ESP NISSAN NOTE 2016 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1319 of 3641

![NISSAN NOTE 2016 Service Workshop Manual EC-192

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

YES >> GO TO 8.

NO >> Replace mass air flow sensor. Refer to

EM-26, "

Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer t NISSAN NOTE 2016 Service Workshop Manual EC-192

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

YES >> GO TO 8.

NO >> Replace mass air flow sensor. Refer to

EM-26, "

Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer t](/img/5/57363/w960_57363-1318.png)

EC-192

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

YES >> GO TO 8.

NO >> Replace mass air flow sensor. Refer to

EM-26, "

Removal and Installation".

8.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000012431407

1.CHECK MASS AIR FLOW SENSOR-I

With CONSULT

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Start engine and warm it up to normal operating temperature.

4. Connect CONSULT and select “DATA MONITOR” mode.

5. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Start engine and warm it up to normal operating temperature.

4. Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK FOR THE CAUSE OF UNEVEN AIR FL OW THROUGH MASS AIR FLOW SENSOR

1. Turn ignition switch OFF.

2. Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

- Crushed air ducts

- Malfunctioning seal of air cleaner element

- Uneven dirt of air cleaner element

- Improper specification of intake air system parts

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK MASS AIR FLOW SENSOR-II

Monitor item Condition MAS A/F SE-B1

MAS A/F SE-B1 Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

ECM

Condition Voltage

Connector Te r m i n a l

+ −

F11 45

(MAF sensor signal) 52Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1320 of 3641

![NISSAN NOTE 2016 Service Workshop Manual P0102, P0103 MAF SENSOREC-193

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operati NISSAN NOTE 2016 Service Workshop Manual P0102, P0103 MAF SENSOREC-193

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operati](/img/5/57363/w960_57363-1319.png)

P0102, P0103 MAF SENSOREC-193

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

With CONSULT

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT

1. Repair or replace malfunctioning part.

2. Start engine and warm it up to normal operating temperature.

3. Check the voltage between ECM harness connector and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK MASS AIR FLOW SENSOR-III

With CONSULT

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor har ness connector and reconnect it again.

3. Start engine and warm it up to normal operating temperature.

4. Connect CONSULT and select “DATA MONITOR” mode.

5. Select “MAS A/F SE-B1” and check indication.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Without CONSULT

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor har ness connector and reconnect it again.

3. Start engine and warm it up to normal operating temperature.

4. Check the voltage between ECM harness connector and ground.

Monitor item Condition MAS A/F SE-B1

MAS A/F SE-B1 Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

ECM

Condition Voltage

Connector Te r m i n a l

+ −

F11 45

(MAF sensor signal) 52Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

Monitor itemCondition MAS A/F SE-B1

MAS A/F SE-B1 Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1321 of 3641

![NISSAN NOTE 2016 Service Workshop Manual EC-194

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSP NISSAN NOTE 2016 Service Workshop Manual EC-194

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSP](/img/5/57363/w960_57363-1320.png)

EC-194

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0102, P0103 MAF SENSOR

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Clean or replace mass air flow sensor. Refer to

EM-26, "

Removal and Installation".

ECM

Condition Voltage

Connector Te r m i n a l

+ −

F11 45

(MAF sensor signal) 52Ignition switch ON (Engine stopped.)

Approx. 0.4 V

Idle (Engine is warmed-up to normal operating temperature.) 0.8 - 1.3 V

2,500 rpm (Engine is warmed-up to normal operating temperature.) 1.4 - 1.9 V

Idle to about 4,000 rpm 0.8 - 1.3 V to Approx. 2.4 V*

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1364 of 3641

![NISSAN NOTE 2016 Service Workshop Manual P0139 HO2S2EC-237

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0139 HO2S2

DTC LogicINFOID:0000000012431449

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switc NISSAN NOTE 2016 Service Workshop Manual P0139 HO2S2EC-237

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0139 HO2S2

DTC LogicINFOID:0000000012431449

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switc](/img/5/57363/w960_57363-1363.png)

P0139 HO2S2EC-237

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0139 HO2S2

DTC LogicINFOID:0000000012431449

DTC DETECTION LOGIC

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel

ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel cut.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT?

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 6.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

For better results, perform “DTC WORK SUPPORT” at a temperature of 0 to 30 °C (32 to 86 °F).

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

8. Make sure that “COOLAN TEMP/S” indicates more than 70 °C (158° F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158° F).

