tire pressure NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2380 of 3641

![NISSAN NOTE 2016 Service Owners Guide MWI-22

< ECU DIAGNOSIS INFORMATION >[TYPE A]

COMBINATION METER

*: Displays “Off” if the brake warning lamp is illumi

nated when the valve check starts, the parking brake switch

is turned ON or the NISSAN NOTE 2016 Service Owners Guide MWI-22

< ECU DIAGNOSIS INFORMATION >[TYPE A]

COMBINATION METER

*: Displays “Off” if the brake warning lamp is illumi

nated when the valve check starts, the parking brake switch

is turned ON or the](/img/5/57363/w960_57363-2379.png)

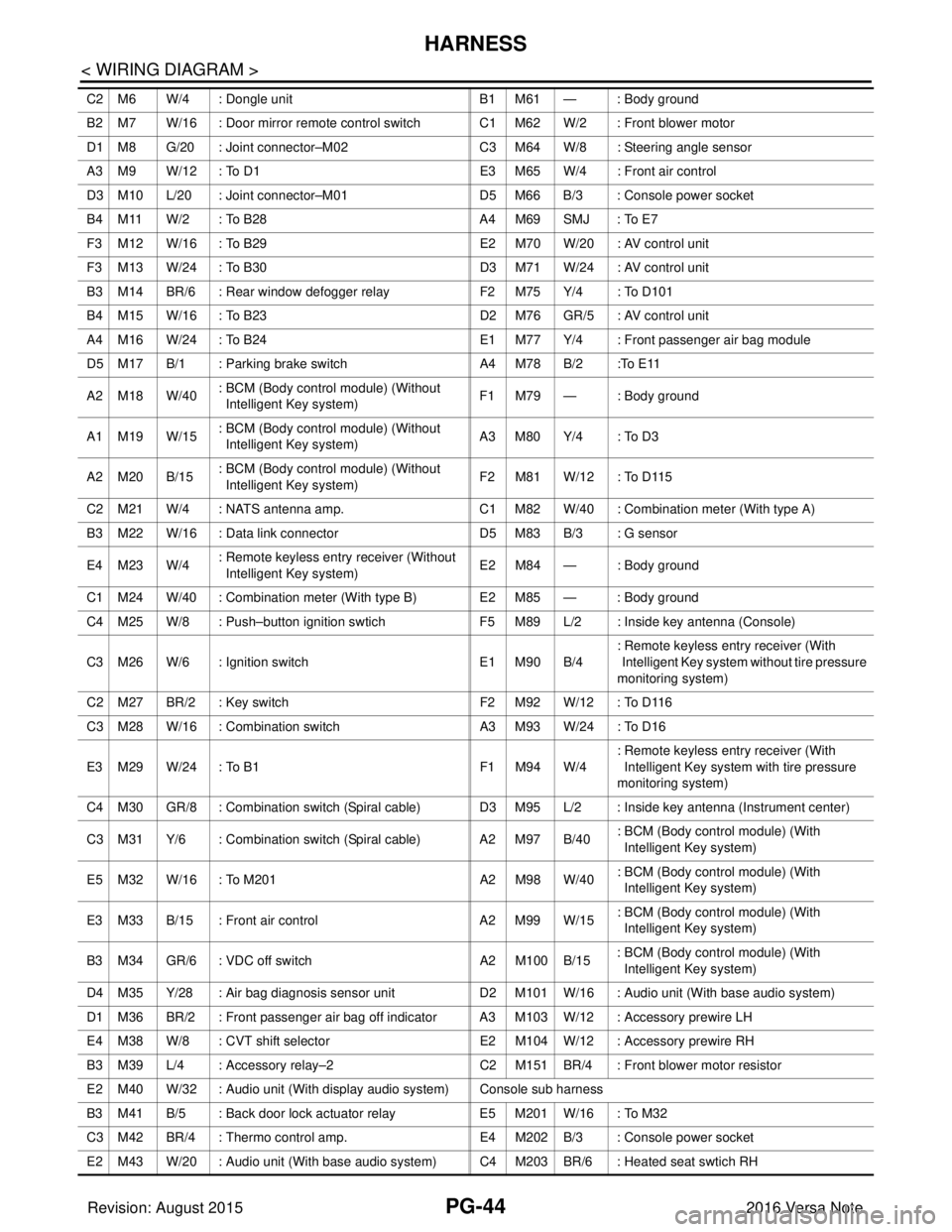

MWI-22

< ECU DIAGNOSIS INFORMATION >[TYPE A]

COMBINATION METER

*: Displays “Off” if the brake warning lamp is illumi

nated when the valve check starts, the parking brake switch

is turned ON or the brake fluid level switch is turned ON.

