water pump NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 65, PDF Size: 2.4 MB

Page 9 of 65

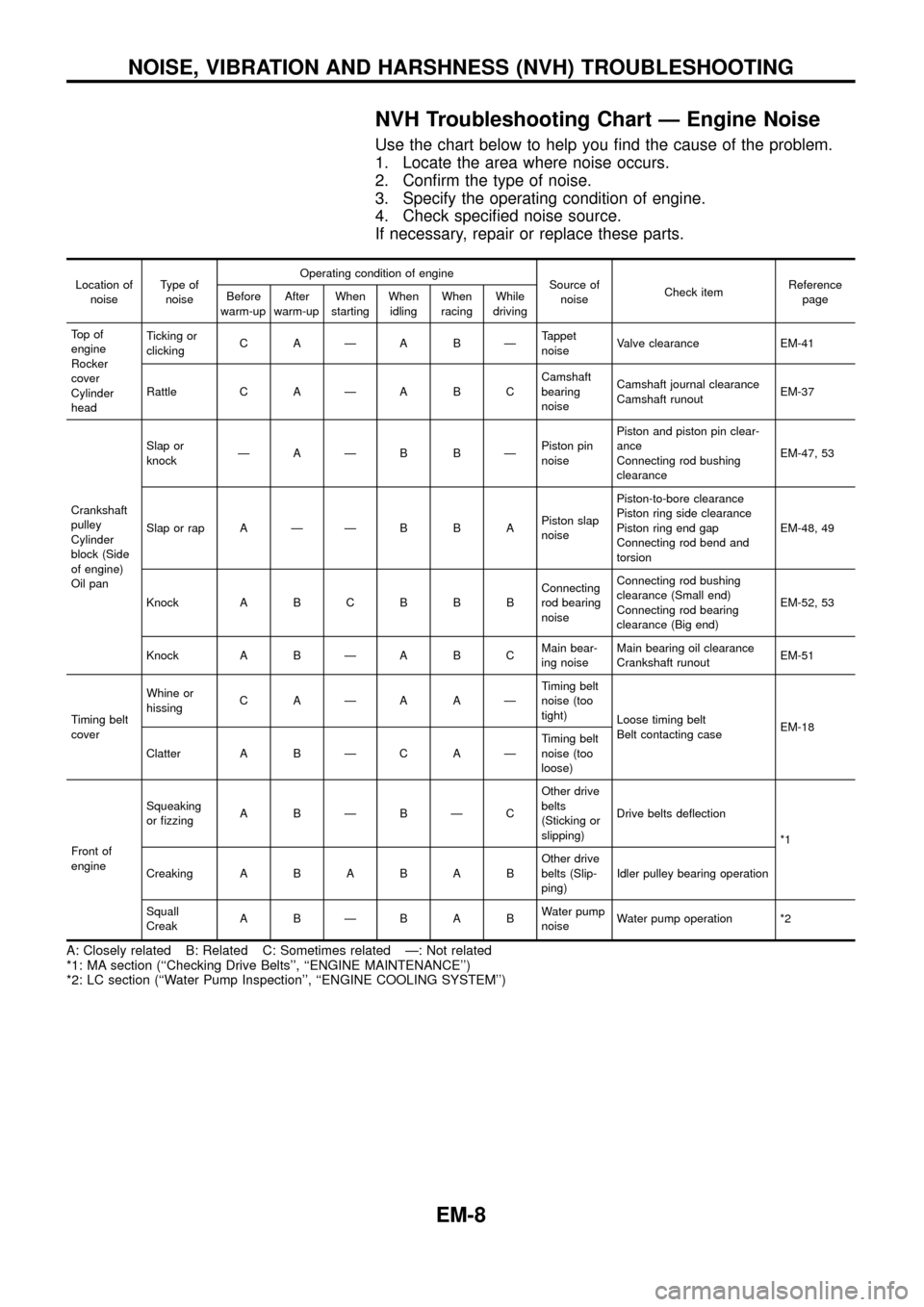

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you ®nd the cause of the problem.

