battery location NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1819 of 3641

FAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431882

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Drive ShaftINFOID:0000000012431883

Observe the following precautions when disassembling and assembling drive shaft.

• Do not disassemble joint sub-assembly because it is non-overhaul parts.

• Perform work in a location which is as dust-free as possible.

• Clean the parts, before disassembling and assembling.

• Prevent the entry of foreign objects dur ing disassembly of the service location.

• Reassemble disassembled parts carefully in the correct order. If work is interrupted, a clean cover must be placed over parts.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• Clean disassembled parts (except for rubber parts) with kerosene which shall be removed by blowing with air or wiping with paper waste.

Precautions for Wheel Hub and KnuckleINFOID:0000000012431884

Observe the following precautions when assembling wheel hub and knuckle.

• Perform work in a location which is as dust-free as possible.

• Use paper waste. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• If any of wheel hub, steering knuckle, wheel bearing, and wheel hub lock nut is dropped, it must not be used.

• Always check that the tools used for press-fit work of wheel hub and wheel bearing have no wear and defor- mation so that a pressure can be applied vertically.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1894 of 3641

GI-6

< HOW TO USE THIS MANUAL >

HOW TO FOLLOW TROUBLE DIAGNOSES

HOW TO FOLLOW TROUBLE DIAGNOSES

DescriptionINFOID:0000000012433148

NOTICE:

Trouble diagnoses indicate work procedures required to diagnose problems effectively. Observe the following

instructions before diagnosing.

• Before performing trouble diagnoses, read the “Work Flow” in each section.

• After repairs, re-check that the problem has been completely eliminated.

• Refer to Component Parts and Harness Connector Location for the Systems described in each section for

identification/location of components and harness connectors.

• When checking circuit continuity, ignition switch should be OFF.

• Refer to the Circuit Diagram for quick pinpoint check. If you need to check circuit continui ty between harness connectors in more detail, such as when a sub-har-

ness is used, refer to Wiring Diagram in each individual section and Harness Layout in PG section for identi-

fication of harness connectors.

• Before checking voltage at connectors, check battery voltage.

• After accomplishing the Diagnosis Procedures and Elec trical Components Inspection, make sure that all

harness connectors are reconnected as they were.

