oil NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 628 of 3641

CL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432210

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

General PrecautionsINFOID:0000000012432211

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not use compressed air.

CAUTION:

• Always use recommended clutch fluid. Refer to MA-11, "

Fluids and Lubricants".

• Do not reuse drained clutch fluid.

• Keep painted surface on the body and other parts free of clutch fluid. If fluid spills, wipe up immedi-

ately and wash the affected area with water.

• Do not use mineral oils, such as gasoline or kerosen e. It will ruin the rubber parts of the hydraulic

system.

• Do not reuse CSC (Concentric Slave Cylinder). CS C slides back to the original position every time

when removing transaxle assembly. At this time, dust on the sliding parts may damage the seal of

CSC and may cause clutch fluid leakage. Refer to CL-17, "

Removal and Installation".

• Do not disassemble clutch master cylinder and CSC.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 630 of 3641

CL-4

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

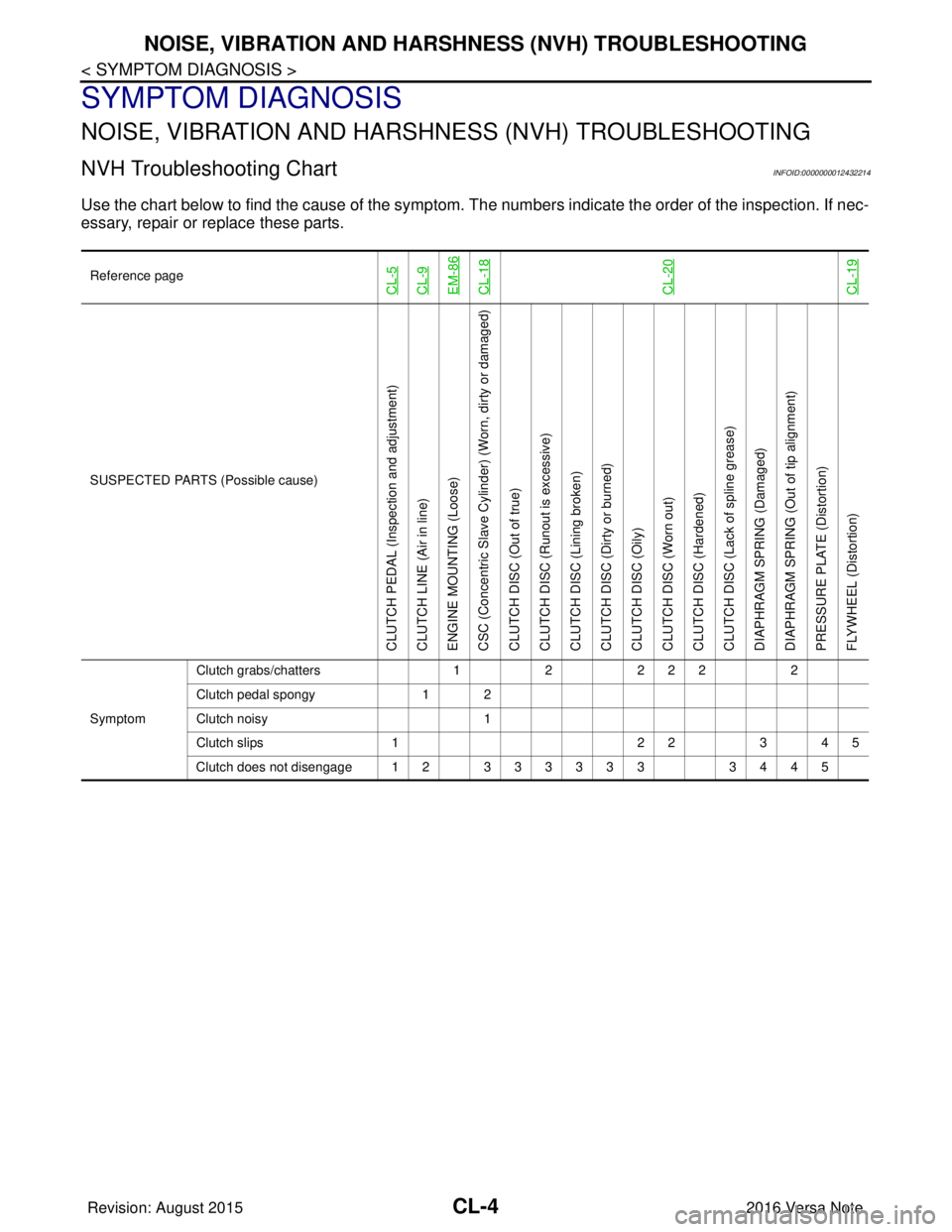

NVH Troubleshooting ChartINFOID:0000000012432214

Use the chart below to find the cause of the symptom. T he numbers indicate the order of the inspection. If nec-

essary, repair or replace these parts.