TERMINAL LAYOUT

PHYSICAL VALUES

O/D OFF IND O/D OFF indicator When O/D OFF indicator lamp is OFF Off

When O/D OFF indicator lamp is ON

On

FUEL W/L Low fuel warning When low fuel warning is ON

On

When low fuel warning is Off Off

AIR PRES W/L Tire pressure wa

rning lamp op-

eration When tire pressure warning lamp is ON

ON

When tire pressure wa rning lamp is OFF Off

EPS W/L EPS warning lamp EPS warning lamp ON

On

EPS warning lamp OFF Off

CHG SIG Charge warning lamp Engine running Off

PASS BUCKLE

SW Seat belt buckle switch RH When seat belt buckle RH is unfastened

On

When seat belt buckle RH is fastened Off

FUEL CAP W/L Loose fuel cap warning Loose fuel filler cap warning is On

On

Loose fuel filler cap warning is OFF Off

PKB SW Parking brake switch When parking brake is active

On

When parking brake is inactive Off

BUCKLE SW Seat belt buckle switch LH When seat belt buckle LH is unfastened

On

When seat belt buckle LH is fastened Off

BRAKE OIL SW Brake fluid level switch When brake fluid level switch ON

On

When brake fluid level switch OFF Off

DISTANCE Distance to empty While driving [mi or km]

FUEL LOW SIG Low fuel warning When low fuel warning is On

On

When low fuel warning is Off Off

BUZZER Buzzer operation When Buzzer is ON

On

When Buzzer is OFF Off

TPMS PRESS L Low tire pressure warning When check tire pressure warning message is On

On

When check tire pressure warning message is

OFF Off

Monitor Item

Display content Data monitor

Condition Reference value in normal

operation

JSNIA5390ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2430 of 3641

![NISSAN NOTE 2016 Service Owners Guide MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of NISSAN NOTE 2016 Service Owners Guide MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of](/img/5/57363/w960_57363-2429.png)

