Diff NISSAN PATROL 2000 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 792 of 1033

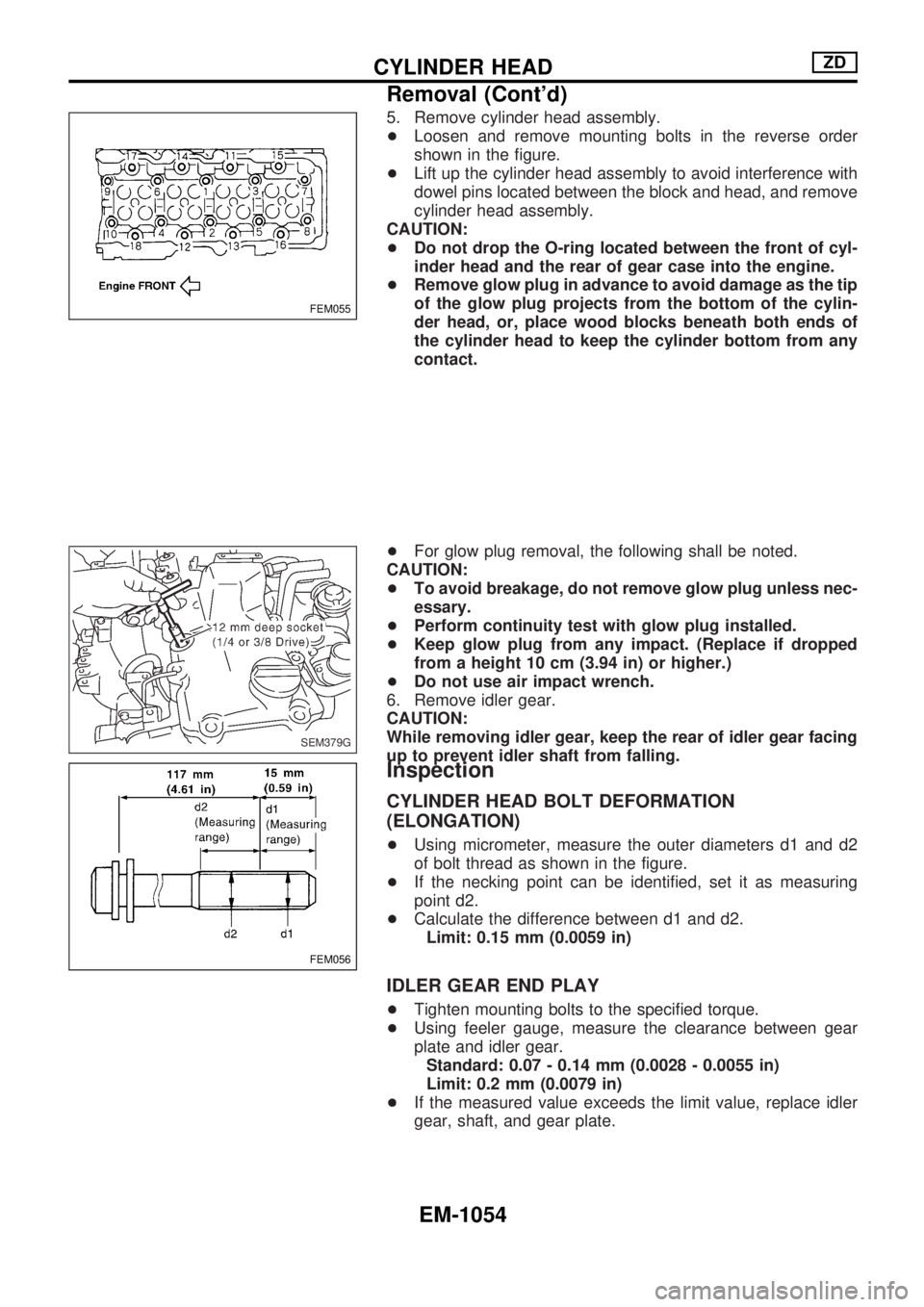

5. Remove cylinder head assembly.

+Loosen and remove mounting bolts in the reverse order

shown in the figure.

+Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

+Do not drop the O-ring located between the front of cyl-

inder head and the rear of gear case into the engine.

+Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylin-

der head, or, place wood blocks beneath both ends of

the cylinder head to keep the cylinder bottom from any

contact.

+For glow plug removal, the following shall be noted.

CAUTION:

+To avoid breakage, do not remove glow plug unless nec-

essary.

+Perform continuity test with glow plug installed.

+Keep glow plug from any impact. (Replace if dropped

from a height 10 cm (3.94 in) or higher.)

+Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing

up to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION

(ELONGATION)

+Using micrometer, measure the outer diameters d1 and d2

of bolt thread as shown in the figure.

+If the necking point can be identified, set it as measuring

point d2.

+Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

+Tighten mounting bolts to the specified torque.

