air suspension NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 453 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON, NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON,](/img/5/57363/w960_57363-452.png)

PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON, brake pedal may vibrate or motor operating noise may be heard from engine compartment. This is a normal condition.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck brake booster operation, brake fluid level and oil

leaks.

• If tire size and type are used in an improper combinati on or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits, and improper wiring.

• VDC system may not operate normally or a VDC OFF indi cator lamp or SLIP indicator lamp may light.

- When replacing the following parts with parts other than genuine parts or making modifications: Suspension- related parts (shock absorber, spring, bushing, etc.), tire s, wheels (other than specified sizes), brake-related

parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-related parts

(roll bar, tower bar, etc.).

- When driving with worn or deteriorated suspension, tires and brake-related parts.

Precaution for Harness RepairINFOID:0000000012430823

• Solder the repair part, and wrap it with tape. [Twisted wire fray

must be 110 mm (4.33 in) or less.]

• Do not bypass the repair point with wire. (If it is bypassed, the turn- out point cannot be separated and the twisted wire characteristics

are lost.)

SKIB8766E

SKIB8767E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 503 of 3641

![NISSAN NOTE 2016 Service Repair Manual INSPECTION AND ADJUSTMENTBRC-55

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN R NISSAN NOTE 2016 Service Repair Manual INSPECTION AND ADJUSTMENTBRC-55

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN R](/img/5/57363/w960_57363-502.png)

INSPECTION AND ADJUSTMENTBRC-55

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000012545169

After replacing the ABS actuator and electric uni t (control unit), perform the following procedures:

• Neutral position adjustment for the steering angle sensor

• Calibration of the decel G sensor (if equipped)

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000012545170

1.PERFORM THE NEUTRAL POSITION ADJUST MENT FOR THE STEERING ANGLE SENSOR

Perform the neutral position adjustm ent for the steering angle sensor.

>> Refer to BRC-55, "

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Spe-

cial Repair Requirement", GO TO 2

2.PERFORM CALIBRATION OF THE DECEL G SENSOR (IF EQUIPPED)

Perform calibration of the decel G sensor.

>> Refer to BRC-56, "

CALIBRATION OF DECEL G SENSOR : Special Repair Requirement".

ADJUSTMENT OF STEERING AN GLE SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SEN SOR NEUTRAL POSITION : Description

INFOID:0000000012545171

Refer to the table below to determine if adjustment of steering angle sensor neutral position is required.

×: Required –: Not required

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Re-

pair Requirement

INFOID:0000000012545172

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

CAUTION:

To adjust neutral position of steering angle sensor, make sure to use CONSULT

(Adjustment cannot be done without CONSULT)

1.ALIGN THE VEHICLE STATUS

Stop vehicle with front wheels in straight-ahead position.

Situation Adjustment of steering angle sensor neutral position

Removing/Insta lling ABS actuator and electr ic unit (control unit) —

Replacing ABS actuator and elec tric unit (control unit) ×

Removing/Installing steering angle sensor ×

Replacing steering angle sensor ×

Removing/Installing steering components ×

Replacing steering components ×

Removing/Installing suspension components ×

Replacing suspension components ×

Change tires to new ones —

Tire rotation —

Adjusting wheel alignment ×

Revision: August 20152016 Versa Note

cardiagn.com

Page 504 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-56

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST

MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT screen, touch “WORK SUPPORT� NISSAN NOTE 2016 Service Repair Manual BRC-56

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST

MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT screen, touch “WORK SUPPORT�](/img/5/57363/w960_57363-503.png)

BRC-56

< BASIC INSPECTION >[VDC/TCS/ABS]

INSPECTION AND ADJUSTMENT

>> GO TO 2

2.PERFORM THE NEUTRAL POSITION ADJUST

MENT FOR THE STEERING ANGLE SENSOR

1. On the CONSULT screen, touch “WORK SUPPORT” and “ST ANGLE SENSOR ADJUSTMENT” in order.

2. Touch “START”. CAUTION:

Do not touch steering wheel whil e adjusting steering angle sensor.

3. After approximately 10 seconds, touch “END”. NOTE:

After approximately 60 seconds, it ends automatically.

4. Turn ignition switch OFF, then turn it ON again. CAUTION:

Be sure to perform above operation.

