Start NISSAN PATROL 1998 Y61 / 5.G Electrical System Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 138 of 326

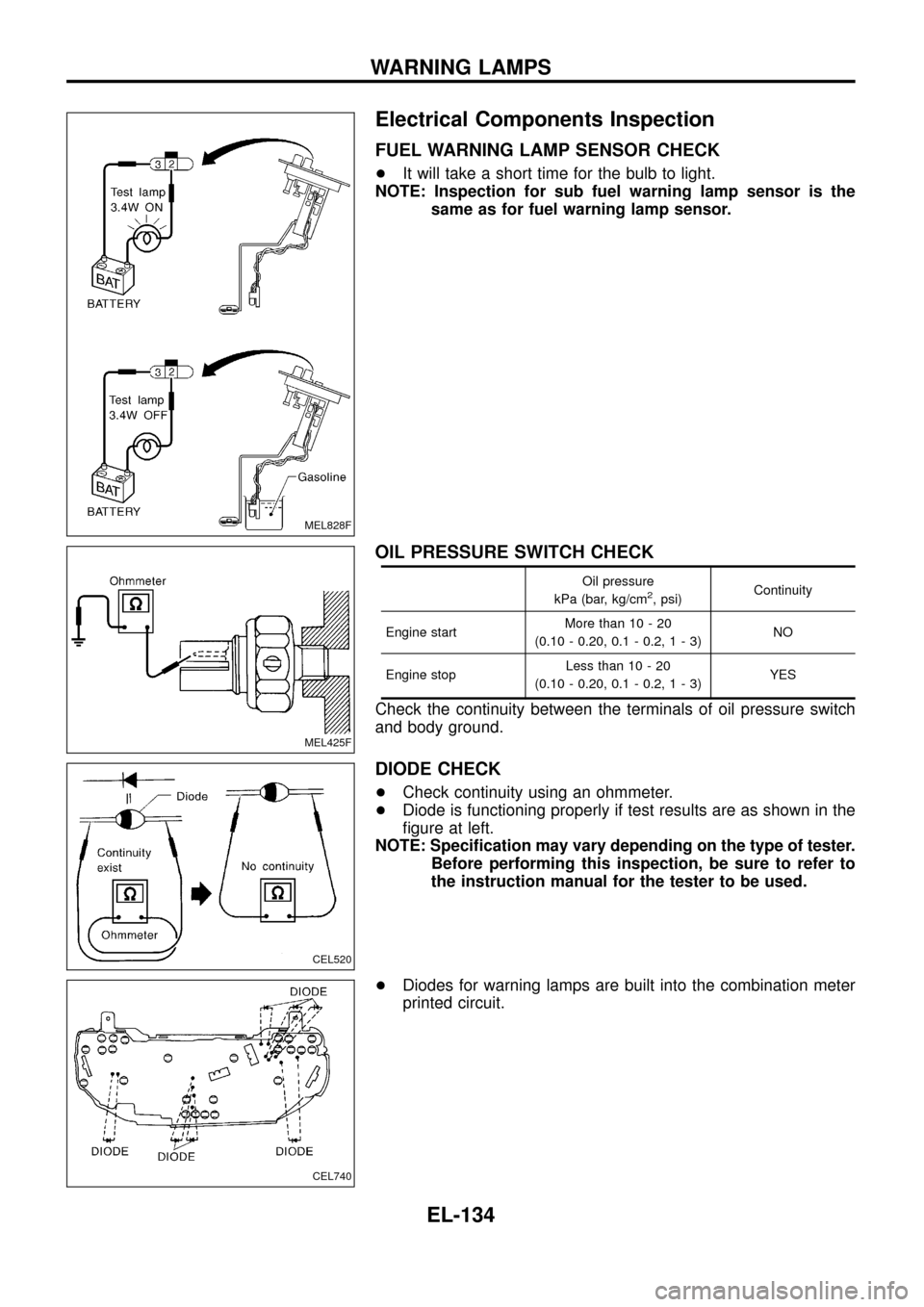

Electrical Components Inspection

FUEL WARNING LAMP SENSOR CHECK

+It will take a short time for the bulb to light.

NOTE: Inspection for sub fuel warning lamp sensor is the

same as for fuel warning lamp sensor.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

+Check continuity using an ohmmeter.

+Diode is functioning properly if test results are as shown in the

®gure at left.

NOTE: Speci®cation may vary depending on the type of tester.

Before performing this inspection, be sure to refer to

the instruction manual for the tester to be used.

+Diodes for warning lamps are built into the combination meter

printed circuit.

MEL828F

MEL425F

CEL520

CEL740

WARNING LAMPS

EL-134

Page 139 of 326

System Description

The warning chime is combined with the smart entrance control unit.

Both the ignition key and light warning chime will not sound, when ignition switch in the ON or START posi-

tion. (When power supply exists at smart entrance control unit terminalj

12.)

IGNITION KEY WARNING CHIME

With the key in the ignition key cylinder, the ignition switch in the OFF or ACC position, and the driver's door

open, the warning chime will sound. A battery positive voltage is supplied

+from key switch terminalj

1

+to smart entrance control unit terminalj1.

Ground is supplied

+through driver side door switch

+to smart entrance control unit terminalj

7.

LIGHT WARNING CHIME

With ignition switch in the OFF or ACC position, driver's door open, and lighting switch in 1ST or 2ND position,

warning chime will sound. A battery positive voltage is supplied

+from lighting switch terminalj

12or daytime light control unit

+to smart entrance control unit terminalj

14.