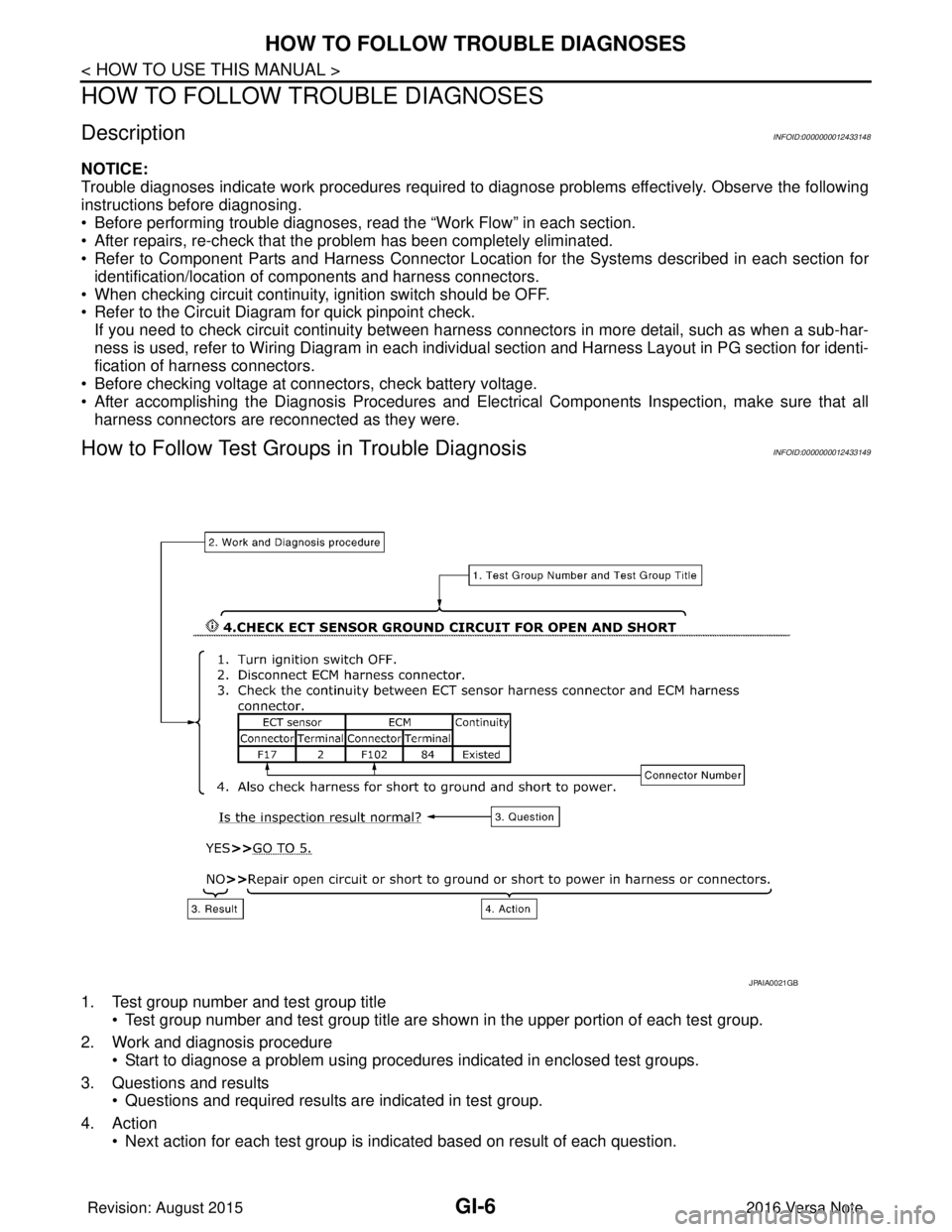

How to Follow Test Grou ps in Trouble DiagnosisINFOID:0000000012433149

1. Test group number and test group title

• Test group number and test group title are s hown in the upper portion of each test group.

2. Work and diagnosis procedure • Start to diagnose a problem using procedures indicated in enclosed test groups.

3. Questions and results • Questions and required results are indicated in test group.

4. Action • Next action for each test group is indicated based on result of each question.

JPAIA0021GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1912 of 3641

GI-24

< PRECAUTION >

PRECAUTIONS

General Precautions

INFOID:0000000012433162

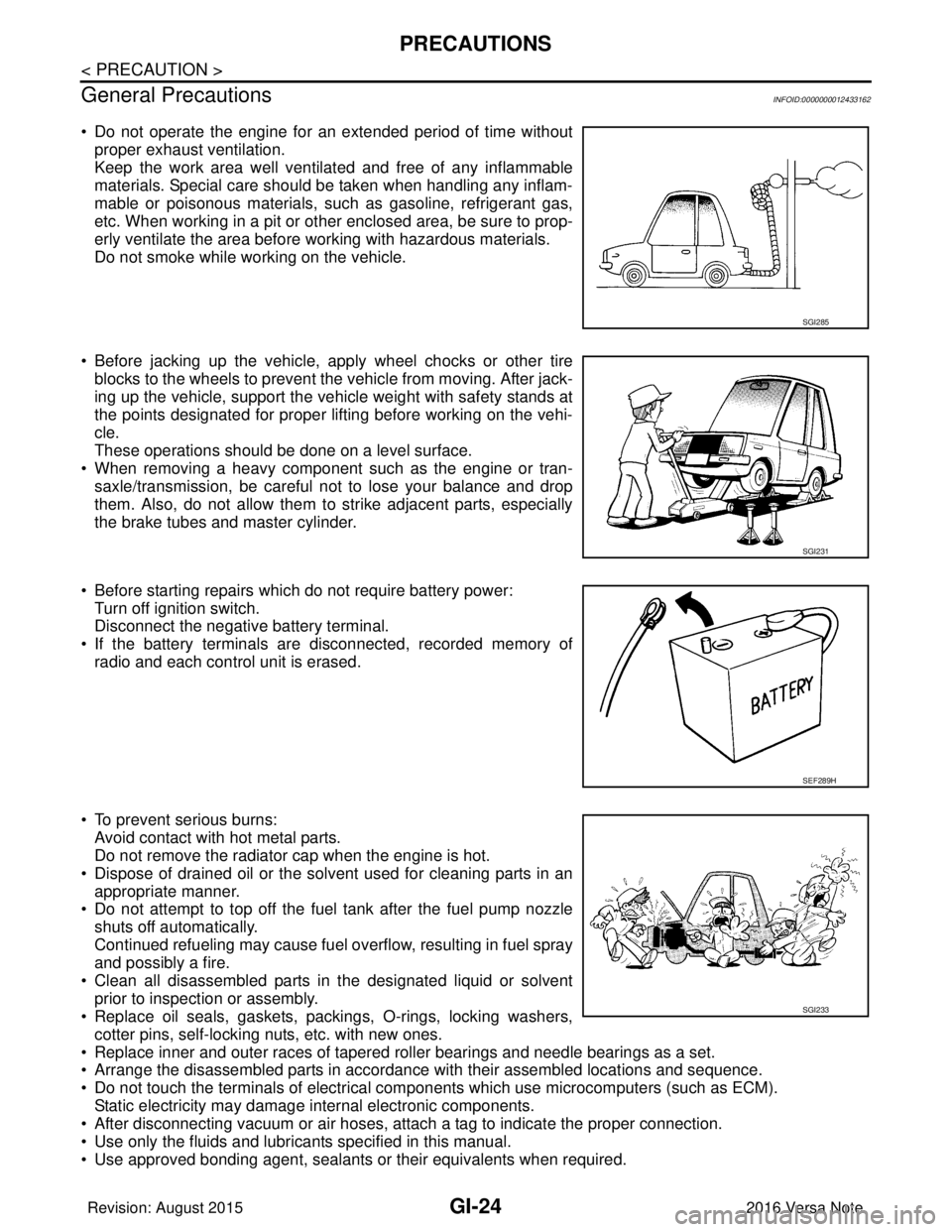

• Do not operate the engine for an extended period of time without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent the vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran- saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

• Before starting repairs which do not require battery power: Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of radio and each control unit is erased.

