engine NISSAN PATHFINDER 1997 R50 / 2.G Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: PATHFINDER, Model: NISSAN PATHFINDER 1997 R50 / 2.GPages: 233, PDF Size: 1.9 MB

Page 196 of 233

7,500 miles (12,000 km) for 2WD vehicles and

3,750 miles (6,000 km) for 4WD vehicles.

Wheel alignment and balanceIf the vehicle

should pull to either side while driving on a

straight and level road, or if you detect uneven

or abnormal tire wear, there may be a need for

wheel alignment.

If the steering wheel or seat vibrates at normal

highway speeds, wheel balancing may be

needed.

Windshield wiper blades*Check for cracks

or wear if they do not wipe properly.

Doors and engine hoodCheck that all doors

and the engine hood, operate properly. Also

ensure that all latches lock securely. Lubricate

hinges, latches, rollers and links if necessary.

Make sure that the secondary latch keeps the

hood from opening when the primary latch is

released.

When driving in areas using road salt or other

corrosive materials, check lubrication fre-

quently.INSIDE THE VEHICLE

The maintenance items listed here should be

checked on a regular basis, such as when

performing periodic maintenance, cleaning the

vehicle, etc.

Lights*Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and installed

securely. Also check headlight aim.

Warning lights and buzzers/chimesMake

sure that all warning lights and buzzers/chimes

are operating properly.

Windshield wiper and washer*Check that

the wipers and washer operate properly and

that the wipers do not streak.

Windshield defrosterCheck that the air

comes out of the defroster outlets properly and

in sufficient quantity when operating the heater

or air conditioner.

Steering wheelCheck for changes in the

steering conditions, such as excessive free-

play, hard steering or strange noises.

SeatsCheck seat position controls such as

seat adjusters, seatback recliner, etc. to en-

sure they operate smoothly and that all latches

lock securely in every position. Check that the

head restraints move up and down smoothlyand that the locks (if so equipped) hold se-

curely in all latched positions.

Seat beltsCheck that all parts of the seat belt

system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and

are installed securely. Check the belt webbing

for cuts, fraying, wear or damage.

Accelerator pedalCheck the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort. Keep

the floor mats away from the pedal.

Clutch pedal*Make sure the pedal operates

smoothly and check that it has the proper free

travel.

BrakesCheck that the brakes do not pull the

vehicle to one side when applied.

Brake pedal and booster*Check the pedal

for smooth operation and make sure it has the

proper distance under it when depressed fully.

Check the brake booster function. Be certain

to keep floormats away from the pedal.

Parking brake*Check that the lever has the

proper travel and confirm that your vehicle is

held securely on a fairly steep hill with only the

parking brake applied.

Automatic transmission ªPark positionº

mechanismOn a fairly steep hill check that

8-3

Z01.2.1/R50-DX

Page 197 of 233

your vehicle is held securely with the selector

lever in the ªPº position without applying any

brakes.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be

checked periodically e.g. each time you check

the engine oil or refuel.

Windshield washer fluid*Check that there is

adequate fluid in the tank.

Engine coolant level*Check the coolant level

when the engine is cold.

Radiator and hosesCheck the front of the

radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure

the hoses have no cracks, deformation, rot or

loose connections.

Brake and clutch fluid levels*Make sure that

the brake and clutch fluid level is between the

ªMAXº and ªMINº lines on the reservoir.

Battery*Check the fluid level in each cell. It

should be between the ªMAXº and ªMINº lines.

Engine drive belts*Make sure that no belt is

frayed, worn, cracked or oily.

Engine oil level*Check the level after parking

the vehicle on a level spot and turning off the

engine. (Be sure to wait a few minutes to allowthe oil to drain back into the sump.)

Power steering fluid level* and linesCheck

the level when the fluid is cold and the engine

is turned off. Check the lines for proper attach-

ment, leaks, cracks, etc.

Automatic transmission fluid level*Check

the level after putting the selector lever in ªPº

with the engine idling.

