Diff NISSAN PATROL 2000 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 680 of 1033

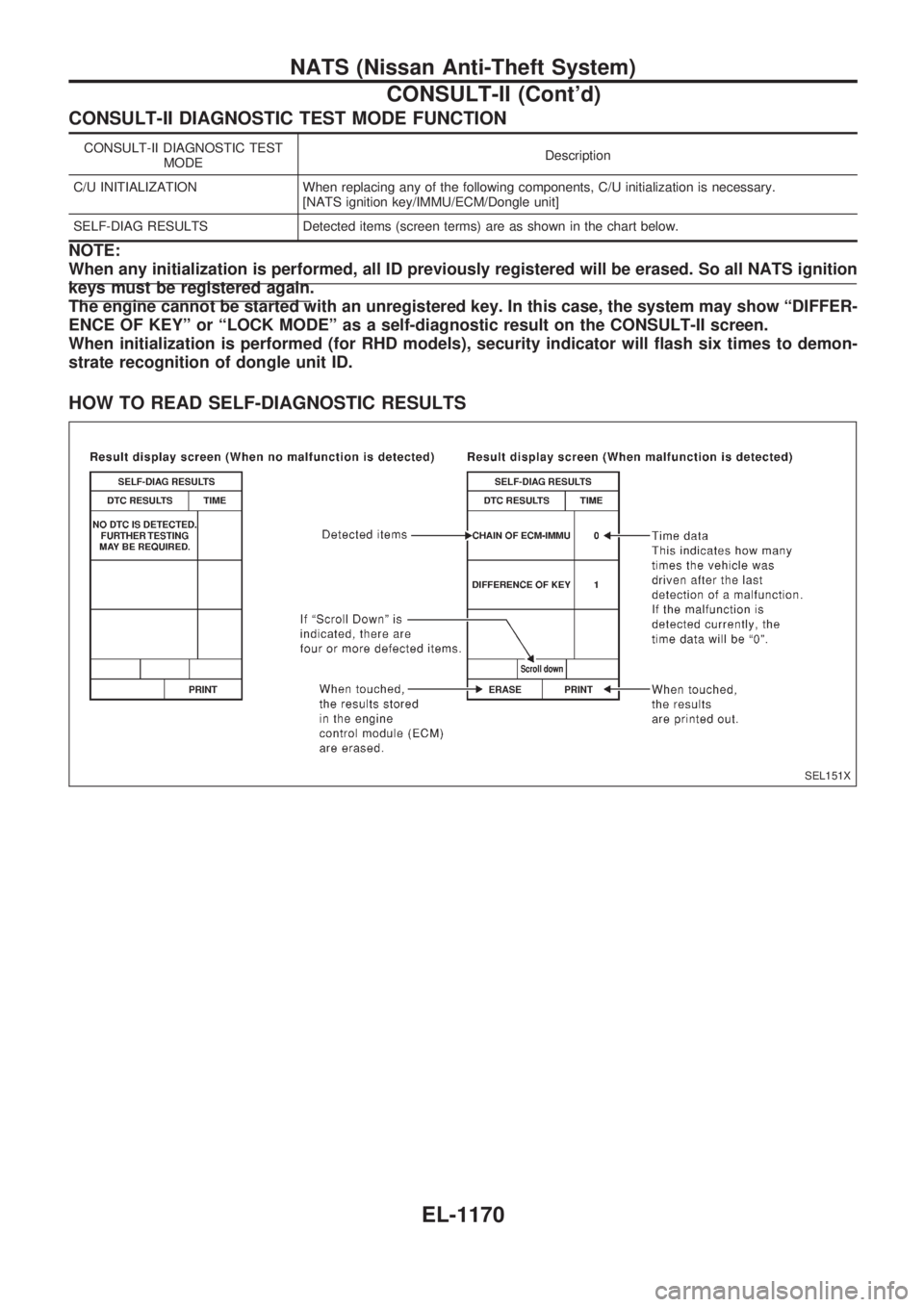

CONSULT-II DIAGNOSTIC TEST MODE FUNCTION

CONSULT-II DIAGNOSTIC TEST

MODEDescription

C/U INITIALIZATION When replacing any of the following components, C/U initialization is necessary.

[NATS ignition key/IMMU/ECM/Dongle unit]

SELF-DIAG RESULTS Detected items (screen terms) are as shown in the chart below.

NOTE:

When any initialization is performed, all ID previously registered will be erased. So all NATS ignition

keys must be registered again.

The engine cannot be started with an unregistered key. In this case, the system may show ªDIFFER-

ENCE OF KEYº or ªLOCK MODEº as a self-diagnostic result on the CONSULT-II screen.

When initialization is performed (for RHD models), security indicator will flash six times to demon-

strate recognition of dongle unit ID.

HOW TO READ SELF-DIAGNOSTIC RESULTS

SEL151X

NATS (Nissan Anti-Theft System)

CONSULT-II (Cont'd)