Ground is supplied

+through driver side door switch

+to smart entrance control unit terminalj

7.

WARNING CHIME

EL-135

Page 158 of 326

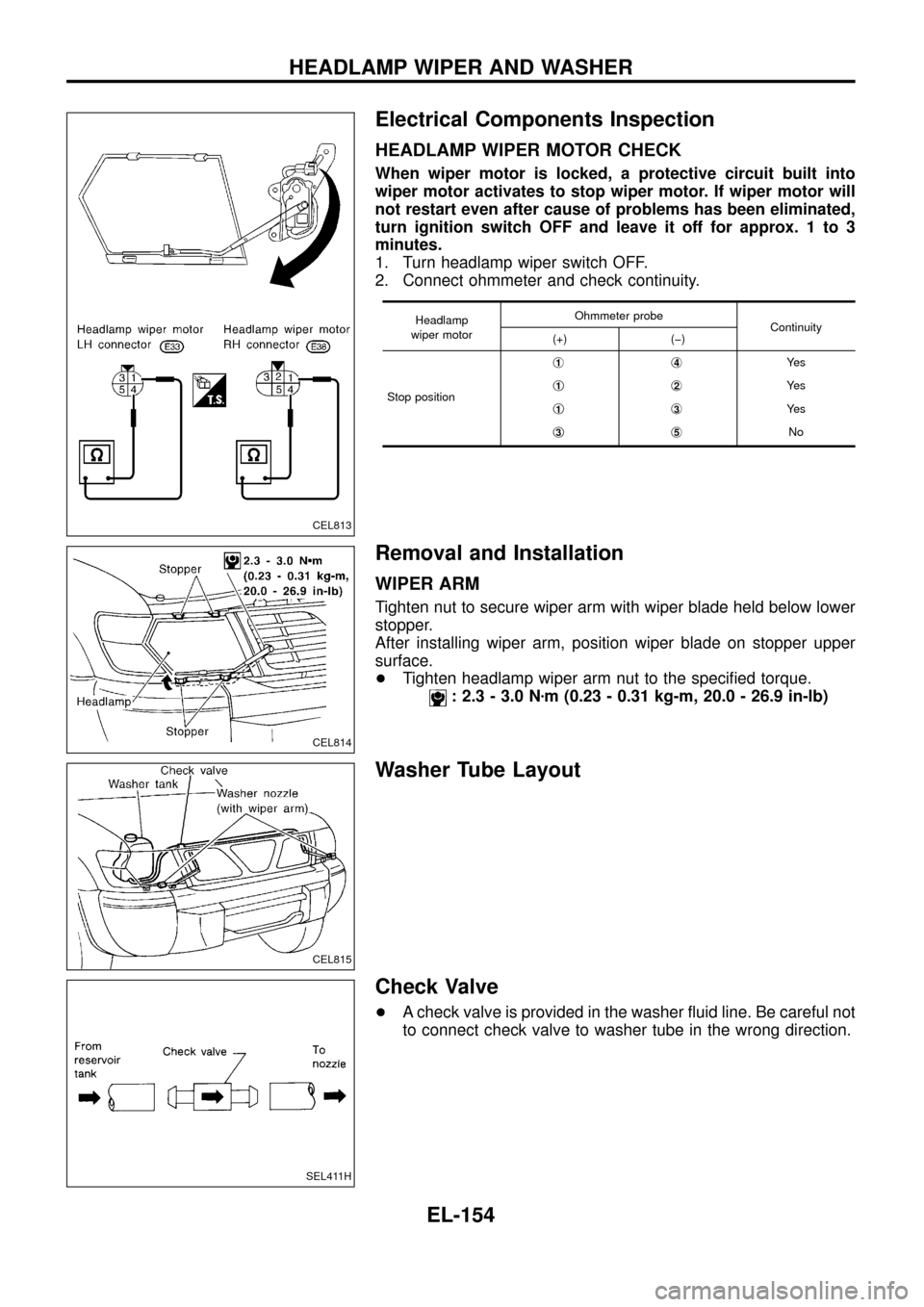

Electrical Components Inspection

HEADLAMP WIPER MOTOR CHECK

When wiper motor is locked, a protective circuit built into

wiper motor activates to stop wiper motor. If wiper motor will

not restart even after cause of problems has been eliminated,

turn ignition switch OFF and leave it off for approx. 1 to 3

minutes.

1. Turn headlamp wiper switch OFF.

2. Connect ohmmeter and check continuity.

Headlamp

wiper motorOhmmeter probe

Continuity

(+) (þ)

Stop positionj

1j4Ye s

j

1j2Ye s

j

1j3Ye s

j

3j5No

Removal and Installation

WIPER ARM

Tighten nut to secure wiper arm with wiper blade held below lower

stopper.

After installing wiper arm, position wiper blade on stopper upper

surface.

+Tighten headlamp wiper arm nut to the speci®ed torque.

: 2.3 - 3.0 Nzm (0.23 - 0.31 kg-m, 20.0 - 26.9 in-lb)

Washer Tube Layout

Check Valve

+A check valve is provided in the washer ¯uid line. Be careful not

to connect check valve to washer tube in the wrong direction.

CEL813

CEL814

CEL815

SEL411H

HEADLAMP WIPER AND WASHER

EL-154

Page 162 of 326

System Description

The rear window defogger system is controlled by the smart entrance control unit. The rear window defogger

operates only for approximately 15 minutes.

