change wheel NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 587 of 3641

![NISSAN NOTE 2016 Service User Guide NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations a NISSAN NOTE 2016 Service User Guide NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations a](/img/5/57363/w960_57363-586.png)

NORMAL OPERATING CONDITIONBRC-139

< SYMPTOM DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000012430924

Symptom Result

Slight vibrations are felt on the brake pedal and operation noises occur when VDC, TCS or ABS is activated. This is a normal condi-

tion due to the VDC,

TCS or ABS activation.

Stopping distance is longer than that of vehicles without ABS when the vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

The brake pedal moves and generates noises when TCS or VDC is activated due to rapid acceleration or

sharp turn.

The brake pedal vibrates and motor operation noises occur from the engine room after the engine starts and

just after the vehicle starts.

This is normal, and it is

caused by the ABS op-

eration check.

Depending on the road conditions, the driver may experience a sluggish feel in the brake pedal. This is normal, because

TCS places the highest

priority on the optimum

traction (stability).

TCS may activate momentarily if wheel speed changes when driving where road friction coefficient varies,

when downshifting, or when fully depressing accelerator pedal.

The ABS warning lamp and SLIP

indicator lamp may turn ON when the vehicle is subject to strong shaking

or large vibration, such as when the vehicle is rotating on a turntable or located on a ship while the engine

is running. In this case, restart the

engine on a normal

road. If the normal con-

dition is restored, there

is no malfunction. At

that time, erase the self-

diagnostic result memo-

ry.

VDC may not operate normally or th

e ABS warning lamp, and SLIP indicato r lamp may illuminate when driv-

ing on a road that is extremely slanted (e.g., bank in a circuit course).

A malfunction may occur in the yaw rate/side/decel G sensor system when the vehicle turns sharply, such

as during a spin turn, axle turn, or drift driving, while the VDC function is OFF (VDC OFF indicator lamp illu-

minated).

The vehicle speed will not increase even though the accelerator pedal is depressed, when inspecting the

speedometer on a 2-wheel chassis dynamometer. Normal (Deactivate the

VDC/TCS function be-

fore performing an in-

spection on a chassis

dynamometer.)

SLIP indicator lamp may simultaneously turn ON when low tire pressure warning lamp turns ON. This is not a VDC sys-

tem error but results

from characteristic

change of tire.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1174 of 3641

![NISSAN NOTE 2016 Service User Guide OPERATIONEC-47

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OPERATION

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (

ASCD) : Switch Name and Function

INFOID: NISSAN NOTE 2016 Service User Guide OPERATIONEC-47

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OPERATION

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (

ASCD) : Switch Name and Function

INFOID:](/img/5/57363/w960_57363-1173.png)

OPERATIONEC-47

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OPERATION

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (

ASCD) : Switch Name and Function

INFOID:0000000012431330

SWITCHES AND INDICATORS

SET SPEED RANGE

ASCD system can be set the following vehicle speed.

SWITCH OPERATION

SET OPERATION

Press MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 38 km/h (24 MPH) and 144 km/h (90

MPH), press COAST/SET switch.

ACCELERATE OPERATION

If the ACCEL/RES switch is press ed during the cruise control driving, increase the vehicle speed until the

switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exis t, cruise operation will be canceled.

• CANCEL switch is pressed

• More than 2 switches at ASCD steer ing switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Clutch pedal is depressed or gear position is changed to neutral position. (M/T models)

• Selector lever is changed to N, P or R position (CVT models)

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

CRUISE indicator SET indicator CANCEL switch

ACCEL/RES switch COAST/SET switch ASCD MAIN switch

On the combination meter

(Information display) On the steering wheel

JPBIA5485ZZ

Minimum speed (Approx.)

Maximum speed (Approx.)

38 km/h (24 MPH) 144 km/h (90 MPH)

ItemFunction

CANCEL switch Cancels the cruise control driving.

ACCEL/RES switch

(ACCELERATE/RESUME) • Resumes the set speed.

• Increases speed incrementally during cruise control driving.

COAST/SET switch • Sets desired cruise speed.

• Decreases speed incrementally during cruise control driving.

ASCD MAIN switch Master switch to activate the ASCD system.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1418 of 3641

![NISSAN NOTE 2016 Service User Guide P0441 EVAP CONTROL SYSTEMEC-291

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2.PERFORM DTC CONFIRMATION PROCEDURE-I

WITH CONSULT

TESTING CONDITION:

Always perform test at a tempe NISSAN NOTE 2016 Service User Guide P0441 EVAP CONTROL SYSTEMEC-291

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2.PERFORM DTC CONFIRMATION PROCEDURE-I

WITH CONSULT

TESTING CONDITION:

Always perform test at a tempe](/img/5/57363/w960_57363-1417.png)

P0441 EVAP CONTROL SYSTEMEC-291

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2.PERFORM DTC CONFIRMATION PROCEDURE-I

WITH CONSULT

TESTING CONDITION:

Always perform test at a temperature of 5 °C (41° F) or more.