• To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

• Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

• Replace inner and outer races of tapered roller bearings and needle bearings as a set.

• Arrange the disassembled parts in accordance with their assembled locations and sequence.

• Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

• After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

• Use only the fluids and lubricants specified in this manual.

• Use approved bonding agent, sealants or their equivalents when required.

SGI285

SGI231

SEF289H

SGI233

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2095 of 3641

INL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION INL

A

B

INL

N

O P

CONTENTS

INTERIOR LIGHTING SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Work ..................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

SYSTEM ..............................................................7

INTERIOR ROOM LAMP CONTROL SYSTEM .... ......7

INTERIOR ROOM LAMP CONTROL SYSTEM :

System Description ...................................................

7

ILLUMINATION CONTROL SYSTEM ................... ......9

ILLUMINATION CONTROL SYSTEM : System

Description ................................................................

9

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .........................................

10

COMMON ITEM ..................................................... ....10

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

10

DOOR LOCK ......................................................... ....11

DOOR LOCK : CONSULT Function (BCM -

DOOR LOCK) .........................................................

11

INT LAMP .............................................................. ....11

INT LAMP : CONSULT Function (BCM - INT

LAMP) .....................................................................

11

INTELLIGENT KEY ............................................... ....12

INTELLIGENT KEY : CONSULT Function (BCM -

INTELLIGENT KEY) ................................................

12

BATTERY SAVER ................................................. ....14

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) ..................................................

14

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

16

COMMON ITEM ..................................................... ....16

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

16

DOOR LOCK .......................................................... ....17

DOOR LOCK : CONSULT Function (BCM -

DOOR LOCK) ..........................................................

17

INT LAMP ............................................................... ....17

INT LAMP : CONSULT Function (BCM - INT

LAMP) ......................................................................

18

BATTERY SAVER ................................................. ....19

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) ..................................................

19

ECU DIAGNOSIS INFO RMATION ..............20

BCM ...................................................................20

List of ECU Reference ......................................... ....20

WIRING DIAGRAM ......................................21

INTERIOR ROOM LAMP CONTROL SYSTEM

...

