fog light NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1190 of 3641

![NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogge NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogge](/img/5/57363/w960_57363-1189.png)

DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogger switch is ON and/or lighting switch is 2nd position.

- OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFFIndicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW ON/OFFIndicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1 msecIndicates the actual fuel injection pulse width com-

pensated by ECM according to the input signals. When the engine is stopped, a certain

computed value is indicated.

IGN TIMING BTDCIndicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE %“Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/sIndicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V %• Indicates the EVAP canister purge volume con-

trol solenoid valve control value computed by the

ECM according to the input signals.

• The opening becomes larger as the value in-

creases.

INT/V TIM(B1) °CA Indicates [ °CA] of intake camshaft advance angle.

EXH/V TIM B1 °CA Indicates [ °CA] of exhaust camshaft retard angle.

INT/V SOL(B1) %• The control value of the intake valve timing con-

trol solenoid valve (determined by ECM accord-

ing to the input signals) is indicated.

• The advance angle becomes larger as the value increases.

AIR COND RLY ON/OFF The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

FUEL PUMP RLY ON/OFF Indicates the fuel pump relay control condition de-

termined by ECM according to the input signals.

VENT CONT/V ON/OFF • The control condition of the EVAP canister vent

control valve (determined by ECM according to

the input signals) is displayed.

- ON: Closed

-OFF: Open

THRTL RELAY ON/OFF Indicates the throttle control motor relay control

condition determined by the ECM according to the

input signals.

COOLING FAN HI/LOW/OFF • Indicates the condition of the cooling fan (deter-

mined by ECM according to the input signals).

- HI: High speed operation

- LOW: Low speed operation

-OFF: Stop

HO2S2 HTR (B1) ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

Monitored item Unit

DescriptionRemarks

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1199 of 3641

![NISSAN NOTE 2016 Service User Guide EC-72

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

EVAP SYS PRES • Ignition switch: ON

Approx. 1.8 - 4.8 V

FUEL LEVEL SE • Ignition switch: ON Depending on fuel level of

fuel tank

START SIGNAL • I NISSAN NOTE 2016 Service User Guide EC-72

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

EVAP SYS PRES • Ignition switch: ON

Approx. 1.8 - 4.8 V

FUEL LEVEL SE • Ignition switch: ON Depending on fuel level of

fuel tank

START SIGNAL • I](/img/5/57363/w960_57363-1198.png)

EC-72

< ECU DIAGNOSIS INFORMATION >[HR16DE]

ECM

EVAP SYS PRES • Ignition switch: ON

Approx. 1.8 - 4.8 V

FUEL LEVEL SE • Ignition switch: ON Depending on fuel level of

fuel tank

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS • Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released

ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG • Engine: After warming up, idle

the engine Air conditioner switch: OFF

OFF

Air conditioner switch: ON

(Compressor operates.) ON

PW/ST SIGNAL • Engine: After warming up, idle

the engine Steering wheel: Not being turned

OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ON Rear window defogger switch: ON

and/or

Lighting switch: 2nd position

ON

Rear window defogger switch and lighting

switch: OFF OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW • Engine: After warming up, idle

the engine Heater fan switch: ON

ON

Heater fan switch: OFF OFF

BRAKE SW • Ignition switch: ON Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1 • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idle

2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idle

4

°BTDC (CVT)

10 °BTDC (M/T)

2,000 rpm 25° - 45 °BTDC

CAL/LD VALUE • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idle

10% - 35%

2,500 rpm 10% - 35%

MASS AIRFLOW • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idle

0.8 - 4.0 g/s

2,500 rpm 2.0 - 10.0 g/s

PURG VOL C/V • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idl

e

0%

2 ,

000 rpm

0% - 50%

INT/V TIM(B1) • Engine: After warming up

• Selector lever position: P or N

(CVT) or Neutral (M/T)

• Air conditioner switch: OFF

•No load Idle

−5° - 5 °CA

When revving engine up to 2,000rpm

Quickly Approx. 0

° - 40 °CA

Monitor Item

Condition Values/Status

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1257 of 3641

![NISSAN NOTE 2016 Service User Guide EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that NISSAN NOTE 2016 Service User Guide EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that](/img/5/57363/w960_57363-1256.png)

EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

Refer to

EC-130, "

Work Procedure".

