ESP NISSAN NOTE 2016 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2565 of 3641

![NISSAN NOTE 2016 Service Manual Online PCS-62

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2618 BCM

B2618 BCM

DTC LogicINFOID:0000000012433307

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. PERFORM SELF DIAGNOSTIC RESULT

1. Tur NISSAN NOTE 2016 Service Manual Online PCS-62

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2618 BCM

B2618 BCM

DTC LogicINFOID:0000000012433307

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. PERFORM SELF DIAGNOSTIC RESULT

1. Tur](/img/5/57363/w960_57363-2564.png)

PCS-62

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2618 BCM

B2618 BCM

DTC LogicINFOID:0000000012433307

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch to ON, and wait for 1 second or more.

2. Check “Self Diagnosis Result” of “BCM” using CONSULT.

Is DTC B2618 detected?

YES >> Refer to PCS-62, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000012433308

Regarding Wiring Diagram information, refer to PCS-42, "Wiring Diagram".

1.CHECK IGNITION RELAY-1 CONTROL SIGNAL VOLTAGE

Check voltage between IPDM E/R connector E47 terminal 90 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-30, "Removal and Installation".

NO >> GO TO 2.

2.CHECK IGNITION RELAY-1 CONTROL SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M98 and IPDM E/R connector E47.

3. Check continuity between BCM connector M98 terminal 98 and IPDM E/R connector E47 terminal 90.

4. Check continuity between BCM connector M98 terminal 98 and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-74, "Removal and Installation".

NO >> Repair or replace harness or connectors.

CONSULT Display DTC Detection Condition Possible Cause

BCM

[B2618] An immediate operation of ignition relay-1 is request-

ed by BCM, but there is no response for more than 1

second • Harness or connectors

•BCM

• IPDM E/R

IPDM E/R

GroundCondition Vol tag e

(Approx.)

Connector Terminal

E47 90—Ignition: OFF Battery voltage

BCM IPDM E/R

Continuity

Connector TerminalConnector Terminal

M98 98E47 90Yes

BCM

GroundContinuity

Connector Terminal

M98 98 No

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2597 of 3641

![NISSAN NOTE 2016 Service Manual Online PG-10

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

• A new style slide-locking type connector is used on certain systems and components, especially those

r NISSAN NOTE 2016 Service Manual Online PG-10

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

• A new style slide-locking type connector is used on certain systems and components, especially those

r](/img/5/57363/w960_57363-2596.png)

PG-10

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

• A new style slide-locking type connector is used on certain systems and components, especially those

related to OBD.

• The slide-locking type connectors help prevent incomplete locking and accidental looseness or disconnec-

tion.

• The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure

below.

CAUTION:

• Do not pull the harness or wires when disconnecting the connector.

• Be careful not to damage the connector su pport bracket when disconnecting the connector.