1. Locate the area where noise occurs.

2. Con®rm the type of noise.

3. Specify the operating condition of engine.

4. Check speci®ed noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance EM-41

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-37

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-47, 53

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-48, 49

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-52, 53

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-51

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-18

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or ®zzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts de¯ection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (``Checking Drive Belts'', ``ENGINE MAINTENANCE'')

*2: LC section (``Water Pump Inspection'', ``ENGINE COOLING SYSTEM'')

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-8

Page 17 of 65

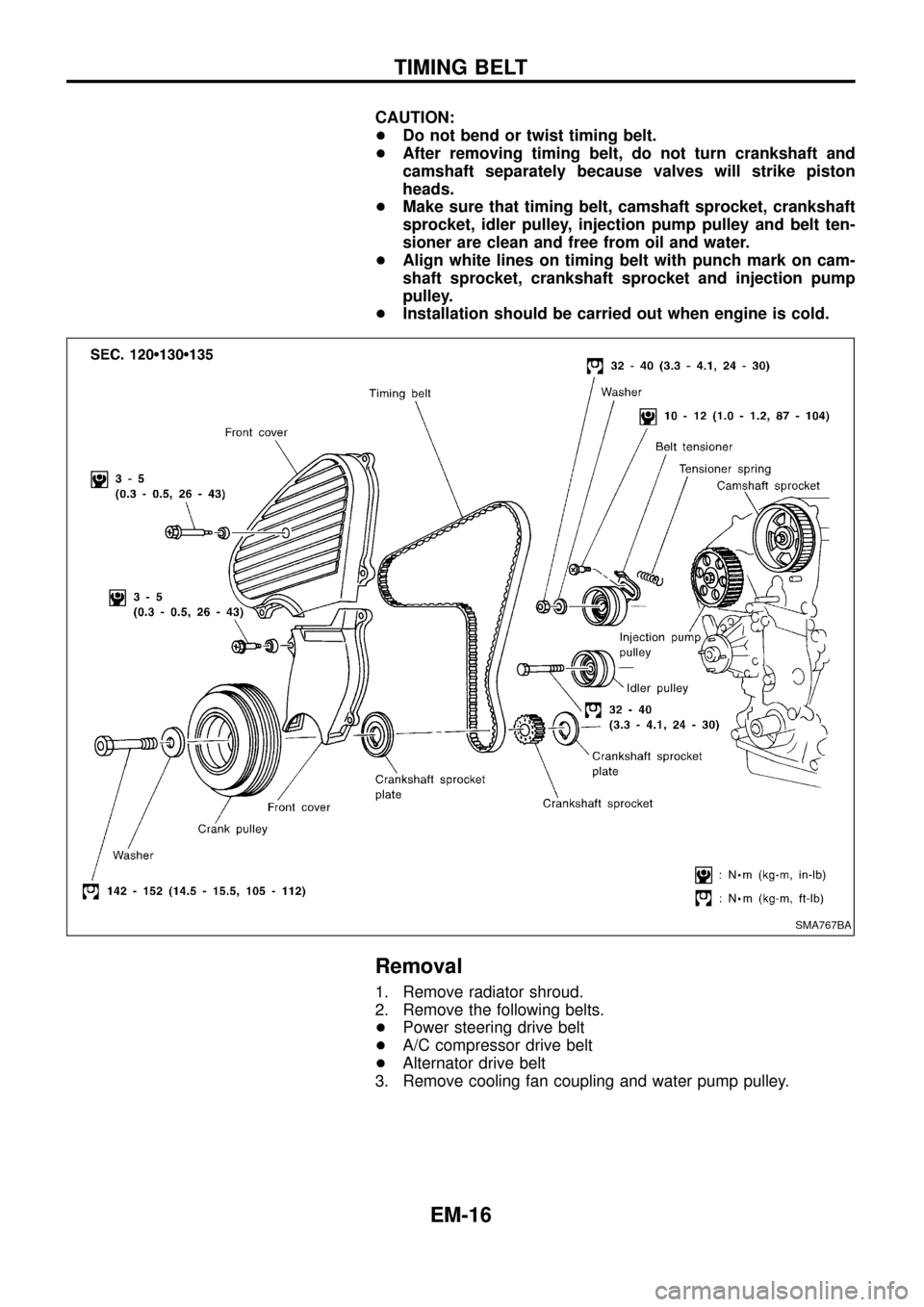

CAUTION:

+Do not bend or twist timing belt.