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and let it idle for at least 70 seconds.

6. Select “PURG FLOW P0441” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode of

“ENGINE” using CONSULT.

7. Touch “START”.

Is

“COMPLETED” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

When the following conditions are met, “TESTING” will be displayed on the CONSULT screen. Maintain the

conditions continuously until “TESTING” changes to “COMPLETED”. (It will take at least 35 seconds.)

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “TESTING” does not change for a long time, retry from step 2.

Is

“COMPLETED” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> Perform DTC CONFIRMATION PROCEDURE again. GO TO 2.

4.PERFORM DTC CONFIRMATION PROCEDURE-III

Touch “SELF-DIAG RESULTS”.

Which is displayed on CONSULT screen?

OK >> INSPECTION END

NG >> Proceed to EC-292, "

Diagnosis Procedure".

5.PERFORM COMPONENT FUNCTION CHECK

WITH GST

Perform component function check. Refer to EC-291, "

Component Function Check".

NOTE:

Use component function check to check the overall m onitoring function of the EVAP control system purge flow

monitoring. During this check, a 1s t trip DTC might not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to EC-292, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000012431491

1.PERFORM COMPONENT FUNCTION CHECK

1. Lift up drive wheels.

2. Start engine (VDC switch OFF) and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

Selector lever Suitable position

VHCL SPEED SE 32 - 120 km/h (20 - 75 MPH)

ENG SPEED 500 - 3,800 rpm

B/FUEL SCHDL 1.0 - 10 msec

COOLAN TEMP/S More than 0°C (32 °F)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1916 of 3641

