key NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1913 of 3641

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

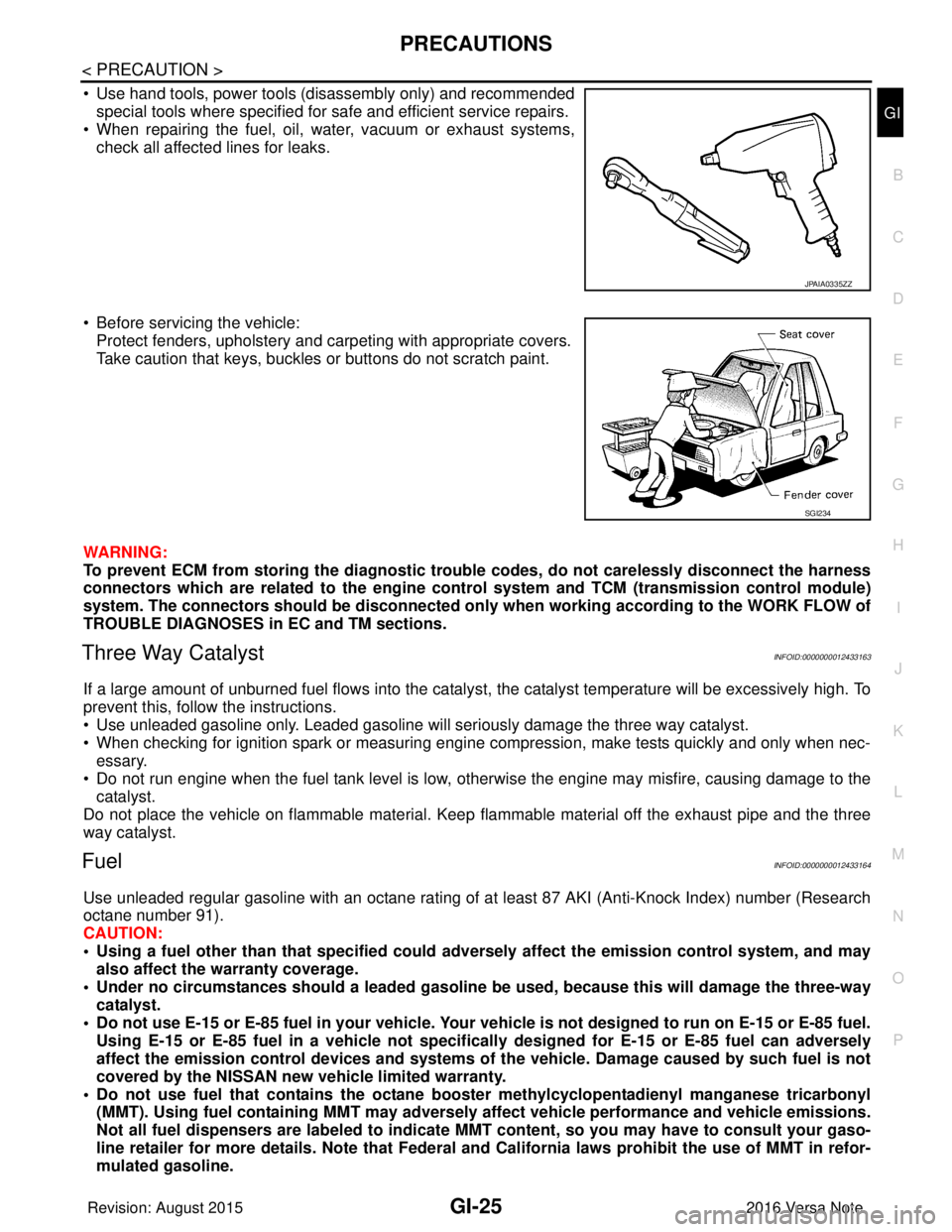

• Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

• Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trou ble codes, do not carelessly disconnect the harness

connectors which are related to the engine cont rol system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and TM sections.