EL-1170

Page 681 of 1033

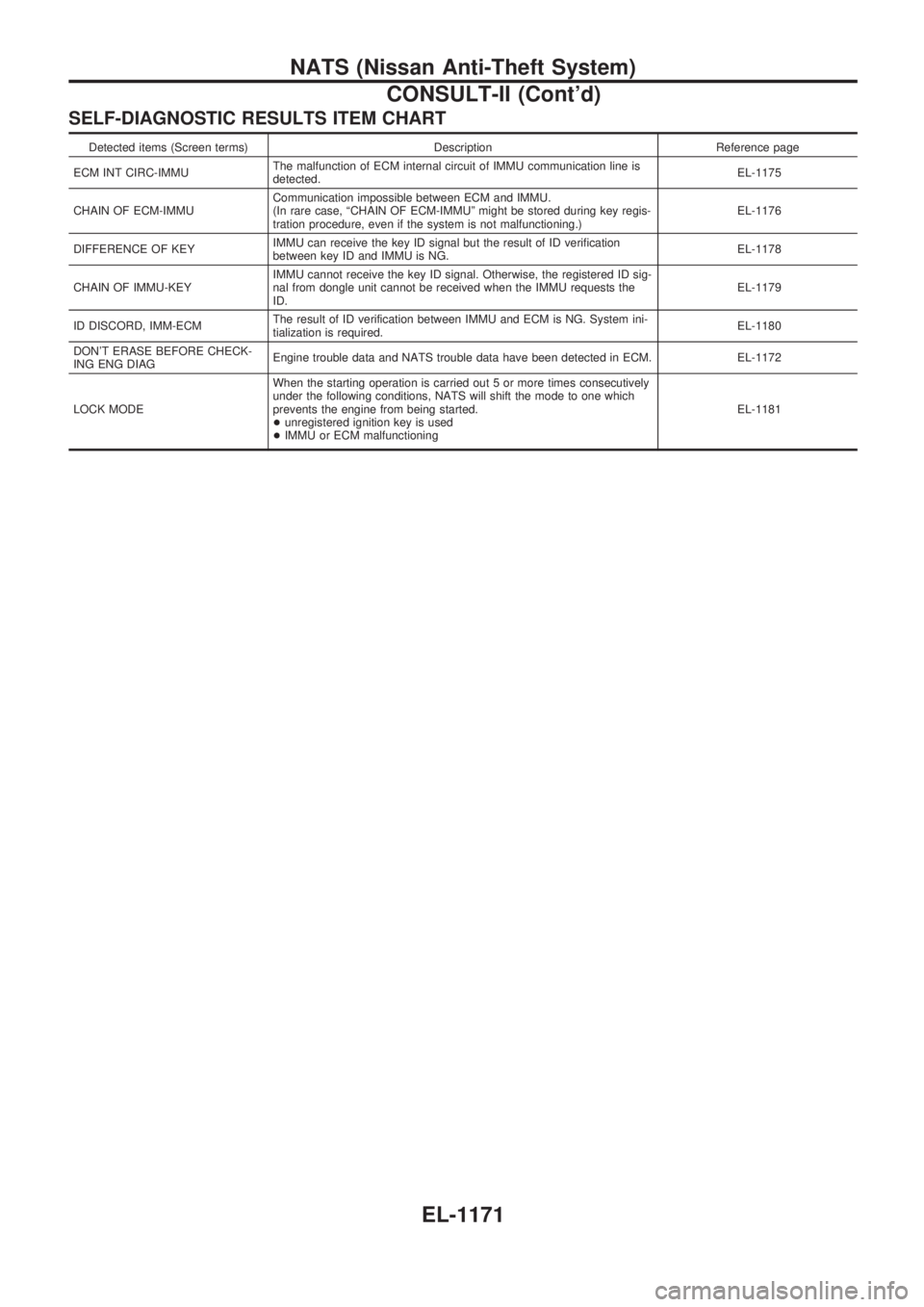

SELF-DIAGNOSTIC RESULTS ITEM CHART

Detected items (Screen terms) Description Reference page

ECM INT CIRC-IMMUThe malfunction of ECM internal circuit of IMMU communication line is

detected.EL-1175

CHAIN OF ECM-IMMUCommunication impossible between ECM and IMMU.

(In rare case, ªCHAIN OF ECM-IMMUº might be stored during key regis-

tration procedure, even if the system is not malfunctioning.)EL-1176

DIFFERENCE OF KEYIMMU can receive the key ID signal but the result of ID verification

between key ID and IMMU is NG.EL-1178

CHAIN OF IMMU-KEYIMMU cannot receive the key ID signal. Otherwise, the registered ID sig-

nal from dongle unit cannot be received when the IMMU requests the

ID.EL-1179

ID DISCORD, IMM-ECMThe result of ID verification between IMMU and ECM is NG. System ini-

tialization is required.EL-1180

DON'T ERASE BEFORE CHECK-

ING ENG DIAGEngine trouble data and NATS trouble data have been detected in ECM. EL-1172

LOCK MODEWhen the starting operation is carried out 5 or more times consecutively

under the following conditions, NATS will shift the mode to one which

prevents the engine from being started.

+unregistered ignition key is used

+IMMU or ECM malfunctioningEL-1181

NATS (Nissan Anti-Theft System)

CONSULT-II (Cont'd)