Power is supplied at all times

+to rear window defogger relay terminalj

3

+through 15A fuse (No.43, located in the fuse and fusible link box) and

+to rear window defogger relay terminalj

6

+through 20A fuse (No.44, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied

+to the rear window defogger relay terminalj

1and

+to smart entrance control unit terminalj

12

+through 7.5A fuse [No.8, located in the fuse block (J/B)].

Ground is supplied to terminalj

2of the rear window defogger switch through body grounds.

When the rear window defogger switch is turned ON, ground is supplied

+through terminalj

1of the rear window defogger switch

+to smart entrance control unit terminalj

8.

Terminalj

9of the smart entrance control unit then supplies ground to the rear window defogger relay termi-

nalj

2.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

+through terminalsj

5andj7of the rear window defogger relay

+to the rear window defogger.

The rear window defogger has an independent ground.

With power and ground supplied, the rear window defogger ®laments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

Power is supplied

+to terminalj

3of the rear window defogger switch

+from terminalj

5of the rear window defogger relay.

Terminalj

4of the rear window defogger switch is grounded through body grounds.

REAR WINDOW DEFOGGER

EL-158

Page 178 of 326

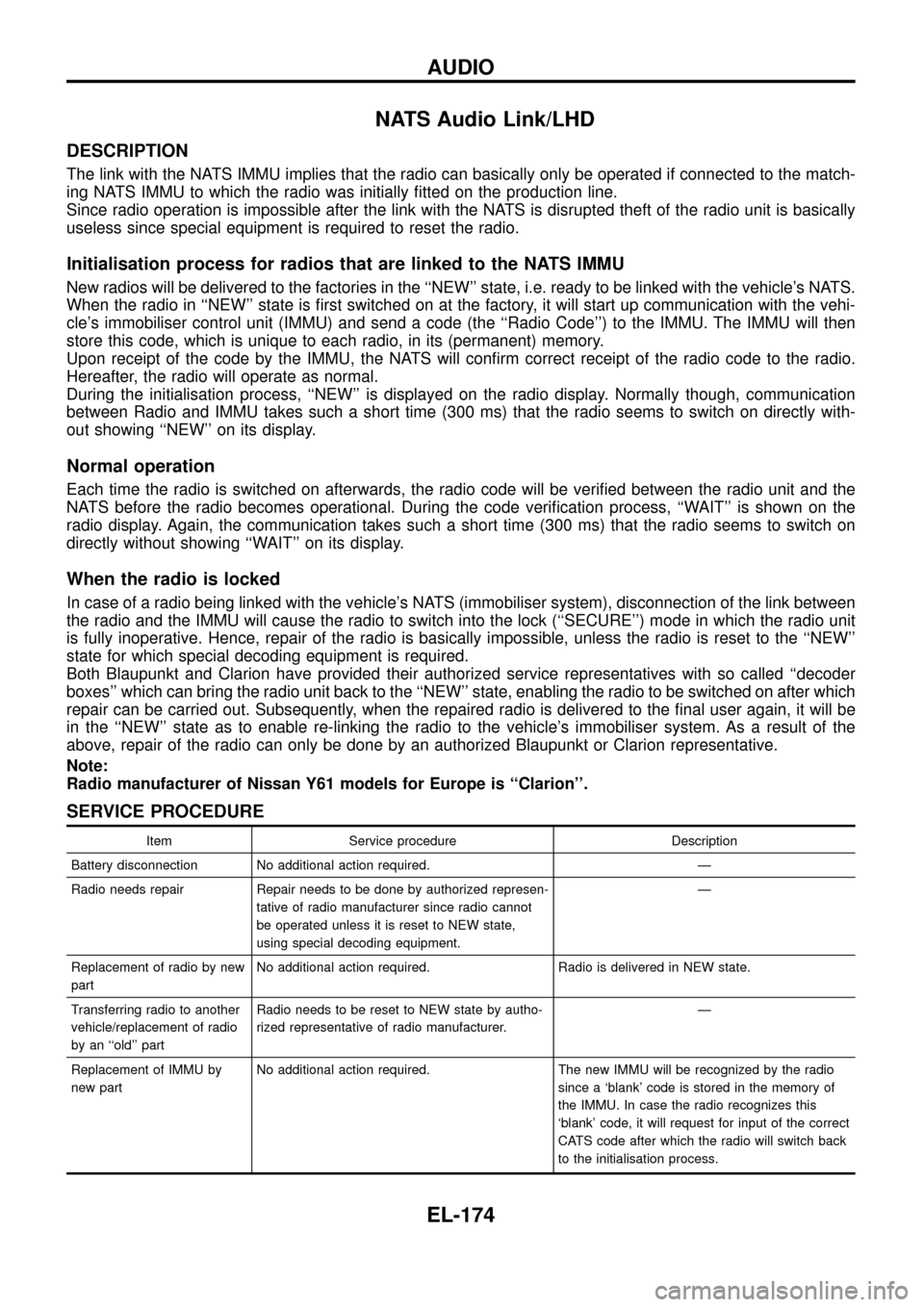

NATS Audio Link/LHD

DESCRIPTION

The link with the NATS IMMU implies that the radio can basically only be operated if connected to the match-

ing NATS IMMU to which the radio was initially ®tted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the radio unit is basically

useless since special equipment is required to reset the radio.

