stop start NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 33 of 192

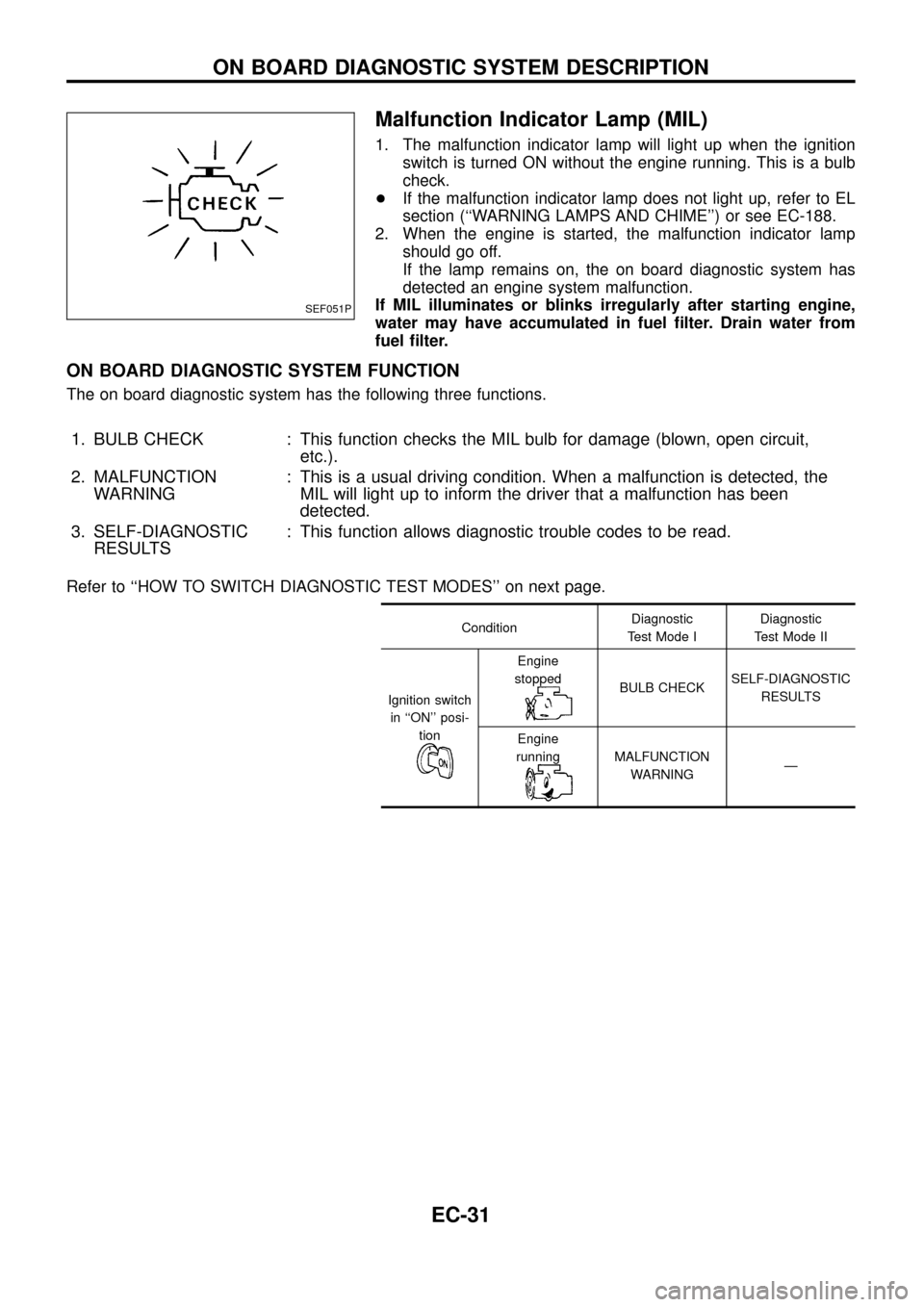

Malfunction Indicator Lamp (MIL)

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is a bulb

check.

+If the malfunction indicator lamp does not light up, refer to EL

section (``WARNING LAMPS AND CHIME'') or see EC-188.

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MIL illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel ®lter. Drain water from

fuel ®lter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

1. BULB CHECK : This function checks the MIL bulb for damage (blown, open circuit,

etc.).

2. MALFUNCTION

WARNING: This is a usual driving condition. When a malfunction is detected, the

MIL will light up to inform the driver that a malfunction has been

detected.

3. SELF-DIAGNOSTIC

RESULTS: This function allows diagnostic trouble codes to be read.

Refer to ``HOW TO SWITCH DIAGNOSTIC TEST MODES'' on next page.

ConditionDiagnostic

Test Mode IDiagnostic

Test Mode II

Ignition switch

in ``ON'' posi-

tion

Engine

stopped

BULB CHECKSELF-DIAGNOSTIC

RESULTS

Engine

running

MALFUNCTION

WARNINGÐ

SEF051P

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

EC-31

Page 41 of 192

![NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.](/img/5/617/w960_617-40.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]

jj

+Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

IGN SW

[ON/OFF]

jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air ¯ow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

ACT INJ TIMG [É]

jj

+The actual injection timing angle deter-

mined by the ECM (an approximate

average angle between injection start

and end from TDC) is displayed.

INJ TIMG C/V [%]+Indicates the duty ratio of fuel injection

timing control valve.

DECELER F/CUT

[ON/OFF]

j

+Indicates [ON/OFF] condition from decel-

eration fuel cut signal.+When the accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more, ``ON'' is displayed.

FUEL CUT S/V

[ON/OFF]

j

+The control condition of the fuel cut sole-

noid valve (determined by ECM accord-

ing to the input signal) is indicted.

+OFF ... Fuel cut solenoid valve is not

operating.

ON ... Fuel cut solenoid valve is operat-

ing.+When the fuel cut solenoid valve is not

operating, fuel is not supplied to injection

nozzles.

