warning NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 269 of 1033

Diagnostic test mode I Ð Bulb check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to EL

section, ªWARNING LAMPS AND CHIMEº or see EC-1276.

Diagnostic test mode I Ð Malfunction warning

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

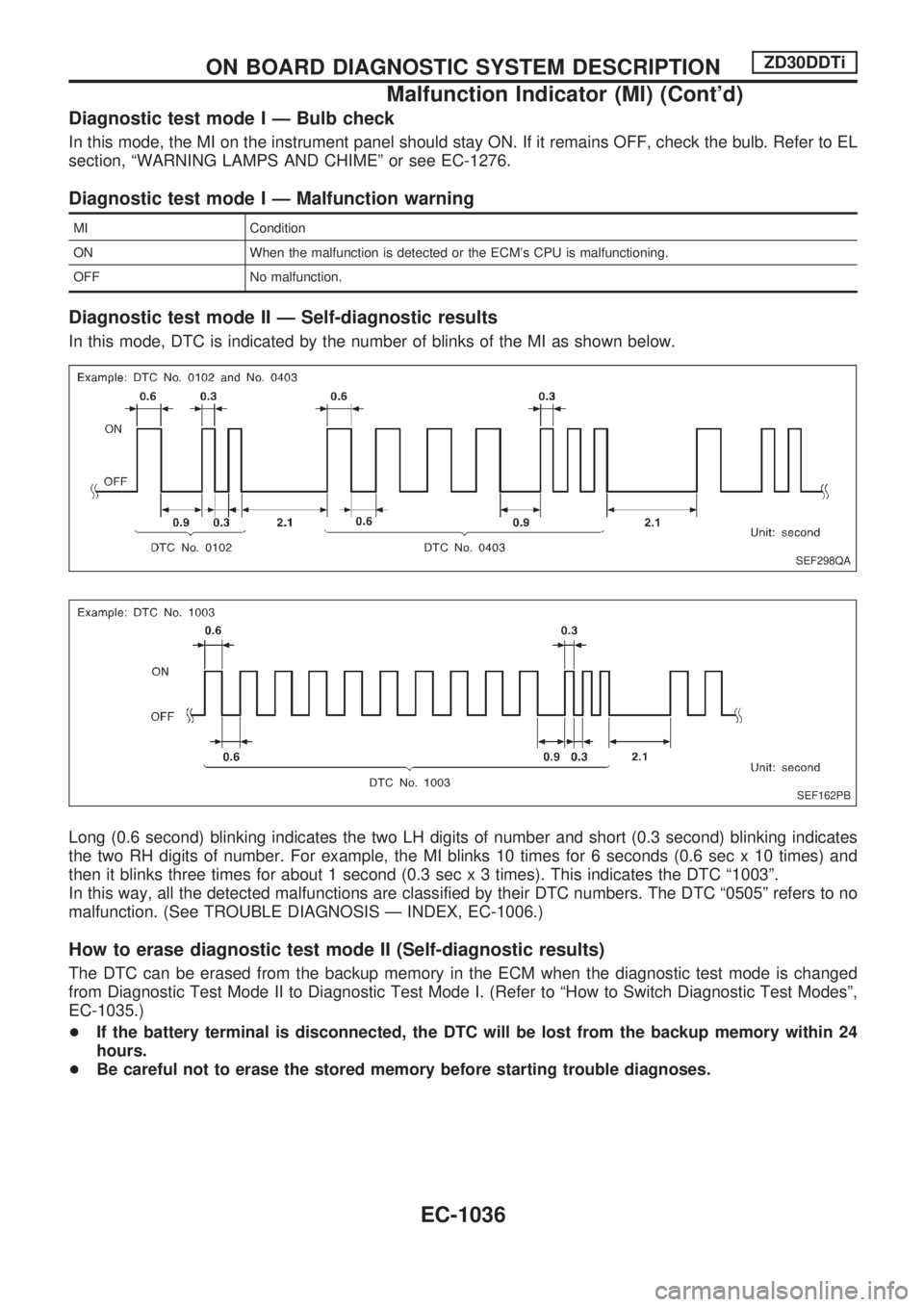

Diagnostic test mode II Ð Self-diagnostic results

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates

the two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and

then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-1006.)

How to erase diagnostic test mode II (Self-diagnostic results)

The DTC can be erased from the backup memory in the ECM when the diagnostic test mode is changed

from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ªHow to Switch Diagnostic Test Modesº,

EC-1035.)

+If the battery terminal is disconnected, the DTC will be lost from the backup memory within 24

hours.

+Be careful not to erase the stored memory before starting trouble diagnoses.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-1036

Page 340 of 1033

Overall Function Check

Use this procedure to check the overall function of the cooling

fan. During this check, a DTC might not be confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Seri-

ous burns could be caused by high pressure fluid escaping

from the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

WITH CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following steps and go to

ªDiagnostic Procedureº, EC-1109.

2) Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, skip the following steps and go to

ªDiagnostic Procedureº, EC-1109.

3) Turn ignition switch ªONº.

4) Perform ªCOOLING FANº in ªACTIVE TESTº mode with

CONSULT-II and make sure that cooling fans operate when

touching ªHIGHº or ªLOWº.

If NG, go to ªDiagnostic Procedureº, EC-1109.

WITHOUT CONSULT-II

1) Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is

below the proper range, skip the following steps and go to

ªDiagnostic Procedureº, EC-1109.

2) Confirm whether customer filled the coolant or not. If cus-

tomer filled the coolant, skip the following steps and go to

ªDiagnostic Procedureº, EC-1109.

3) Disconnect engine coolant temperature sensor harness con-

nector.

4) Connect 150Wresistor to engine coolant temperature sensor

harness connector.

5) Start engine and make sure that cooling fan operates.

Be careful not to overheat engine.

6) If NG, go to ªDiagnostic Procedureº, EC-1109.

AEC640

SEF111X

MEC475B

DTC 0208 OVER HEATZD30DDTi

EC-1107

Page 454 of 1033

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Crankshaft position

sensor (TDC)Engine speed

Glow

controlGlow lamp,

Glow relay

¯

Glow plugs Engine coolant tem-

perature sensorEngine coolant tem-

perature

When engine coolant temperature is more than approximately

75ÉC (167ÉF), the glow relay turns off, inactivating the quick-glow

control until coolant temperature drops below approximately

55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

+Ignition switch ON

After ignition switch has turned to ON, the glow relay turns

ON for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

+Cranking

The glow relay turns ON, allowing current to flow through

glow plug.

+Starting

After engine has started, current continues to flow through

glow plug (after-glow mode) for a certain period in relation to

engine coolant temperature.

