fuse NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 431 of 1033

Diagnostic Procedure

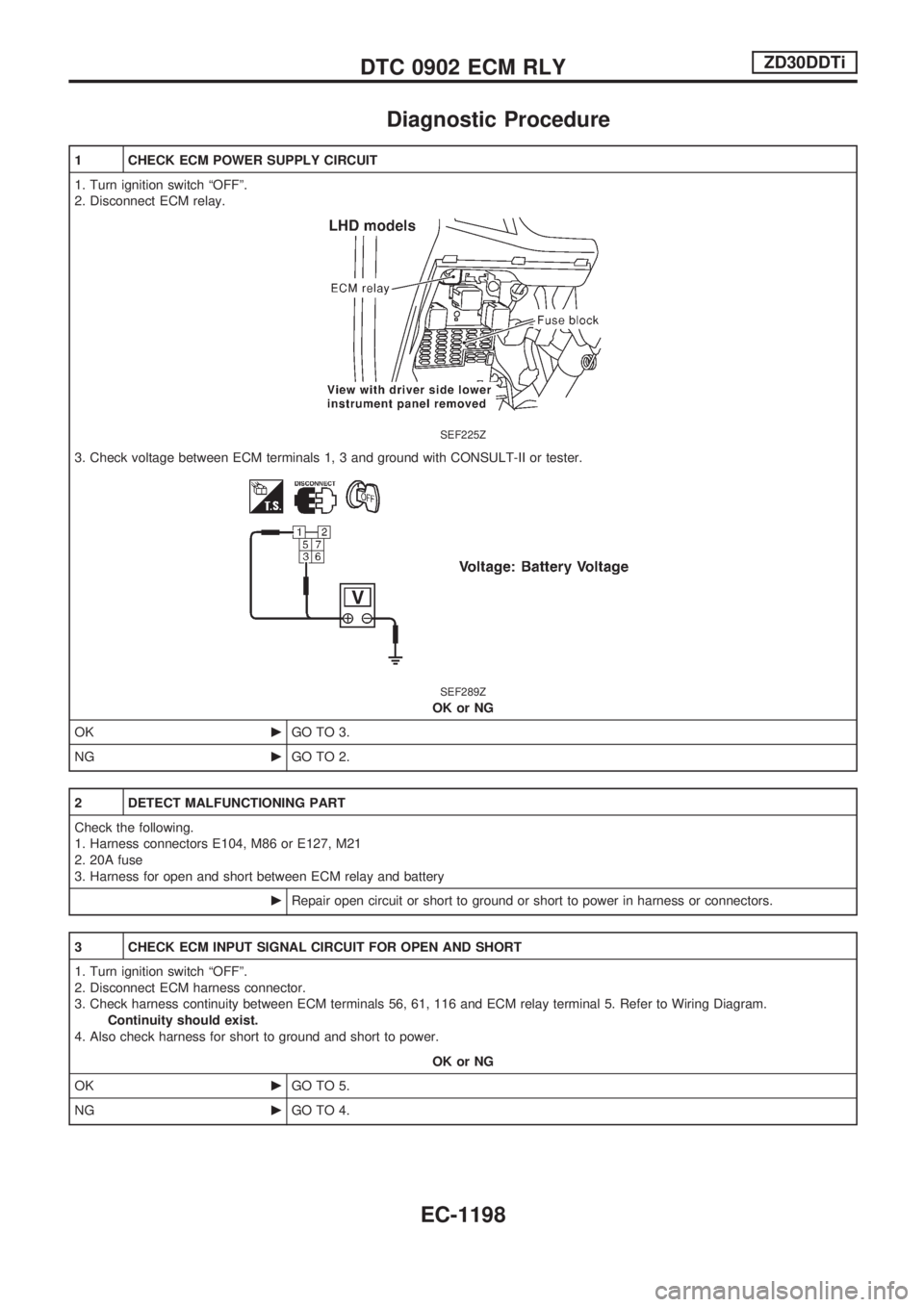

1 CHECK ECM POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

SEF225Z

3. Check voltage between ECM terminals 1, 3 and ground with CONSULT-II or tester.

SEF289Z

OK or NG

OKcGO TO 3.

NGcGO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

1. Harness connectors E104, M86 or E127, M21

2. 20A fuse

3. Harness for open and short between ECM relay and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ECM INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 56, 61, 116 and ECM relay terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0902 ECM RLYZD30DDTi

