wheel torque NISSAN PATHFINDER 1999 R50 / 2.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PATHFINDER, Model: NISSAN PATHFINDER 1999 R50 / 2.GPages: 274, PDF Size: 2.34 MB

Page 183 of 274

INever get under the vehicle while it is

supported only by the jack.

IUse only the jack provided with your

vehicle. Do not use the jack provided

with your vehicle on other vehicles.

The jack is designed only for lifting

your vehicle during a tire change.

IUse the correct jack up points; never

use any other part of the vehicle for

jack support.

INever jack up the vehicle more than

necessary.

INever use blocks on or under the

jack.

IDo not start or run engine while ve-

hicle is on the jack, as it may cause

the vehicle to move. This is especially

true for vehicle with limited slip dif-

ferential carriers.

IDo not allow passengers to stay in

the vehicle while it is on the jack.

Installing the spare tire1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the wheel on and tighten the

wheel nuts finger tight.

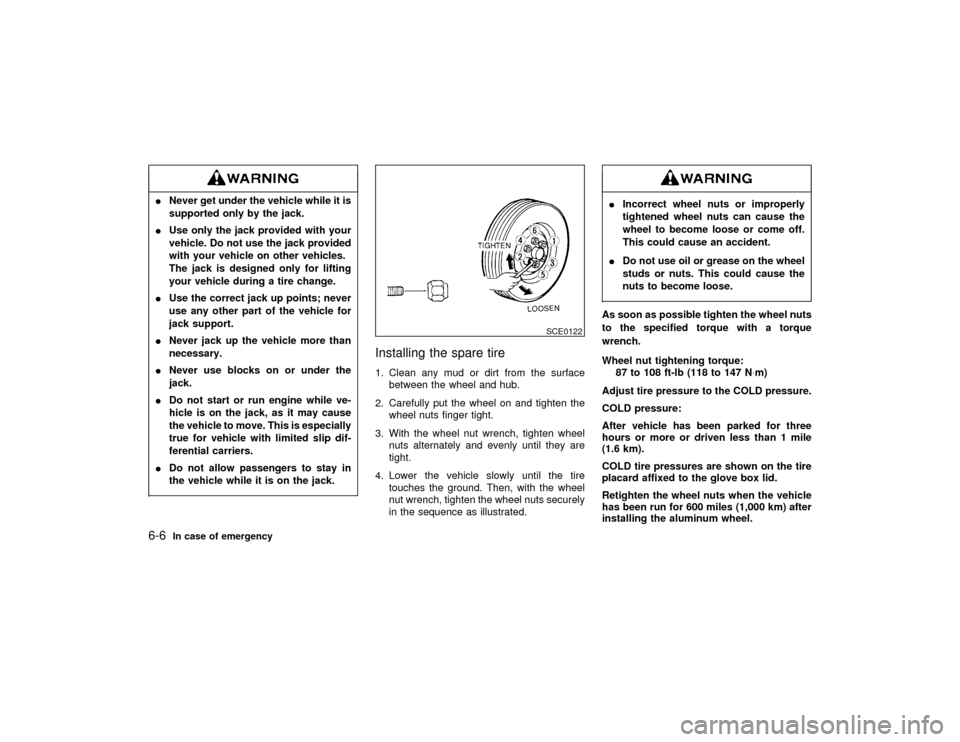

3. With the wheel nut wrench, tighten wheel

nuts alternately and evenly until they are

tight.

4. Lower the vehicle slowly until the tire

touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated.

IIncorrect wheel nuts or improperly

tightened wheel nuts can cause the

wheel to become loose or come off.

This could cause an accident.

IDo not use oil or grease on the wheel

studs or nuts. This could cause the

nuts to become loose.As soon as possible tighten the wheel nuts

to the specified torque with a torque

wrench.

Wheel nut tightening torque:

87 to 108 ft-lb (118 to 147 N×m)

Adjust tire pressure to the COLD pressure.

COLD pressure:

After vehicle has been parked for three

hours or more or driven less than 1 mile

(1.6 km).