Work ProcedureINFOID:0000000012431359

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (CVT), Neutral (M/T)

• Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

- For vehicles equipped with dayt ime light systems, perform one of the following procedures before

starting engine not to illuminate headlamps.

• Apply parking brake

• Set lighting switch to the 1st position

• Steering wheel: Neutral (Straight-ahead position) position

• Vehicle speed: Stopped

• Transmission: Warmed-up

- CVT models

• With CONSULT: Drive vehicle until “FLUID TEMP SE ” in “DATA MONITOR” mode of “TRANSMISSION” sys-

tem indicates less than 0.9 V.

• Without CONSULT: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode with CONSULT.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1264 of 3641

![NISSAN NOTE 2016 Service User Guide FUEL PRESSURE CHECKEC-137

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE CHECK

Work ProcedureINFOID:0000000012431363

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CON NISSAN NOTE 2016 Service User Guide FUEL PRESSURE CHECKEC-137

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE CHECK

Work ProcedureINFOID:0000000012431363

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CON](/img/5/57363/w960_57363-1263.png)

FUEL PRESSURE CHECKEC-137

< BASIC INSPECTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE CHECK

Work ProcedureINFOID:0000000012431363

FUEL PRESSURE RELEASE

1.FUEL PRESSURE RELEASE

With CONSULT

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode with CONSULT.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT

1. Remove fuel pump fuse located in IPDM E/R.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

>> INSPECTION END

FUEL PRESSURE CHECK

1.FUEL PRESSURE CHECK

CAUTION:

• Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

• The fuel hose connection method used when taki ng fuel pressure check must not be used for other

purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick

connector maintains seal abil ity with O-rings inside.

• Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C, etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pres-

sure cannot be completely released because th is models do not have fuel return system.

1. Release fuel pressure to zero.

2. Prepare fuel hose for fuel pressure check (B) and fuel tube adapter [SST: KV10118400 or KV10120000] (D), then connect

fuel pressure gauge (A).

CAUTION:

• Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use mod- erately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with damage or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose.

CAUTION:

Do not twist or kink fuel hose because it is plastic hose.

To quick connector

To fuel tube (engine side)

C : Hose clamp

PBIB2982E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1278 of 3641

![NISSAN NOTE 2016 Service User Guide TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000 NISSAN NOTE 2016 Service User Guide TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000](/img/5/57363/w960_57363-1277.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000012431370

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode of CONSULT during normal operation of the Engine Control System. When the value in “SPEC” of

“DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When the value

in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may have one

or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc- tion)

• A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Component Function CheckINFOID:0000000012431371

1.START

Make sure that all of the following conditions are satisfied.

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30 °C (68 - 86° F)

• Engine coolant temperature: 75 - 95 °C (167 - 203° F)

• Transmission: Warmed-up

- CVT models: After the engine is warmed up to normal operating temperature, drive vehicle until “FLUID TEMP SE” (CVT fluid temperature sensor signal) indicates more than 60 °C (140° F).

- M/T models: After the engine is warmed up to normal operating temperature, drive vehicle for 5 minutes.

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

• Engine speed: Idle

>> GO TO 2.

2.PERFORM “SPEC” OF “DATA MONITOR” MODE

With CONSULT

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform EC-133, "

Work Procedure".

2. Select “B/FUEL SCHDL”, “A/F ALPHA-B1” and “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode

with CONSULT.

3. Make sure that monitor items are within the SP value.

Is the inspection result normal?

YES >> END

NO >> Go to EC-152, "

Diagnosis Procedure".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1571 of 3641

![NISSAN NOTE 2016 Service User Guide EC-444

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000012431645

The electrical load signal (Headlamp switch signal, rear window defogger switc NISSAN NOTE 2016 Service User Guide EC-444

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000012431645

The electrical load signal (Headlamp switch signal, rear window defogger switc](/img/5/57363/w960_57363-1570.png)

EC-444

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000012431645

The electrical load signal (Headlamp switch signal, rear window defogger switch signal, etc.) is transferred to

ECM through the CAN communication line.