EL-1171

Page 683 of 1033

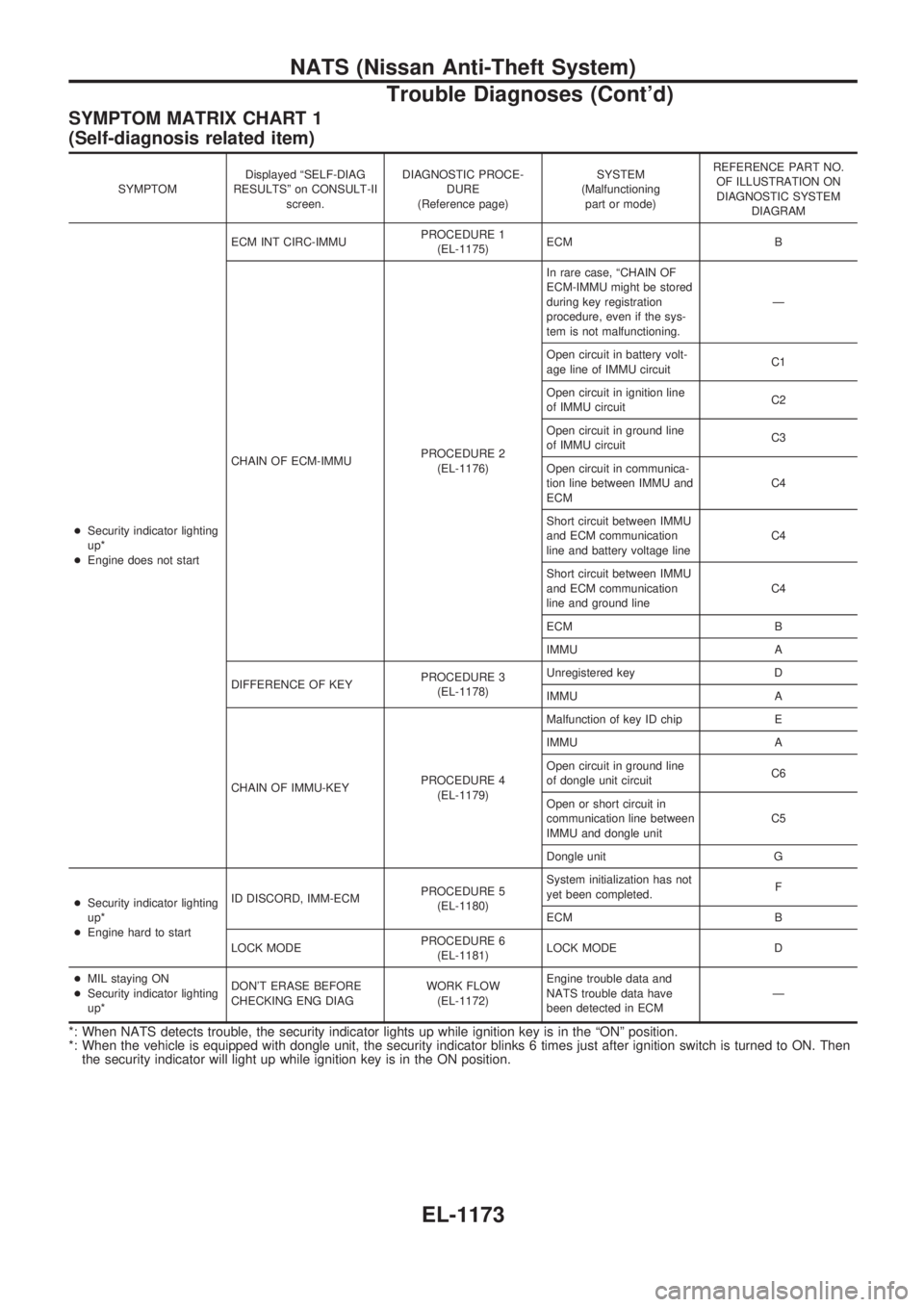

SYMPTOM MATRIX CHART 1

(Self-diagnosis related item)

SYMPTOMDisplayed ªSELF-DIAG

RESULTSº on CONSULT-II

screen.DIAGNOSTIC PROCE-

DURE

(Reference page)SYSTEM

(Malfunctioning

part or mode)REFERENCE PART NO.

OF ILLUSTRATION ON

DIAGNOSTIC SYSTEM

DIAGRAM

+Security indicator lighting

up*

+Engine does not startECM INT CIRC-IMMUPROCEDURE 1

(EL-1175)ECM B

CHAIN OF ECM-IMMUPROCEDURE 2

(EL-1176)In rare case, ªCHAIN OF

ECM-IMMU might be stored

during key registration

procedure, even if the sys-

tem is not malfunctioning.Ð

Open circuit in battery volt-

age line of IMMU circuitC1

Open circuit in ignition line

of IMMU circuitC2

Open circuit in ground line

of IMMU circuitC3

Open circuit in communica-

tion line between IMMU and

ECMC4

Short circuit between IMMU

and ECM communication

line and battery voltage lineC4

Short circuit between IMMU

and ECM communication

line and ground lineC4

ECM B

IMMU A

DIFFERENCE OF KEYPROCEDURE 3

(EL-1178)Unregistered key D

IMMU A

CHAIN OF IMMU-KEYPROCEDURE 4

(EL-1179)Malfunction of key ID chip E

IMMU A

Open circuit in ground line

of dongle unit circuitC6

Open or short circuit in

communication line between

IMMU and dongle unitC5

Dongle unit G

+Security indicator lighting

up*

+Engine hard to startID DISCORD, IMM-ECMPROCEDURE 5

(EL-1180)System initialization has not

yet been completed.F

ECM B

LOCK MODEPROCEDURE 6

(EL-1181)LOCK MODE D

+MIL staying ON

+Security indicator lighting

up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(EL-1172)Engine trouble data and

NATS trouble data have

been detected in ECMÐ

*: When NATS detects trouble, the security indicator lights up while ignition key is in the ªONº position.

*: When the vehicle is equipped with dongle unit, the security indicator blinks 6 times just after ignition switch is turned to ON. Then

the security indicator will light up while ignition key is in the ON position.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1173

