NISSAN PATROL 1998 Y61 / 5.G General Information Owner's Guide

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 47, PDF Size: 1.07 MB

Page 31 of 47

NOTICE:

The ¯ow chart indicates work procedures required to diagnose

problems effectively. Observe the following instructions before

diagnosing.

1) Use the ¯ow chart after locating probable causes of a prob-

lem following the ``Preliminary Check'', the ``Symptom

Chart'' or the ``Work Flow''.

2) After repairs, re-check that the problem has been com-

pletely eliminated.

3) Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identi®cation/location of components and harness con-

nectors.

4) Refer to the Circuit Diagram for Quick Pinpoint Check.

If you must check circuit continuity between harness con-

nectors in more detail, such as when a sub-harness is

used, refer to Wiring Diagram in each individual section

and Harness Layout in EL section for identi®cation of har-

ness connectors.

5) When checking circuit continuity, ignition switch should

be ``OFF''.

6) Before checking voltage at connectors, check battery volt-

age.

7) After accomplishing the Diagnostic Procedures and Elec-

trical Components Inspection, make sure that all harness

connectors are reconnected as they were.

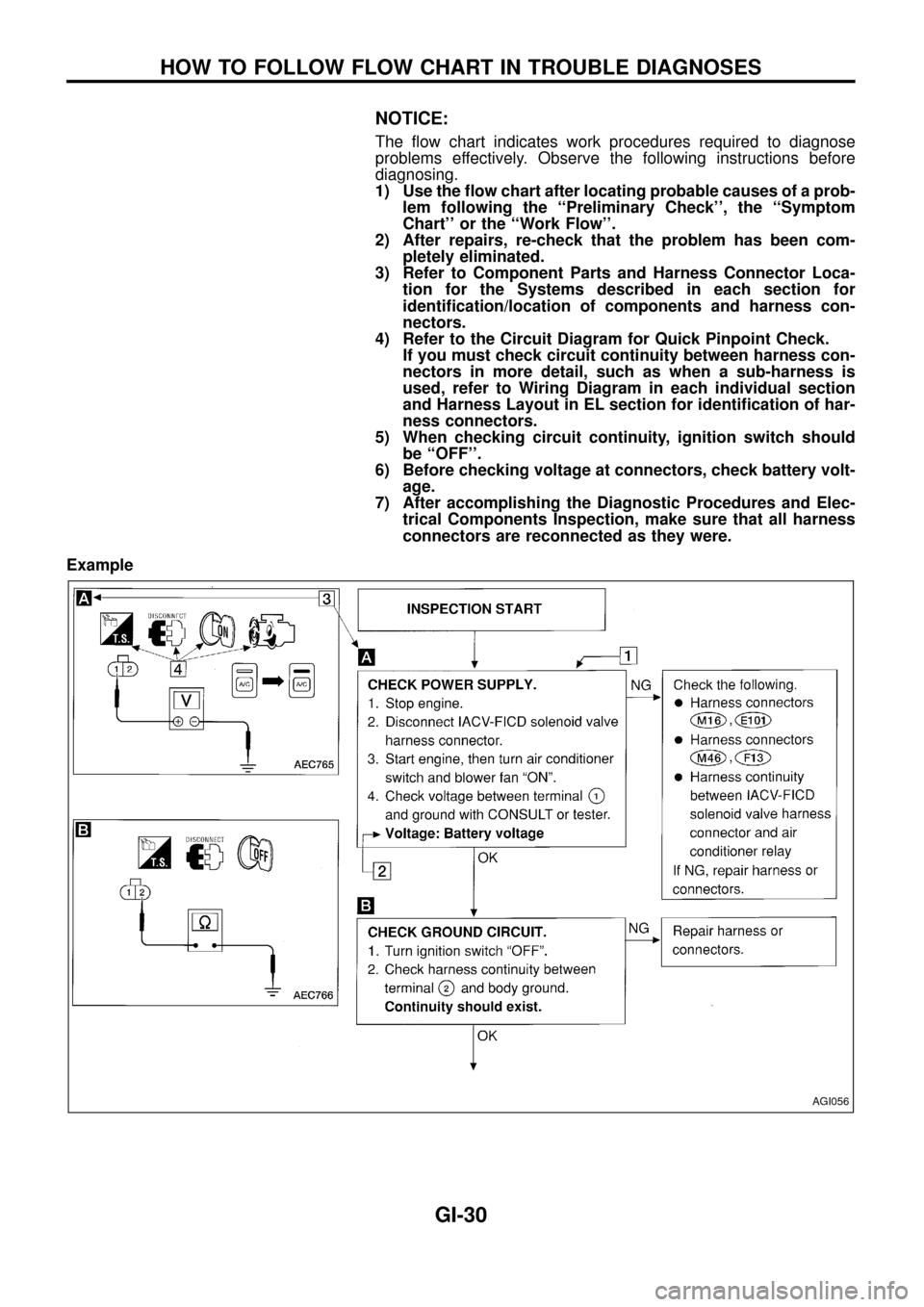

Example

AGI056