+Using feeler gauge, measure the clearance between gear

plate and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

+If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-1054

Page 795 of 1033

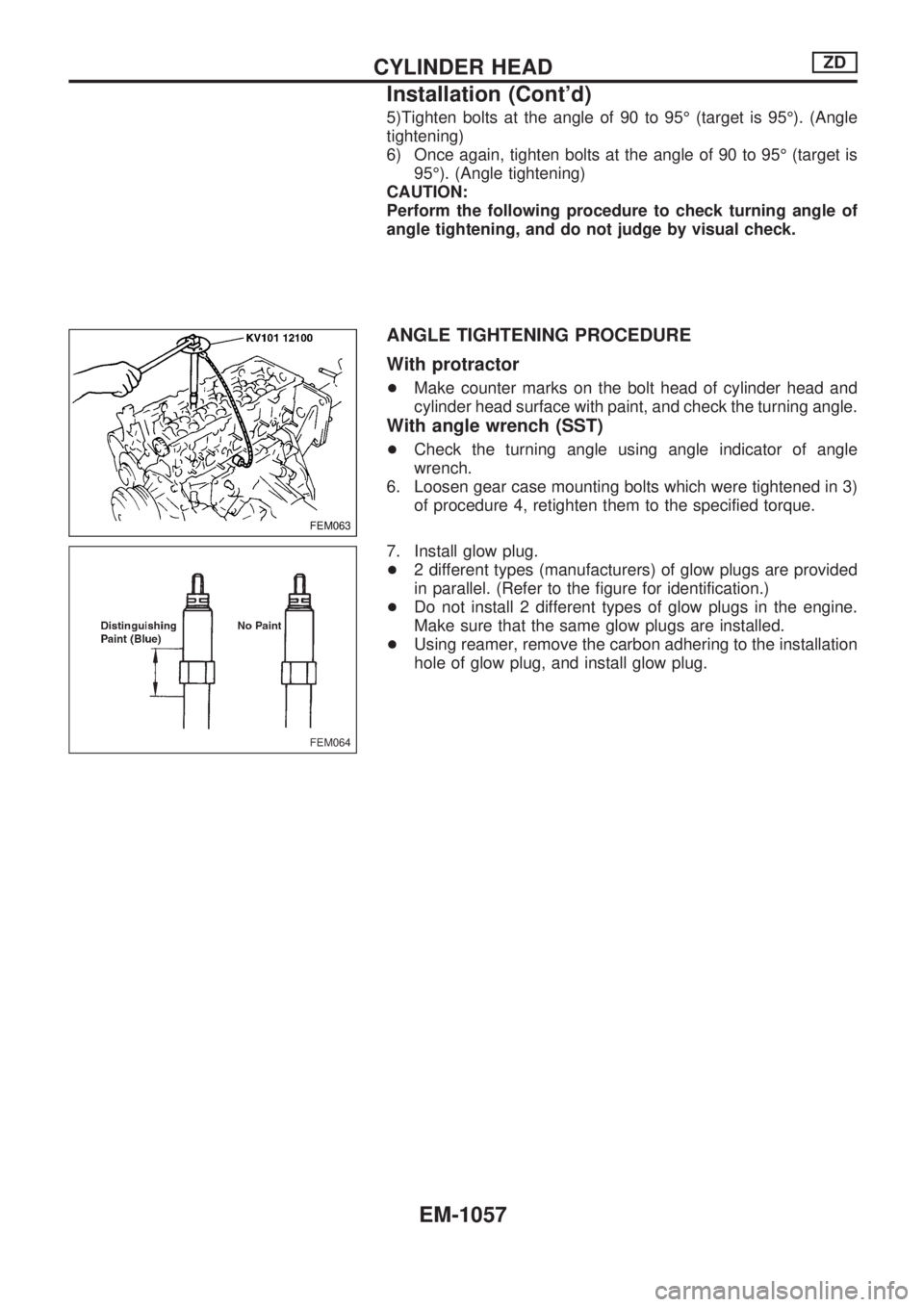

5)Tighten bolts at the angle of 90 to 95É (target is 95É). (Angle

tightening)

6) Once again, tighten bolts at the angle of 90 to 95É (target is

95É). (Angle tightening)

CAUTION:

Perform the following procedure to check turning angle of

angle tightening, and do not judge by visual check.

ANGLE TIGHTENING PROCEDURE

With protractor

+Make counter marks on the bolt head of cylinder head and

cylinder head surface with paint, and check the turning angle.

With angle wrench (SST)

+Check the turning angle using angle indicator of angle

wrench.

6. Loosen gear case mounting bolts which were tightened in 3)

of procedure 4, retighten them to the specified torque.

7. Install glow plug.

+2 different types (manufacturers) of glow plugs are provided

in parallel. (Refer to the figure for identification.)

+Do not install 2 different types of glow plugs in the engine.

Make sure that the same glow plugs are installed.

+Using reamer, remove the carbon adhering to the installation

hole of glow plug, and install glow plug.

FEM063

FEM064

CYLINDER HEADZD

Installation (Cont'd)

EM-1057

Page 800 of 1033

For details, Refer to EM-1088, ªValve Seatº in ªSERVICE DATA

AND SPECIFICATIONS (SDS)º.