Three Way CatalystINFOID:0000000012433163

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

FuelINFOID:0000000012433164

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

CAUTION:

• Using a fuel other than that specified could adversely affect th e emission control system, and may

also affect the warranty coverage.

• Under no circumstances should a leaded gasoline be used, because this will damage the three-way

catalyst.

• Do not use E-15 or E-85 fuel in your vehicle. Your vehicle is not designed to run on E-15 or E-85 fuel. Using E-15 or E-85 fuel in a vehicle not specifically designed for E-15 or E-85 fuel can adversely

affect the emission control devices and systems of the vehicle. Damage caused by such fuel is not

covered by the NISSAN new vehicle limited warranty.

• Do not use fuel that contains the octane boo ster methylcyclopentadienyl manganese tricarbonyl

(MMT). Using fuel containing MM T may adversely affect vehicle pe rformance and vehicle emissions.

Not all fuel dispensers are labeled to indicate MMT content, so you may have to consult your gaso-

line retailer for more details. Note that Federal and California laws prohibit the use of MMT in refor-

mulated gasoline.

JPAIA0335ZZ

SGI234

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1919 of 3641

TOW TRUCK TOWINGGI-31

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PTOW TRUCK TOWING

To w T r u c k To w i n gINFOID:0000000012433173

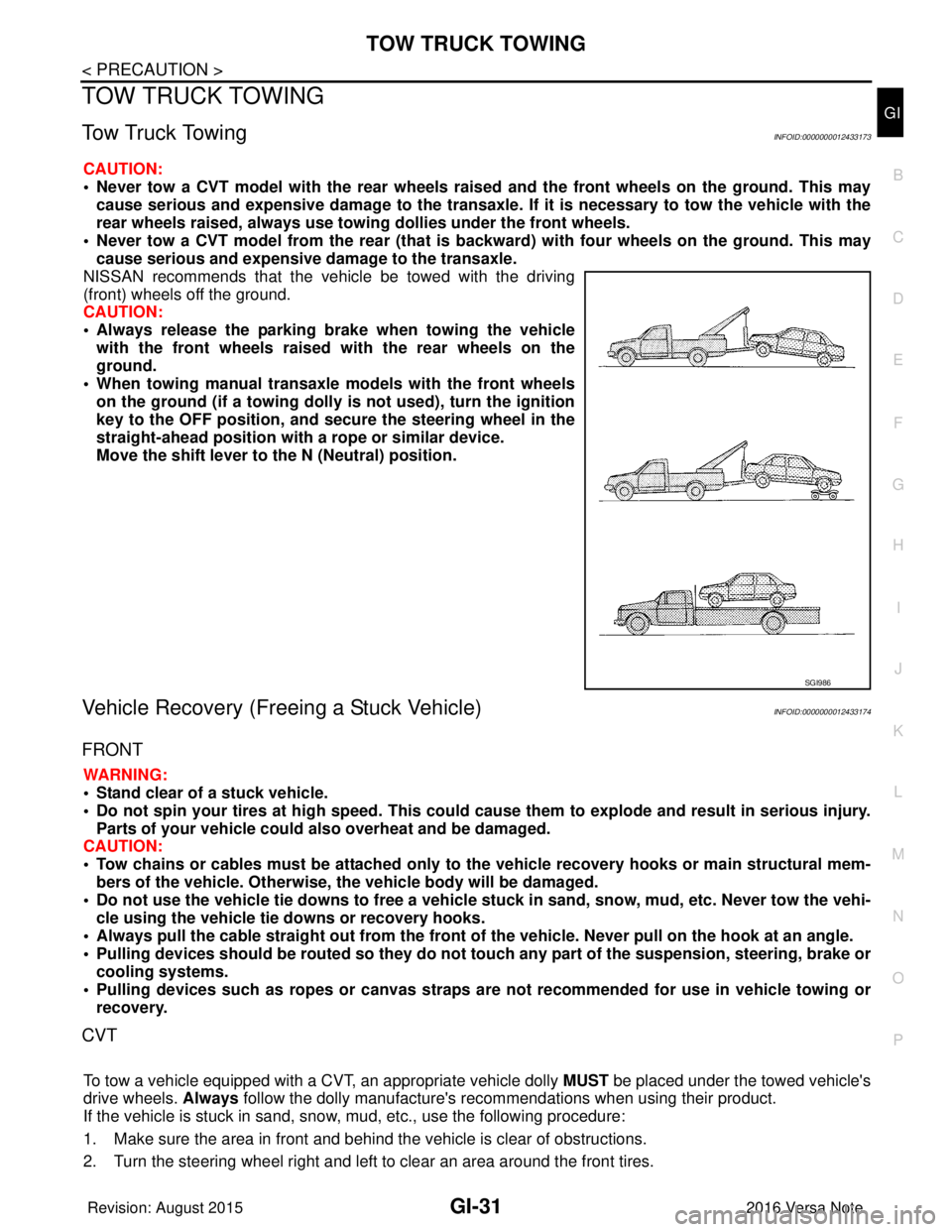

CAUTION:

• Never tow a CVT model with the rear wheels raised and the front wheels on the ground. This may

cause serious and expensive damage to the transaxle. If it is necessary to tow the vehicle with the

rear wheels raised, always use towin g dollies under the front wheels.

• Never tow a CVT model from the rear (that is b ackward) with four wheels on the ground. This may