GLOW RLY [ON/OFF]

j

+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

j

+Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

+LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

I/C FAN RLY

[ON/OFF]

j

+Indicates the control condition of the

charge air cooler fan (determined by

ECM according to the input signals).

EGRC SOL/V A

[ON/OFF]+The control condition of the EGRC-sole-

noid valve A (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve A is not

operating.

ON ... EGRC-solenoid valve A is operat-

ing.

EGRC SOL/V B

[ON/OFF]+The control condition of the EGRC-sole-

noid valve B (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... EGRC-solenoid valve B is not

operating.

ON ... EGRC-solenoid valve B is operat-

ing.

THROT RLY

[ON/OFF]+The control condition of the throttle con-

trol solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

+OFF ... Throttle control solenoid valve is

not operating.

ON ... Throttle control solenoid valve is

operating.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT (Cont'd)

EC-39

Page 45 of 192

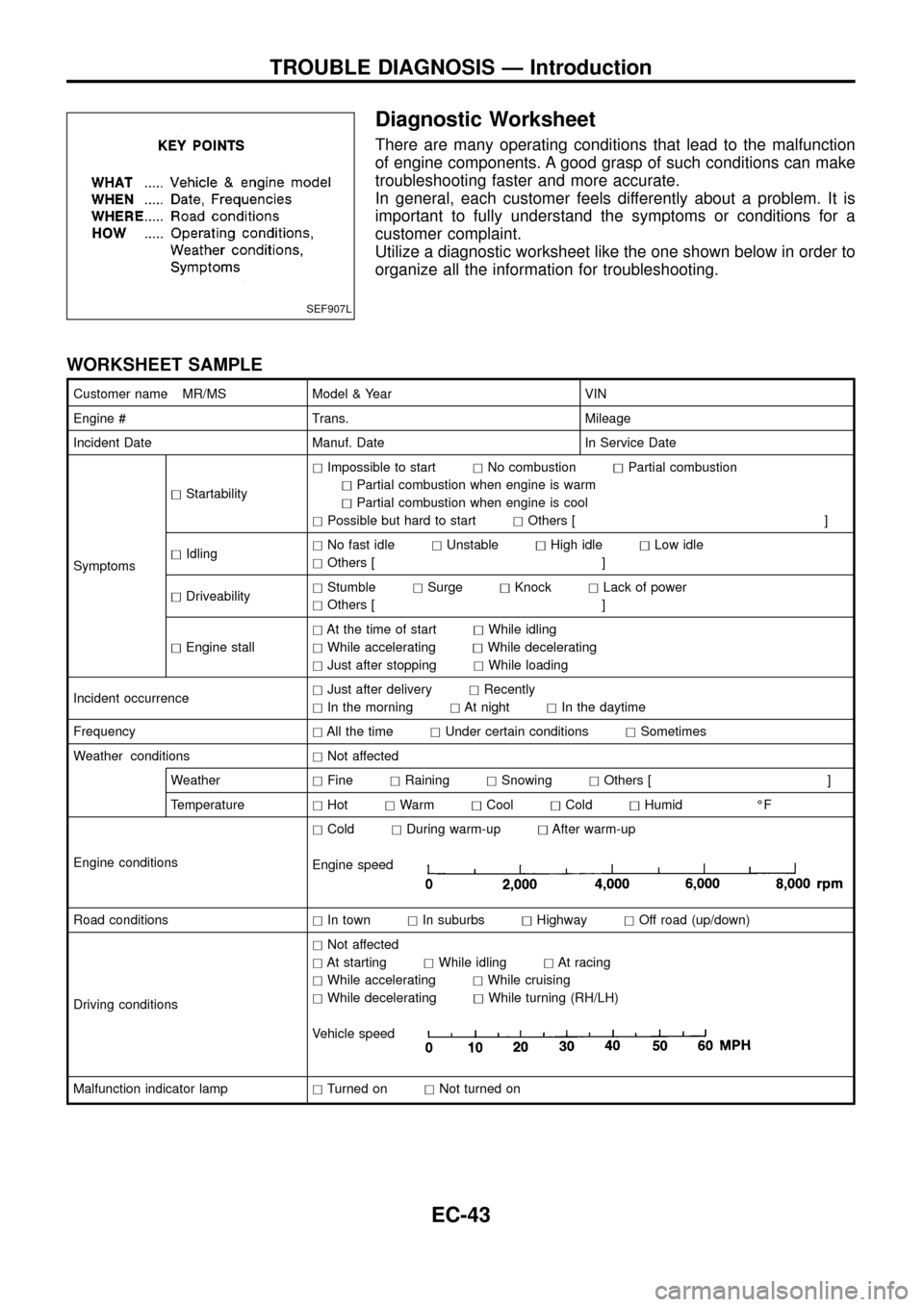

Diagnostic Worksheet

There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one shown below in order to

organize all the information for troubleshooting.

WORKSHEET SAMPLE

Customer name MR/MS Model & Year VIN

Engine # Trans. Mileage

Incident Date Manuf. Date In Service Date

SymptomshStartabilityhImpossible to starthNo combustionhPartial combustion

hPartial combustion when engine is warm

hPartial combustion when engine is cool

hPossible but hard to starthOthers [ ]

hIdlinghNo fast idlehUnstablehHigh idlehLow idle

hOthers [ ]

hDriveabilityhStumblehSurgehKnockhLack of power

hOthers [ ]

hEngine stallhAt the time of starthWhile idling

hWhile acceleratinghWhile decelerating

hJust after stoppinghWhile loading

Incident occurrencehJust after deliveryhRecently

hIn the morninghAt nighthIn the daytime

FrequencyhAll the timehUnder certain conditionshSometimes

Weather conditionshNot affected

WeatherhFinehRaininghSnowinghOthers [ ]

TemperaturehHothWarmhCoolhColdhHumid ÉF

Engine conditionshColdhDuring warm-uphAfter warm-up

Engine speed

Road conditionshIn townhIn suburbshHighwayhOff road (up/down)

Driving conditionshNot affected

hAt startinghWhile idlinghAt racing

hWhile acceleratinghWhile cruising

hWhile deceleratinghWhile turning (RH/LH)