Page 688 of 1033

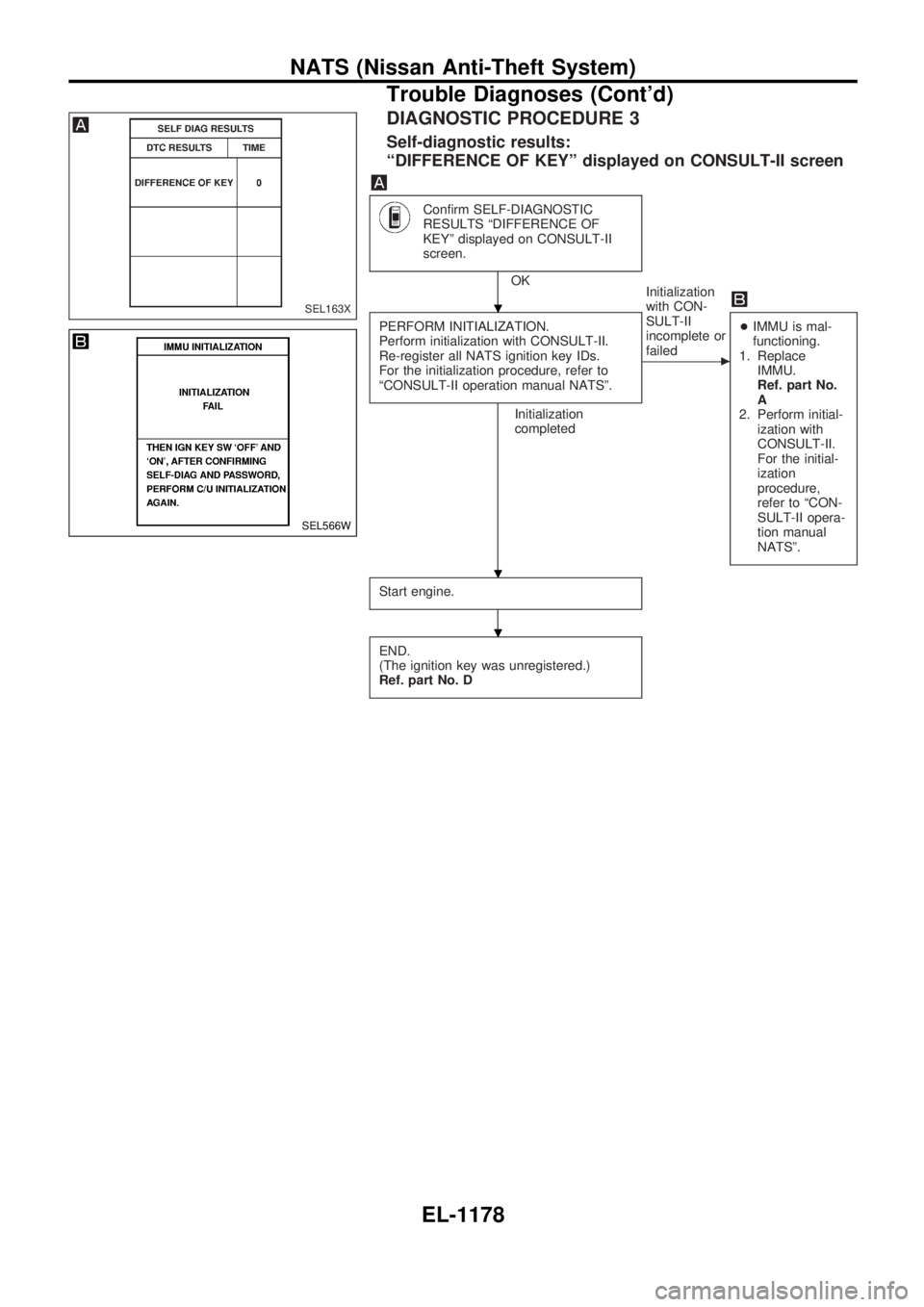

DIAGNOSTIC PROCEDURE 3

Self-diagnostic results:

ªDIFFERENCE OF KEYº displayed on CONSULT-II screen

Confirm SELF-DIAGNOSTIC

RESULTS ªDIFFERENCE OF

KEYº displayed on CONSULT-II

screen.

OK

PERFORM INITIALIZATION.

Perform initialization with CONSULT-II.

Re-register all NATS ignition key IDs.

For the initialization procedure, refer to

ªCONSULT-II operation manual NATSº.

Initialization

completedInitialization

with CON-

SULT-II

incomplete or

failed

c

+IMMU is mal-

functioning.

1. Replace

IMMU.

Ref. part No.

A

2. Perform initial-

ization with

CONSULT-II.

For the initial-

ization

procedure,

refer to ªCON-

SULT-II opera-

tion manual

NATSº.

Start engine.

END.

(The ignition key was unregistered.)

Ref. part No. D

SEL163X

SEL566W

.

.

.

NATS (Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

EL-1178

Page 737 of 1033

Wiring Diagram Codes (Cell Codes)

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (Page number) of each wiring diagram.

Code Section Wiring Diagram Name

A/C,A HA Auto Air Conditioner

A/C,M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Control

A/T AT A/T

ABS BR Anti-lock Brake System

ACC/SW EC Accelerator Switch (FC)

ACL/SW EC Accelerator Position Switch

APS EC Accelerator Position Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

BACK/L EL Back-up Lamp

BCDD EC BCDD System

BOOST EC Turbo Charger Boost Sensor

BRK/SW EC Brake Switch Signal

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CKPS EC Crankshaft Position Sensor (OBD)

COOL/B HA Cool Box

COOL/F EC Cooling Fan Control

CORNER EL Cornering Lamp

DEF EL Rear Window Defogger

DIFF/L PD Differential Lock Control System

DTRL ELHeadlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGVC/V EC EGR Volume Control Valve

EXH ECExhaust Gas Control Valve Control

Solenoid Valve

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FCUT EC Fuel Cut System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI POT

FPCM EC Fuel Pump Control Module

GLOW EC Quick Glow System

HEATER HA Heater System

HEATUP EC Heat up SwitchCode Section Wiring Diagram Name

HLC EL Headlamp Wiper and Washer

HORN EL Horn

IGN EC Ignition Control System

ILL EL Illumination

INJPMP ECElectronic Control Fuel Injection

Pump

INT/V ECIntake Air Control Valve Control

Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.,

Oil and Fuel Gauges

MIL/DL EC Mil and Data Link Connectors

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

P/ANT EL Power Antenna

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

R/COOL HA Rear Cooler System

R/FOG EL Rear Fog Lamp

R/HEAT HA Rear Heater System

REMOTE EL Audio (Remote Control Switch)

ROOM/L EL Interior Room Lamp

S/LOCK EL Power Door Lock Ð Super Lock

S/SIG EC Start Signal

S/TANK FE Sub Fuel Tank Control System

SHIFT AT A/T Shift Lock System

SRS RS Supplemental Restraint System

STAB RA Stabilizer Release Device

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WIRING DIAGRAM CODES (CELL CODES)