cause serious and expensive damage to the transaxle.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground.

CAUTION:

• Always release the parking br ake when towing the vehicle

with the front wheels raised with the rear wheels on the

ground.

• When towing manual transaxle models with the front wheels on the ground (if a towing dolly is not used), turn the ignition

key to the OFF position, and secu re the steering wheel in the

straight-ahead position with a rope or similar device.

Move the shift lever to th e N (Neutral) position.

Vehicle Recovery (Freeing a Stuck Vehicle)INFOID:0000000012433174

FRONT

WARNING:

• Stand clear of a stuck vehicle.

• Do not spin your tires at high speed. This could cause them to explode and result in serious injury.

Parts of your vehicle could also overheat and be damaged.

CAUTION:

• Tow chains or cables must be attached only to the vehicle recovery hooks or main structural mem-

bers of the vehicle. Otherwise, the vehicle body will be damaged.

• Do not use the vehicle tie downs to free a vehicle stuck in sand, snow, mud, etc. Never tow the vehi-

cle using the vehicle tie downs or recovery hooks.

• Always pull the cable straight out from the front of the vehicle. Never pull on the hook at an angle.

• Pulling devices should be routed so they do not touch any part of the suspension, steering, brake or

cooling systems.

• Pulling devices such as ropes or canvas straps ar e not recommended for use in vehicle towing or

recovery.

CVT

To tow a vehicle equipped with a CVT, an appropriate vehicle dolly MUST be placed under the towed vehicle's

drive wheels. Always follow the dolly manufacture's re commendations when using their product.

If the vehicle is stuck in sand, snow , mud, etc., use the following procedure:

1. Make sure the area in front and behind the vehicle is clear of obstructions.

2. Turn the steering wheel right and left to clear an area around the front tires.

SGI986

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1926 of 3641

GI-38

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

BASIC INSPECTION

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

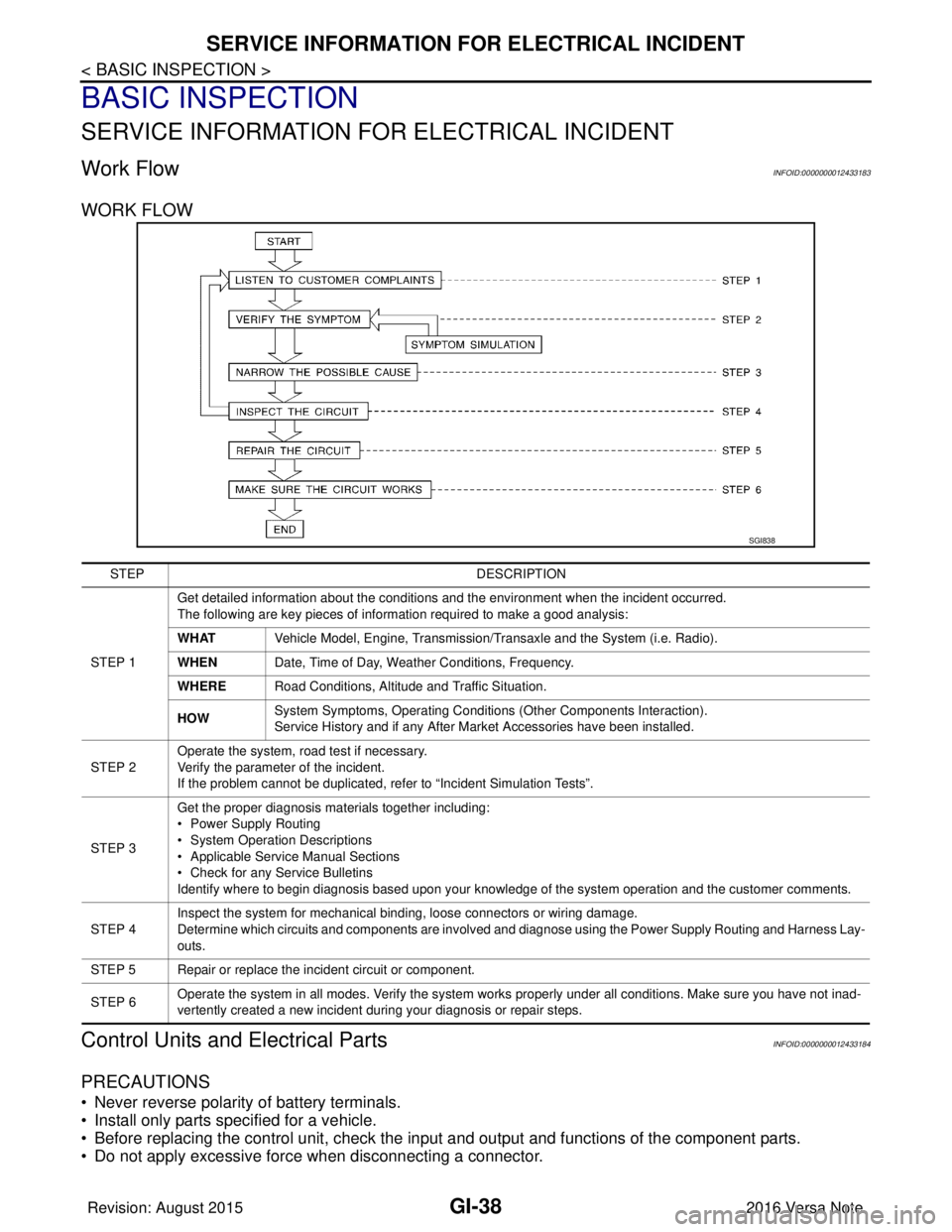

Work FlowINFOID:0000000012433183

WORK FLOW

Control Units and Electrical PartsINFOID:0000000012433184

PRECAUTIONS

• Never reverse polarity of battery terminals.

• Install only parts specified for a vehicle.

• Before replacing the control unit, check the i nput and output and functions of the component parts.

• Do not apply excessive force when disconnecting a connector.

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions

(Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3 Get the proper diagnosis materials together including:

• Power Supply Routing

• System Operation Descriptions

• Applicable Service Manual Sections

• Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1934 of 3641

GI-46

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a knowngood ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse ter- minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage. voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

• When inspecting a ground connection follow these rules:

- Remove the ground bolt or screw.