Vehicle speed

Malfunction indicator lamphTurned onhNot turned on

SEF907L

TROUBLE DIAGNOSIS Ð Introduction

EC-43

Page 49 of 192

jA

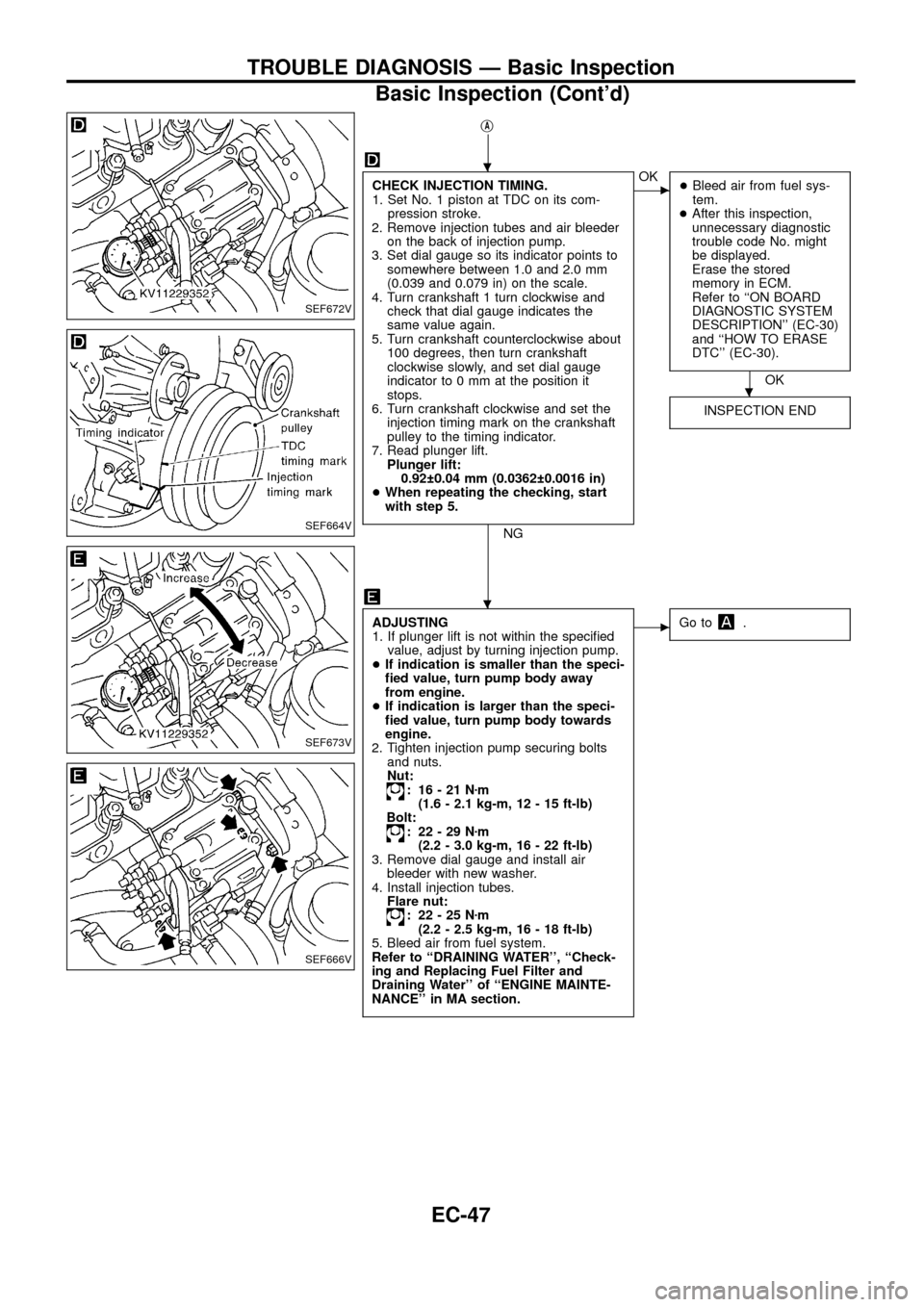

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft 1 turn clockwise and

check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set the

injection timing mark on the crankshaft

pulley to the timing indicator.

7. Read plunger lift.

Plunger lift:

0.92 0.04 mm (0.0362 0.0016 in)

+When repeating the checking, start

with step 5.

NG

cOK

+Bleed air from fuel sys-

tem.

+After this inspection,

unnecessary diagnostic

trouble code No. might

be displayed.

Erase the stored

memory in ECM.

Refer to ``ON BOARD

DIAGNOSTIC SYSTEM

DESCRIPTION'' (EC-30)

and ``HOW TO ERASE

DTC'' (EC-30).

OK

INSPECTION END

ADJUSTING

1. If plunger lift is not within the speci®ed

value, adjust by turning injection pump.

+If indication is smaller than the speci-

®ed value, turn pump body away

from engine.

+If indication is larger than the speci-

®ed value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 16-21Nzm

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

Bolt:

: 22-29Nzm

(2.2 - 3.0 kg-m, 16 - 22 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 22-25Nzm

(2.2 - 2.5 kg-m, 16 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ``DRAINING WATER'', ``Check-

ing and Replacing Fuel Filter and

Draining Water'' of ``ENGINE MAINTE-

NANCE'' in MA section.

cGo to.