EL-1227

Page 748 of 1033

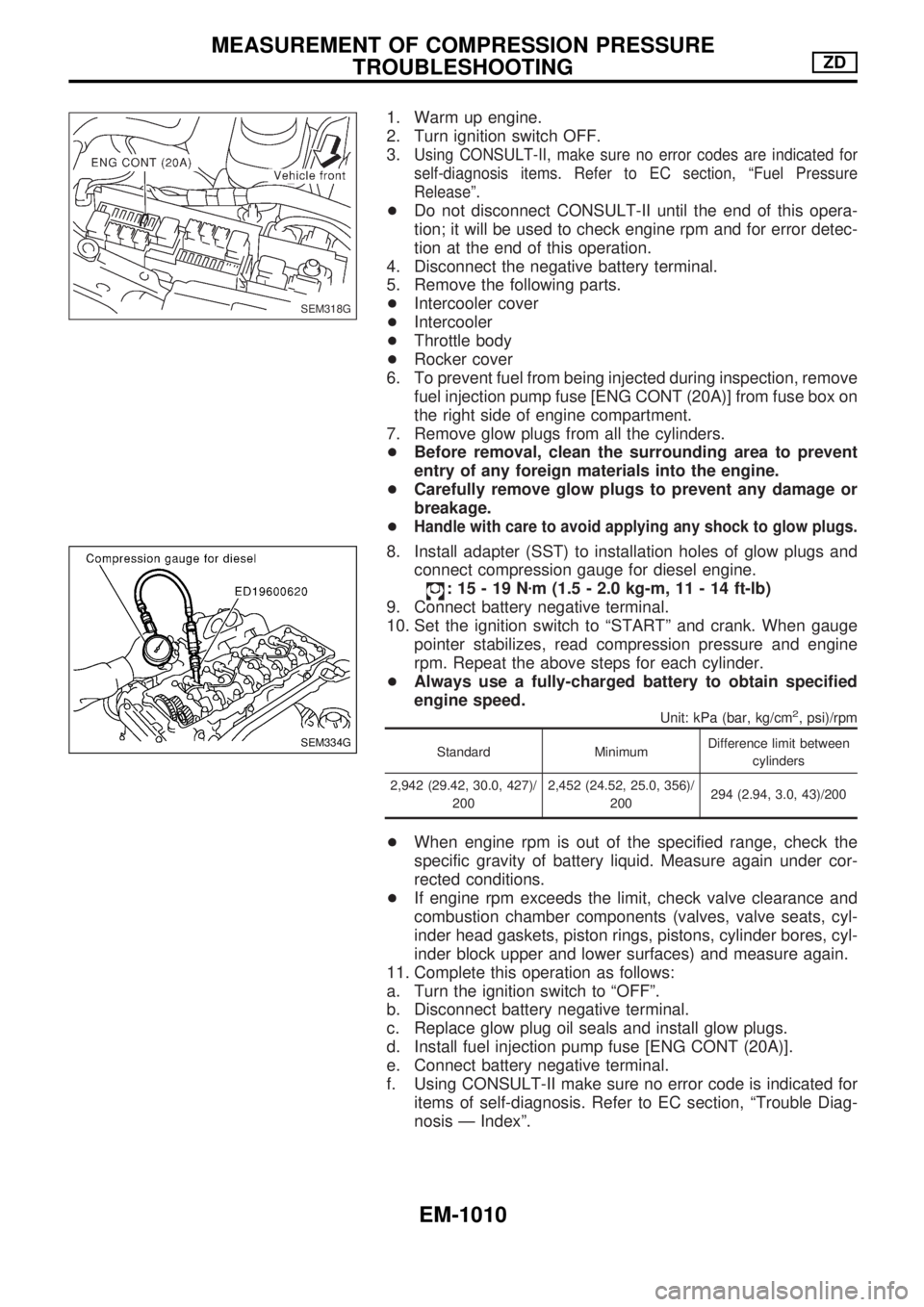

1. Warm up engine.

2. Turn ignition switch OFF.

3.

Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

+Intercooler cover

+Intercooler

+Throttle body

+Rocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT (20A)] from fuse box on

the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+

Handle with care to avoid applying any shock to glow plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diag-

nosis Ð Indexº.