SEL769DA

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2669 of 3641

PWC-8

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

System DescriptionINFOID:0000000012431798

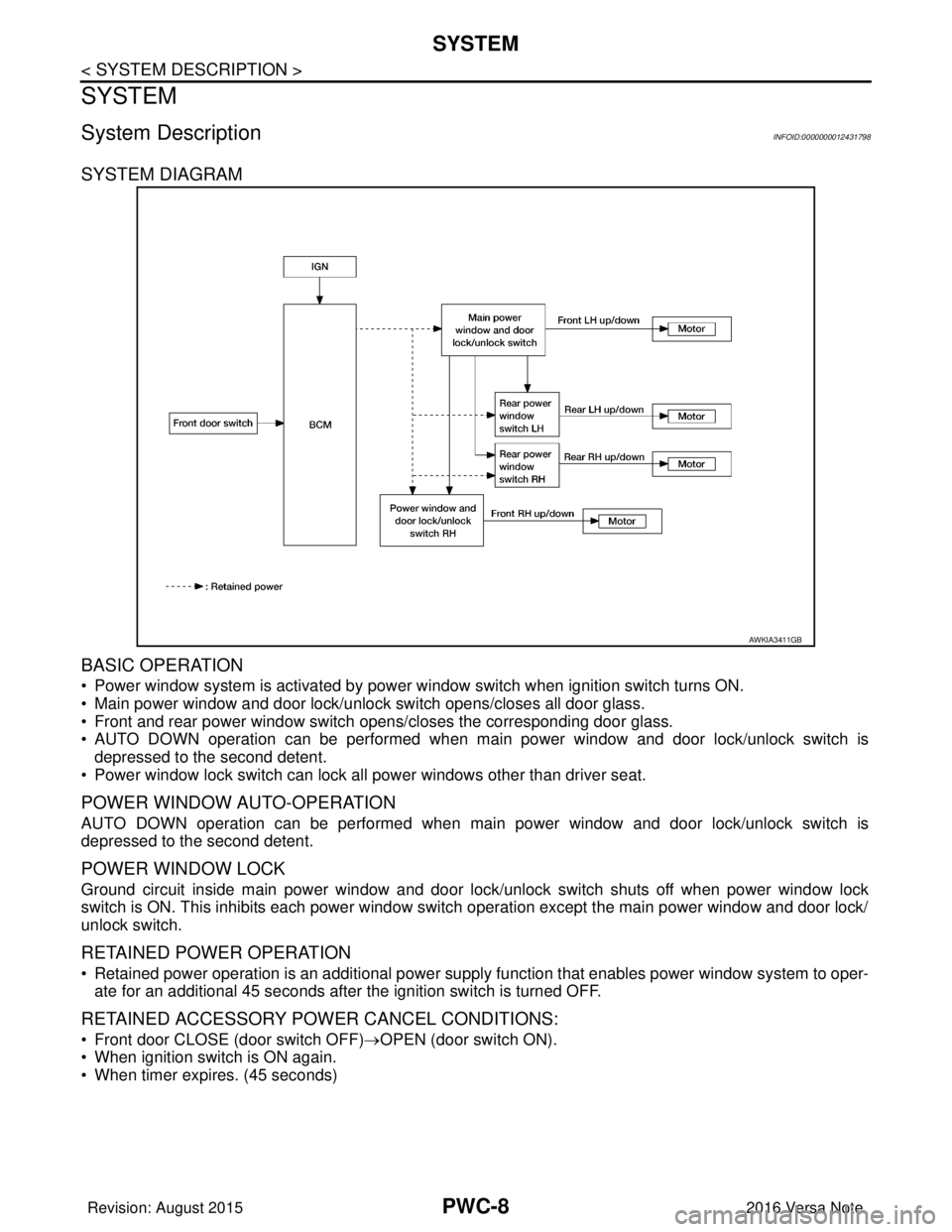

SYSTEM DIAGRAM

BASIC OPERATION

• Power window system is activated by power window switch when ignition switch turns ON.

• Main power window and door lock/unlock switch opens/closes all door glass.

• Front and rear power window switch opens/closes the corresponding door glass.

• AUTO DOWN operation can be performed when main power window and door lock/u\

nlock switch isdepressed to the second detent.

• Power window lock switch can lock all power windows other than driver seat.

POWER WINDOW AUTO-OPERATION

AUTO DOWN operation can be performed when main power window and door lock/unlock switch is

depressed to the second detent.

POWER WINDOW LOCK

Ground circuit inside main power window and door lock/unlock switch shuts off when power window lock

switch is ON. This inhibits each power window switch operation except the main power window and door lock/

unlock switch.

RETAINED POWER OPERATION

• Retained power operation is an additional power supply function that enables power window system to oper-

ate for an additional 45 seconds after the ignition switch is turned OFF.

RETAINED ACCESSORY POWER CANCEL CONDITIONS:

• Front door CLOSE (door switch OFF) →OPEN (door switch ON).

• When ignition switch is ON again.

• When timer expires. (45 seconds)