EC-1198

Page 444 of 1033

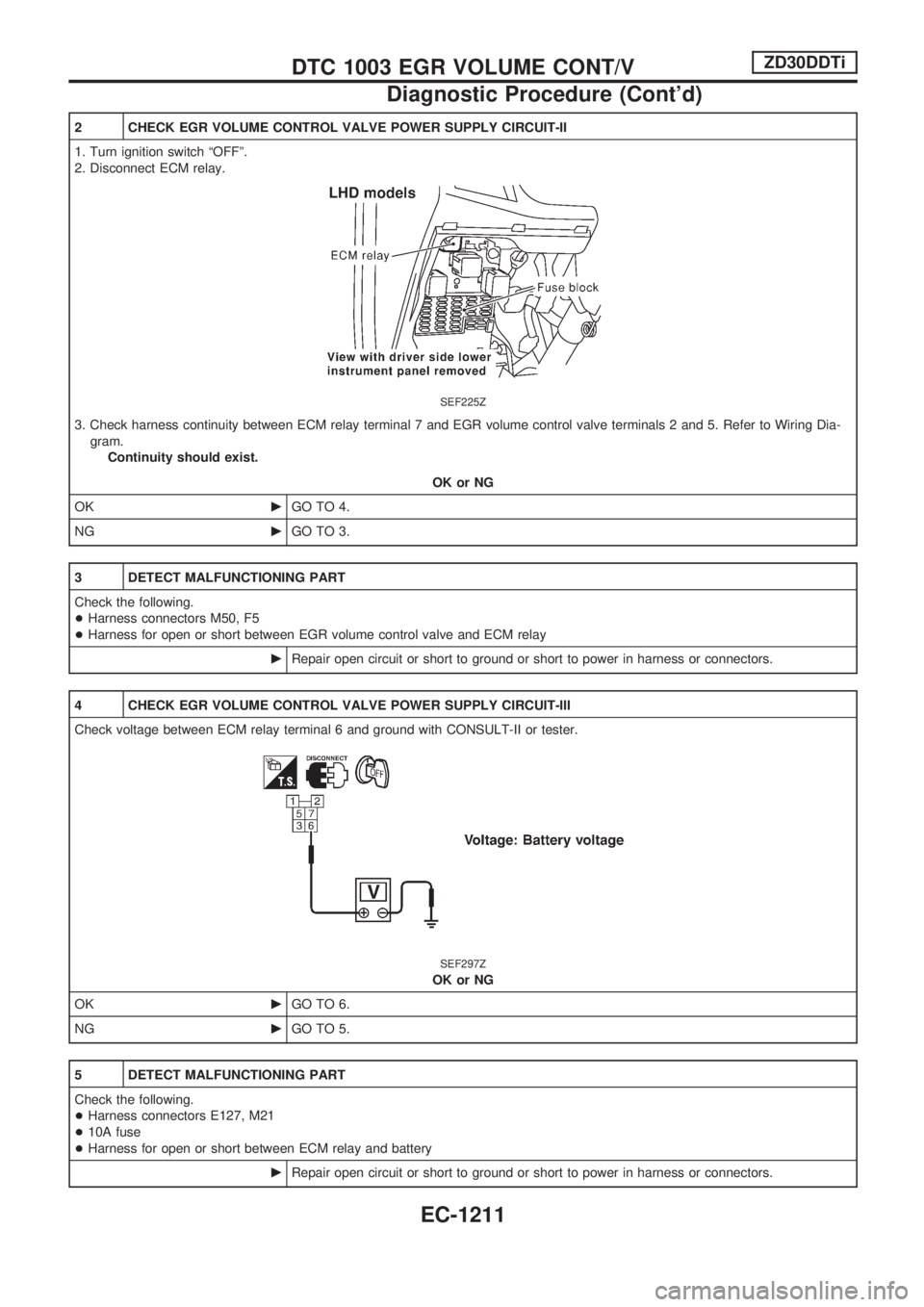

2 CHECK EGR VOLUME CONTROL VALVE POWER SUPPLY CIRCUIT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

SEF225Z

3. Check harness continuity between ECM relay terminal 7 and EGR volume control valve terminals 2 and 5. Refer to Wiring Dia-

gram.

Continuity should exist.

OK or NG

OKcGO TO 4.

NGcGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F5

+Harness for open or short between EGR volume control valve and ECM relay

cRepair open circuit or short to ground or short to power in harness or connectors.

4 CHECK EGR VOLUME CONTROL VALVE POWER SUPPLY CIRCUIT-III

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF297Z

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E127, M21

+10A fuse

+Harness for open or short between ECM relay and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 1003 EGR VOLUME CONT/VZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1211

