NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 54, PDF Size: 1.85 MB

Page 1 of 54

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

PROPELLER SHAFT......................................................5

Front Propeller Shaft ...................................................5

Rear Propeller Shaft ....................................................5

On-vehicle Service.......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE (Final Drive)..........................10

Front Oil Seal Replacement ......................................10

REMOVAL AND INSTALLATION.................................. 11

Removal ..................................................................... 11

Installation .................................................................. 11

FRONT FINAL DRIVE...................................................12

REAR FINAL DRIVE.....................................................13

DISASSEMBLY..............................................................14

Pre-inspection ............................................................14

Differential Carrier......................................................15

Differential Case ........................................................17

INSPECTION..................................................................19

Ring Gear and Drive Pinion ......................................19

Differential Case Assembly........................................19Bearing.......................................................................19

LIMITED SLIP DIFFERENTIAL.....................................20

Preparation for Disassembly .....................................20

Disassembly...............................................................21

Inspection...................................................................21

Adjustment .................................................................23

Assembly ...................................................................24

ADJUSTMENT...............................................................27

Drive Pinion Height ....................................................27

Tooth Contact.............................................................29

ASSEMBLY....................................................................31

Differential Case Ð 4-pinion type Ð.........................31

Differential Case Ð 2-pinion type Ð.........................32

Differential Carrier......................................................33

DIFFERENTIAL LOCK..................................................37

Actuator and Fork ......................................................37

Disassembly...............................................................38

Inspection...................................................................39

Assembly ...................................................................40

System Description ....................................................43

Component Parts Location ........................................44

Wiring Diagram Ð DIFF/L Ð/LHD Models ...............45

Wiring Diagram Ð DIFF/L Ð/RHD Models ...............47

Electrical Components Inspection .............................49

SERVICE DATA AND SPECIFICATIONS (SDS)..........51

Propeller Shaft ...........................................................51

Final Drive..................................................................52

PD

Page 2 of 54

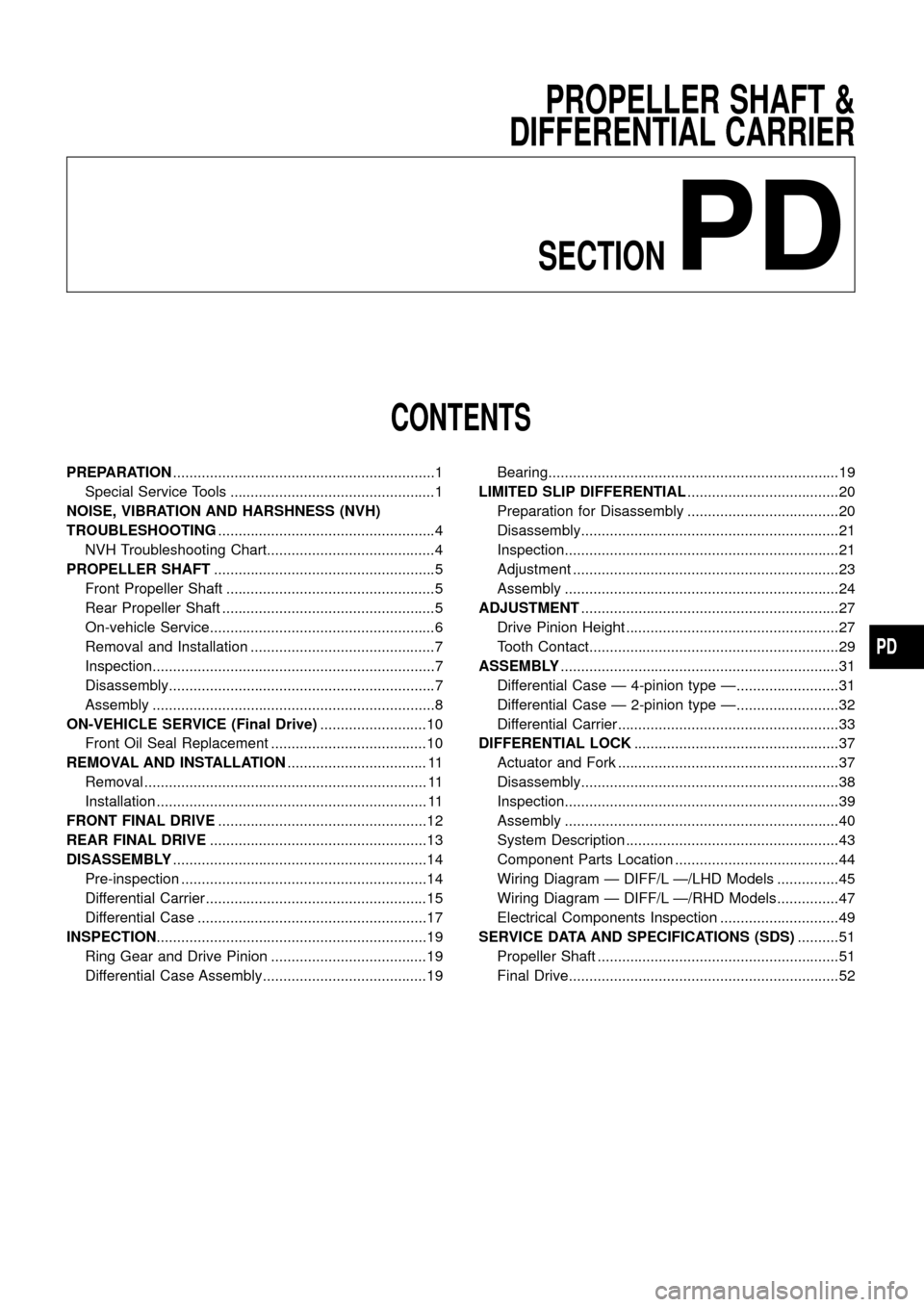

Special Service Tools

*: For front differential carrier only

Tool number

Tool nameDescriptionUnit application

H233B

ST0501S000

Engine stand

V1ST05011000

Engine stand

V2ST05012000

Base

NT042

Mounting differential attach-

ment

X

ST06340000

Differential attachment

NT140

Mounting ®nal drive

X

ST30611000

Drive pinion bearing outer

race drift bar

NT090

Installing pinion rear bearing

outer race

(Use with ST30621000 or

ST30613000)X

ST30613000

Drive pinion front bearing

outer race drift

NT073

Installing pinion front bearing

outer race

(Use with ST30613000)

X

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

ST30621000

Drive pinion rear bearing

outer race drift

NT073

Installing pinion rear bearing

outer race

(Use with ST30613000)