Initialisation process for radios that are linked to the NATS IMMU

New radios will be delivered to the factories in the ``NEW'' state, i.e. ready to be linked with the vehicle's NATS.

When the radio in ``NEW'' state is ®rst switched on at the factory, it will start up communication with the vehi-

cle's immobiliser control unit (IMMU) and send a code (the ``Radio Code'') to the IMMU. The IMMU will then

store this code, which is unique to each radio, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will con®rm correct receipt of the radio code to the radio.

Hereafter, the radio will operate as normal.

During the initialisation process, ``NEW'' is displayed on the radio display. Normally though, communication

between Radio and IMMU takes such a short time (300 ms) that the radio seems to switch on directly with-

out showing ``NEW'' on its display.

Normal operation

Each time the radio is switched on afterwards, the radio code will be veri®ed between the radio unit and the

NATS before the radio becomes operational. During the code veri®cation process, ``WAIT'' is shown on the

radio display. Again, the communication takes such a short time (300 ms) that the radio seems to switch on

directly without showing ``WAIT'' on its display.

When the radio is locked

In case of a radio being linked with the vehicle's NATS (immobiliser system), disconnection of the link between

the radio and the IMMU will cause the radio to switch into the lock (``SECURE'') mode in which the radio unit

is fully inoperative. Hence, repair of the radio is basically impossible, unless the radio is reset to the ``NEW''

state for which special decoding equipment is required.

Both Blaupunkt and Clarion have provided their authorized service representatives with so called ``decoder

boxes'' which can bring the radio unit back to the ``NEW'' state, enabling the radio to be switched on after which

repair can be carried out. Subsequently, when the repaired radio is delivered to the ®nal user again, it will be

in the ``NEW'' state as to enable re-linking the radio to the vehicle's immobiliser system. As a result of the

above, repair of the radio can only be done by an authorized Blaupunkt or Clarion representative.

Note:

Radio manufacturer of Nissan Y61 models for Europe is ``Clarion''.

SERVICE PROCEDURE

Item Service procedure Description

Battery disconnection No additional action required. Ð

Radio needs repair Repair needs to be done by authorized represen-

tative of radio manufacturer since radio cannot

be operated unless it is reset to NEW state,

using special decoding equipment.Ð

Replacement of radio by new

partNo additional action required. Radio is delivered in NEW state.

Transferring radio to another

vehicle/replacement of radio

by an ``old'' partRadio needs to be reset to NEW state by autho-

rized representative of radio manufacturer.Ð

Replacement of IMMU by

new partNo additional action required. The new IMMU will be recognized by the radio

since a `blank' code is stored in the memory of

the IMMU. In case the radio recognizes this

`blank' code, it will request for input of the correct

CATS code after which the radio will switch back

to the initialisation process.