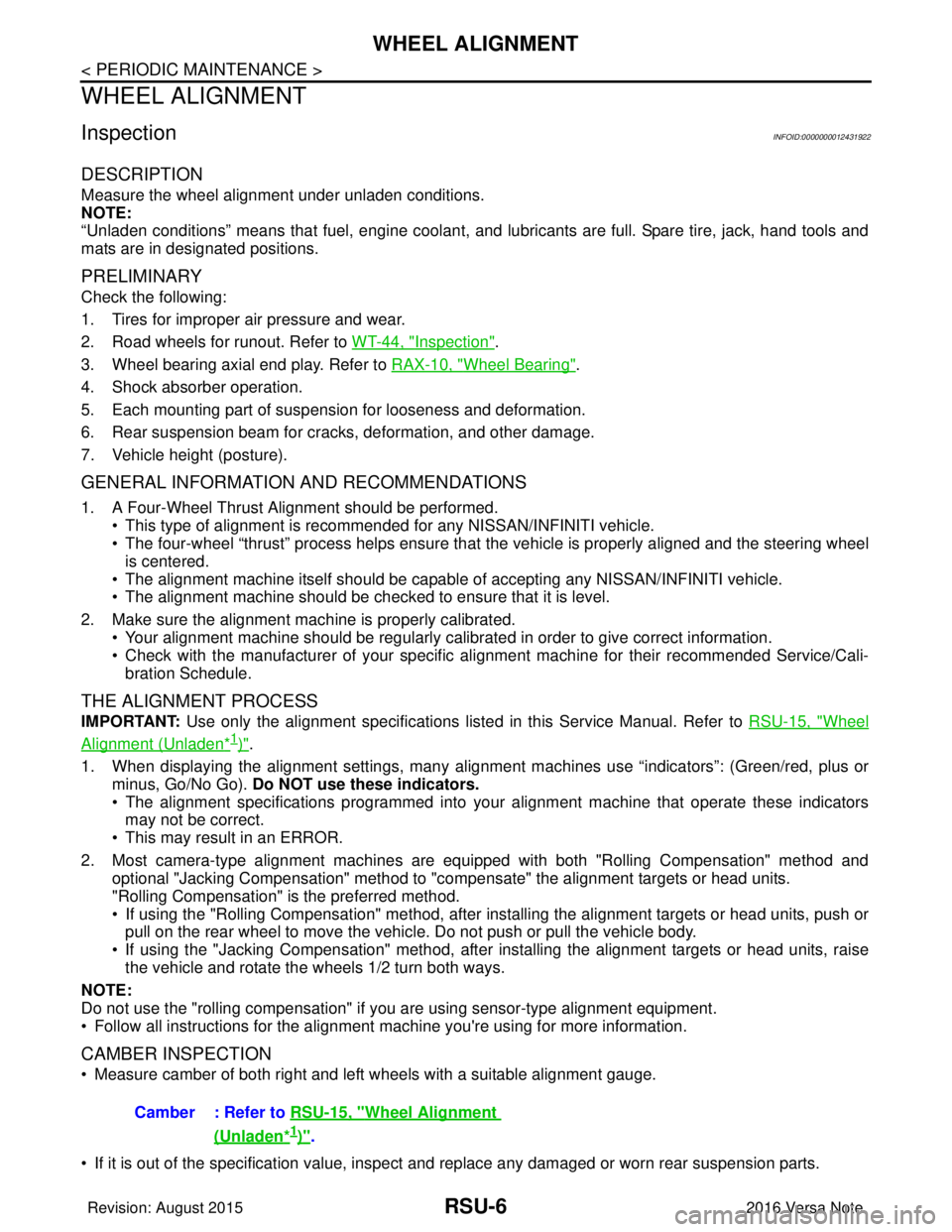

MWI-72

< SYSTEM DESCRIPTION >[TYPE B]

DIAGNOSIS SYSTEM (COMBINATION METER)

VDC/TCS IND

[ON/OFF]Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND

[ON/OFF] Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L

[On/Off] Displays [ON/OFF] condition of brake warning indicator.

DOOR W/L

[On/Off] Displays [ON/OFF] condition of door warning indicator.

HI-BEAM IND

[On/Off] Displays [ON/OFF] condition of high beam indicator.

TURN IND

[On/Off] Displays [ON/OFF] condition of turn indicator.

LIGHT IND

[On/Off] Displays [ON/OFF] condition of light indicator.

OIL W/L

[On/Off] Displays [ON/OFF] condition of engine oil pressure warning indicator.

MIL

[On/Off] Displays [ON/OFF] condition of malfunction indicator.

CRUISE IND

[Off] Displays [ON/OFF]

condition of CRUISE indicator.

O/D OFF IND

[On/Off] Displays [ON/OFF] condition of O/D OFF indicator.

FUEL W/L

[On/Off] Displays [ON/OFF] condition of

low-fuel warning indicator.

PASS BUCKLE SW

[On/Off] Status of seat belt buckle switch RH.

AIR PRES W/L

[ON/OFF] Displays [ON/OFF] condition of tire pressure warning lamp.

KEY G/Y W/L

[ON/OFF] Displays [ON/OFF] condition of key warning lamp.

EPS W/L

[On/Off] Displays [ON/OFF] condition of EPS indicator.

FUEL CAP W/L

[Off] Displays [ON/OFF] condition of loose fuel cap warning message.

PKB SW

[On/Off] Status of parking brake switch.

BUCKLE SW

[On/Off] Status of seat belt buckle switch (LH).

BRAKE OIL SW

[On/Off] Status of brake fluid level switch.

CHG SIG

[On/Off] Displays [ON/OFF] condition of charge warning indicator.

DISTANCE

[km] or [Mi] Displays distance to empty.

OUTSIDE TEMP

[ ° F] or [ °C] Displays the ambient temperature, which is input from ambient sensor.

FUEL LOW SIG

[ON/OFF] Displays [ON/OFF] condition

of low-fuel warning signal.

BUZZER

[On/Off] X Displays [ON/OFF] condition of buzzer.

Display item [Unit]

MAIN

SIGNALS Description

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2431 of 3641

![NISSAN NOTE 2016 Service Owners Guide MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-73

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

NOTE:

Some items are not available according to vehicle specification.

WORK SUPPORT

WARNING NISSAN NOTE 2016 Service Owners Guide MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-73

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

NOTE:

Some items are not available according to vehicle specification.