COLD tire pressures are shown on the tire

placard affixed to the glove box lid.

Retighten the wheel nuts when the vehicle

has been run for 600 miles (1,000 km) after

installing the aluminum wheel.

SCE0122

6-6

In case of emergency

Z

01.1.22/R50-D/V5

X

Page 228 of 274

Wheel nut tightening torque:

87 to 108 ft-lb (118 to 147 N×m)IAfter rotating the tires, adjust the tire

pressure.

IRetighten the wheel nuts after the

aluminum wheel has been run for the

first 600 miles (1,000 km). (also in

cases of a flat tire, etc.)

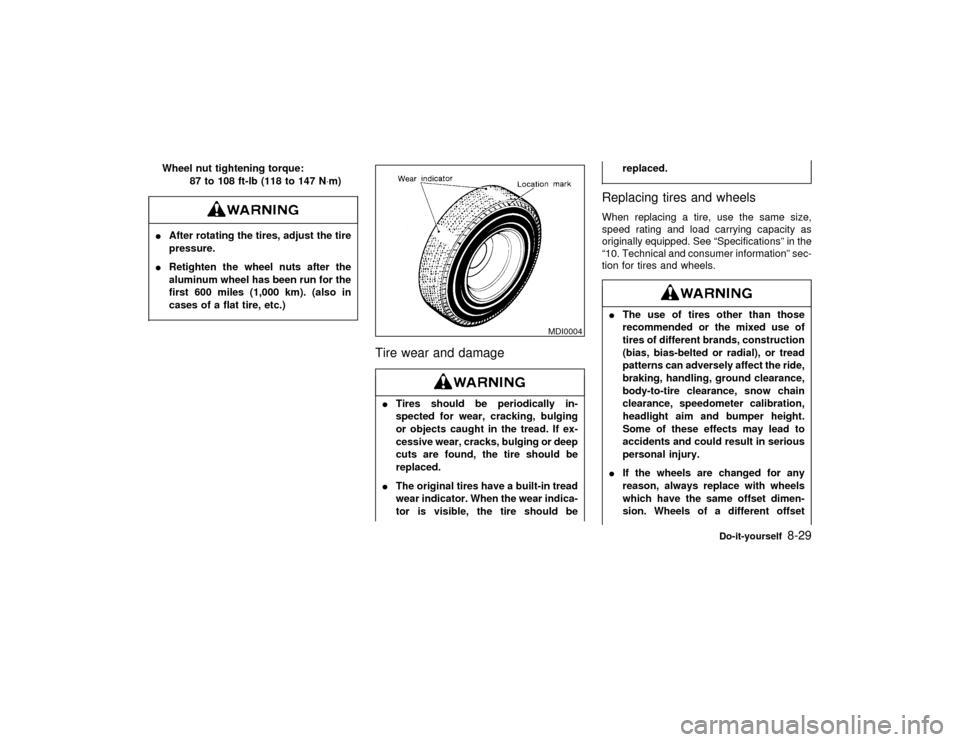

Tire wear and damageITires should be periodically in-

spected for wear, cracking, bulging

or objects caught in the tread. If ex-

cessive wear, cracks, bulging or deep

cuts are found, the tire should be

replaced.

IThe original tires have a built-in tread

wear indicator. When the wear indica-

tor is visible, the tire should bereplaced.

Replacing tires and wheelsWhen replacing a tire, use the same size,

speed rating and load carrying capacity as

originally equipped. See ªSpecificationsº in the

ª10. Technical and consumer informationº sec-

tion for tires and wheels.IThe use of tires other than those

recommended or the mixed use of

tires of different brands, construction

(bias, bias-belted or radial), or tread

patterns can adversely affect the ride,

braking, handling, ground clearance,

body-to-tire clearance, snow chain

clearance, speedometer calibration,

headlight aim and bumper height.

Some of these effects may lead to

accidents and could result in serious

personal injury.

IIf the wheels are changed for any

reason, always replace with wheels

which have the same offset dimen-

sion. Wheels of a different offset

MDI0004

Do-it-yourself

8-29

Z

01.1.22/R50-D/V5

X