air suspension NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2722 of 3641

RAX-4

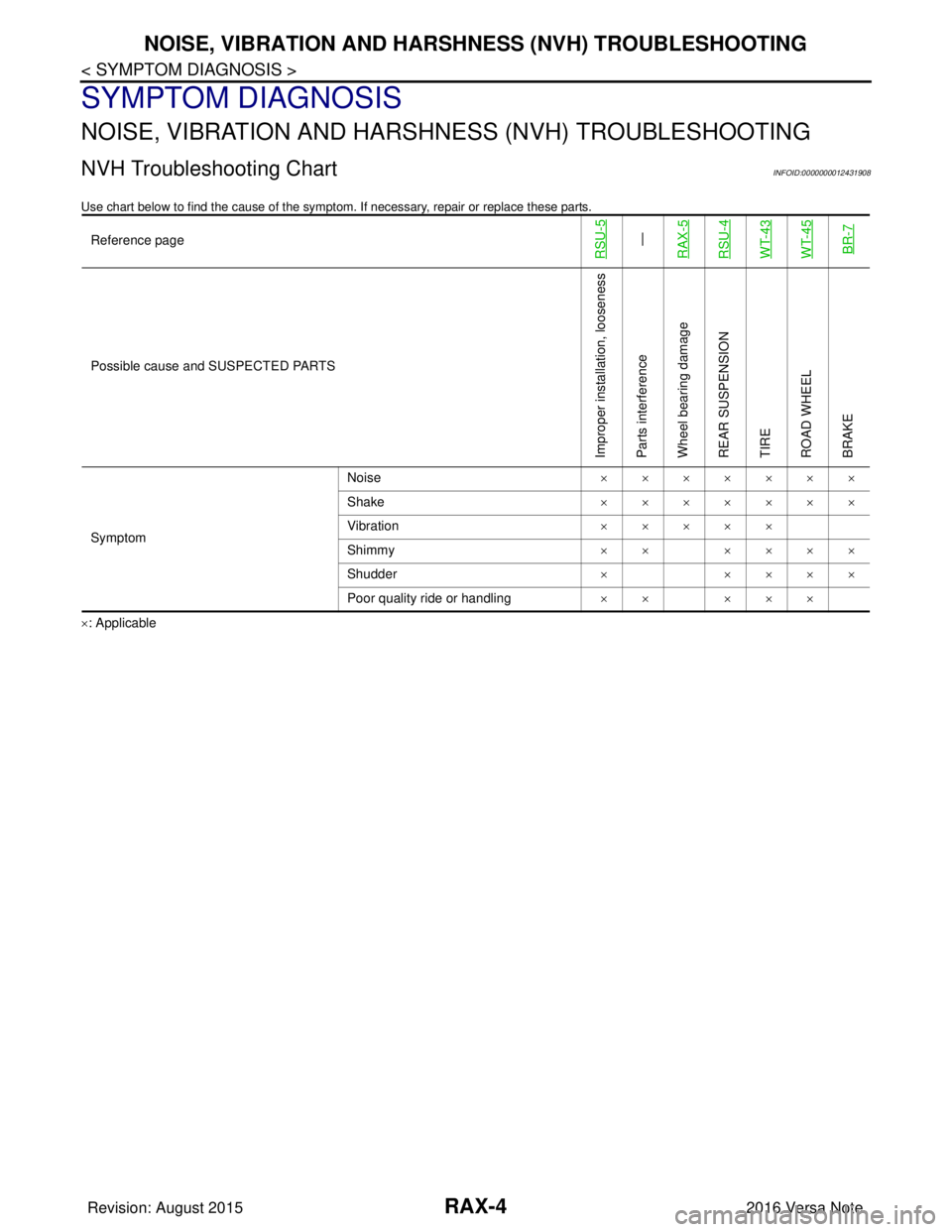

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000012431908

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-5—

RAX-5RSU-4WT-43WT-45BR-7

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Parts interference

Wheel bearing damage

REAR SUSPENSION

TIRE

ROAD WHEEL

BRAKE

Symptom Noise

×××××××

Shake ×××××××

Vibration ×××××

Shimmy ×× ××××

Shudder ×××× ×

Poor quality ride or handling ×× ×××

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2729 of 3641

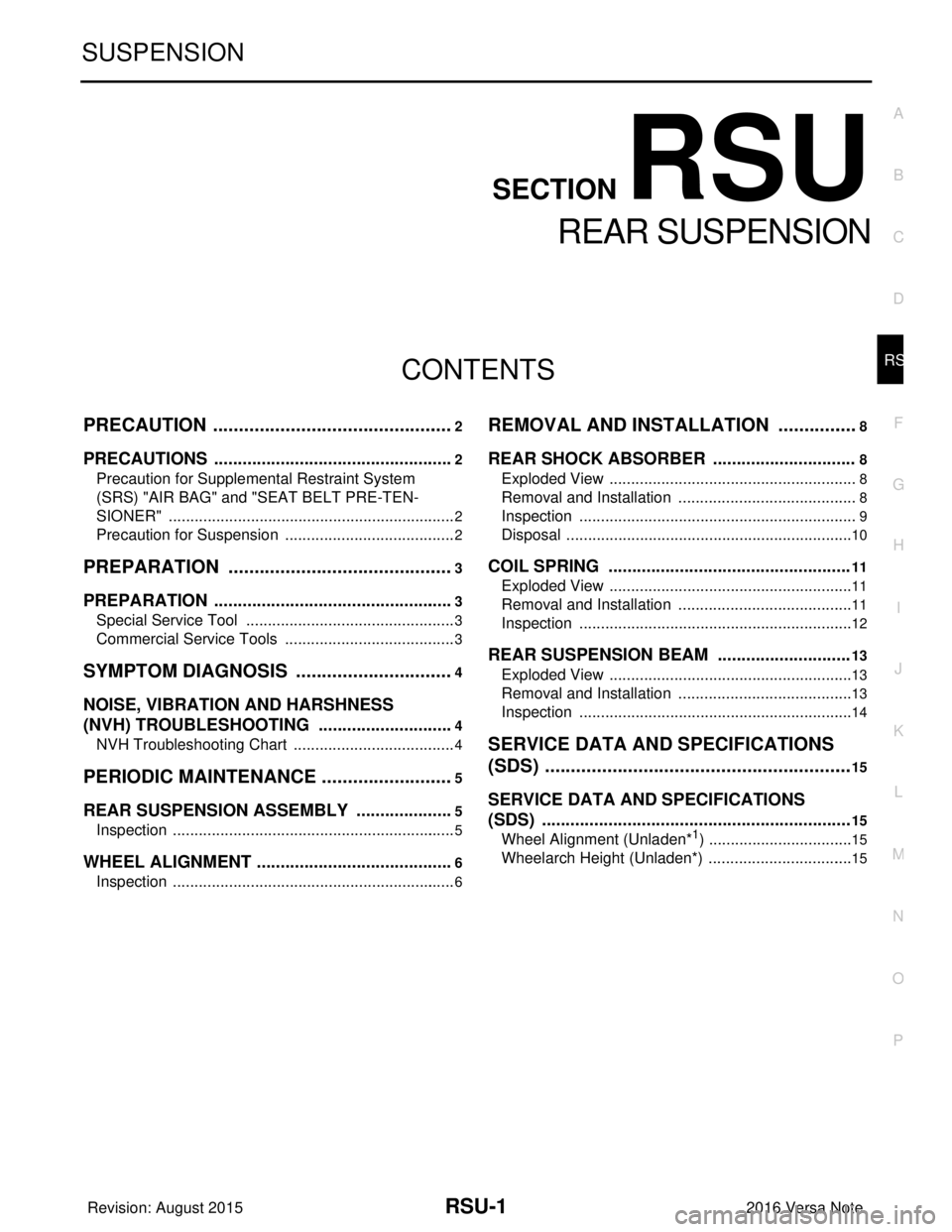

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Suspension ........................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

4

NVH Troubleshooting Chart ................................ ......4

PERIODIC MAINTENANCE ..........................5

REAR SUSPENSION ASSEMBLY ................ .....5

Inspection ............................................................ ......5

WHEEL ALIGNMENT ..........................................6

Inspection ............................................................ ......6

REMOVAL AND INSTALLATION ................8

REAR SHOCK ABSORBER ..............................8