WORK SUPPORT

WARNING](/img/5/57363/w960_57363-2430.png)

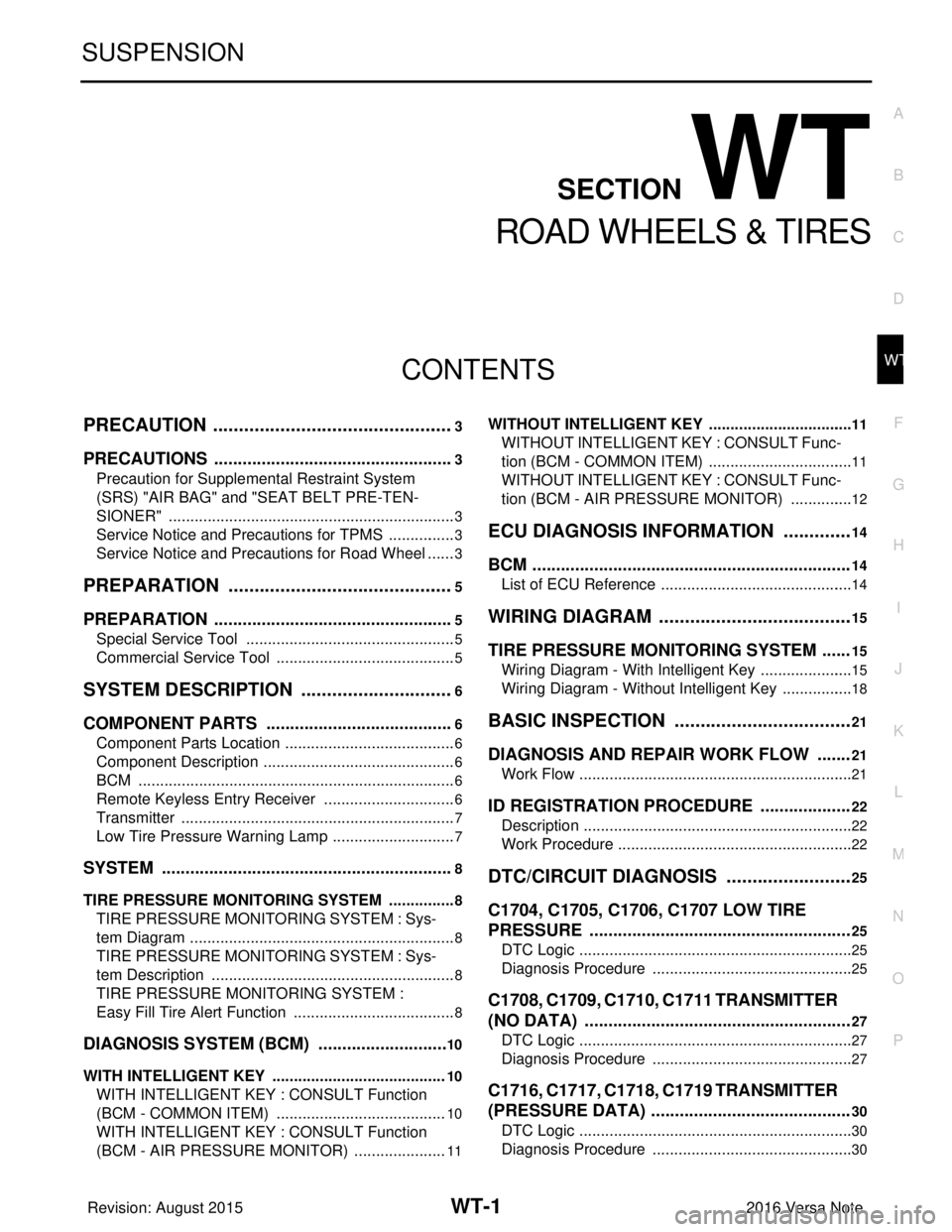

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)MWI-73

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

NOTE:

Some items are not available according to vehicle specification.

WORK SUPPORT

WARNING HISTORY

W/L ON HISTORY

• Stores histories when warning/indicator lamp is turned on.

• “W/L ON HISTORY” indicates the “TIME” when the warning/ indicator lamp is turned on.

• The “TIME” above is:

- 0: The condition that the warning/indicator lamp has been turned on 1 or more times after starting the engine and waiting for 30 seconds.

- 1 - 39: The number of times the engi ne was restarted after the 0 condition.

- NO W/L ON HISTORY: Stores NO (0) turning on history of warning/indicator lamp.

NOTE:

• W/L ON HISTORY is not stored for approximately 30 seconds after the engine starts.

• Brake warning lamp does not store any history when the parking brake is applied or the brake fluid level gets

low.

FR FOG IND

[On/Off] Displays [ON/OFF] condition of front fog lamp indicator.

TPMS PRESS L

[On/Off] Displays [ON/OFF] condition of check tire pressure warning message.

Display item [Unit]

MAIN

SIGNALS Description

Work support item

Description

Outside air temperature diagnosis A possible malfunction can be narrowed down by following the displayed instructions.