Component Function CheckINFOID:0000000012431646

1.CHECK REAR WINDOW DEFOGGER SWITCH FUNCTION

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Go to EC-444, "

Diagnosis Procedure".

2.CHECK LIGHTING SWITCH FUNCTION

Check “LOAD SIGNAL” indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Go to EC-444, "

Diagnosis Procedure".

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-444, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431647

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-444, "

Compo-

nent Function Check".

Which circuit is related to the incident?

Rear window defogger>>GO TO 2

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Perform trouble diagnosis of rear window defogger system. Refer to DEF-17, "

Work Flow".

Monitor itemConditionIndication

LOAD SIGNAL Rear window defogger switch ON ON

OFF OFF

Monitor item

ConditionIndication

LOAD SIGNAL Lighting switch ON at 2nd position ON

OFF

OFF

Monitor item ConditionIndication

HEATER FAN SW Heater fan control switch ON ON

OFF OFF

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1605 of 3641

![NISSAN NOTE 2016 Service User Guide EC-478

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000012431 NISSAN NOTE 2016 Service User Guide EC-478

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000012431](/img/5/57363/w960_57363-1604.png)

EC-478

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000012431675

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Ignition TimingINFOID:0000000012431676

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000012431677

Mass Air Flow SensorINFOID:0000000012431678

*: Engine is warmed up to normal operating temperature and running under no load.Transmission Condition Specification

CVT No load* (in P or N position) 650 ± 50 rpm

M/T No load* (in Neutral position) 650 ± 50 rpm

Transmission ConditionSpecification

CVT No load* (in P or N position) 4 ± 5 °BTDC

M/T No load* (in Neutral position) 10 ± 5°BTDC

Condition Specification (Using CONSULT or GST)

At idle 10 – 35%

At 2,500 rpm 10 – 35%

Supply voltageBattery voltage (11 – 14 V)

Output voltage at idle 0.8 – 1.3 V*

Mass air flow (Using CONSULT or GST) 0.8 – 4.0 g/s at idle*

2.0 – 10.0 g/s at 2,500 rpm*

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1653 of 3641

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

PRECAUTION ....... ........................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

SYSTEM ..............................................................8

HEADLAMP SYSTEM .................................................8

HEADLAMP SYSTEM : Syst em Diagram .................8

HEADLAMP SYSTEM : System Description ....... ......8

DAYTIME RUNNING LIGHT SYSTEM ........................9

DAYTIME RUNNING LIGHT SYSTEM : System

Diagram ............................................................... ......

9

DAYTIME RUNNING LIGHT SYSTEM : System

Description ................................................................

9

FRONT FOG LAMP SYSTEM .....................................9

FRONT FOG LAMP SYSTEM : System Diagram ......9

FRONT FOG LAMP SYSTEM : System Descrip-

tion ..........................................................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM ................................................................ ....

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Diagram ....................................

10

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Description ...............................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM .......................................... ...........................

10

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Diagram ................................ ....

11

PARKING, LICENSE PLATE AND TAIL LAMP

SYSTEM : System Description ................................

11

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .......................................

12

COMMON ITEM ..................................................... ....12

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

12

HEADLAMP ........................................................... ....13

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

13

FLASHER ............................................................... ....13

FLASHER : CONSULT Function (BCM - FLASH-

ER) ..........................................................................

14

COMB SW .............................................................. ....14

COMB SW : CONSULT Function (BCM - COMB

SW) ..........................................................................

14

BATTERY SAVER ................................................. ....15

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) ..................................................

15

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

16

COMMON ITEM ..................................................... ....16

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

16

HEADLAMP ........................................................... ....17

HEADLAMP : CONSULT Function (BCM - HEAD

LAMP) ......................................................................

17

FLASHER ............................................................... ....17

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1654 of 3641

EXL-2

FLASHER : CONSULT Function (BCM - FLASH-

ER) .........................................................................

17

COMB SW .............................................................. ...18

COMB SW : CONSULT Function (BCM - COMB

SW) .........................................................................

18

BATTERY SAVER ................................................. ...18

BATTERY SAVER : CONSULT Function (BCM -

BATTERY SAVER) .................................................