+After removing timing belt, do not turn crankshaft and

camshaft separately because valves will strike piston

heads.

+Make sure that timing belt, camshaft sprocket, crankshaft

sprocket, idler pulley, injection pump pulley and belt ten-

sioner are clean and free from oil and water.

+Align white lines on timing belt with punch mark on cam-

shaft sprocket, crankshaft sprocket and injection pump

pulley.

+Installation should be carried out when engine is cold.

Removal

1. Remove radiator shroud.

2. Remove the following belts.

+Power steering drive belt

+A/C compressor drive belt

+Alternator drive belt

3. Remove cooling fan coupling and water pump pulley.

SMA767BA

TIMING BELT

EM-16

Page 19 of 65

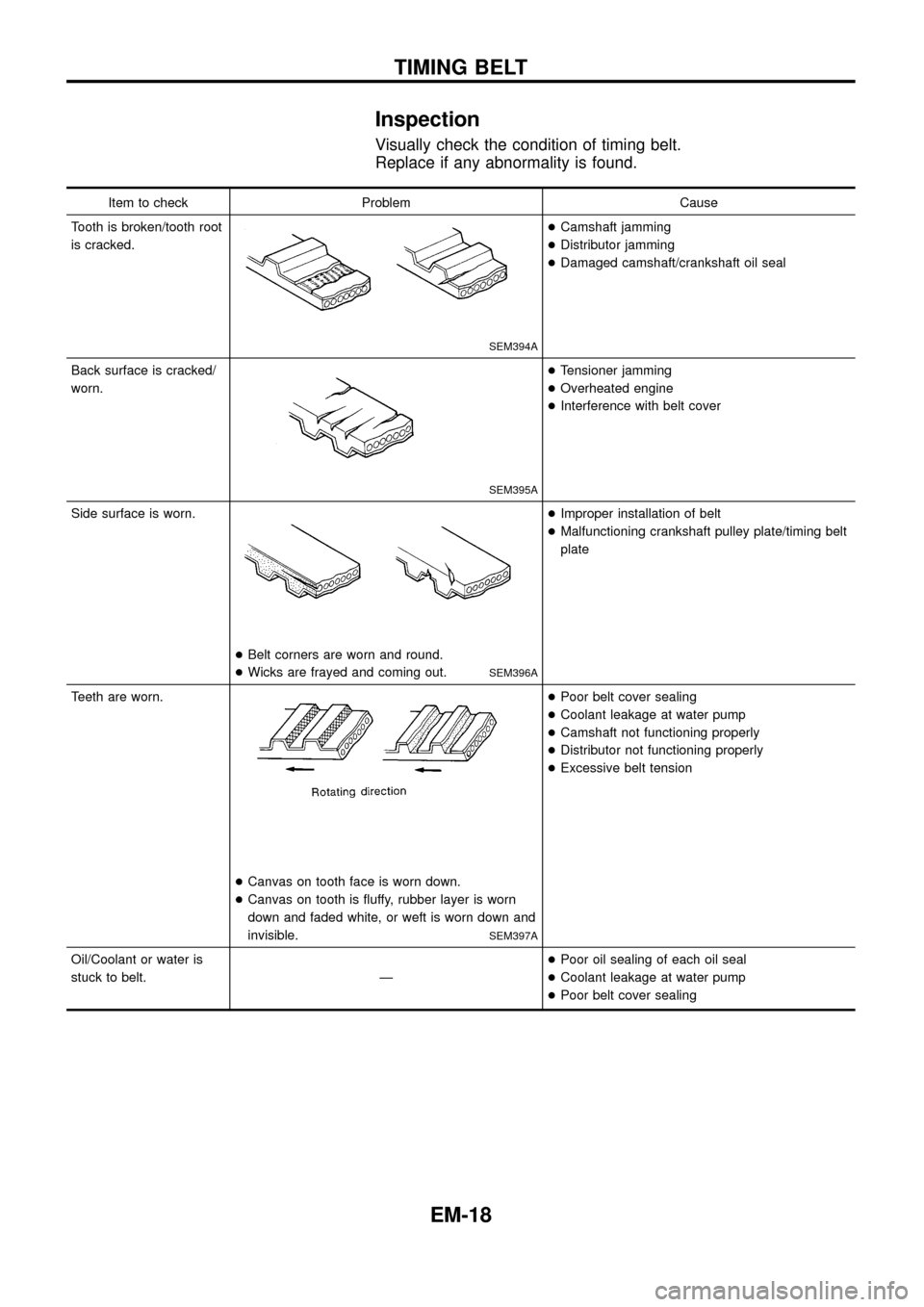

Inspection

Visually check the condition of timing belt.

Replace if any abnormality is found.

Item to check Problem Cause

Tooth is broken/tooth root

is cracked.

SEM394A

+Camshaft jamming

+Distributor jamming

+Damaged camshaft/crankshaft oil seal

Back surface is cracked/

worn.

SEM395A

+Tensioner jamming

+Overheated engine

+Interference with belt cover

Side surface is worn.

+Belt corners are worn and round.

+Wicks are frayed and coming out.

SEM396A

+Improper installation of belt

+Malfunctioning crankshaft pulley plate/timing belt

plate

Teeth are worn.

+Canvas on tooth face is worn down.

+Canvas on tooth is ¯uffy, rubber layer is worn

down and faded white, or weft is worn down and

invisible.