SEM318G

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

TROUBLESHOOTINGZD

EM-1010

Page 762 of 1033

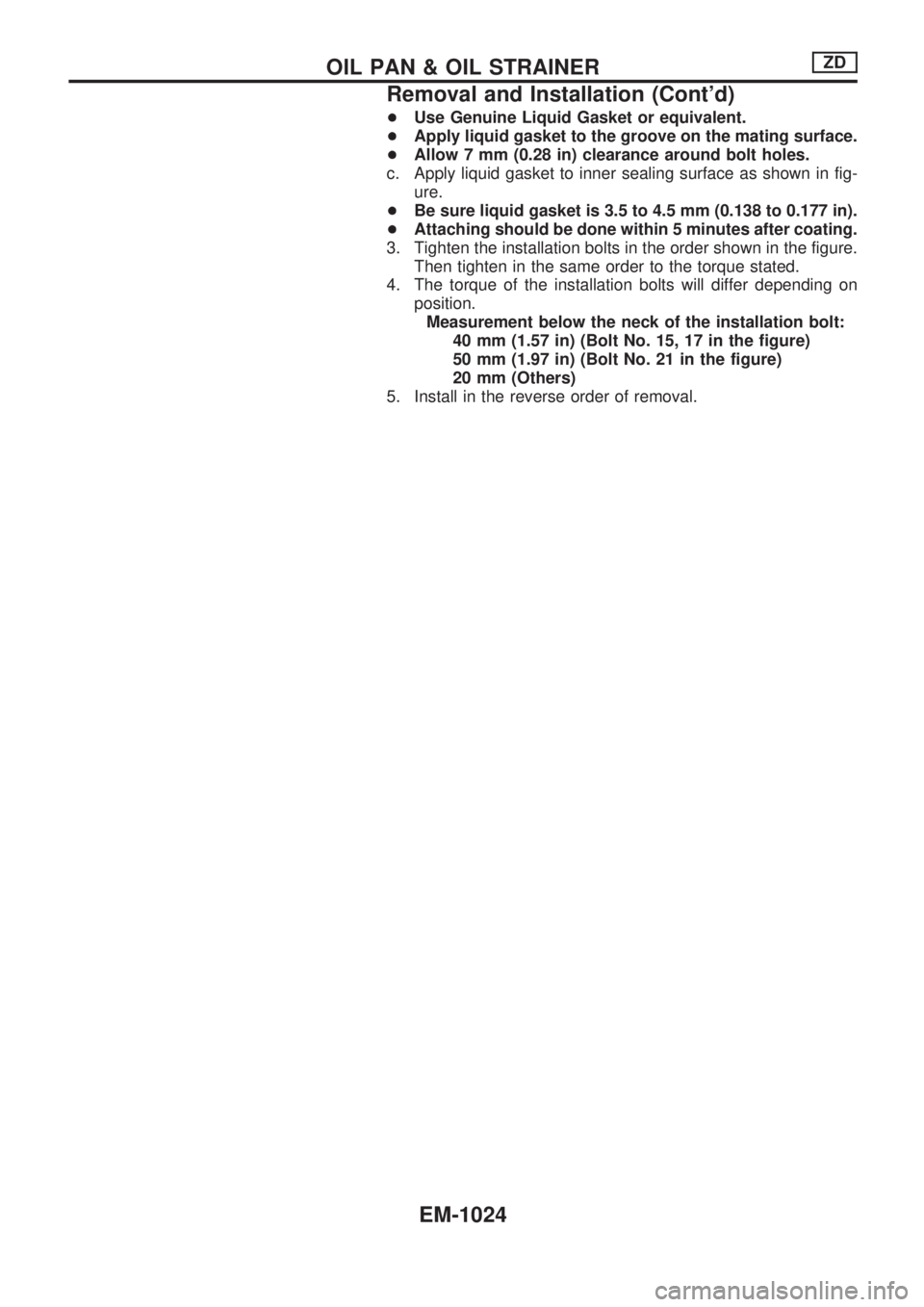

+Use Genuine Liquid Gasket or equivalent.

+Apply liquid gasket to the groove on the mating surface.

+Allow 7 mm (0.28 in) clearance around bolt holes.

c. Apply liquid gasket to inner sealing surface as shown in fig-

ure.

+Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in).

+Attaching should be done within 5 minutes after coating.

3. Tighten the installation bolts in the order shown in the figure.

Then tighten in the same order to the torque stated.

4. The torque of the installation bolts will differ depending on

position.

Measurement below the neck of the installation bolt:

40 mm (1.57 in) (Bolt No. 15, 17 in the figure)

50 mm (1.97 in) (Bolt No. 21 in the figure)

20 mm (Others)

5. Install in the reverse order of removal.

OIL PAN & OIL STRAINERZD

Removal and Installation (Cont'd)