>> GO TO 3

3.CHECK DATA MONITOR

1. Run vehicle with front wheels in straight-ahead position, then stop.

2. Select “DATA MONITOR”. Then make sure “STR ANGLE SIG” is within 0 ±2.5 °.

Is the steering angle within the specified range?

YES >> GO TO 4

NO >> Perform the neutral position adjustment fo r the steering angle sensor again, GO TO 1

4.ERASE THE SELF-DIAGNOSIS MEMORY

Erase the self-diagnosis memory of the ABS ac tuator and electric unit (control unit) and ECM.

• ABS actuator and electric unit (control unit): Refer to BRC-31, "

CONSULT Function (ABS)".

• ECM: Refer to EC-60, "

CONSULT Function".

Are the memories erased?

YES >> Inspection End

NO >> Check the items indicated by the self-diagnosis.

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR : DescriptionINFOID:0000000012545173

Refer to the table below to determine if calibration of the decel G sensor is required.

×: Required –: Not required

CALIBRATION OF DECEL G SENSOR : Special Repair RequirementINFOID:0000000012545174

CALIBRATION OF DECEL G SENSOR (IF EQUIPPED)

CAUTION:

To calibrate the decel G sensor, make sure to use CONSULT

(Calibration cannot be done without CONSULT)

Situation Calibration of decel G sensor

Removing/Installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit) ×

Removing/Installing steering components —

Replacing steering components —

Removing/Installing suspension components —

Replacing suspension components —

Change tires to new ones —

Tire rotation —

Adjusting wheel alignment —

Removing/Installing yaw rate/side/decel G sensor ×

Replacing yaw rate/side/decel G sensor ×

Revision: August 20152016 Versa Note

cardiagn.com

Page 1749 of 3641

HEADLAMP AIMING ADJUSTMENTEXL-97

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432828

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Confirm headlamp aiming switch is set to "0" (zero) position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