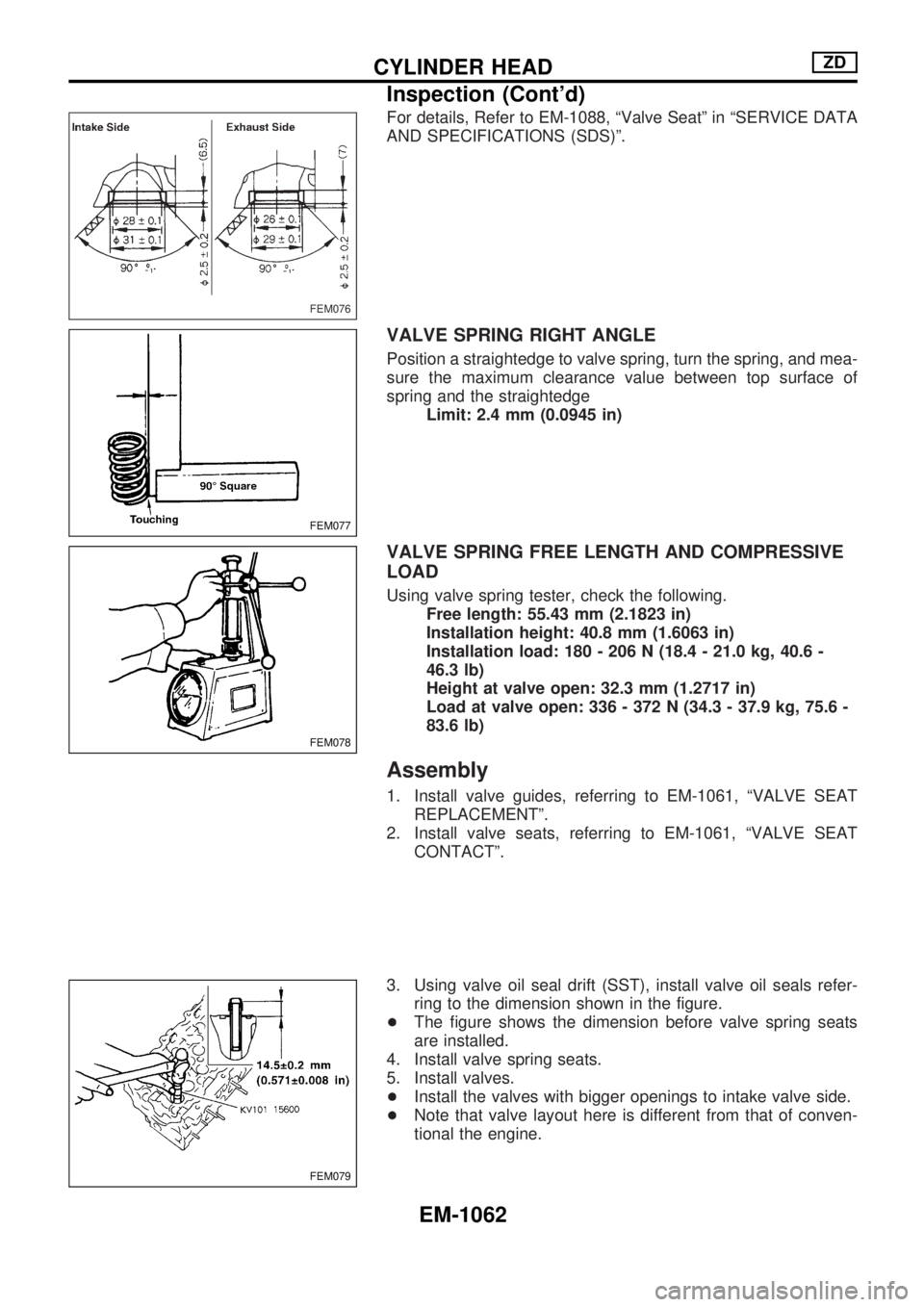

VALVE SPRING RIGHT ANGLE

Position a straightedge to valve spring, turn the spring, and mea-

sure the maximum clearance value between top surface of

spring and the straightedge

Limit: 2.4 mm (0.0945 in)

VALVE SPRING FREE LENGTH AND COMPRESSIVE

LOAD

Using valve spring tester, check the following.

Free length: 55.43 mm (2.1823 in)

Installation height: 40.8 mm (1.6063 in)

Installation load: 180 - 206 N (18.4 - 21.0 kg, 40.6 -

46.3 lb)

Height at valve open: 32.3 mm (1.2717 in)

Load at valve open: 336 - 372 N (34.3 - 37.9 kg, 75.6 -

83.6 lb)

Assembly

1. Install valve guides, referring to EM-1061, ªVALVE SEAT

REPLACEMENTº.

2. Install valve seats, referring to EM-1061, ªVALVE SEAT

CONTACTº.

3. Using valve oil seal drift (SST), install valve oil seals refer-

ring to the dimension shown in the figure.

+The figure shows the dimension before valve spring seats

are installed.

4. Install valve spring seats.

5. Install valves.

+Install the valves with bigger openings to intake valve side.

+Note that valve layout here is different from that of conven-

tional the engine.

FEM076

FEM077

FEM078

FEM079

CYLINDER HEADZD

Inspection (Cont'd)

EM-1062

Page 815 of 1033

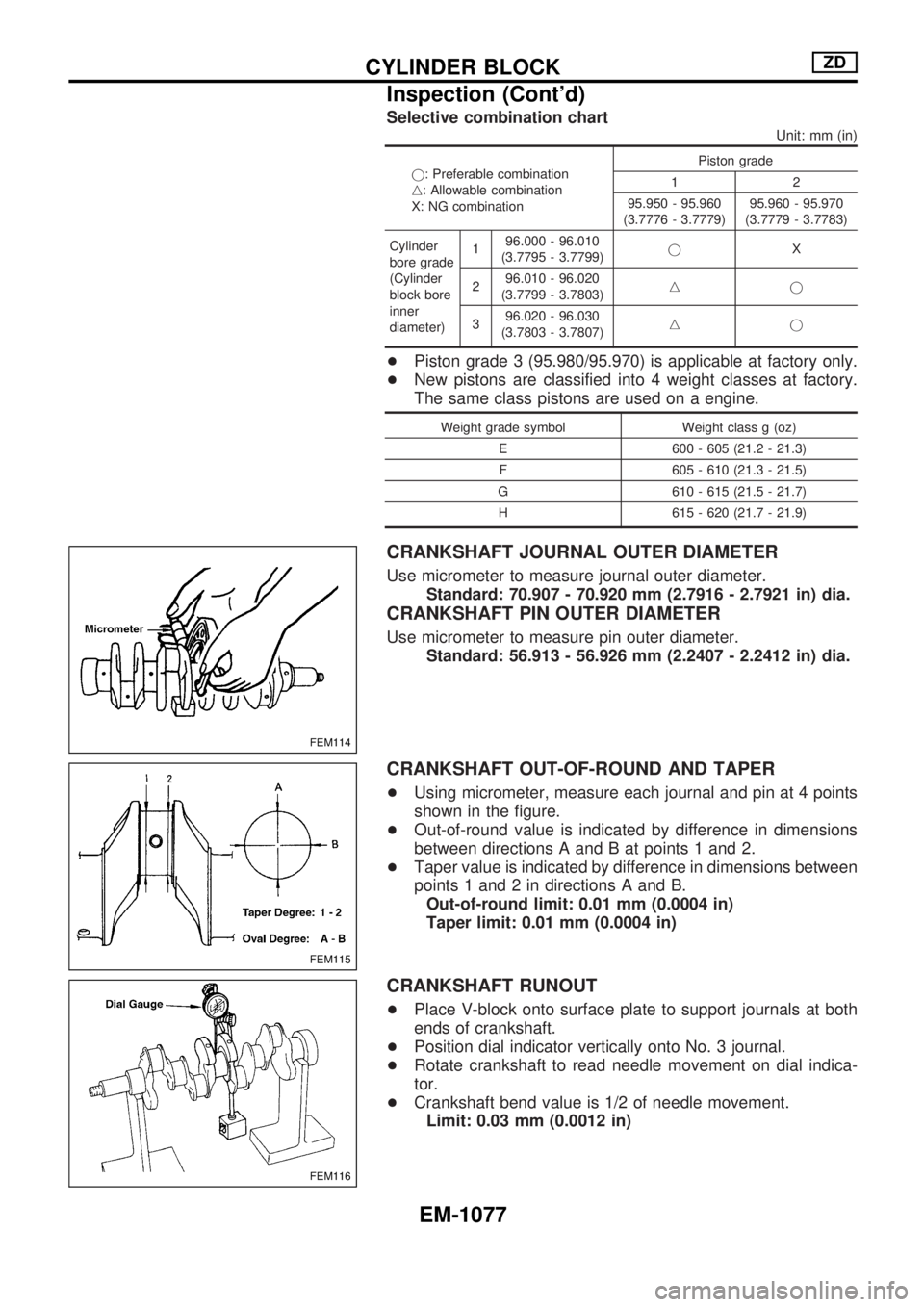

Selective combination chart

Unit: mm (in)