When engine speed exceeds approximately 4,800 rpm, cur-

rent flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

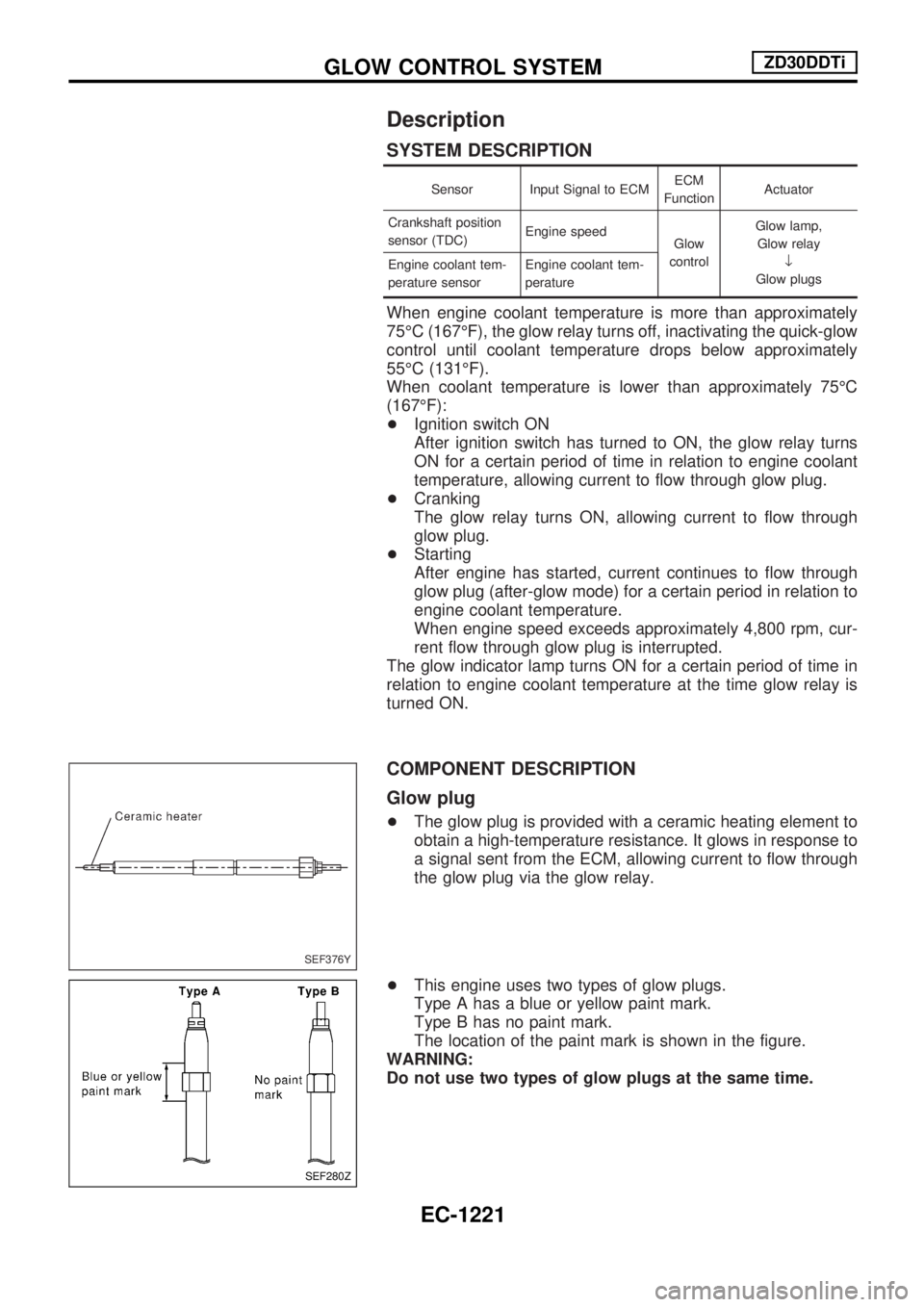

COMPONENT DESCRIPTION

Glow plug

+The glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to

a signal sent from the ECM, allowing current to flow through

the glow plug via the glow relay.

