NISSAN PATROL 1998 Y61 / 5.G Clutch Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 17, PDF Size: 0.49 MB

Page 1 of 17

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Precautions ..................................................................1

Special Service Tools ..................................................1

Commercial Service Tools ...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

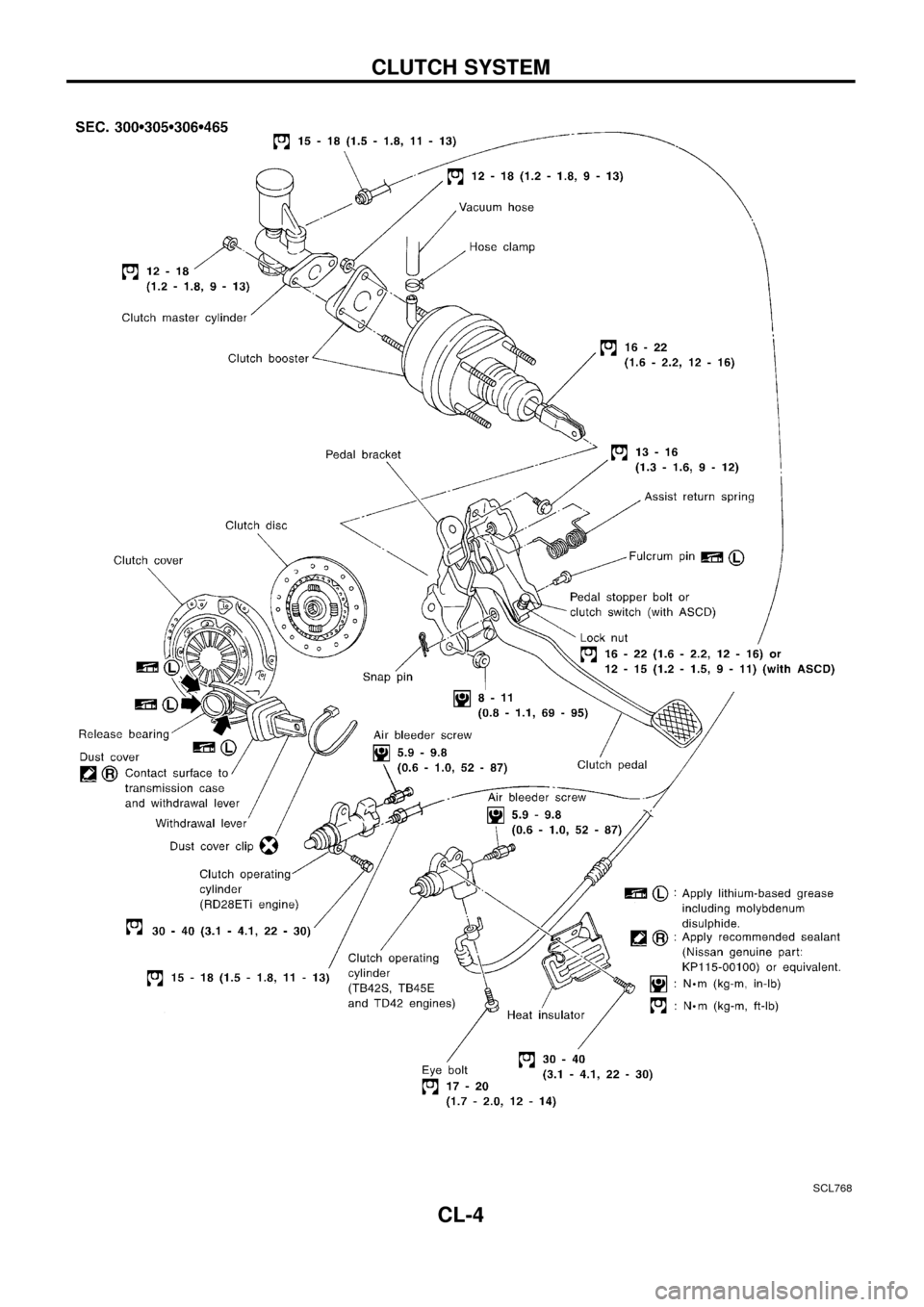

CLUTCH SYSTEM...........................................................4

INSPECTION AND ADJUSTMENT.................................5

Adjusting Clutch Pedal ................................................5

Air Bleeding Procedure................................................6HYDRAULIC CLUTCH CONTROL.................................7

Clutch Master Cylinder ................................................7

Clutch Operating Cylinder ...........................................8

Clutch Booster .............................................................9

CLUTCH RELEASE MECHANISM............................... 11

CLUTCH DISC AND CLUTCH COVER........................13

Clutch Disc.................................................................13

Clutch Cover and Flywheel .......................................14

SERVICE DATA AND SPECIFICATIONS (SDS)..........16

General Speci®cations ...............................................16

Inspection and Adjustment ........................................16

CL

Page 2 of 17

Precautions

+Recommended ¯uid is brake ¯uid ``DOT 3''.

+Do not reuse drained brake ¯uid.

+Be careful not to splash brake ¯uid on painted areas.

+When removing and installing clutch piping, use Tool.

+Use new brake ¯uid to clean or wash all parts of master

cylinder, operating cylinder and clutch damper.

+Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

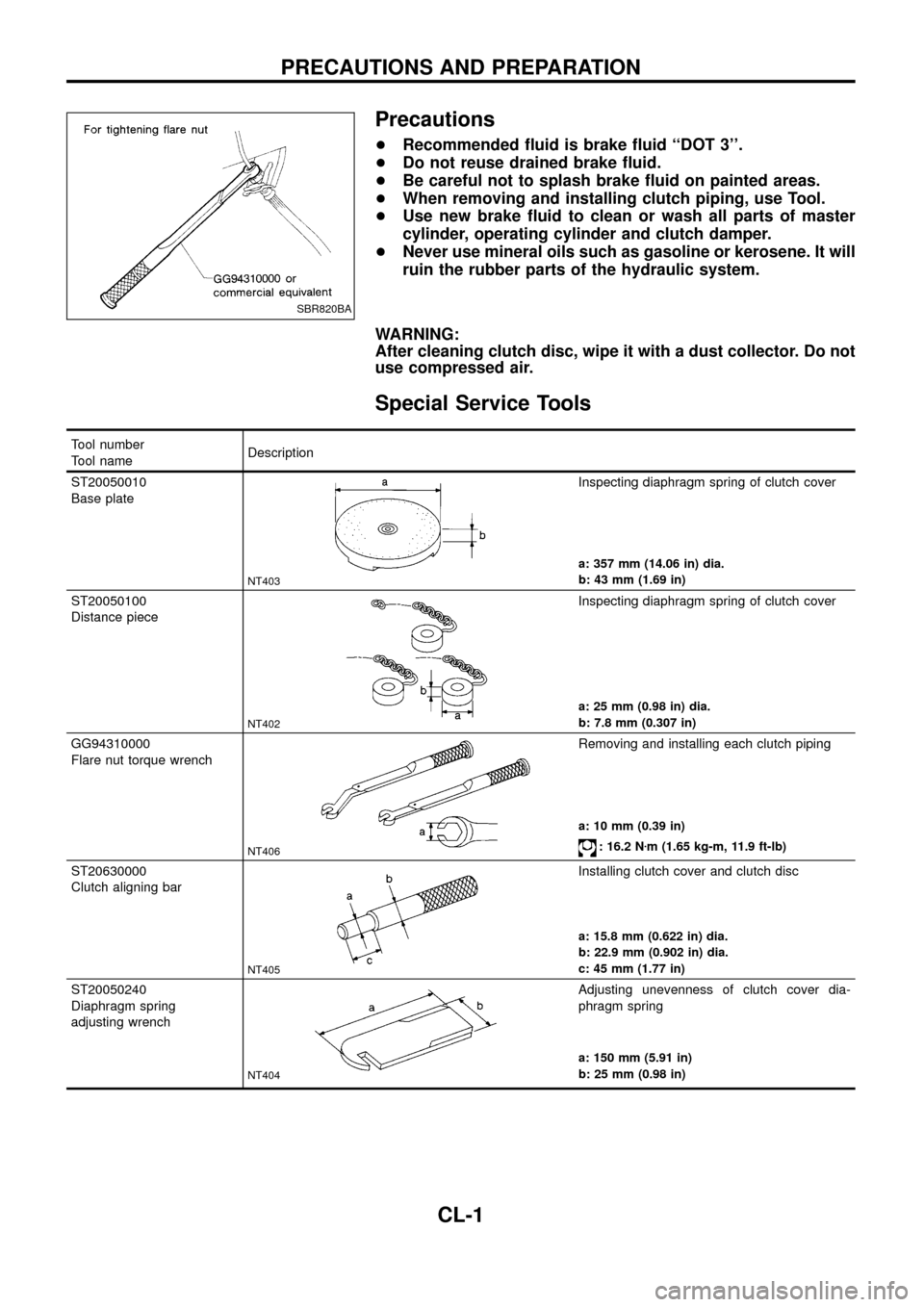

Special Service Tools

Tool number

Tool nameDescription

ST20050010

Base plate

NT403

Inspecting diaphragm spring of clutch cover

a: 357 mm (14.06 in) dia.

b: 43 mm (1.69 in)

ST20050100

Distance piece

NT402

Inspecting diaphragm spring of clutch cover

a: 25 mm (0.98 in) dia.

b: 7.8 mm (0.307 in)

GG94310000

Flare nut torque wrench

NT406

Removing and installing each clutch piping

a: 10 mm (0.39 in)

: 16.2 Nzm (1.65 kg-m, 11.9 ft-lb)

ST20630000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45 mm (1.77 in)