21

Wiring Diagram .................................................... ....21

ILLUMINATION .................................................28

Wiring Diagram ........................................................28

BASIC INSPECTION ...................................37

DIAGNOSIS AND REPAIR WORKFLOW ........37

Work Flow ............................................................ ....37

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2100 of 3641

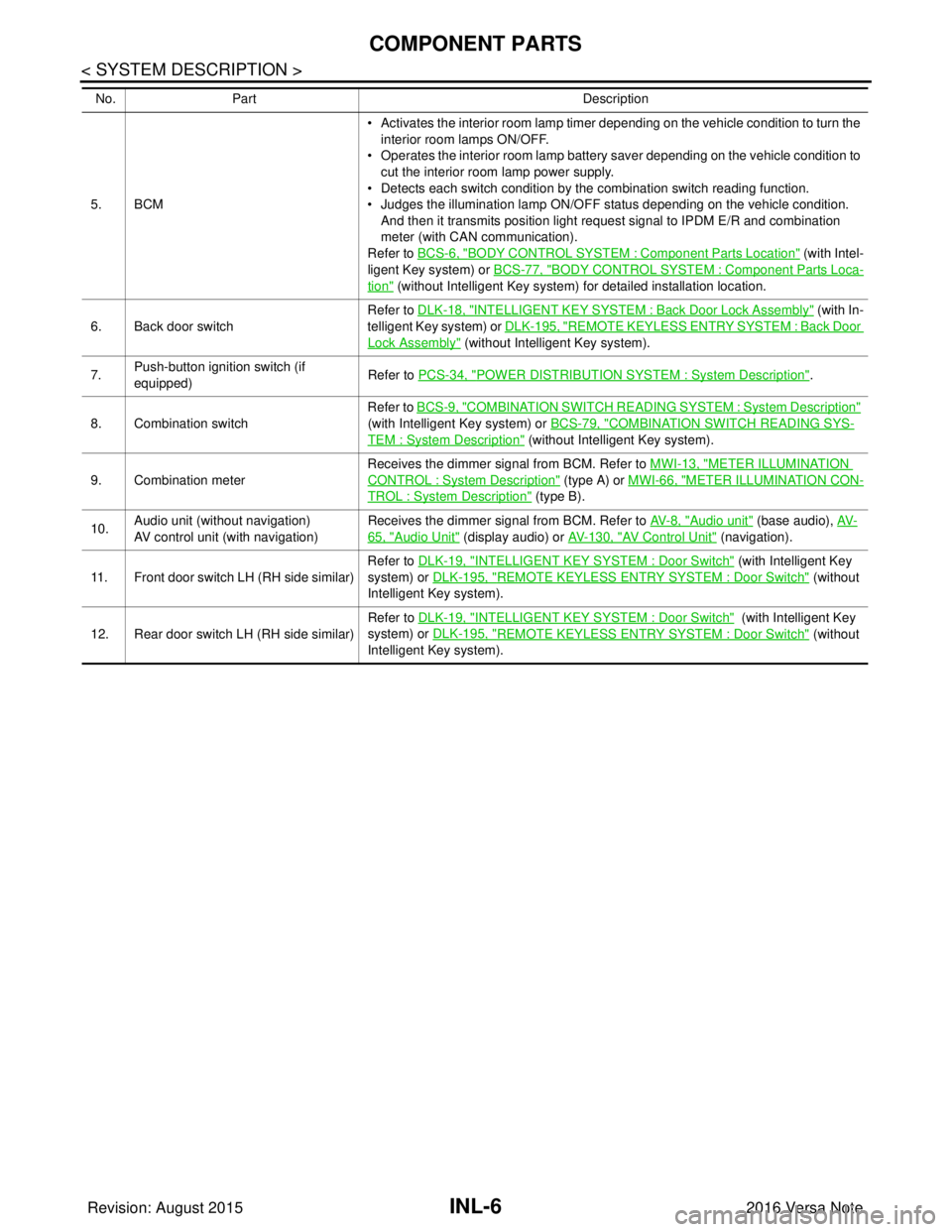

INL-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

5. BCM• Activates the interior room lamp timer depending on the vehicle condition to turn the

interior room lamps ON/OFF.

• Operates the interior room lamp battery saver depending on the vehicle condition to cut the interior room lamp power supply.

• Detects each switch condition by the combination switch reading function.

• Judges the illumination lamp ON/OFF status depending on the vehicle condition.

And then it transmits position light request signal to IPDM E/R and combination

meter (with CAN communication).

Refer to BCS-6, "

BODY CONTROL SYSTEM : Component Part s Location" (with Intel-

ligent Key system) or BCS-77, "

BODY CONTROL SYSTEM : Component Parts Loca-

tion" (without Intelligent Key system) for detailed installation location.

6. Back door switch Refer to DLK-18, "

INTELLIGENT KEY SYSTEM : Ba

ck Door Lock Assembly" (with In-

telligent Key system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Back Door

Lock Assembly" (without Intelligent Key system).

7. Push-button ignition switch (if

equipped) Refer to PCS-34, "

POWER DISTRIBUTION SYSTEM : System Description".

8. Combination switch Refer to

BCS-9, "

COMBINATION SWITCH READING SY STEM : System Description"

(with Intelligent Key system) or BCS-79, "

COMBINATION SWITCH READING SYS-

TEM : System Description" (without Intelligent Key system).

9. Combination meter Receives the dimmer signal from BCM. Refer to

MWI-13, "

METER ILLUMINATION

CONTROL : System Description" (type A) or MWI-66, "METER ILLUMINATION CON-

TROL : System Description" (type B).

10. Audio unit (without navigation)

AV control unit (with navigation) Receives the dimmer signal from BCM. Refer to

AV- 8 , "

Audio unit" (base audio), AV-

65, "Audio Unit" (display audio) or AV- 1 3 0 , "AV Control Unit" (navigation).

11. Front door switch LH (RH side similar) Refer to DLK-19, "

INTELLIGENT KEY SYSTEM : Door Switch" (with Intelligent Key

system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Door Switch" (without

Intelligent Key system).

12. Rear door switch LH (RH side similar) Refer to DLK-19, "

INTELLIGENT KEY SYSTEM : Door Switch" (with Intelligent Key

system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Door Switch" (without

Intelligent Key system).

No.