X*

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST3090S000

Drive pinion rear bearing

inner race puller set

V1ST30031000

Puller

V2ST30911000

Base

NT527

Removing and installing drive

pinion rear inner race

X

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

PREPARATION

PD-1

Page 3 of 54

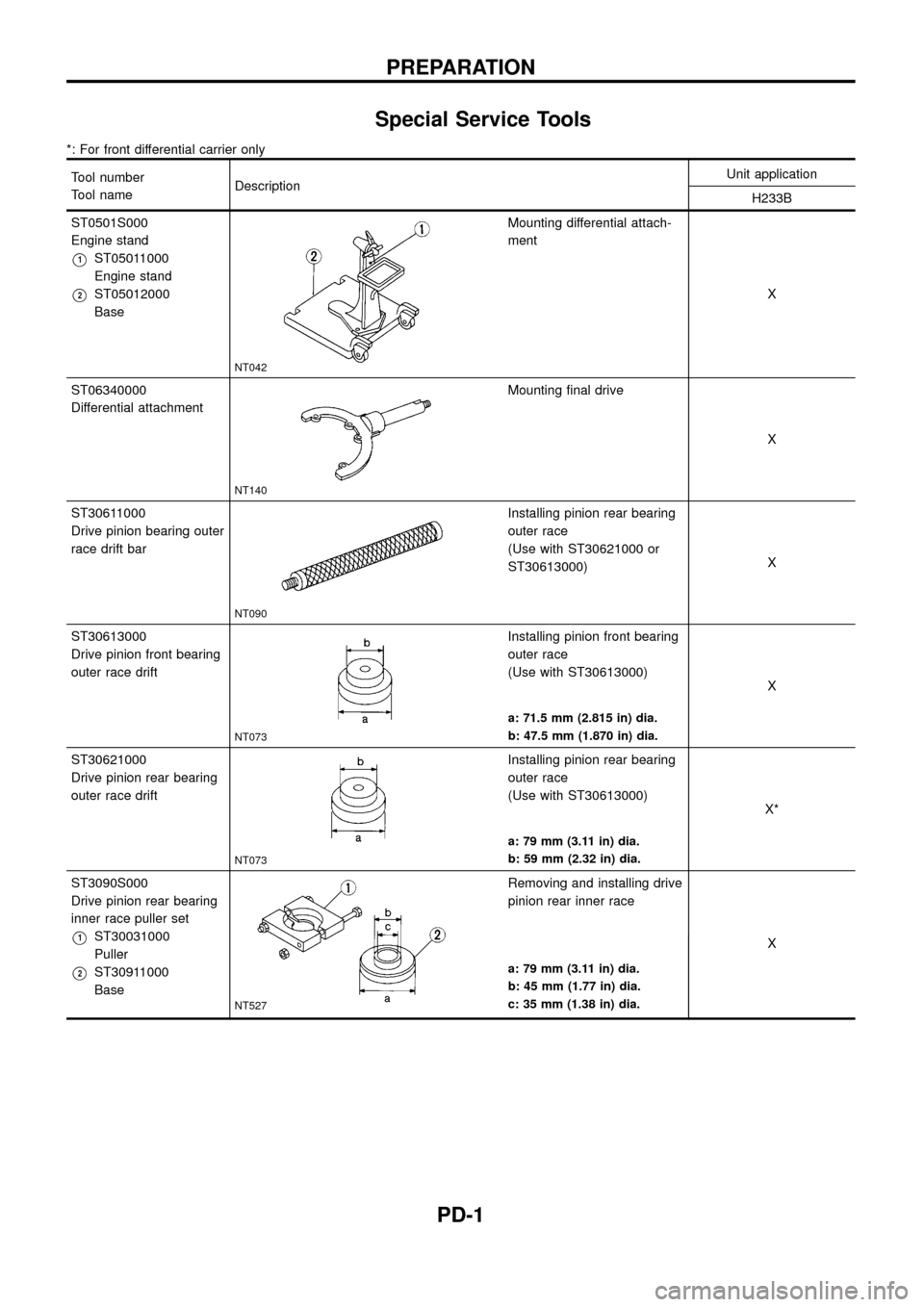

Tool number

Tool nameDescriptionUnit application

H233B

ST3127S000

Preload gauge

V1GG91030000

Torque wrench

V2HT62900000

Socket adapter (1/2²)

V3HT62940000

Socket adapter (3/8²)NT124

Measuring pinion bearing

preload and total preload

X

ST3125S000

Drive pinion setting

gauge set

V1ST31251000

Drive pinion height

gauge

V2ST31181001

Dummy shaft

NT524

Selecting pinion height

adjusting washer

X

KV40104000

Drive pinion ¯ange

wrench

NT113

Removing and installing pro-

peller shaft lock nut and drive

pinion lock nut

X

ST0237S000

Differential side bearing

puller set

V1ST33051001

Puller

V2ST02371000

Adapter

NT072

Removing and installing side

bearing inner race

X

a: 40 mm (1.57 in) dia.

b: 50 mm (1.97 in) dia.

ST33081000

Adapter

NT431

Installing side bearing inner

cone

X

a: 43 mm (1.69 in) dia.

b: 33.5 mm (1.319 in) dia.

ST33190000

Differential side bearing

drift

NT085

Installing side bearing inner

cone

X

a: 52 mm (2.05 in) dia.

b: 45.5 mm (1.791 in) dia.

c: 34 mm (1.34 in) dia.

KV31100300

Fork rod pin punch

NT410

Removing pinion mate shaft

lock pin

X

a: 4.5 mm (0.177 in) dia.

PREPARATION

Special Service Tools (Cont'd)