GI-28

< PRECAUTION >

LIFTING POINT

LIFTING POINT

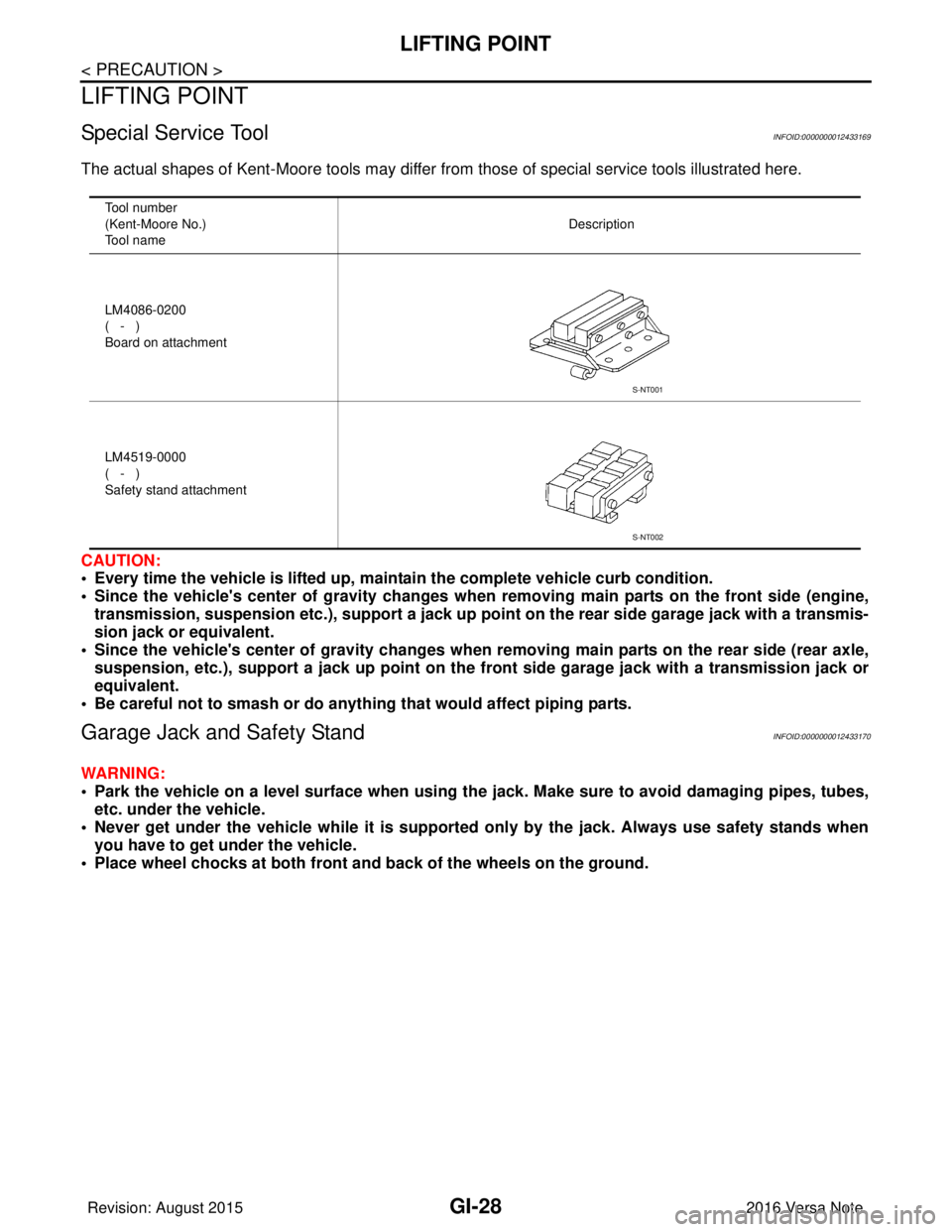

Special Service ToolINFOID:0000000012433169

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

CAUTION:

• Every time the vehicle is lifted up, main tain the complete vehicle curb condition.

• Since the vehicle's center of gravity changes when removing main parts on the front side (engine, transmission, suspension etc.), supp ort a jack up point on the rear side garage jack with a transmis-

sion jack or equivalent.

• Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the front side garage jack with a transmission jack or

equivalent.

• Be careful not to smash or do anything that would affect piping parts.

Garage Jack and Safety StandINFOID:0000000012433170

WARNING:

• Park the vehicle on a level surface when using the jack. Make sure to avoid damaging pipes, tubes,

etc. under the vehicle.

• Never get under the vehicle while it is supported only by the jack. Always use safety stands when

you have to get under the vehicle.

• Place wheel chocks at both front an d back of the wheels on the ground.

Tool number

(Kent-Moore No.)

Tool name Description

LM4086-0200

( - )

Board on attachment

LM4519-0000

( - )