SEM397A

+Poor belt cover sealing

+Coolant leakage at water pump

+Camshaft not functioning properly

+Distributor not functioning properly

+Excessive belt tension

Oil/Coolant or water is

stuck to belt. Ð+Poor oil sealing of each oil seal

+Coolant leakage at water pump

+Poor belt cover sealing

TIMING BELT

EM-18

Page 20 of 65

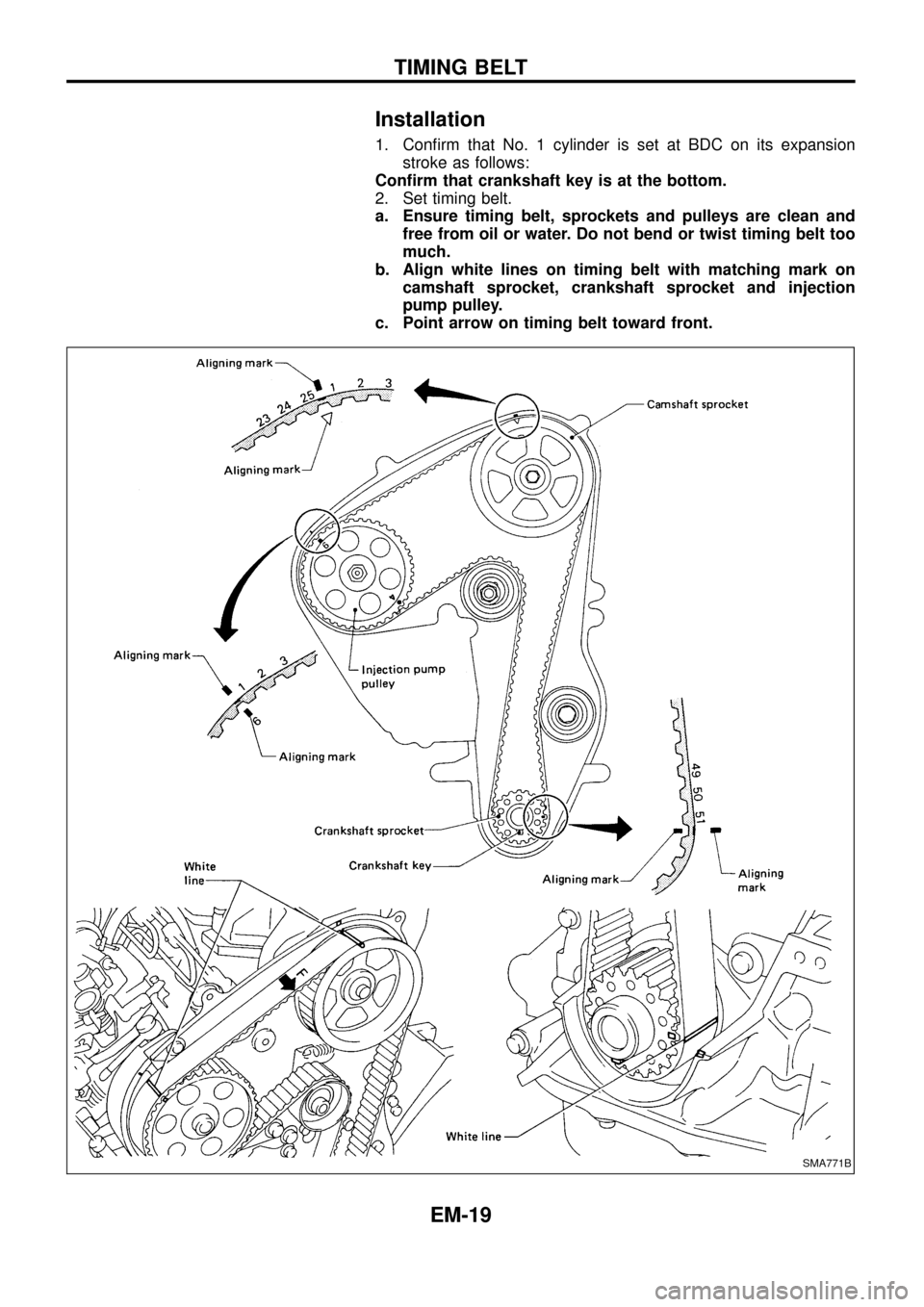

Installation

1. Con®rm that No. 1 cylinder is set at BDC on its expansion

stroke as follows:

Con®rm that crankshaft key is at the bottom.

2. Set timing belt.

a. Ensure timing belt, sprockets and pulleys are clean and

free from oil or water. Do not bend or twist timing belt too

much.

b. Align white lines on timing belt with matching mark on

camshaft sprocket, crankshaft sprocket and injection

pump pulley.

c. Point arrow on timing belt toward front.