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-30

Page 32 of 47

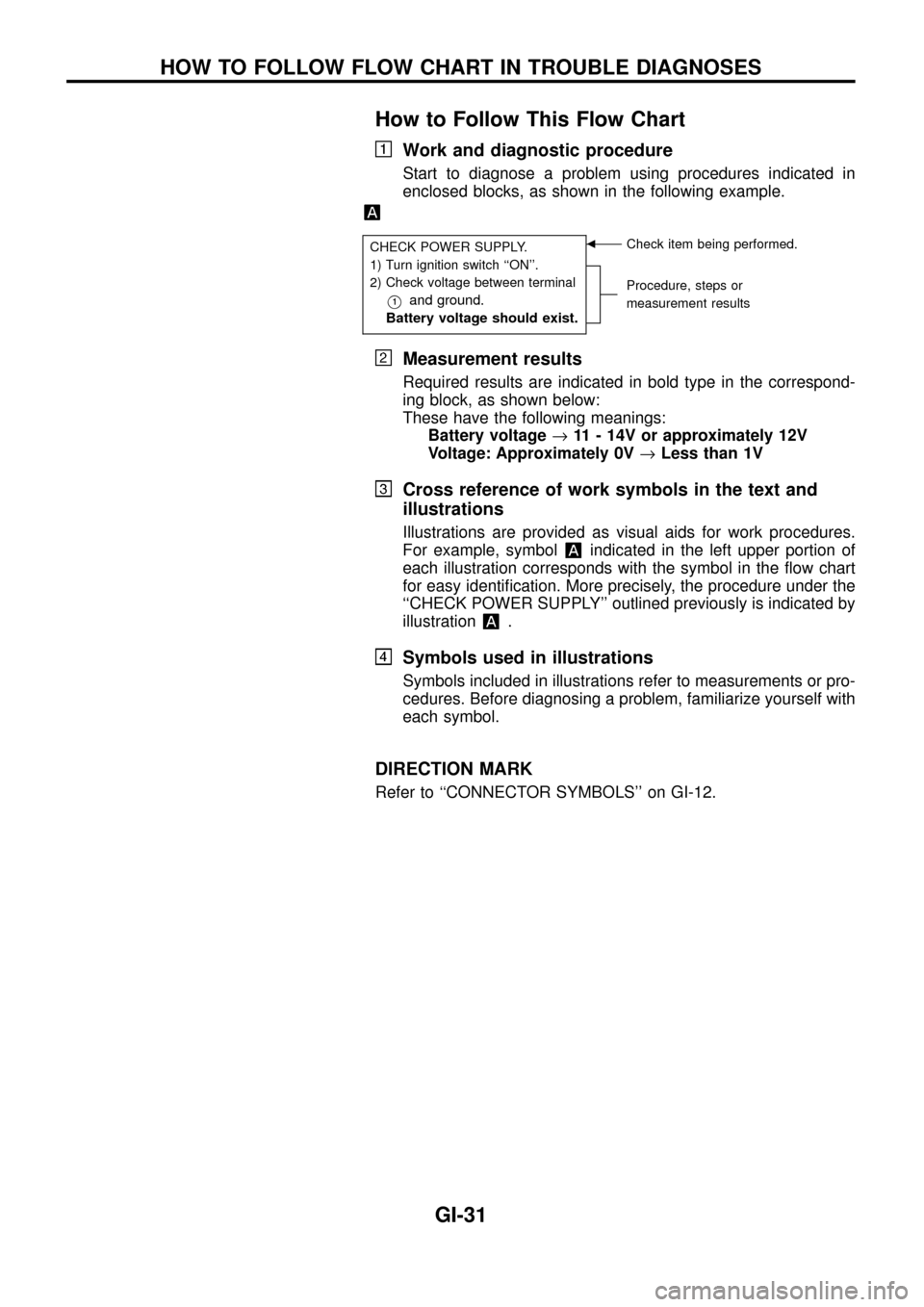

How to Follow This Flow Chart

Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in

enclosed blocks, as shown in the following example.

CHECK POWER SUPPLY.

1) Turn ignition switch ``ON''.

2) Check voltage between terminal

V1and ground.

Battery voltage should exist.

bCheck item being performed.

Procedure, steps or

measurement results

Measurement results

Required results are indicated in bold type in the correspond-

ing block, as shown below:

These have the following meanings:

Battery voltage®11 - 14V or approximately 12V

Voltage: Approximately 0V®Less than 1V

Cross reference of work symbols in the text and

illustrations

Illustrations are provided as visual aids for work procedures.

For example, symbol

indicated in the left upper portion of

each illustration corresponds with the symbol in the ¯ow chart

for easy identi®cation. More precisely, the procedure under the

``CHECK POWER SUPPLY'' outlined previously is indicated by

illustration

.

Symbols used in illustrations

Symbols included in illustrations refer to measurements or pro-

cedures. Before diagnosing a problem, familiarize yourself with

each symbol.

DIRECTION MARK

Refer to ``CONNECTOR SYMBOLS'' on GI-12.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-31