ST20050240

Diaphragm spring

adjusting wrench

NT404

Adjusting unevenness of clutch cover dia-

phragm spring

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

SBR820BA

PRECAUTIONS AND PREPARATION

CL-1

Page 3 of 17

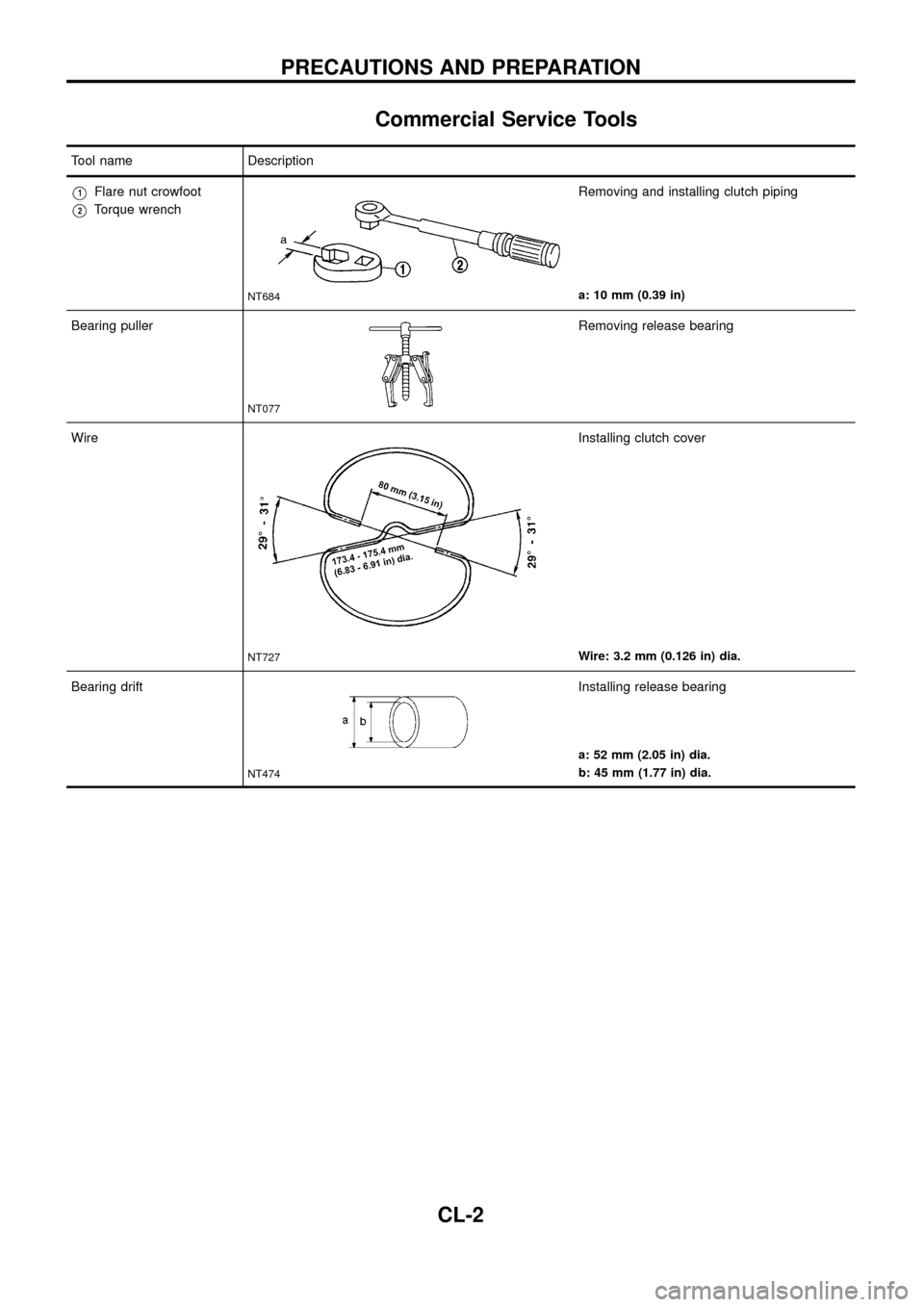

Commercial Service Tools

Tool name Description

V1Flare nut crowfoot

V2Torque wrench

NT684

Removing and installing clutch piping

a: 10 mm (0.39 in)

Bearing puller

NT077

Removing release bearing

Wire

NT727

Installing clutch cover

Wire: 3.2 mm (0.126 in) dia.