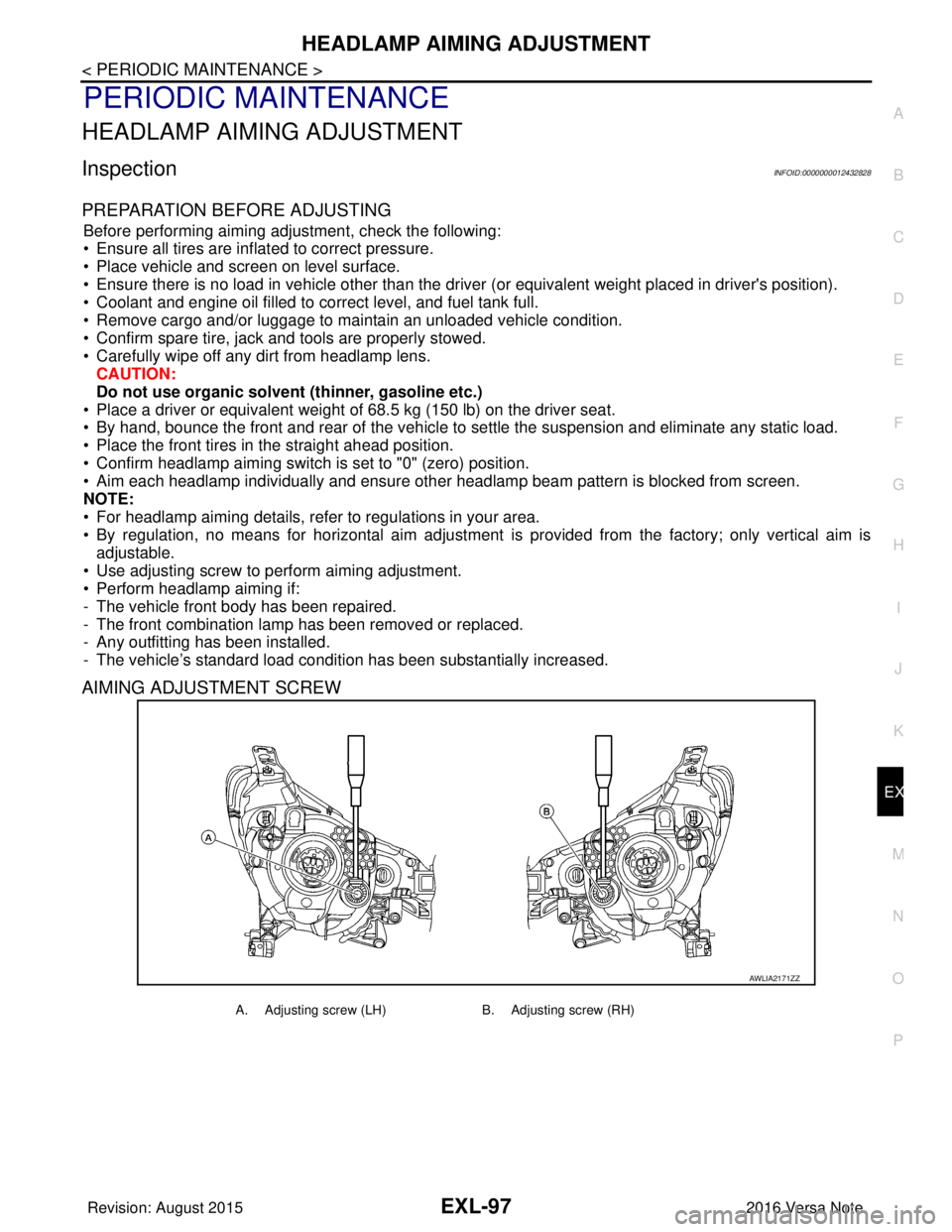

AIMING ADJUSTMENT SCREW

AWLIA2171ZZ

A. Adjusting screw (LH) B. Adjusting screw (RH)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1752 of 3641

EXL-100

< PERIODIC MAINTENANCE >

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

InspectionINFOID:0000000012432830

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment procedure, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from fog lamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