Page 33 of 47

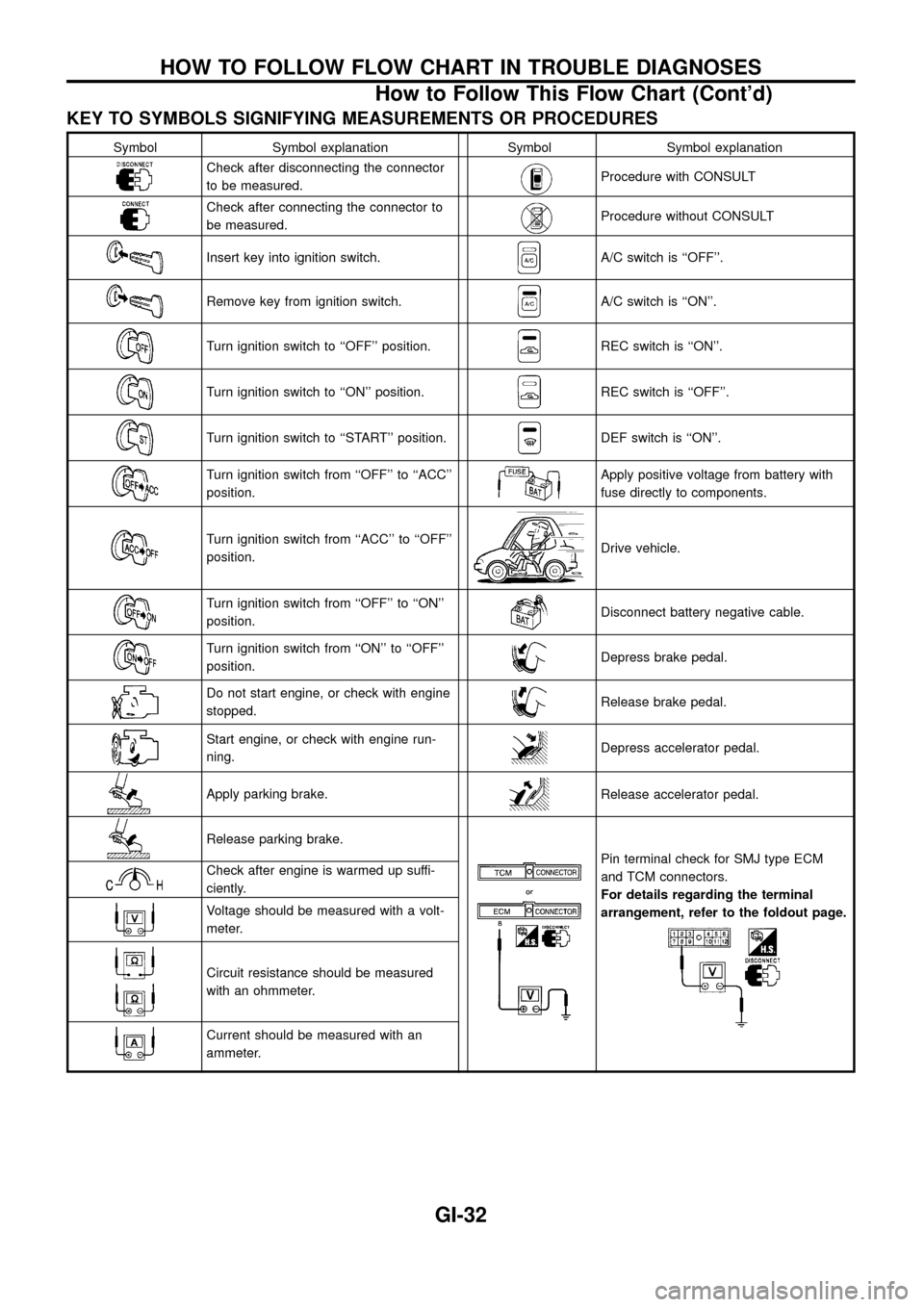

KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connector

to be measured.Procedure with CONSULT

Check after connecting the connector to

be measured.Procedure without CONSULT

Insert key into ignition switch.A/C switch is ``OFF''.

Remove key from ignition switch.A/C switch is ``ON''.

Turn ignition switch to ``OFF'' position.REC switch is ``ON''.

Turn ignition switch to ``ON'' position.REC switch is ``OFF''.

Turn ignition switch to ``START'' position.DEF switch is ``ON''.

Turn ignition switch from ``OFF'' to ``ACC''

position.Apply positive voltage from battery with

fuse directly to components.

Turn ignition switch from ``ACC'' to ``OFF''

position.Drive vehicle.

Turn ignition switch from ``OFF'' to ``ON''

position.Disconnect battery negative cable.

Turn ignition switch from ``ON'' to ``OFF''

position.Depress brake pedal.

Do not start engine, or check with engine

stopped.Release brake pedal.

Start engine, or check with engine run-

ning.Depress accelerator pedal.

Apply parking brake.Release accelerator pedal.

Release parking brake.

Pin terminal check for SMJ type ECM

and TCM connectors.

For details regarding the terminal

arrangement, refer to the foldout page.Check after engine is warmed up suffi-

ciently.

Voltage should be measured with a volt-

meter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

How to Follow This Flow Chart (Cont'd)

GI-32

Page 34 of 47

Function and System Application

Diagnostic

test modeFunction ECCS Air bag ABS*

Work supportThis mode enables a technician to adjust

some devices faster and more accurately by

following the indications on CONSULT.xÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read and

erased quickly.xxx

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐxÐ

ECU discriminated

No.Classi®cation number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐxÐ

Data monitor Input/Output data in the ECM can be read. x Ð x

Active testDiagnostic Test Mode in which CONSULT

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

®ed range.xÐx

ECM part number ECM part number can be read. x Ð x

Function testConducted by CONSULT instead of a tech-

nician to determine whether each system is

``OK'' or ``NG''.xÐÐ

x: Applicable

*: EE960 program card is not applicable to ABS. Use on board diagnostic system with ABS warning lamp until the next program card

will be introduced.

Lithium Battery Replacement

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd., CR2032 only. Use of another battery may

present a risk of ®re or explosion. The battery may present a ®re or chemical burn hazard if mistreated.