18

DIAGNOSIS SYSTEM (IPDM E/R) ................. ...20

Diagnosis Description .......................................... ...20

CONSULT Function (IPDM E/R) ............................21

ECU DIAGNOSIS INFORMATION ..............24

BCM, IPDM E/R .............................................. ...24

List of ECU Reference ......................................... ...24

WIRING DIAGRAM .....................................25

HEADLAMP .................................................... ...25

Wiring Diagram - For USA ................................... ...25

Wiring Diagram - For Canada .................................31

DAYTIME LIGHT SYSTEM ............................. ...37

Wiring Diagram .................................................... ...37

FRONT FOG LAMP ...........................................43

Wiring Diagram .................................................... ...43

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .............................................. ...

48

Wiring Diagram .................................................... ...48

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ............................................ ...

55

Wiring Diagram .................................................... ...55

STOP LAMP ......................................................63

Wiring Diagram .................................................... ...63

BACK-UP LAMP ................................................67

Wiring Diagram .................................................... ...67

BASIC INSPECTION ...................................71

DIAGNOSIS AND REPAIR WORKFLOW ...... ...71

Work Flow ............................................................ ...71

DTC/CIRCUIT DIAGNOSIS ...................... ...74

POWER SUPPLY AND GROUND CIRCUIT .. ...74

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) ..... .......................................

74

BCM (BODY CONTROL S YSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Dia gnosis Procedure .....

74

BCM (BODY CONTROL SYST EM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) . ....................................

74

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ...................................................................... ...

74

IPDM E/R ................................................................ ...75

IPDM E/R : Diagnosis Procedure ............................75

HEADLAMP (HI) CIRCUIT ................................77

Description ........................................................... ...77

Component Function Check ...................................77

Diagnosis Procedure ...............................................77

HEADLAMP (LO) CIRCUIT ...............................79

Description ........................................................... ...79

Component Function Check ...................................79

Diagnosis Procedure ...............................................79

PARKING LAMP CIRCUIT ................................82

Description ........................................................... ...82

Component Function Check ...................................82

Diagnosis Procedure ...............................................82

TURN SIGNAL LAMP CIRCUIT ........................85

Description ........................................................... ...85

Component Function Check ...................................85

Diagnosis Procedure ...............................................85

FRONT FOG LAMP CIRCUIT ...........................88

Component Function Check ................................ ...88

Diagnosis Procedure ...............................................88

Component Inspection ............................................90

SYMPTOM DIAGNOSIS ............................91

EXTERIOR LIGHTING SYSTEM SYMPTOMS ...91

Symptom Table .................................................... ...91

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM .................................................

93

Description ........................................................... ...93

Diagnosis Procedure ...............................................93

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ......................................................

94

Description ..............................................................94

Diagnosis Procedure ...............................................94

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON .......................

95

Description ........................................................... ...95

Diagnosis Procedure ...............................................95

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ......................................................

96

Description ..............................................................96

Diagnosis Procedure ...............................................96

PERIODIC MAINTENANCE .......................97

HEADLAMP AIMING ADJUSTMENT ............ ...97

Inspection ............................................................. ...97

Aiming Adjustment Procedure ................................98

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1661 of 3641

SYSTEMEXL-9

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Under this condition, the headlamps remain illuminated for 45 seconds unless the lighting switch position is

changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT. Refer to BCS-20, "

HEADLAMP : CONSULT Function (BCM -

HEAD LAMP)" (with Intelligent Key system) or BCS-93, "HEADLAMP : CONSULT Function (BCM - HEAD

LAMP)" (without Intelligent Key system).