Reference pageCL-5CL-9EM-86CL-18CL-20CL-19

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

ENGINE MOUNTING (Loose)

CSC (Concentric Slave Cylinder) (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Ru nout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

Symptom Clutch grabs/chatters

122 2 2 2

Clutch pedal spongy 1 2

Clutch noisy 1

Clutch slips 1 2 23 4 5

Clutch does not disengage 12 333333 3445

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 687 of 3641

DEF-36

< REMOVAL AND INSTALLATION >

FILAMENT

REMOVAL AND INSTALLATION

FILAMENT

Inspection and RepairINFOID:0000000012431789

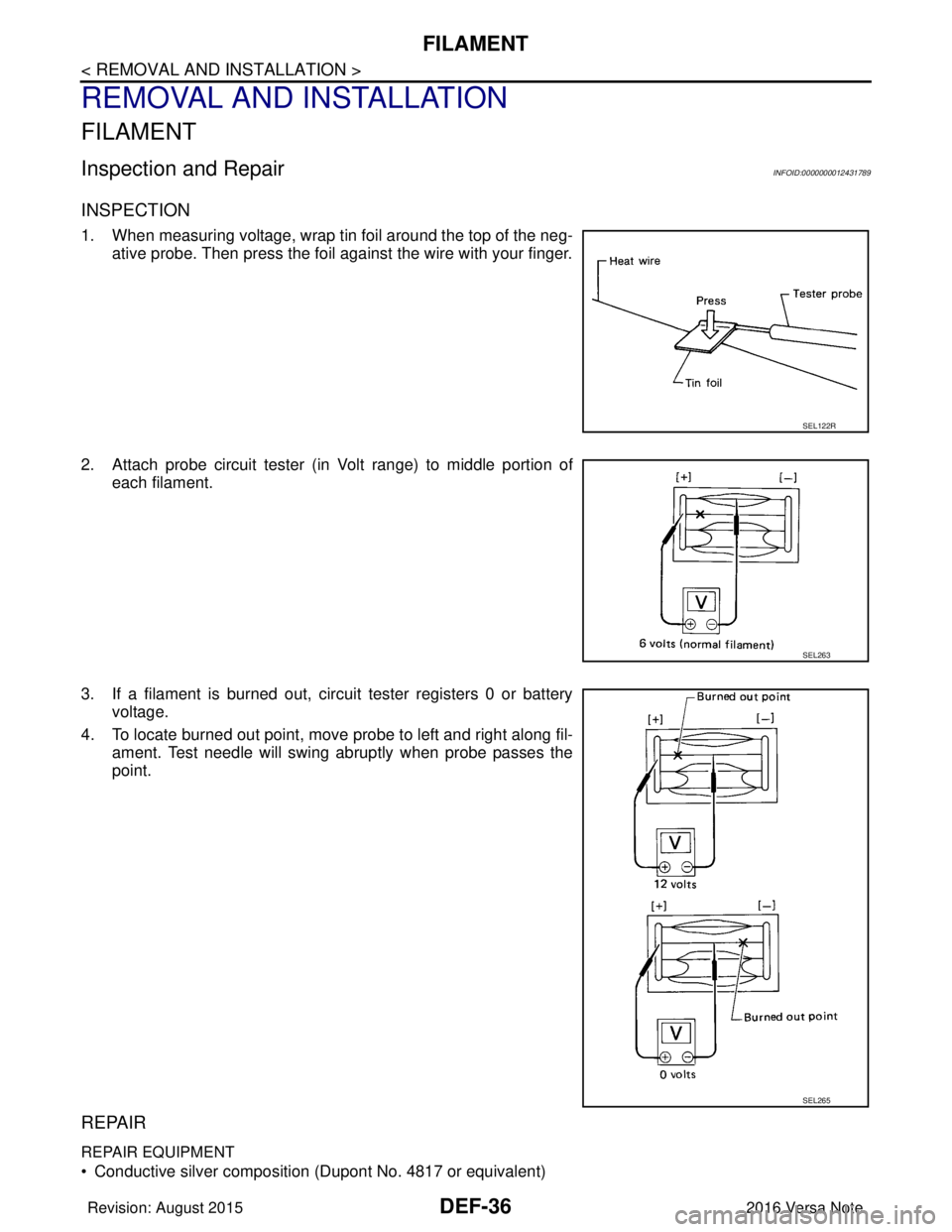

INSPECTION

1. When measuring voltage, wrap tin foil around the top of the neg-ative probe. Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of each filament.