Exploded View ..................................................... .....8

Removal and Installation ..........................................8

Inspection .................................................................9

Disposal ...................................................................10

COIL SPRING ...................................................11

Exploded View .........................................................11

Removal and Installation .........................................11

Inspection ................................................................12

REAR SUSPENSION BEAM ............................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................14

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

15

Wheel Alignment (Unladen*1) ..................................15

Wheelarch Height (Unladen*) .............................. ....15

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2730 of 3641

RSU-2

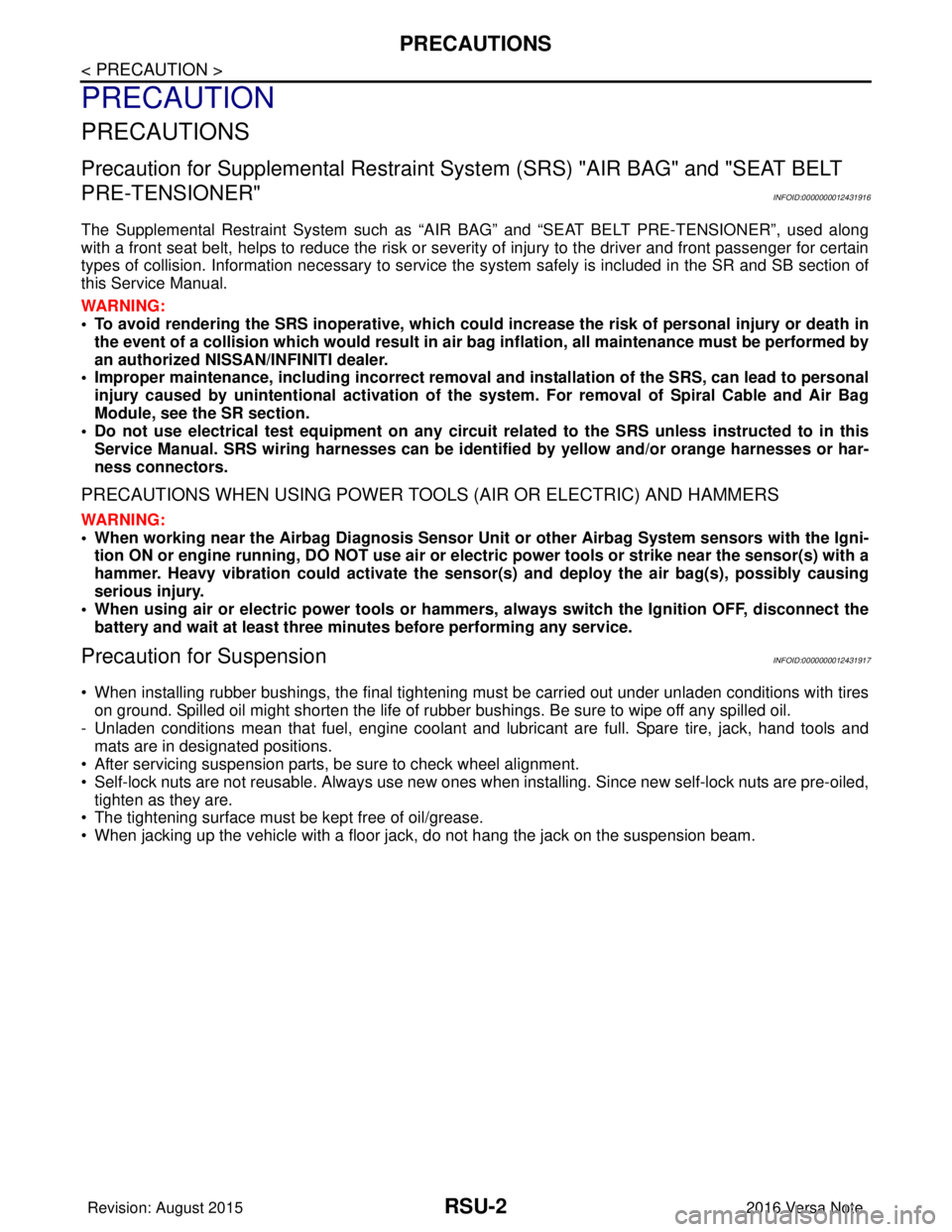

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431916

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for SuspensionINFOID:0000000012431917

• When installing rubber bushings, the final tightening mu st be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

• The tightening surface must be kept free of oil/grease.