AWKIA3411GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2752 of 3641

SYSTEMWT-9

< SYSTEM DESCRIPTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

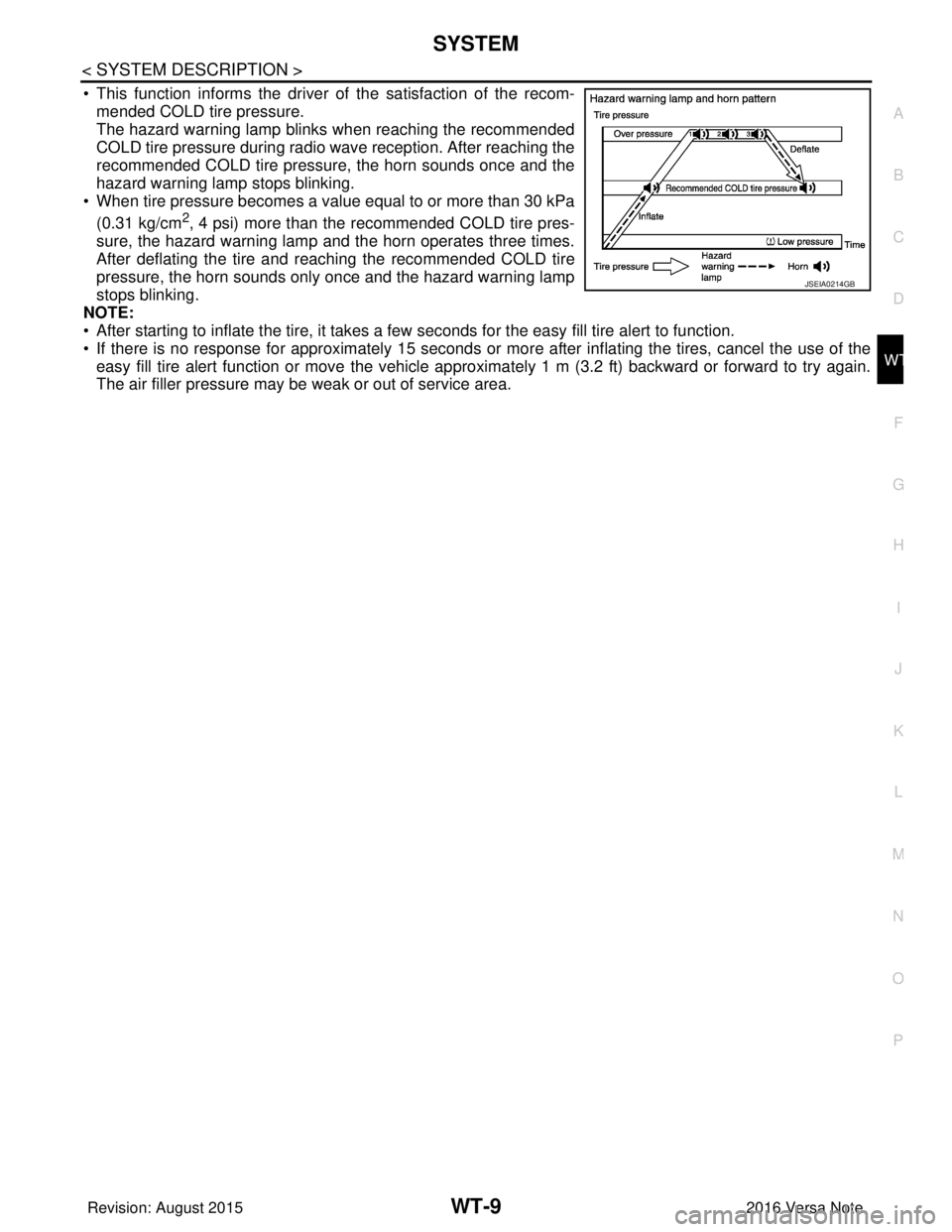

• This function informs the driver of the satisfaction of the recom- mended COLD tire pressure.

The hazard warning lamp blinks when reaching the recommended

COLD tire pressure during radio wave reception. After reaching the

recommended COLD tire pressure, the horn sounds once and the

hazard warning lamp stops blinking.

• When tire pressure becomes a value equal to or more than 30 kPa

(0.31 kg/cm

2, 4 psi) more than the recommended COLD tire pres-

sure, the hazard warning lamp and the horn operates three times.

After deflating the tire and reaching the recommended COLD tire

pressure, the horn sounds only once and the hazard warning lamp

stops blinking.

NOTE:

• After starting to inflate the tire, it takes a fe w seconds for the easy fill tire alert to function.

• If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

easy fill tire alert function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try again.

The air filler pressure may be weak or out of service area.

JSEIA0214GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2783 of 3641

WT-40

< SYMPTOM DIAGNOSIS >

EASY FILL TIRE ALERT DOES NOT ACTIVATE

EASY FILL TIRE ALERT DOES NOT ACTIVATE

DescriptionINFOID:0000000012432461

The easy fill tire alert does not function while inflating a tire when the select lever position is in P-range with the

ignition switch ON.

NOTE:

• After starting to inflate the tire, it takes a few seconds for the easy fill tire alert to function.

• If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

easy fill tire alert function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try again.

The air filler pressure may be weak or out of service area.

• For easy fill tire alert, Refer to WT-8, "

TIRE PRESSURE MONITORING SYST EM : Easy Fill Tire Alert Func-

tion".

Diagnosis ProcedureINFOID:0000000012432462

1. LOCATION CHANGE

Move the vehicle to other area and repeat the procedure of the easy fill tire alert function. Refer to WT-8,

"TIRE PRESSURE MONITORING SYSTEM : Easy Fill Tire Alert Function".

Is the function normal?