AUDIO

EL-174

Page 184 of 326

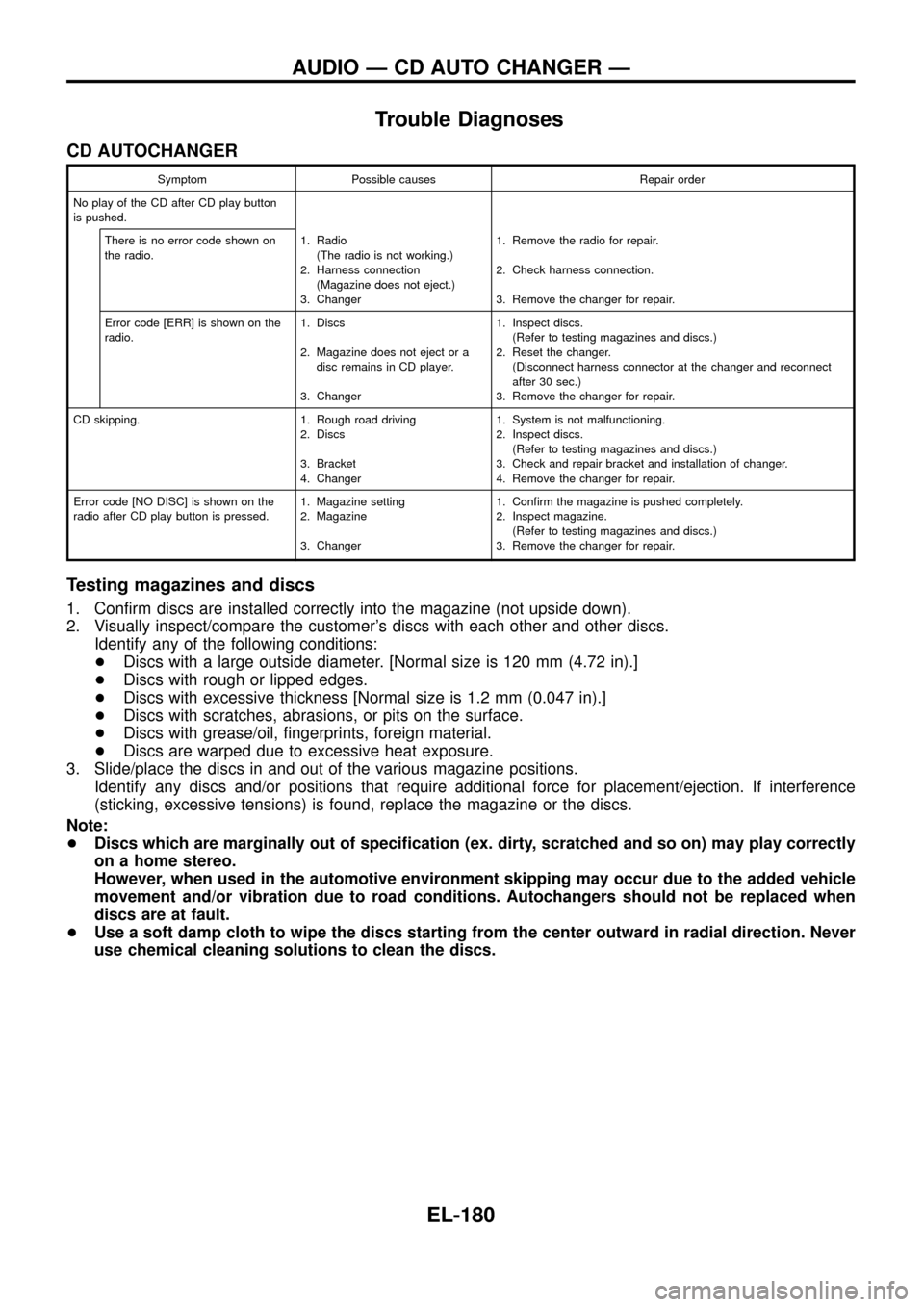

Trouble Diagnoses

CD AUTOCHANGER

Symptom Possible causes Repair order

No play of the CD after CD play button

is pushed.

There is no error code shown on

the radio.1. Radio

(The radio is not working.)

2. Harness connection

(Magazine does not eject.)

3. Changer1. Remove the radio for repair.

2. Check harness connection.

3. Remove the changer for repair.

Error code [ERR] is shown on the

radio.1. Discs

2. Magazine does not eject or a

disc remains in CD player.

3. Changer1. Inspect discs.

(Refer to testing magazines and discs.)

2. Reset the changer.

(Disconnect harness connector at the changer and reconnect

after 30 sec.)

3. Remove the changer for repair.

CD skipping. 1. Rough road driving

2. Discs

3. Bracket

4. Changer1. System is not malfunctioning.

2. Inspect discs.

(Refer to testing magazines and discs.)

3. Check and repair bracket and installation of changer.

4. Remove the changer for repair.

Error code [NO DISC] is shown on the

radio after CD play button is pressed.1. Magazine setting

2. Magazine

3. Changer1. Con®rm the magazine is pushed completely.

2. Inspect magazine.

(Refer to testing magazines and discs.)

3. Remove the changer for repair.

Testing magazines and discs

1. Con®rm discs are installed correctly into the magazine (not upside down).

2. Visually inspect/compare the customer's discs with each other and other discs.

Identify any of the following conditions:

+Discs with a large outside diameter. [Normal size is 120 mm (4.72 in).]

+Discs with rough or lipped edges.

+Discs with excessive thickness [Normal size is 1.2 mm (0.047 in).]

+Discs with scratches, abrasions, or pits on the surface.

+Discs with grease/oil, ®ngerprints, foreign material.

+Discs are warped due to excessive heat exposure.

3. Slide/place the discs in and out of the various magazine positions.

Identify any discs and/or positions that require additional force for placement/ejection. If interference

(sticking, excessive tensions) is found, replace the magazine or the discs.

Note:

+Discs which are marginally out of speci®cation (ex. dirty, scratched and so on) may play correctly

on a home stereo.

However, when used in the automotive environment skipping may occur due to the added vehicle

movement and/or vibration due to road conditions. Autochangers should not be replaced when

discs are at fault.

+Use a soft damp cloth to wipe the discs starting from the center outward in radial direction. Never

use chemical cleaning solutions to clean the discs.

AUDIO Ð CD AUTO CHANGER Ð

EL-180

Page 200 of 326

![NISSAN PATROL 1998 Y61 / 5.G Electrical System Owners Manual System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela NISSAN PATROL 1998 Y61 / 5.G Electrical System Owners Manual System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window rela](/img/5/616/w960_616-199.png)

System Description

With ignition switch in ON or START position, power is supplied

+through 7.5A fuse [No.

8, located in the fuse block (J/B)]

+to power window relay terminalj

1.

The power window relay is energized and power is supplied

+through power window relay terminalj

5

+to power window main switch terminalj1,

+to power window sub switch terminalj

5.

MANUAL OPERATION

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

Driver side

When the driver side switch in the power window main switch is pressed in the up position, power is supplied

+to driver side power window regulator terminal (j

2,j1)

+through power window main switch terminal (j

9,j8).

Ground is supplied

+to driver side power window regulator terminal (j

1,j2)

+through power window main switch terminal (j

8,j9).

Then, the motor raises or lowers the window until the switch is released.

Passenger side

MAIN SWITCH OPERATION

Power is supplied

+through power window main switch (j

5,j6)

+to front power window sub-switch (j

3,j4).

The subsequent operation is the same as the sub-switch operation.

SUB-SWITCH OPERATION

Power is supplied

+through front power window sub-switch (j

1,j2)

+to passenger side power window regulator (j

2,j1).

Ground is supplied

+to passenger side power window regulator (j

1,j2)

+through front power window sub-switch (j

2,j1)

+to front power window sub-switch (j

4,j3)

+through power window main switch (j

6,j5).

Then, the motor raises or lowers the window until the switch is released.

Rear door

Rear door windows will raise and lower in the same manner as passenger side door window.

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the driver's window without holding the

window switch in the respective position.

When the AUTO switch in the main switch is pressed and released, the driver's window will travel to the fully

open or closed position.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver's door window.