Bearing drift

NT474

Installing release bearing

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

PRECAUTIONS AND PREPARATION

CL-2

Page 4 of 17

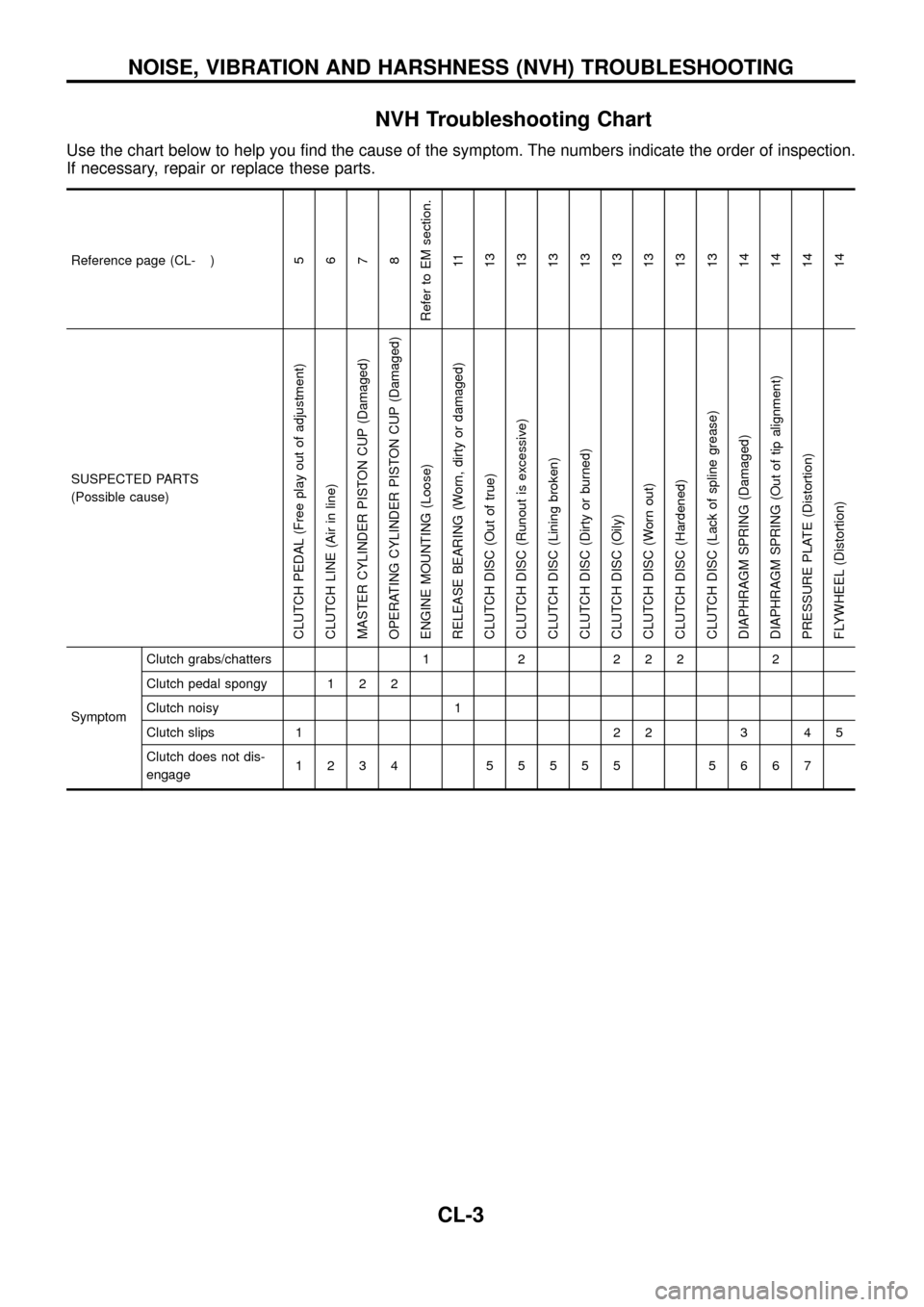

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. The numbers indicate the order of inspection.

If necessary, repair or replace these parts.

Reference page (CL- )5

6

7

8

Refer to EM section.

