fuse NISSAN PATROL 2000 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 658 of 1033

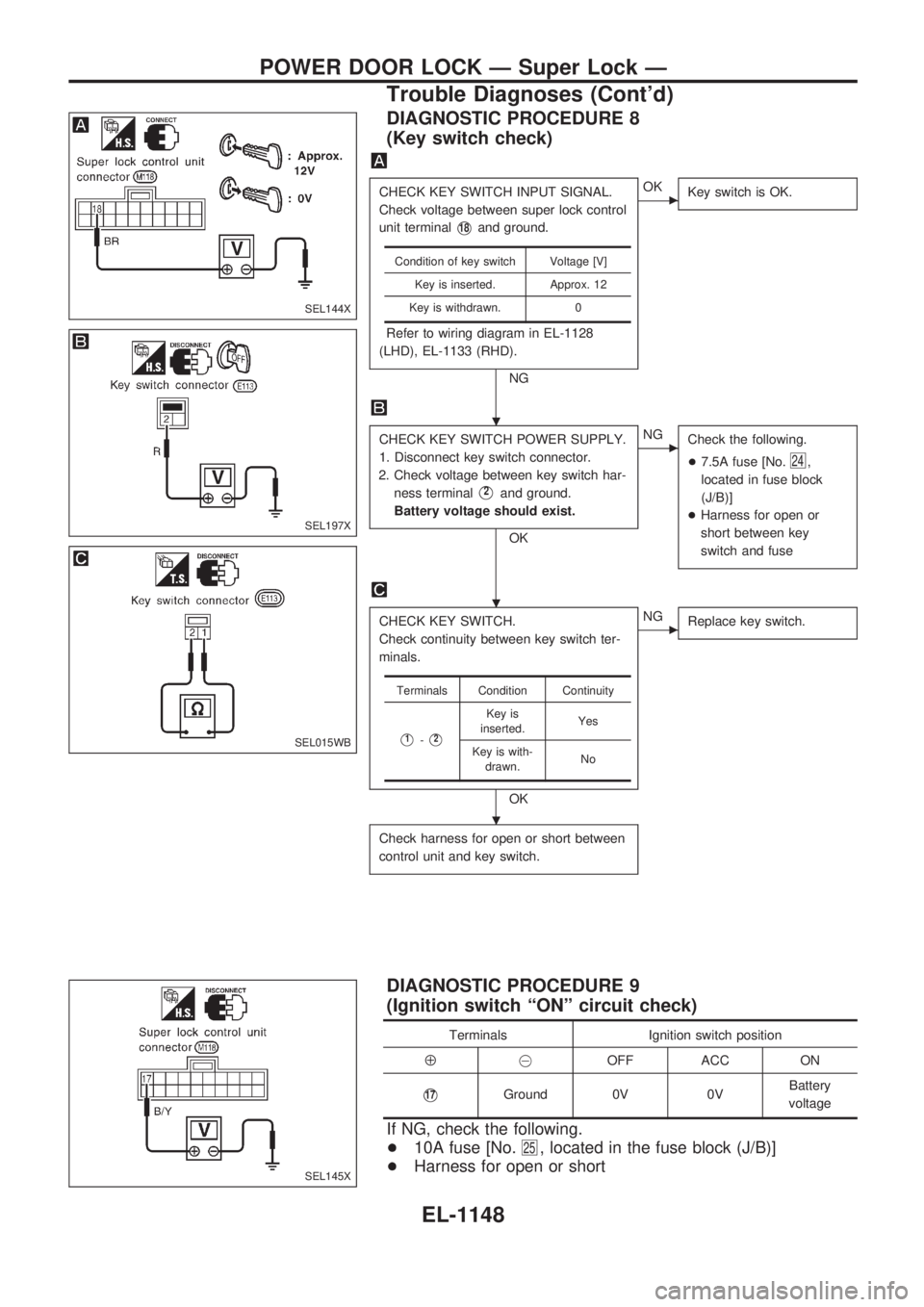

DIAGNOSTIC PROCEDURE 8

(Key switch check)

CHECK KEY SWITCH INPUT SIGNAL.

Check voltage between super lock control

unit terminal

V18and ground.

Refer to wiring diagram in EL-1128

(LHD), EL-1133 (RHD).

NG

cOK

Key switch is OK.

CHECK KEY SWITCH POWER SUPPLY.

1. Disconnect key switch connector.

2. Check voltage between key switch har-

ness terminal

V2and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

24,

located in fuse block

(J/B)]

+Harness for open or

short between key

switch and fuse

CHECK KEY SWITCH.

Check continuity between key switch ter-

minals.

OK

cNG

Replace key switch.

Check harness for open or short between

control unit and key switch.

Condition of key switch Voltage [V]

Key is inserted. Approx. 12

Key is withdrawn. 0

Terminals Condition Continuity

V1-V2

Key is

inserted.Yes

Key is with-

drawn.No

DIAGNOSTIC PROCEDURE 9

(Ignition switch ªONº circuit check)

Terminals Ignition switch position

Å@OFF ACC ON

V17Ground 0V 0VBattery

voltage

If NG, check the following.

+10A fuse [No.