j: Preferable combination

n: Allowable combination

X: NG combinationPiston grade

12

95.950 - 95.960

(3.7776 - 3.7779)95.960 - 95.970

(3.7779 - 3.7783)

Cylinder

bore grade

(Cylinder

block bore

inner

diameter)196.000 - 96.010

(3.7795 - 3.7799)jX

296.010 - 96.020

(3.7799 - 3.7803)nj

396.020 - 96.030

(3.7803 - 3.7807)nj

+Piston grade 3 (95.980/95.970) is applicable at factory only.

+New pistons are classified into 4 weight classes at factory.

The same class pistons are used on a engine.

Weight grade symbol Weight class g (oz)

E 600 - 605 (21.2 - 21.3)

F 605 - 610 (21.3 - 21.5)

G 610 - 615 (21.5 - 21.7)

H 615 - 620 (21.7 - 21.9)

CRANKSHAFT JOURNAL OUTER DIAMETER

Use micrometer to measure journal outer diameter.

Standard: 70.907 - 70.920 mm (2.7916 - 2.7921 in) dia.

CRANKSHAFT PIN OUTER DIAMETER

Use micrometer to measure pin outer diameter.

Standard: 56.913 - 56.926 mm (2.2407 - 2.2412 in) dia.

CRANKSHAFT OUT-OF-ROUND AND TAPER

+Using micrometer, measure each journal and pin at 4 points

shown in the figure.

+Out-of-round value is indicated by difference in dimensions

between directions A and B at points 1 and 2.

+Taper value is indicated by difference in dimensions between

points 1 and 2 in directions A and B.

Out-of-round limit: 0.01 mm (0.0004 in)

Taper limit: 0.01 mm (0.0004 in)

CRANKSHAFT RUNOUT

+Place V-block onto surface plate to support journals at both

ends of crankshaft.

+Position dial indicator vertically onto No. 3 journal.

+Rotate crankshaft to read needle movement on dial indica-

tor.

+Crankshaft bend value is 1/2 of needle movement.

Limit: 0.03 mm (0.0012 in)

FEM114

FEM115

FEM116

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-1077

Page 823 of 1033

General Specifications

Cylinder arrangementIn-line 4

Displacementcm

3(cu in) 2,953 (180.19)

Bore and strokemm (in) 96 x 102 (3.78 x 4.02)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil1

Number of main bearings5

Compression ratio17.9

Compression Pressure

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressureStandard 2,942 (29.4, 30.0, 427)

Minimum 2,452 (24.5, 25.0, 356)

Differential limit between cylinders 294 (2.94, 3.0, 43)