Page 459 of 1033

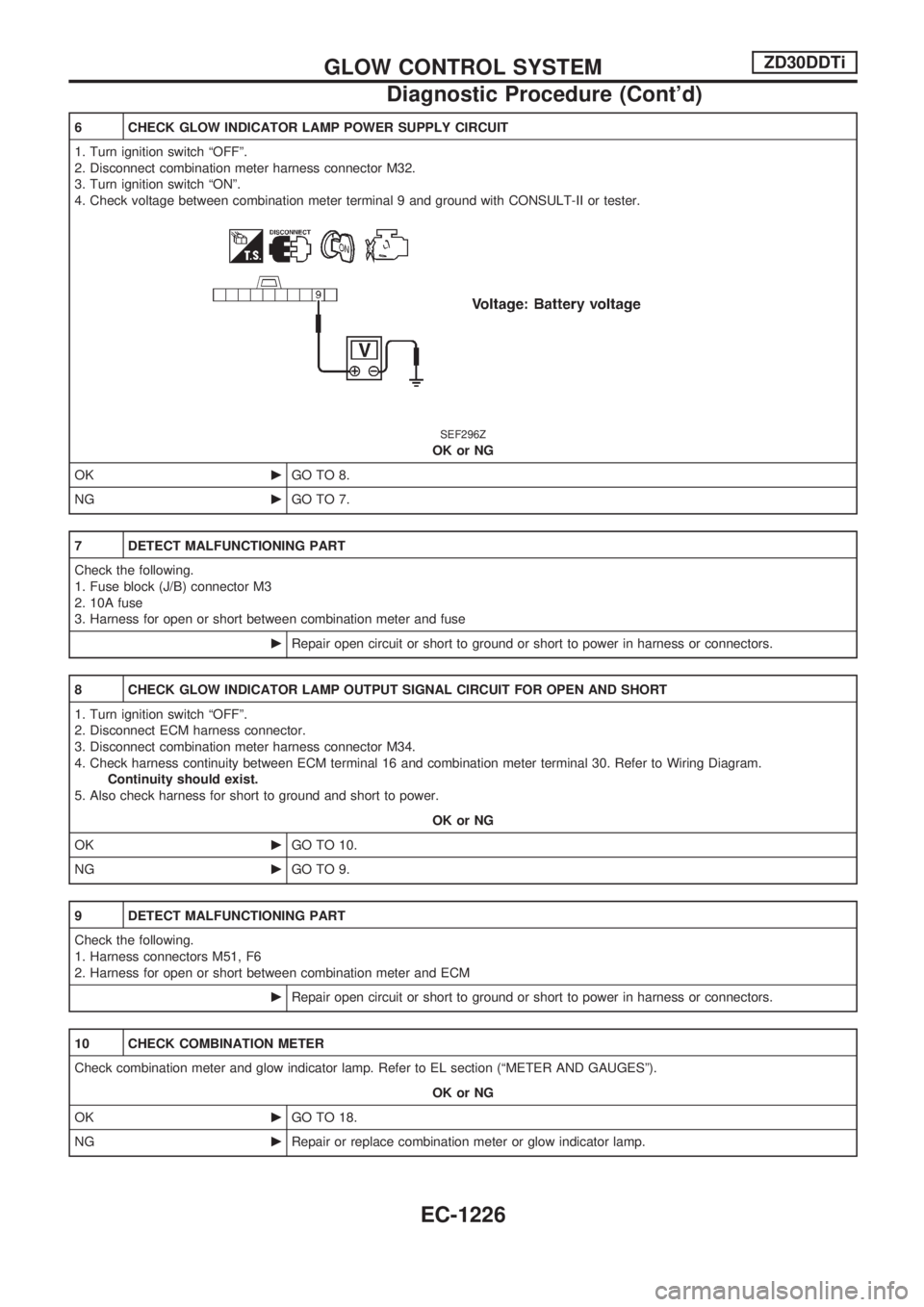

6 CHECK GLOW INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector M32.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal 9 and ground with CONSULT-II or tester.

SEF296Z

OK or NG

OKcGO TO 8.

NGcGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Fuse block (J/B) connector M3

2. 10A fuse

3. Harness for open or short between combination meter and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK GLOW INDICATOR LAMP OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector M34.

4. Check harness continuity between ECM terminal 16 and combination meter terminal 30. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

1. Harness connectors M51, F6

2. Harness for open or short between combination meter and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK COMBINATION METER

Check combination meter and glow indicator lamp. Refer to EL section (ªMETER AND GAUGESº).

OK or NG

OKcGO TO 18.

NGcRepair or replace combination meter or glow indicator lamp.