11

13

13

13

13

13

13

13

13

14

14

14

14

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not dis-

engage1234 55555 5667

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

CL-3

Page 5 of 17

SCL768

CLUTCH SYSTEM

CL-4

Page 6 of 17

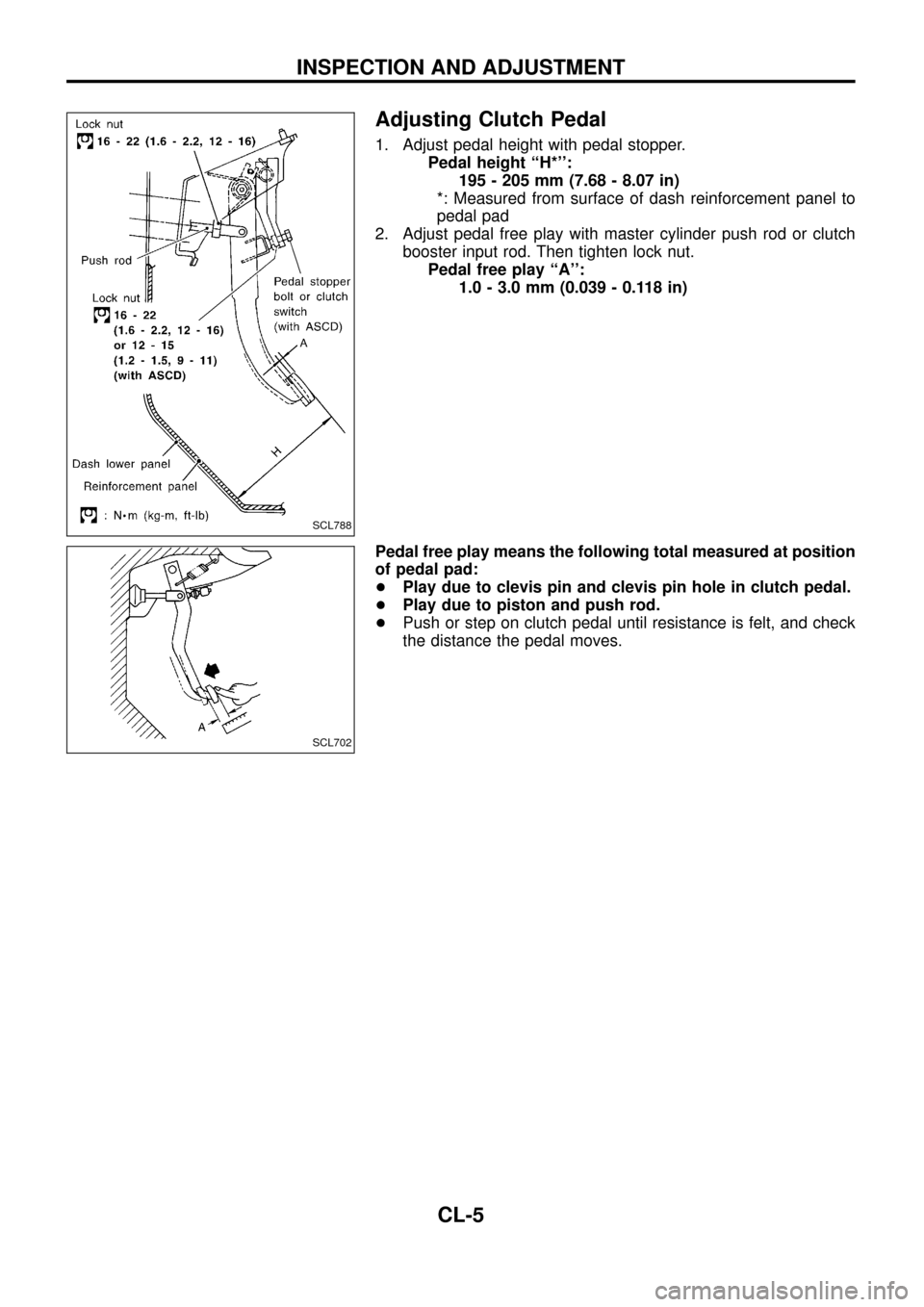

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

Pedal height ``H*'':

195 - 205 mm (7.68 - 8.07 in)

*: Measured from surface of dash reinforcement panel to

pedal pad

2. Adjust pedal free play with master cylinder push rod or clutch

booster input rod. Then tighten lock nut.

Pedal free play ``A'':

1.0 - 3.0 mm (0.039 - 0.118 in)

Pedal free play means the following total measured at position

of pedal pad:

+Play due to clevis pin and clevis pin hole in clutch pedal.

+Play due to piston and push rod.

+Push or step on clutch pedal until resistance is felt, and check

the distance the pedal moves.