Part Description

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2588 of 3641

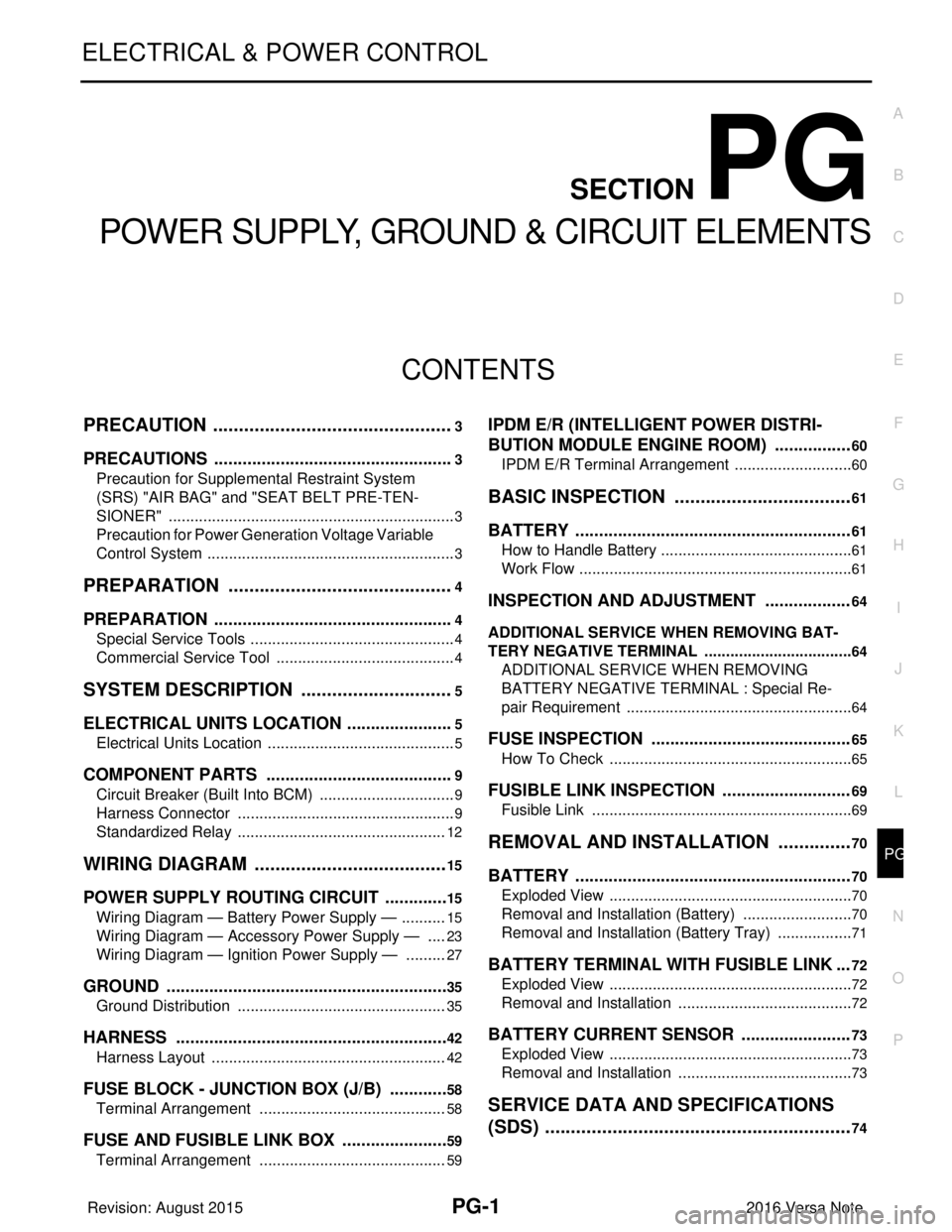

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Power Generation Voltage Variable

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

Commercial Service Tool ..........................................4

SYSTEM DESCRIPTION ..............................5

ELECTRICAL UNITS LOCATION .................. .....5

Electrical Units Location ...................................... ......5

COMPONENT PARTS ........................................9

Circuit Breaker (Built Into BCM) .......................... ......9

Harness Connector ...................................................9

Standardized Relay ............................................. ....12

WIRING DIAGRAM ......................................15

POWER SUPPLY ROUTING CIRCUIT .......... ....15

Wiring Diagram — Battery Power Supply — ....... ....15

Wiring Diagram — Accessory Power Supply — .....23

Wiring Diagram — Ignition Power Supply — ..........27

GROUND ............................................................35

Ground Distribution ............................................. ....35

HARNESS ...................................................... ....42

Harness Layout ................................................... ....42

FUSE BLOCK - JUNCTION BOX (J/B) .............58

Terminal Arrangement ............................................58

FUSE AND FUSIBLE LINK BOX ................... ....59

Terminal Arrangement ............................................59

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

60

IPDM E/R Terminal Arrangement ........................ ....60

BASIC INSPECTION ...................................61

BATTERY ..........................................................61

How to Handle Battery ......................................... ....61

Work Flow ................................................................61

INSPECTION AND ADJUSTMENT ..................64

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ....

64

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement .....................................................