25, located in the fuse block (J/B)]

+Harness for open or short

SEL144X

SEL197X

SEL015WB

SEL145X

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-1148

Page 672 of 1033

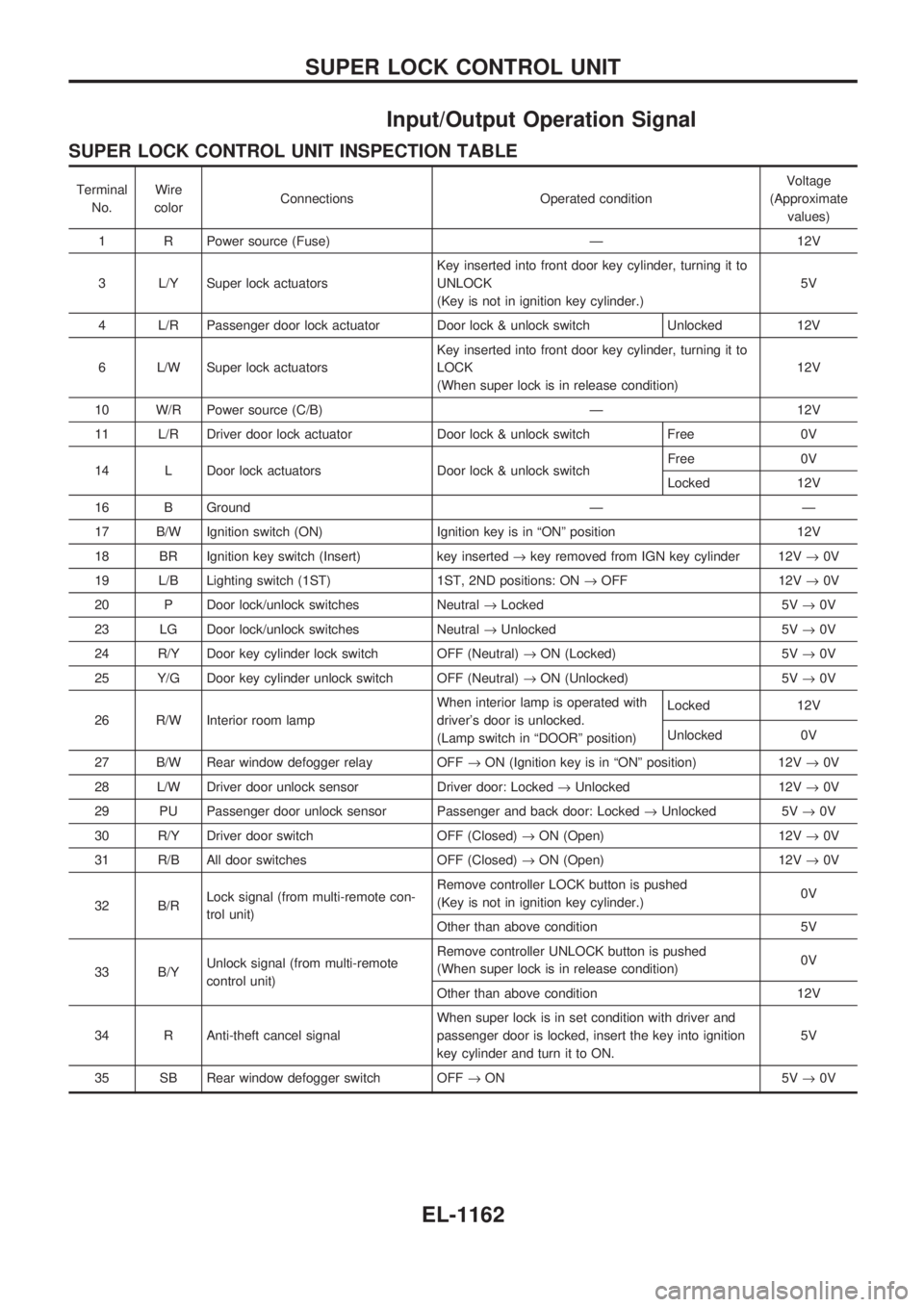

Input/Output Operation Signal

SUPER LOCK CONTROL UNIT INSPECTION TABLE

Terminal

No.Wire

colorConnections Operated conditionVoltage

(Approximate

values)

1 R Power source (Fuse) Ð 12V

3 L/Y Super lock actuatorsKey inserted into front door key cylinder, turning it to

UNLOCK

(Key is not in ignition key cylinder.)5V

4 L/R Passenger door lock actuator Door lock & unlock switch Unlocked 12V

6 L/W Super lock actuatorsKey inserted into front door key cylinder, turning it to

LOCK

(When super lock is in release condition)12V

10 W/R Power source (C/B) Ð 12V

11 L/R Driver door lock actuator Door lock & unlock switch Free 0V

14 L Door lock actuators Door lock & unlock switchFree 0V

Locked 12V

16 B Ground Ð Ð

17 B/W Ignition switch (ON) Ignition key is in ªONº position 12V

18 BR Ignition key switch (Insert) key inserted®key removed from IGN key cylinder 12V®0V

19 L/B Lighting switch (1ST) 1ST, 2ND positions: ON®OFF 12V®0V

20 P Door lock/unlock switches Neutral®Locked 5V®0V

23 LG Door lock/unlock switches Neutral®Unlocked 5V®0V

24 R/Y Door key cylinder lock switch OFF (Neutral)®ON (Locked) 5V®0V

25 Y/G Door key cylinder unlock switch OFF (Neutral)®ON (Unlocked) 5V®0V

26 R/W Interior room lampWhen interior lamp is operated with

driver's door is unlocked.