+This engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-1221

Page 512 of 1033

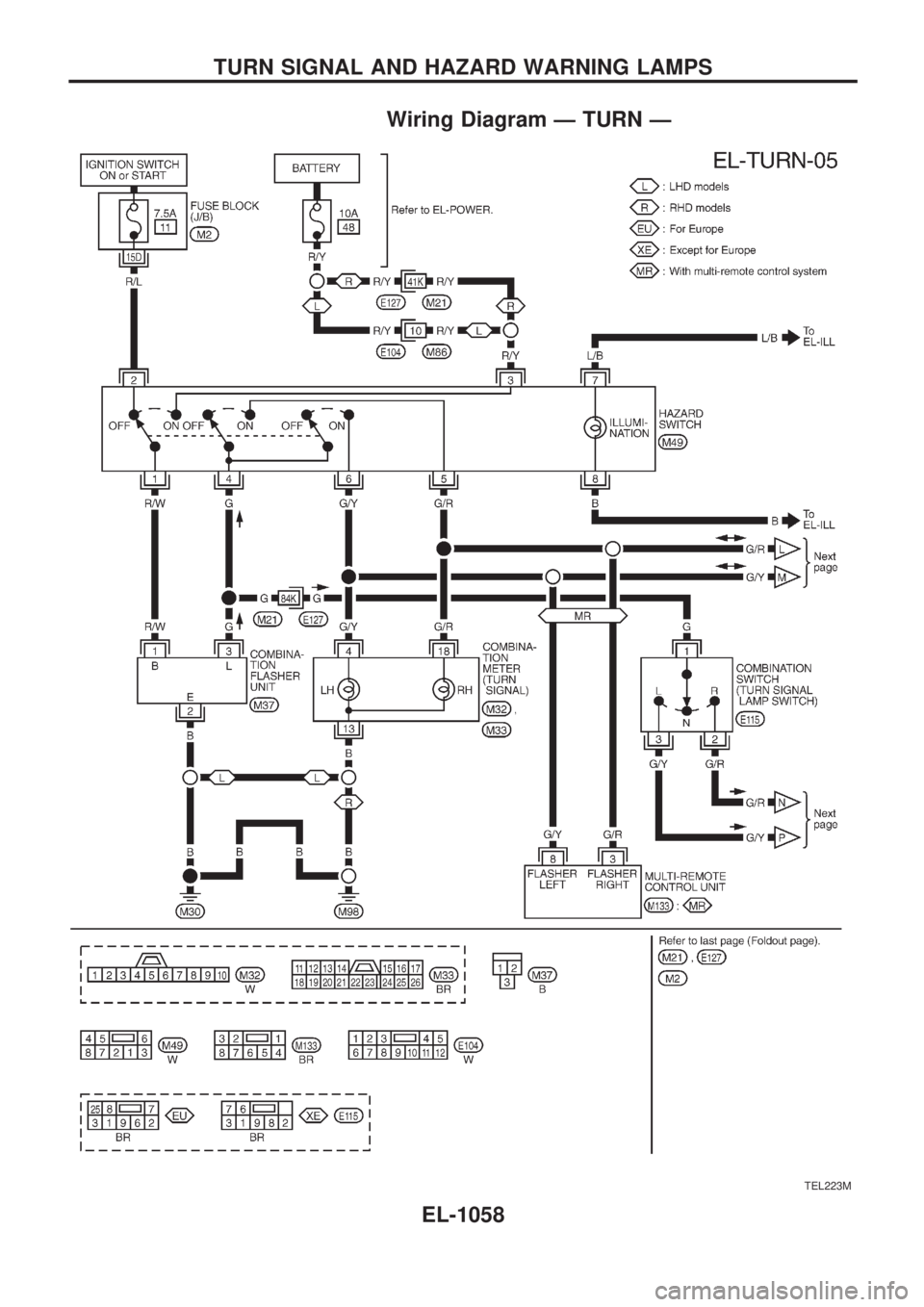

TURN SIGNAL AND HAZARD WARNING

LAMPS................................................................. 1058

Wiring Diagram Ð TURN Ð ........................... 1058

ILLUMINATION .................................................... 1060

Schematic ........................................................ 1060

Wiring Diagram Ð ILL Ð ................................ 1061

INTERIOR ROOM LAMP ..................................... 1067

System Description .......................................... 1067

Wiring Diagram Ð ROOM/L Ð/LHD Models .. 1068

Wiring Diagram Ð ROOM/L Ð/RHD Models.. 1070

Trouble Diagnoses ........................................... 1072

METER AND GAUGES ....................................... 1073

Wiring Diagram Ð METER Ð/LHD Models .... 1073

Wiring Diagram Ð METER Ð/RHD Models ... 1075

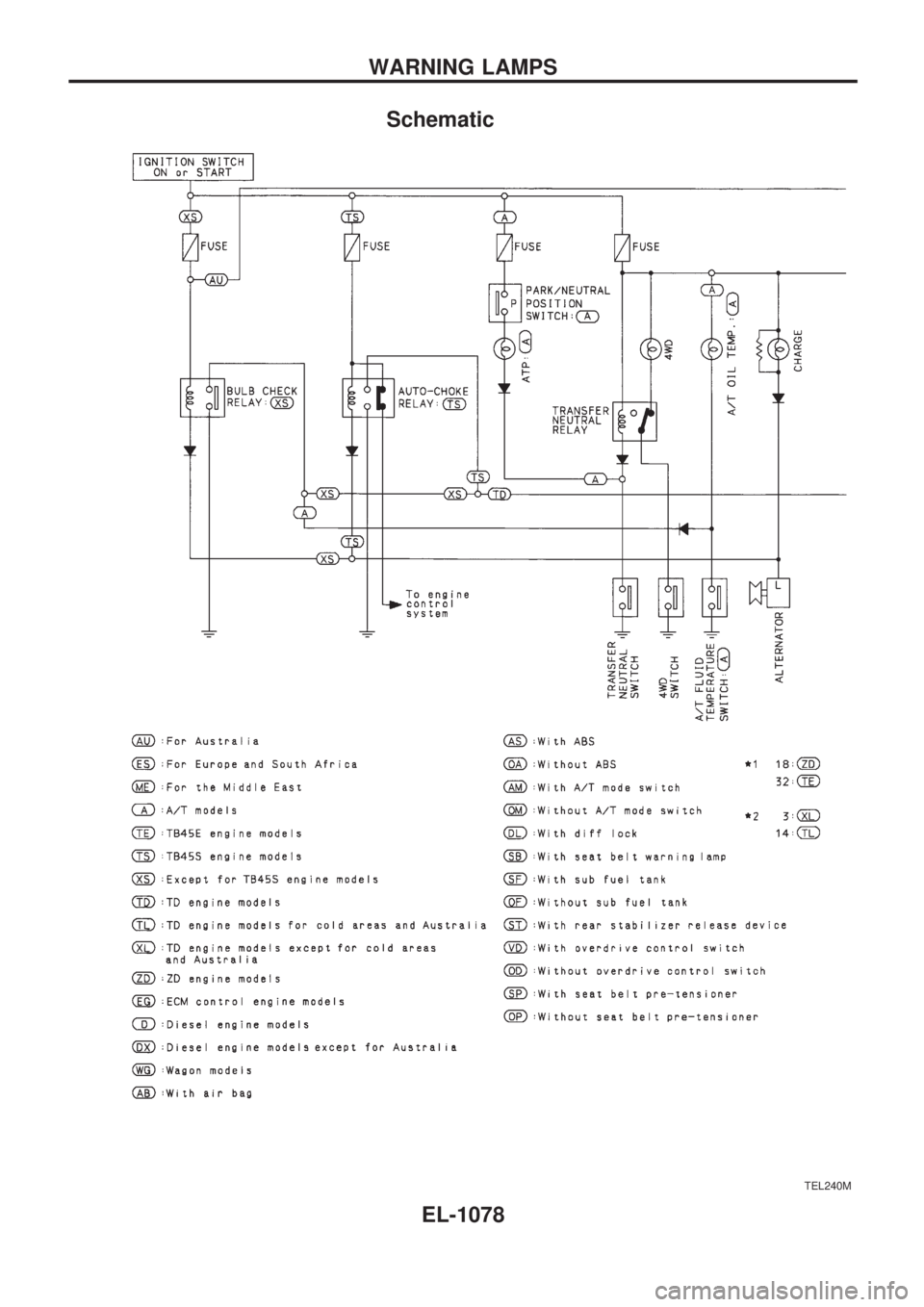

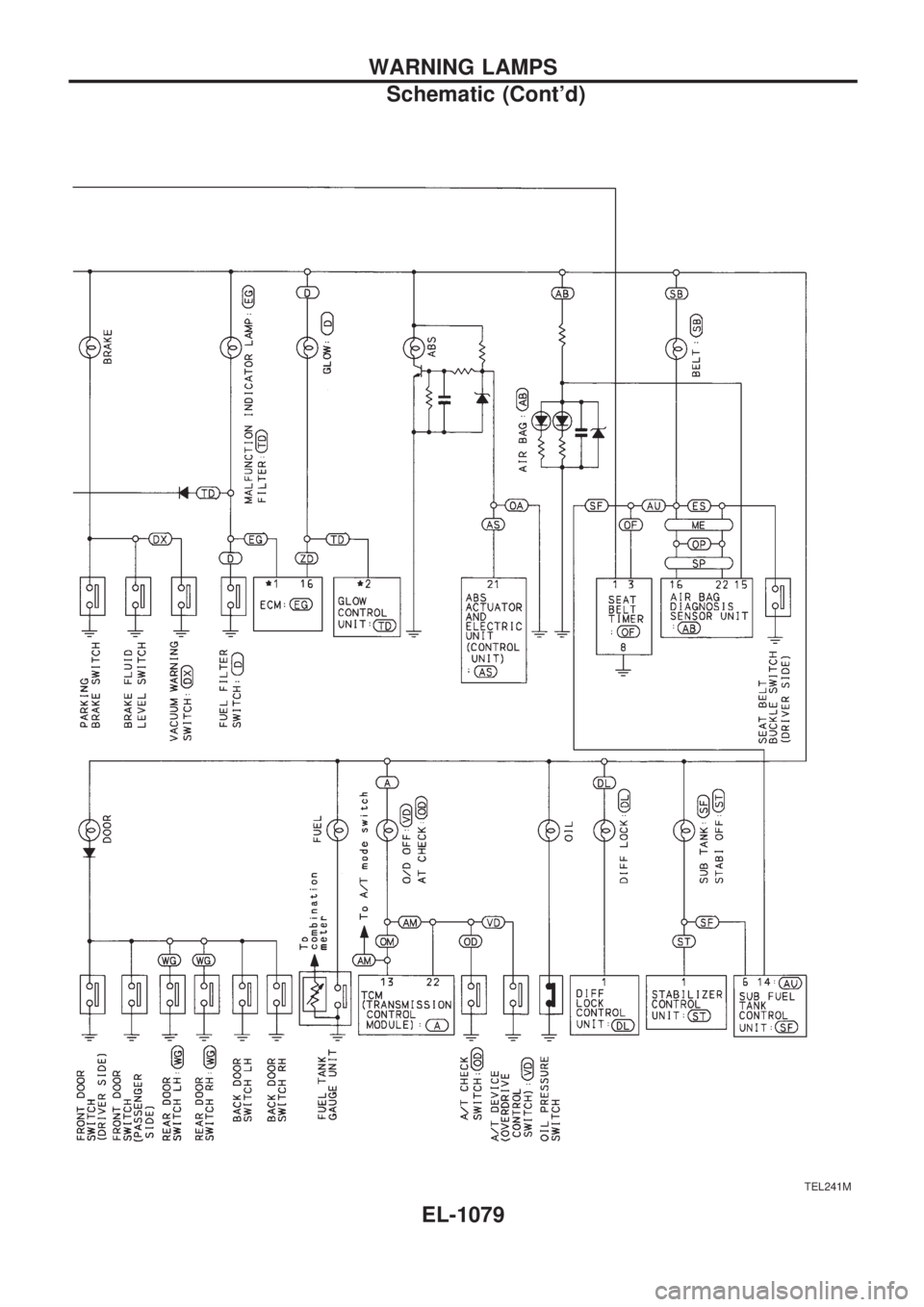

WARNING LAMPS .............................................. 1078

Schematic ........................................................ 1078