3. If a filament is burned out, circuit tester registers 0 or battery voltage.

4. To locate burned out point, move probe to left and right along fil- ament. Test needle will swing abruptly when probe passes the

point.

REPAIR

REPAIR EQUIPMENT

• Conductive silver composition (Dupont No. 4817 or equivalent)

SEL122R

SEL263

SEL265

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 699 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-10

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that each p NISSAN NOTE 2016 Service User Guide DLK-10

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that each p](/img/5/57363/w960_57363-698.png)

DLK-10

< PRECAUTION >[WITH INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precaution for WorkINFOID:0000000012918340

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 853 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-164

< REMOVAL AND INSTALLATION >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR

1. Secure back door stay (1) using a vice (C).

CAUTION:

When cutting back door stay, al ways cover suitable tool (A)

using a NISSAN NOTE 2016 Service User Guide DLK-164

< REMOVAL AND INSTALLATION >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR

1. Secure back door stay (1) using a vice (C).

CAUTION:

When cutting back door stay, al ways cover suitable tool (A)

using a](/img/5/57363/w960_57363-852.png)

DLK-164

< REMOVAL AND INSTALLATION >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR

1. Secure back door stay (1) using a vice (C).

CAUTION:

When cutting back door stay, al ways cover suitable tool (A)

using a shop cloth (B) to avo id scattering metal fragments

or oil.

2. Slowly cut a hole in back door stay and drain the gas using a hacksaw at position (B) as shown.

A: 20 mm (0.79 in)

BACK DOOR WEATHER-STRIP

BACK DOOR WEATHER-STRIP : Removal and InstallationINFOID:0000000012430117

REMOVAL

1. Support back door using a suitable tool.

2. Carefully remove back door weather-strip from opening door joint.

INSTALLATION

1. Beginning with upper section, align weather-strip mark with vehicle center position mark and install

weather strip to the vehicle.

2. For the lower section, align weather-strip seam with center of back door striker.

NOTE:

Pull weather-strip gently to make sure that there are no loose sections.

JMKIA3336ZZ

JMKIA5421ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 879 of 3641

![NISSAN NOTE 2016 Service User Guide DLK-190

< PRECAUTION >[WITHOUT INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that ea NISSAN NOTE 2016 Service User Guide DLK-190

< PRECAUTION >[WITHOUT INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that ea](/img/5/57363/w960_57363-878.png)

DLK-190

< PRECAUTION >[WITHOUT INTELLIGENT KEY SYSTEM]

PRECAUTIONS

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure

to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precaution for WorkINFOID:0000000012918341

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 980 of 3641

![NISSAN NOTE 2016 Service User Guide BACK DOORDLK-291

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

1. Secure back door stay (1) using a vice (C). CAUTION:

When cutting back door stay, al NISSAN NOTE 2016 Service User Guide BACK DOORDLK-291

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

1. Secure back door stay (1) using a vice (C). CAUTION:

When cutting back door stay, al](/img/5/57363/w960_57363-979.png)

BACK DOORDLK-291

< REMOVAL AND INSTALLATION > [WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

1. Secure back door stay (1) using a vice (C). CAUTION:

When cutting back door stay, al ways cover suitable tool (A)

using a shop cloth (B) to avoid scattering metal fragments

or oil.

2. Slowly cut a hole in back door stay and drain the gas using a hacksaw at position (B) as shown.

A: 20 mm (0.79 in)

BACK DOOR WEATHER-STRIP

BACK DOOR WEATHER-STRIP : Removal and InstallationINFOID:0000000012430263

REMOVAL

1. Support back door using a suitable tool.

2. Carefully remove back door weather-strip from opening door joint.

INSTALLATION

1. Beginning with upper section, align weather-strip mark with vehicle center position mark and install

weather strip to the vehicle.

2. For the lower section, align weather-str ip seam with center of back door striker.

NOTE:

Pull weather-strip gently to make sure that there are no loose sections.