YES >> Normal (the easy fill tire alert may not operate, depending on reception condition.)

NO >> GO TO 2.

2.PERFORM BCM SELF-DIAGNOSIS

With CONSULT

Perform self-diagnosis for “AIR PRESSURE MONITOR”.

Is any DTC detected?

YES >> Perform trouble diagnosis for detected DTC. Refer to BCS-50, "DTCIndex" (with Intelligent Key

system) or BCS-115, "

DTCIndex" (without Intelligent Key system).

NO >> GO TO 3.

3.CHECK HAZARD WARNING LAMP OPERATION

Check hazard warning lamp operation with hazard switch.

Does the hazard warning lamp blink?

YES >> GO TO 4.

NO >> Perform trouble diagnosis for the hazard warning lamp. Refer to EXL-85, "

Diagnosis Procedure" .

4.PERFORM TCM SELF-DIAGNOSIS

With CONSULT

Perform self-diagnosis for “TRANSMISSION”.

Is any DTC detected?

YES >> Check malfunctioning circuit. Refer to TM-110, "DTC Index".

NO >> GO TO 5.

5.CHECK HORN OPERATION

Check horn operation. Refer to HRN-3, "

Wiring Diagram".

Is the operation normal?

YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.PERFORM BCM SELF-DIAGNOSIS

With CONSULT

1. Drive for 10 minutes at a speed of 40 km/h (25 MPH) or more.

CAUTION:

Total time driving at a speed of 40 km/h (25 MPH) or more must be 10 minutes.