• When jacking up the vehicle with a floor jack, do not hang the jack on the suspension beam.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2732 of 3641

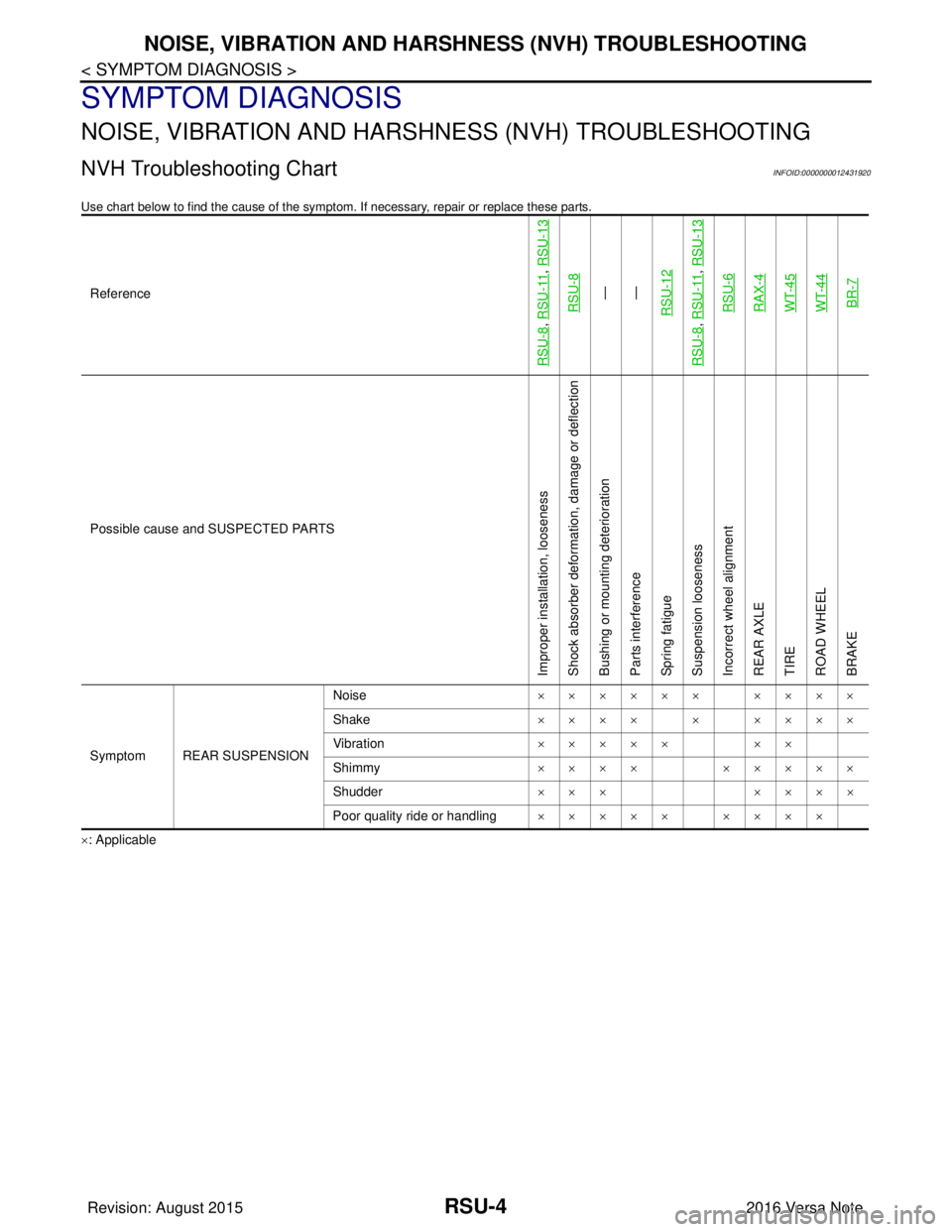

RSU-4

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000012431920

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference

RSU-8

,

RSU-11

, RSU-13

RSU-8—

—

RSU-12

RSU-8

, RSU-11

, RSU-13

RSU-6RAX-4WT-45WT-44BR-7

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

REAR AXLE

TIRE

ROAD WHEEL

BRAKE

Symptom REAR SUSPENSION Noise

×××××× ××××

Shake ×××× × ××××

Vibration ××××× ××

Shimmy ×××× ×××××

Shudder ××× ××××

Poor quality ride or handling ××××× ××××

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2734 of 3641

RSU-6

< PERIODIC MAINTENANCE >

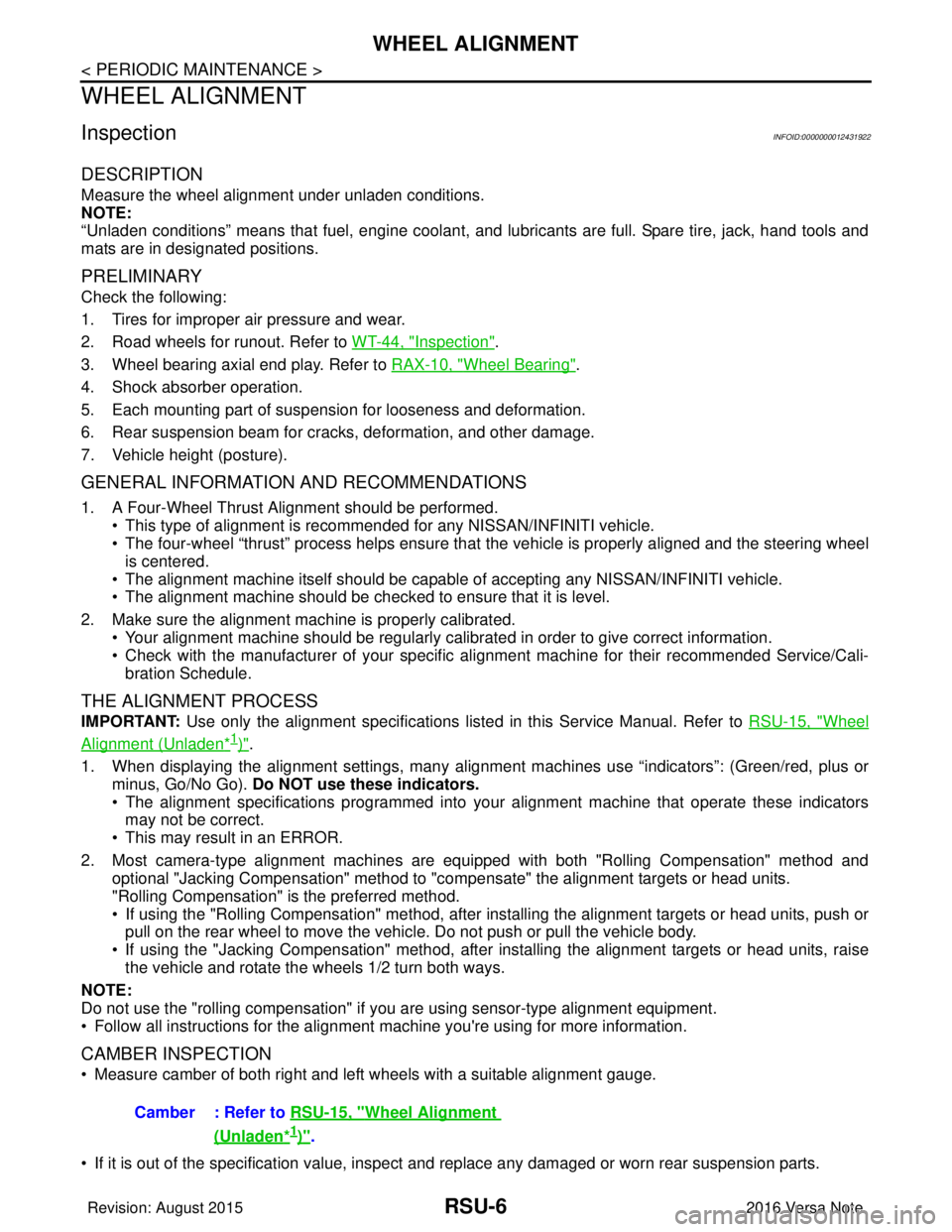

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000012431922

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-44, "

Inspection".

3. Wheel bearing axial end play. Refer to RAX-10, "

Wheel Bearing".

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed. • This type of alignment is recommended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capabl e of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific al ignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-15, "Wheel

Alignment (Unladen*1)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Most camera-type alignment machines are equipped with both "Rolling Compensation" method and optional "Jacking Compensation" method to "com pensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

• If using the "Rolling Compensation" method, after installing the alignment targets or head units, push or pull on the rear wheel to move the vehicle. Do not push or pull the vehicle body.

• If using the "Jacking Compensation" method, after in stalling the alignment targets or head units, raise

the vehicle and rotate the wheels 1/2 turn both ways.

NOTE:

Do not use the "rolling compensation" if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER INSPECTION

• Measure camber of both right and left wheels with a suitable alignment gauge.

• If it is out of the specificati on value, inspect and replace any damaged or worn rear suspension parts.

Camber : Refer to RSU-15, "

Wheel Alignment

(Unladen*1)".