Do not recharge, disassemble of dispose of in ®re.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

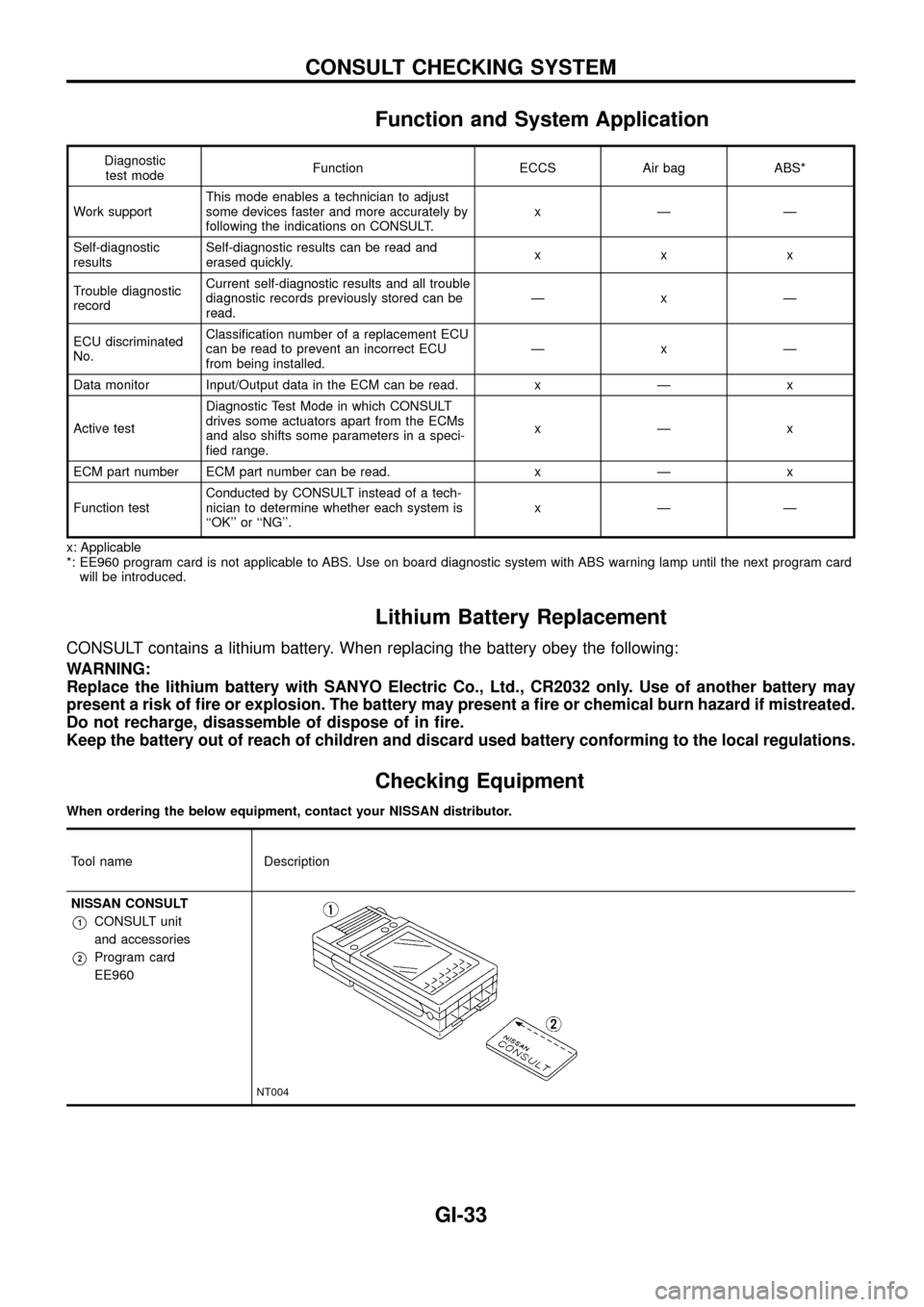

Checking Equipment

When ordering the below equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT

V1CONSULT unit

and accessories

V2Program card

EE960

NT004

CONSULT CHECKING SYSTEM

GI-33

Page 35 of 47

Loading Procedure

CONSULT Data Link Connector (DLC) Circuit

INSPECTION PROCEDURE

If the CONSULT cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT cannot access

any system.+CONSULT DLC power supply circuit (Terminal 7) and ground circuit (Terminal 8)

(For detailed circuit, refer to ``MIL & Data Link Connectors Wiring Diagram'' in EC section.)

+CONSULT DDL cable

CONSULT cannot access

individual system. (Other sys-

tems can be accessed.)+CONSULT program card (Check the appropriate CONSULT program card for the system. Refer

to GI-33.)

+Power supply and ground circuit for the control unit of the system

(For detailed circuit, refer to wiring diagram for each system.)

+Open or short circuit between the system and CONSULT DLC

(For detailed circuit, refer to wiring diagram for each system.)