PD-2

Page 4 of 54

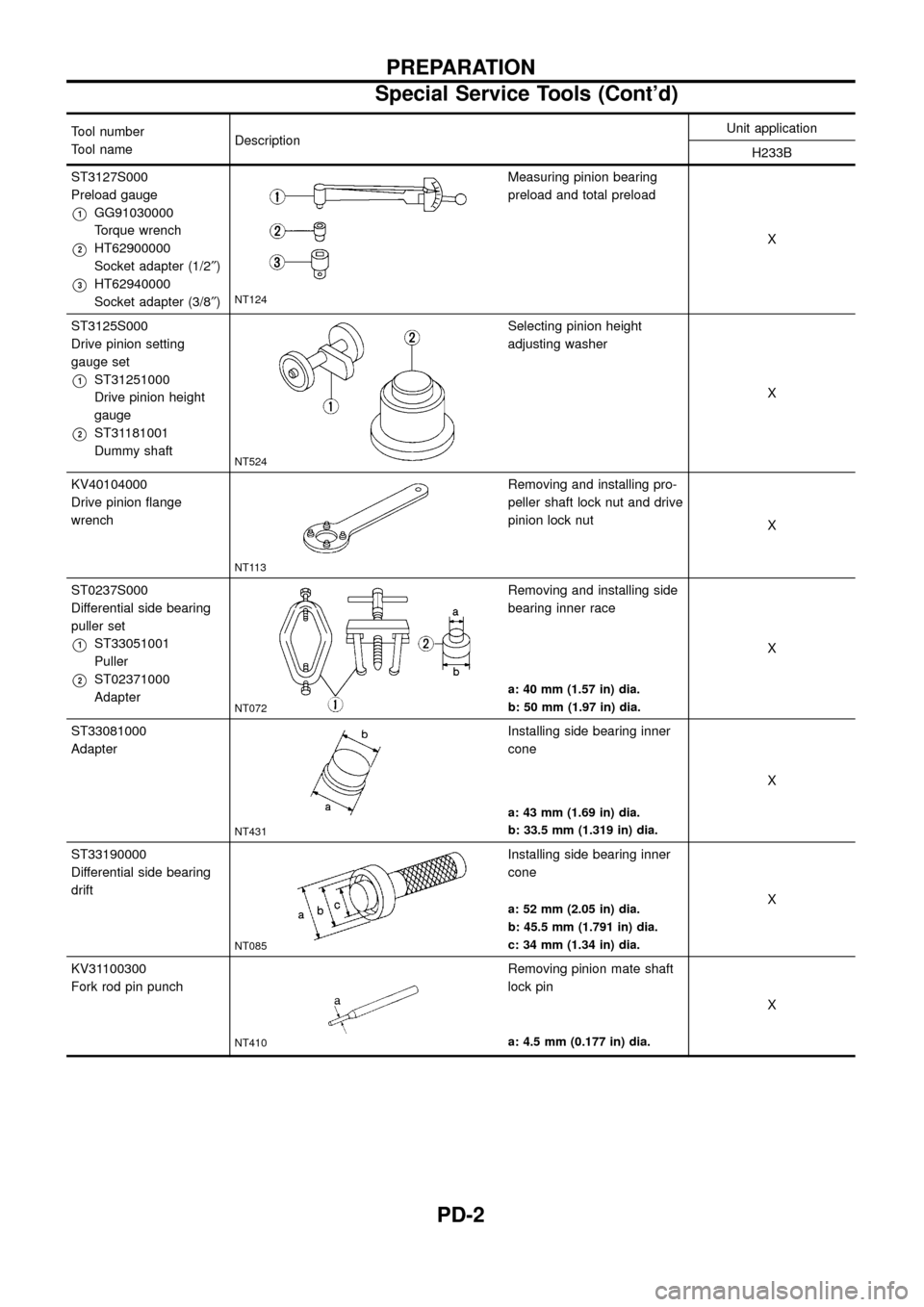

Tool number

Tool nameDescriptionUnit application

H233B

KV381025S0

Oil seal ®tting tool

V1ST30720000

Drift bar

V2KV38102510

Drift

NT525

Installing front oil seal

X

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

c: 71 mm (2.80 in) dia.

d: 65 mm (2.56 in) dia.

ST32580000

Differential side bearing

adjusting nut wrench

NT141

Adjusting side bearing pre-

load and backlash (ring gear-

drive pinion)

X

PREPARATION

Special Service Tools (Cont'd)