SEF672V

SEF664V

SEF673V

SEF666V

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Basic Inspection (Cont'd)

EC-47

Page 52 of 192

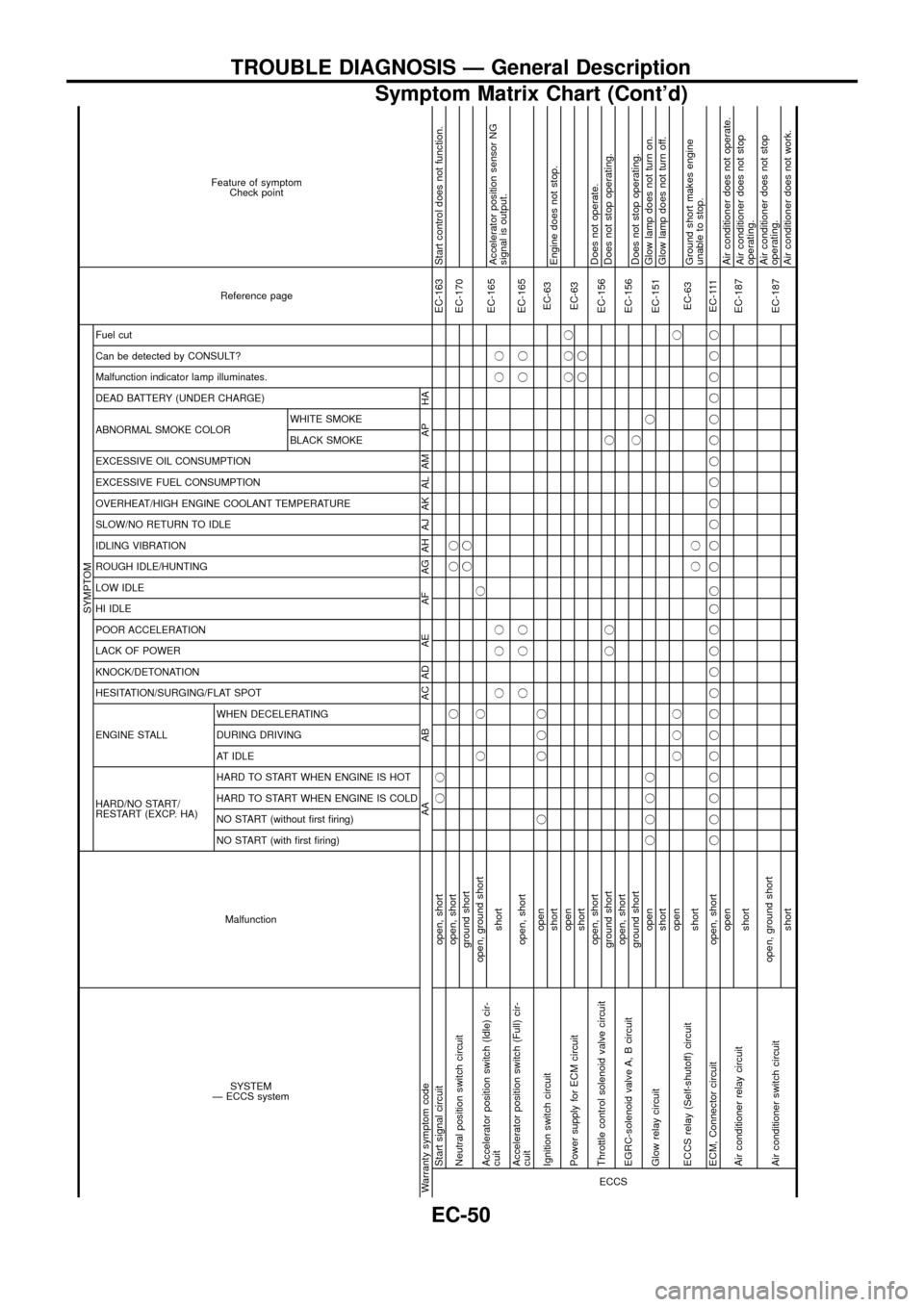

SYSTEM

Ð ECCS systemMalfunction

SYMPTOM

Reference page Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT?

Fuel cut

NO START (with ®rst ®ring) NO START (without ®rst ®ring)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM AP HAECCS

Start signal circuit open, shortjjEC-163 Start control does not function.

Neutral position switch circuitopen, shortjjj

EC-170

ground shortjj

Accelerator position switch (Idle) cir-

cuitopen, ground shortjj j

EC-165

shortjjj jjAccelerator position sensor NG

signal is output.

Accelerator position switch (Full) cir-

cuitopen, shortjjj jjEC-165

Ignition switch circuitopenj jjj

EC-63

shortEngine does not stop.

Power supply for ECM circuitopenjjj

EC-63

shortjj

Throttle control solenoid valve circuitopen, short

EC-156Does not operate.

ground shortjj jDoes not stop operating.

EGRC-solenoid valve A, B circuitopen, short

EC-156

ground shortjDoes not stop operating.

Glow relay circuitopenjjjjj

EC-151Glow lamp does not turn on.

shortGlow lamp does not turn off.

ECCS relay (Self-shutoff) circuitopenjjjj

EC-63

shortjjGround short makes engine

unable to stop.

ECM, Connector circuit open, shortjjjjjjjjjjjjj jjjjjjjjjjjjEC-111

Air conditioner relay circuitopen

EC-187Air conditioner does not operate.

shortAir conditioner does not stop

operating.

Air conditioner switch circuitopen, ground short

EC-187Air conditioner does not stop

operating.

shortAir conditioner does not work.

TROUBLE DIAGNOSIS Ð General Description

Symptom Matrix Chart (Cont'd)