Fuel meter diagnosis(Analog pointer)

Warning lamp diagnosis

Display item Description

W/L ON HISTORY Lighting history of warning lamp and indicator lamp can be checked.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2433 of 3641

![NISSAN NOTE 2016 Service Owners Guide MWI

COMBINATION METERMWI-75

< ECU DIAGNOSIS INFORMATION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

*: Displays “Off” if the brake warning lamp is illumi nated when the valve check starts, the parkin NISSAN NOTE 2016 Service Owners Guide MWI

COMBINATION METERMWI-75

< ECU DIAGNOSIS INFORMATION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

*: Displays “Off” if the brake warning lamp is illumi nated when the valve check starts, the parkin](/img/5/57363/w960_57363-2432.png)

MWI

COMBINATION METERMWI-75

< ECU DIAGNOSIS INFORMATION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

*: Displays “Off” if the brake warning lamp is illumi nated when the valve check starts, the parking brake switch

is turned ON or the brake fluid level switch is turned ON.

CRUISE IND Cruise indicator

lampWhen cruise indicator lamp is ON.

ON

When cruise indicator lamp is OFF. Off

O/D OFF IND O/D OFF indi-

cator When O/D OFF indicator lamp is OFF.

Off

When O/D OFF indicator lamp is ON. On

FUEL W/L Low fuel warn-

ingWhen low fuel warning is ON

On

When low fuel warning is Off Off

AIR PRES W/L Tire pressure

warning lamp

operationWhen tire pressure warning lamp is ON

ON

When tire pressure warning lamp is OFF Off

EPS W/L EPS warning

lamp EPS warning lamp ON

On

EPS warning lamp OFF Off

KEY G/Y W/L Key warning

lamp When key warning lamp is ON

On

When key warning lamp is OFF Off

CHG SIG Charge warn-

ing lampEngine running

Off

PASS BUCKLE SW Seat belt buck-

le switch RHWhen seat belt buckle RH is unfastened

On

When seat belt buckle RH is fastened Off

FUEL CAP W/L Loose fuel cap

warningLoose fuel filler cap warning is ON

On

Loose fuel filler cap warning is OFF Off

PKB SW Parking brake

switchWhen parking brake is active

On

When parking brake is inactive Off

BUCKLE SW Seat belt buck-

le switch LHWhen seat belt buckle is unfastened LH.

On

When seat belt buckle is fastened LH. Off

BRAKE OIL SW Brake fluid level

switchWhen brake fluid level switch ON

On

When brake fluid level switch OFF Off

OUTSIDE TEMP

[ ° F] or [ °C] Outside tem-

perature

Ignition ON Displays the ambient air temperature

which is input from the ambient sensor.

DISTANCE Distance to

empty

While driving

[mph or km/h]