Safety stand attachment

S-NT001

S-NT002

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2320 of 3641

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PERIODIC MAINTENANCE

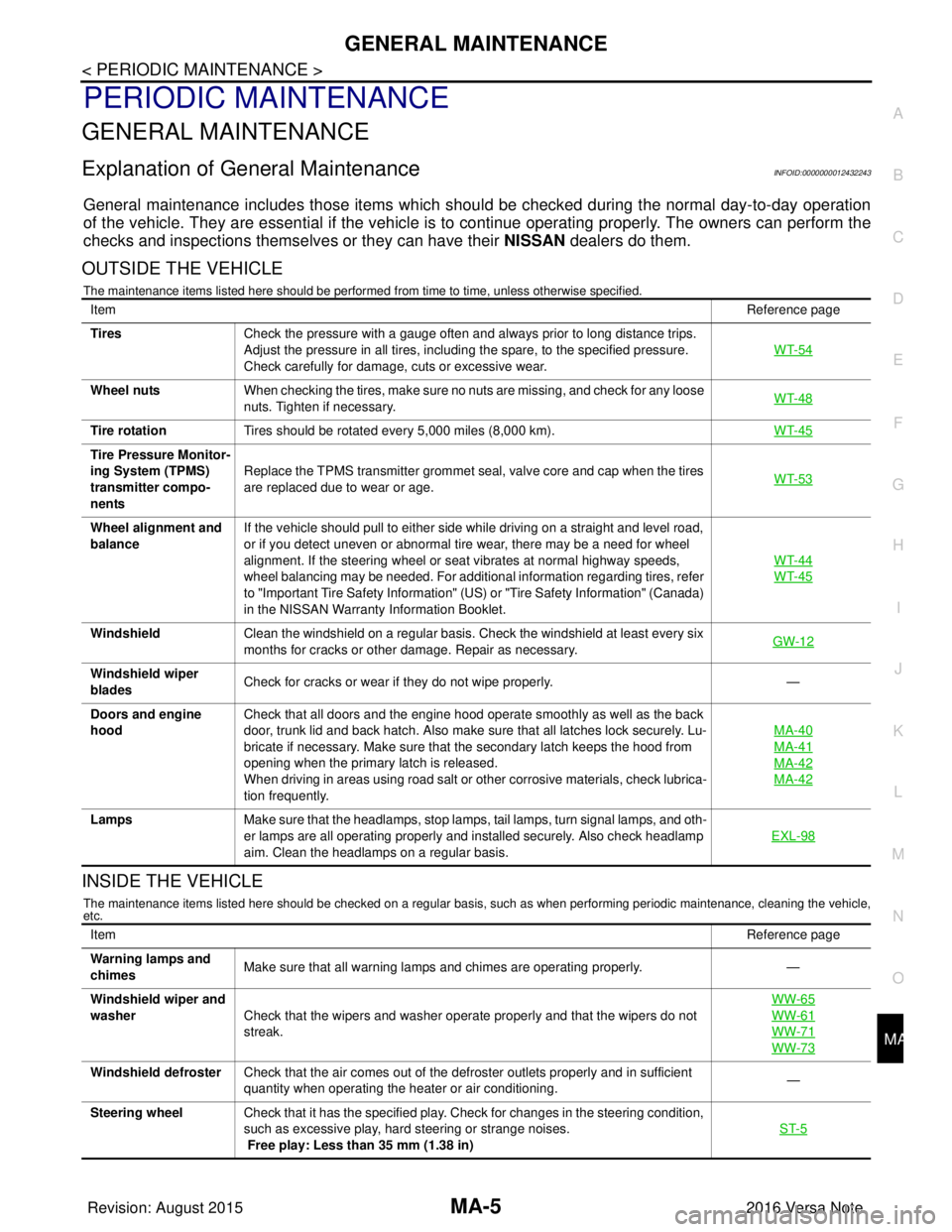

GENERAL MAINTENANCE

Explanation of Gene

ral MaintenanceINFOID:0000000012432243

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operati ng properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-54

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-48

Tire rotation

Tires should be rotated every 5,000 miles (8,000 km). WT-45

Tire Pressure Monitor-

ing System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-53

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. For additional information regarding tires, refer

to "Important Tire Safety Information" (US) or "Tire Safety Information" (Canada)

in the NISSAN Warranty

Information Booklet. WT-44

WT-45

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. GW-12

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door, trunk lid and back hatch. Also make sure that all latches lock securely. Lu-

bricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-40

MA-41

MA-42

MA-42

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. EXL-98

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak. WW-65

WW-61

WW-71

WW-73

Windshield defroster

Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) ST-5

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2792 of 3641

TRANSMITTERWT-49

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

TRANSMITTER

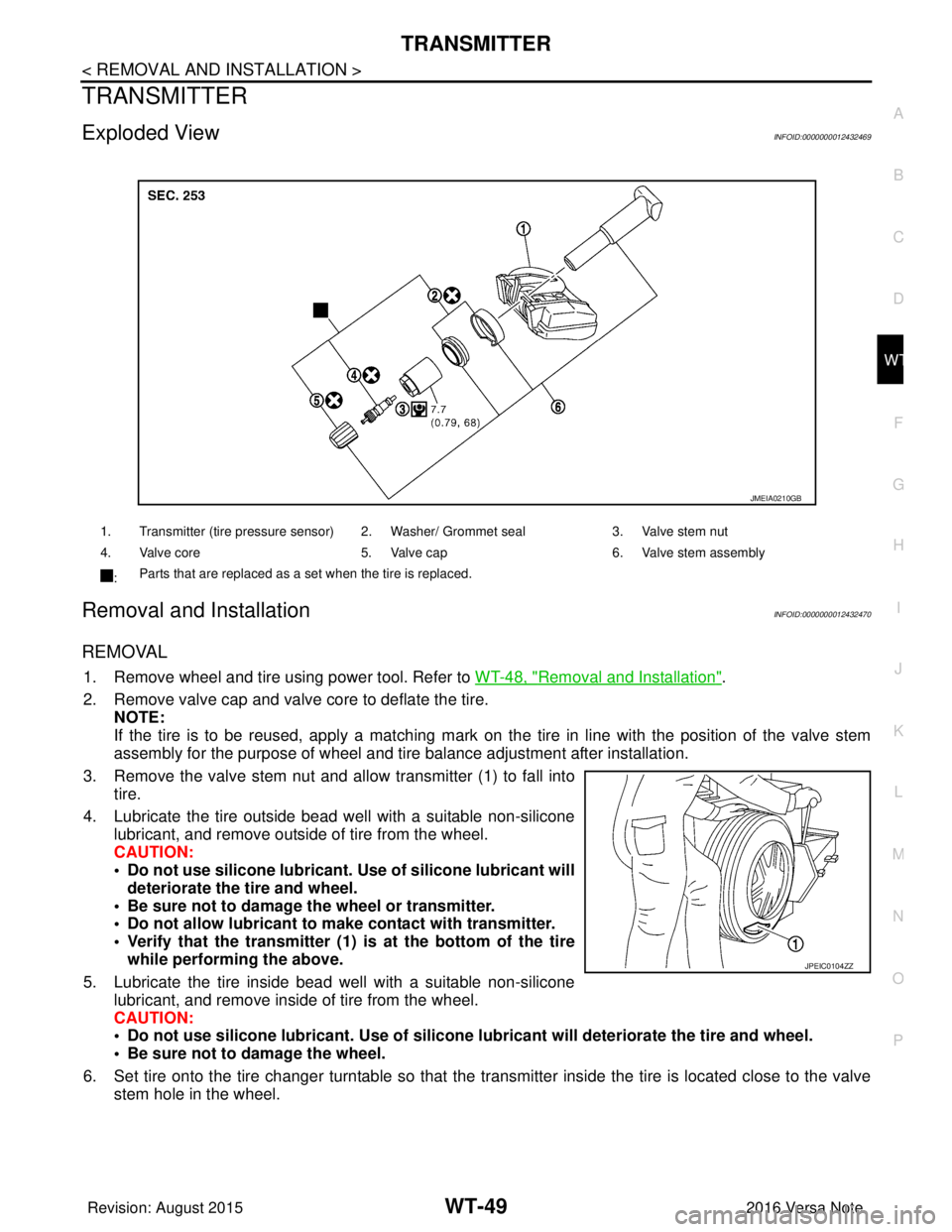

Exploded ViewINFOID:0000000012432469

Removal and InstallationINFOID:0000000012432470

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Remove valve cap and valve core to deflate the tire. NOTE:

If the tire is to be reused, apply a matching mark on the tire in line with the position of the valve stem

assembly for the purpose of wheel and tire balance adjustment after installation.

3. Remove the valve stem nut and allow transmitter (1) to fall into tire.

4. Lubricate the tire outside bead well with a suitable non-silicone lubricant, and remove outside of tire from the wheel.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will

deteriorate the tire and wheel.

• Be sure not to damage the wheel or transmitter.

• Do not allow lubricant to make contact with transmitter.

• Verify that the transmitter (1) is at the bottom of the tire while performing the above.

5. Lubricate the tire inside bead well with a suitable non-silicone lubricant, and remove inside of tire from the wheel.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

• Be sure not to damage the wheel.

6. Set tire onto the tire changer turntable so that the transmitter inside the tire is located close to the valve stem hole in the wheel.

1. Transmitter (tire pressure sensor) 2. Washer/ Grommet seal 3. Valve stem nut

4. Valve core 5. Valve cap6. Valve stem assembly

: Parts that are replaced as a set when the tire is replaced.