PD-3

Page 5 of 54

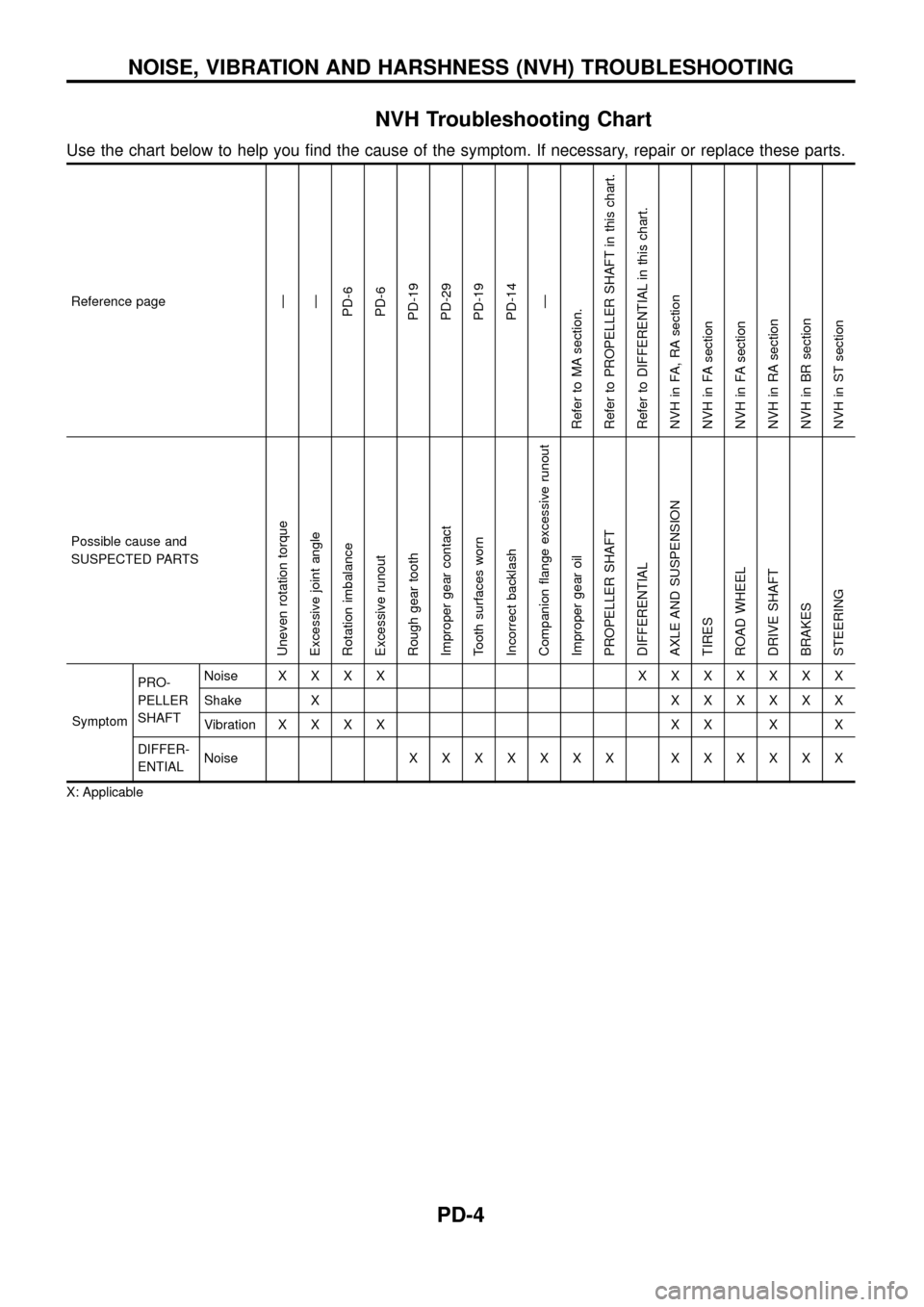

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

PD-6

PD-6

PD-19

PD-29

PD-19

PD-14

Ð

Refer to MA section.

Refer to PROPELLER SHAFT in this chart.

Refer to DIFFERENTIAL in this chart.

NVH in FA, RA section

NVH in FA section

NVH in FA section

NVH in RA section

NVH in BR section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion ¯ange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomPRO-