Exhaust systemMake sure there are no

loose supports, cracks or holes. If the sound of

the exhaust seems unusual or there is a smell

of exhaust fumes, immediately locate the

trouble and correct it. (See the carbon monox-

ide warning in the ªStarting and drivingº sec-

tion)

UnderbodyThe underbody is frequently ex-

posed to corrosive substances such as those

used on icy roads or to control dust. It is very

important to remove these substances, other-

wise rust will form on the floor pan, frame, fuel

lines and around the exhaust system. At the

end of winter, the underbody should be thor-

oughly flushed with plain water, being careful

to clean those areas where mud and dirt may

accumulate. See the ªAppearance and Interior

Careº section for additional information.

Fluid leaksCheck under the vehicle for fuel,

oil, water or other fluid leaks after the vehiclehas been parked for a while. Water dripping

from the air conditioner after use is normal. If

you should notice any leaks or if gasoline

fumes are evident, check for the cause and

have it corrected immediately.

8-4

Z01.2.1/R50-DX

Page 199 of 233

![NISSAN PATHFINDER 1997 R50 / 2.G Manual PDF SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers NISSAN PATHFINDER 1997 R50 / 2.G Manual PDF SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers](/img/5/603/w960_603-198.png)

SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles´1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km´1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

Emission control system maintenance

Drive beltsI* I*

Air cleaner filter See NOTE (1) [R] [R]

Vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (2)*

Engine coolant See NOTE (3)R*

Engine oilRRRRRRRRRRRRRRRR

Engine oil filter

(Use Part No. 15208 31U00 or equivalent.)RRRRRRRRRRRRRRRR

Spark plugs[R] [R]

Timing beltReplace every 105,000 miles (168,000 km)

NOTE: (1) If operating mainly in dusty conditions, more frequent maintenance may be required.

(2) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) Maintenance items and intervals with ª*º are recommended by NISSAN for reliable vehicle operation. The owner need not perform such

maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-6

Z01.2.1/R50-DX

Page 201 of 233

![NISSAN PATHFINDER 1997 R50 / 2.G Manual PDF SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers NISSAN PATHFINDER 1997 R50 / 2.G Manual PDF SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers](/img/5/603/w960_603-200.png)

SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles´1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km´1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Emission control system maintenance

Drive beltsI* I*

Air cleaner filter[R] [R]

Vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (1)*

Engine coolant See NOTE (2)R*

Engine oilRRRRRRRR

Engine oil filter (Use Part No. 15208 31U00 or equivalent.)RRRRRRRR

Spark plugs[R] [R]

Timing beltReplace every 105,000 miles (168,000 km)

NOTE: (1) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or

extremely high, the filters might become clogged. In such an event, replace them immediately.

(2) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(3) Maintenance items and intervals with ª*º are recommended by NISSAN for reliable vehicle operation. The owner need not perform such

maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-8

Z01.2.1/R50-DX

Page 203 of 233

EXPLANATION OF MAINTENANCE

ITEMS

Additional information on the following

items with ª*º is found in the ªDo-it-

yourself operationsº section.

Emission control system

maintenance

Drive belts*Check drive belts for wear, fray-

ing or cracking and also for proper tension.

Replace the drive belts if found damaged.

Air cleaner filterUnder normal driving condi-

tions, the air cleaner filter should be replaced

in accordance with the maintenance schedule.

However, driving the vehicle in dusty areas

may cause more rapid clogging of the element.

Consequently, the element may have to be

replaced more frequently.

Vapor linesCheck vapor lines and connec-

tions for failure or looseness. If leaks are

found, replace the lines.

Fuel linesCheck the fuel hoses, piping and

connections for leaks, looseness or deteriora-

tion. Replace any parts if they are damaged.

Fuel filterIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are either

extremely low or extremely high, the filtermight become clogged. In such an event,

replace the filter immediately.

Engine coolant*Flush and refill the cooling

system.

Engine oil & oil filter*Under normal driving

conditions, the engine oil and oil filter should

be replaced in accordance with the mainte-

nance schedule. However, under severe driv-

ing conditions, they may have to be replaced

more frequently.

Spark plugs*Replace with new plugs having

the correct heat range.

Timing belt

Replace the timing belt for driving the cam-

shafts.