SCL788

SCL702

INSPECTION AND ADJUSTMENT

CL-5

Page 7 of 17

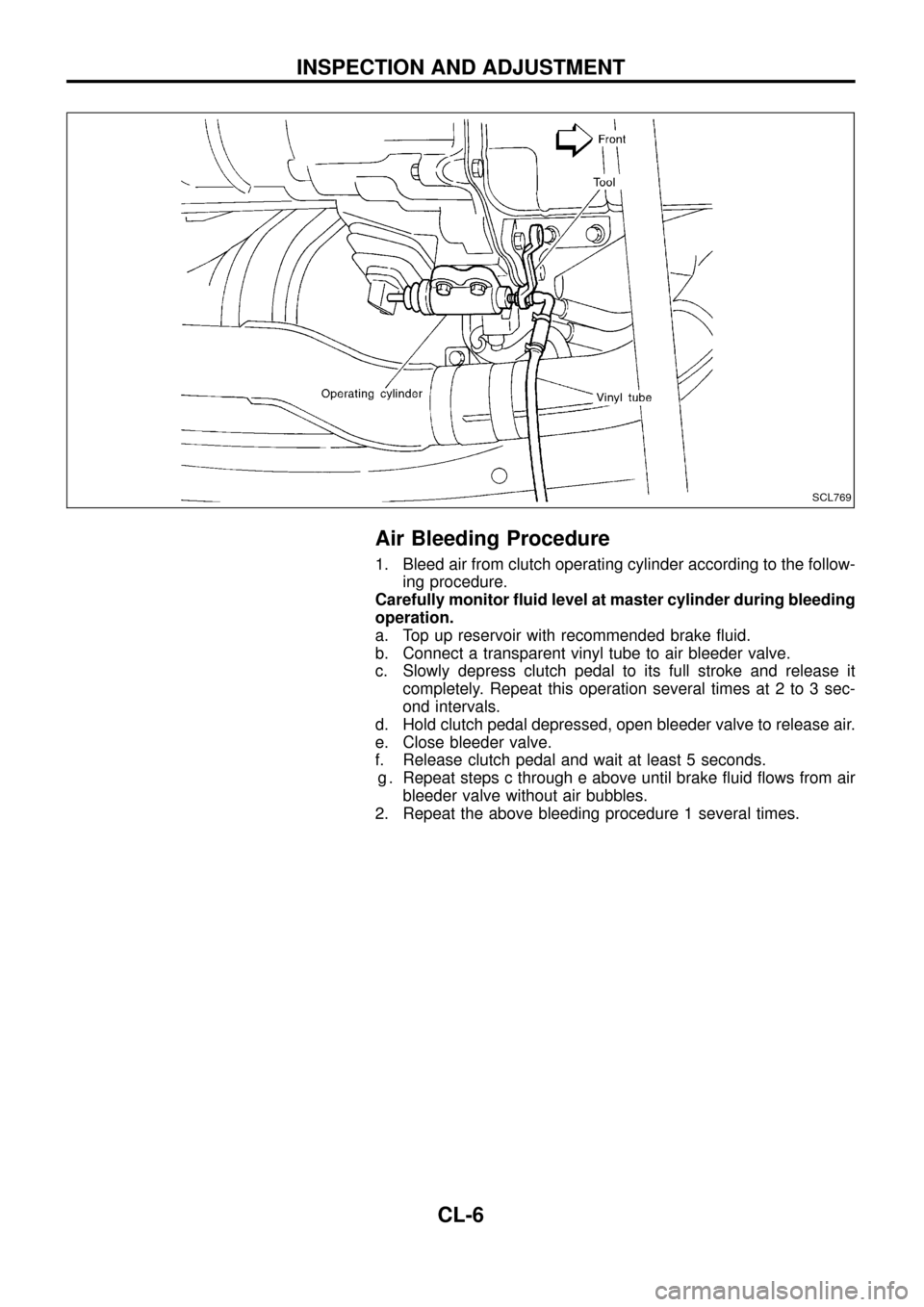

Air Bleeding Procedure

1. Bleed air from clutch operating cylinder according to the follow-

ing procedure.

Carefully monitor ¯uid level at master cylinder during bleeding

operation.

a. Top up reservoir with recommended brake ¯uid.

b. Connect a transparent vinyl tube to air bleeder valve.

c. Slowly depress clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec-

ond intervals.

d. Hold clutch pedal depressed, open bleeder valve to release air.

e. Close bleeder valve.

f. Release clutch pedal and wait at least 5 seconds.

g . Repeat steps c through e above until brake ¯uid ¯ows from air

bleeder valve without air bubbles.

2. Repeat the above bleeding procedure 1 several times.

SCL769

INSPECTION AND ADJUSTMENT

CL-6

Page 8 of 17

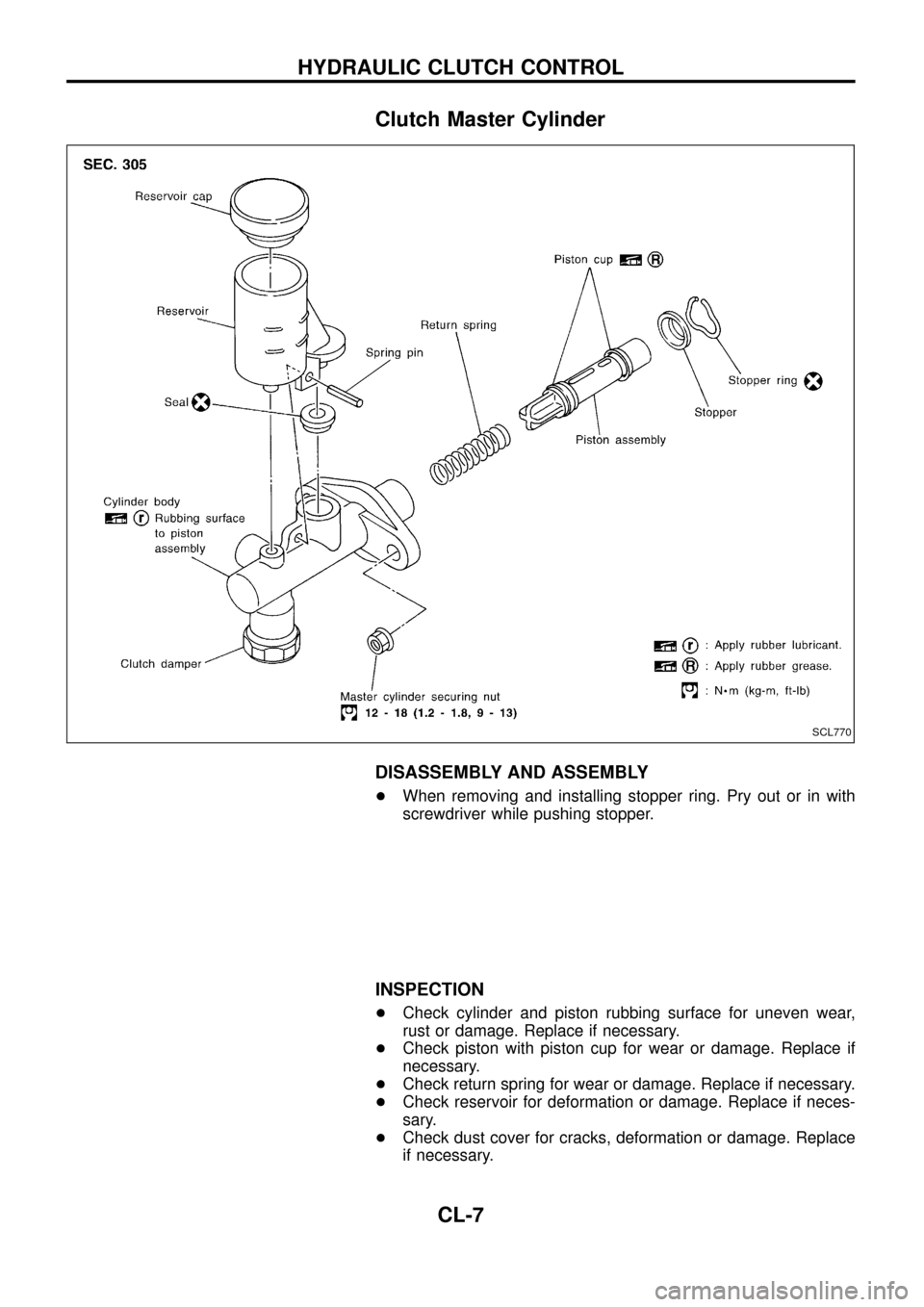

Clutch Master Cylinder

DISASSEMBLY AND ASSEMBLY

+When removing and installing stopper ring. Pry out or in with

screwdriver while pushing stopper.