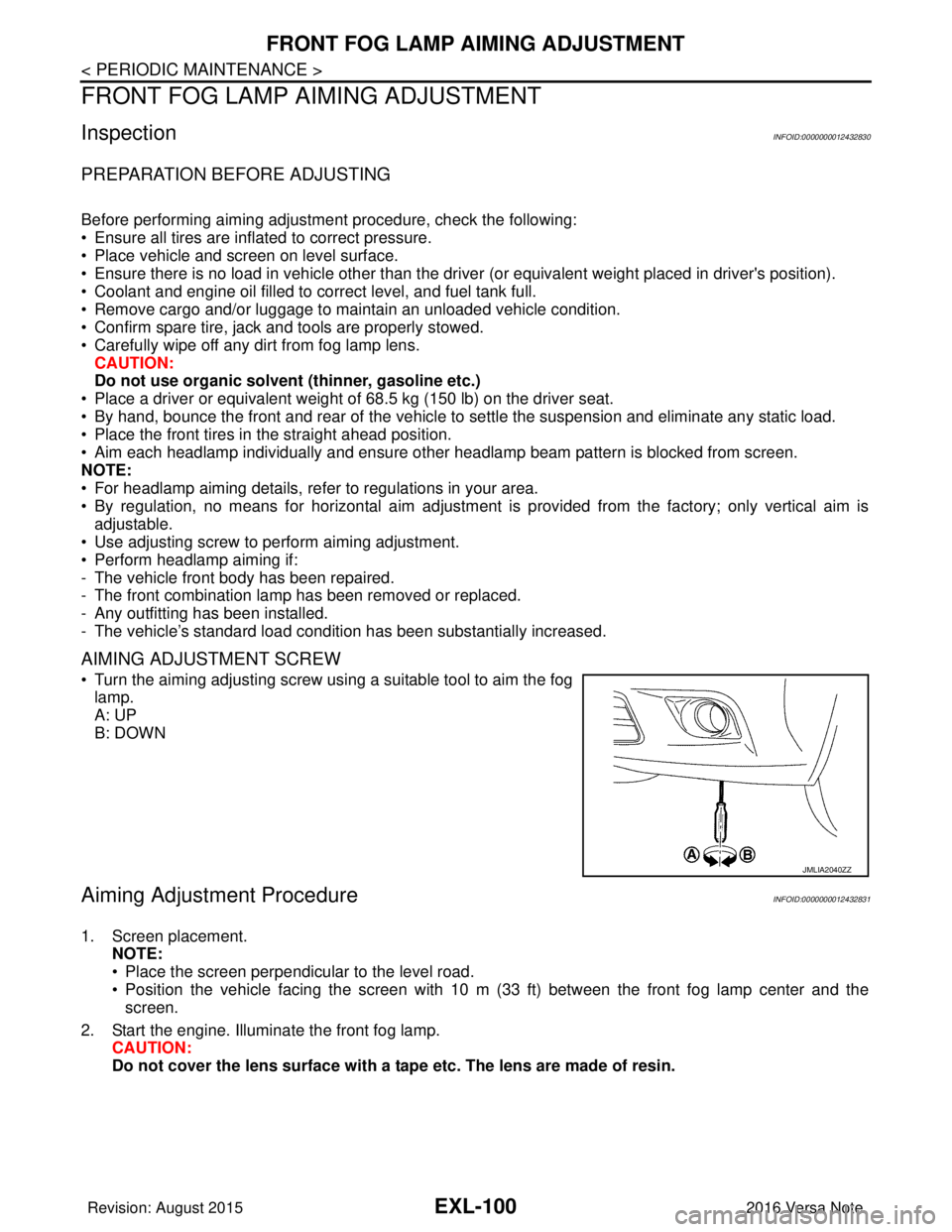

AIMING ADJUSTMENT SCREW

• Turn the aiming adjusting screw using a suitable tool to aim the fog

lamp.

A: UP

B: DOWN

Aiming Adjustment ProcedureINFOID:0000000012432831

1. Screen placement. NOTE:

• Place the screen perpendicular to the level road.

• Position the vehicle facing the screen with 10 m (33 ft) between the front fog lamp center and thescreen.

2. Start the engine. Illuminate the front fog lamp. CAUTION:

Do not cover the lens surface with a tape etc. The lens are made of resin.

