NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 65, PDF Size: 2.4 MB

Page 1 of 65

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................1

Parts Requiring Angular Tightening .............................1

Liquid Gasket Application Procedure ..........................1

PREPARATION................................................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart Ð Engine Noise .............7

OUTER COMPONENT PARTS.......................................8

COMPRESSION PRESSURE........................................10

Measurement of Compression Pressure ...................10

OIL PAN.........................................................................13

Removal .....................................................................13

Installation ..................................................................14

TIMING BELT.................................................................15

Removal .....................................................................15

Inspection...................................................................17

Installation ..................................................................18

OIL SEAL REPLACEMENT..........................................20

TURBOCHARGER.........................................................23

Removal and Installation ...........................................23

Inspection...................................................................24CHARGE AIR COOLERS..............................................27

CYLINDER HEAD..........................................................28

Removal .....................................................................29

Disassembly...............................................................30

Inspection...................................................................31

Assembly ...................................................................37

Installation ..................................................................37

VALVE CLEARANCE....................................................40

Checking ....................................................................40

Adjusting ....................................................................41

ENGINE REMOVAL.......................................................43

Removal .....................................................................44

Installation ..................................................................44

CYLINDER BLOCK.......................................................45

Disassembly...............................................................46

Inspection...................................................................46

Assembly ...................................................................53

SERVICE DATA AND SPECIFICATIONS (SDS)..........56

General Speci®cations ...............................................56

Inspection and Adjustment ........................................56

EM

Page 2 of 65

Parts Requiring Angular Tightening

+Some important engine parts are tightened using an angular-

tightening method rather than a torque setting method.

+If these parts are tightened using a torque setting method, dis-

persal of the tightening force (axial bolt force) will be two or

three times that of the dispersal produced by using the correct

angular-tightening method.

+Although the torque setting values (described in this manual)

are equivalent to those used when bolts and nuts are tightened

with an angular-tightening method, they should be used for

reference only.

+To assure the satisfactory maintenance of the engine, bolts and

nuts must be tightened using an angular-tightening method.

+Before tightening the bolts and nuts, ensure that the thread and

seating surfaces are clean and then coated with engine oil.

+The bolts and nuts which require the angular-tightening method

are cylinder head bolts.