JMKIA3336ZZ

JMKIA5421ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1002 of 3641

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

HR16DE

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

Draining Engine Coolant ...........................................3

Disconnecting Fuel Piping .........................................3

Removal and Disassembly ........................................3

Inspection, Repair and Replacement ........................4

Assembly and Installation .........................................4

Parts Requiring Angle Tightening ....................... ......4

Precaution for Liquid Gasket .....................................4

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tools .......................................... ......6

Commercial Service Tools ........................................7

BASIC INSPECTION ...................................10

CAMSHAFT VALVE CLEARANCE ............... ....10

Inspection and Adjustment .................................. ....10

COMPRESSION PRESSURE ............................13

Inspection ............................................................ ....13

SYMPTOM DIAGNOSIS ..............................14

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

14

NVH troubleshooting Chart ................................. ....14

PERIODIC MAINTENANCE .........................16

DRIVE BELT ................................................... ....16

Exploded View .................................................... ....16

Removal and Installation .........................................16

Inspection ............................................................ ....17

Adjustment ...............................................................17

AIR CLEANER FILTER .....................................19

Exploded View .........................................................19

Removal and Installation .........................................19

SPARK PLUG ...................................................21

Exploded View .........................................................21

Removal and Installation .........................................21

REMOVAL AND INSTALLATION ...............24

DRIVE BELT IDLER PULLEY ..........................24

Exploded View ..................................................... ....24

Removal and Installation .........................................24

AIR CLEANER AND AIR DUCT .......................26

Exploded View .........................................................26

Removal and Installation .........................................26

INTAKE MANIFOLD .........................................28

Exploded View .........................................................28

Removal and Installation .........................................28

EXHAUST MANIFOLD ......................................31

Exploded View .........................................................31

Removal and Installation .........................................31

OIL PAN AND OIL STRAINER .........................34

Exploded View .........................................................34

Removal and Installation (Lower Oil Pan) ...............34

Removal and Installation (Upper Oil Pan) ........... ....37

FUEL INJECTOR AND FUEL TUBE ................40

Exploded View .........................................................40

Removal and Installation .........................................40

IGNITION COIL .................................................47

Exploded View .........................................................47

Removal and Installation .........................................47

ROCKER COVER .............................................48

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1003 of 3641

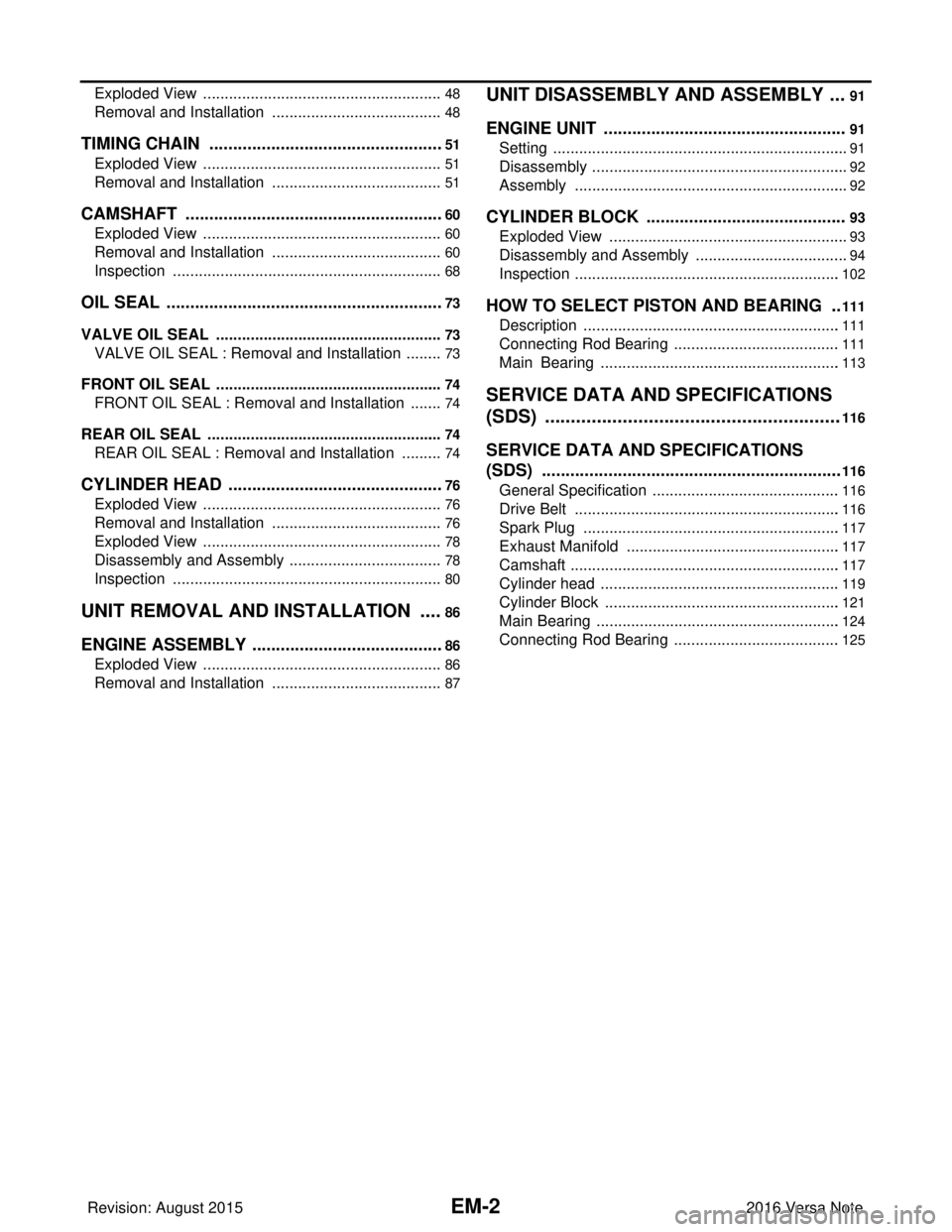

EM-2

Exploded View ........................................................48

Removal and Installation ........................................48

TIMING CHAIN ............................................... ...51

Exploded View ..................................................... ...51

Removal and Installation ........................................51

CAMSHAFT .......................................................60