FUEL LOW SIG Low fuel warn-

ingWhen low fuel warning is On

On

When low fuel warning is Off Off

BUZZER Buzzer opera-

tionWhen Buzzer is ON

On

When Buzzer is OFF Off

TPMS PRESS L Low tire pres-

sure warningWhen check tire pressure warning mes-

sage is On

On

When check tire pressure warning mes-

sage is OFF Off

Monitor Item Display content

Data monitor

Condition Reference value in normal operation

Revision: August 2015 2016 Versa Note

cardiagn.com

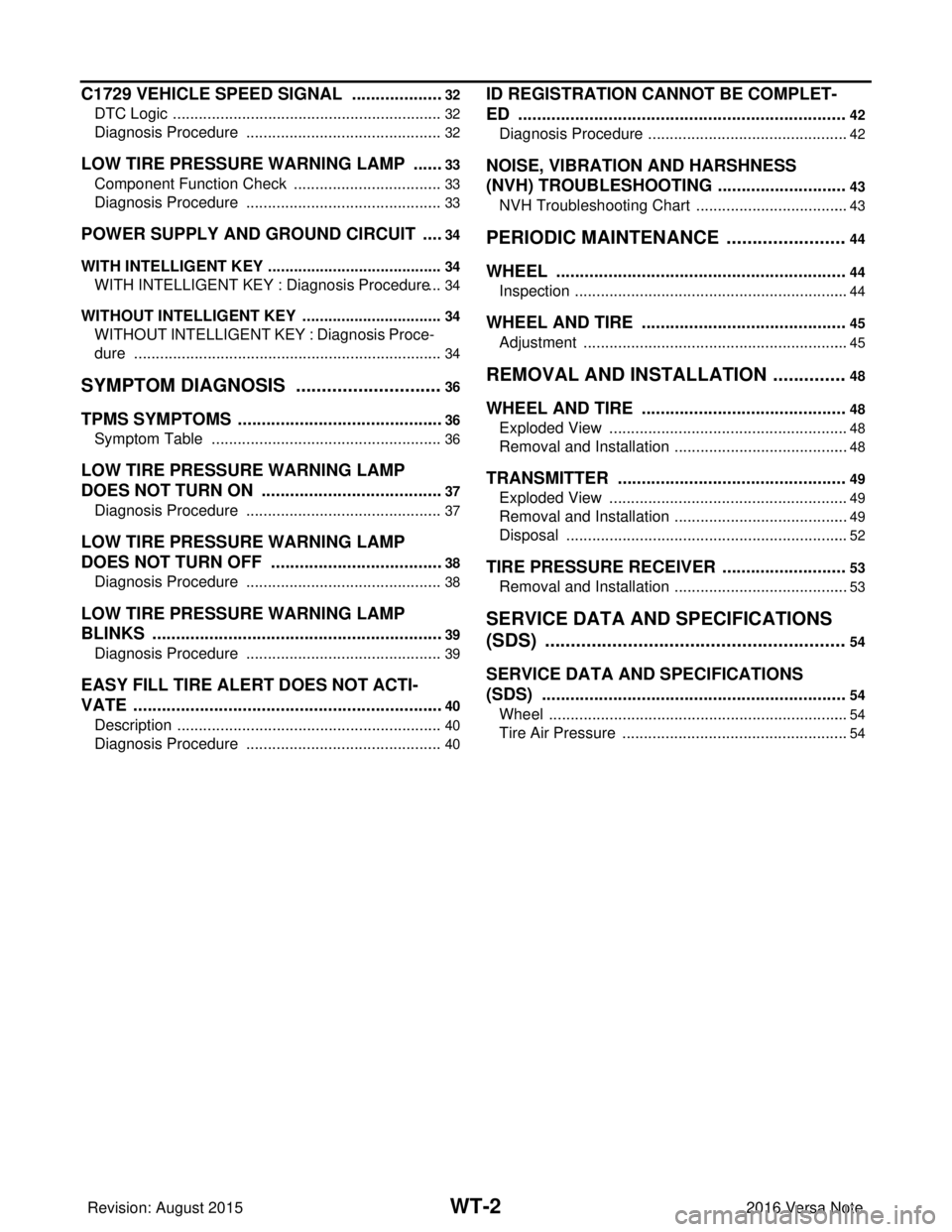

Page 2631 of 3641

PG-44

< WIRING DIAGRAM >

HARNESS

C2 M6 W/4 : Dongle unitB1 M61 — : Body ground

B2 M7 W/16 : Door mirror remote control switch C1 M62 W/2 : Front blower motor

D1 M8 G/20 : Joint connector–M02 C3 M64 W/8 : Steering angle sensor

A3 M9 W/12 : To D1 E3 M65 W/4 : Front air control

D3 M10 L/20 : Joint connector–M01 D5 M66 B/3 : Console power socket

B4 M11 W/2 : To B28 A4 M69 SMJ : To E7

F3 M12 W/16 : To B29 E2 M70 W/20 : AV control unit

F3 M13 W/24 : To B30 D3 M71 W/24 : AV control unit

B3 M14 BR/6 : Rear window defogger relay F2 M75 Y/4 : To D101

B4 M15 W/16 : To B23 D2 M76 GR/5 : AV control unit

A4 M16 W/24 : To B24 E1 M77 Y/4 : Front passenger air bag module

D5 M17 B/1 : Parking brake switch A4 M78 B/2 :To E11

A2 M18 W/40 : BCM (Body contro

l module) (Without

Intelligent Key system) F1 M79 — : Body ground

A1 M19 W/15 : BCM (Body contro

l module) (Without

Intelligent Key system) A 3 M 8 0 Y / 4 : T o D 3

A2 M20 B/15 : BCM (Body contro

l module) (Without

Intelligent Key system) F2 M81 W/12 : To D115

C2 M21 W/4 : NATS antenna amp. C1 M82 W/40 : Combination meter (With type A)

B3 M22 W/16 : Data link connector D5 M83 B/3 : G sensor

E 4 M 2 3 W / 4 : Remote keyless entry receiver (Without

Intelligent Key system) E2 M84 — : Body ground

C1 M24 W/40 : Combination meter (With type B) E2 M85 — : Body ground

C4 M25 W/8 : Push–button ignition swtich F5 M89 L/2 : Inside key antenna (Console)