(Lamp switch in ªDOORº position)Locked 12V

Unlocked 0V

27 B/W Rear window defogger relay OFF®ON (Ignition key is in ªONº position) 12V®0V

28 L/W Driver door unlock sensor Driver door: Locked®Unlocked 12V®0V

29 PU Passenger door unlock sensor Passenger and back door: Locked®Unlocked 5V®0V

30 R/Y Driver door switch OFF (Closed)®ON (Open) 12V®0V

31 R/B All door switches OFF (Closed)®ON (Open) 12V®0V

32 B/RLock signal (from multi-remote con-

trol unit)Remove controller LOCK button is pushed

(Key is not in ignition key cylinder.)0V

Other than above condition 5V

33 B/YUnlock signal (from multi-remote

control unit)Remove controller UNLOCK button is pushed

(When super lock is in release condition)0V

Other than above condition 12V

34 R Anti-theft cancel signalWhen super lock is in set condition with driver and

passenger door is locked, insert the key into ignition

key cylinder and turn it to ON.5V

35 SB Rear window defogger switch OFF®ON 5V®0V

SUPER LOCK CONTROL UNIT

EL-1162

Page 679 of 1033

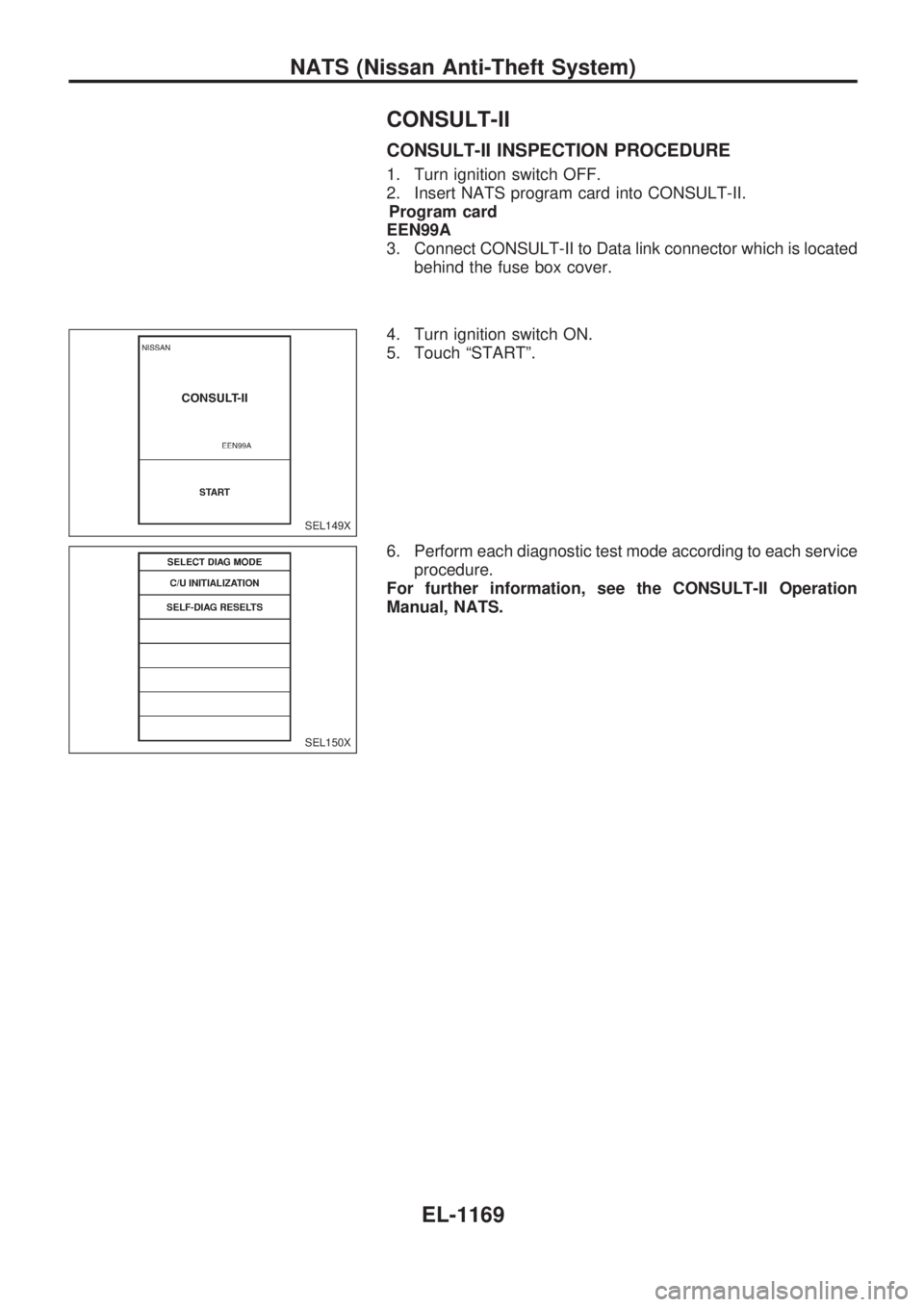

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Insert NATS program card into CONSULT-II.

Program card

EEN99A

3. Connect CONSULT-II to Data link connector which is located

behind the fuse box cover.

4. Turn ignition switch ON.

5. Touch ªSTARTº.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation

Manual, NATS.

SEL149X

SEL150X

NATS (Nissan Anti-Theft System)