JMEIA0210GB

JPEIC0104ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3193 of 3641

EPS CONTROL UNITSTC-9

< ECU DIAGNOSIS INFORMATION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

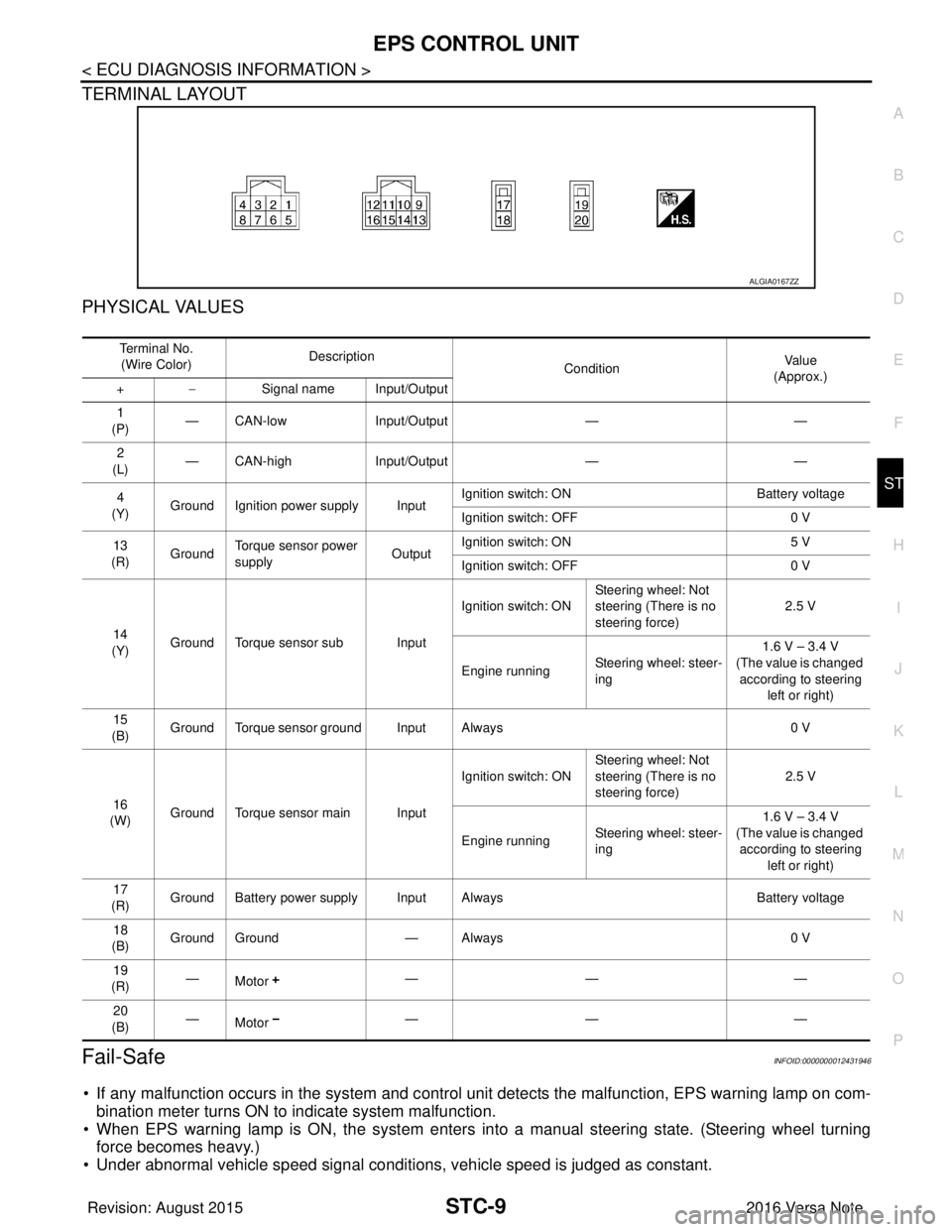

TERMINAL LAYOUT

PHYSICAL VALUES

Fail-SafeINFOID:0000000012431946

• If any malfunction occurs in the system and control uni t detects the malfunction, EPS warning lamp on com-

bination meter turns ON to indicate system malfunction.

• When EPS warning lamp is ON, the system enters into a manual steering state. (Steering wheel turning force becomes heavy.)

• Under abnormal vehicle speed signal conditions, vehicle speed is judged as constant.

ALGIA0167ZZ

Te r m i n a l N o .

(Wire Color) Description

ConditionVa l u e

(Approx.)

+ − Signal name Input/Output

1

(P) — CAN-low

Input/Output ——

2

(L) — CAN-high

Input/Output ——

4

(Y) Ground Ignition power supply Input Ignition switch: ON

Battery voltage

Ignition switch: OFF 0 V

13

(R) Ground Torque sensor power

supply

OutputIgnition switch: ON

5 V

Ignition switch: OFF 0 V

14

(Y) Ground Torque sensor sub Input Ignition switch: ON

Steering wheel: Not

steering (There is no

steering force) 2.5 V

Engine running Steering wheel: steer-

ing 1.6 V – 3.4 V

(The value is changed according to steering

left or right)

15

(B) Ground Torque sensor ground Input Always

0 V

16

(W) Ground Torque sensor main Input Ignition switch: ON

Steering wheel: Not

steering (There is no

steering force) 2.5 V

Engine running Steering wheel: steer-

ing 1.6 V – 3.4 V

(The value is changed according to steering left or right)