SGI983

SGI984

CONSULT CHECKING SYSTEM

GI-34

Page 36 of 47

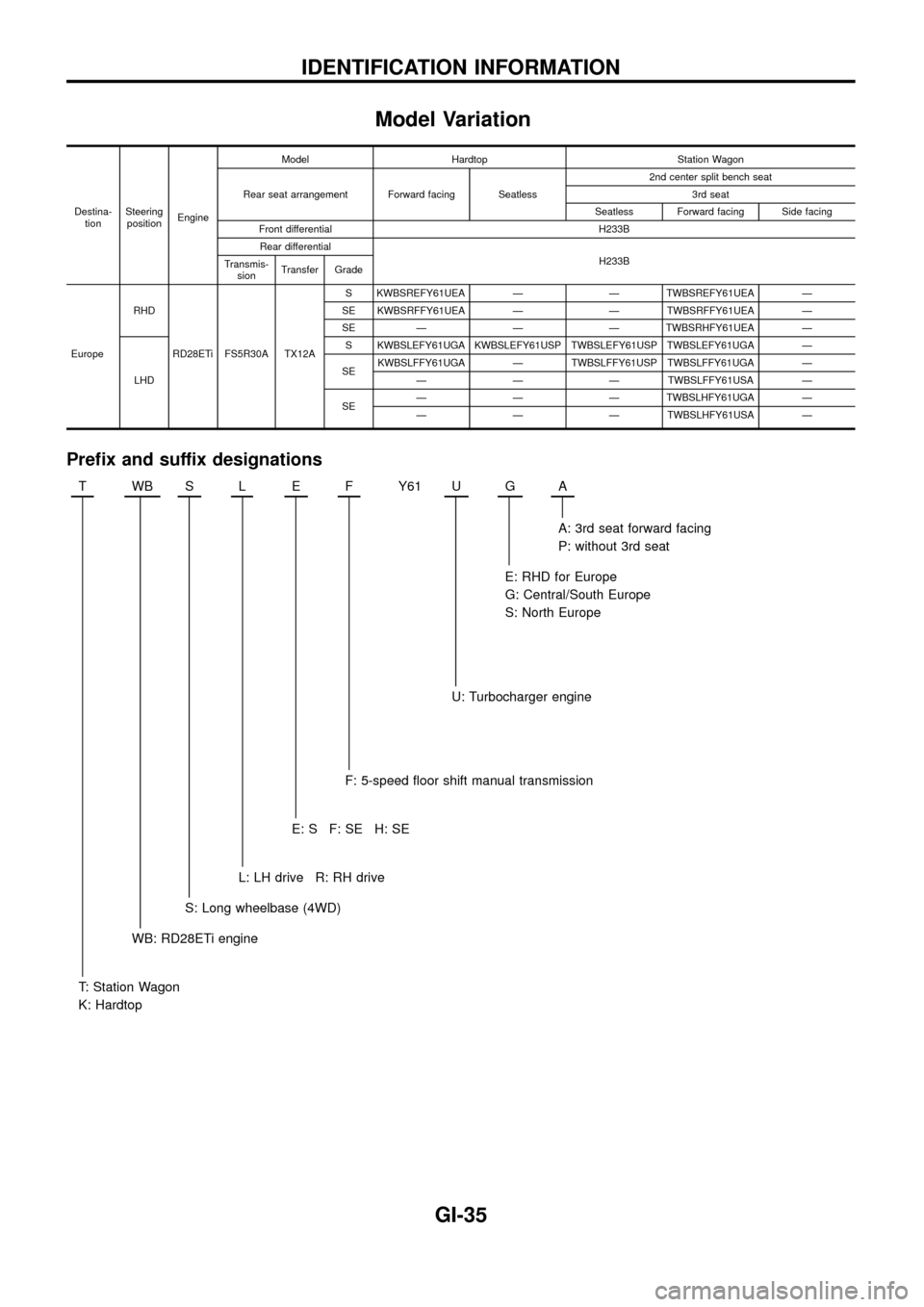

Model Variation

Destina-

tionSteering

positionEngineModel Hardtop Station Wagon

Rear seat arrangement Forward facing Seatless2nd center split bench seat

3rd seat

Seatless Forward facing Side facing

Front differential H233B

Rear differential

H233B

Transmis-

sionTransfer Grade

EuropeRHD

RD28ETi FS5R30A TX12AS KWBSREFY61UEA Ð Ð TWBSREFY61UEA Ð

SE KWBSRFFY61UEA Ð Ð TWBSRFFY61UEA Ð

SE Ð Ð Ð TWBSRHFY61UEA Ð

LHDS KWBSLEFY61UGA KWBSLEFY61USP TWBSLEFY61USP TWBSLEFY61UGA Ð

SEKWBSLFFY61UGA Ð TWBSLFFY61USP TWBSLFFY61UGA Ð

Ð Ð Ð TWBSLFFY61USA Ð

SEÐ Ð Ð TWBSLHFY61UGA Ð

Ð Ð Ð TWBSLHFY61USA Ð

Pre®x and suffix designations

TWBSLEFY61 UGA

A: 3rd seat forward facing

P: without 3rd seat

E: RHD for Europe

G: Central/South Europe

S: North Europe

U: Turbocharger engine

F: 5-speed ¯oor shift manual transmission

E:SF:SEH:SE

L: LH drive R: RH drive

S: Long wheelbase (4WD)