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2744 of 3641

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

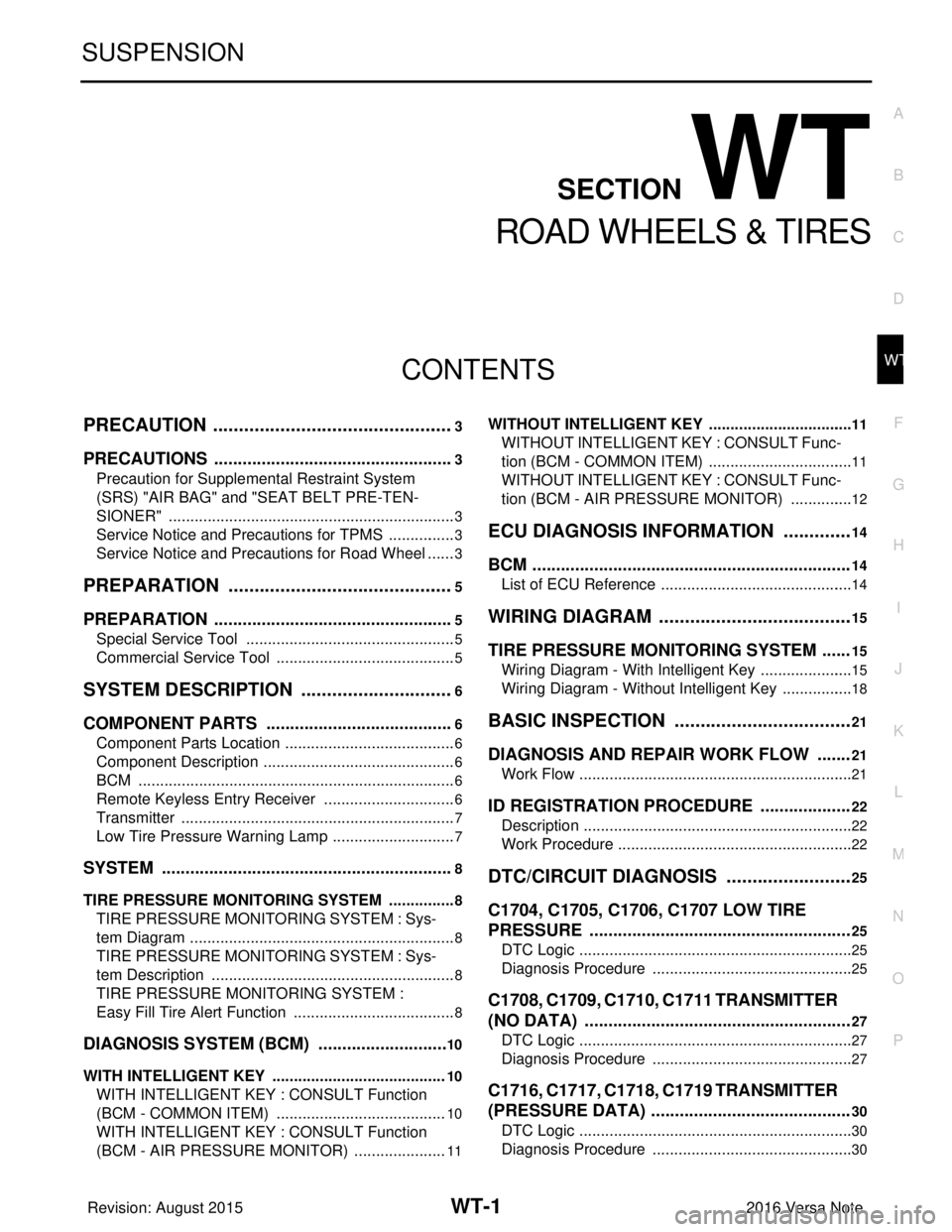

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for TPMS ................3

Service Notice and Precautions for Road Wheel ......3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

BCM ..........................................................................6

Remote Keyless Entry Receiver ...............................6

Transmitter ................................................................7

Low Tire Pressure Warning Lamp .............................7

SYSTEM ......................................................... .....8

TIRE PRESSURE MONITORING SYSTEM .......... ......8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Diagram ..............................................................

8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Description .........................................................

8

TIRE PRESSURE MONITORING SYSTEM :

Easy Fill Tire Alert Function ......................................

8

DIAGNOSIS SYSTEM (BCM) ............................10

WITH INTELLIGENT KEY ..................................... ....10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - COMMON ITEM) ........................................

10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - AIR PRESSURE MONITOR) ......................

11

WITHOUT INTELLIGENT KEY .............................. ....11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - COMMON ITEM) ..................................

11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - AIR PRESSURE MONITOR) ...............