- Inspect all mating surfaces for tarnish, dirt, rust, etc.

- Clean as required to assure good contact.

- Reinstall bolt or screw securely.

- Inspect for “add-on” accessories which may be interfering with the ground circuit.

- If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1969 of 3641

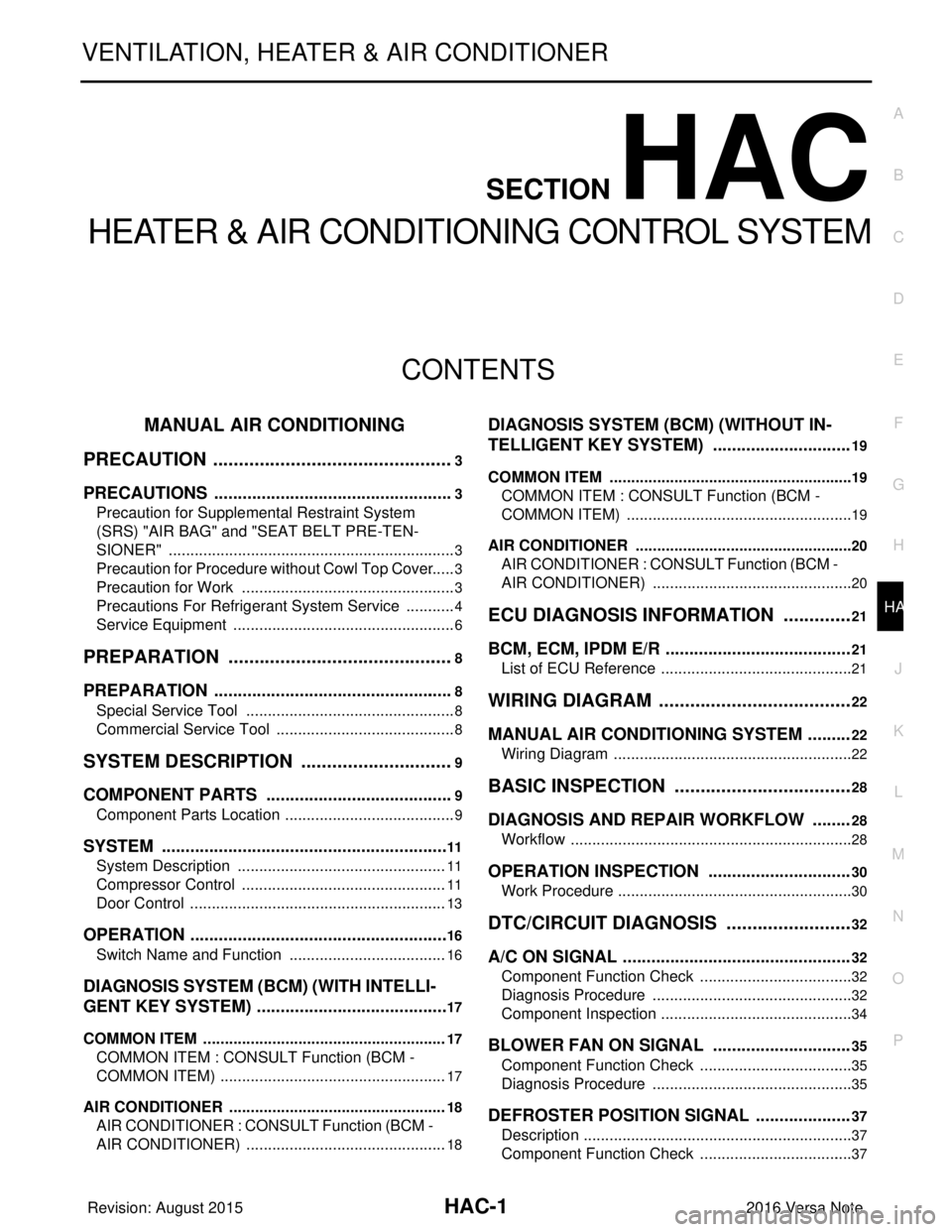

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HAC

A

B

HAC

N

O P

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

MANUAL AIR CONDITIONING

PRECAUTION ....... ........................................