WB: RD28ETi engine

T: Station Wagon

K: Hardtop

IDENTIFICATION INFORMATION

GI-35

Page 37 of 47

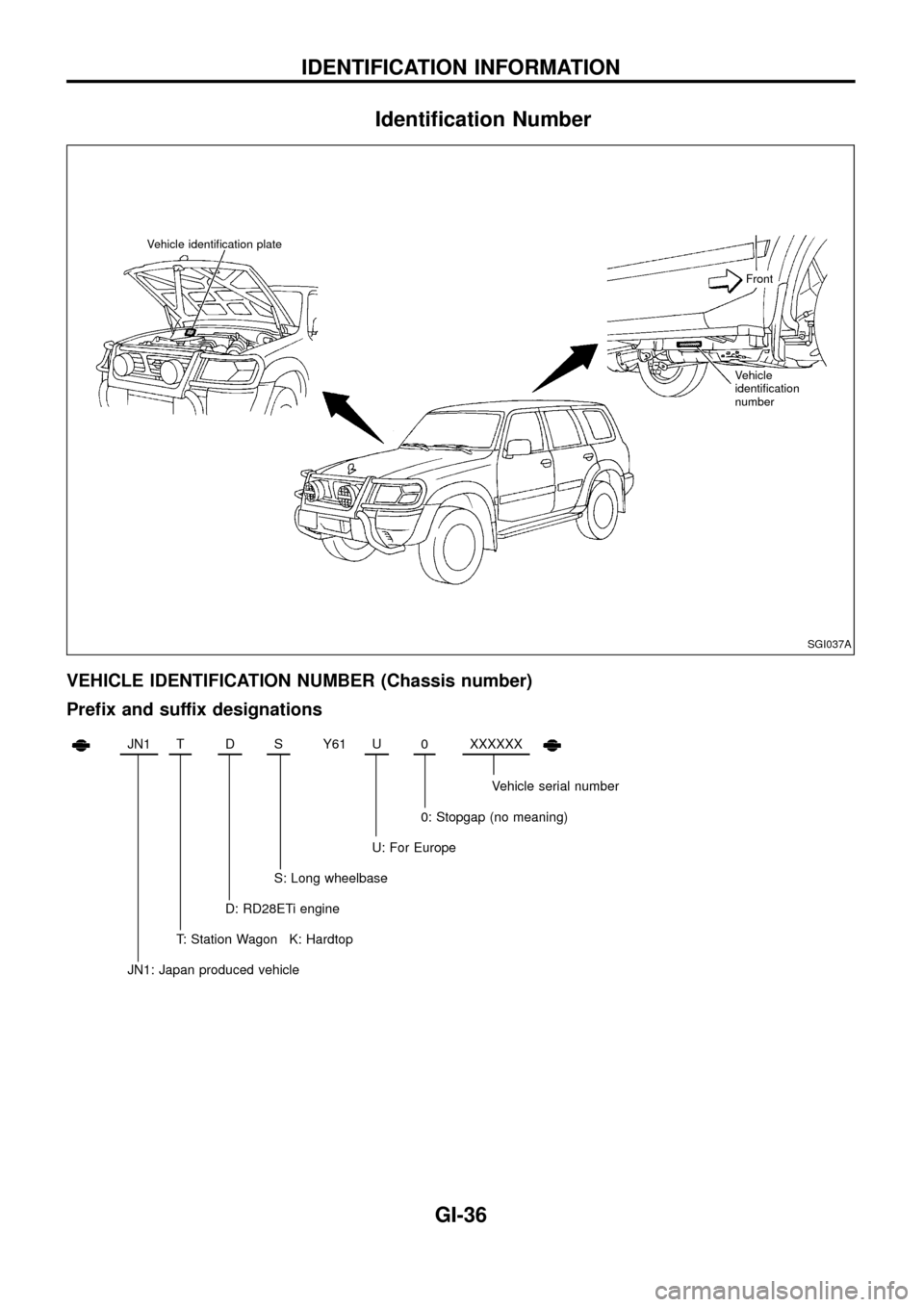

Identi®cation Number

VEHICLE IDENTIFICATION NUMBER (Chassis number)

Pre®x and suffix designations

JN1TDSY61 U0XXXXXX

Vehicle serial number

0: Stopgap (no meaning)