DAYTIME RUNNING LIGHT SYSTEM

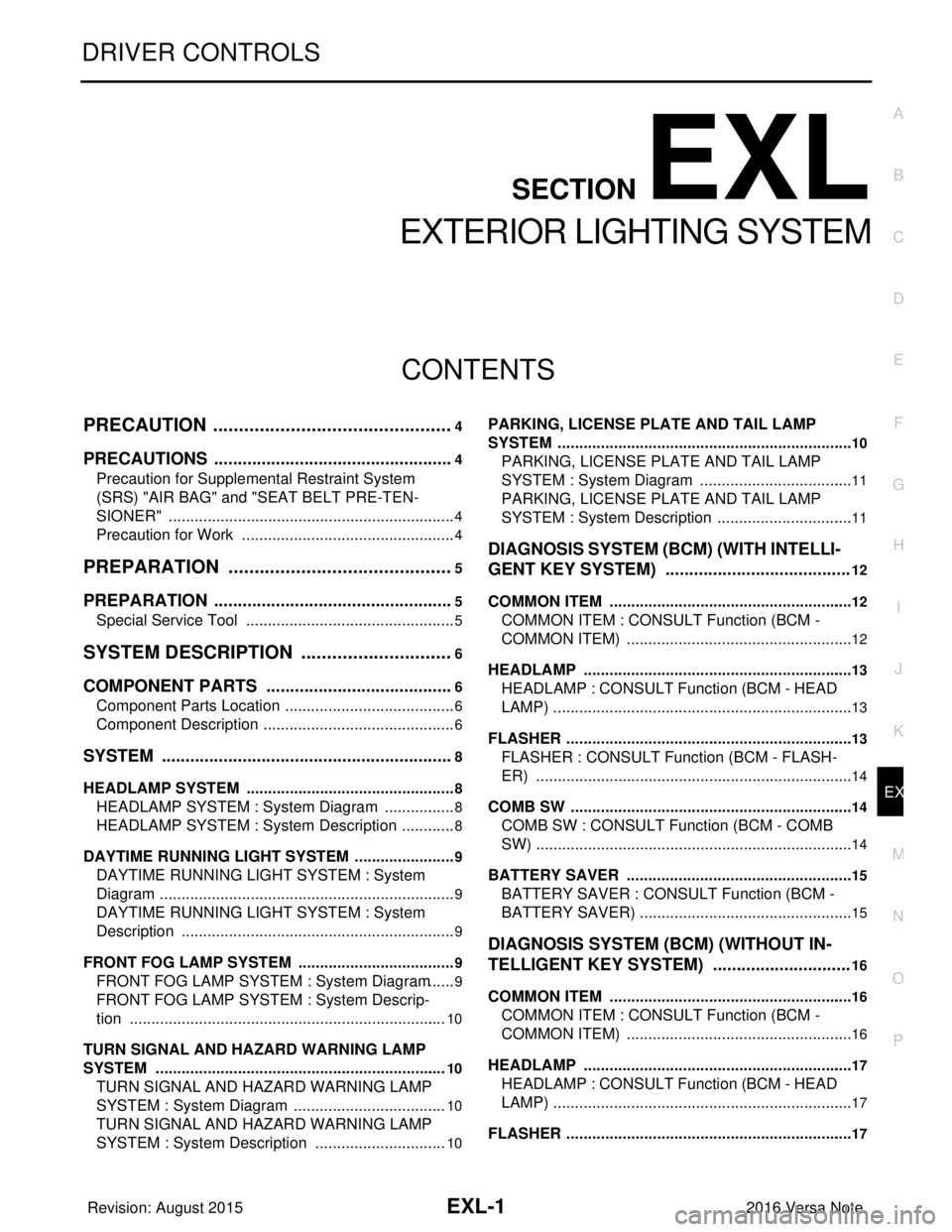

DAYTIME RUNNING LIGHT SYSTEM : System DiagramINFOID:0000000012432771

DAYTIME RUNNING LIGHT SYST EM : System DescriptionINFOID:0000000012432772

The headlamp system is equipped with a daytime running light control that activates the high beam head-

lamps at approximately half illumination whenever the e ngine is operating. If the parking brake is applied

before the engine is started the daytime running lights will not be illuminated. The daytime running lights will

illuminate once the parking brake is released. Thereaf ter, the daytime running lights will continue to operate

when the parking brake is applied.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime running light system. The BCM sends a daytime running

light request to the IPDM E/R via the CAN communication lines. The IPDM E/R grounds the daytime running

light relay 1 which in turn, provides power to the LH high beam lamp. Power flows through the LH high beam

lamp to the RH high beam lamp. The high beam lamps are wired in series which causes them to illuminate at

a reduced intensity. When daytime light relay 2 is open, it prevents headlamp low beam from turning on while

daytime running lights are operating.