EM-1024

Page 763 of 1033

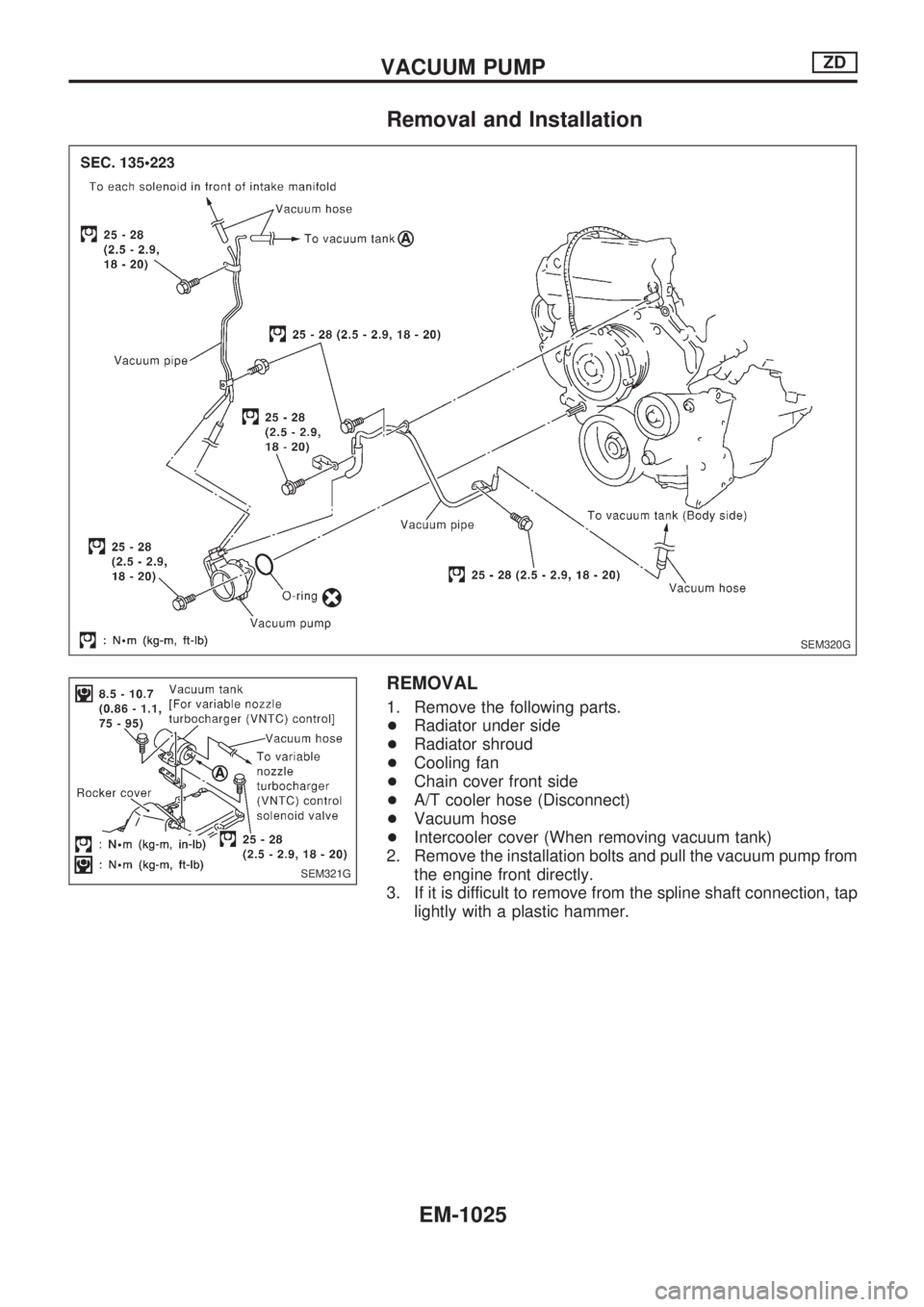

Removal and Installation

REMOVAL

1. Remove the following parts.

+Radiator under side

+Radiator shroud

+Cooling fan

+Chain cover front side

+A/T cooler hose (Disconnect)

+Vacuum hose

+Intercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from

the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap

lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-1025

Page 769 of 1033

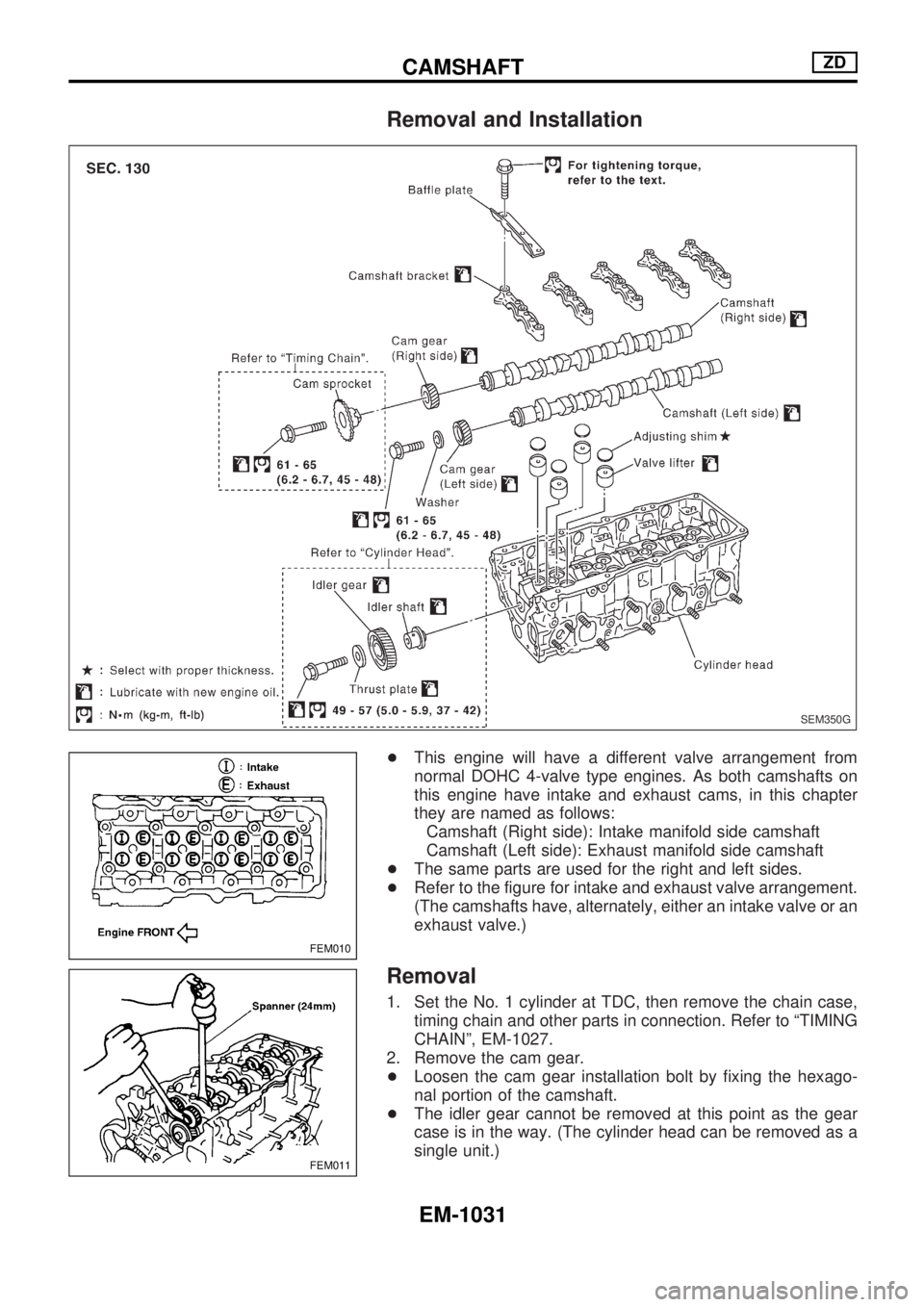

Removal and Installation

+This engine will have a different valve arrangement from

normal DOHC 4-valve type engines. As both camshafts on

this engine have intake and exhaust cams, in this chapter

they are named as follows:

Camshaft (Right side): Intake manifold side camshaft

Camshaft (Left side): Exhaust manifold side camshaft

+The same parts are used for the right and left sides.