17

(R) Ground Battery power supply Input Always

Battery voltage

18

(B) Ground Ground

— Always 0 V

19

(R) —

Motor —— —

20

(B) —

Motor —— —

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3206 of 3641

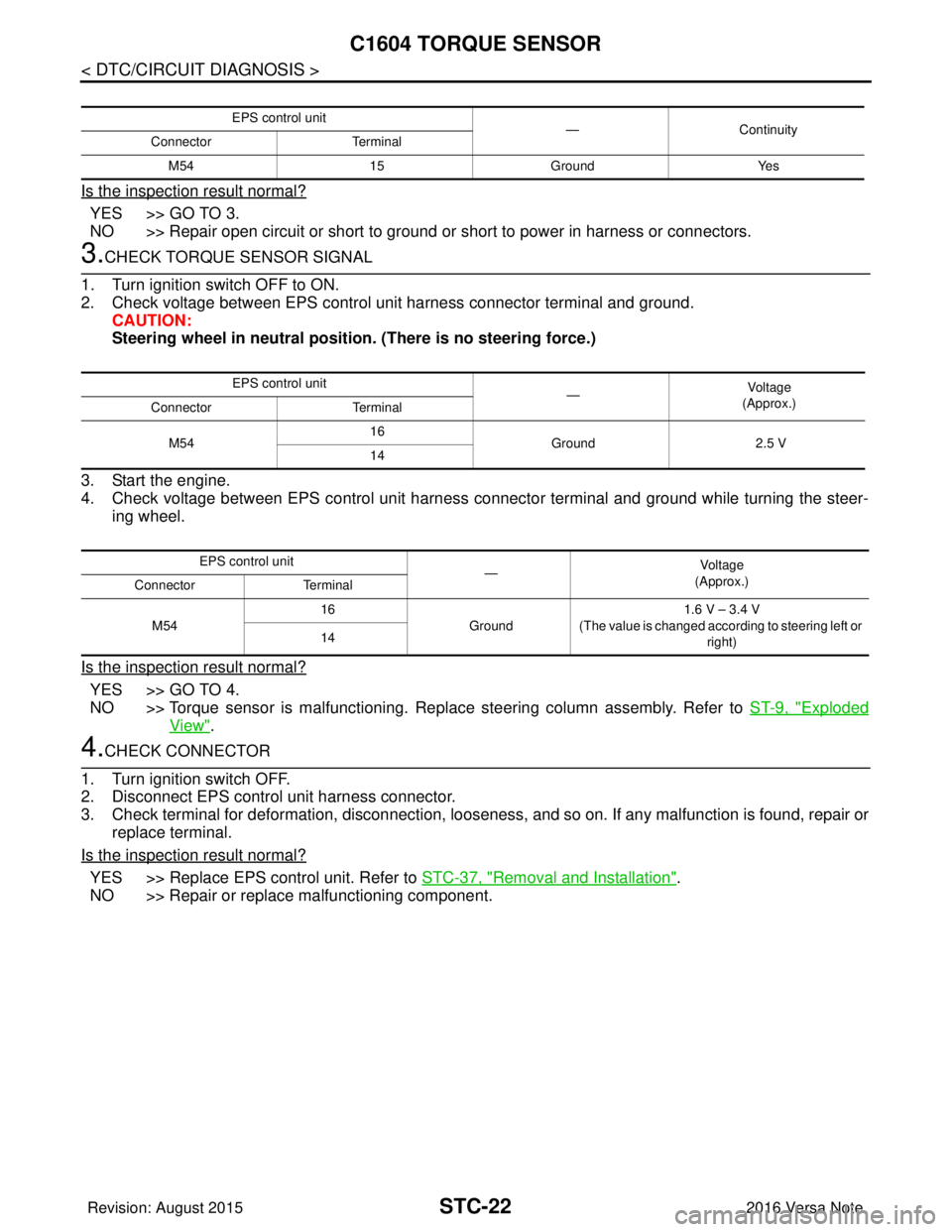

STC-22

< DTC/CIRCUIT DIAGNOSIS >

C1604 TORQUE SENSOR

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK TORQUE SENSOR SIGNAL

1. Turn ignition switch OFF to ON.

2. Check voltage between EPS control unit harness connector terminal and ground. CAUTION:

Steering wheel in neutral position. (There is no steering force.)

3. Start the engine.

4. Check voltage between EPS control unit harness connector terminal and ground while turning the steer- ing wheel.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Torque sensor is malfunctioning. Repl ace steering column assembly. Refer to ST-9, "

Exploded

View".

4.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect EPS control unit harness connector.

3. Check terminal for deformation, disconnection, looseness, and so on. If any malfunction is found, repair or replace terminal.

Is the inspection result normal?

YES >> Replace EPS control unit. Refer to STC-37, "Removal and Installation".

NO >> Repair or replace malfunctioning component.

EPS control unit —Continuity

Connector Terminal

M54 15Ground Yes

EPS control unit

—Vo l ta g e

(Approx.)

Connector Terminal

M54 16

Ground 2.5 V

14

EPS control unit —Voltag e

(Approx.)

Connector Terminal

M54 16

Ground 1.6 V – 3.4 V

(The value is changed according to steering left or right)

14

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3321 of 3641

![NISSAN NOTE 2016 Service User Guide TM-80

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

CVT CONTROL SYSTEM : Protection Control

INFOID:0000000012431020

The TCM becomes the protection control status temporarily to protect the safety when NISSAN NOTE 2016 Service User Guide TM-80

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

CVT CONTROL SYSTEM : Protection Control

INFOID:0000000012431020

The TCM becomes the protection control status temporarily to protect the safety when](/img/5/57363/w960_57363-3320.png)

TM-80

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

SYSTEM

CVT CONTROL SYSTEM : Protection Control

INFOID:0000000012431020

The TCM becomes the protection control status temporarily to protect the safety when the safety of TCM and

transmission is lost. It automatically returns to the normal status if the safety is secured.