64

FUSE INSPECTION ..........................................65

How To Check .........................................................65

FUSIBLE LINK INSPECTION ...........................69

Fusible Link .............................................................69

REMOVAL AND INSTALLATION ...............70

BATTERY ..........................................................70

Exploded View ..................................................... ....70

Removal and Installation (Battery) ..........................70

Removal and Installation (Battery Tray) ..................71

BATTERY TERMINAL WITH FUSIBLE LINK ...72

Exploded View .........................................................72

Removal and Installation .........................................72

BATTERY CURRENT SENSOR .......................73

Exploded View .........................................................73

Removal and Installation .........................................73

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

74

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2720 of 3641

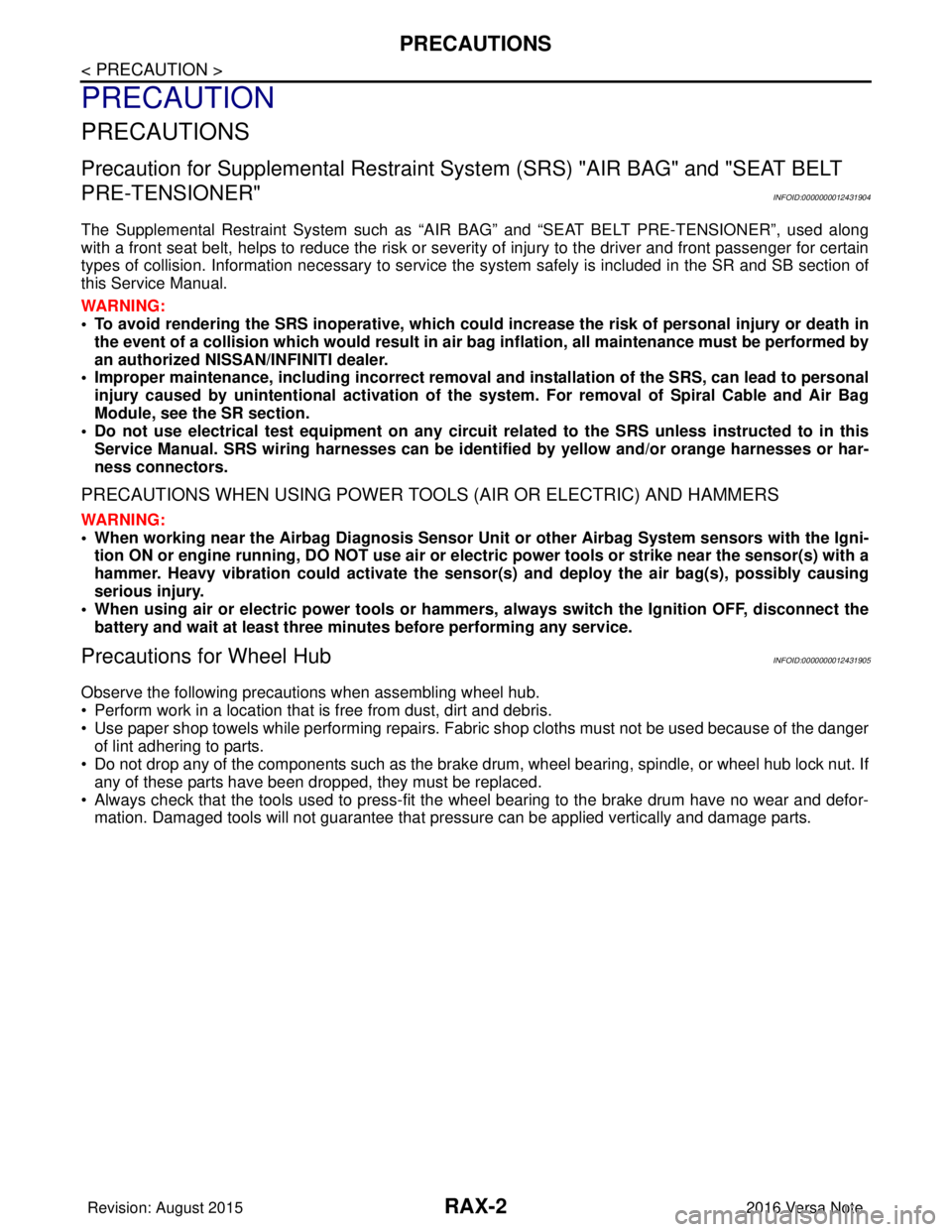

RAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431904

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precautions for Wheel HubINFOID:0000000012431905

Observe the following precautions when assembling wheel hub.

• Perform work in a location that is free from dust, dirt and debris.

• Use paper shop towels while performing repairs. Fabric shop cloths must not be used because of the danger of lint adhering to parts.

• Do not drop any of the components such as the brake drum, wheel bearing, spindle, or wheel hub lock nut. If

any of these parts have been dropped, they must be replaced.

• Always check that the tools used to press-fit the wheel bearing to the brake drum have no wear and defor-

mation. Damaged tools will not guarantee that pre ssure can be applied vertically and damage parts.