+Refer to the figure for intake and exhaust valve arrangement.

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

Removal

1. Set the No. 1 cylinder at TDC, then remove the chain case,

timing chain and other parts in connection. Refer to ªTIMING

CHAINº, EM-1027.

2. Remove the cam gear.

+Loosen the cam gear installation bolt by fixing the hexago-

nal portion of the camshaft.

+The idler gear cannot be removed at this point as the gear

case is in the way. (The cylinder head can be removed as a

single unit.)

SEM350G

FEM010

FEM011

CAMSHAFTZD

EM-1031

Page 774 of 1033

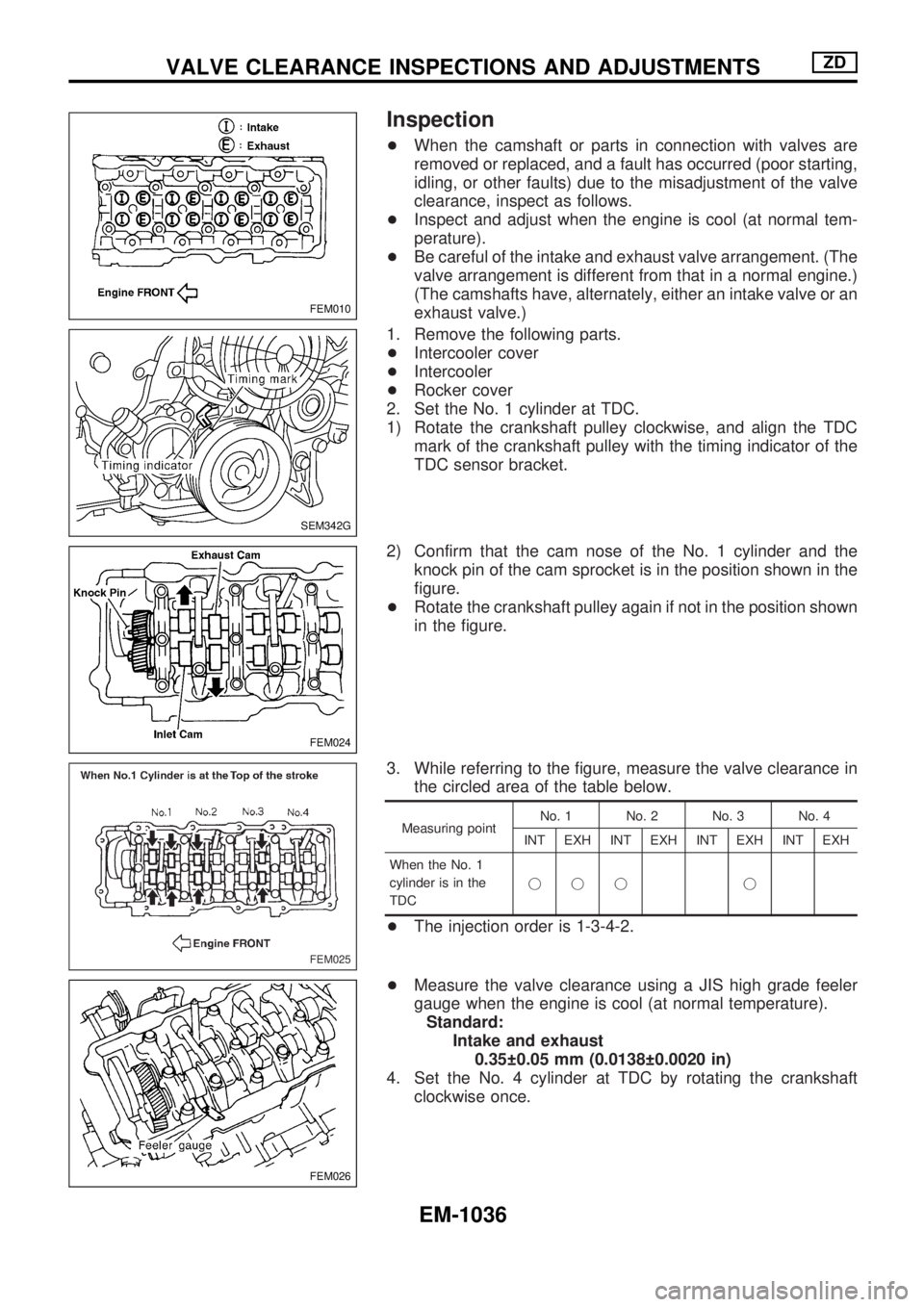

Inspection

+When the camshaft or parts in connection with valves are

removed or replaced, and a fault has occurred (poor starting,

idling, or other faults) due to the misadjustment of the valve

clearance, inspect as follows.

+Inspect and adjust when the engine is cool (at normal tem-

perature).

+Be careful of the intake and exhaust valve arrangement. (The

valve arrangement is different from that in a normal engine.)

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

1. Remove the following parts.

+Intercooler cover

+Intercooler

+Rocker cover

2. Set the No. 1 cylinder at TDC.

1) Rotate the crankshaft pulley clockwise, and align the TDC

mark of the crankshaft pulley with the timing indicator of the

TDC sensor bracket.

2) Confirm that the cam nose of the No. 1 cylinder and the

knock pin of the cam sprocket is in the position shown in the

figure.

+Rotate the crankshaft pulley again if not in the position shown

in the figure.

3. While referring to the figure, measure the valve clearance in

the circled area of the table below.

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 1

cylinder is in the

TDCjjj j

+The injection order is 1-3-4-2.

+Measure the valve clearance using a JIS high grade feeler

gauge when the engine is cool (at normal temperature).

Standard:

Intake and exhaust

0.35 0.05 mm (0.0138 0.0020 in)

4. Set the No. 4 cylinder at TDC by rotating the crankshaft

clockwise once.

FEM010

SEM342G

FEM024

FEM025

FEM026

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-1036