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1226

Page 464 of 1033

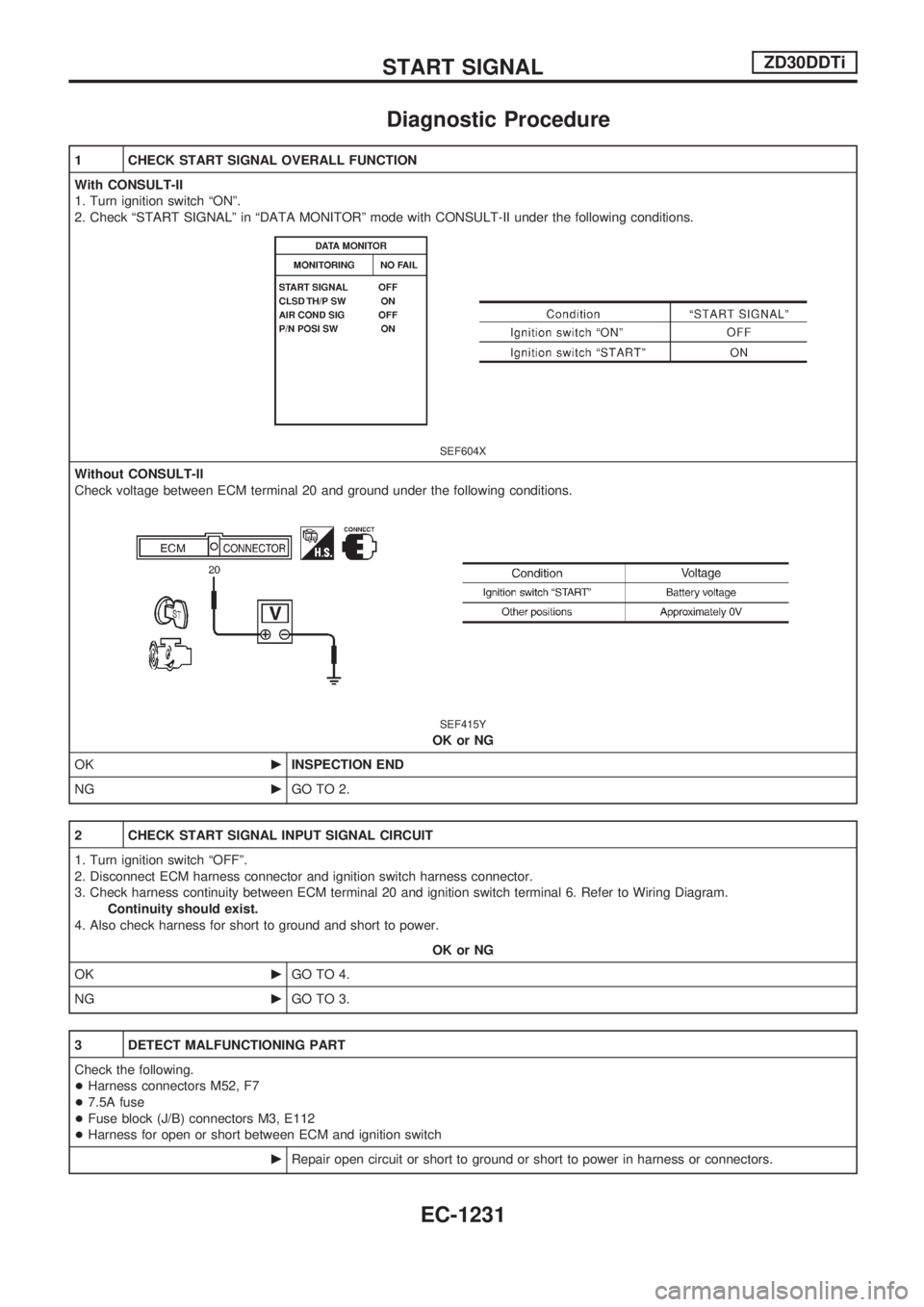

Diagnostic Procedure

1 CHECK START SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF604X

Without CONSULT-II

Check voltage between ECM terminal 20 and ground under the following conditions.

SEF415Y

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 20 and ignition switch terminal 6. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 4.

NGcGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M52, F7

+7.5A fuse

+Fuse block (J/B) connectors M3, E112

+Harness for open or short between ECM and ignition switch

cRepair open circuit or short to ground or short to power in harness or connectors.