9. Open engine hood.

10. Select “HO2S2 (B1) P0139” in “DTC WORK SUPPORT” mode of “ENGINE” using CONSULT.

SEF302U

DTC No. Trouble diagnosis content DTC detecting conditionPossible cause

P0139 Heated oxygen sensor 2

circuit slow response It takes more time for the sensor to respond

between rich and lean than the specified time. • Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2

• Fuel pressure

• Fuel injector

• Intake air leaks

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1370 of 3641

![NISSAN NOTE 2016 Service Workshop Manual P014C, P014D, P015A, P015B, A/F SENSOR 1EC-243

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P014C, P014D, P015A, P015B, A/F SENSOR 1

DTC LogicINFOID:0000000012431453

DTC DETECTIO NISSAN NOTE 2016 Service Workshop Manual P014C, P014D, P015A, P015B, A/F SENSOR 1EC-243

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P014C, P014D, P015A, P015B, A/F SENSOR 1

DTC LogicINFOID:0000000012431453

DTC DETECTIO](/img/5/57363/w960_57363-1369.png)

P014C, P014D, P015A, P015B, A/F SENSOR 1EC-243

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P014C, P014D, P015A, P015B, A/F SENSOR 1

DTC LogicINFOID:0000000012431453

DTC DETECTION LOGIC

To judge malfunctions, this diagnosis measures response time of the A/F signal co

mputed by ECM from the A/

F sensor 1 signal. The time is compensated by engi ne operating (speed and load), fuel feedback control con-

stant, and the A/F sensor 1 temperature index. Judgment is based on whether the compensated time (the A/F

signal cycling time index) is inordinately long or not.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 5.

2.PERFORM DTC CONFIRMATION PROCEDURE-1

With CONSULT

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1minute under no load.

6. Let engine idle for 1 minute.

7. Increase the engine speed up to about 3,600 rpm and keep it for 10 seconds.

8. Fully release accelerator pedal and then let engine idle for about 1 minute.

9. Check the items status of “DATA MONITOR” as follows. NOTE:

If “PRSNT” changed to “ABSNT”, refer to EC-151, "

Component Function Check".

Is

“PRSNT” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-2

With CONSULT

Perform DTC confirmation procedure-1 again.

Is

“PRSNT” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> Refer to EC-151, "

Component Function Check".

DTC No. Trouble diagnosis content DTC detecting conditionPossible Cause

P014C Air fuel ratio (A/F) sensor 1 (bank 1) circuit slow re-

sponse • The response time of a A/F sensor 1 signal de-

lays more than the specified time computed by

ECM. • Harness or connectors

(The A/F sensor 1 circuit is open or

shorted.)

• A/F sensor 1

P014D

P015A Air fuel ratio (A/F) sensor 1

(bank 1) circuit delayed re-

sponse

P015B

Data monitor item

Status

A/F SEN1 DIAG3 (B1) PRSNT

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1376 of 3641

![NISSAN NOTE 2016 Service Workshop Manual P0171 FUEL INJECTION SYSTEM FUNCTIONEC-249

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE-III

1. Turn ignition switch OFF and wa NISSAN NOTE 2016 Service Workshop Manual P0171 FUEL INJECTION SYSTEM FUNCTIONEC-249

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE-III

1. Turn ignition switch OFF and wa](/img/5/57363/w960_57363-1375.png)

P0171 FUEL INJECTION SYSTEM FUNCTIONEC-249

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NO >> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine.

3. Maintain the following conditions for at least 10 consecutive minutes. Hold the accelerator pedal as steady as possible.

CAUTION:

Always drive vehicle at a safe speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-249, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431456

1.CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

Is exhaust gas leak detected?

YES >> Repair or replace.

NO >> GO TO 2.

2.CHECK FOR INTAKE AIR LEAK AND PCV HOSE

1. Listen for an intake air leak after the mass air flow sensor.

2. Check PCV hose connection.

Intake air leak detected?

YES >> Repair or replace.

NO >> GO TO 3.

3.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect corresponding A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

5. Check the continuity between A/F sensor 1 harness connector or ECM harness connector and ground.

VHCL SPEED SE50 – 120 km/h (31 – 75 MPH)

PBIB1216E

A/F sensor 1ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

25 3

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1380 of 3641

![NISSAN NOTE 2016 Service Workshop Manual P0172 FUEL INJECTION SYSTEM FUNCTIONEC-253

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine.

3. Maintain the NISSAN NOTE 2016 Service Workshop Manual P0172 FUEL INJECTION SYSTEM FUNCTIONEC-253

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine.

3. Maintain the](/img/5/57363/w960_57363-1379.png)

P0172 FUEL INJECTION SYSTEM FUNCTIONEC-253

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine.

3. Maintain the following conditions for at least 10 consecutive minutes.

Hold the accelerator pedal as steady as possible.