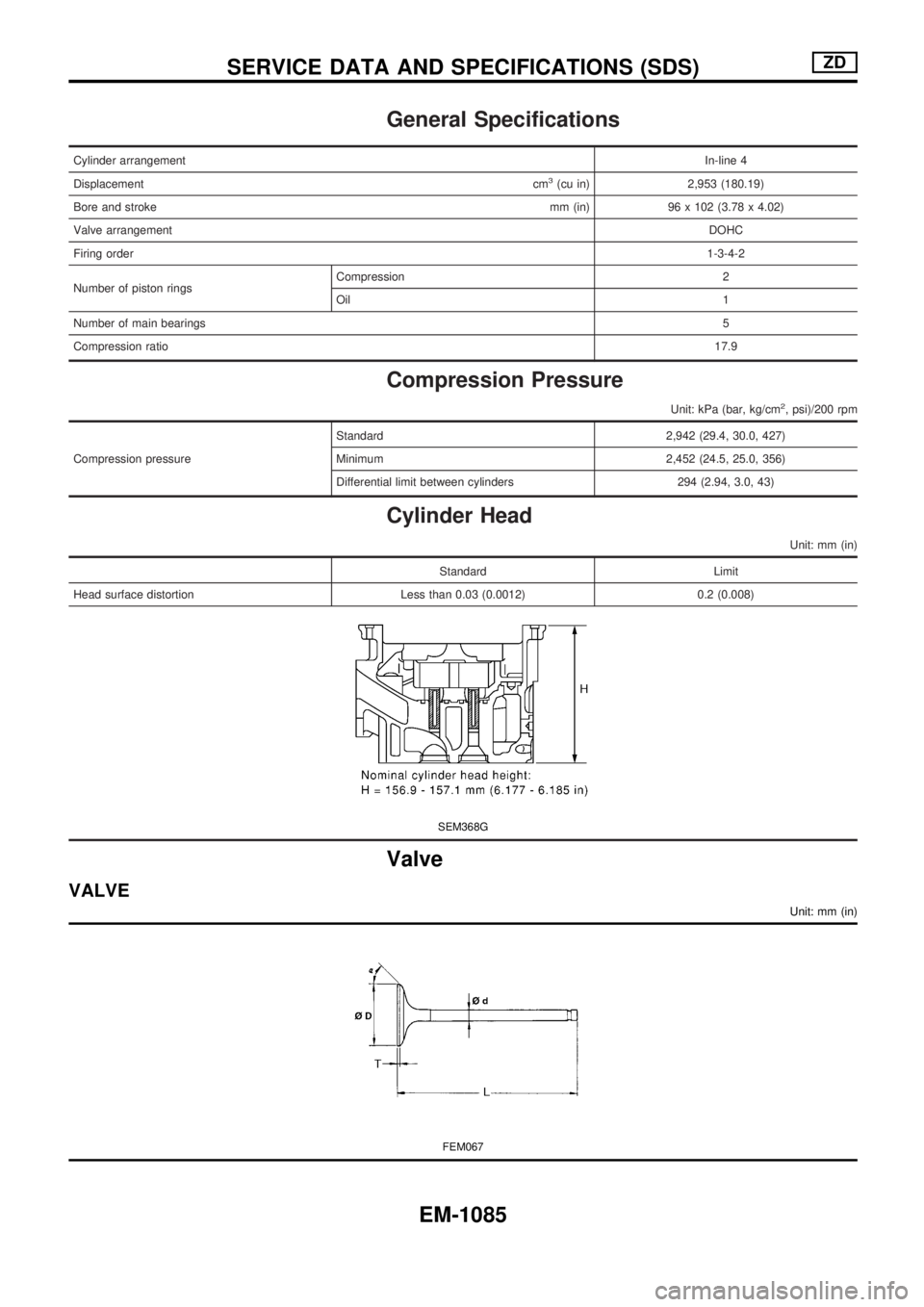

Cylinder Head

Unit: mm (in)

Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.2 (0.008)

SEM368G

Valve

VALVE

Unit: mm (in)

FEM067

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-1085

Page 829 of 1033

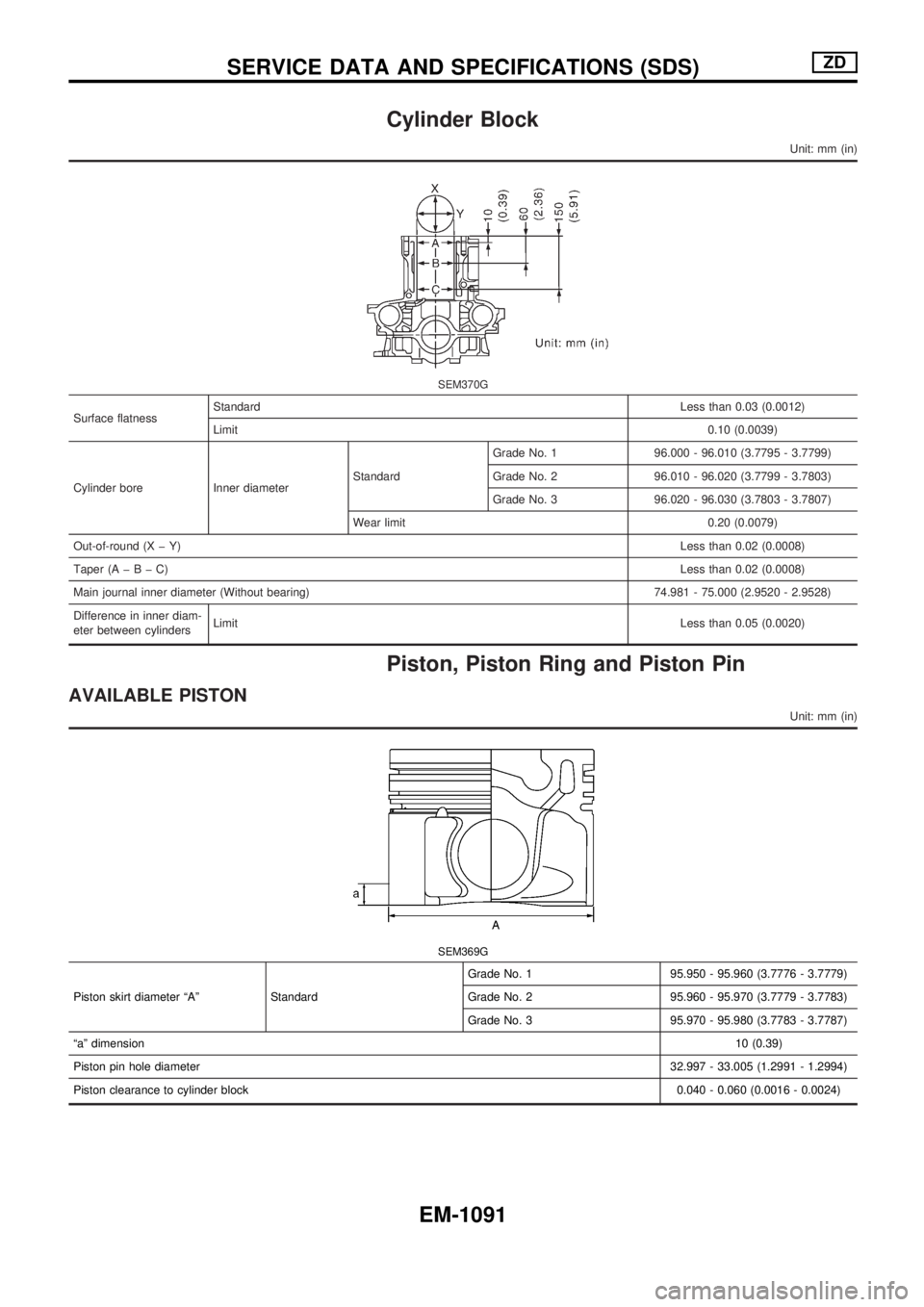

Cylinder Block

Unit: mm (in)

SEM370G

Surface flatnessStandardLess than 0.03 (0.0012)

Limit0.10 (0.0039)

Cylinder bore Inner diameterStandardGrade No. 1 96.000 - 96.010 (3.7795 - 3.7799)

Grade No. 2 96.010 - 96.020 (3.7799 - 3.7803)

Grade No. 3 96.020 - 96.030 (3.7803 - 3.7807)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y)Less than 0.02 (0.0008)

Taper (AþBþC)Less than 0.02 (0.0008)

Main journal inner diameter (Without bearing) 74.981 - 75.000 (2.9520 - 2.9528)

Difference in inner diam-

eter between cylindersLimitLess than 0.05 (0.0020)

Piston, Piston Ring and Piston Pin

AVAILABLE PISTON

Unit: mm (in)