12

ECU DIAGNOSIS INFORMATION ..............14

BCM ...................................................................14

List of ECU Reference ......................................... ....14

WIRING DIAGRAM ......................................15

TIRE PRESSURE MONITORING SYSTEM ......15

Wiring Diagram - With Inte lligent Key ......................15

Wiring Diagram - Without Intelligent Ke y .................18

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORK FLOW .......21

Work Flow ............................................................ ....21

ID REGISTRATION PROCEDURE ...................22

Description ...............................................................22

Work Procedure .......................................................22

DTC/CIRCUIT DIAGNOSIS .........................25

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

25

DTC Logic ............................................................ ....25

Diagnosis Procedure ...............................................25

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

30

DTC Logic ............................................................ ....30

Diagnosis Procedure ...............................................30

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2786 of 3641

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-43

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

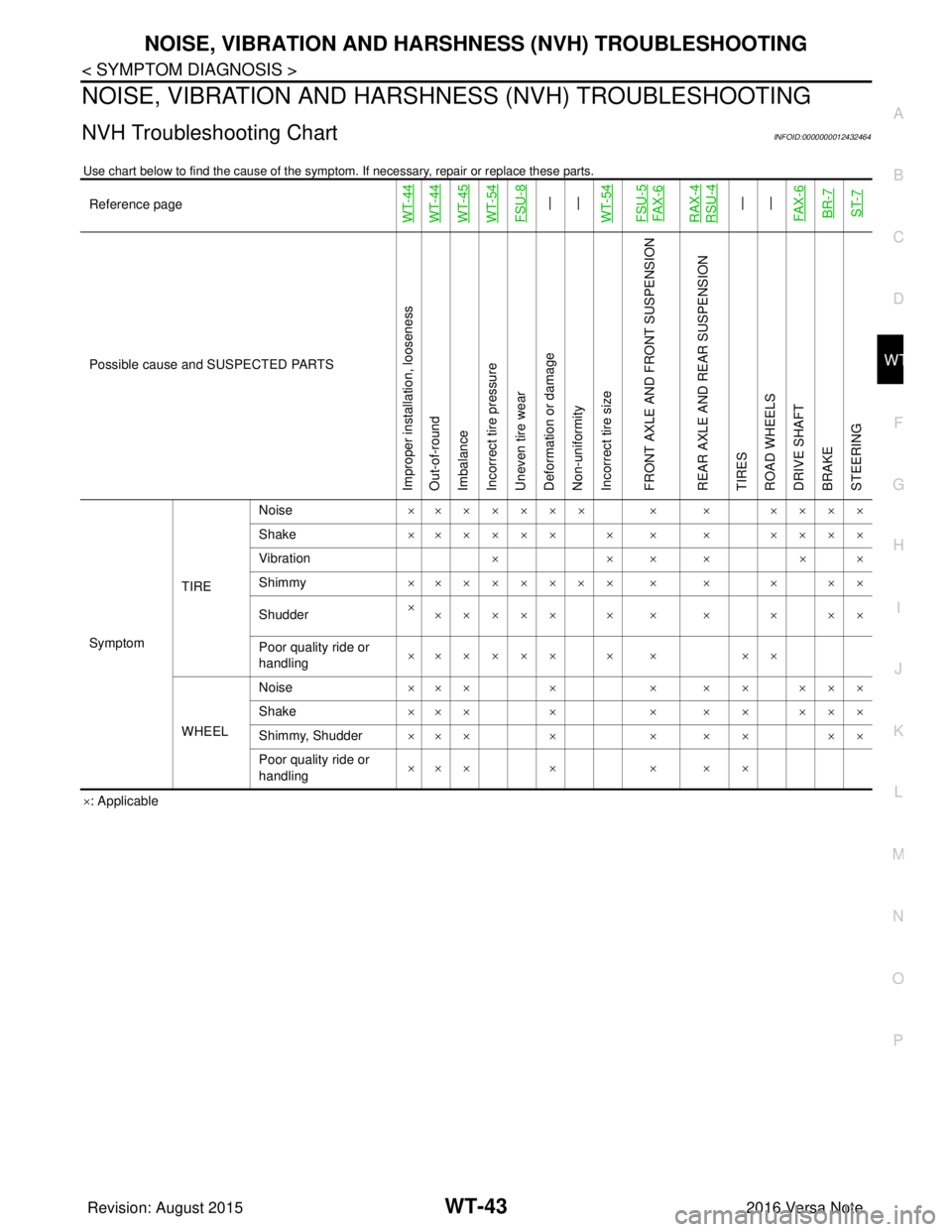

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000012432464

Use chart below to find the cause of the symptom . If necessary, repair or replace these parts.

×: Applicable

Reference page

WT-44WT-44WT-45WT-54FSU-8—

—

WT-54FSU-5FA X - 6RAX-4RSU-4—

—

FA X - 6BR-7ST-7

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRENoise

××××××× × × ××××

Shake ×××××× × × × ××××

Vibration ××××××

Shimmy ×××××××× × × × ××

Shudder ×

××××× × × × × ××

Poor quality ride or

handling ×××××× × × ××

WHEEL Noise

××× × × × × ×××

Shake ××× × × × × ×××

Shimmy, Shudder ×××× ×××××

Poor quality ride or

handling ×× × ×

× × ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3187 of 3641

PRECAUTIONSSTC-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

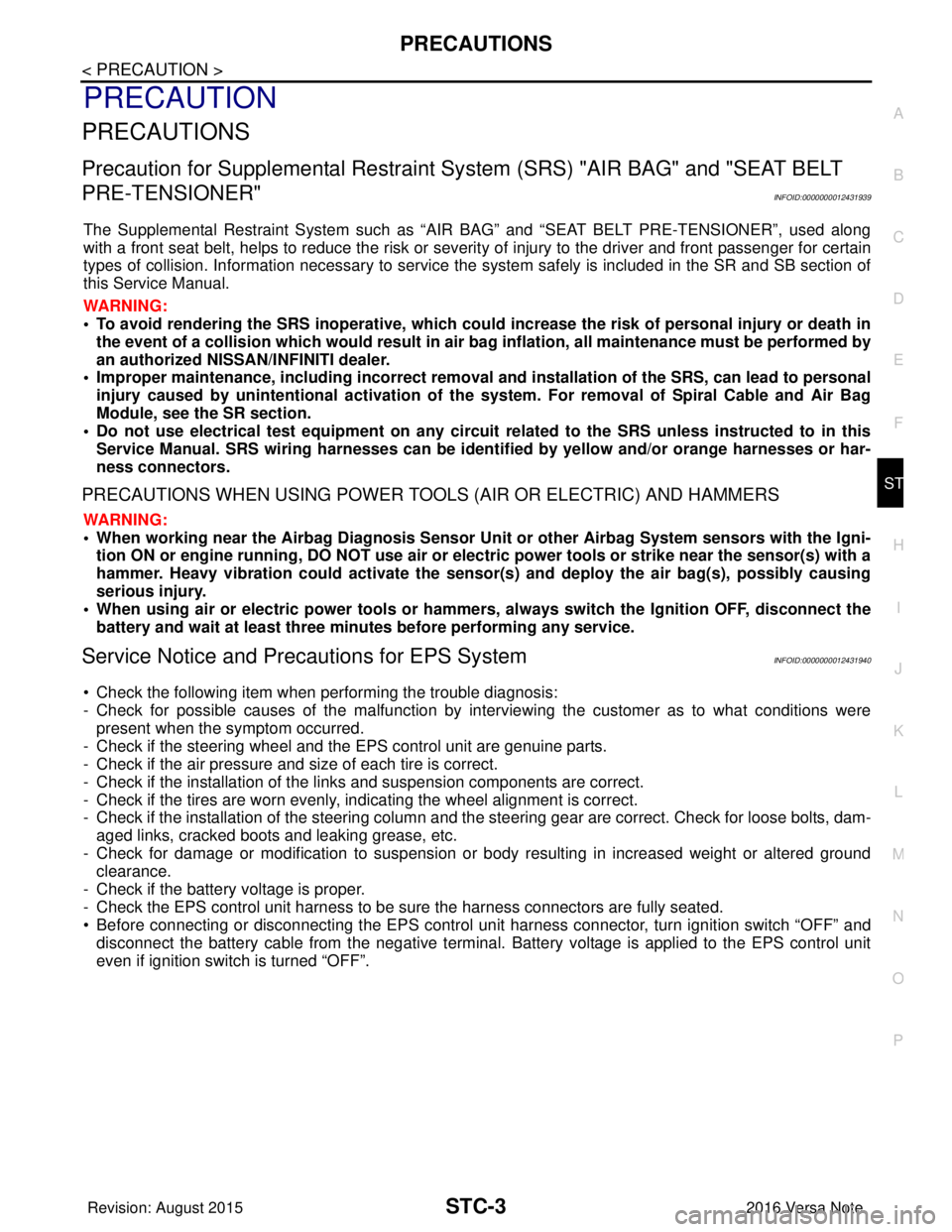

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431939

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for EPS SystemINFOID:0000000012431940

• Check the following item when performing the trouble diagnosis:

- Check for possible causes of the malfunction by inte rviewing the customer as to what conditions were

present when the symptom occurred.