Chassis and body maintenance

Brake lines & cablesCheck the brake lines

and hoses (including brake booster vacuum

hoses, connections & check valve) and park-

ing brake cables for proper attachment, leaks,

cracks, chafing, abrasion, deterioration, etc.

Brake pads, discs, drums & liningsCheck

these and the other neighboring brake compo-

nents for wear, deterioration and leaks. Under

severe driving conditions, they may have to be

inspected more frequently.Manual and automatic transmission, trans-

fer & differential gear oilVisually inspect for

signs of leakage and replace oil for limited-slip

differential. Under severe driving conditions,

the oil should be replaced at the specified

interval.

Steering gear & linkage, axle & suspension

parts & drive axle shaft bootsCheck for

damage, looseness and leakage of oil or

grease. Under severe driving conditions, more

frequent inspection should be performed.

Steering linkage ball joints & front suspen-

sion ball jointsCheck the ball joints for dam-

age, looseness and grease leakage. Under

severe driving conditions, more frequent in-

spection should be performed.

Propeller shaft(s)Check the propeller

shaft(s) for damage, looseness and grease

leakage under severe driving condition

(only).

Propeller shaft greaseApply specified

grease to the greasing points of propeller

shafts in accordance with the maintenance

schedule. In the case of driving in water,

greasing should be performed immediately

afterwards.