Wiring Diagram Ð WARN Ð .......................... 1080

WARNING CHIME ............................................... 1091

System Description .......................................... 1091

Wiring Diagram Ð CHIME Ð/LHD Models ..... 1092

Wiring Diagram Ð CHIME Ð/RHD Models .... 1093

Trouble Diagnoses ........................................... 1094

Electrical Components Inspection ................... 1097

FRONT WIPER AND WASHER .......................... 1098

Wiring Diagram Ð WIPER Ð.......................... 1098

HEADLAMP WIPER AND WASHER .................. 1099

Wiring Diagram Ð HLC Ð .............................. 1099

HORN ................................................................... 1100

Wiring Diagram Ð HORN Ð ........................... 1100

REAR WINDOW DEFOGGER ............................. 1101

System Description .......................................... 1101

Wiring Diagram Ð DEF Ð/LHD Models ......... 1102

Wiring Diagram Ð DEF Ð/RHD Models......... 1104

Trouble Diagnoses ........................................... 1106

Electrical Components Inspection ................... 1107

AUDIO .................................................................. 1108

Wiring Diagram Ð REMOTE Ð ...................... 1108

AUDIO ANTENNA ............................................... 1109

Wiring Diagram Ð P/ANT Ð/RHD Models ..... 1109

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ................................................................. 1110

Schematic ........................................................ 1110

Wiring Diagram Ð ASCD Ð ........................... 1111

POWER WINDOW ............................................... 1115

System Description .......................................... 1115

Schematic ........................................................ 1116

Wiring Diagram Ð WINDOW Ð...................... 1117

Trouble Diagnoses ........................................... 1122

POWER DOOR LOCK Ð Super Lock Ð .......... 1124

Component Parts and Harness Connector

Location............................................................ 1124

System Description .......................................... 1125

Schematic ........................................................ 1127

Wiring Diagram Ð S/LOCK Ð/LHD Models ... 1128 Wiring Diagram Ð S/LOCK Ð/RHD Models... 1133