EL-1169

Page 684 of 1033

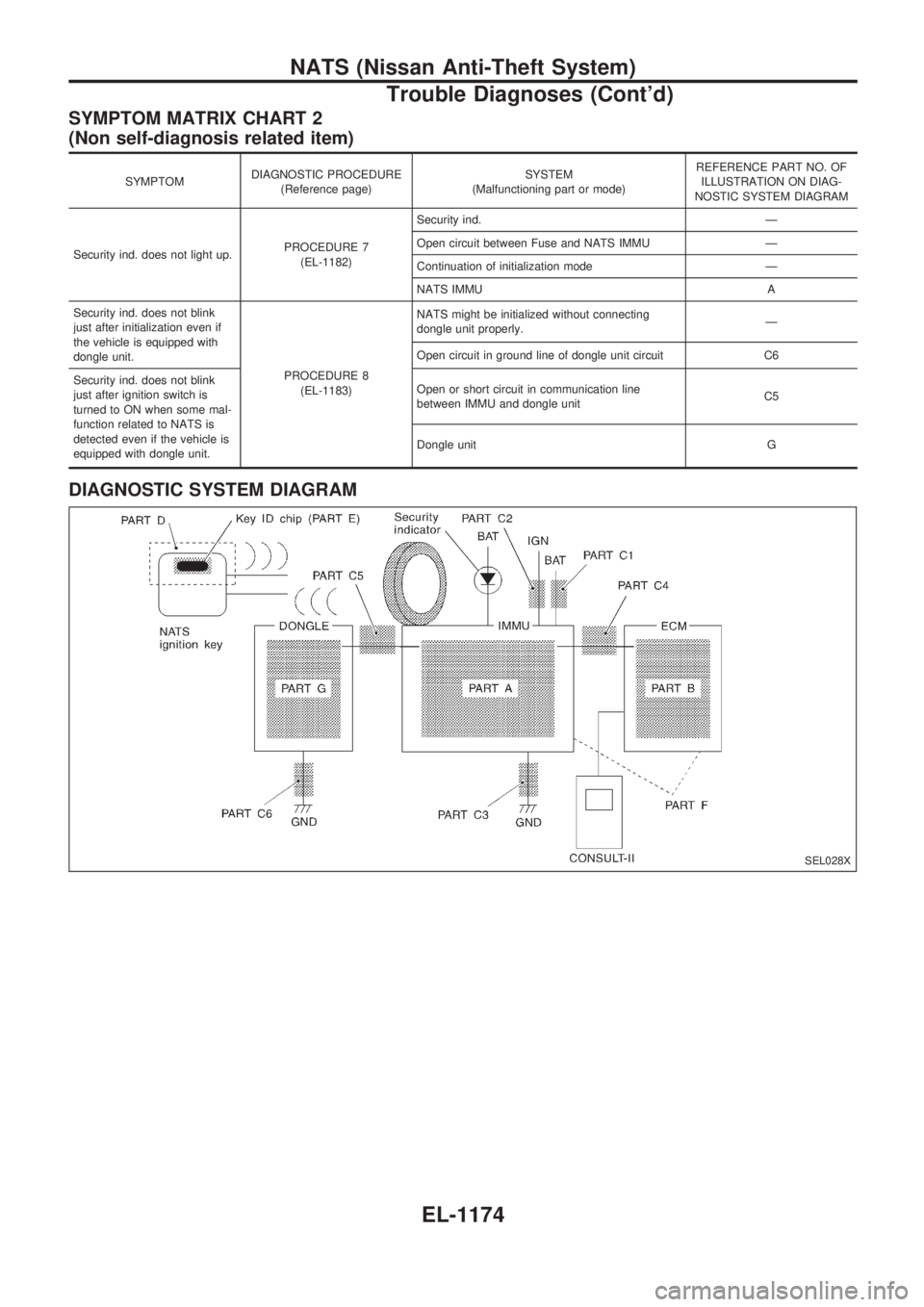

SYMPTOM MATRIX CHART 2

(Non self-diagnosis related item)

SYMPTOMDIAGNOSTIC PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)REFERENCE PART NO. OF

ILLUSTRATION ON DIAG-

NOSTIC SYSTEM DIAGRAM

Security ind. does not light up.PROCEDURE 7

(EL-1182)Security ind. Ð

Open circuit between Fuse and NATS IMMU Ð

Continuation of initialization mode Ð

NATS IMMU A

Security ind. does not blink

just after initialization even if

the vehicle is equipped with

dongle unit.