START SIGNALZD30DDTi

EC-1231

Page 472 of 1033

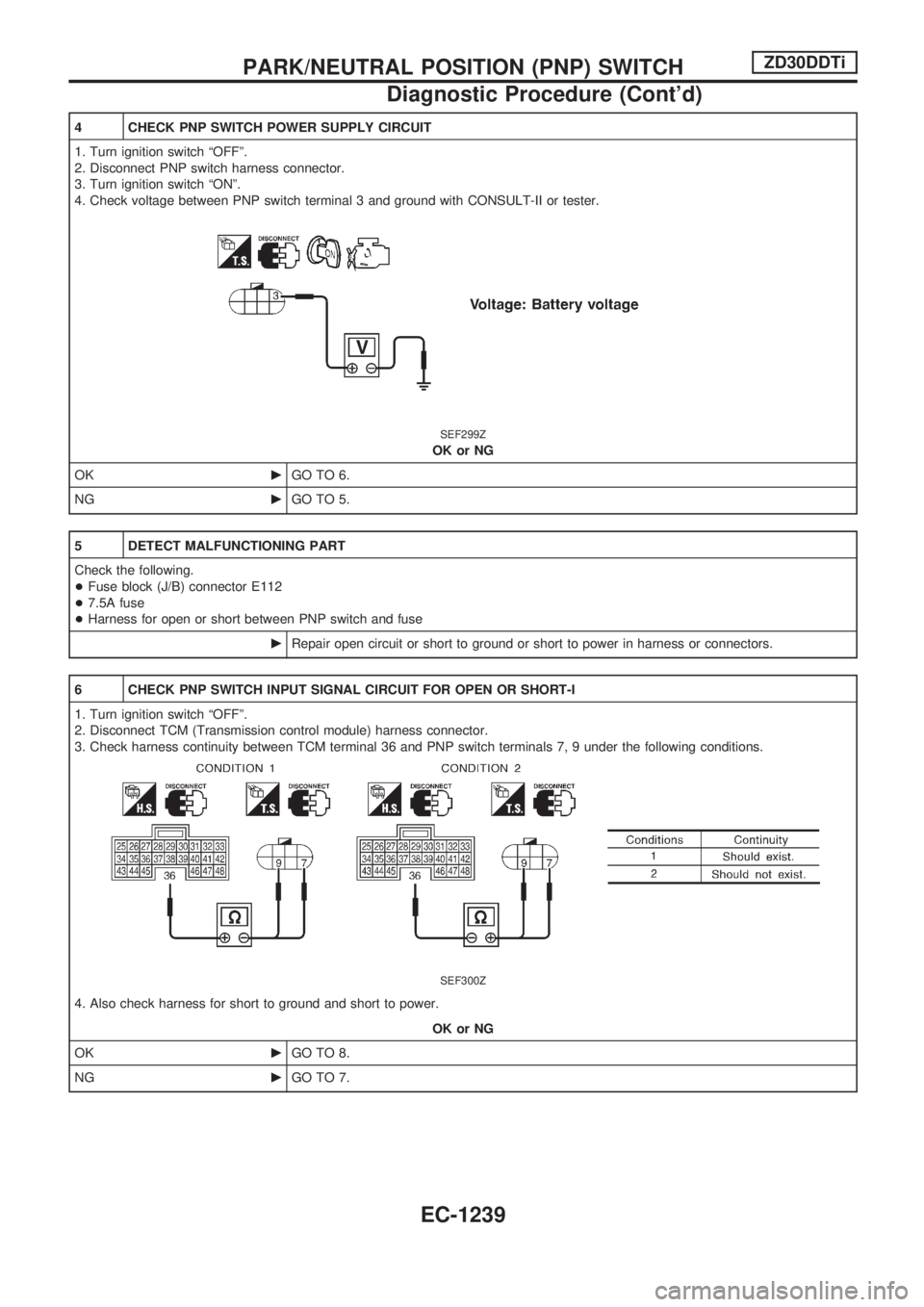

4 CHECK PNP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between PNP switch terminal 3 and ground with CONSULT-II or tester.

SEF299Z

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector E112

+7.5A fuse

+Harness for open or short between PNP switch and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

6 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect TCM (Transmission control module) harness connector.

3. Check harness continuity between TCM terminal 36 and PNP switch terminals 7, 9 under the following conditions.

SEF300Z

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 8.

NGcGO TO 7.

PARK/NEUTRAL POSITION (PNP) SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1239