EC-50

Page 53 of 192

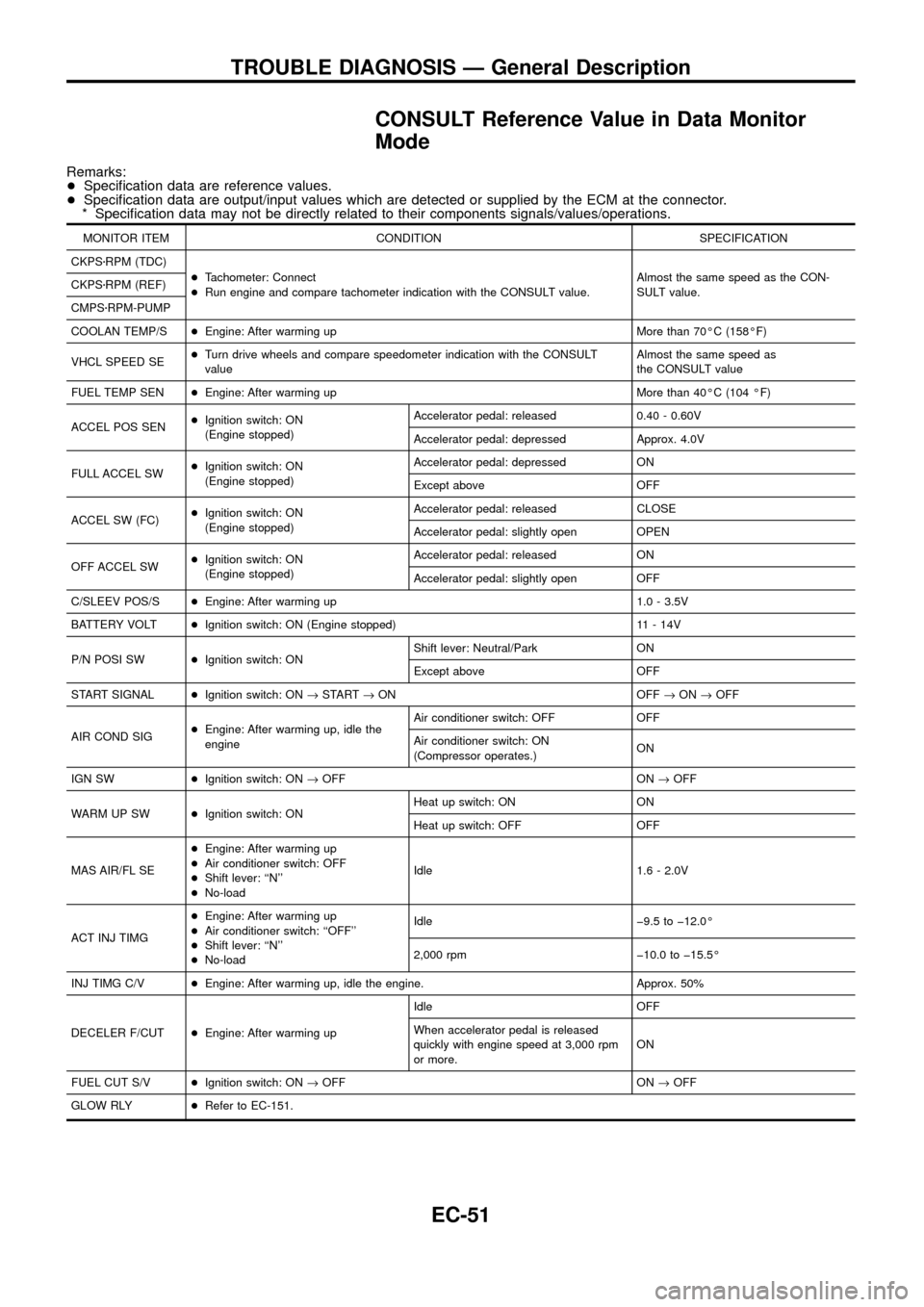

CONSULT Reference Value in Data Monitor

Mode

Remarks:

+Speci®cation data are reference values.

+Speci®cation data are output/input values which are detected or supplied by the ECM at the connector.

* Speci®cation data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT value.Almost the same speed as the CON-

SULT value. CKPSzRPM (REF)

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CONSULT

valueAlmost the same speed as

the CONSULT value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104 ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.0V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: depressed ON

Except above OFF

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: released ON

Accelerator pedal: slightly open OFF

C/SLEEV POS/S+Engine: After warming up 1.0 - 3.5V

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW+Ignition switch: ONShift lever: Neutral/Park ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: ``N''

+No-loadIdle 1.6 - 2.0V

ACT INJ TIMG+Engine: After warming up

+Air conditioner switch: ``OFF''

+Shift lever: ``N''

+No-loadIdle þ9.5 to þ12.0É

2,000 rpm þ10.0 to þ15.5É

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50%

DECELER F/CUT+Engine: After warming upIdle OFF

When accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more.ON

FUEL CUT S/V+Ignition switch: ON®OFF ON®OFF

GLOW RLY+Refer to EC-151.