Front wheel bearing greaseCheck the wheel

bearing for grease leakage around grease

8-10

Z01.2.1/R50-DX

Page 206 of 233

9 Technical and consumer information

Capacities and recommended fuel/lubricants ......... 9-2

Engine .................................................................. 9-10

Wheels and tires .................................................. 9-11

Dimensions and weights ...................................... 9-12

When traveling or registering your vehicle in

another country .................................................... 9-12

Vehicle identification ............................................ 9-13

Trailer towing ....................................................... 9-16

Towing load/specification chart ............................ 9-18

Emission control system warranty ....................... 9-20

Reporting safety defects (For U.S.A.) ................... 9-20

Readiness for inspection/maintenance

(I/M) test (For U.S.A.) ........................................... 9-21

Z01.2.1/R50-DX

Page 207 of 233

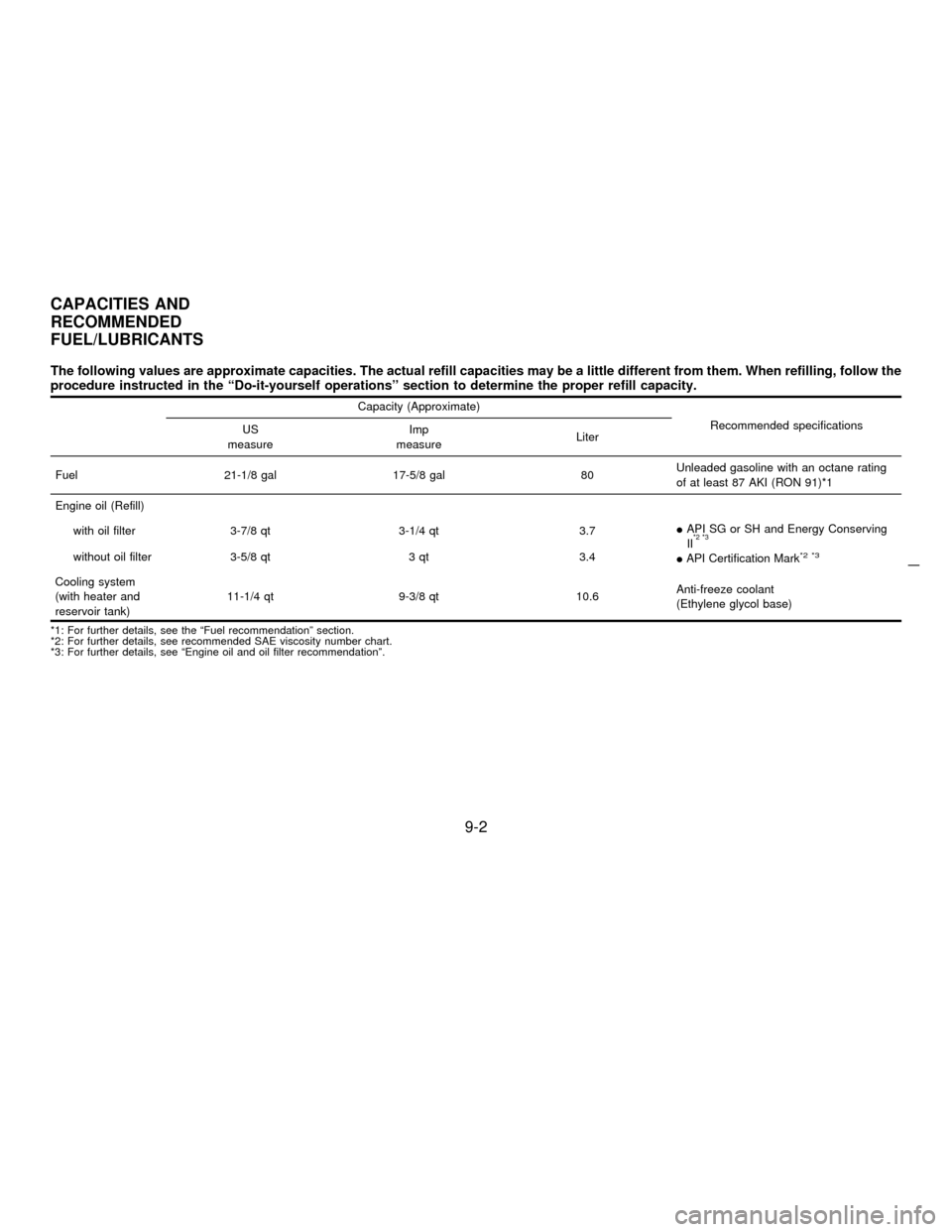

The following values are approximate capacities. The actual refill capacities may be a little different from them. When refilling, follow the

procedure instructed in the ªDo-it-yourself operationsº section to determine the proper refill capacity.

Capacity (Approximate)

Recommended specifications

US

measureImp

measureLiter

Fuel 21-1/8 gal 17-5/8 gal 80Unleaded gasoline with an octane rating

of at least 87 AKI (RON 91)*1

Engine oil (Refill)

with oil filter 3-7/8 qt 3-1/4 qt 3.7IAPI SG or SH and Energy Conserving

II

*2 *3

IAPI Certification Mark*2 *3without oil filter 3-5/8 qt 3 qt 3.4

Cooling system

(with heater and

reservoir tank)11-1/4 qt 9-3/8 qt 10.6Anti-freeze coolant

(Ethylene glycol base)

*1: For further details, see the ªFuel recommendationº section.

*2: For further details, see recommended SAE viscosity number chart.

*3: For further details, see ªEngine oil and oil filter recommendationº.

CAPACITIES AND

RECOMMENDED

FUEL/LUBRICANTS

9-2

Z01.2.1/R50-DX

Page 209 of 233

FUEL RECOMMENDATION

All models are designed to operate on

unleaded gasoline with an octane rating of

at least 87 AKI (Anti-Knock Index) number

(Research octane number 91).

Using a fuel other than that specified

could adversely affect the emission con-

trol devices and systems, and could

also affect the warranty coverage.

Under no circumstances should a

leaded gasoline be used since this will

damage the three-way catalyst.

Reformulated gasoline

Some fuel suppliers are now producing refor-

mulated gasolines. These gasolines are spe-

cially designed to reduce vehicle emissions.

NISSAN supports efforts towards cleaner air

and suggest that you use reformulated gaso-

line when available.

Gasoline containing oxygenates

Some fuel suppliers sell gasoline containing

oxygenates such as ethanol, MTBE andmethanol with or without advertising their pres-

ence. Nissan does not recommend the use of

fuels of which the oxygenate content and the

fuel compatibility for your Nissan cannot be

readily determined.

If you use oxygenate-blend gasoline, please

take the following precautions as the usage of

such fuels may cause vehicle performance

problems and/or fuel system damage.

IThe fuel should be unleaded and have

an octane rating no lower than that rec-

ommended for unleaded gasoline.

IIf an oxygenate-blend, excepting a

methanol blend, is used, it should con-

tain no more than 10% oxygenate.

(MTBE may, however, be added up to

15%.)