3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Work ..................................................3

Precautions For Refrigerant System Service ............4

Service Equipment .............................................. ......6

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ..........................................8

SYSTEM DESCRIPTION ..............................9

COMPONENT PARTS ................................... .....9

Component Parts Location .................................. ......9

SYSTEM .............................................................11

System Description ............................................. ....11

Compressor Control ................................................11

Door Control ............................................................13

OPERATION .......................................................16

Switch Name and Function ................................. ....16

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .........................................

17

COMMON ITEM ..................................................... ....17

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

17

AIR CONDITIONER ............................................... ....18

AIR CONDITIONER : CONSULT Function (BCM -

AIR CONDITIONER) ........................................... ....

18

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

19

COMMON ITEM ..................................................... ....19

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

19

AIR CONDITIONER ............................................... ....20

AIR CONDITIONER : CONSULT Function (BCM -

AIR CONDITIONER) ........................................... ....

20

ECU DIAGNOSIS INFORMATION ..............21

BCM, ECM, IPDM E/R .......................................21

List of ECU Reference ......................................... ....21

WIRING DIAGRAM ......................................22

MANUAL AIR CONDITIONING SYSTEM .........22

Wiring Diagram .................................................... ....22

BASIC INSPECTION ...................................28

DIAGNOSIS AND REPAIR WORKFLOW ........28

Workflow .............................................................. ....28

OPERATION INSPECTION ..............................30

Work Procedure .......................................................30

DTC/CIRCUIT DIAGNOSIS .........................32

A/C ON SIGNAL ................................................32

Component Function Check ................................ ....32

Diagnosis Procedure ...............................................32

Component Inspection .............................................34

BLOWER FAN ON SIGNAL .............................35

Component Function Check ....................................35

Diagnosis Procedure ...............................................35

DEFROSTER POSITION SIGNAL ....................37

Description ...............................................................37

Component Function Check ....................................37

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1979 of 3641

![NISSAN NOTE 2016 Service Repair Manual SYSTEMHAC-11

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYSTEM

System DescriptionINFOID:0000000012430717

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• The manual air co NISSAN NOTE 2016 Service Repair Manual SYSTEMHAC-11

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYSTEM

System DescriptionINFOID:0000000012430717

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• The manual air co](/img/5/57363/w960_57363-1978.png)

SYSTEMHAC-11

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

SYSTEM

System DescriptionINFOID:0000000012430717

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

• The manual air conditioning system is c ontrolled by a sequence of functions from the front air control, BCM,

ECM, and IPDM E/R.

• The fan speed of the front blower motor is changed by t he combination of the fan control dial (fan switch)

operation and blower resistor control.

Compressor ControlINFOID:0000000012430718

PRINCIPLE OF OPERATION

Compressor is not activated.

Functional Circuit Diagram

ALIIA0813GB

Module/Function Door control A/C request signalCompressor control Cooling fan control

Front air control HAC-13

— HAC-11—

BCM —BCS-7

(With Intelligent Key system)

BCS-78

(Without Intelligent Key system) ——

ECM — —HAC-11

EC-38

IPDM E/R — —HAC-11EC-38

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1985 of 3641

![NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COM NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COM](/img/5/57363/w960_57363-1984.png)

DIAGNOSIS SYSTEM (BCM) (WITH INTELLIGENT KEY SYSTEM)

HAC-17

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WIT H INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)INFOID:0000000012542299

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

Direct Diagnostic Mode Description

ECU Identification The BCM part number is displayed.

Self Diagnostic Result The BCM self diagnostic results are displayed.

Data Monitor The BCM input/output data is displayed in real time.

Active Test The BCM activates outputs to test components.

Work support The settings for BCM functions can be changed.