JMLIA2040ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1823 of 3641

FAX-6

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

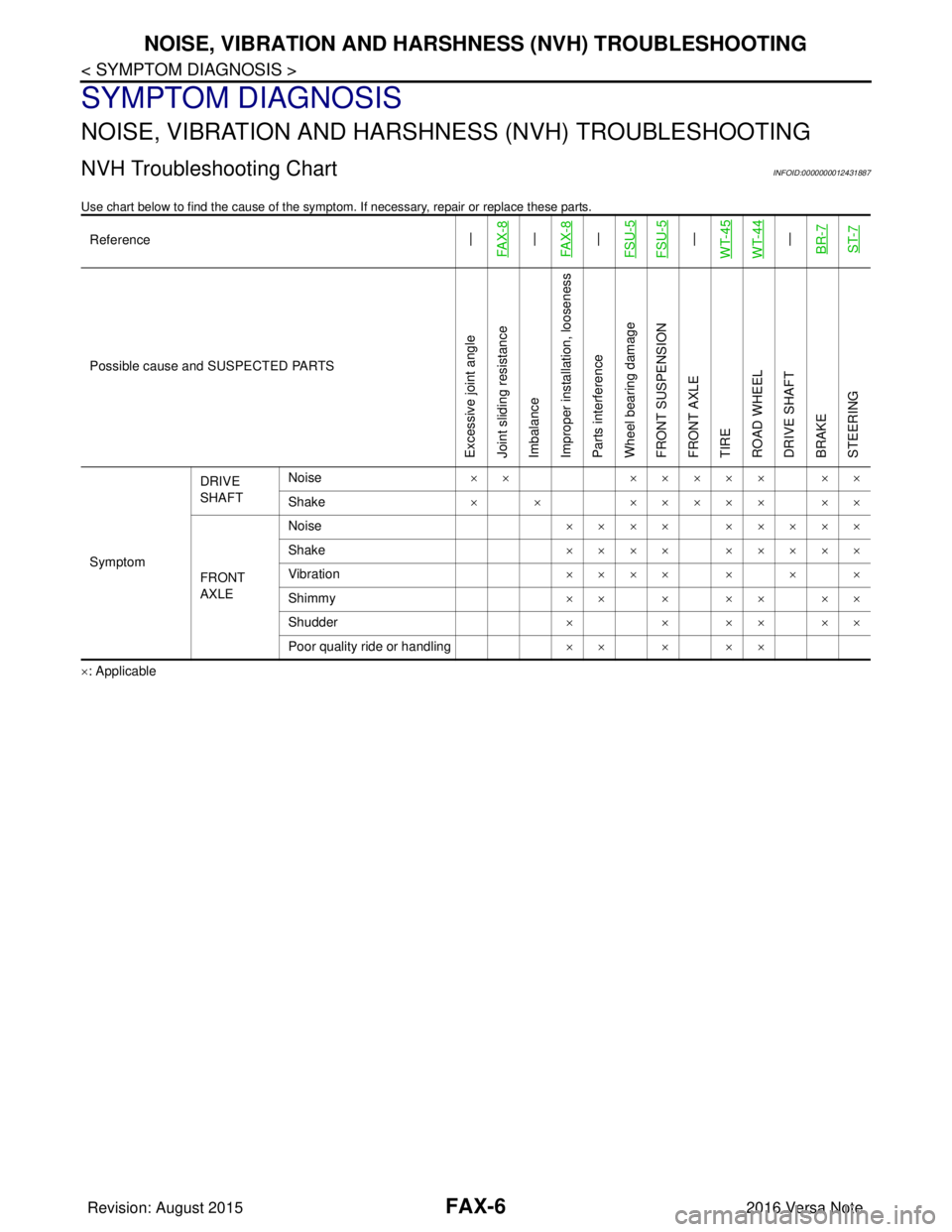

NVH Troubleshooting ChartINFOID:0000000012431887

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference

—

FAX-8—

FAX-8—

FSU-5FSU-5—

WT-45WT-44—

BR-7ST-7

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

FRONT SUSPENSION

FRONT AXLE

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

Symptom DRIVE

SHAFT

Noise

××××××× ××

Shake × × ××××× ××

FRONT

AXLE Noise

×××× ×××××

Shake ×××× ×××××

Vibration ×××××××

Shimmy ×××××××

Shudder × × ×× ××

Poor quality ride or handling ×××××

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1846 of 3641

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

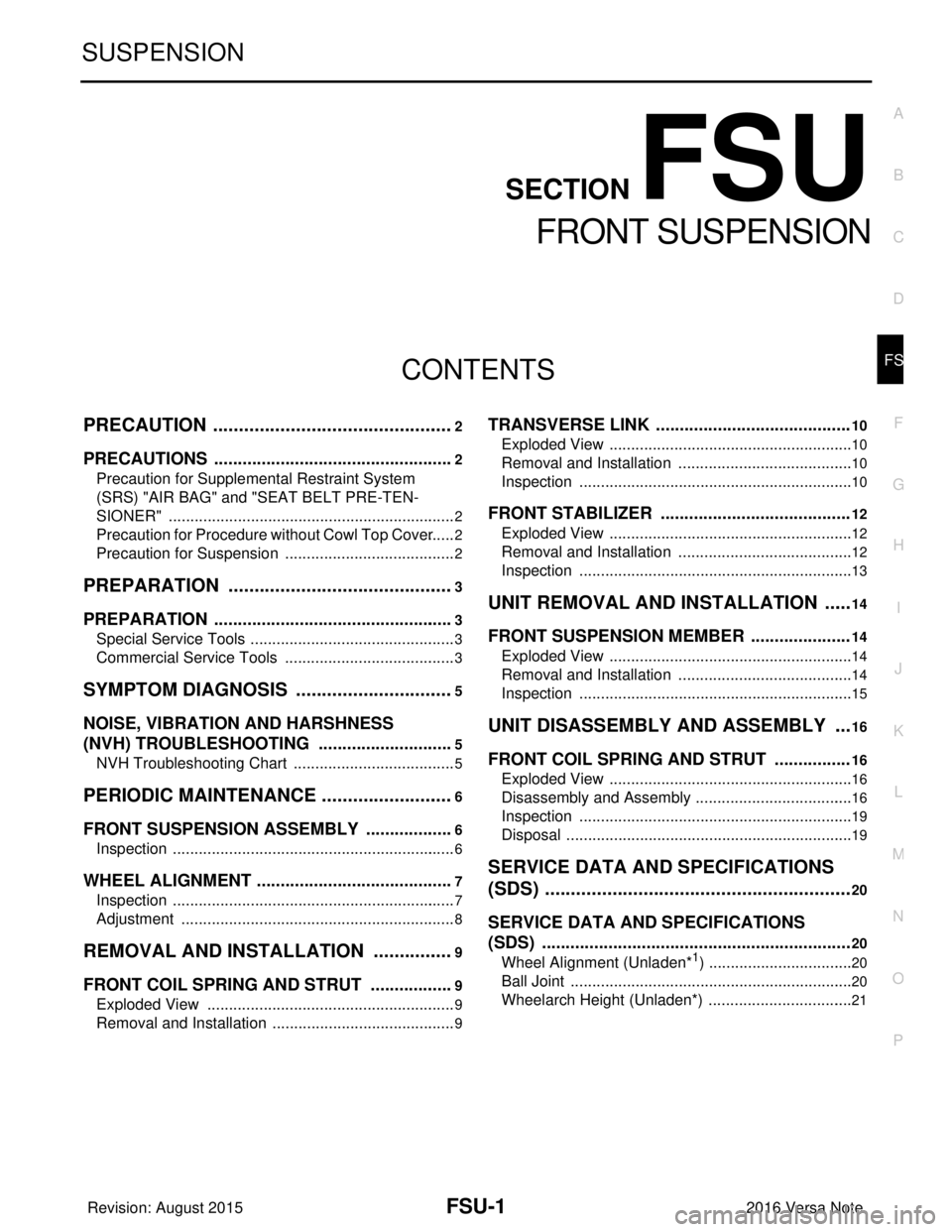

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Procedure without Cowl Top Cover ......2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tools .......................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

PERIODIC MAINTENANCE ..........................6

FRONT SUSPENSION ASSEMBLY .............. .....6

Inspection ............................................................ ......6

WHEEL ALIGNMENT ..........................................7

Inspection ............................................................ ......7

Adjustment ................................................................8

REMOVAL AND INSTALLATION ................9

FRONT COIL SPRING AND STRUT ............. .....9

Exploded View .................................................... ......9

Removal and Installation ...........................................9

TRANSVERSE LINK .........................................10

Exploded View ..................................................... ....10

Removal and Installation .........................................10

Inspection ................................................................10

FRONT STABILIZER ........................................12

Exploded View .........................................................12

Removal and Installation .........................................12

Inspection ................................................................13

UNIT REMOVAL AND INSTALLATION ......14

FRONT SUSPENSION MEMBER .....................14

Exploded View ..................................................... ....14

Removal and Installation .........................................14

Inspection ................................................................15

UNIT DISASSEMBLY AND ASSEMBLY ....16

FRONT COIL SPRING AND STRUT ................16

Exploded View ..................................................... ....16

Disassembly and Assembly .....................................16

Inspection ................................................................19

Disposal ...................................................................19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

20

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Wheel Alignment (Unladen*1) ..................................20

Ball Joint .............................................................. ....20

Wheelarch Height (Unladen*) ..................................21

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1847 of 3641

FSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430294

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000012430295

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precaution for SuspensionINFOID:0000000012430296

• When installing rubber bushings, the final tightening mu st be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

• When jacking up the vehicle with a floor jack, do not hang the jack on the torque rod.