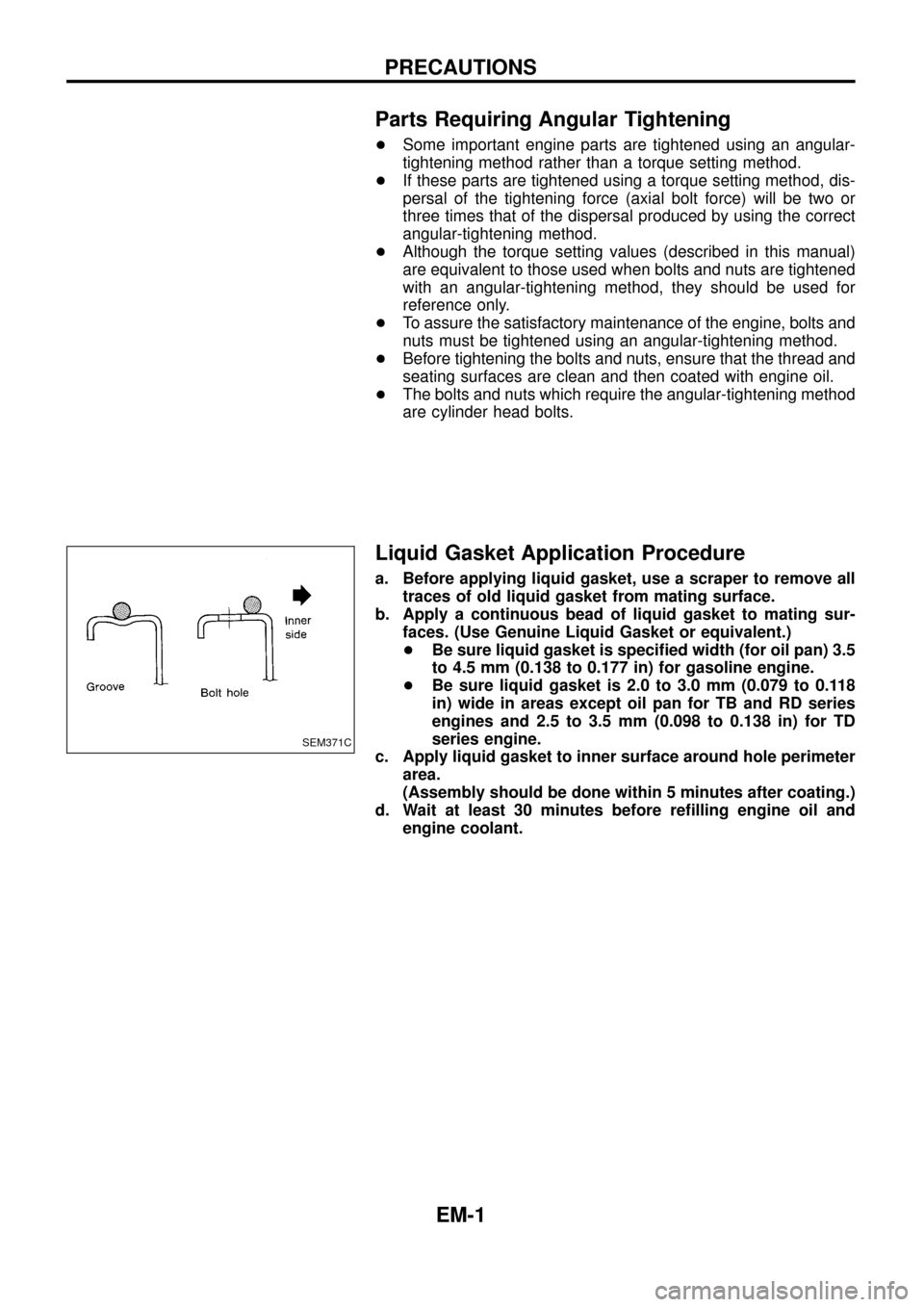

Liquid Gasket Application Procedure

a. Before applying liquid gasket, use a scraper to remove all

traces of old liquid gasket from mating surface.

b. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+Be sure liquid gasket is speci®ed width (for oil pan) 3.5

to 4.5 mm (0.138 to 0.177 in) for gasoline engine.

+Be sure liquid gasket is 2.0 to 3.0 mm (0.079 to 0.118

in) wide in areas except oil pan for TB and RD series

engines and 2.5 to 3.5 mm (0.098 to 0.138 in) for TD

series engine.

c. Apply liquid gasket to inner surface around hole perimeter

area.

(Assembly should be done within 5 minutes after coating.)

d. Wait at least 30 minutes before re®lling engine oil and

engine coolant.