- Check if the steering wheel and the EPS control unit are genuine parts.

- Check if the air pressure and size of each tire is correct.

- Check if the installation of the links and suspension components are correct.

- Check if the tires are worn evenly, indicating the wheel alignment is correct.

- Check if the installation of the steering column and t he steering gear are correct. Check for loose bolts, dam-

aged links, cracked boots and leaking grease, etc.

- Check for damage or modification to suspension or body resulting in increased weight or altered ground clearance.

- Check if the battery voltage is proper.

- Check the EPS control unit harness to be sure the harness connectors are fully seated.

• Before connecting or disconnecting the EPS control uni t harness connector, turn ignition switch “OFF” and

disconnect the battery cable from the negative terminal. Battery voltage is applied to the EPS control unit

even if ignition switch is turned “OFF”.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3226 of 3641

STEERING WHEELST-5

< BASIC INSPECTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

BASIC INSPECTION

STEERING WHEEL

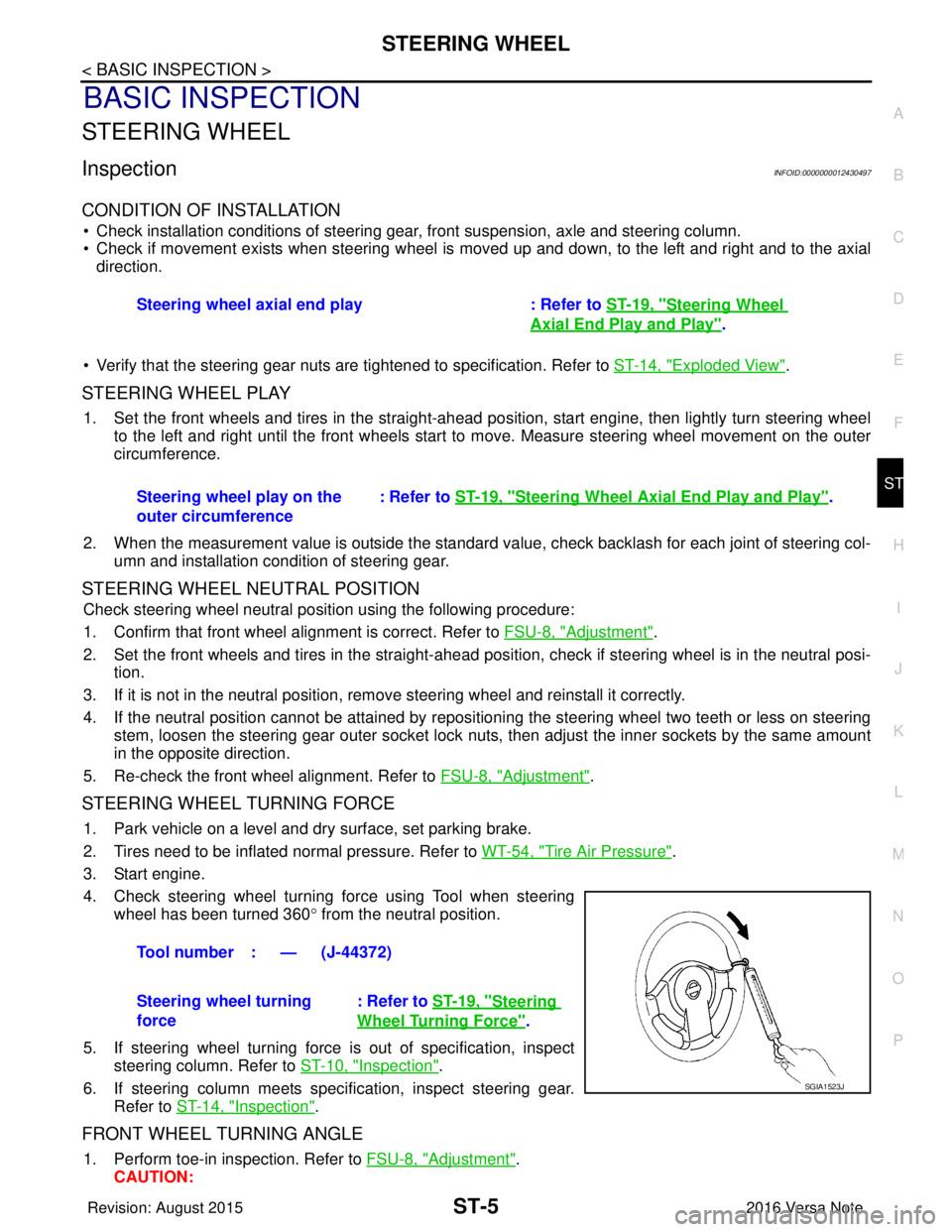

InspectionINFOID:0000000012430497

CONDITION OF INSTALLATION

• Check installation conditions of steering gear, front suspension, axle and steering column.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Verify that the steering gear nuts are tightened to specification. Refer to ST-14, "

Exploded View".

STEERING WHEEL PLAY

1. Set the front wheels and tires in the straight-ahead position, start engine, then lightly turn steering wheel

to the left and right until the front wheels start to move. Measure steering wheel movement on the outer

circumference.

2. When the measurement value is outside the standard va lue, check backlash for each joint of steering col-

umn and installation condition of steering gear.

STEERING WHEEL NEUTRAL POSITION

Check steering wheel neutral position using the following procedure:

1. Confirm that front wheel alignment is correct. Refer to FSU-8, "

Adjustment".

2. Set the front wheels and tires in the straight-ahead posit ion, check if steering wheel is in the neutral posi-

tion.

3. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

4. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen the steering gear outer socket lock nuts, then adjust the inner sockets by the same amount

in the opposite direction.

