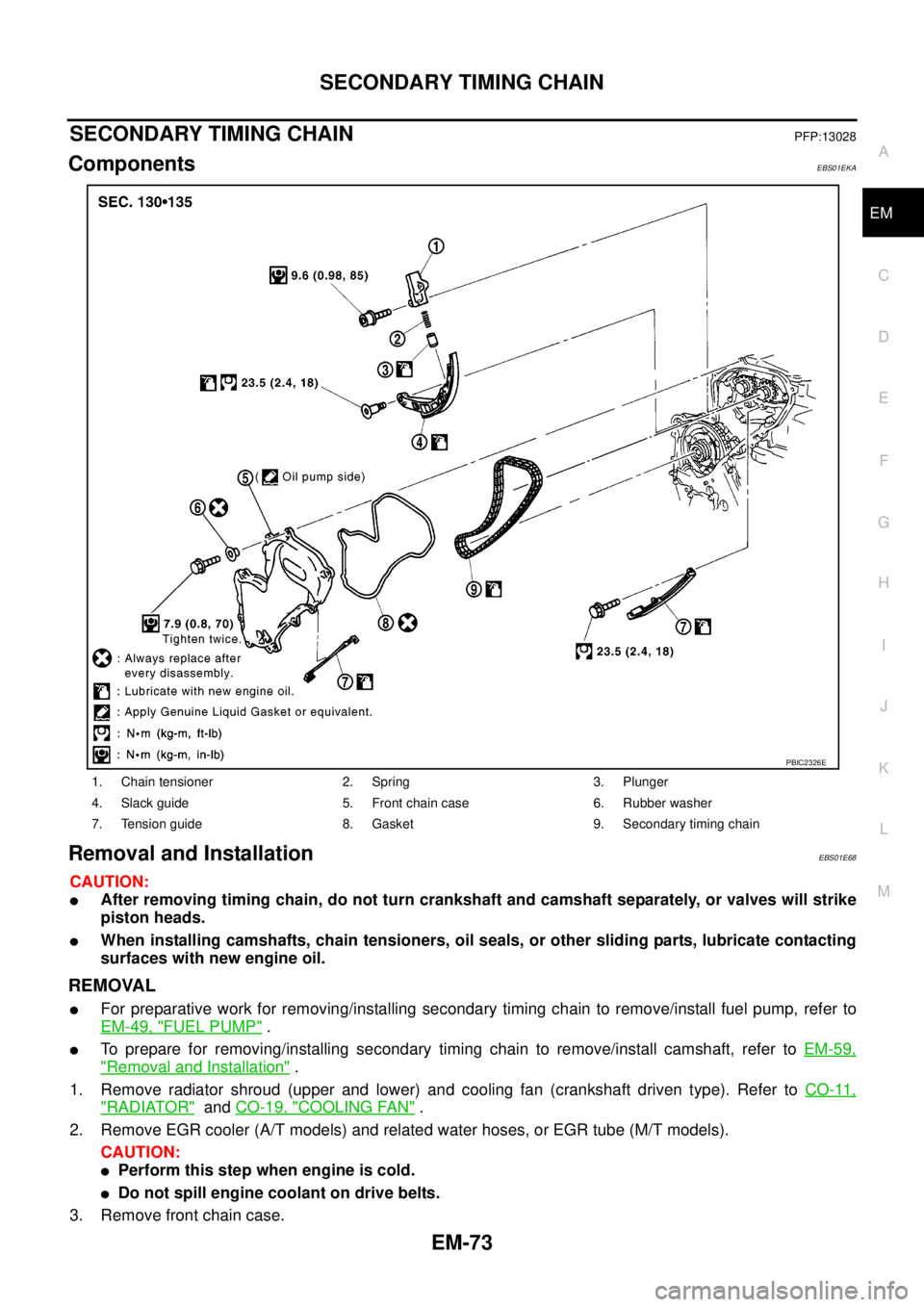

SECONDARY TIMING CHAINPFP:13028

ComponentsEBS01EKA

Removal and InstallationEBS01E68

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals, or other sliding parts, lubricate contacting

surfaces with new engine oil.

REMOVAL

lFor preparative work for removing/installing secondary timing chain to remove/install fuel pump, refer to

EM-49, "

FUEL PUMP".

lTo prepare for removing/installing secondary timing chain to remove/install camshaft, refer toEM-59,

"Removal and Installation".

1. Remove radiator shroud (upper and lower) and cooling fan (crankshaft driven type). Refer toCO-11,

"RADIATOR"andCO-19, "COOLING FAN".

2. Remove EGR cooler (A/T models) and related water hoses, or EGR tube (M/T models).

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

3. Remove front chain case.

1. Chain tensioner 2. Spring 3. Plunger

4. Slack guide 5. Front chain case 6. Rubber washer

7. Tension guide 8. Gasket 9. Secondary timing chain

PBIC2326E