SEM371C

PRECAUTIONS

EM-1

Page 3 of 65

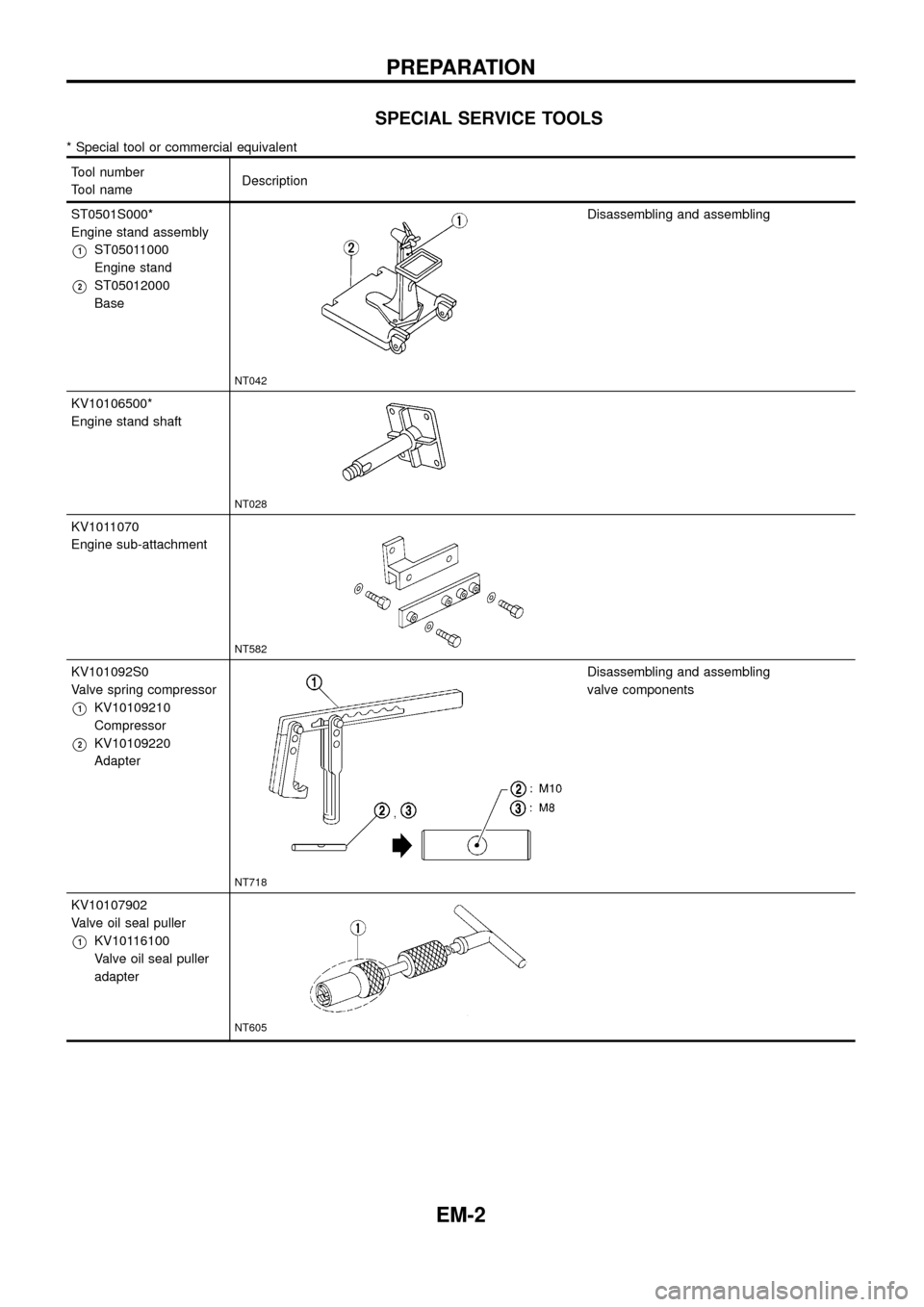

SPECIAL SERVICE TOOLS

* Special tool or commercial equivalent

Tool number

Tool nameDescription

ST0501S000*

Engine stand assembly

V1ST05011000

Engine stand

V2ST05012000

Base

NT042

Disassembling and assembling

KV10106500*

Engine stand shaft

NT028

KV1011070

Engine sub-attachment

NT582

KV101092S0

Valve spring compressor

V1KV10109210

Compressor

V2KV10109220

Adapter

NT718

Disassembling and assembling

valve components

KV10107902

Valve oil seal puller

V1KV10116100

Valve oil seal puller

adapter

NT605

PREPARATION