2. Stop the vehicle.

3. Perform self-diagnosis for “AIR PRESSURE MONITOR”.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2821 of 3641

SE-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

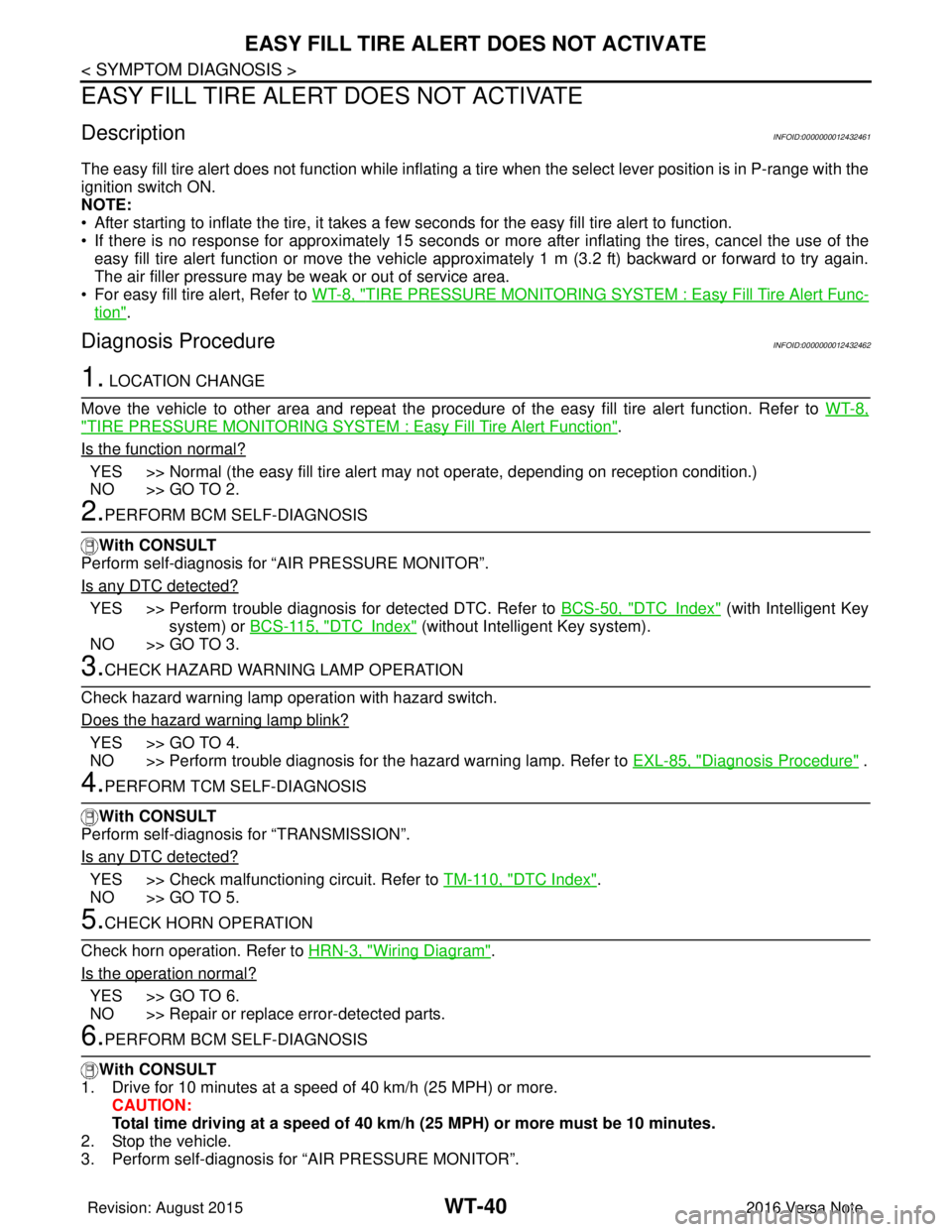

Work FlowINFOID:0000000012432031

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to SE-12, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3026 of 3641