PELLER

SHAFTNoiseXXXX XXXXXXX

Shake XXXXXXX

VibrationXXXX XX X X

DIFFER-

ENTIALNoiseXXXXXXX XXXXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PD-4

Page 6 of 54

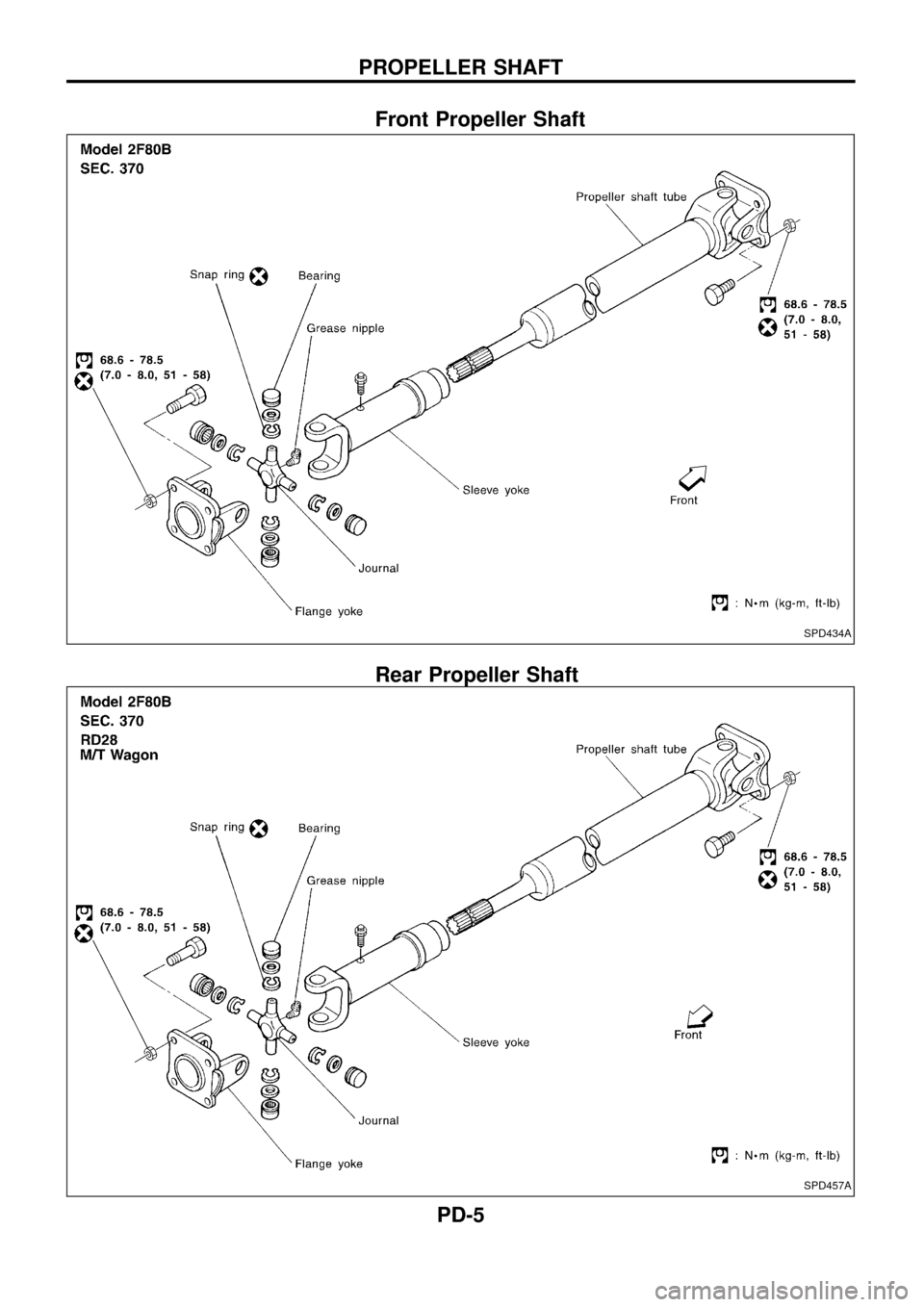

Front Propeller Shaft

Rear Propeller Shaft

SPD434A

SPD457A

PROPELLER SHAFT

PD-5

Page 7 of 54

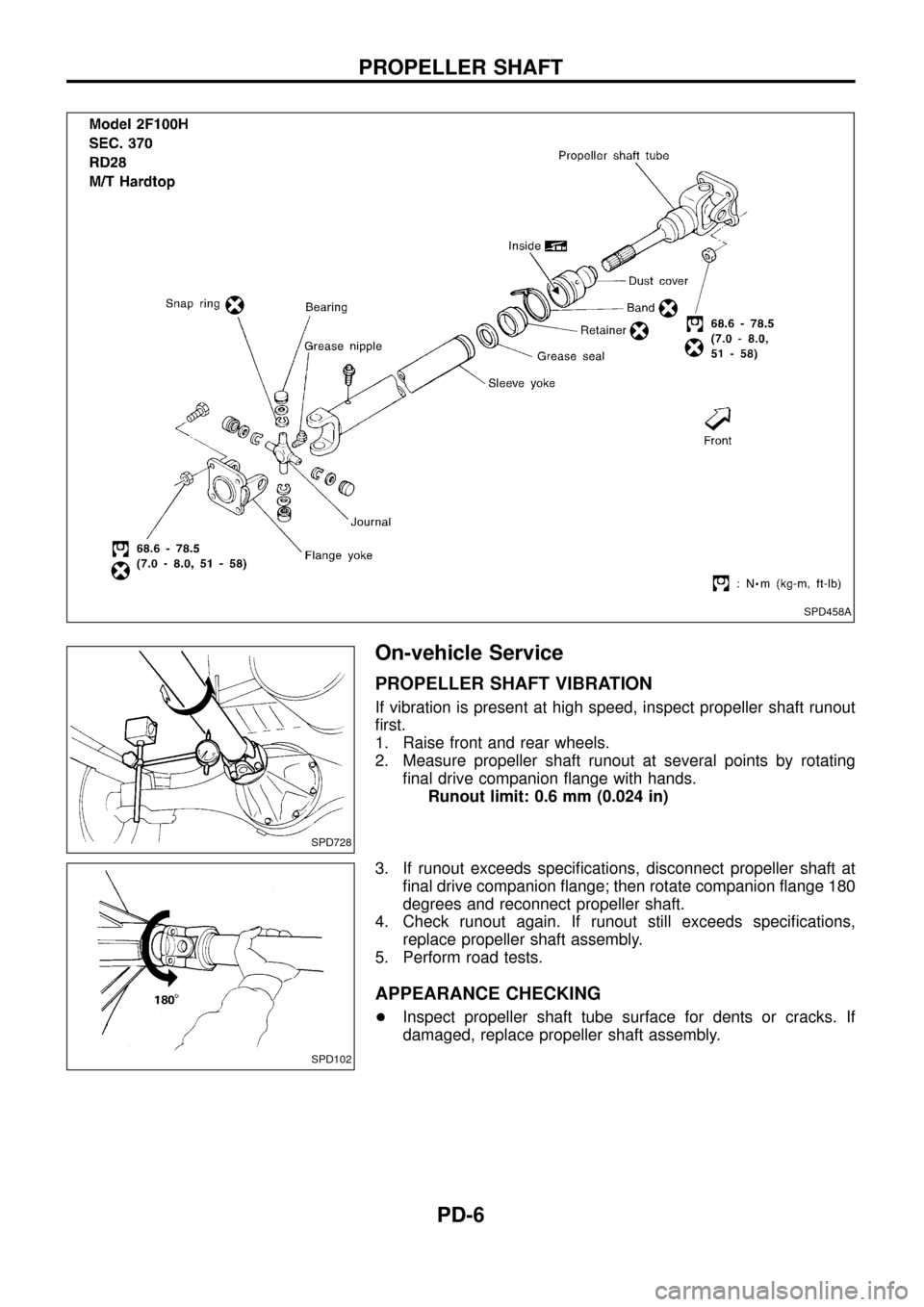

On-vehicle Service

PROPELLER SHAFT VIBRATION

If vibration is present at high speed, inspect propeller shaft runout

®rst.

1. Raise front and rear wheels.

2. Measure propeller shaft runout at several points by rotating

®nal drive companion ¯ange with hands.

Runout limit: 0.6 mm (0.024 in)

3. If runout exceeds speci®cations, disconnect propeller shaft at

®nal drive companion ¯ange; then rotate companion ¯ange 180

degrees and reconnect propeller shaft.

4. Check runout again. If runout still exceeds speci®cations,

replace propeller shaft assembly.

5. Perform road tests.

APPEARANCE CHECKING

+Inspect propeller shaft tube surface for dents or cracks. If

damaged, replace propeller shaft assembly.