C3 M26 W/6 : Ignition switch E1 M90 B/4: Remote keyless entry receiver (With

Intelligent Key system without tire pressure

monitoring system)

C2 M27 BR/2 : Key switch F2 M92 W/12 : To D116

C3 M28 W/16 : Combination switch A3 M93 W/24 : To D16

E 3 M 2 9 W / 2 4 : T o B 1 F 1 M 9 4 W / 4: Remote keyless entry receiver (With

Intelligent Key system with tire pressure

monitoring system)

C4 M30 GR/8 : Combination switch (Spiral cable) D3 M95 L/2 : Inside key antenna (Instrument center)

C3 M31 Y/6 : Combination switch (Spiral cable) A2 M97 B/40 : BCM (Body contro

l module) (With

Intelligent Key system)

E5 M32 W/16 : To M201 A2 M98 W/40: BCM (Body contro

l module) (With

Intelligent Key system)

E3 M33 B/15 : Front air control A2 M99 W/15: BCM (Body contro

l module) (With

Intelligent Key system)

B3 M34 GR/6 : VDC off switch A2 M100 B / 1 5: BCM (Body contro

l module) (With

Intelligent Key system)

D4 M35 Y/28 : Air bag diagnosis sensor unit D2 M101 W/16 : Audio unit (With base audio system)

D1 M36 BR/2 : Front passenger air bag off indicator A3 M103 W/12 : Accessory prewire LH

E4 M38 W/8 : CVT shift selector E2 M104 W/12 : Accessory prewire RH

B3 M39 L/4 : Accessory relay–2 C2 M151 BR/4 : Front blower motor resistor

E2 M40 W/32 : Audio unit (With display audio system) Console sub harness

B3 M41 B/5 : Back door lock actuator relay E5 M201 W / 1 6 : T o M 3 2

C3 M42 BR/4 : Thermo control amp. E4 M202 B/3 : Console power socket

E2 M43 W/20 : Audio unit (With base audio system) C4 M203 BR/6 : Heated seat swtich RH

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2734 of 3641

RSU-6

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000012431922

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-44, "

Inspection".

3. Wheel bearing axial end play. Refer to RAX-10, "

Wheel Bearing".

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-15, "Wheel

Alignment (Unladen*1)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Most camera-type alignment machines are equipped with both "Rolling Compensation" method and optional "Jacking Compensation" method to "com pensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

• If using the "Rolling Compensation" method, after installing the alignment targets or head units, push or pull on the rear wheel to move the vehicle. Do not push or pull the vehicle body.

• If using the "Jacking Compensation" method, after in stalling the alignment targets or head units, raise

the vehicle and rotate the wheels 1/2 turn both ways.

NOTE:

Do not use the "rolling compensation" if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER INSPECTION

• Measure camber of both right and left wheels with a suitable alignment gauge.

• If it is out of the specificati on value, inspect and replace any damaged or worn rear suspension parts.

Camber : Refer to RSU-15, "

Wheel Alignment

(Unladen*1)".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2744 of 3641

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for TPMS ................3

Service Notice and Precautions for Road Wheel ......3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

BCM ..........................................................................6

Remote Keyless Entry Receiver ...............................6

Transmitter ................................................................7

Low Tire Pressure Warning Lamp .............................7

SYSTEM ......................................................... .....8

TIRE PRESSURE MONITORING SYSTEM .......... ......8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Diagram ..............................................................

8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Description .........................................................

8

TIRE PRESSURE MONITORING SYSTEM :

Easy Fill Tire Alert Function ......................................

8

DIAGNOSIS SYSTEM (BCM) ............................10

WITH INTELLIGENT KEY ..................................... ....10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - COMMON ITEM) ........................................

10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - AIR PRESSURE MONITOR) ......................

11

WITHOUT INTELLIGENT KEY .............................. ....11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - COMMON ITEM) ..................................

11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - AIR PRESSURE MONITOR) ...............