TROUBLE DIAGNOSIS Ð General Description

EC-51

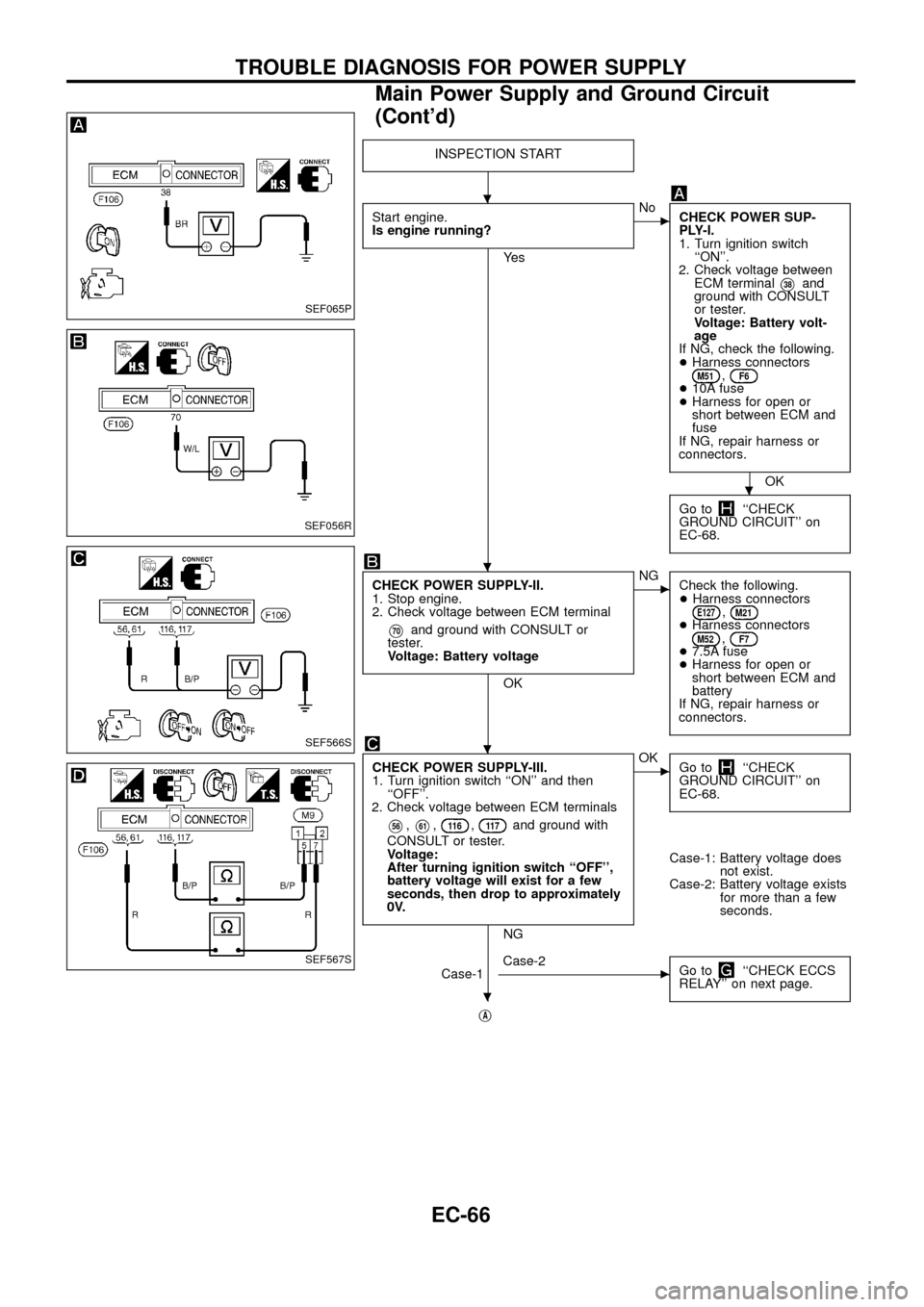

Page 68 of 192

INSPECTION START

Start engine.

Is engine running?

Ye s

cNo

CHECK POWER SUP-

PLY-I.

1. Turn ignition switch

``ON''.

2. Check voltage between

ECM terminal

V38and

ground with CONSULT

or tester.

Voltage: Battery volt-

age

If NG, check the following.

+Harness connectors

M51,F6+10A fuse

+Harness for open or

short between ECM and

fuse

If NG, repair harness or

connectors.

OK

Go to

``CHECK

GROUND CIRCUIT'' on

EC-68.

CHECK POWER SUPPLY-II.

1. Stop engine.

2. Check voltage between ECM terminal

V70and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

E127,M21+Harness connectorsM52,F7+7.5A fuse

+Harness for open or

short between ECM and

battery

If NG, repair harness or

connectors.

CHECK POWER SUPPLY-III.

1. Turn ignition switch ``ON'' and then

``OFF''.

2. Check voltage between ECM terminals

V56,V61,11 6,11 7and ground with

CONSULT or tester.

Voltage:

After turning ignition switch ``OFF'',

battery voltage will exist for a few

seconds, then drop to approximately

0V.

NG

cOK

Go to``CHECK

GROUND CIRCUIT'' on

EC-68.

Case-1: Battery voltage does

not exist.

Case-2: Battery voltage exists

for more than a few

seconds.

Case-1

cCase-2

Go to``CHECK ECCS

RELAY'' on next page.

jA

SEF065P

SEF056R

SEF566S

SEF567S

.

.

.

.

.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Main Power Supply and Ground Circuit

(Cont'd)