SPD458A

SPD728

SPD102

PROPELLER SHAFT

PD-6

Page 8 of 54

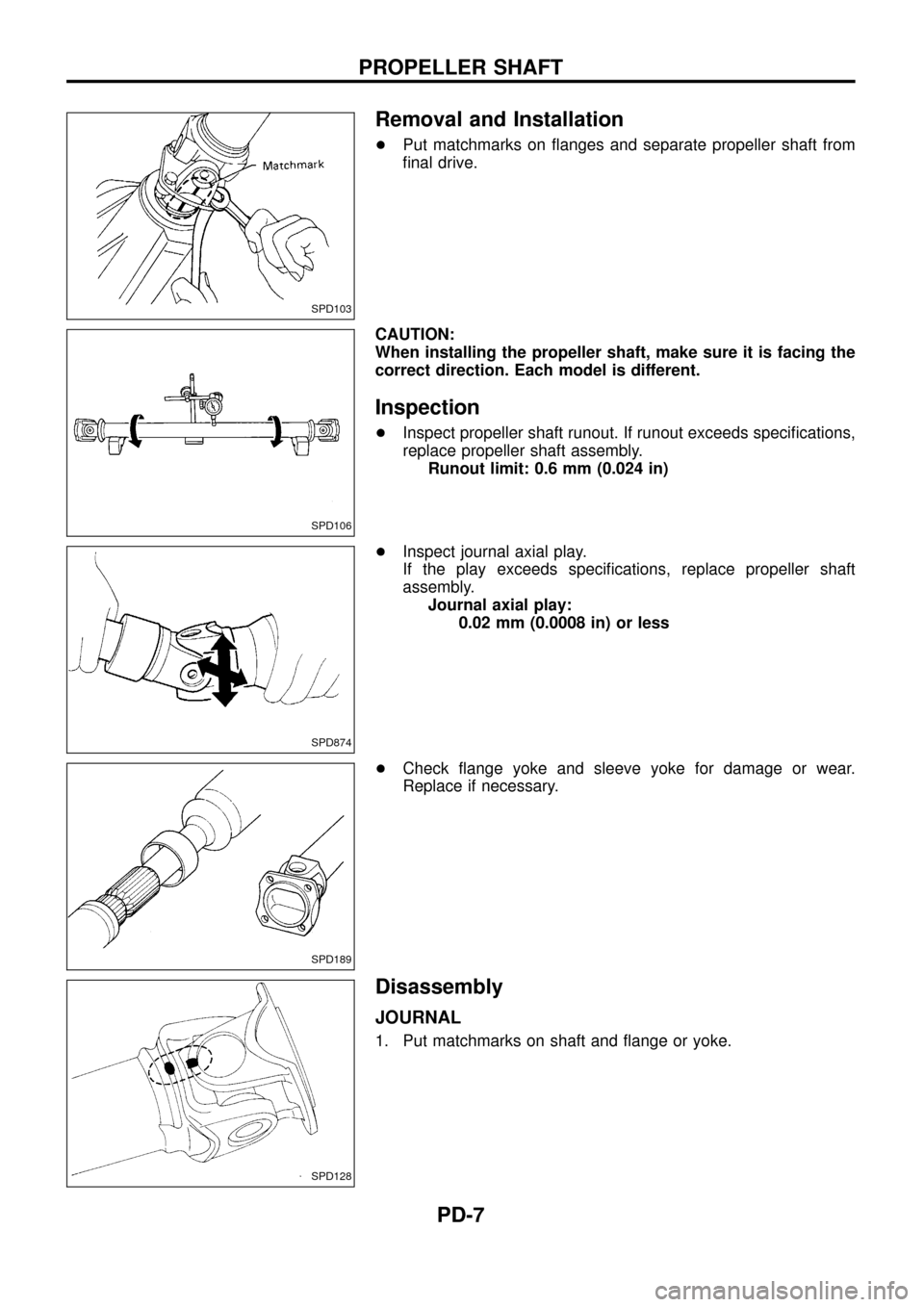

Removal and Installation

+Put matchmarks on ¯anges and separate propeller shaft from

®nal drive.

CAUTION:

When installing the propeller shaft, make sure it is facing the

correct direction. Each model is different.

Inspection

+Inspect propeller shaft runout. If runout exceeds speci®cations,

replace propeller shaft assembly.

Runout limit: 0.6 mm (0.024 in)

+Inspect journal axial play.

If the play exceeds speci®cations, replace propeller shaft

assembly.

Journal axial play:

0.02 mm (0.0008 in) or less

+Check ¯ange yoke and sleeve yoke for damage or wear.

Replace if necessary.