CAUTION:

Always drive vehicle at a safe speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-253, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431458

1.CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

Is exhaust gas leak detected?

YES >> Repair or replace.

NO >> GO TO 2.

2.CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

Is intake air leak detected?

YES >> Repair or replace.

NO >> GO TO 3.

3.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect corresponding A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

5. Check the continuity between A/F sensor 1 harness connector or ECM harness connector and ground.

VHCL SPEED SE50 – 120 km/h (31 – 75 MPH)

PBIB1216E

A/F sensor 1ECM

Continuity

Connector Terminal Connector Terminal

F12 1

F11 49

Existed

25 3

A/F sensor 1 GroundContinuity

Connector Terminal

F12 1

Ground Not existed

2

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1491 of 3641

![NISSAN NOTE 2016 Service Workshop Manual EC-364

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1148 CLOSED LOOP CONTROL

P1148 CLOSED LOOP CONTROL

DTC LogicINFOID:0000000012431563

DTC DETECTION LOGIC

NOTE:

DTC P1148 is displayed with DTC for A/F sensor 1 NISSAN NOTE 2016 Service Workshop Manual EC-364

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1148 CLOSED LOOP CONTROL

P1148 CLOSED LOOP CONTROL

DTC LogicINFOID:0000000012431563

DTC DETECTION LOGIC

NOTE:

DTC P1148 is displayed with DTC for A/F sensor 1](/img/5/57363/w960_57363-1490.png)

EC-364

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1148 CLOSED LOOP CONTROL

P1148 CLOSED LOOP CONTROL

DTC LogicINFOID:0000000012431563

DTC DETECTION LOGIC

NOTE:

DTC P1148 is displayed with DTC for A/F sensor 1.

When the DTC is detected, perform the trouble di

agnosis of DTC corresponding to A/F sensor 1.

Diagnosis ProcedureINFOID:0000000012431564

DTC P1148 is displayed with DTC for A/F sensor 1.

When the DTC is detected, perform the trouble diagnosis of DTC corresponding to A/F sensor 1.

Refer to EC-87, "

DTCIndex".

DTC No. CONSULT screen terms

(Trouble diagnosis content) DTC detecting condition

Possible cause

P1148 CLOSED LOOP-B1

(Closed loop control func-

tion) The closed loop control function does not

operate even when vehicle is being driven in

the specified condition. • Harness or connectors

(A/F sensor 1 circuit is open or shorted.)

• A/F sensor 1

• A/F sensor 1 heater

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1662 of 3641

EXL-10

< SYSTEM DESCRIPTION >

SYSTEM

FRONT FOG LAMP SYSTEM : System Description

INFOID:0000000012432774

FRONT FOG LAMP OPERATION

When the combination switch (lighting and turn signal switch) is in front fog lamp ON position and also in 1ST

or 2ND position (headlamp is ON), the BCM detects FR FOG ON and the HEAD LAMP 1 or 2 ON. The BCM

sends a front fog lamp request ON signal through the CAN communication lines to the IPDM E/R. The IPDM

E/R then turns ON the front fog lamp relay sending power to the front fog lamps.