U: For Europe

S: Long wheelbase

D: RD28ETi engine

T: Station Wagon K: Hardtop

JN1: Japan produced vehicle

SGI037A

Vehicle identi®cation plate

Vehicle

identi®cation

numberFront

IDENTIFICATION INFORMATION

GI-36

Page 38 of 47

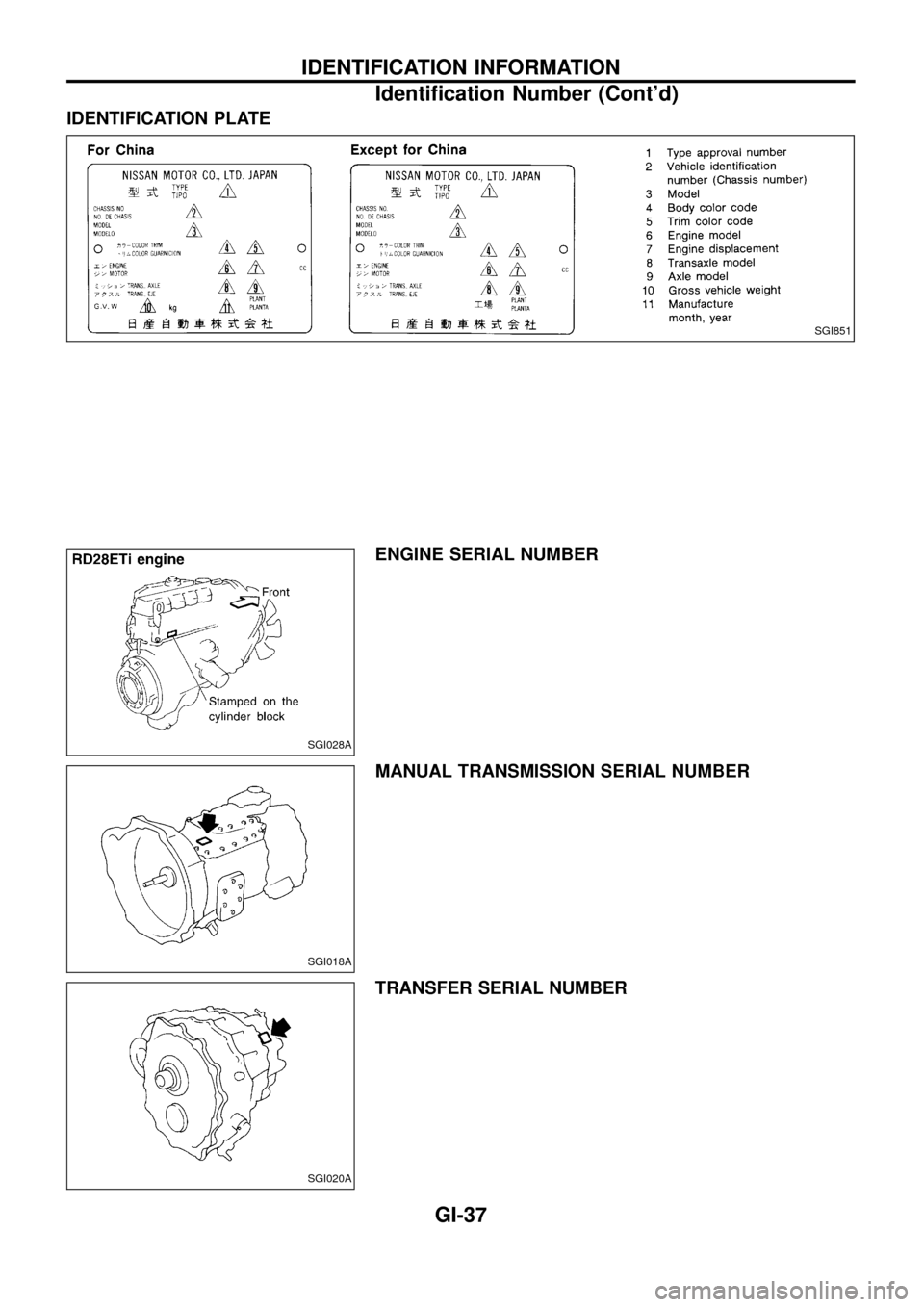

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

MANUAL TRANSMISSION SERIAL NUMBER

TRANSFER SERIAL NUMBER

SGI851

SGI028A

SGI018A

SGI020A

IDENTIFICATION INFORMATION

Identi®cation Number (Cont'd)

GI-37

Page 39 of 47

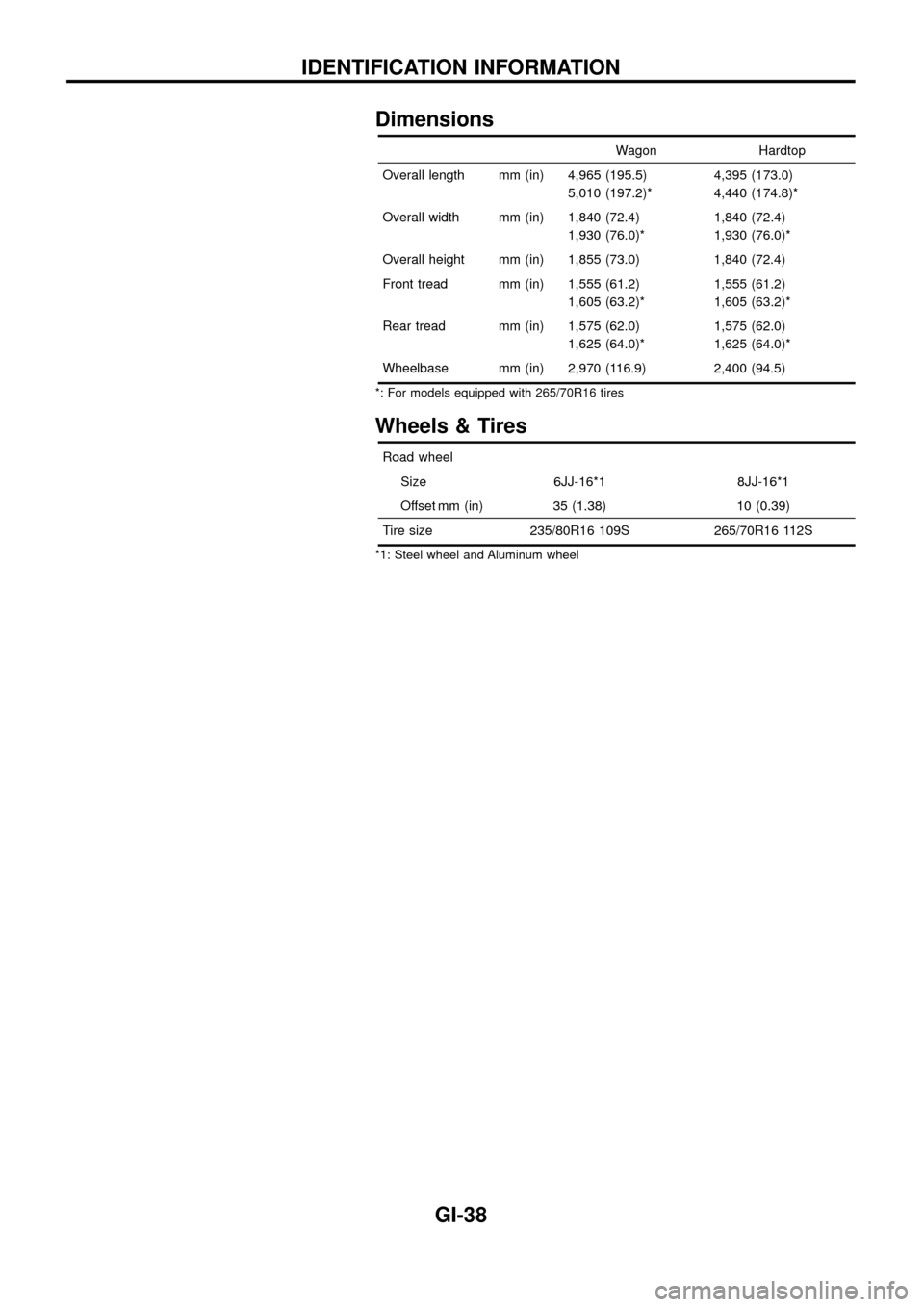

Dimensions

Wagon Hardtop

Overall length mm (in) 4,965 (195.5)