SEM369G

Piston skirt diameter ªAº StandardGrade No. 1 95.950 - 95.960 (3.7776 - 3.7779)

Grade No. 2 95.960 - 95.970 (3.7779 - 3.7783)

Grade No. 3 95.970 - 95.980 (3.7783 - 3.7787)

ªaº dimension10 (0.39)

Piston pin hole diameter32.997 - 33.005 (1.2991 - 1.2994)

Piston clearance to cylinder block0.040 - 0.060 (0.0016 - 0.0024)

SERVICE DATA AND SPECIFICATIONS (SDS)ZD

EM-1091

Page 850 of 1033

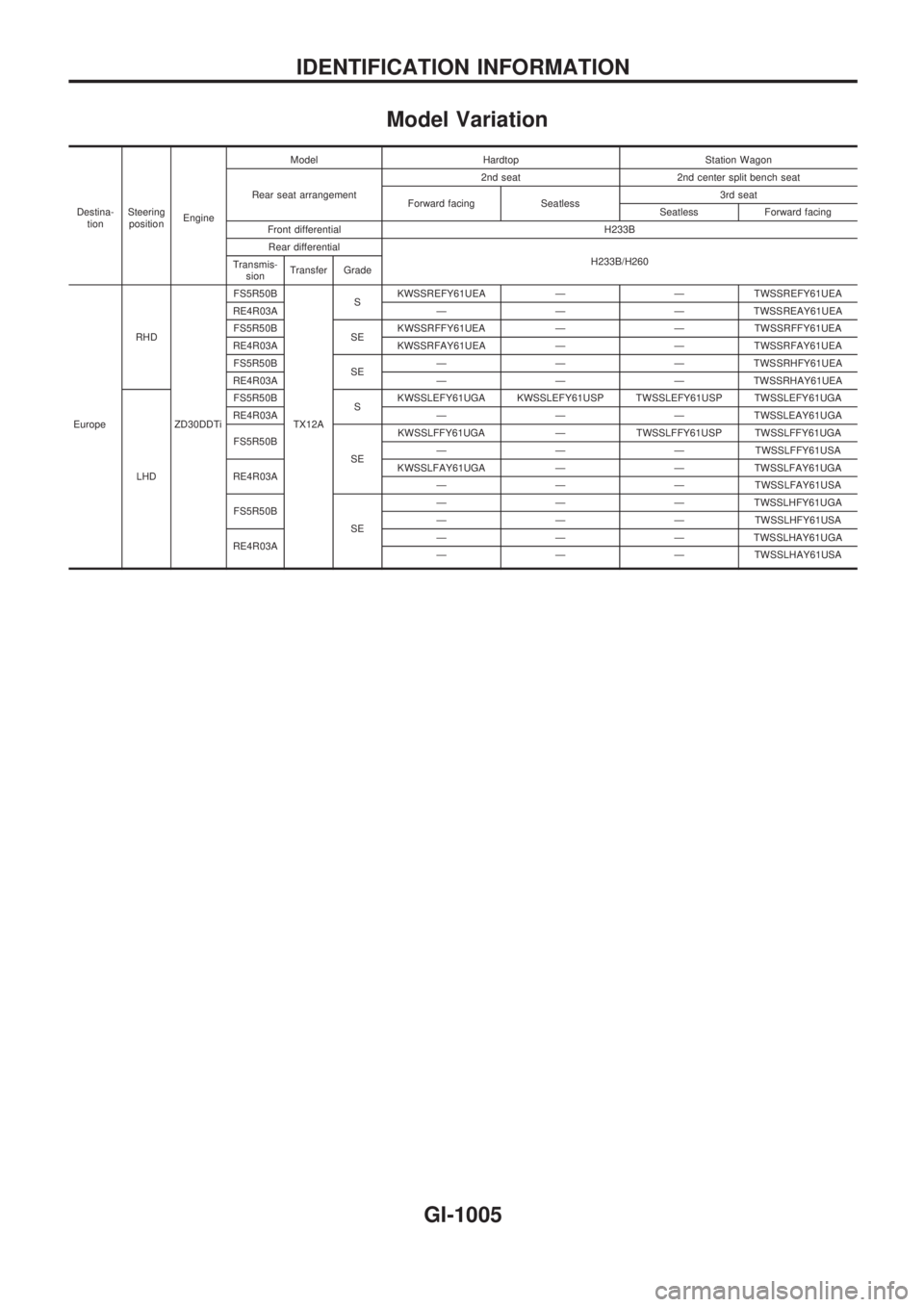

Model Variation

Destina-

tionSteering

positionEngineModel Hardtop Station Wagon

Rear seat arrangement2nd seat 2nd center split bench seat

Forward facing Seatless3rd seat

Seatless Forward facing

Front differential H233B

Rear differential

H233B/H260

Transmis-

sionTransfer Grade

EuropeRHD

ZD30DDTiFS5R50B

TX12ASKWSSREFY61UEA Ð Ð TWSSREFY61UEA

RE4R03A Ð Ð Ð TWSSREAY61UEA

FS5R50B

SEKWSSRFFY61UEA Ð Ð TWSSRFFY61UEA

RE4R03A KWSSRFAY61UEA Ð Ð TWSSRFAY61UEA

FS5R50B

SEÐ Ð Ð TWSSRHFY61UEA

RE4R03A Ð Ð Ð TWSSRHAY61UEA

LHDFS5R50B

SKWSSLEFY61UGA KWSSLEFY61USP TWSSLEFY61USP TWSSLEFY61UGA

RE4R03A Ð Ð Ð TWSSLEAY61UGA

FS5R50B

SEKWSSLFFY61UGA Ð TWSSLFFY61USP TWSSLFFY61UGA

Ð Ð Ð TWSSLFFY61USA

RE4R03AKWSSLFAY61UGA Ð Ð TWSSLFAY61UGA

Ð Ð Ð TWSSLFAY61USA

FS5R50B

SEÐ Ð Ð TWSSLHFY61UGA

Ð Ð Ð TWSSLHFY61USA

RE4R03AÐ Ð Ð TWSSLHAY61UGA

Ð Ð Ð TWSSLHAY61USA

IDENTIFICATION INFORMATION

GI-1005

Page 886 of 1033

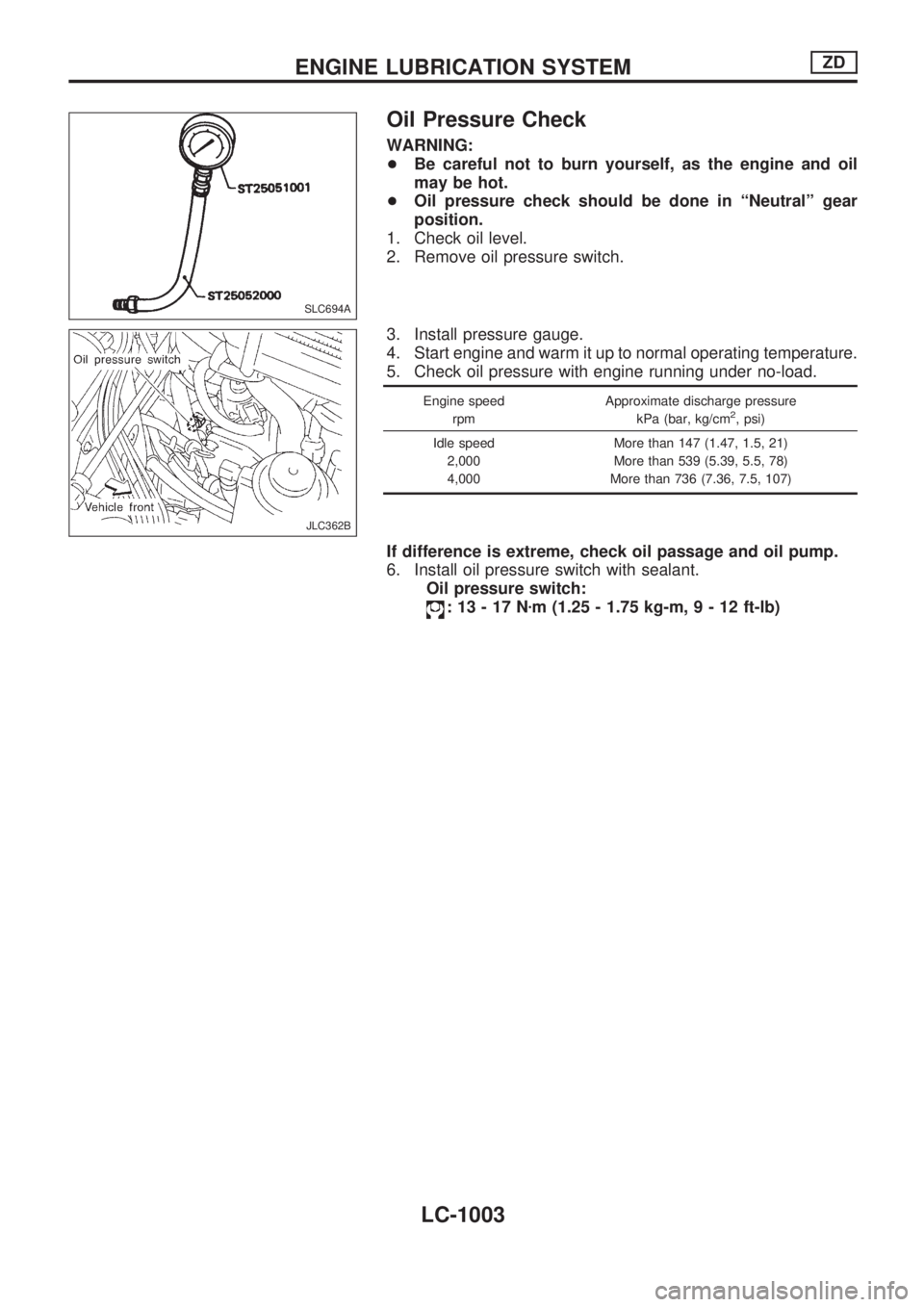

Oil Pressure Check

WARNING:

+Be careful not to burn yourself, as the engine and oil

may be hot.

+Oil pressure check should be done in ªNeutralº gear

position.

1. Check oil level.

2. Remove oil pressure switch.

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed

2,000

4,000More than 147 (1.47, 1.5, 21)

More than 539 (5.39, 5.5, 78)

More than 736 (7.36, 7.5, 107)

If difference is extreme, check oil passage and oil pump.

6. Install oil pressure switch with sealant.

Oil pressure switch:

:13-17Nzm (1.25 - 1.75 kg-m,9-12ft-lb)