Disassembly

JOURNAL

1. Put matchmarks on shaft and ¯ange or yoke.

SPD103

SPD106

SPD874

SPD189

SPD128

PROPELLER SHAFT

PD-7

Page 9 of 54

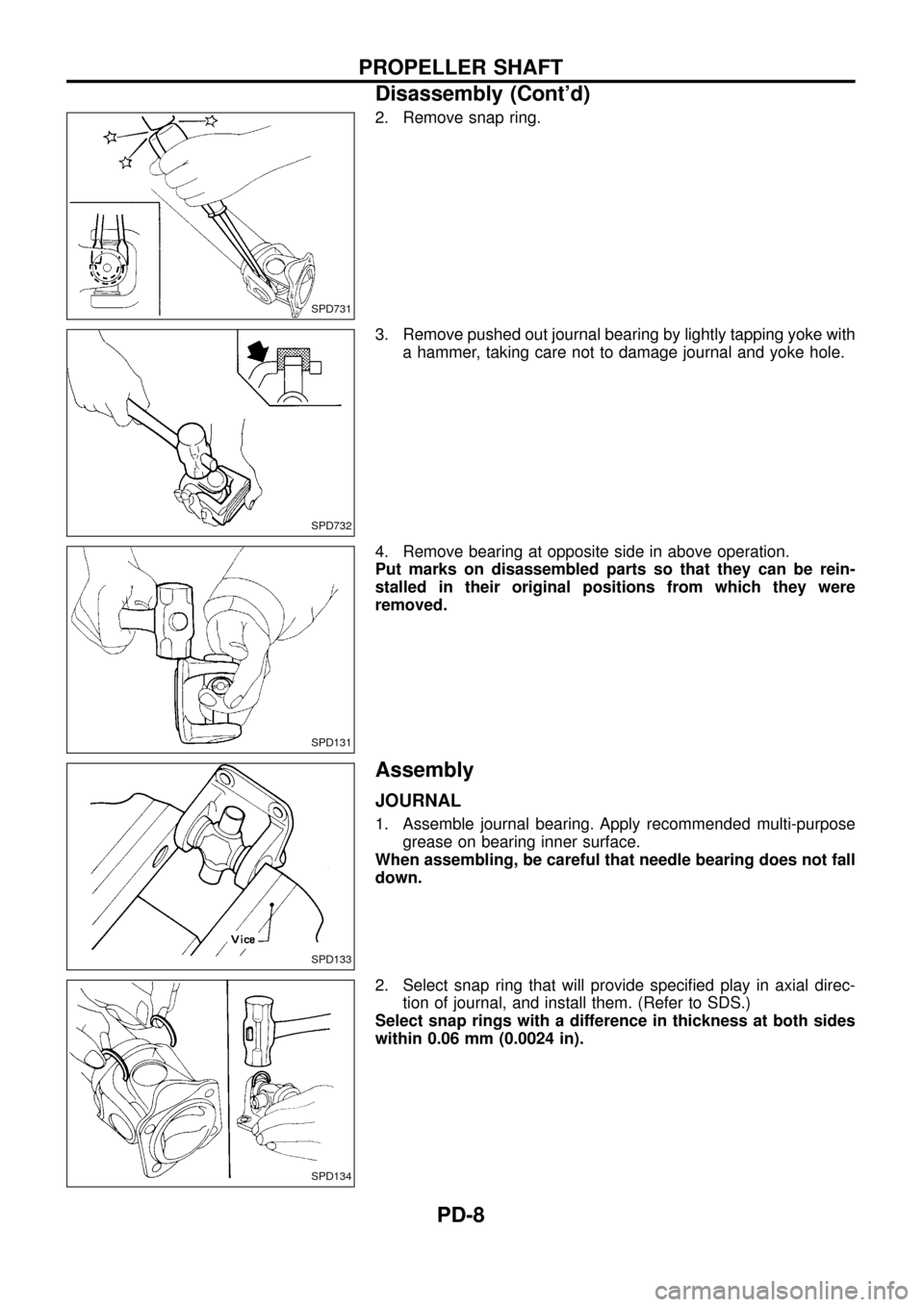

2. Remove snap ring.

3. Remove pushed out journal bearing by lightly tapping yoke with

a hammer, taking care not to damage journal and yoke hole.

4. Remove bearing at opposite side in above operation.

Put marks on disassembled parts so that they can be rein-

stalled in their original positions from which they were

removed.

Assembly

JOURNAL

1. Assemble journal bearing. Apply recommended multi-purpose

grease on bearing inner surface.

When assembling, be careful that needle bearing does not fall

down.

2. Select snap ring that will provide speci®ed play in axial direc-

tion of journal, and install them. (Refer to SDS.)

Select snap rings with a difference in thickness at both sides

within 0.06 mm (0.0024 in).

SPD731

SPD732

SPD131

SPD133

SPD134

PROPELLER SHAFT

Disassembly (Cont'd)

PD-8

Page 10 of 54

3. Adjust thrust clearance between bearing and snap ring to zero

by tapping yoke.

4. Check to see that journal moves smoothly and check for axial

play.

Axial play: 0.02 mm (0.0008 in) or less

SPD732

SPD874

PROPELLER SHAFT

Assembly (Cont'd)

PD-9