EC-66

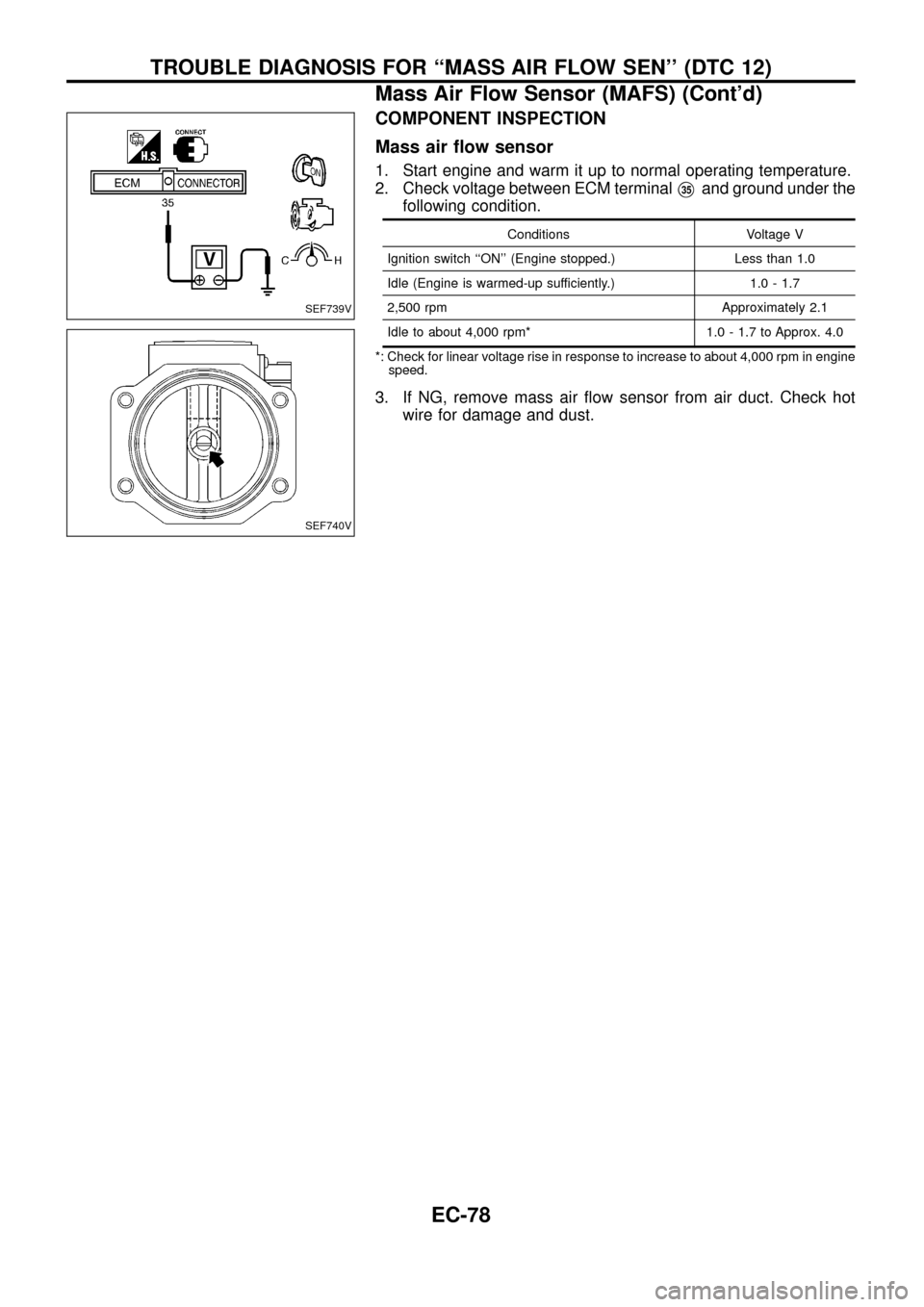

Page 80 of 192

COMPONENT INSPECTION

Mass air ¯ow sensor

1. Start engine and warm it up to normal operating temperature.

2. Check voltage between ECM terminal

V35and ground under the

following condition.

Conditions Voltage V

Ignition switch ``ON'' (Engine stopped.) Less than 1.0

Idle (Engine is warmed-up sufficiently.) 1.0 - 1.7

2,500 rpm Approximately 2.1

Idle to about 4,000 rpm* 1.0 - 1.7 to Approx. 4.0

*: Check for linear voltage rise in response to increase to about 4,000 rpm in engine

speed.

3. If NG, remove mass air ¯ow sensor from air duct. Check hot

wire for damage and dust.

SEF739V

SEF740V

TROUBLE DIAGNOSIS FOR ``MASS AIR FLOW SEN'' (DTC 12)

Mass Air Flow Sensor (MAFS) (Cont'd)

EC-78

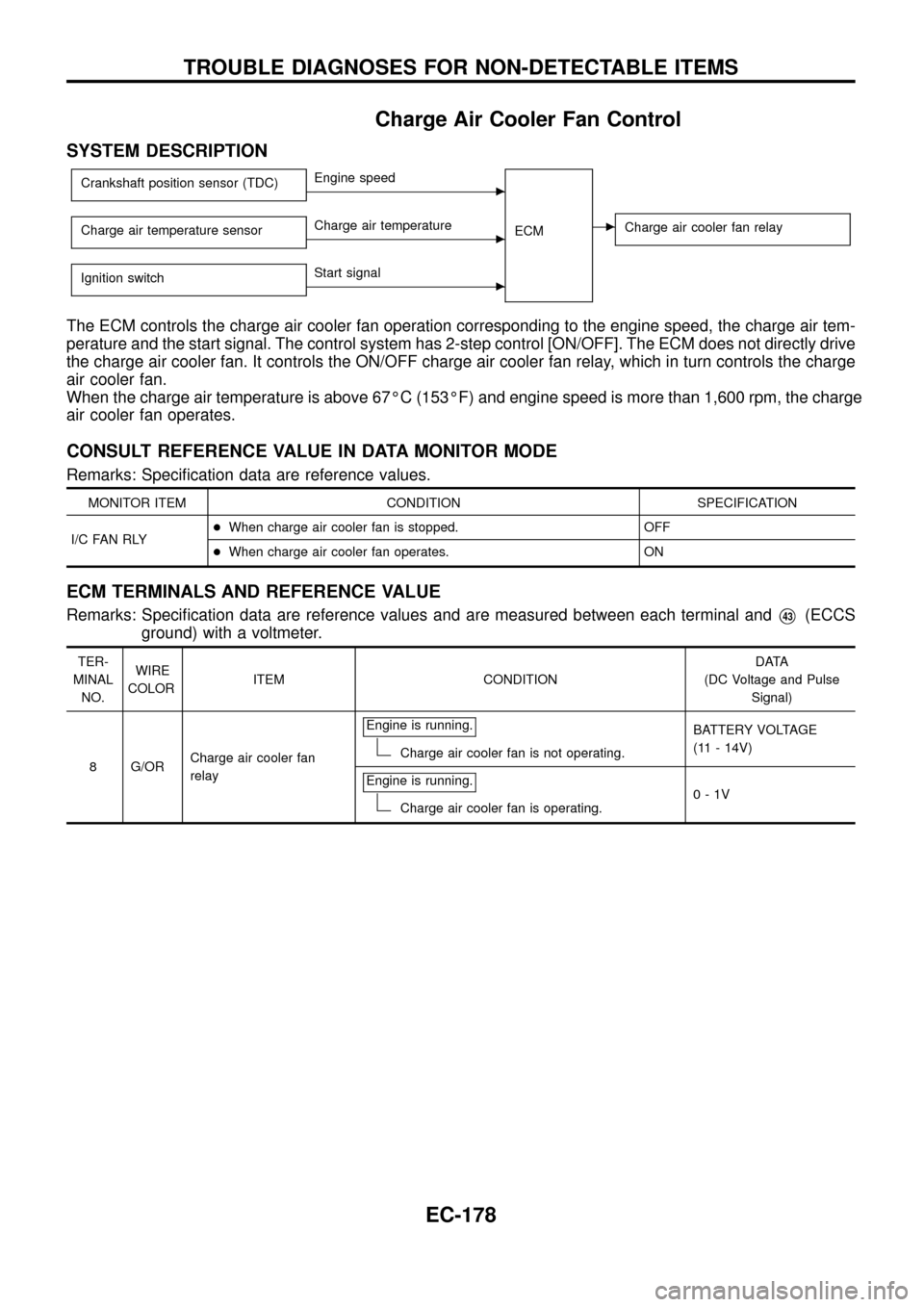

Page 180 of 192

Charge Air Cooler Fan Control

SYSTEM DESCRIPTION

Crankshaft position sensor (TDC)cEngine speed

ECM

cCharge air cooler fan relayCharge air temperature sensorcCharge air temperature

Ignition switch

cStart signal

The ECM controls the charge air cooler fan operation corresponding to the engine speed, the charge air tem-

perature and the start signal. The control system has 2-step control [ON/OFF]. The ECM does not directly drive

the charge air cooler fan. It controls the ON/OFF charge air cooler fan relay, which in turn controls the charge

air cooler fan.