SLC694A

JLC362B

ENGINE LUBRICATION SYSTEMZD

LC-1003

Page 901 of 1033

![NISSAN PATROL 2000 Electronic Owners Manual Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE NISSAN PATROL 2000 Electronic Owners Manual Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE](/img/5/57367/w960_57367-900.png)

Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten, [ ] = At the specified mileage only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform on a kilometer basis, but on an annual basis

when driving less than 15,000 km (9,000 miles) per

year.km x 1,000 15 30 45 60 75 90

(miles x 1,000) (9) (18) (27) (36) (45) (54)

Months 12 24 36 48 60 72

Underhood and under vehicleReference

pages

Headlamp aimingIIIIII Ð

When alignment (if necessary, balance & rotate wheels)IIIIII Ð

Brake pads, rotors & other brake componentsHIIIIII Ð

Foot brake, parking brake & clutch (for free play, stroke & operation)IIIIII Ð

Brake booster vacuum hoses, connections & check valve I I I Ð

Brake & clutch, systems and fluid (for level and leaks)IIIIII Ð

Brake fluidHRRRÐ

Power steering fluid and lines (for level and leaks)IIIIII Ð

Supplemental air bag systems See NOTE (1)RS-1007

Ventilation air filterHRRRÐ

Manual transmission oil (Inspect for leaks. Replace if leaks are found.)IIIII[R] Ð

Automatic transmission fluid (for level and leaks)HIIIIII Ð

Greasing point of propeller shaft See NOTE (2)LLLLLL Ð

Transfer fluid and limited-slip differential (LSD) gear oil (for

level & leaks or replace)HSee NOTE (3) I I I R I I Ð

Drive shafts & steering damperHIIIIII Ð

Front wheel bearing greaseHIRIRIR Ð

Front axle joint in knuckle flangeLLLÐ

Free-running hub greaseHIIIIII Ð

Body mounting bolts & nutsTTTTTT Ð

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust systemHIIIIII Ð

Body corrosion See NOTE (4)Ð

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Including differential gear with differential lock.