Configuration • The vehicle specification can be read and saved.

• The vehicle specification can be written when replacing BCM.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

System Sub System Direct Diagnostic Mode

ECU Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN DIAG SUPPORT MNTR

Door lock

DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

Air conditioner AIR CONDITIONER ×

Intelligent Key system INTELLIGENT KEY ××××

Combination switch COMB SW ×

BCM BCM× × ×××

Immobilizer IMMU ××××

Interior room lamp battery saver BATTERY SAVER ×××

Vehicle security system THEFT ALM ××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

Panic alarm system PANIC ALARM ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1986 of 3641

![NISSAN NOTE 2016 Service Repair Manual HAC-18

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WIT

H INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Func tion (BCM - AIR CONDITIONER)INFOID:000000001 NISSAN NOTE 2016 Service Repair Manual HAC-18

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WIT

H INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Func tion (BCM - AIR CONDITIONER)INFOID:000000001](/img/5/57363/w960_57363-1985.png)

HAC-18

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WIT

H INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Func tion (BCM - AIR CONDITIONER)INFOID:0000000012542298

DATA MONITOR

Monitor Item [Unit] Description

FAN ON SIG [On/Off] Indicates condition of fan switch.

AIR COND SW [On/Off] Indicates condition of A/C switch.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1987 of 3641

![NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)HAC-19

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WITHO UT INTELLIGENT KEY SYSTEM NISSAN NOTE 2016 Service Repair Manual DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)HAC-19

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WITHO UT INTELLIGENT KEY SYSTEM](/img/5/57363/w960_57363-1986.png)

DIAGNOSIS SYSTEM (BCM) (WITHOUT INTELLIGENT KEY SYSTEM)HAC-19

< SYSTEM DESCRIPTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (BCM) (WITHO UT INTELLIGENT KEY SYSTEM)

COMMON ITEM

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)INFOID:0000000012542301

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions.

Direct Diagnostic Mode Description

ECU Identification The BCM part number is displayed.

Self Diagnostic Result The BCM self diagnostic results are displayed.

Data Monitor The BCM input/output data is displayed in real time.

Active Test The BCM activates outputs to test components.

Work support The settings for BCM functions can be changed.

Configuration • The vehicle specification can be read and saved.

• The vehicle specification can be written when replacing BCM.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication is displayed.

System Sub System Direct Diagnostic Mode

ECU Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN DIAG SUPPORT MNTR

Door lock

DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITIONER ×

Combination switch COMB SW ×

BCM BCM× × ×××

Immobilizer IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Vehicle security system THEFT ALM ××

RAP system RETAINED PWR ××

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

Panic alarm system PANIC ALARM ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1988 of 3641

![NISSAN NOTE 2016 Service Repair Manual HAC-20

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WITHO

UT INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Function (BCM - AIR CONDITIONER)INFOID:0000000 NISSAN NOTE 2016 Service Repair Manual HAC-20

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WITHO

UT INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Function (BCM - AIR CONDITIONER)INFOID:0000000](/img/5/57363/w960_57363-1987.png)

HAC-20

< SYSTEM DESCRIPTION >[MANUAL AIR CONDITIONING]

DIAGNOSIS SYSTEM (BCM) (WITHO

UT INTELLIGENT KEY SYSTEM)

AIR CONDITIONER

AIR CONDITIONER : CONSULT Function (BCM - AIR CONDITIONER)INFOID:0000000012542300

DATA MONITOR

Monitor Item [Unit] Description

IGN ON SW [On/Off] Indicates condition of ignition switch ON position.

FAN ON SIG [On/Off] Indicates condition of fan switch.

AIR COND SW [On/Off] Indicates condition of A/C switch.

THERMO AMP [On/Off] Indicates condition of thermo amp.

FR DEF SW [On/Off] Indicates condition of front defrost switch.

Revision: August 2015 2016 Versa Note

cardiagn.com