Revision: August 2015 2016 Versa Note

cardiagn.com

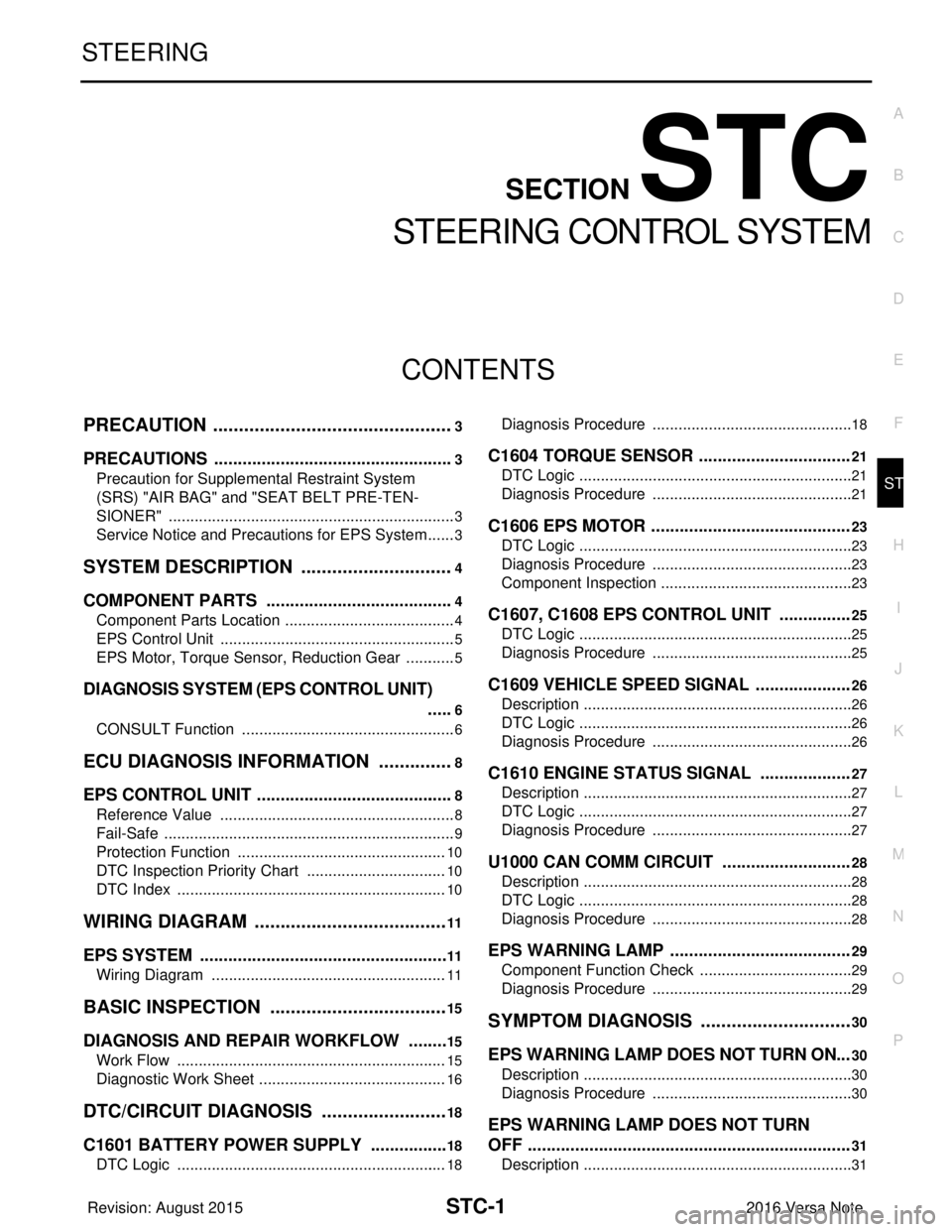

Page 3185 of 3641

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for EPS System ......3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

EPS Control Unit .......................................................5

EPS Motor, Torque Sensor, Reduction Gear ............5

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

.....

6

CONSULT Function ............................................ ......6

ECU DIAGNOSIS INFORMATION ...............8

EPS CONTROL UNIT ..................................... .....8

Reference Value ................................................. ......8

Fail-Safe ....................................................................9

Protection Function .................................................10

DTC Inspection Priority Chart ............................. ....10

DTC Index ........................................................... ....10

WIRING DIAGRAM ......................................11

EPS SYSTEM ... .............................................. ....11

Wiring Diagram ................................................... ....11

BASIC INSPECTION ...................................15

DIAGNOSIS AND REPAIR WORKFLOW ..... ....15

Work Flow ........................................................... ....15

Diagnostic Work Sheet ............................................16

DTC/CIRCUIT DIAGNOSIS .........................18

C1601 BATTERY POWER SUPPLY .................18

DTC Logic ........................................................... ....18

Diagnosis Procedure ........................................... ....18

C1604 TORQUE SENSOR ................................21

DTC Logic ................................................................21

Diagnosis Procedure ...............................................21

C1606 EPS MOTOR ..........................................23

DTC Logic ................................................................23

Diagnosis Procedure ...............................................23

Component Inspection .............................................23

C1607, C1608 EPS CONTROL UNIT ...............25

DTC Logic ................................................................25

Diagnosis Procedure ...............................................25

C1609 VEHICLE SPEED SIGNAL ....................26

Description ...............................................................26

DTC Logic ................................................................26

Diagnosis Procedure ...............................................26

C1610 ENGINE STATUS SIGNAL ...................27

Description ...............................................................27

DTC Logic ................................................................27

Diagnosis Procedure ...............................................27

U1000 CAN COMM CIRCUIT ...........................28

Description ...............................................................28

DTC Logic ................................................................28

Diagnosis Procedure ...............................................28

EPS WARNING LAMP ......................................29

Component Function Check ....................................29

Diagnosis Procedure ...............................................29

SYMPTOM DIAGNOSIS ..............................30

EPS WARNING LAMP DOES NOT TURN ON ...30

Description ........................................................... ....30

Diagnosis Procedure ...............................................30

EPS WARNING LAMP DOES NOT TURN

OFF ....................................................................

31

Description ...............................................................31

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3223 of 3641

ST-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430493

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Service Notice or Precautions for Steering SystemINFOID:0000000012430494

• In case of removing the steering gear, make the final tightening with grounded and unloaded vehicle condi- tion, and then check wheel alignment.

• Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Do not reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

FOR ELECTRIC POWER STEERING (EPS)

• During quick steering, rasping noise may be heard from around the steering wheel. This is not a malfunction.

The noise is an operating noise of the EPS system under normal conditions. If the rasping noise occurs dur-

ing slow steering, this may not be an operating noise of the system. In this case, it is necessary to find out

the location of the noise and repair, if necessary.