COMPONENT PARTSSRC-9

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

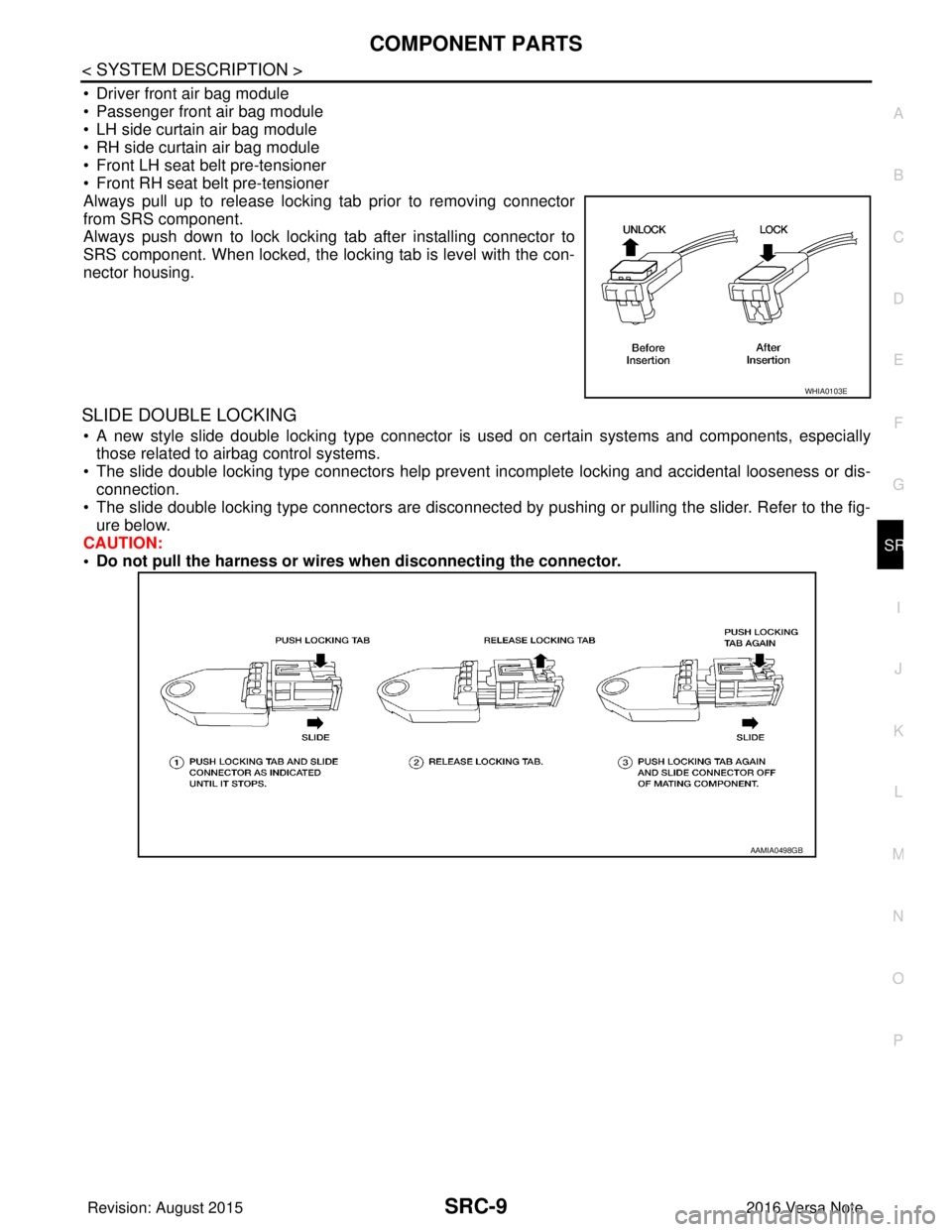

• Driver front air bag module

• Passenger front air bag module

• LH side curtain air bag module

• RH side curtain air bag module

• Front LH seat belt pre-tensioner

• Front RH seat belt pre-tensioner

Always pull up to release locking tab prior to removing connector

from SRS component.