When the charge air temperature is above 67ÉC (153ÉF) and engine speed is more than 1,600 rpm, the charge

air cooler fan operates.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

I/C FAN RLY+When charge air cooler fan is stopped. OFF

+When charge air cooler fan operates. ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

8 G/ORCharge air cooler fan

relayEngine is running.

Charge air cooler fan is not operating.BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Charge air cooler fan is operating.0-1V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-178

Page 182 of 192

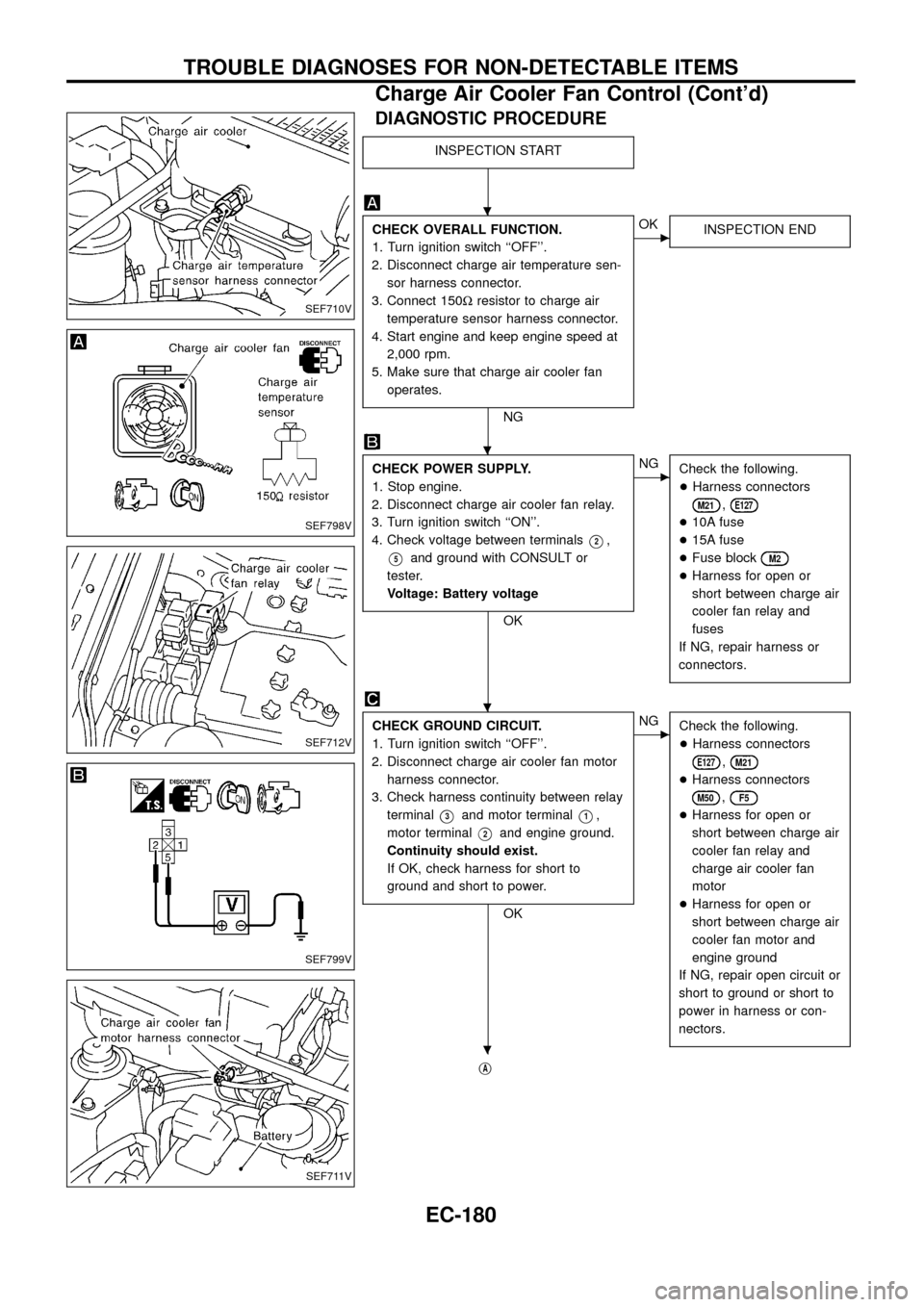

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air temperature sen-

sor harness connector.

3. Connect 150Wresistor to charge air

temperature sensor harness connector.

4. Start engine and keep engine speed at

2,000 rpm.

5. Make sure that charge air cooler fan

operates.

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect charge air cooler fan relay.

3. Turn ignition switch ``ON''.

4. Check voltage between terminals

V2,

V5and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M21,E127

+10A fuse

+15A fuse

+Fuse block

M2

+Harness for open or

short between charge air

cooler fan relay and

fuses

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air cooler fan motor

harness connector.

3. Check harness continuity between relay

terminal

V3and motor terminalV1,

motor terminal

V2and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M50,F5

+Harness for open or

short between charge air

cooler fan relay and

charge air cooler fan

motor

+Harness for open or

short between charge air

cooler fan motor and

engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF710V

SEF798V

SEF712V

SEF799V

SEF711V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-180