SMA771B

TIMING BELT

EM-19

Page 21 of 65

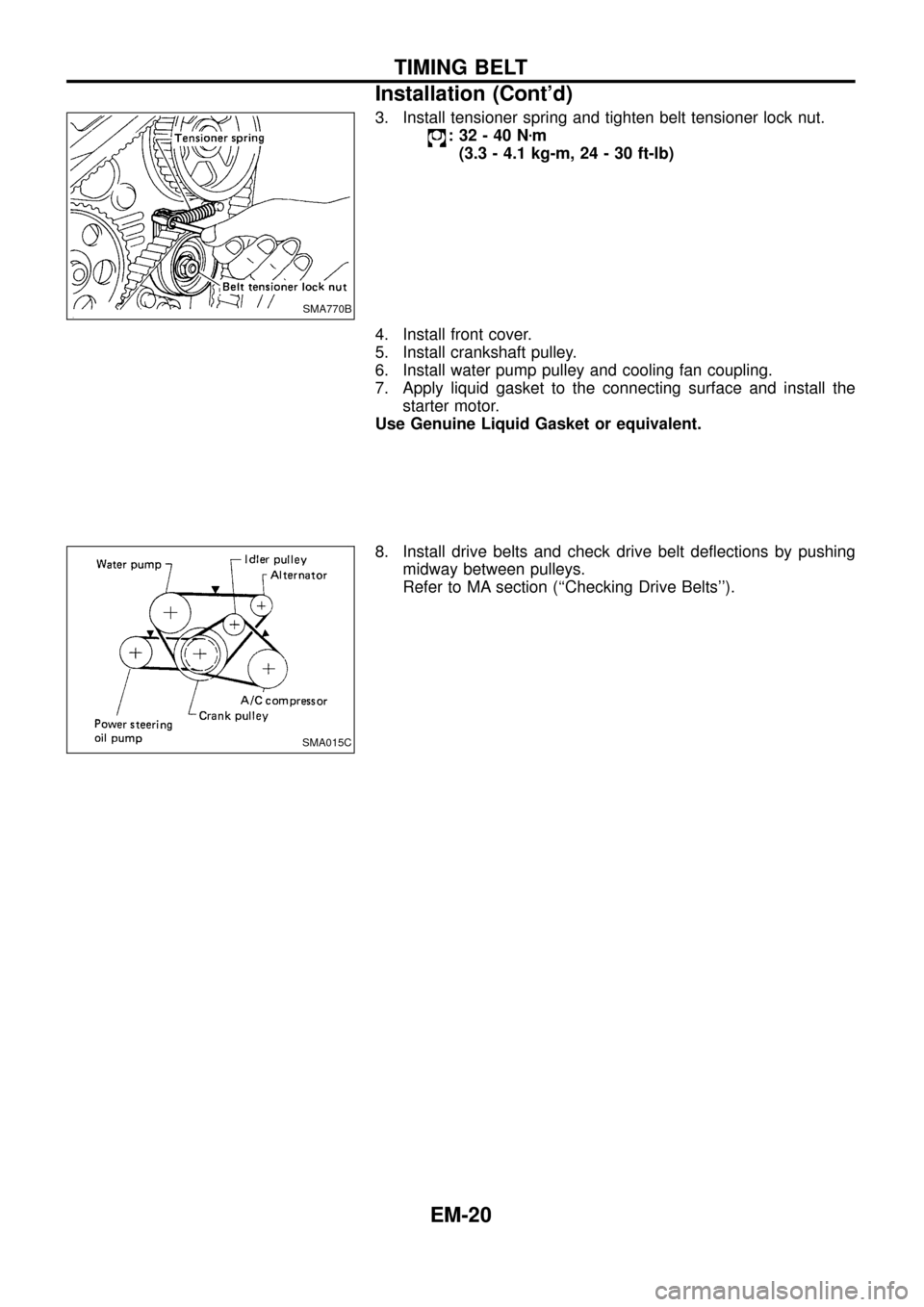

3. Install tensioner spring and tighten belt tensioner lock nut.

:32-40Nzm

(3.3 - 4.1 kg-m, 24 - 30 ft-lb)

4. Install front cover.

5. Install crankshaft pulley.

6. Install water pump pulley and cooling fan coupling.

7. Apply liquid gasket to the connecting surface and install the

starter motor.

Use Genuine Liquid Gasket or equivalent.

8. Install drive belts and check drive belt de¯ections by pushing

midway between pulleys.

Refer to MA section (``Checking Drive Belts'').

SMA770B

SMA015C

TIMING BELT

Installation (Cont'd)

EM-20

Page 48 of 65

CAUTION:

+When installing sliding parts such as bearings and

pistons, apply engine oil to the sliding surfaces.

+Place removed parts, such as bearings and bearing caps,

in their proper order and direction.

+When installing connecting rod bolts and main bearing cap

bolts, apply new engine oil to threads and seating surfaces

of nuts.

+Do not allow any magnetic materials to contact the ring

gear teeth of drive plate.