EM-2

Page 4 of 65

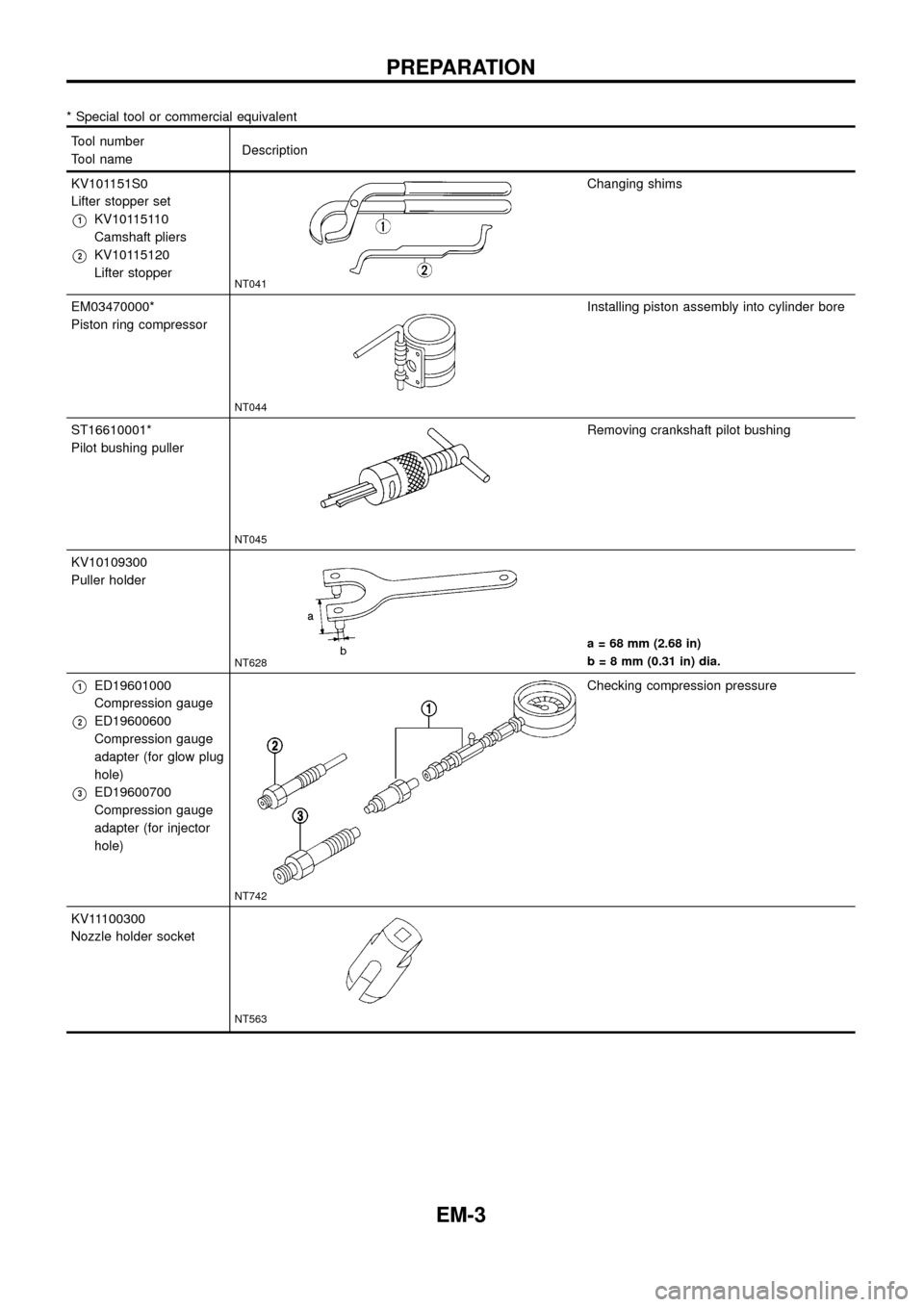

* Special tool or commercial equivalent

Tool number

Tool nameDescription

KV101151S0

Lifter stopper set

V1KV10115110

Camshaft pliers

V2KV10115120

Lifter stopper

NT041

Changing shims

EM03470000*

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

ST16610001*

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV10109300

Puller holder

NT628

a = 68 mm (2.68 in)

b = 8 mm (0.31 in) dia.

V1ED19601000

Compression gauge

V2ED19600600

Compression gauge

adapter (for glow plug

hole)

V3ED19600700

Compression gauge

adapter (for injector

hole)