5,010 (197.2)*4,395 (173.0)

4,440 (174.8)*

Overall width mm (in) 1,840 (72.4)

1,930 (76.0)*1,840 (72.4)

1,930 (76.0)*

Overall height mm (in) 1,855 (73.0) 1,840 (72.4)

Front tread mm (in) 1,555 (61.2)

1,605 (63.2)*1,555 (61.2)

1,605 (63.2)*

Rear tread mm (in) 1,575 (62.0)

1,625 (64.0)*1,575 (62.0)

1,625 (64.0)*

Wheelbase mm (in) 2,970 (116.9) 2,400 (94.5)

*: For models equipped with 265/70R16 tires

Wheels & Tires

Road wheel

Size 6JJ-16*1 8JJ-16*1

Offset mm (in) 35 (1.38) 10 (0.39)

Tire size 235/80R16 109S 265/70R16 112S

*1: Steel wheel and Aluminum wheel

IDENTIFICATION INFORMATION

GI-38

Page 40 of 47

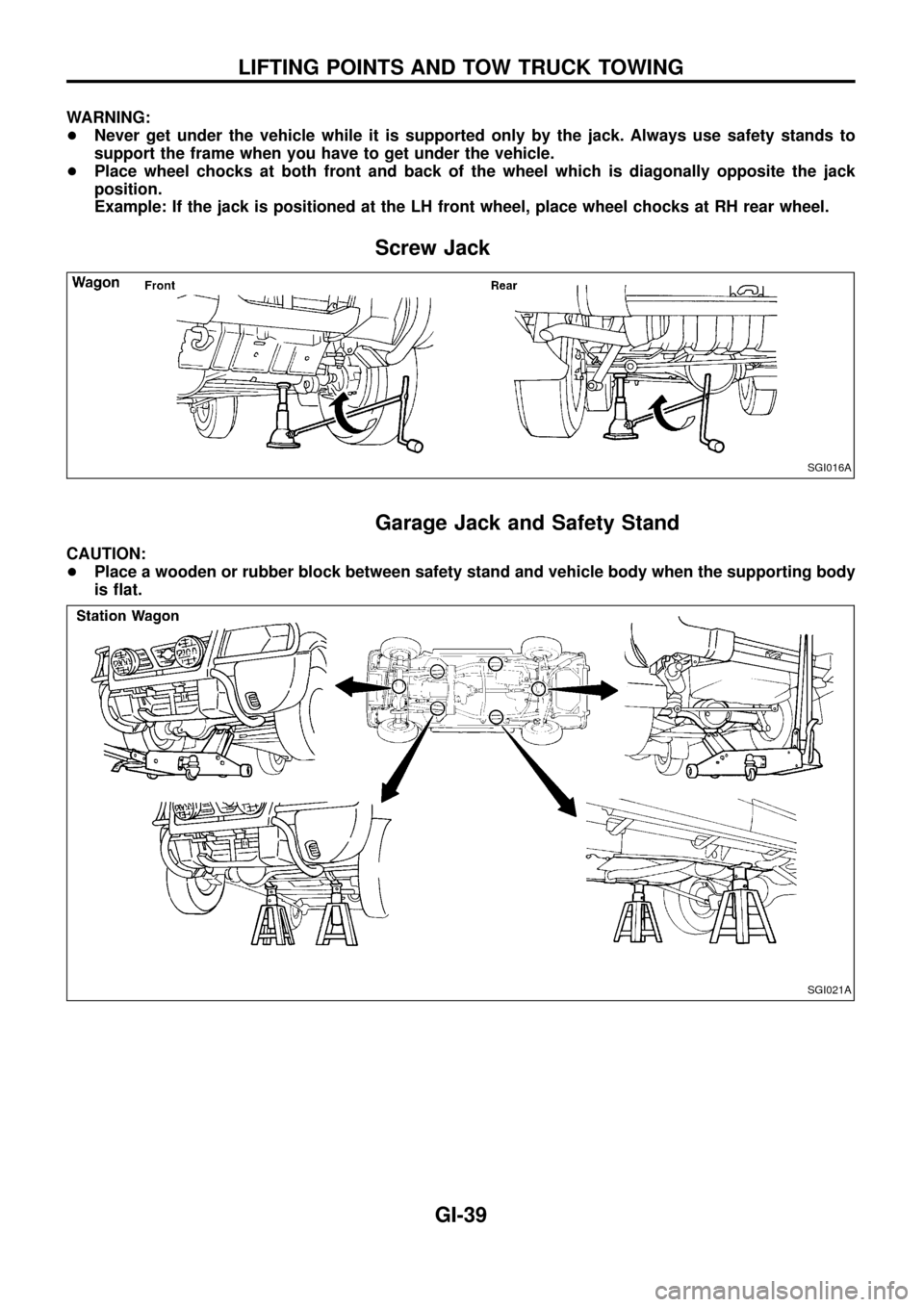

WARNING:

+Never get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

+Place wheel chocks at both front and back of the wheel which is diagonally opposite the jack

position.

Example: If the jack is positioned at the LH front wheel, place wheel chocks at RH rear wheel.

Screw Jack

Garage Jack and Safety Stand

CAUTION:

+Place a wooden or rubber block between safety stand and vehicle body when the supporting body

is ¯at.

SGI016A

SGI021A

LIFTING POINTS AND TOW TRUCK TOWING

GI-39