12

ECU DIAGNOSIS INFORMATION ..............14

BCM ...................................................................14

List of ECU Reference ......................................... ....14

WIRING DIAGRAM ......................................15

TIRE PRESSURE MONITORING SYSTEM ......15

Wiring Diagram - With Inte lligent Key ......................15

Wiring Diagram - Without Intelligent Ke y .................18

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORK FLOW .......21

Work Flow ............................................................ ....21

ID REGISTRATION PROCEDURE ...................22

Description ...............................................................22

Work Procedure .......................................................22

DTC/CIRCUIT DIAGNOSIS .........................25

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

25

DTC Logic ............................................................ ....25

Diagnosis Procedure ...............................................25

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

30

DTC Logic ............................................................ ....30

Diagnosis Procedure ...............................................30

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2745 of 3641

WT-2

C1729 VEHICLE SPEED SIGNAL ....................32

DTC Logic ............................................................ ...32

Diagnosis Procedure ..............................................32

LOW TIRE PRESSURE WARNING LAMP .......33

Component Function Check ................................ ...33

Diagnosis Procedure ..............................................33

POWER SUPPLY AND GROUND CIRCUIT .....34

WITH INTELLIGENT KEY ...................................... ...34

WITH INTELLIGENT KEY : Diagnosis Procedure ...34

WITHOUT INTELLIGENT KEY .............................. ...34

WITHOUT INTELLIGENT KEY : Diagnosis Proce-

dure ........................................................................

34

SYMPTOM DIAGNOSIS .............................36

TPMS SYMPTOMS ......................................... ...36

Symptom Table ................................................... ...36

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

37

Diagnosis Procedure ..............................................37

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

38

Diagnosis Procedure ........................................... ...38

LOW TIRE PRESSURE WARNING LAMP

BLINKS ..............................................................

39

Diagnosis Procedure ........................................... ...39

EASY FILL TIRE ALERT DOES NOT ACTI-

VATE ..................................................................

40

Description ........................................................... ...40

Diagnosis Procedure ..............................................40

ID REGISTRATION CANNOT BE COMPLET-

ED ......................................................................

42

Diagnosis Procedure ............................................ ...42

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

43

NVH Troubleshooting Chart ....................................43

PERIODIC MAINTENANCE .......................44

WHEEL ........................................................... ...44

Inspection ............................................................. ...44

WHEEL AND TIRE ............................................45

Adjustment ........................................................... ...45

REMOVAL AND INSTALLATION ..............48

WHEEL AND TIRE ......................................... ...48

Exploded View ..................................................... ...48

Removal and Installation .........................................48

TRANSMITTER .............................................. ...49

Exploded View ..................................................... ...49

Removal and Installation .........................................49

Disposal ............................................................... ...52

TIRE PRESSURE RECEIVER ...........................53

Removal and Installation .........................................53

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

54

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

54

Wheel ................................................................... ...54

Tire Air Pressure .....................................................54

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2746 of 3641

PRECAUTIONSWT-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012432421

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for TPMSINFOID:0000000012432422

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical equipment manufacturer for the possible influences before use.

• Low tire pressure warning lamp blinks for 1 minute, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories fo r Tire Pressure Monitoring System (TPMS), or regis-

ter the ID to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-22, "

Work Procedure".

• ID registration is required when replacing or rotating wheels, replacing tire pressure sensor or BCM. Refer to WT-22, "

Work Procedure".

• Replace grommet seal, valve core and valve cap of tire pressure sensor in TPMS, when replacing each tire by reaching the wear limit. Refer to WT-49, "

Removal and Installation".

• Because the tire pressure sensor conforms to North America radio law, the following items must be

observed.

- The sensor may be used only in North America.

- It may not be used in any method other than the specified method.

- It must not be disassembled or modified.

Service Notice and Pr ecautions for Road WheelINFOID:0000000012432423

• Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

• Use Genuine NISSAN parts for the road wheels, valve caps and wheel nuts.

• Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

• Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other items that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

• After driving on roads scattered with anti-icing salts, wash off the wheels completely.

• When installing road wheels onto the vehicle, always wipe off any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2748 of 3641

PREPARATIONWT-5

< PREPARATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000012432424

The actual shape of the tools may di ffer from those illustrated here.

Commercial Service ToolINFOID:0000000012432425

Tool number

(TechMate No.)

Tool name Description

—

(J-50190)

Signal Tech II • Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS

transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

• Test remote keyless entry keyfob relative signal strength

• Check Intelligent Key relative signal strength

• Confirm vehicle Intelligent Key antenna sig-

nal strength

• Compatible with future sensors

• Equipped with a display

KV48105501

(J-45295-A)

Transmitter activation tool • Activate TPMS transmitter IDs

• Compatible with future sensors

• Equipped with a display (KV48105501 only)

ALEIA0131ZZ

ALEIA0183ZZ

To o l n a m e

Description

Power tool Loosening nuts, screws and bolts

PIIB1407E

Revision: August 2015 2016 Versa Note

cardiagn.com