INSPECTION

+Check cylinder and piston rubbing surface for uneven wear,

rust or damage. Replace if necessary.

+Check piston with piston cup for wear or damage. Replace if

necessary.

+Check return spring for wear or damage. Replace if necessary.

+Check reservoir for deformation or damage. Replace if neces-

sary.

+Check dust cover for cracks, deformation or damage. Replace

if necessary.

SCL770

HYDRAULIC CLUTCH CONTROL

CL-7

Page 9 of 17

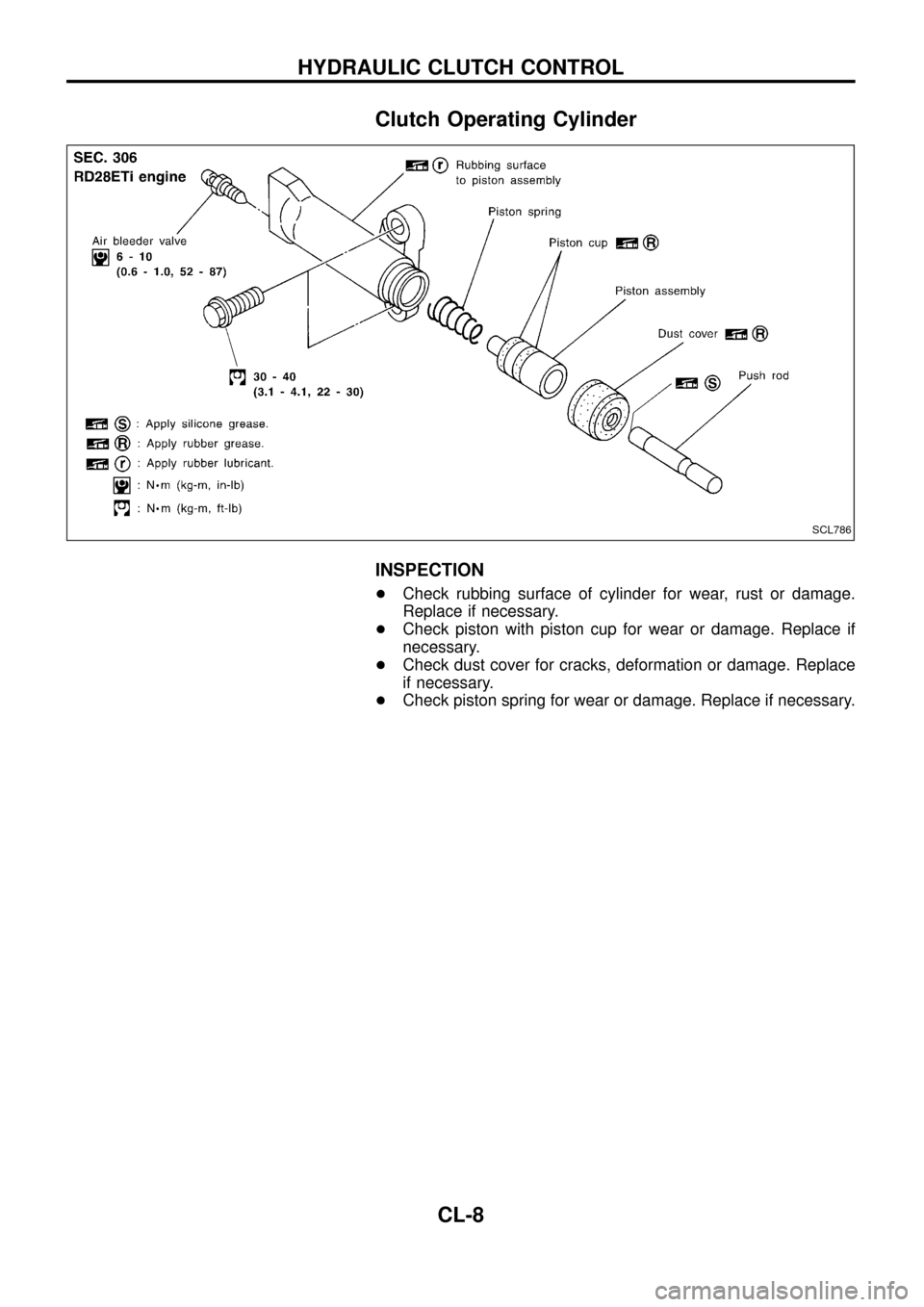

Clutch Operating Cylinder

INSPECTION

+Check rubbing surface of cylinder for wear, rust or damage.