IIf a methanol blend is used, it should

contain no more than 5% methanol (me-

thyl alcohol, wood alcohol). It should

also contain a suitable amount of appro-

priate cosolvents and corrosion inhibi-

tors. If not properly formulated with ap-

propriate cosolvents and corrosion

inhibitors, such methanol blends may

cause fuel system damage and/or ve-

hicle performance problems. At this

time, sufficient data is not available to

ensure that all methanol blends are suit-able for use in Nissan vehicles.

If any undesirable driveability problems such

as engine stalling and hard hot starting are

experienced after using oxygenate-blend fu-

els, immediately change to a non-oxygenate

fuel or a fuel with a low blend of MTBE.

Take care not to spill gasoline during refu-

eling. Gasoline containing oxygenates can

cause paint damage.

After market fuel additives

NISSAN does not recommend the use of any

fuel additives (i.e.: fuel injector cleaner, octane

booster, intake valve deposit removers, etc.)

which are sold commercially. Many of these

additives intended for gum, varnish or deposit

removal may contain active solvents or similar

ingredients that can be harmful to the fuel

system and engine.

Octane rating tips

In most parts of North America, you should use

unleaded gasoline with an octane rating of at

least 87 AKI (Anti-Knock Index) number. How-

ever, you may use unleaded gasoline with an

octane rating as low as 85 AKI (Anti-Knock

Index) number in these high altitude areas

[over 4,000 ft (1,219 m)] such as: Colorado,

Montana, New Mexico, Utah, Wyoming, north-

9-4

Z01.2.1/R50-DX

Page 210 of 233

eastern Nevada, southern Idaho, western

South Dakota, western Nebraska, and that

part of Texas which is directly south of New

Mexico.

Using unleaded gasoline with an octane

rating lower than stated above can cause

persistent, heavy ªspark knockº. (ªSpark

knockº is a metallic rapping noise.) If se-

vere, this can lead to engine damage. If you

detect a persistent heavy spark knock even

when using gasoline of the stated octane

rating, or if you hear steady spark knock

while holding a steady speed on level

roads, have your dealer correct the condi-

tion. Failure to correct the condition is

misuse of the vehicle, for which NISSAN is

not responsible.

Incorrect ignition timing will result in knocking,

after-run or overheating. This in turn may

cause excessive fuel consumption or damage

to the engine. If any of the above symptoms

are encountered, have your vehicle checked at

a NISSAN dealer or other competent service

facility.

However, now and then you may notice

light spark knock for a short time while

accelerating or driving up hills. This is no

cause for concern, because you get the

greatest fuel benefit when there is lightspark knock for a short time.