5. Re-check the front wheel alignment. Refer to FSU-8, "

Adjustment".

STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated normal pressure. Refer to WT-54, "

Tire Air Pressure".

3. Start engine.

4. Check steering wheel turning force using Tool when steering wheel has been turned 360 ° from the neutral position.

5. If steering wheel turning force is out of specification, inspect steering column. Refer to ST-10, "

Inspection".

6. If steering column meets specification, inspect steering gear. Refer to ST-14, "

Inspection".

FRONT WHEEL TURNING ANGLE

1. Perform toe-in inspection. Refer to FSU-8, "Adjustment".

CAUTION: Steering wheel axial end play : Refer to

ST-19, "

Steering Wheel

Axial End Play and Play".

Steering wheel play on the

outer circumference : Refer to

ST-19, "

Steering Wheel Axia l End Play and Play".

Tool number : — (J-44372)

Steering wheel turning

force : Refer to

ST-19, "

Steering

Wheel Turning Force".

SGIA1523J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3228 of 3641

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGST-7

< SYMPTOM DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

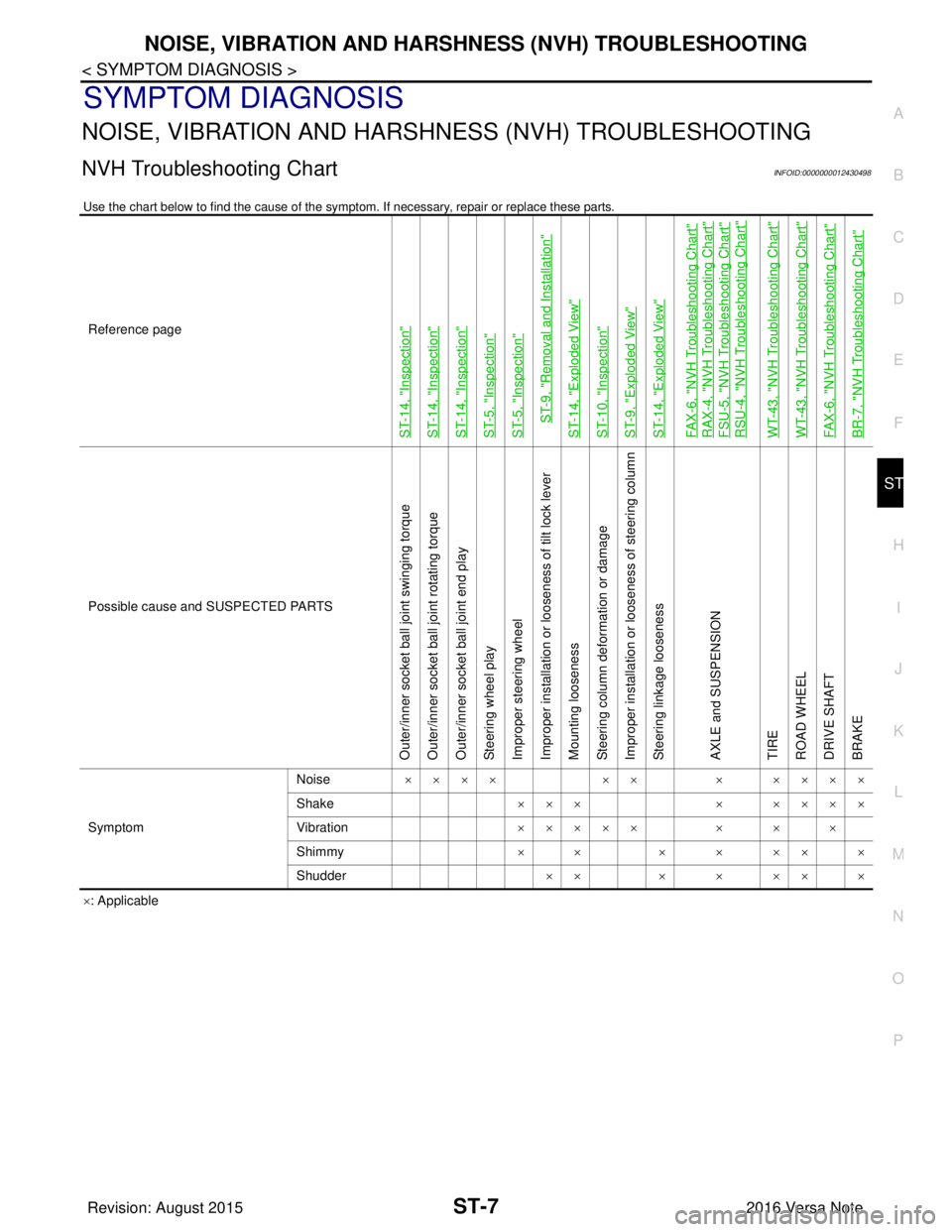

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000012430498

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: Applicable

Reference page

ST-14, "

Inspection

"

ST-14, "

Inspection

"

ST-14, "

Inspection

"

ST-5, "

Inspection

"

ST-5, "

Inspection

"

ST-9, "

Removal and Installation

"

ST-14, "

Exploded View

"

ST-10, "

Inspection

"

ST-9, "

Exploded View

"

ST-14, "

Exploded View

"

FAX-6, "

NVH Troubleshooting Chart

"

RAX-4, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

RSU-4, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

FAX-6, "

NVH Troubleshooting Chart

"

BR-7, "

NVH Troubleshooting Chart

"

Possible cause and

SUSPECTED PARTS

Outer/inner socket ball joint swinging torque

Outer/inner socket ball joint rotating torque

Outer/inner socket ball joint end play

Steering wheel play

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting looseness

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

AXLE and SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

Symptom Noise

×××× ×× × ××××

Shake ×××× ××××

Vibration ××××× × × ×

Shimmy ×× × ××××

Shudder ×× × × ×× ×

Revision: August 2015 2016 Versa Note

cardiagn.com