Replace if necessary.

+Check piston with piston cup for wear or damage. Replace if

necessary.

+Check dust cover for cracks, deformation or damage. Replace

if necessary.

+Check piston spring for wear or damage. Replace if necessary.

SCL786

HYDRAULIC CLUTCH CONTROL

CL-8

Page 10 of 17

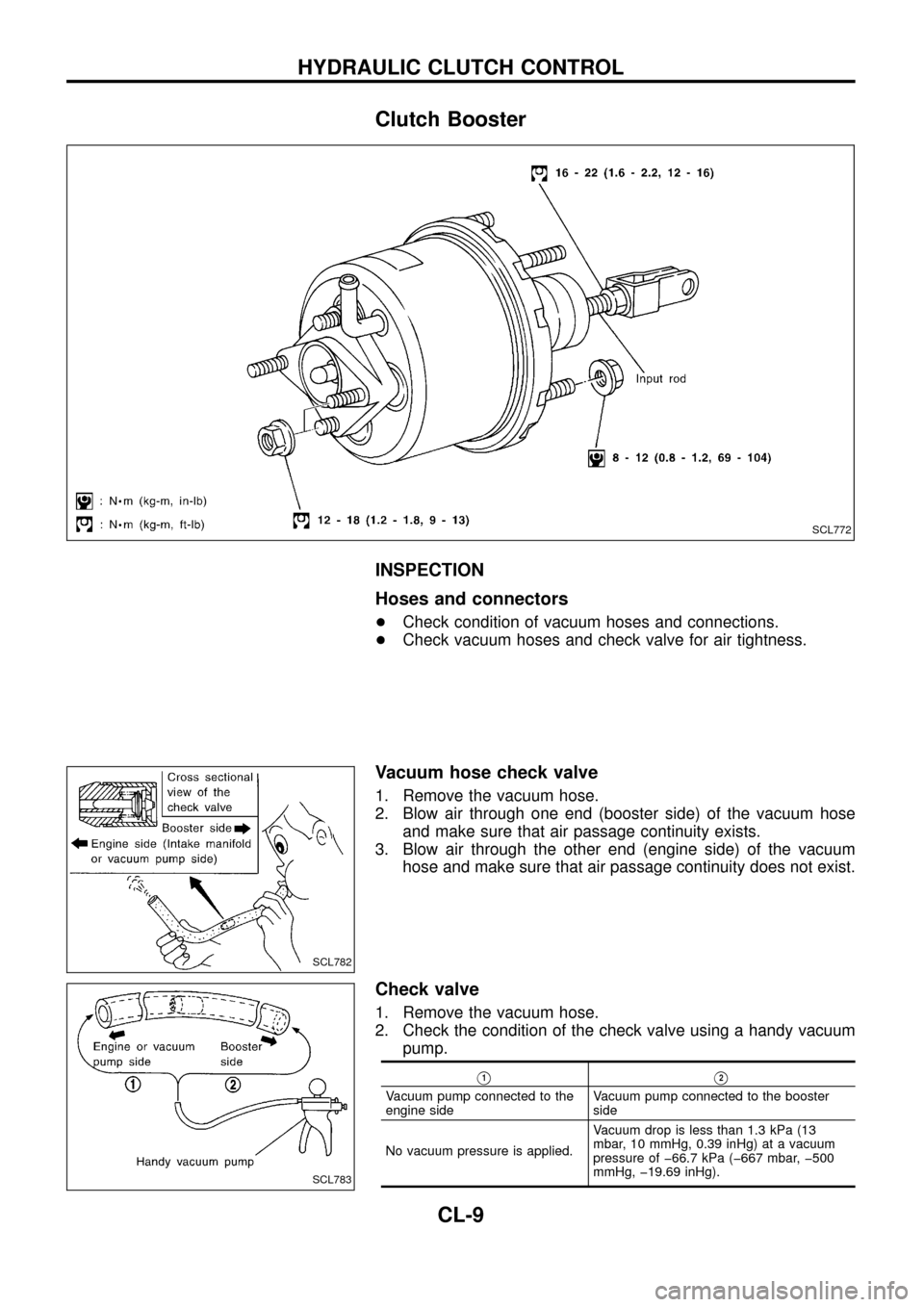

Clutch Booster

INSPECTION

Hoses and connectors

+Check condition of vacuum hoses and connections.

+Check vacuum hoses and check valve for air tightness.

Vacuum hose check valve

1. Remove the vacuum hose.

2. Blow air through one end (booster side) of the vacuum hose

and make sure that air passage continuity exists.

3. Blow air through the other end (engine side) of the vacuum

hose and make sure that air passage continuity does not exist.

Check valve

1. Remove the vacuum hose.

2. Check the condition of the check valve using a handy vacuum

pump.

V1V2

Vacuum pump connected to the

engine sideVacuum pump connected to the booster

side

No vacuum pressure is applied.Vacuum drop is less than 1.3 kPa (13

mbar, 10 mmHg, 0.39 inHg) at a vacuum

pressure of þ66.7 kPa (þ667 mbar, þ500

mmHg, þ19.69 inHg).

SCL772

SCL782

SCL783

HYDRAULIC CLUTCH CONTROL

CL-9