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM

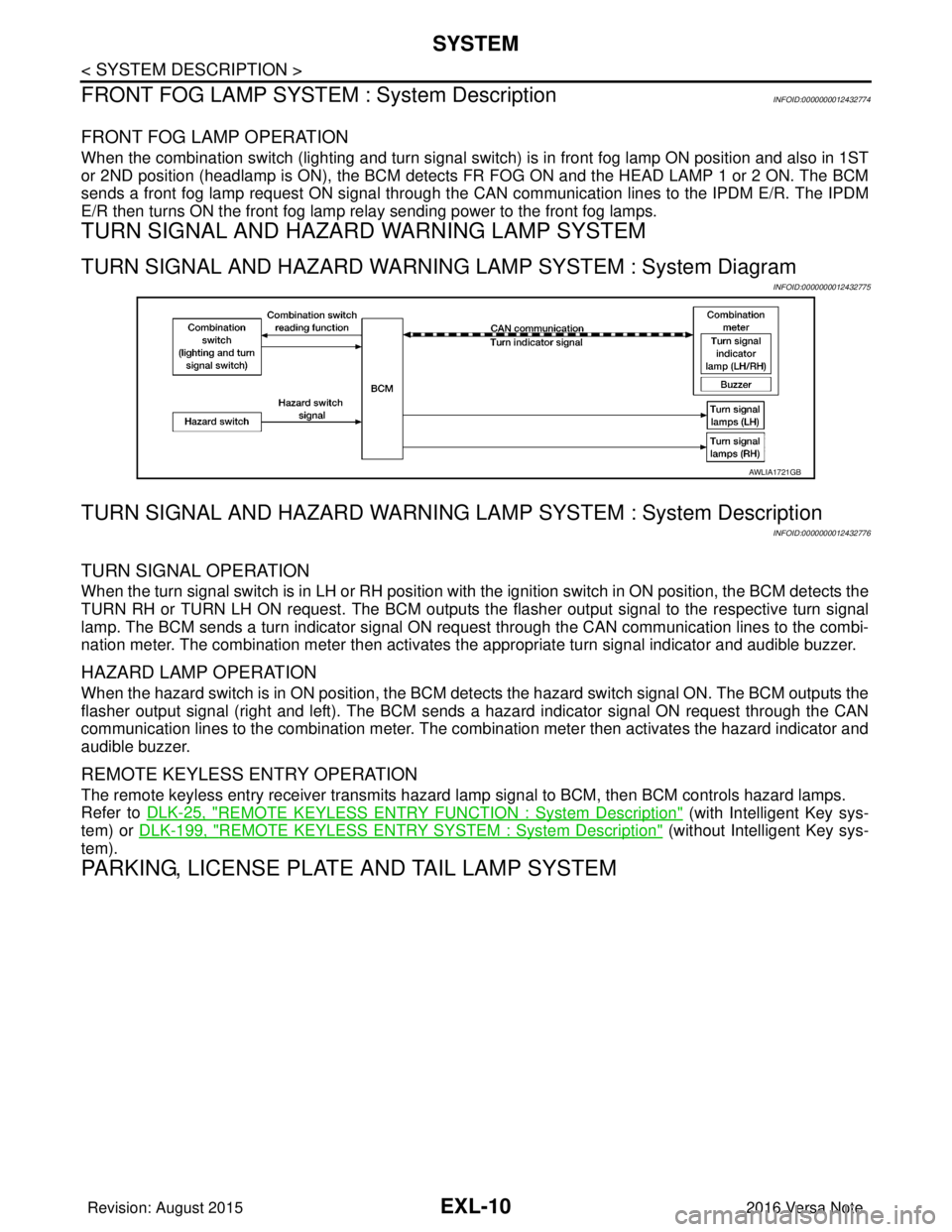

TURN SIGNAL AND HAZARD WARNING LAMP SYSTEM : System Diagram

INFOID:0000000012432775

TURN SIGNAL AND HAZARD WARNING LA MP SYSTEM : System Description

INFOID:0000000012432776

TURN SIGNAL OPERATION

When the turn signal switch is in LH or RH position with the ignition switch in ON position, the BCM detects the

TURN RH or TURN LH ON request. The BCM outputs the flasher output signal to the respective turn signal

lamp. The BCM sends a turn indicator signal ON request through the CAN communication lines to the combi-

nation meter. The combination meter then activates the appropriate turn signal indicator and audible buzzer.

HAZARD LAMP OPERATION

When the hazard switch is in ON position, the BCM det ects the hazard switch signal ON. The BCM outputs the

flasher output signal (right and left). The BCM sends a hazard indicator signal ON request through the CAN

communication lines to the combination meter. The combination meter then activates the hazard indicator and

audible buzzer.

REMOTE KEYLESS ENTRY OPERATION

The remote keyless entry receiver transmits hazard lamp signal to BCM, then BCM controls hazard lamps.

Refer to DLK-25, "

REMOTE KEYLESS ENTRY FUNCTION : System Description" (with Intelligent Key sys-

tem) or DLK-199, "

REMOTE KEYLESS ENTRY SYSTEM : System Description" (without Intelligent Key sys-

tem).