PROCEDURE 8

(EL-1183)NATS might be initialized without connecting

dongle unit properly.Ð

Open circuit in ground line of dongle unit circuit C6

Security ind. does not blink

just after ignition switch is

turned to ON when some mal-

function related to NATS is

detected even if the vehicle is

equipped with dongle unit.Open or short circuit in communication line

between IMMU and dongle unitC5

Dongle unit G

DIAGNOSTIC SYSTEM DIAGRAM

SEL028X

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1174

Page 686 of 1033

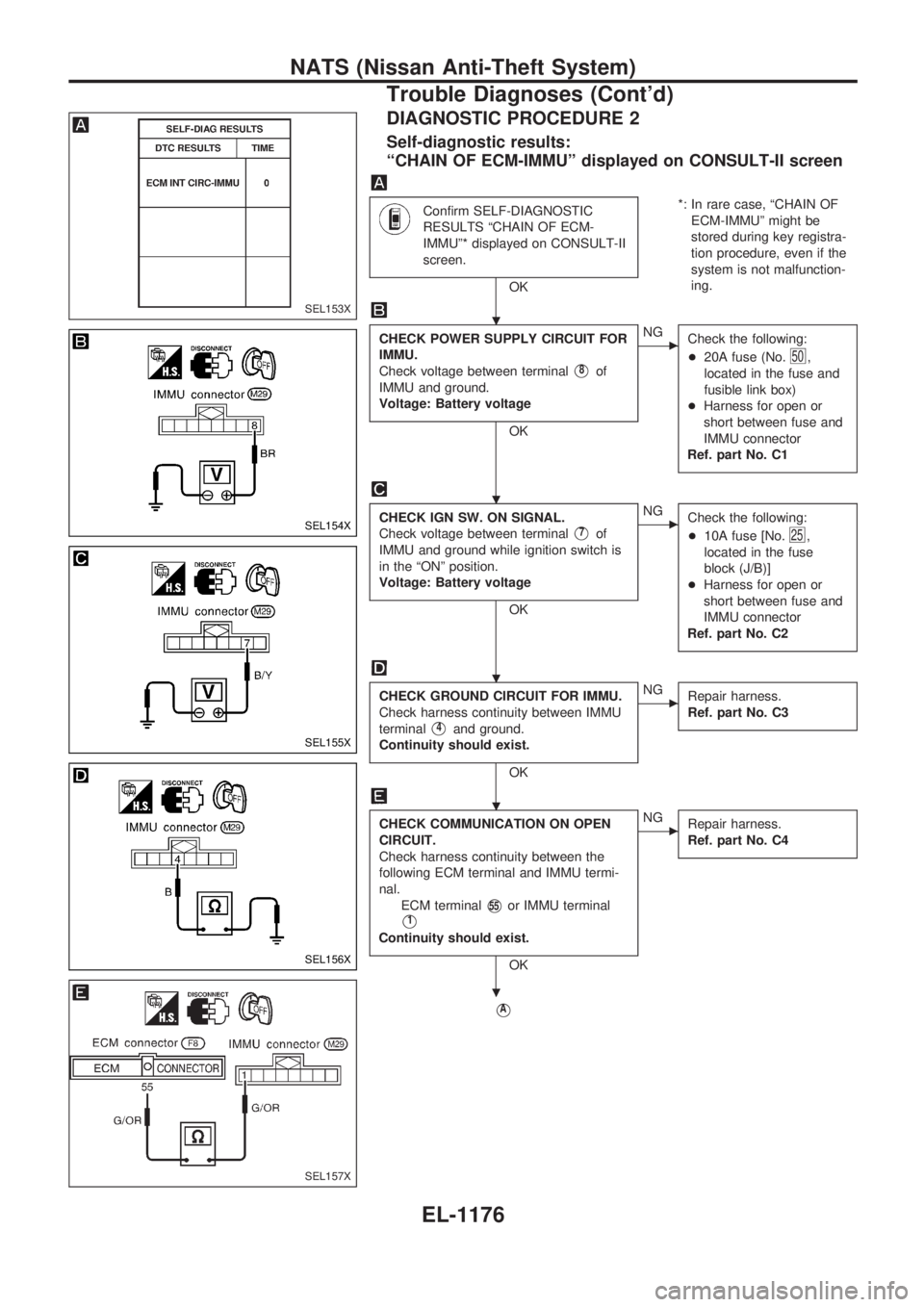

DIAGNOSTIC PROCEDURE 2

Self-diagnostic results:

ªCHAIN OF ECM-IMMUº displayed on CONSULT-II screen

Confirm SELF-DIAGNOSTIC

RESULTS ªCHAIN OF ECM-

IMMUº* displayed on CONSULT-II

screen.

OK*: In rare case, ªCHAIN OF

ECM-IMMUº might be

stored during key registra-

tion procedure, even if the

system is not malfunction-

ing.

CHECK POWER SUPPLY CIRCUIT FOR

IMMU.

Check voltage between terminal

V8of

IMMU and ground.

Voltage: Battery voltage

OK

cNG

Check the following:

+20A fuse (No.

50,

located in the fuse and

fusible link box)

+Harness for open or

short between fuse and

IMMU connector

Ref. part No. C1

CHECK IGN SW. ON SIGNAL.

Check voltage between terminal

V7of

IMMU and ground while ignition switch is

in the ªONº position.

Voltage: Battery voltage

OK

cNG

Check the following:

+10A fuse [No.

25,

located in the fuse

block (J/B)]

+Harness for open or

short between fuse and

IMMU connector

Ref. part No. C2

CHECK GROUND CIRCUIT FOR IMMU.

Check harness continuity between IMMU

terminal

V4and ground.

Continuity should exist.

OK

cNG

Repair harness.

Ref. part No. C3

CHECK COMMUNICATION ON OPEN

CIRCUIT.

Check harness continuity between the

following ECM terminal and IMMU termi-

nal.

ECM terminal

V55or IMMU terminal

V1

Continuity should exist.

OK

cNG

Repair harness.

Ref. part No. C4

VA

SEL153X

SEL154X

SEL155X

SEL156X

SEL157X

.

.

.

.

.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1176

Page 692 of 1033

![NISSAN PATROL 2000 Electronic Owners Guide DIAGNOSTIC PROCEDURE 7

ªSECURITY IND. DOES NOT LIGHT UPº

Check 7.5A fuse [No.24, located in the

fuse block (J/B)].

OK

cNG

Replace fuse.

NATS INITIALIZATION

1) Install the 7.5A fuse.

2) Perform initi NISSAN PATROL 2000 Electronic Owners Guide DIAGNOSTIC PROCEDURE 7

ªSECURITY IND. DOES NOT LIGHT UPº

Check 7.5A fuse [No.24, located in the

fuse block (J/B)].

OK

cNG

Replace fuse.

NATS INITIALIZATION

1) Install the 7.5A fuse.

2) Perform initi](/img/5/57367/w960_57367-691.png)

DIAGNOSTIC PROCEDURE 7

ªSECURITY IND. DOES NOT LIGHT UPº

Check 7.5A fuse [No.24, located in the

fuse block (J/B)].

OK

cNG

Replace fuse.

NATS INITIALIZATION

1) Install the 7.5A fuse.

2) Perform initialization with CON-

SULT-II.

For the operation of

initialization, refer to ªCON-

SULT-II operation manual

NATSº.

Turn ignition switch ªOFFº.

Start engine and turn ignition switch

ªOFFº.

Check the security ind. lighting.

NG

cOK

END

Check voltage between security ind. con-

nector terminal

V1and ground.

Voltage: Battery voltage

OK

cNG

Check harness for open or

short between fuse and

security ind.

CHECK INDICATOR LAMP.

OK

cNG

Repair harness.

CHECK NATS IMMU FUNCTION.

1. Connect NATS IMMU connector.

2. Disconnect security ind. connector.

3. Check continuity between NATS IMMU

terminal

V6and ground.

Continuity should exist intermit-

tently.

OK

cNG

NATS IMMU is malfunc-

tioning. Replace IMMU.

Perform initializa-

tion with CON-

SULT-II.

For the operation

of initialization,

refer to ªCON-

SULT-II operation

manual NATSº.

Check harness for open or short between

security indicator and NATS IMMU.

SEL931UA

SEL164X

.

.

.

.

.

.

.

.