• Do not repeat static steering. (Mot or and EPS control unit could be heated.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3601 of 3641

WW-36

< DTC/CIRCUIT DIAGNOSIS >

FRONT WIPER MOTOR LO CIRCUIT

FRONT WIPER MOTOR LO CIRCUIT

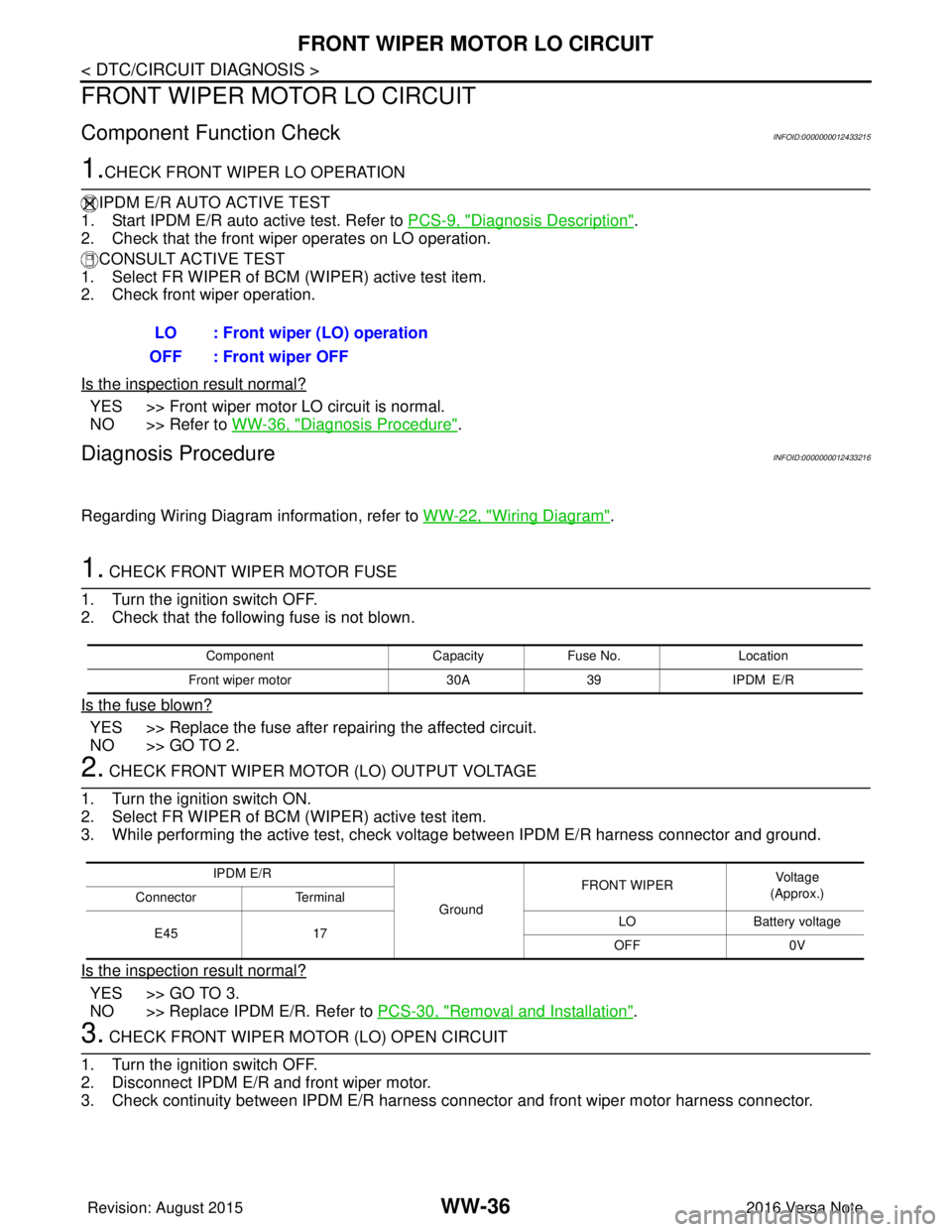

Component Function CheckINFOID:0000000012433215

1.CHECK FRONT WIPER LO OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the front wiper operates on LO operation.

CONSULT ACTIVE TEST

1. Select FR WIPER of BCM (WIPER) active test item.

2. Check front wiper operation.

Is the inspection result normal?

YES >> Front wiper motor LO circuit is normal.

NO >> Refer to WW-36, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012433216

Regarding Wiring Diagram information, refer to WW-22, "Wiring Diagram".

1. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 2.

2. CHECK FRONT WIPER MOTOR (LO) OUTPUT VOLTAGE

1. Turn the ignition switch ON.

2. Select FR WIPER of BCM (WIPER) active test item.

3. While performing the active test, check vo ltage between IPDM E/R harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace IPDM E/R. Refer to PCS-30, "

Removal and Installation".

3. CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

LO : Front wiper (LO) operation

OFF : Front wiper OFF

Component CapacityFuse No. Location

Front wiper motor 30A39 IPDM E/R

IPDM E/R

GroundFRONT WIPER

Vo l ta g e

(Approx.)

Connector Terminal

E45 17 LO

Battery voltage

OFF 0V

Revision: August 2015 2016 Versa Note

cardiagn.com