NT742

Checking compression pressure

KV11100300

Nozzle holder socket

NT563

PREPARATION

EM-3

Page 5 of 65

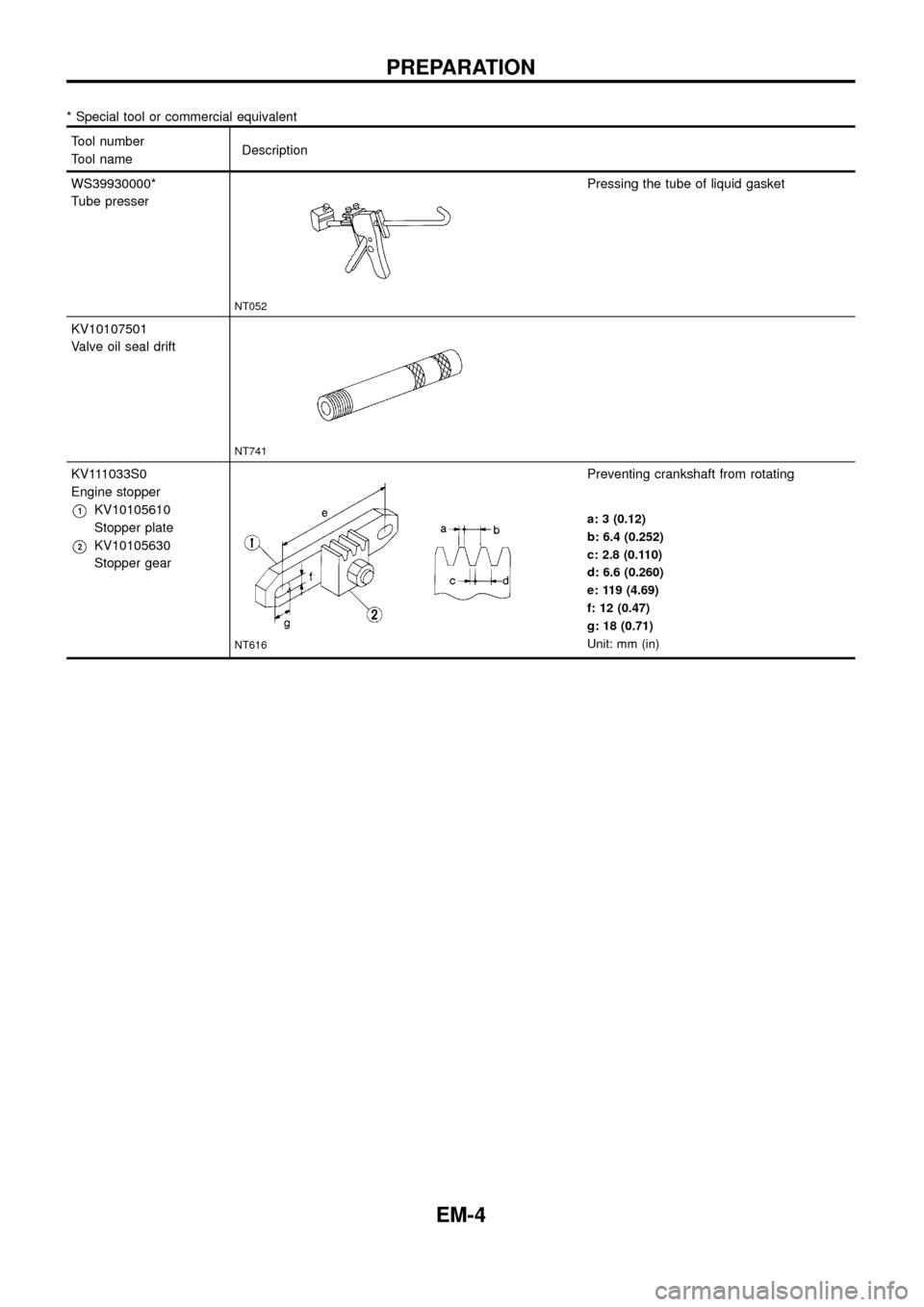

* Special tool or commercial equivalent

Tool number

Tool nameDescription

WS39930000*

Tube presser

NT052

Pressing the tube of liquid gasket

KV10107501

Valve oil seal drift

NT741

KV111033S0

Engine stopper

V1KV10105610

Stopper plate

V2KV10105630

Stopper gear

NT616

Preventing crankshaft from rotating

a: 3 (0.12)

b: 6.4 (0.252)

c: 2.8 (0.110)

d: 6.6 (0.260)

e: 119 (4.69)

f: 12 (0.47)

g: 18 (0.71)

Unit: mm (in)

PREPARATION

EM-4

Page 6 of 65

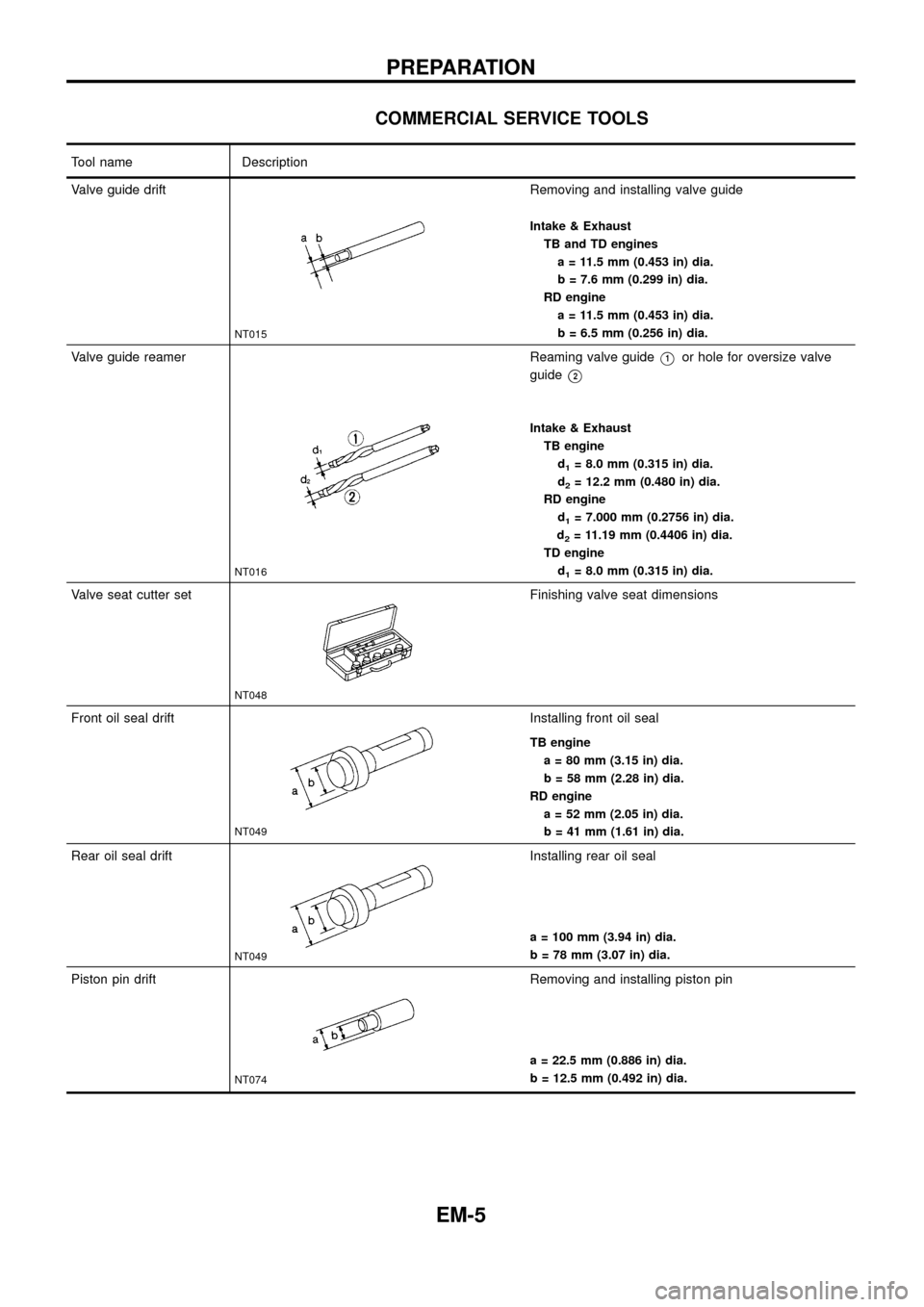

COMMERCIAL SERVICE TOOLS

Tool name Description

Valve guide drift

NT015

Removing and installing valve guide

Intake & Exhaust

TB and TD engines

a = 11.5 mm (0.453 in) dia.