.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1182

Page 748 of 1033

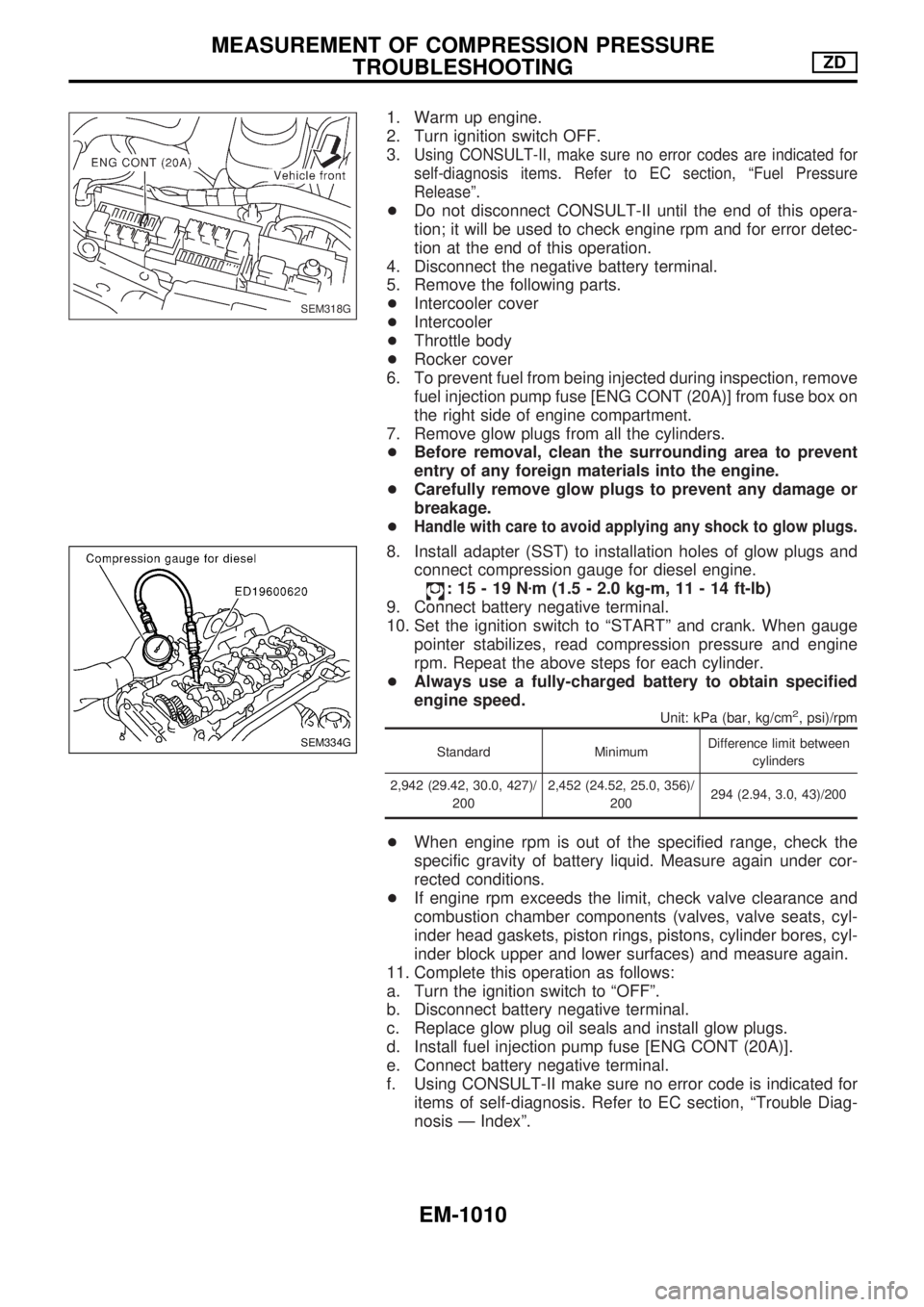

1. Warm up engine.

2. Turn ignition switch OFF.

3.

Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

+Intercooler cover

+Intercooler

+Throttle body

+Rocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT (20A)] from fuse box on

the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+

Handle with care to avoid applying any shock to glow plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diag-

nosis Ð Indexº.