Trouble Diagnoses ........................................... 1138

MULTI-REMOTE CONTROL SYSTEM ............... 1149

System Description .......................................... 1149

Wiring Diagram Ð MULTI Ð/LHD Models...... 1150

Wiring Diagram Ð MULTI Ð/RHD Models ..... 1152

Trouble Diagnoses ........................................... 1154

ID Code Entry Procedure ................................ 1156

Remote Controller Battery Replacement ......... 1157

SUPER LOCK CONTROL UNIT ......................... 1159

Description ....................................................... 1159

Schematic ........................................................ 1160

Input/Output Operation Signal ......................... 1162

NATS (Nissan Anti-Theft System) .................... 1163

Component Parts and Harness Connector

Location............................................................ 1163

System Description .......................................... 1164

System Composition ........................................ 1165

Wiring Diagram Ð NATS Ð ............................ 1166

Wiring Diagram Ð NATS Ð/LHD Models ....... 1167

Wiring Diagram Ð NATS Ð/RHD Models ...... 1168

CONSULT-II ..................................................... 1169

Trouble Diagnoses ........................................... 1172

How to Replace NATS IMMU .......................... 1183

LOCATION OF ELECTRICAL UNITS ................. 1185

Engine Compartment ....................................... 1185

Passenger Compartment Ð LHD Models ....... 1186

Passenger Compartment Ð RHD Models ...... 1188

HARNESS LAYOUT ............................................ 1191

How to Read Harness Layout ......................... 1191

Main Harness/LHD Models .............................. 1192

Main Harness/RHD Models ............................. 1196

Engine Room Harness/LHD Models................ 1200

Engine Room Harness/RHD Models ............... 1204

Engine Harness ............................................... 1208

Engine Control Harness................................... 1209

Body Harness/LHD Models ............................. 1210

Body Harness/RHD Models ............................. 1214

Body No. 2 Harness/LHD Models ................... 1218

Body No. 2 Harness/RHD Models ................... 1220

Chassis Harness .............................................. 1222

Room Lamp Harness ....................................... 1223

Front Door Harness (Driver side) .................... 1224

Front Door Harness (Passenger side)............. 1225

Back Door Harness and Rear Window

Defogger Harness ............................................ 1226

WIRING DIAGRAM CODES (CELL CODES) ..... 1227

Wiring Diagram Codes (Cell Codes) ............... 1227

ELECTRICAL SYSTEM

Page 513 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS AND PREPARATION

EL-1003

Page 568 of 1033

Wiring Diagram Ð TURN Ð

TEL223M

TURN SIGNAL AND HAZARD WARNING LAMPS

EL-1058

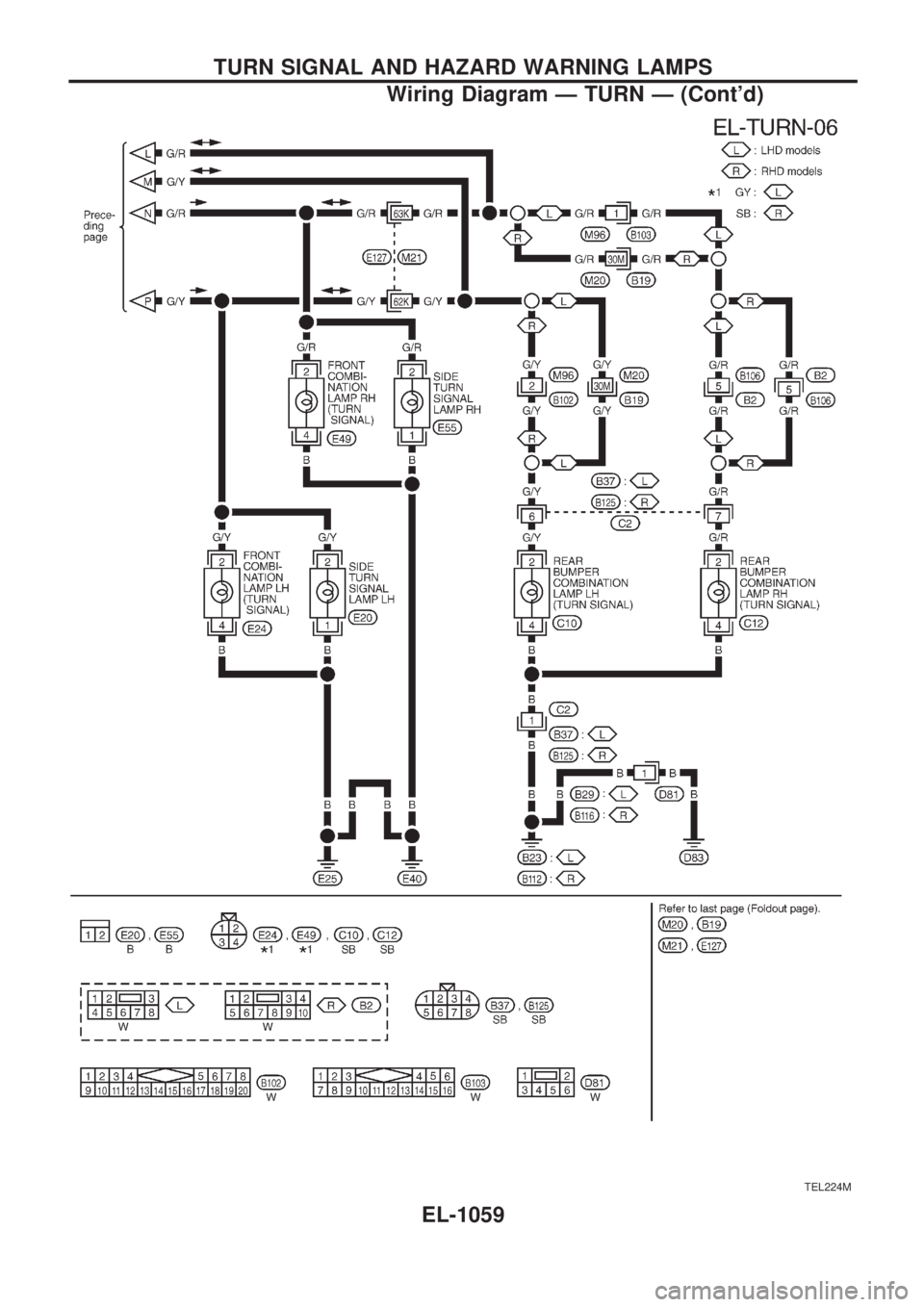

Page 569 of 1033

TEL224M

TURN SIGNAL AND HAZARD WARNING LAMPS

Wiring Diagram Ð TURN Ð (Cont'd)