PARKING, LICENSE PLATE AND TAIL LAMP SYSTEM

AWLIA1721GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1778 of 3641

SYSTEMEXT-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

SYSTEM

ACTIVE GRILLE SHUTTER SYSTEM

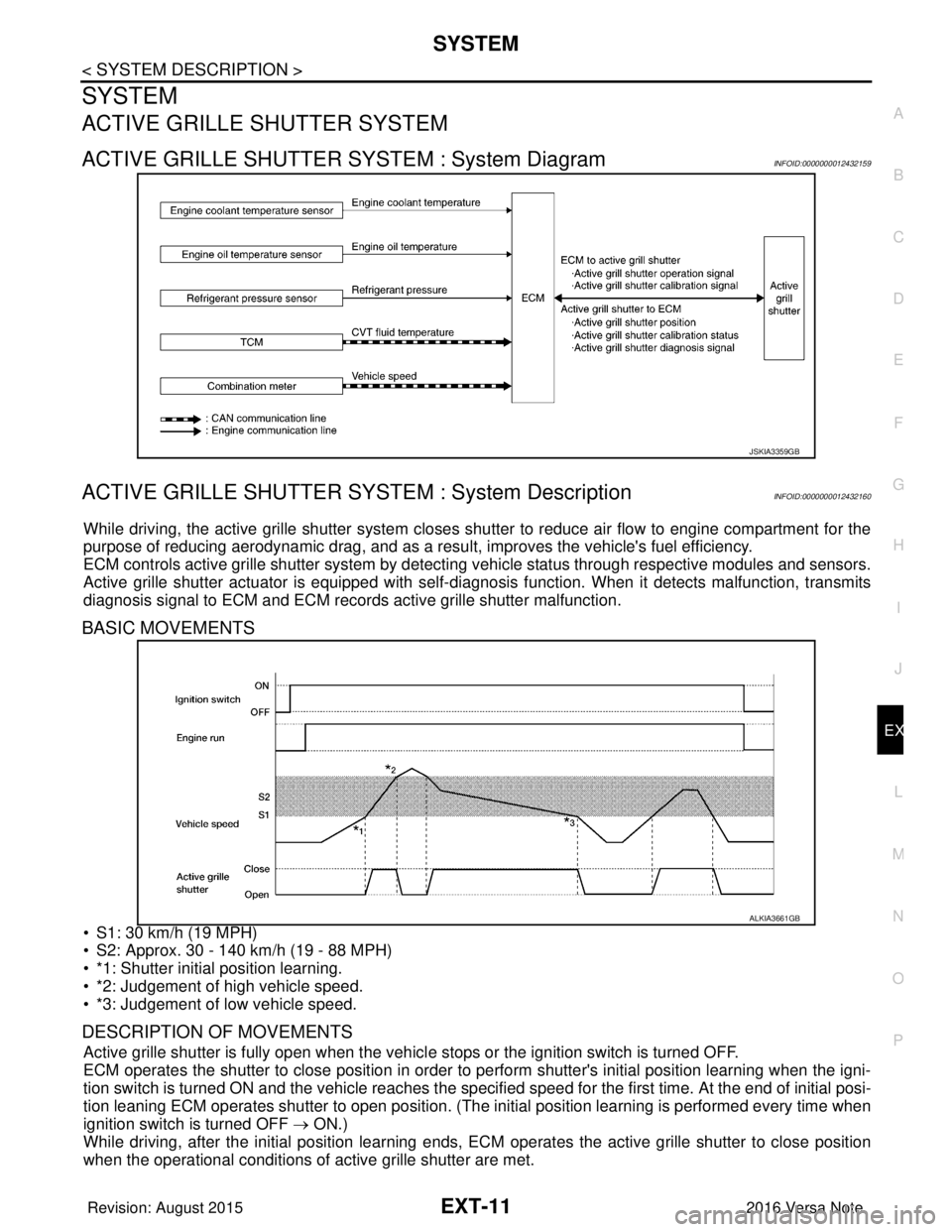

ACTIVE GRILLE SHUTTER SYSTEM : System DiagramINFOID:0000000012432159

ACTIVE GRILLE SHUTTER SYSTEM : System DescriptionINFOID:0000000012432160

While driving, the active grille shutter system closes shutter to reduce air flow to engine compartment for the

purpose of reducing aerodynamic drag, and as a resu lt, improves the vehicle's fuel efficiency.

ECM controls active grille shutter system by detecting vehicle status through respective modules and sensors.

Active grille shutter actuator is equipped with self-d iagnosis function. When it detects malfunction, transmits

diagnosis signal to ECM and ECM records active grille shutter malfunction.

BASIC MOVEMENTS

• S1: 30 km/h (19 MPH)

• S2: Approx. 30 - 140 km/h (19 - 88 MPH)

• *1: Shutter initial position learning.

• *2: Judgement of high vehicle speed.

• *3: Judgement of low vehicle speed.

DESCRIPTION OF MOVEMENTS

Active grille shutter is fully open when the vehicl e stops or the ignition switch is turned OFF.

ECM operates the shutter to close position in order to perform shutter's initial position learning when the igni-

tion switch is turned ON and the vehicle reaches the specified speed for the first time. At the end of initial posi-

tion leaning ECM operates shutter to open position. (The in itial position learning is performed every time when

ignition switch is turned OFF → ON.)

While driving, after the initial position learning ends, EC M operates the active grille shutter to close position

when the operational conditions of active grille shutter are met.

JSKIA3359GB

ALKIA3661GB

Revision: August 2015 2016 Versa Note

cardiagn.com