Page 477 of 1033

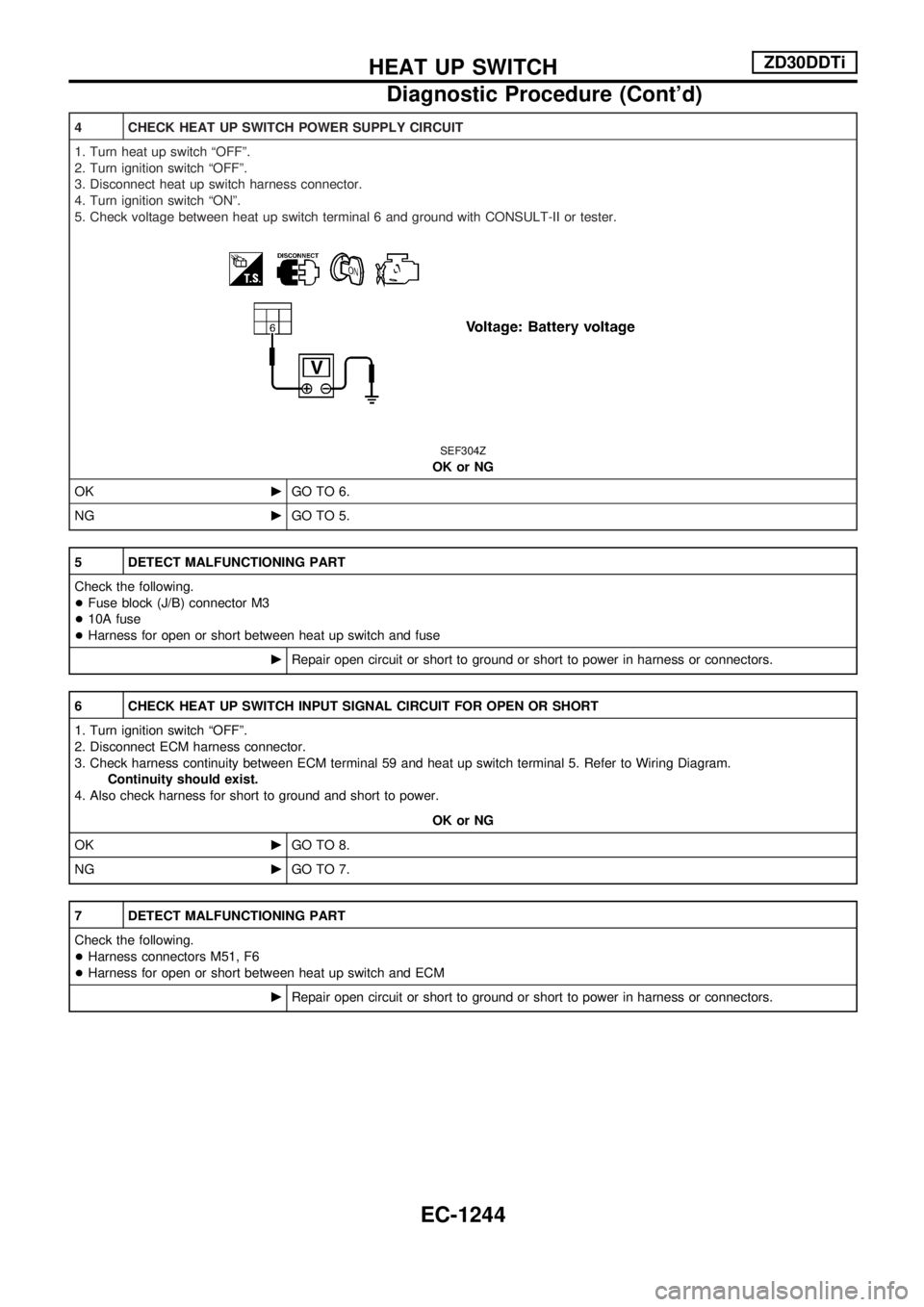

4 CHECK HEAT UP SWITCH POWER SUPPLY CIRCUIT

1. Turn heat up switch ªOFFº.

2. Turn ignition switch ªOFFº.

3. Disconnect heat up switch harness connector.

4. Turn ignition switch ªONº.

5. Check voltage between heat up switch terminal 6 and ground with CONSULT-II or tester.

SEF304Z

OK or NG

OKcGO TO 6.

NGcGO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector M3

+10A fuse

+Harness for open or short between heat up switch and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

6 CHECK HEAT UP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 59 and heat up switch terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 8.

NGcGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M51, F6

+Harness for open or short between heat up switch and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

HEAT UP SWITCHZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1244

Page 485 of 1033

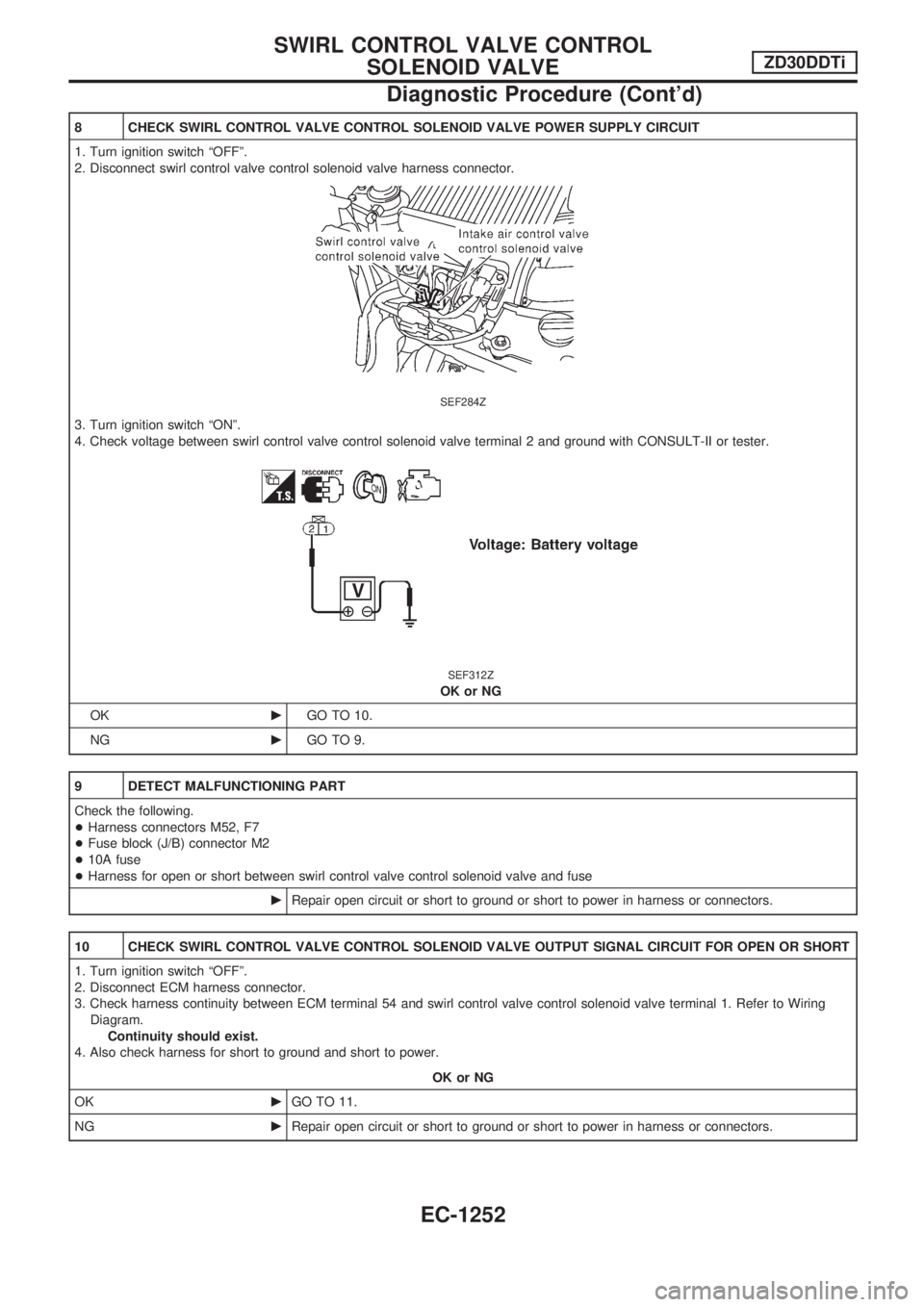

8 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect swirl control valve control solenoid valve harness connector.