When the lock switch is pressed to lock position, ground of the sub-switches in the power window main switch

is disconnected. This prevents the power window motors from operating.

POWER WINDOW

EL-196

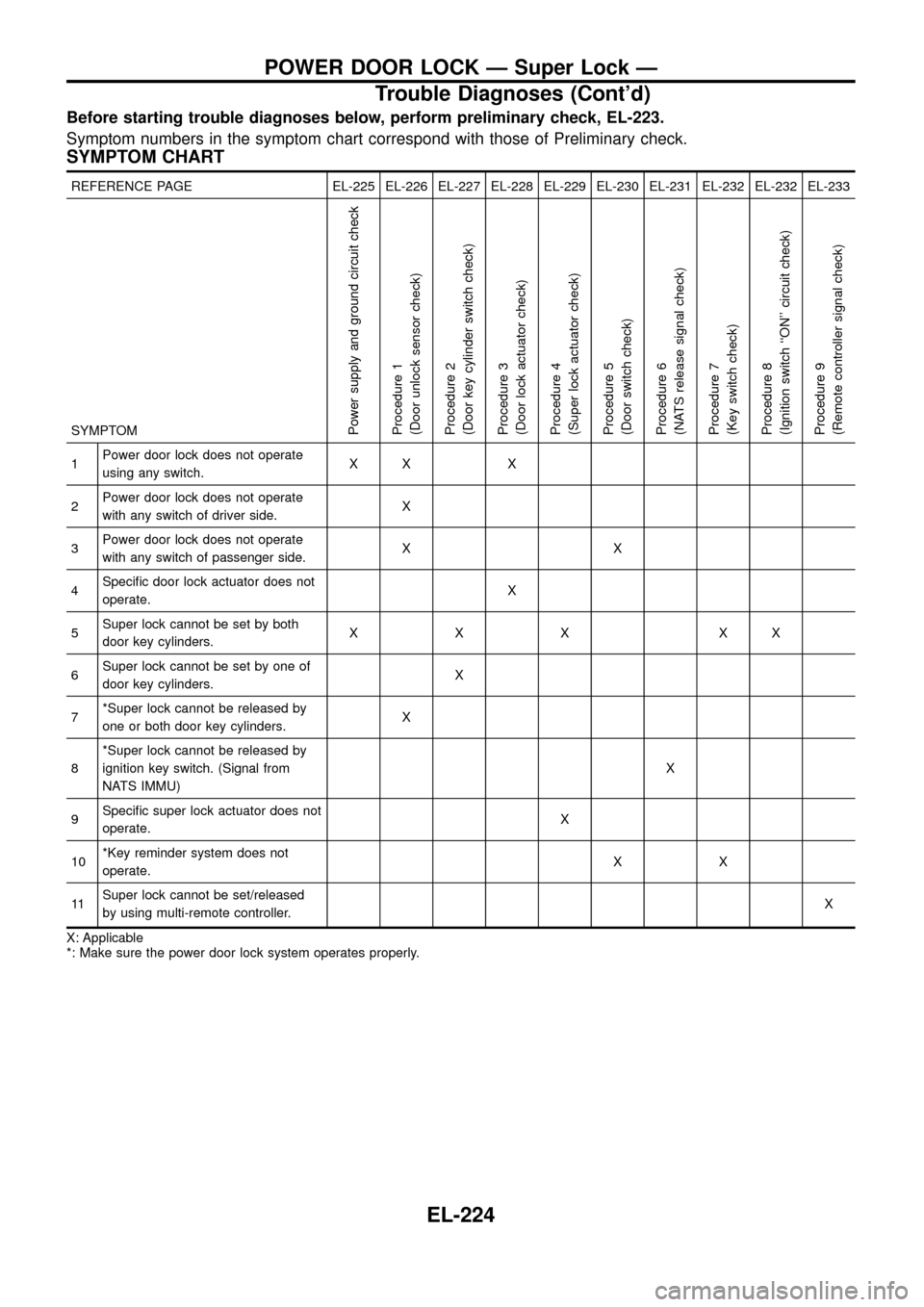

Page 228 of 326

Before starting trouble diagnoses below, perform preliminary check, EL-223.

Symptom numbers in the symptom chart correspond with those of Preliminary check.

SYMPTOM CHART

REFERENCE PAGE EL-225 EL-226 EL-227 EL-228 EL-229 EL-230 EL-231 EL-232 EL-232 EL-233

SYMPTOM

Power supply and ground circuit check

Procedure 1

(Door unlock sensor check)

Procedure 2

(Door key cylinder switch check)

Procedure 3

(Door lock actuator check)

Procedure 4

(Super lock actuator check)

Procedure 5

(Door switch check)

Procedure 6

(NATS release signal check)

Procedure 7

(Key switch check)

Procedure 8

(Ignition switch ``ON'' circuit check)

Procedure 9

(Remote controller signal check)

1Power door lock does not operate

using any switch.XX X

2Power door lock does not operate

with any switch of driver side.X

3Power door lock does not operate

with any switch of passenger side.XX

4Speci®c door lock actuator does not

operate.X

5Super lock cannot be set by both

door key cylinders.XXX XX

6Super lock cannot be set by one of

door key cylinders.X

7*Super lock cannot be released by

one or both door key cylinders.X

8*Super lock cannot be released by

ignition key switch. (Signal from

NATS IMMU)X

9Speci®c super lock actuator does not

operate.X

10*Key reminder system does not

operate.XX

11Super lock cannot be set/released

by using multi-remote controller.X

X: Applicable

*: Make sure the power door lock system operates properly.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-224