SEM318G

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

TROUBLESHOOTINGZD

EM-1010

Page 780 of 1033

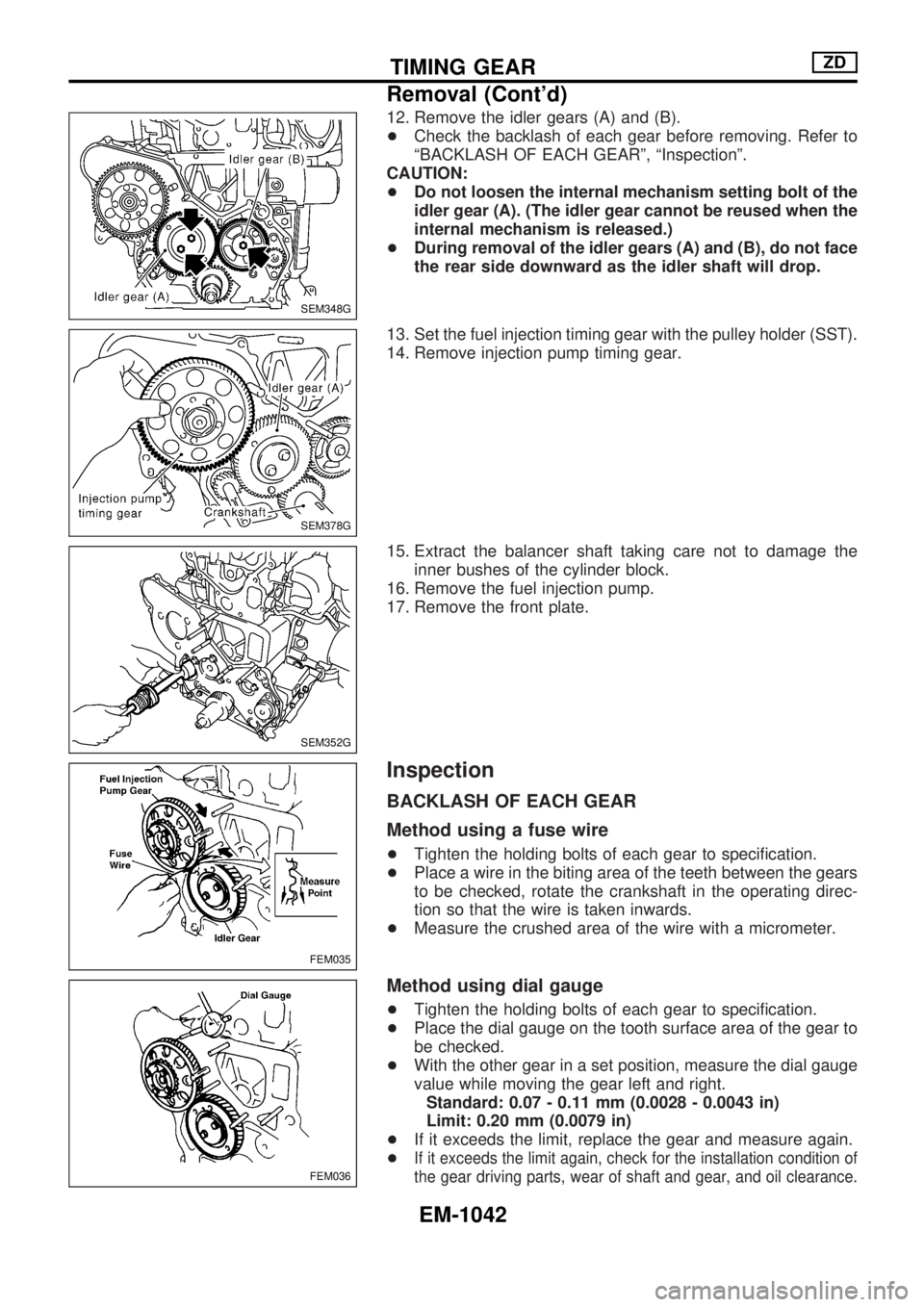

12. Remove the idler gears (A) and (B).

+Check the backlash of each gear before removing. Refer to

ªBACKLASH OF EACH GEARº, ªInspectionº.

CAUTION:

+Do not loosen the internal mechanism setting bolt of the

idler gear (A). (The idler gear cannot be reused when the

internal mechanism is released.)

+During removal of the idler gears (A) and (B), do not face

the rear side downward as the idler shaft will drop.

13. Set the fuel injection timing gear with the pulley holder (SST).

14. Remove injection pump timing gear.

15. Extract the balancer shaft taking care not to damage the

inner bushes of the cylinder block.

16. Remove the fuel injection pump.

17. Remove the front plate.

Inspection

BACKLASH OF EACH GEAR

Method using a fuse wire

+Tighten the holding bolts of each gear to specification.

+Place a wire in the biting area of the teeth between the gears

to be checked, rotate the crankshaft in the operating direc-

tion so that the wire is taken inwards.

+Measure the crushed area of the wire with a micrometer.

Method using dial gauge

+Tighten the holding bolts of each gear to specification.

+Place the dial gauge on the tooth surface area of the gear to

be checked.

+With the other gear in a set position, measure the dial gauge

value while moving the gear left and right.

Standard: 0.07 - 0.11 mm (0.0028 - 0.0043 in)

Limit: 0.20 mm (0.0079 in)

+If it exceeds the limit, replace the gear and measure again.

+

If it exceeds the limit again, check for the installation condition of

the gear driving parts, wear of shaft and gear, and oil clearance.

SEM348G

SEM378G

SEM352G

FEM035

FEM036

TIMING GEARZD

Removal (Cont'd)