b = 7.6 mm (0.299 in) dia.

RD engine

a = 11.5 mm (0.453 in) dia.

b = 6.5 mm (0.256 in) dia.

Valve guide reamer

NT016

Reaming valve guideV1or hole for oversize valve

guide

V2

Intake & Exhaust

TB engine

d

1= 8.0 mm (0.315 in) dia.

d

2= 12.2 mm (0.480 in) dia.

RD engine

d

1= 7.000 mm (0.2756 in) dia.

d

2= 11.19 mm (0.4406 in) dia.

TD engine

d

1= 8.0 mm (0.315 in) dia.

Valve seat cutter set

NT048

Finishing valve seat dimensions

Front oil seal drift

NT049

Installing front oil seal

TB engine

a = 80 mm (3.15 in) dia.

b = 58 mm (2.28 in) dia.

RD engine

a = 52 mm (2.05 in) dia.

b = 41 mm (1.61 in) dia.

Rear oil seal drift

NT049

Installing rear oil seal

a = 100 mm (3.94 in) dia.

b = 78 mm (3.07 in) dia.

Piston pin drift

NT074

Removing and installing piston pin

a = 22.5 mm (0.886 in) dia.

b = 12.5 mm (0.492 in) dia.

PREPARATION

EM-5

Page 7 of 65

Tool name Description

Piston ring expander

NT030

Removing and installing piston ring

PREPARATION

EM-6

Page 8 of 65

SEM808F

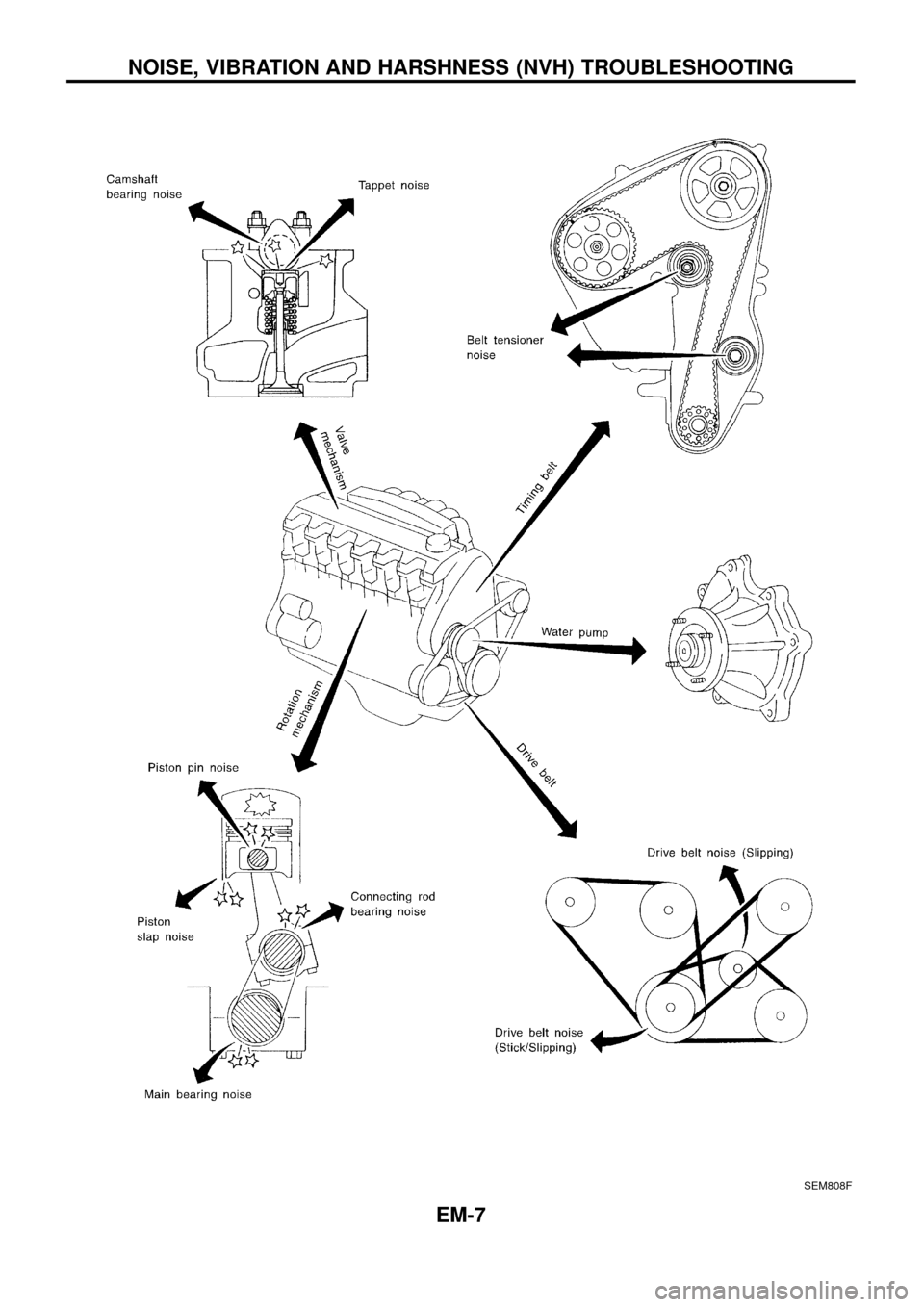

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-7

Page 9 of 65

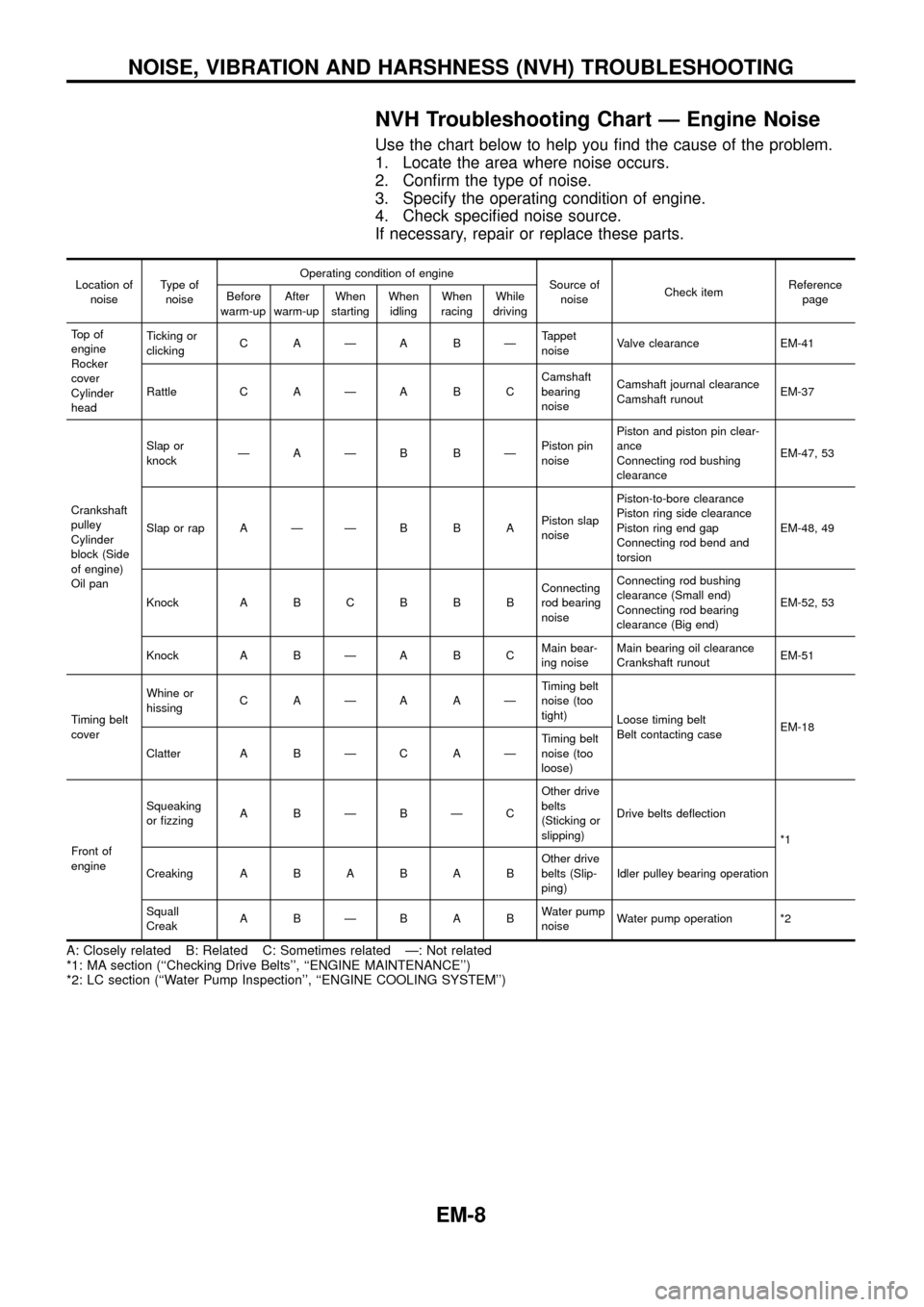

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you ®nd the cause of the problem.