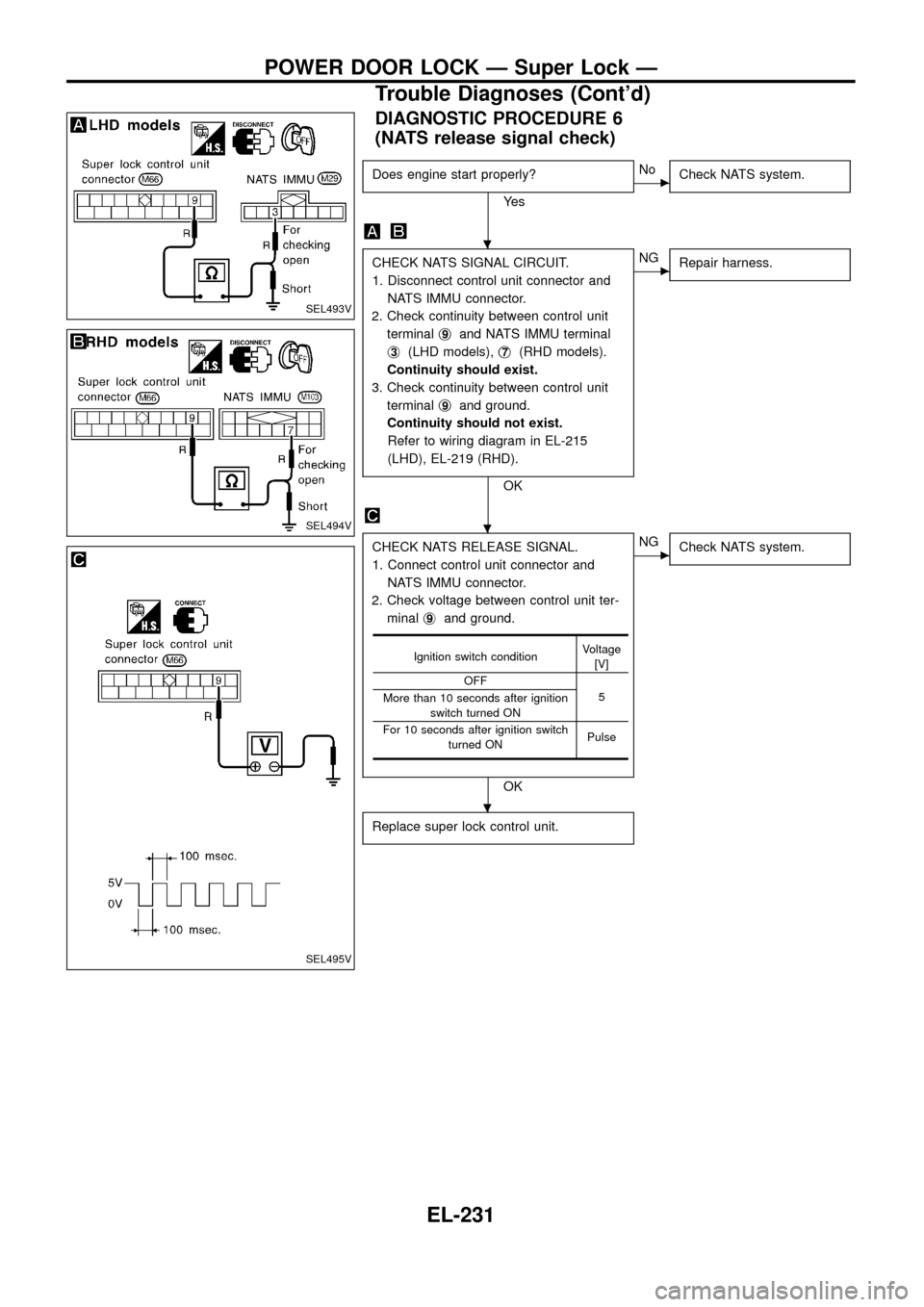

Page 235 of 326

DIAGNOSTIC PROCEDURE 6

(NATS release signal check)

Does engine start properly?

Ye s

cNo

Check NATS system.

CHECK NATS SIGNAL CIRCUIT.

1. Disconnect control unit connector and

NATS IMMU connector.

2. Check continuity between control unit

terminalj

9and NATS IMMU terminal

j

3(LHD models),j7(RHD models).

Continuity should exist.

3. Check continuity between control unit

terminalj

9and ground.

Continuity should not exist.

Refer to wiring diagram in EL-215

(LHD), EL-219 (RHD).

OK

cNG

Repair harness.

CHECK NATS RELEASE SIGNAL.

1. Connect control unit connector and

NATS IMMU connector.

2. Check voltage between control unit ter-

minalj

9and ground.

OK

cNG

Check NATS system.

Replace super lock control unit.

Ignition switch conditionVoltage

[V]

OFF

5

More than 10 seconds after ignition

switch turned ON

For 10 seconds after ignition switch

turned ONPulse

SEL493V

SEL494V

SEL495V

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-231

Page 244 of 326

System Description

NATS has the following immobiliser functions:

+Since only NATS ignition keys, whose ID nos. have been registered into the ECM and IMMU of NATS,

allow the engine to run, operation of a stolen vehicle without a NATS registered key is prevented by NATS.