(4) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance under severe driv-

ing conditionsº.

PERIODIC MAINTENANCE

MA-1003

Page 902 of 1033

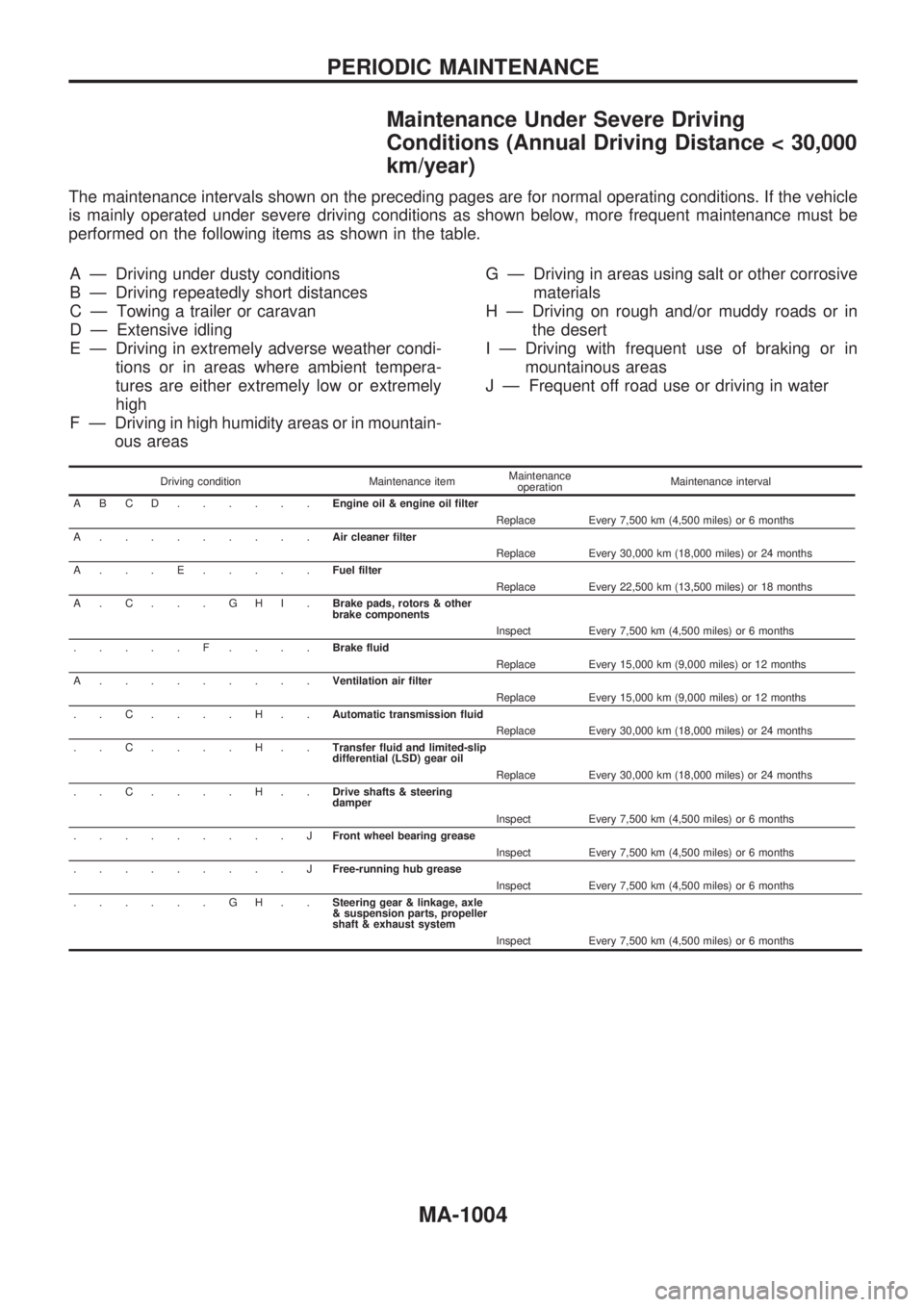

Maintenance Under Severe Driving

Conditions (Annual Driving Distance < 30,000

km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be

performed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi-

tions or in areas where ambient tempera-

tures are either extremely low or extremely

high

F Ð Driving in high humidity areas or in mountain-

ous areasG Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in

the desert

I Ð Driving with frequent use of braking or in

mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance itemMaintenance

operationMaintenance interval

ABCD......Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles) or 6 months

A.........Air cleaner filter

Replace Every 30,000 km (18,000 miles) or 24 months

A...E.....Fuel filter

Replace Every 22,500 km (13,500 miles) or 18 months

A.C...GHI.Brake pads, rotors & other

brake components

Inspect Every 7,500 km (4,500 miles) or 6 months

.....F....Brake fluid

Replace Every 15,000 km (9,000 miles) or 12 months

A.........Ventilation air filter

Replace Every 15,000 km (9,000 miles) or 12 months

..C....H..Automatic transmission fluid

Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Transfer fluid and limited-slip

differential (LSD) gear oil

Replace Every 30,000 km (18,000 miles) or 24 months

..C....H..Drive shafts & steering

damper

Inspect Every 7,500 km (4,500 miles) or 6 months

.........JFront wheel bearing grease

Inspect Every 7,500 km (4,500 miles) or 6 months

.........JFree-running hub grease

Inspect Every 7,500 km (4,500 miles) or 6 months

......GH..Steering gear & linkage, axle

& suspension parts, propeller

shaft & exhaust system

Inspect Every 7,500 km (4,500 miles) or 6 months

PERIODIC MAINTENANCE

MA-1004