SEF284Z

3. Turn ignition switch ªONº.

4. Check voltage between swirl control valve control solenoid valve terminal 2 and ground with CONSULT-II or tester.

SEF312Z

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M52, F7

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between swirl control valve control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK SWIRL CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 54 and swirl control valve control solenoid valve terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 11.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

SWIRL CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1252

Page 492 of 1033

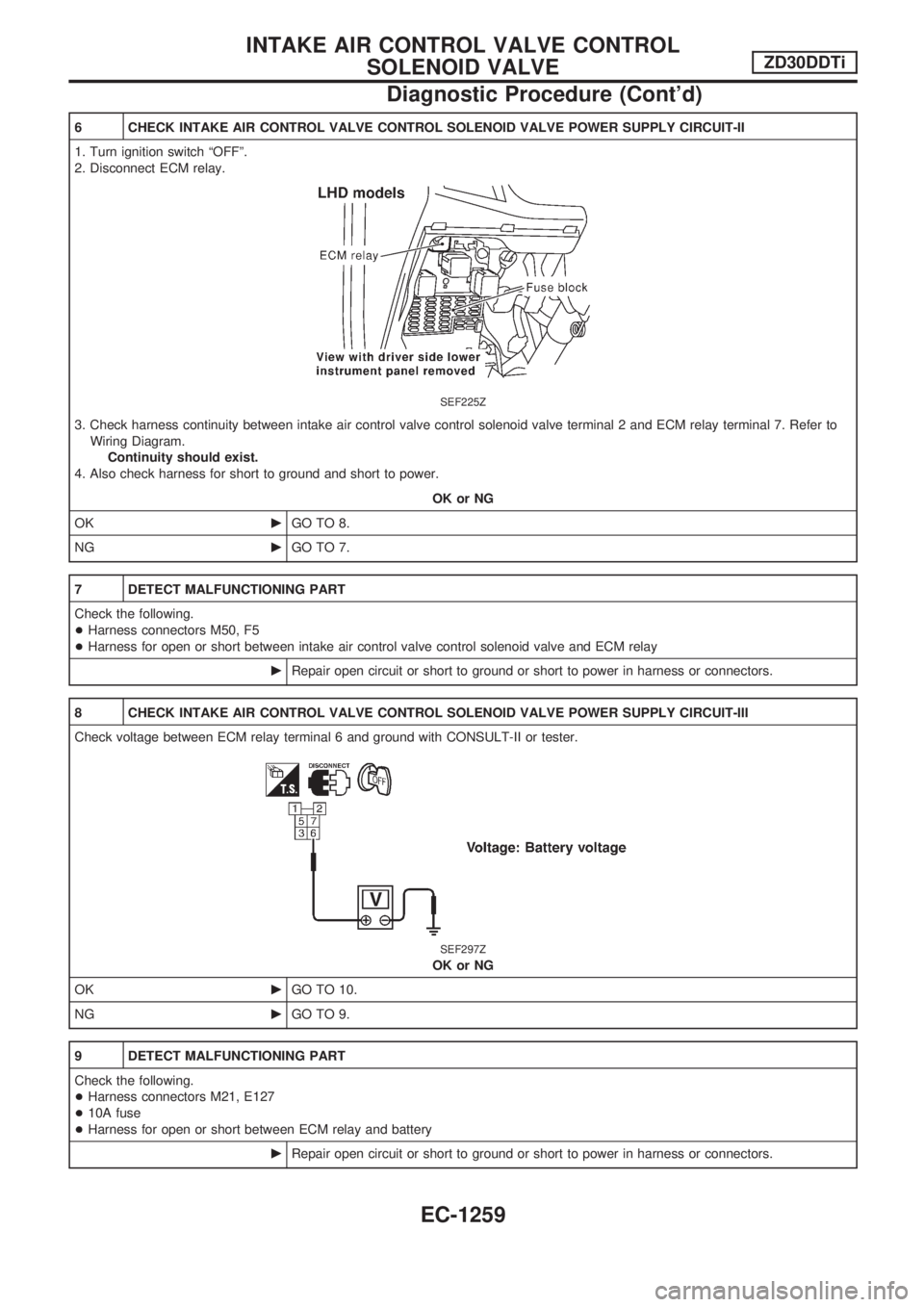

6 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

SEF225Z

3. Check harness continuity between intake air control valve control solenoid valve terminal 2 and ECM relay terminal 7. Refer to

Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 8.

NGcGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F5

+Harness for open or short between intake air control valve control solenoid valve and ECM relay

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT-III

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF297Z

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+10A fuse

+Harness for open or short between ECM relay and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1259

Page 500 of 1033

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Harness connectors E69, E202

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between variable nozzle turbocharger control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 101 and variable nozzle turbocharger control solenoid valve terminal 1. Refer

to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness for open or short between variable nozzle turbocharger control solenoid valve and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1267

Page 507 of 1033

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between exhaust gas control valve control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK EXHAUST GAS CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN

OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 11 and exhaust gas control valve control solenoid valve terminal 1. Refer to

Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Harness connectors M50, F5

+Harness for open or short between exhaust gas control valve control solenoid valve and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

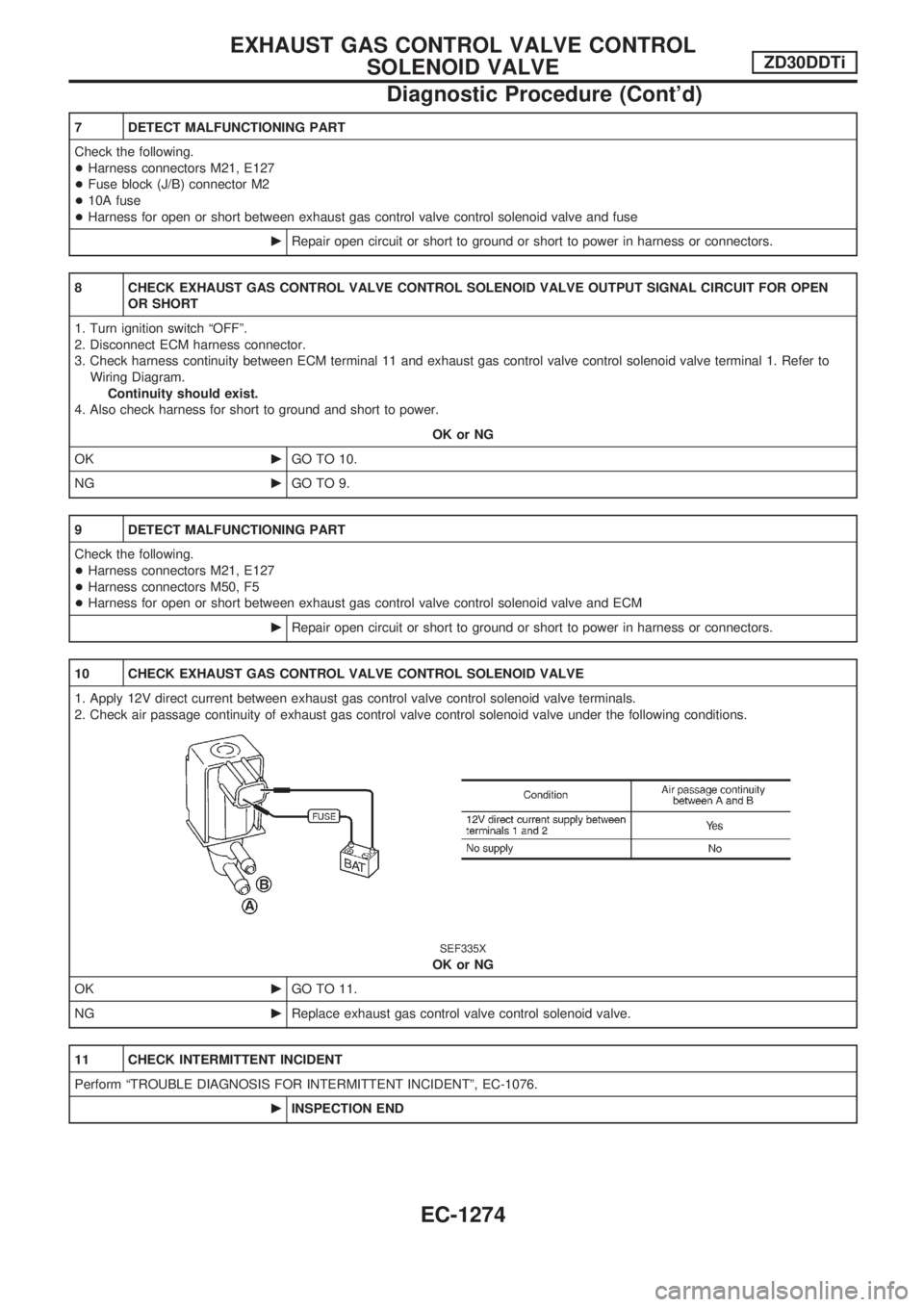

10 CHECK EXHAUST GAS CONTROL VALVE CONTROL SOLENOID VALVE

1. Apply 12V direct current between exhaust gas control valve control solenoid valve terminals.

2. Check air passage continuity of exhaust gas control valve control solenoid valve under the following conditions.

SEF335X

OK or NG

OKcGO TO 11.

NGcReplace exhaust gas control valve control solenoid valve.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1274