9-5

Z01.2.1/R50-DX

Page 211 of 233

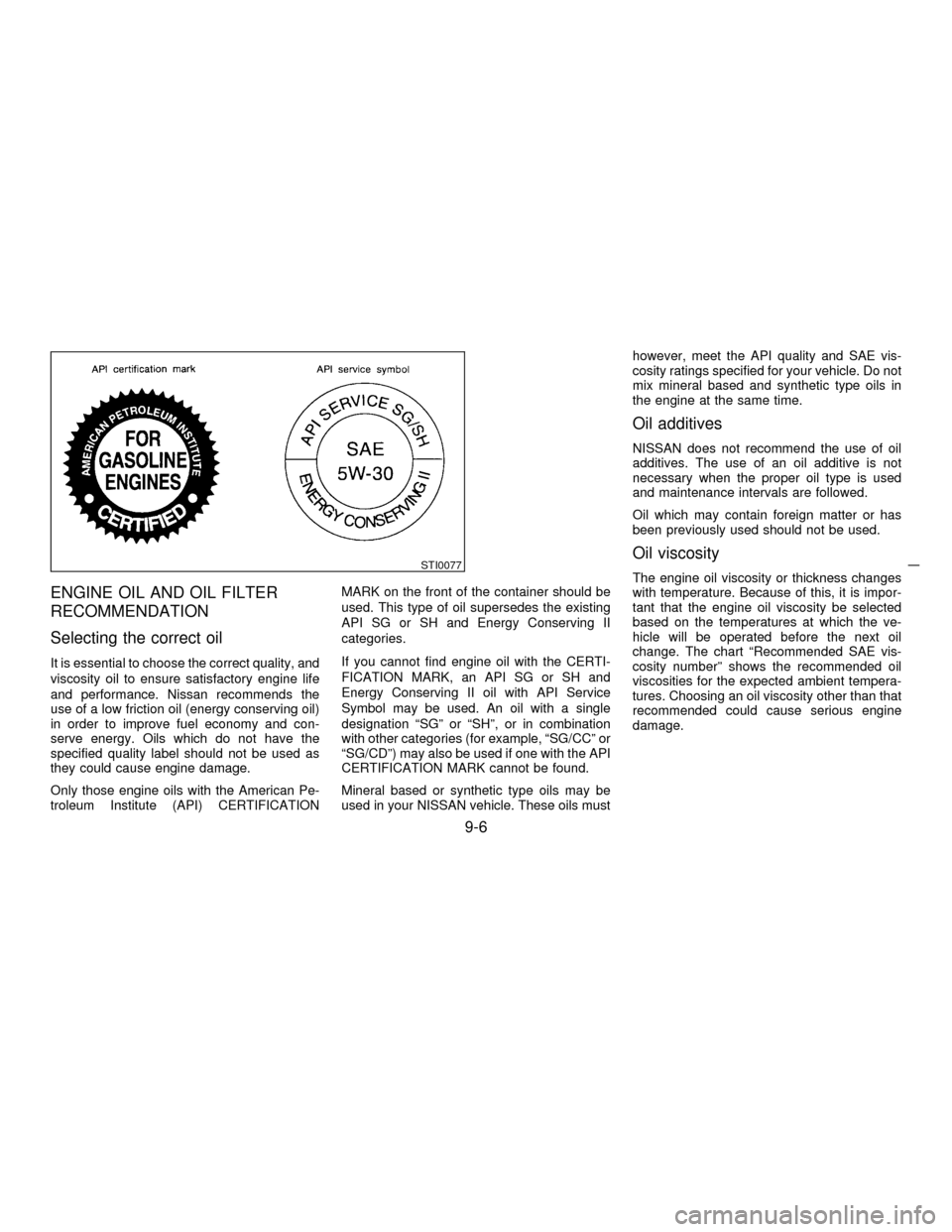

ENGINE OIL AND OIL FILTER

RECOMMENDATION

Selecting the correct oil

It is essential to choose the correct quality, and

viscosity oil to ensure satisfactory engine life

and performance. Nissan recommends the

use of a low friction oil (energy conserving oil)

in order to improve fuel economy and con-

serve energy. Oils which do not have the

specified quality label should not be used as

they could cause engine damage.

Only those engine oils with the American Pe-

troleum Institute (API) CERTIFICATIONMARK on the front of the container should be

used. This type of oil supersedes the existing

API SG or SH and Energy Conserving II

categories.

If you cannot find engine oil with the CERTI-

FICATION MARK, an API SG or SH and

Energy Conserving II oil with API Service

Symbol may be used. An oil with a single

designation ªSGº or ªSHº, or in combination

with other categories (for example, ªSG/CCº or

ªSG/CDº) may also be used if one with the API

CERTIFICATION MARK cannot be found.

Mineral based or synthetic type oils may be

used in your NISSAN vehicle. These oils musthowever, meet the API quality and SAE vis-

cosity ratings specified for your vehicle. Do not

mix mineral based and synthetic type oils in

the engine at the same time.

Oil additives

NISSAN does not recommend the use of oil

additives. The use of an oil additive is not

necessary when the proper oil type is used

and maintenance intervals are followed.

Oil which may contain foreign matter or has

been previously used should not be used.

Oil viscosity

The engine oil viscosity or thickness changes

with temperature. Because of this, it is impor-

tant that the engine oil viscosity be selected

based on the temperatures at which the ve-

hicle will be operated before the next oil

change. The chart ªRecommended SAE vis-

cosity numberº shows the recommended oil

viscosities for the expected ambient tempera-

tures. Choosing an oil viscosity other than that

recommended could cause serious engine

damage.STI0077

9-6

Z01.2.1/R50-DX