The TCM has the following protection control.

CONTROL FOR WHEEL SPIN

P0999•Start is slow

• Lock-up is not performed

Wire disconnection

• Vehicle speed is not increased

• Lock-up is not performed Voltage shorting

P099B Start is slow —

P099C •Start is slow

• Lock-up is not performed

Wire disconnection

• Vehicle speed is not increased

• Lock-up is not performed Voltage shorting

P1586 Idle neutral control is not performed —

P1588 Idle neutral control is not performed —

P2765 • Selector shock is large

•Start is slow

• Acceleration is slow

• Vehicle speed is not increased

• Lock-up is not performed

—

P2857 •Start is slow

• Lock-up is not performed —

P2858 • Vehicle speed is not increased

• Lock-up is not performed —

P2859 Vehicle speed is not increased —

P285A Start is slow —

U0073 • Selector shock is large

•Start is slow

• Acceleration is slow

• Lock-up is not performed —

U0100 • Selector shock is large

•Start is slow

• Acceleration is slow

• Lock-up is not performed —

U0140 Not changed from normal driving —

U0141 Not changed from normal driving —

U0155 Not changed from normal driving —

U0300 • Selector shock is large

•Start is slow

• Acceleration is slow

• Lock-up is not performed —

U1000 Not changed from normal driving —

U1114 Not changed from normal driving —

U1117 Not changed from normal driving —

DTC

Vehicle behavior Conditions of vehicle

ControlWhen a wheel spin is detected, the engine output and gear ratio are limited and the line pressure is increased.

At the 1GR, the clutch pressure is increased.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 3416 of 3641

![NISSAN NOTE 2016 Service User Guide P0846 TRANSMISSION FLUID PRESSURE SEN/SW BTM-175

< DTC/CIRCUIT DIAGNOSIS > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

P0846 TRANSMISSION FLUI D PRESSURE SEN/SW B

DTC LogicINFOID:0000000012431111

D NISSAN NOTE 2016 Service User Guide P0846 TRANSMISSION FLUID PRESSURE SEN/SW BTM-175

< DTC/CIRCUIT DIAGNOSIS > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

P0846 TRANSMISSION FLUI D PRESSURE SEN/SW B

DTC LogicINFOID:0000000012431111

D](/img/5/57363/w960_57363-3415.png)

P0846 TRANSMISSION FLUID PRESSURE SEN/SW BTM-175

< DTC/CIRCUIT DIAGNOSIS > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

P0846 TRANSMISSION FLUI D PRESSURE SEN/SW B

DTC LogicINFOID:0000000012431111

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Shift the selector lever to “D” position.

3. Drive the vehicle at a constant velocity of 40 km/h (25 MPH) at lease for 10 seconds.

CAUTION:

At the same time, the accelerator pedal angle must be maintained constant.

4. Stop the vehicle.

5. Check the first trip DTC.

Is

“P0846”detected?

YES >> Go to TM-175, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431112

1.CHECK TCM INPUT SIGNAL

1. Start the engine.

2. Check voltage between TCM connector terminal and ground.

DTC Trouble diagnosis name DTC detection conditionPossible causes

P0846 Transmission Fluid Pressure

Sensor/Switch B Circuit

Range/Performance The detection conditions continuously for 5

seconds or more under the following diagno-

sis conditions:

• Diagnosis conditions

- Selector lever:

“D” position

- The primary pulley speed experienced 306 rpm or more and the secondary pulley

speed experienced 230 rpm or more at

least once.

- Wheel spin is not being detected.

- The rate of change in pulley ratio: Between −0.09 and +0.09 inclusive

- Solenoid valve output current: 750 mA or more

- GND short diagnosis of the solenoid valve circuit is not satisfied.

- TCM power supply voltage: More than 11 V

• Detection conditions

- After the value of “Actual secondary pres-

sure − Target secondary pressure” exceeds

0.675 MPa:

• The rate of change in vehicle speed [km/h (MPH)]: Between −49 ( −30) and +49 (+30)

inclusive

• The rate of change in accelerator pedal an- gle: Between −1.3/8 and +1.3/8 inclusive • Secondary pressure sensor

• Control valve assembly

Revision: August 2015

2016 Versa Note

cardiagn.com