EM-1042

Page 796 of 1033

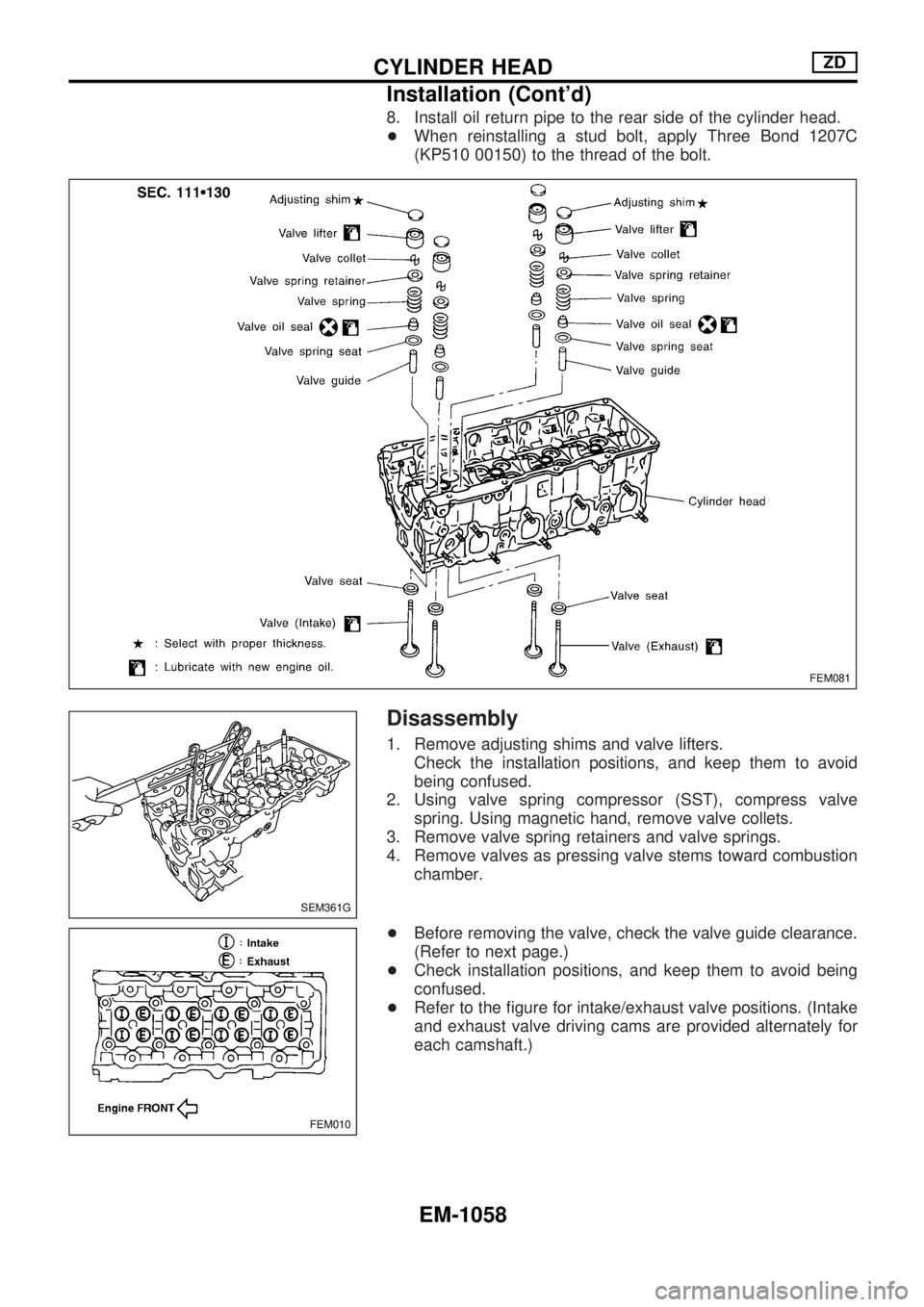

8. Install oil return pipe to the rear side of the cylinder head.

+When reinstalling a stud bolt, apply Three Bond 1207C

(KP510 00150) to the thread of the bolt.

Disassembly

1. Remove adjusting shims and valve lifters.

Check the installation positions, and keep them to avoid

being confused.

2. Using valve spring compressor (SST), compress valve

spring. Using magnetic hand, remove valve collets.

3. Remove valve spring retainers and valve springs.

4. Remove valves as pressing valve stems toward combustion

chamber.

+Before removing the valve, check the valve guide clearance.

(Refer to next page.)

+Check installation positions, and keep them to avoid being

confused.

+Refer to the figure for intake/exhaust valve positions. (Intake

and exhaust valve driving cams are provided alternately for

each camshaft.)

FEM081

SEM361G

FEM010

CYLINDER HEADZD

Installation (Cont'd)

EM-1058

Page 843 of 1033

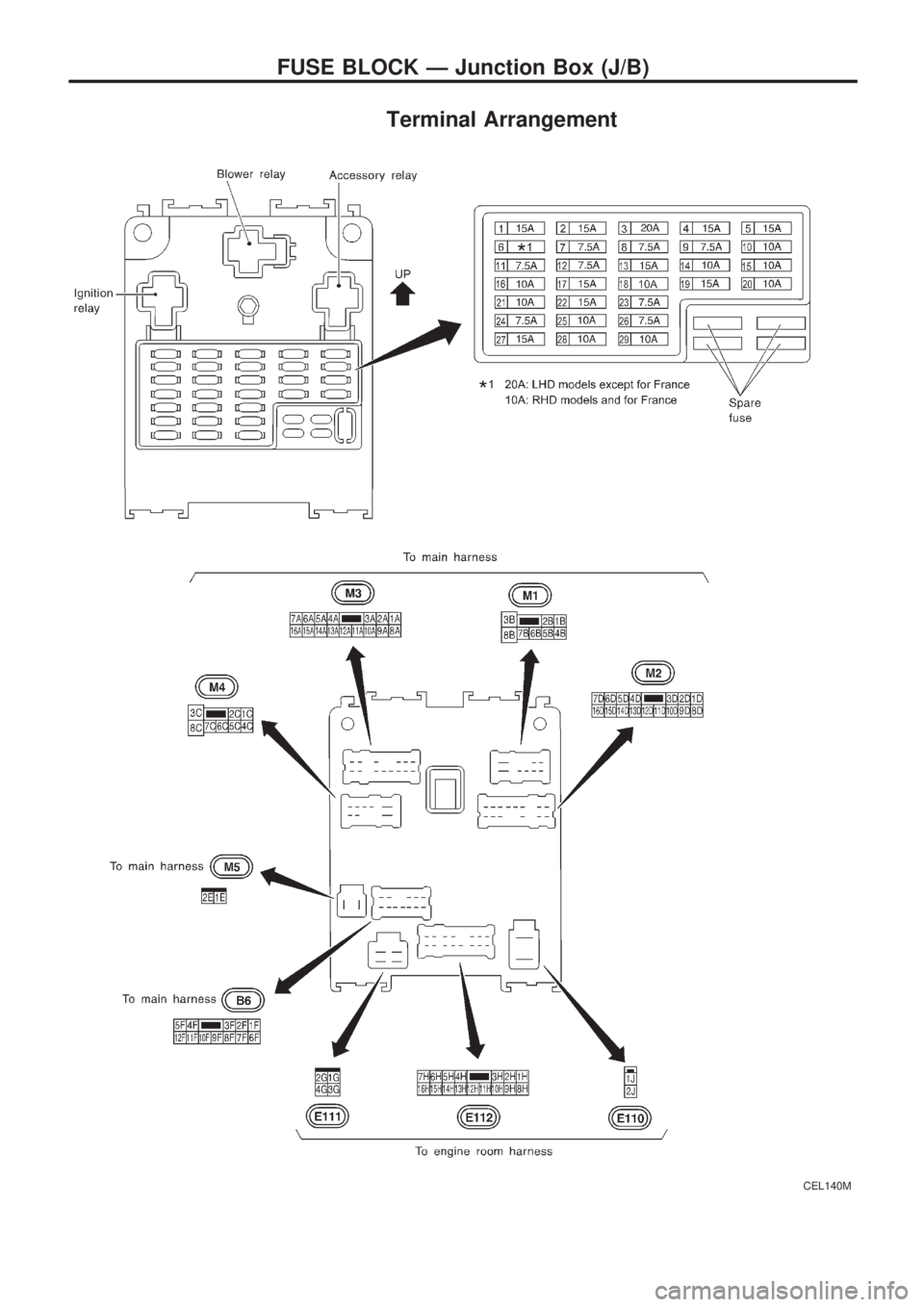

Terminal Arrangement

CEL140M

FUSE BLOCK Ð Junction Box (J/B)