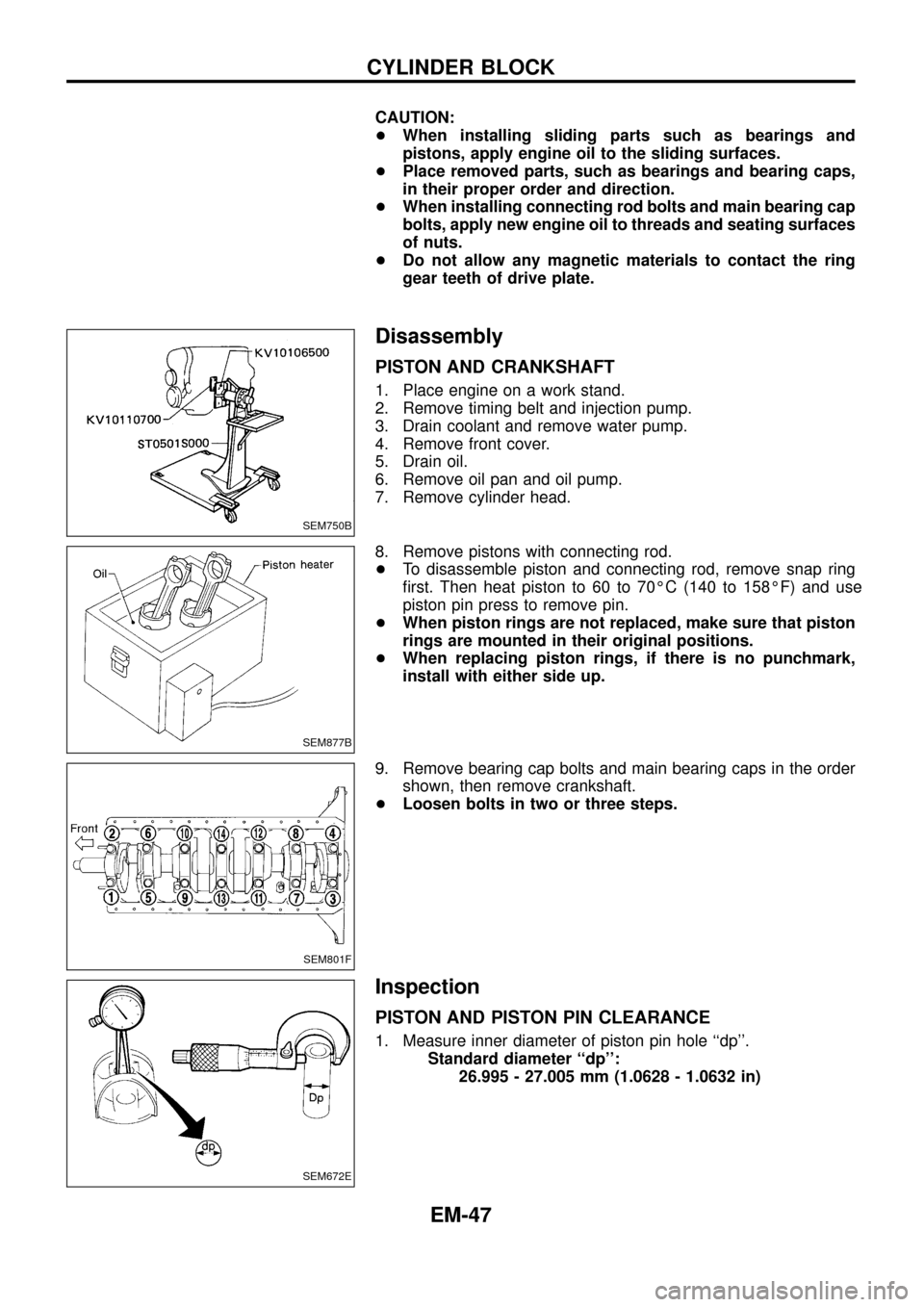

Disassembly

PISTON AND CRANKSHAFT

1. Place engine on a work stand.

2. Remove timing belt and injection pump.

3. Drain coolant and remove water pump.

4. Remove front cover.

5. Drain oil.

6. Remove oil pan and oil pump.

7. Remove cylinder head.

8. Remove pistons with connecting rod.

+To disassemble piston and connecting rod, remove snap ring

®rst. Then heat piston to 60 to 70ÉC (140 to 158ÉF) and use

piston pin press to remove pin.

+When piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

+When replacing piston rings, if there is no punchmark,

install with either side up.

9. Remove bearing cap bolts and main bearing caps in the order

shown, then remove crankshaft.

+Loosen bolts in two or three steps.

Inspection

PISTON AND PISTON PIN CLEARANCE

1. Measure inner diameter of piston pin hole ``dp''.

Standard diameter ``dp'':

26.995 - 27.005 mm (1.0628 - 1.0632 in)

SEM750B

SEM877B

SEM801F

SEM672E

CYLINDER BLOCK

EM-47