That is to say, NATS will immobilize the engine if someone tries to start it without the registered key of

NATS.

+Both of the originally supplied ignition key IDs have been NATS registered.

If requested by the vehicle owner, a maximum of four key IDs can be registered into the NATS compo-

nents.

+The NATS security indicator (NATS security ind.) blinks when the ignition switch is in ``OFF'' or ``ACC''

position. Therefore, NATS warns outsiders that the vehicle is equipped with the anti-theft system.

+When NATS detects trouble, the malfunction indicator lamp (MIL) blinks.

+NATS trouble diagnoses, system initialisation and additional registration of other NATS ignition key IDs

must be carried out using CONSULT hardware and CONSULT NATS software.

When NATS initialisation has been completed, the ID of the inserted ignition key is automatically NATS

registered. Then, if necessary, additional registration of other NATS ignition key IDs can be carried out.

Regarding the procedures of NATS initialisation and NATS ignition key ID registration, refer to CONSULT

operation manual, NATS.

+When servicing a malfunction of the NATS (indicated by ¯ashing of Malfunction Indicator Lamp)

or registering another NATS ignition key ID no., it may be necessary to re-register original key

identi®cation. Therefore, be sure to receive all keys from vehicle owner.

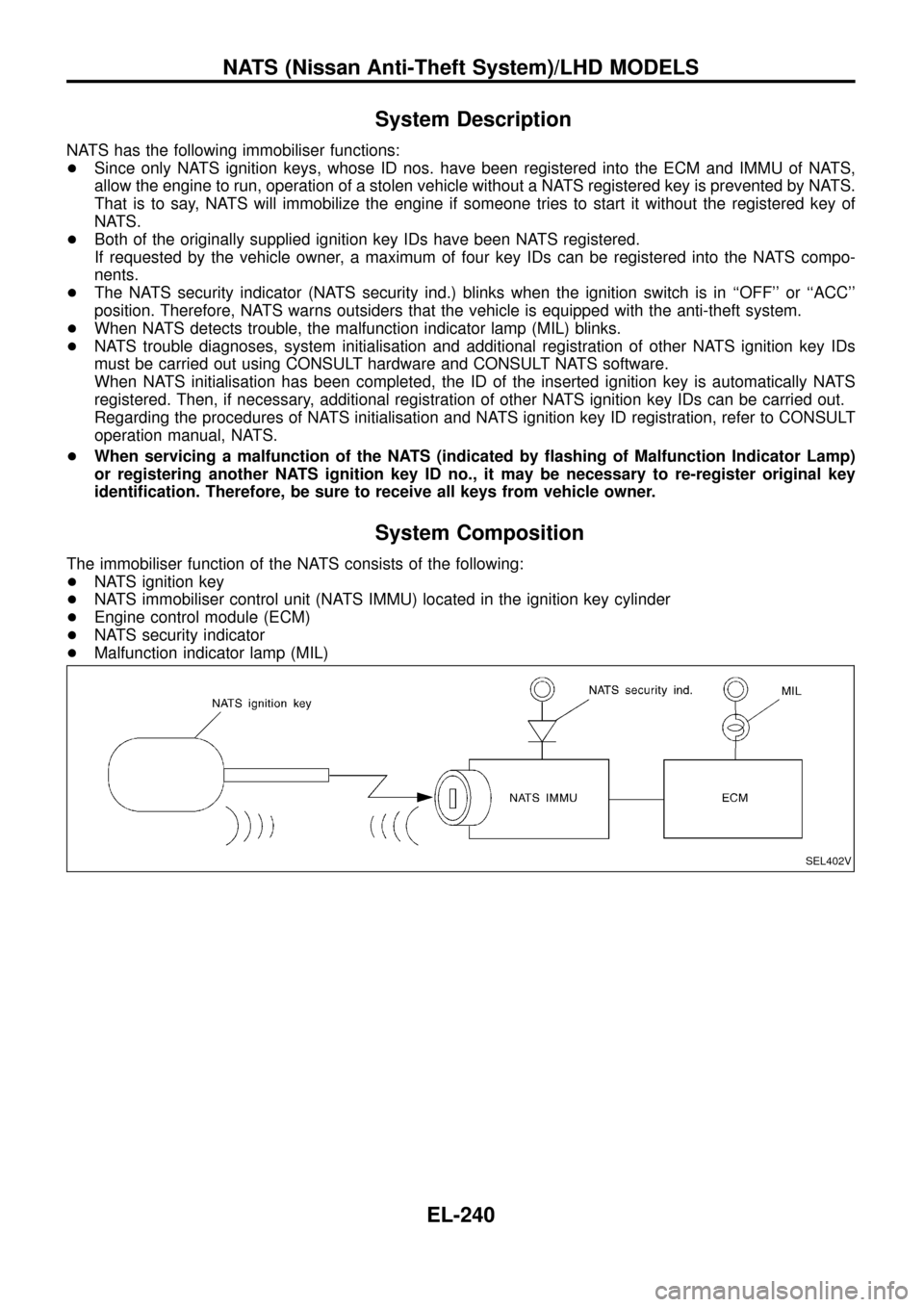

System Composition

The immobiliser function of the NATS consists of the following:

+NATS ignition key

+NATS immobiliser control unit (NATS IMMU) located in the ignition key cylinder

+Engine control module (ECM)

+NATS security indicator

+Malfunction indicator lamp (MIL)

SEL402V

NATS (Nissan Anti-Theft System)/LHD MODELS

EL-240