Exploded View ..................................................... ...60

Removal and Installation ........................................60

Inspection ...............................................................68

OIL SEAL ...........................................................73

VALVE OIL SEAL .................................................. ...73

VALVE OIL SEAL : Removal and Installation .........73

FRONT OIL SEAL .................................................. ...74

FRONT OIL SEAL : Removal and Installation ........74

REAR OIL SEAL .................................................... ...74

REAR OIL SEAL : Removal and Installation ..........74

CYLINDER HEAD ........................................... ...76

Exploded View ..................................................... ...76

Removal and Installation ........................................76

Exploded View ........................................................78

Disassembly and Assembly ....................................78

Inspection ...............................................................80

UNIT REMOVAL AND INSTALLATION .....86

ENGINE ASSEMBLY ...................................... ...86

Exploded View ..................................................... ...86

Removal and Installation ........................................87

UNIT DISASSEMBLY AND ASSEMBLY ...91

ENGINE UNIT ....................................................91

Setting .................................................................. ...91

Disassembly ............................................................92

Assembly ................................................................92

CYLINDER BLOCK ...........................................93

Exploded View ........................................................93

Disassembly and Assembly ....................................94

Inspection ..............................................................102

HOW TO SELECT PISTON AND BEARING ...111

Description ........................................................... .111

Connecting Rod Bearing .......................................111

Main Bearing ........................................................113

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

116

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

116

General Specification ........................................... .116

Drive Belt ..............................................................116

Spark Plug ............................................................117

Exhaust Manifold ..................................................117

Camshaft ...............................................................117

Cylinder head ........................................................119

Cylinder Block .......................................................121

Main Bearing .........................................................124

Connecting Rod Bearing .......................................125

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1004 of 3641

![NISSAN NOTE 2016 Service User Guide PRECAUTIONSEM-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000 NISSAN NOTE 2016 Service User Guide PRECAUTIONSEM-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:00000](/img/5/57363/w960_57363-1003.png)

PRECAUTIONSEM-3

< PRECAUTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental

Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431679

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000012431680

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Draining Engine CoolantINFOID:0000000012431681

Drain engine coolant and engine oil when the engine is cooled.

Disconnecting Fuel PipingINFOID:0000000012431682

• Before starting work, check no fire or spark producing items are in the work area.

• Release fuel pressure before disconnecting and disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Removal and DisassemblyINFOID:0000000012431683

• When instructed to use SST, use specified tools. Alwa ys be careful to work safely, avoid forceful or unin-

structed operations.

• Use care to avoid damage to mating or sliding surfaces.

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com