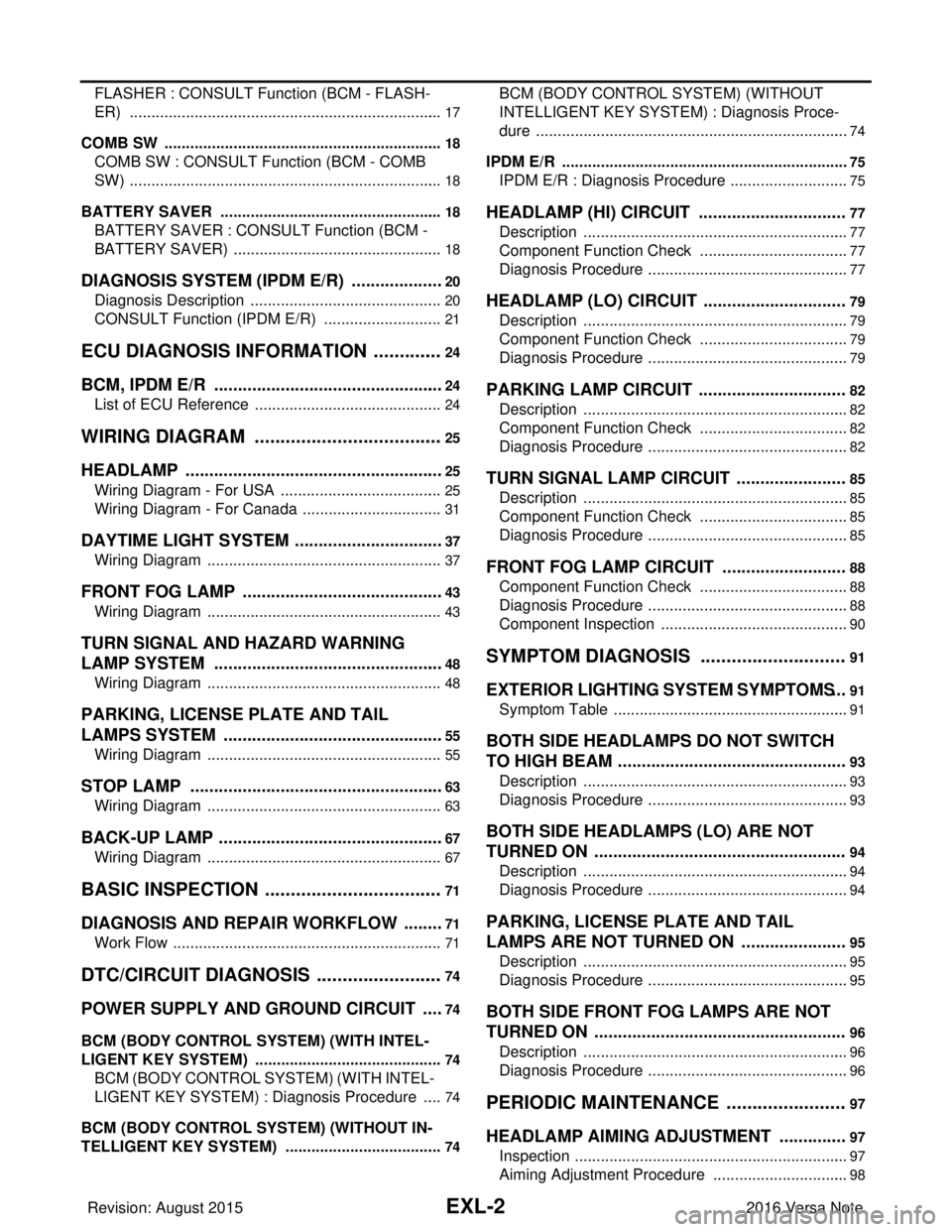

FRONT FOG LAMP SYSTEM

FRONT FOG LAMP SYSTEM : System DiagramINFOID:0000000012432773

ALLIA1577GB

ALLIA1578GB

Revision: August 2015 2016 Versa Note

cardiagn.com