Always push down to lock locking tab after installing connector to

SRS component. When locked, the locking tab is level with the con-

nector housing.

SLIDE DOUBLE LOCKING

• A new style slide double locking type connector is used on certain systems and components, especially those related to airbag control systems.

• The slide double locking type connectors help prevent incomplete locking and accidental looseness or dis-

connection.

• The slide double locking type connectors are disconnected by pushing or pulling the slider. Refer to the fig- ure below.

CAUTION:

• Do not pull the harness or wires when disconnecting the connector.

WHIA0103E

AAMIA0498GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3191 of 3641

DIAGNOSIS SYSTEM (EPS CONTROL UNIT)

STC-7

< SYSTEM DESCRIPTION >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

*2: Normally displays 100%. In case of an excessive stationary steering, the assist curvature gradually falls.

However, it returns to 100% when left standing.

*3: It is not a malfunction, though it might not be corresponding just after ignition switch in turned ON.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3192 of 3641

STC-8

< ECU DIAGNOSIS INFORMATION >

EPS CONTROL UNIT

ECU DIAGNOSIS INFORMATION

EPS CONTROL UNIT

Reference ValueINFOID:0000000012431945

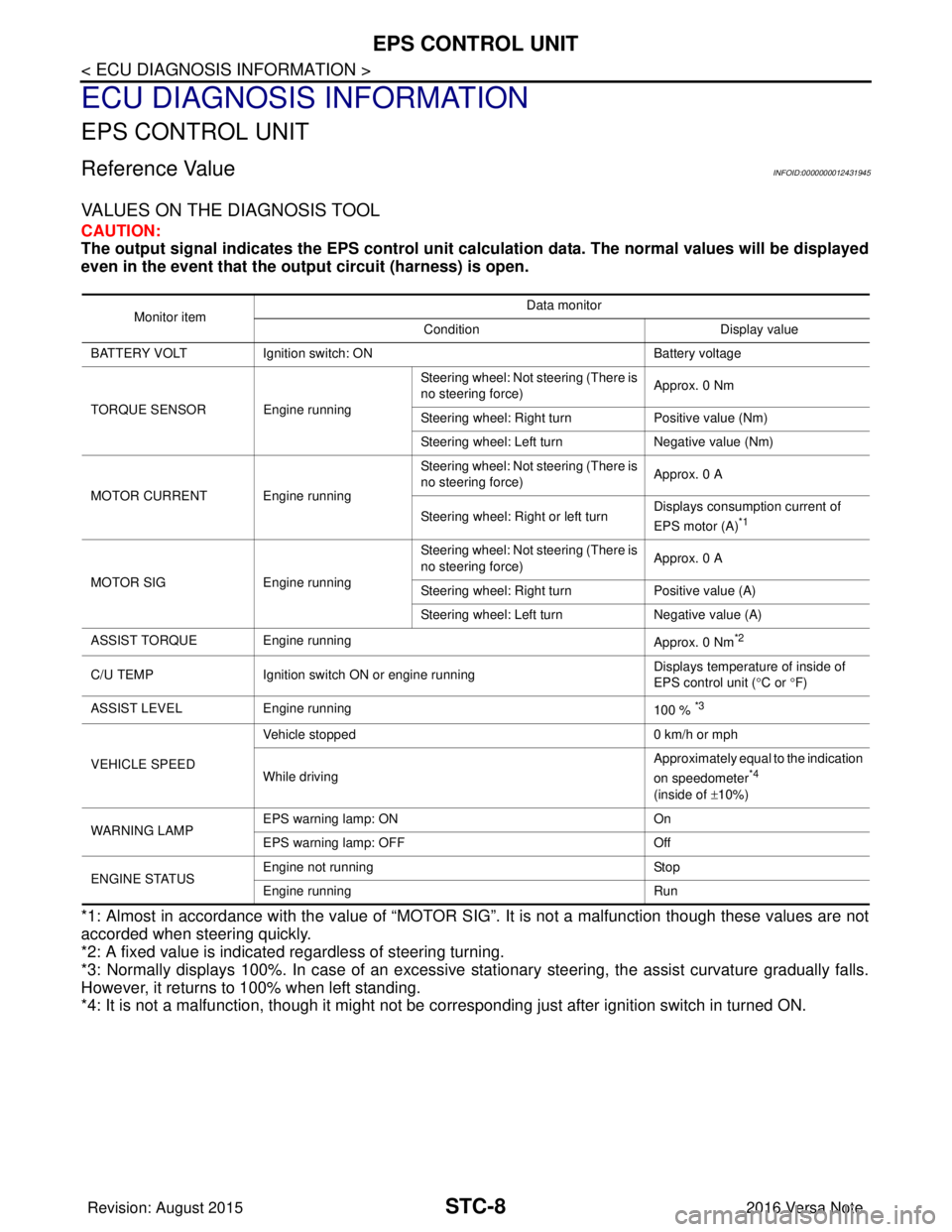

VALUES ON THE DIAGNOSIS TOOL

CAUTION:

The output signal indicates the EPS control unit calculation data. The normal values will be displayed

even in the event that the output circuit (harness) is open.

*1: Almost in accordance with the value of “MOTOR S IG”. It is not a malfunction though these values are not

accorded when steering quickly.

*2: A fixed value is indicated regardless of steering turning.

*3: Normally displays 100%. In case of an excessive stat ionary steering, the assist curvature gradually falls.

However, it returns to 100% when left standing.

*4: It is not a malfunction, though it might not be co rresponding just after ignition switch in turned ON.

Monitor item Data monitor

Condition Display value

BATTERY VOLT Ignition switch: ON Battery voltage

TORQUE SENSOR Engine running Steering wheel: Not

steering (There is

no steering force) Approx. 0 Nm

Steering wheel: Right turn Positive value (Nm)

Steering wheel: Left turn Negative value (Nm)

MOTOR CURRENT Engine running Steering wheel: Not

steering (There is

no steering force) Approx. 0 A

Steering wheel: Right or left turn Displays consumption current of

EPS motor (A)

*1

MOTOR SIG

Engine runningSteering wheel: Not

steering (There is

no steering force) Approx. 0 A

Steering wheel: Right turn Positive value (A)

Steering wheel: Left turn Negative value (A)

ASSIST TORQUE Engine running Approx. 0 Nm

*2

C/U TEMPIgnition switch ON or engine running Displays temperature of inside of

EPS control unit (

°C or °F)

ASSIST LEVEL Engine running

100 %

*3

VEHICLE SPEEDVehicle stopped

0 km/h or mph

While driving Approximately equal to the indication

on speedometer*4

(inside of ±

10%)

WARNING LAMP EPS warning lamp: ON

On

EPS warning lamp: OFF Off

ENGINE STATUS Engine not running

Stop

Engine running Run

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3312 of 3641

![NISSAN NOTE 2016 Service Manual Online STRUCTURE AND OPERATIONTM-71

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Mechanism

It is composed of a pair of pulleys (the groove width is changed freely in the axial direct NISSAN NOTE 2016 Service Manual Online STRUCTURE AND OPERATIONTM-71

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Mechanism

It is composed of a pair of pulleys (the groove width is changed freely in the axial direct](/img/5/57363/w960_57363-3311.png)