PIIB3706J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1850 of 3641

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGFSU-5

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

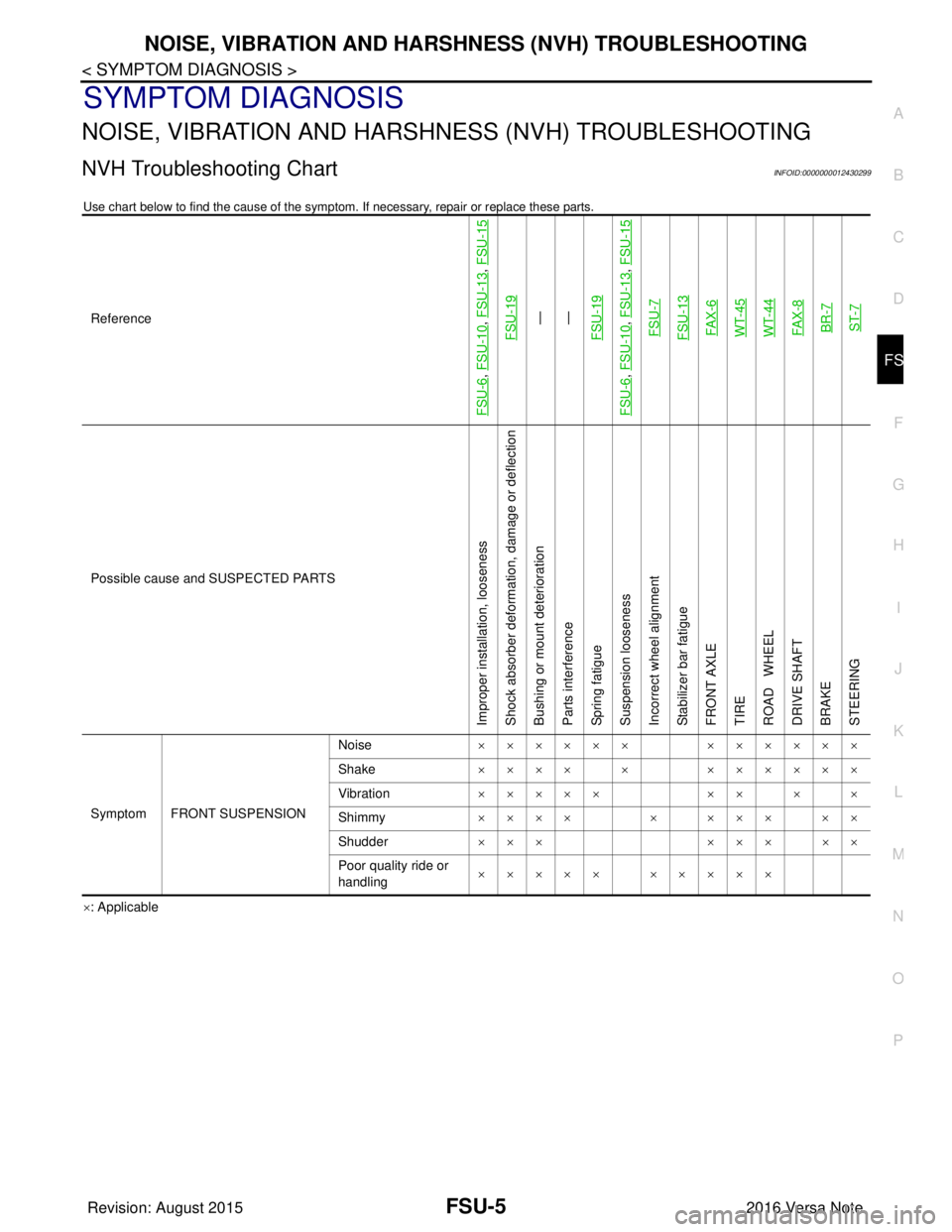

NVH Troubleshooting ChartINFOID:0000000012430299

Use chart below to find the cause of the symptom . If necessary, repair or replace these parts.

×: ApplicableReference

FSU-6

, FSU-10

, FSU-13

,

FSU-15

FSU-19

—

—

FSU-19

FSU-6

, FSU-10

, FSU-13

, FSU-15

FSU-7FSU-13FA X - 6WT-45WT-44FA X - 8BR-7ST-7

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mount deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

FRONT AXLE

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

Symptom FRONT SUSPENSION Noise

×××××× ××××××

Shake ×××× × ××××××

Vibration ××××× ×× × ×

Shimmy ×××× × ××× ××

Shudder ××× ××× ××

Poor quality ride or

handling ××××× ×××××

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1852 of 3641

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000012430301

PRELIMINARY INSPECTION

WARNING:

Always adjust the wheel alignment with the vehicle on a flat surface.

NOTE:

If the wheel alignment is out of s pecification, inspect and replace any damaged or worn rear suspension parts

before making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, engine coolant, and lubricants are full; the spare tire, jack, hand tools and mats are in

designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-54, "

Wheel".

4. Check the wheel bearing axial end play. Refer to FAX-27, "

Wheel Bearing".

5. Check the shock absorbers for leaks or damage.

6. Check each mount point of the suspension co mponents for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-21, "

Wheelarch Height (Unladen*)".

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-20, "Wheel

Alignment (Unladen*1)".

• When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

- The alignment specifications programmed into your alignment machine that operate these indicators may

not be correct.

- This may result in an ERROR.

• Most camera-type alignment machines are equipped with "Rolling Compensation" method and optional

"Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

- If using the "Rolling Compensation" method, after inst alling the alignment targets or head units, push or pull

on the rear wheel to move the vehicle. Do not push or pull on the vehicle body.

- If using the "Jacking Compensation" method, after inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn in either direction.

NOTE:

Do not use the "Rolling Compensation" method if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, set the front wheels onto a turning radius gauge. Set the rear wheels onto a pad that has

the same height so the vehicle will remain horizontal.

TOTAL TOE-IN INSPECTION

Measure the total toe-in using the following procedure.

Revision: August 2015 2016 Versa Note

cardiagn.com