EL-1059

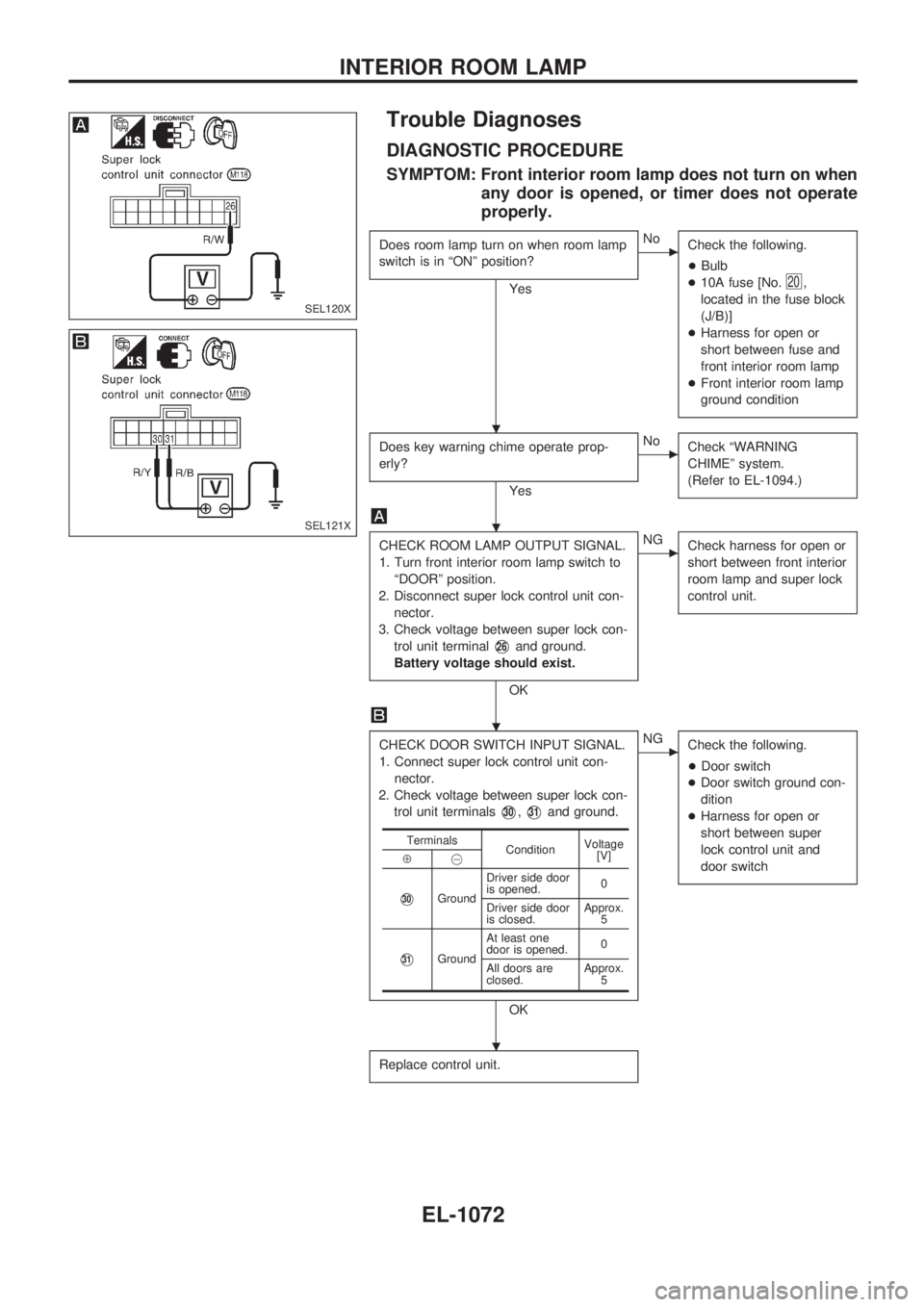

Page 582 of 1033

Trouble Diagnoses

DIAGNOSTIC PROCEDURE

SYMPTOM: Front interior room lamp does not turn on when

any door is opened, or timer does not operate

properly.

Does room lamp turn on when room lamp

switch is in ªONº position?

Yes

cNo

Check the following.

+Bulb

+10A fuse [No.

20,

located in the fuse block

(J/B)]

+Harness for open or

short between fuse and

front interior room lamp

+Front interior room lamp

ground condition

Does key warning chime operate prop-

erly?

Yes

cNo

Check ªWARNING

CHIMEº system.

(Refer to EL-1094.)

CHECK ROOM LAMP OUTPUT SIGNAL.

1. Turn front interior room lamp switch to

ªDOORº position.

2. Disconnect super lock control unit con-

nector.

3. Check voltage between super lock con-

trol unit terminal

V26and ground.

Battery voltage should exist.

OK

cNG

Check harness for open or

short between front interior

room lamp and super lock

control unit.

CHECK DOOR SWITCH INPUT SIGNAL.

1. Connect super lock control unit con-

nector.

2. Check voltage between super lock con-

trol unit terminals

V30,V31and ground.

OK

cNG

Check the following.

+Door switch

+Door switch ground con-

dition

+Harness for open or

short between super

lock control unit and

door switch

Replace control unit.

Terminals

ConditionVoltage

[V]

Å@

V30GroundDriver side door

is opened.0

Driver side door

is closed.Approx.

5

V31GroundAt least one

door is opened.0

All doors are

closed.Approx.

5

SEL120X

SEL121X

.

.

.

.

INTERIOR ROOM LAMP

EL-1072

Page 588 of 1033

Schematic

TEL240M

WARNING LAMPS

EL-1078

Page 589 of 1033

TEL241M

WARNING LAMPS

Schematic (Cont'd)

EL-1079