1. Locate the area where noise occurs.

2. Con®rm the type of noise.

3. Specify the operating condition of engine.

4. Check speci®ed noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance EM-41

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-37

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-47, 53

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-48, 49

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-52, 53

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-51

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-18

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or ®zzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts de¯ection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (``Checking Drive Belts'', ``ENGINE MAINTENANCE'')

*2: LC section (``Water Pump Inspection'', ``ENGINE COOLING SYSTEM'')

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-8

Page 10 of 65

SEM780F

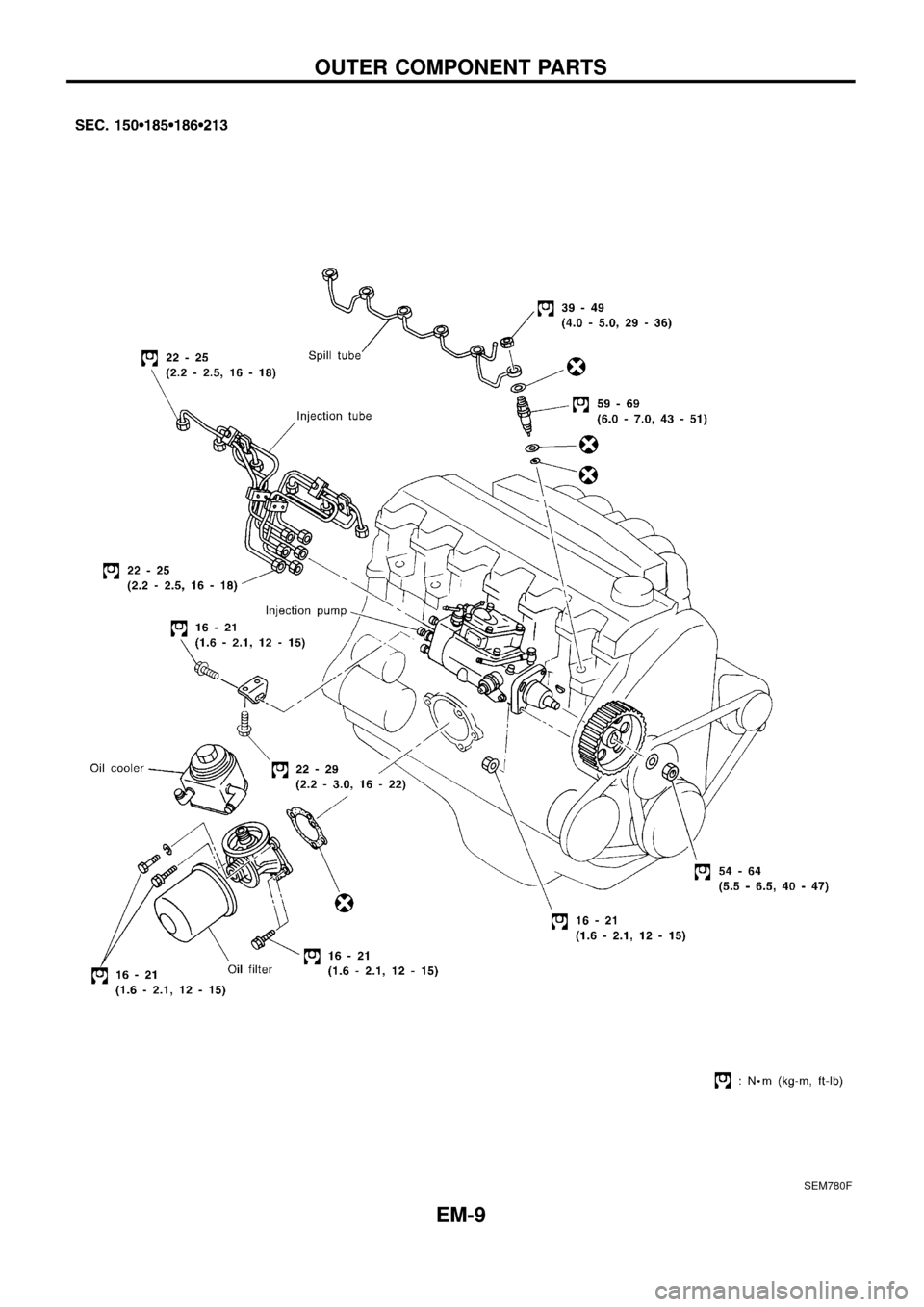

OUTER COMPONENT PARTS

EM-9