STRUCTURE AND OPERATIONTM-71

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

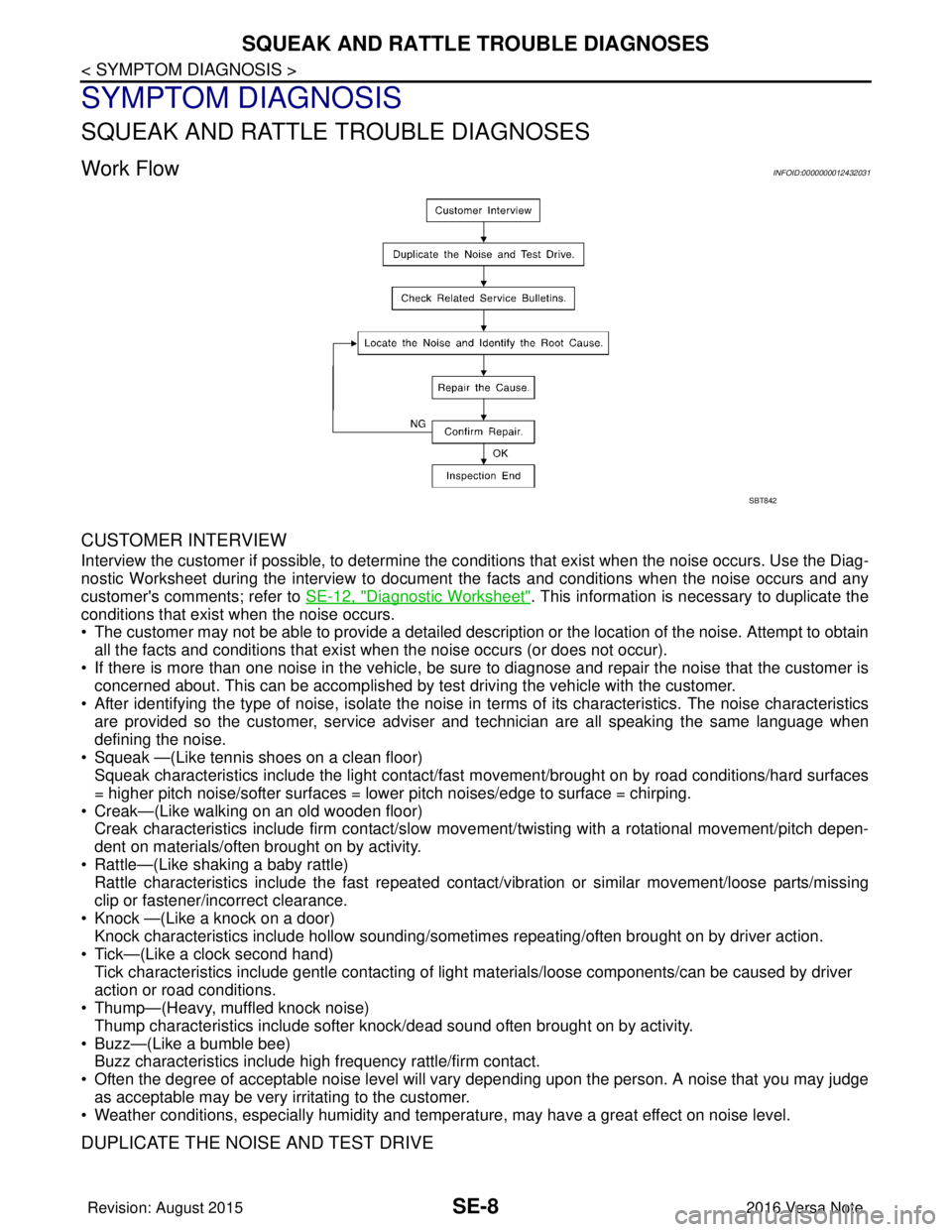

Mechanism

It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the steel belt

(the steel plates are placed conti

nuously and the belt is guided with the multilayer steel rings on both sides).

The groove width changes according to wrapping radius of steel belt and pulley from low status to overdrive

status continuously with non-step. It is controlled with the oil pressures of primary pulley and secondary pulley.

Steel belt

It is composed of multiple steel plates (A) and two steel rings (B)

stacked to a several number. The feature of this steel belt transmits

power with compression of the steel plate in contrast with transmis-

sion of power in pulling with a rubber belt. Friction force is required

with the pulley slope to transmit power from the steel plate. The force

is generated with the following mechanism:

Oil pressure applies to the secondary pulley to nip the plate. ⇒The

plate is pushed and extended outward. ⇒The steel ring shows with-

stands. ⇒Pulling force is generated on the steel ring. ⇒ The plate of

the primary pulley is nipped between the pulley. ⇒Friction force is

generated between the steel belt and the pulley.

Therefore, responsibilities are divided by the steel plate that trans-

mits the power with compression and the steel ring that main tains necessary friction force. In this way, the

tension of the steel ring is distributed on the entire su rface and stress variation is limited, resulting in good

durability.

Pulley

The primary pulley (input shaft side) and the secondary pulley (output shaft side) have the shaft with slope

(fixed cone surface), movable sheave (movable cone surface that can move in the axial direction) and oil pres-

sure chamber at the back of the movable sheave.

Pulley gear shifting operation

• Pulley gear shifting operation The movable sheave slides on the shaft to change the groove width of the pulley. Input signals of engine

load (accelerator pedal opening), engine revolution and gear ratio (vehicle speed) change the operation

pressures of the primary pulley and the secondary pulle y, and controls the pulley groove width. Along with

change of the pulley groove width, the belt contact radi us is changed. This allows continuous and stepless

JSDIA1966ZZ

JSDIA1779GB

Revision: August 2015 2016 Versa Note

cardiagn.com