Diff NISSAN PATROL 2000 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 904 of 1033

Chassis and Body Maintenance

Abbreviations: R = Replace, I = Inspect: Correct or replace if necessary, L = Lubricate, T = Tighten

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform on a kilometer

basis onlykm x 1,000 10 20 30 40 50 60 70 80 90 100 110 120

(miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72)

Underhood and under vehicleReference

pages

Headlamp aimingIIIIÐ

When alignment (if necessary, balance & rotate wheels)IIIIÐ

Brake pads, rotors & other brake componentsHIIIIÐ

Foot brake, parking brake & clutch (for free play, stroke & operation)IIIIÐ

Brake booster vacuum hoses, connections & check valve I I Ð

Brake & clutch, systems and fluid (for level and leaks)IIIIÐ

Brake fluidHRRÐ

Power steering fluid and lines (for level and leaks)IIIIÐ

Supplemental air bag systems See NOTE (1)RS-1007

Ventilation air filterHRRRRÐ

Manual transmission oil (Inspect for leaks. Replace if leaks are found.) I I R I Ð

Automatic transmission fluid (for level and leaks)HIIIIÐ

Greasing point of propeller shaft See NOTE (2)LLLLÐ

Transfer fluid and limited-slip differential (LSD) gear oil

(for level & leaks or replace)HSee NOTE (3) I R I R Ð

Drive shafts & steering damperHIIIIÐ

Front wheel bearing greaseHIRIRÐ

Front axle joint in knuckle flangeLLÐ

Free-running hub greaseHIIIIÐ

Body mounting bolts & nutsTTTTÐ

Steering gear & linkage, axle & suspension parts, propeller shaft & exhaust systemHIIIIÐ

Body corrosion See NOTE (4)Ð

NOTE: (1) Inspect after 10 years, then every 2 years.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Including differential gear with differential lock.

(4) Inspect once per year.

HMaintenance items with ªHº should be performed more frequently according to ªMaintenance under severe driv-

ing conditionsº.

PERIODIC MAINTENANCE

MA-1006

Page 905 of 1033

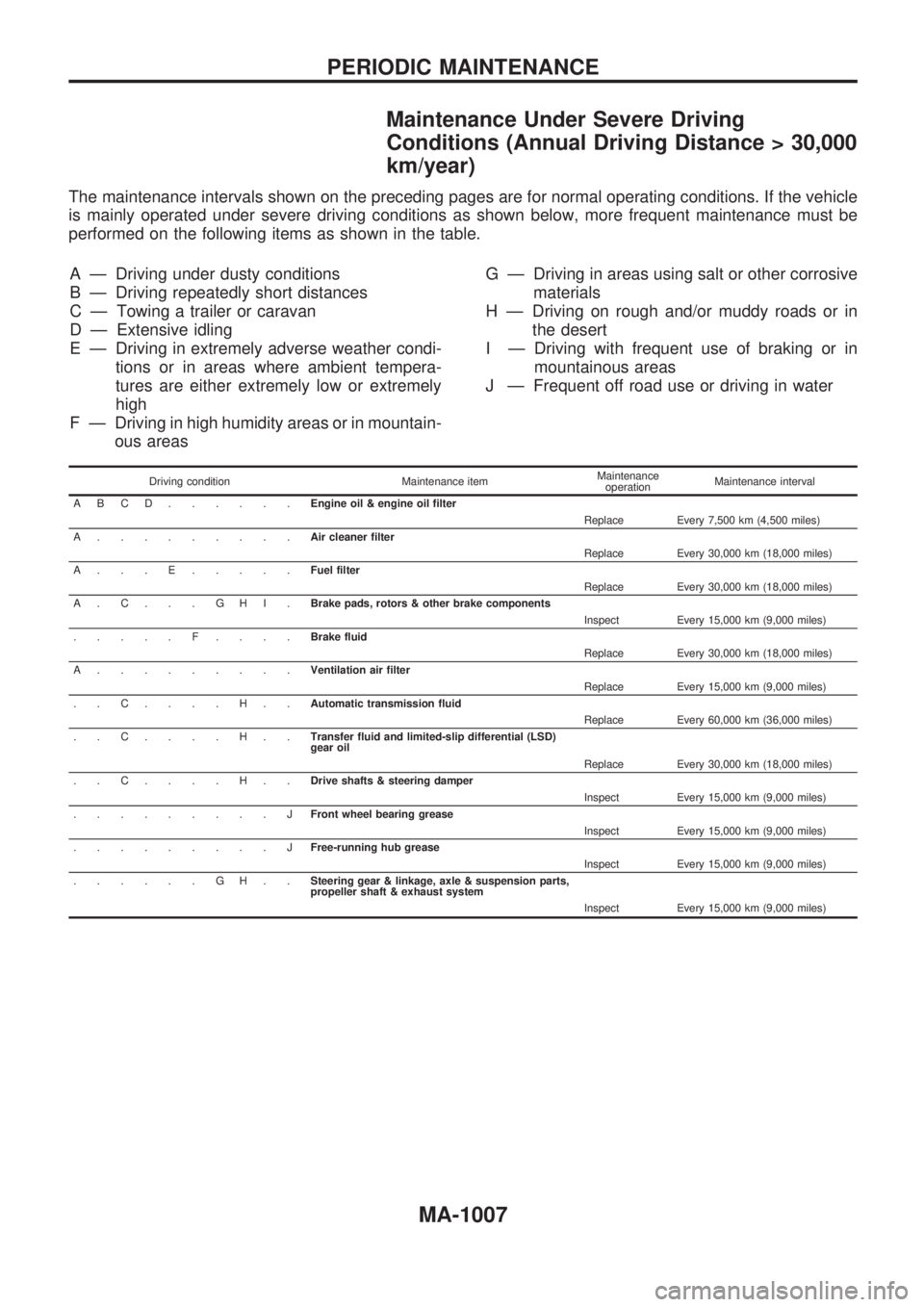

MaintenanceUnderSevereDriving

Conditions (Annual Driving Distance > 30,000

km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be

performed on the following items as shown in the table.

A Ð Driving under dusty conditions

B Ð Driving repeatedly short distances

C Ð Towing a trailer or caravan

D Ð Extensive idling

E Ð Driving in extremely adverse weather condi- tions or in areas where ambient tempera-

tures are either extremely low or extremely

high

F Ð Driving in high humidity areas or in mountain- ous areas G Ð Driving in areas using salt or other corrosive

materials

H Ð Driving on rough and/or muddy roads or in the desert

I Ð Driving with frequent use of braking or in mountainous areas

J Ð Frequent off road use or driving in water

Driving condition Maintenance item Maintenance

operation Maintenance interval

ABCD...... Engine oil & engine oil filter

Replace Every 7,500 km (4,500 miles)

A......... Air cleaner filter

Replace Every 30,000 km (18,000 miles)

A...E..... Fuel filter

Replace Every 30,000 km (18,000 miles)

A.C...GHI. Brake pads, rotors & other brake components

Inspect Every 15,000 km (9,000 miles)

.....F.... Brake fluid

Replace Every 30,000 km (18,000 miles)

A......... Ventilation air filter

Replace Every 15,000 km (9,000 miles)

..C....H.. Automatic transmission fluid

Replace Every 60,000 km (36,000 miles)

..C....H.. Transfer fluid and limited-slip differential (LSD)

gear oil

Replace Every 30,000 km (18,000 miles)

..C....H.. Drive shafts & steering damper

Inspect Every 15,000 km (9,000 miles)

.........J Front wheel bearing grease

Inspect Every 15,000 km (9,000 miles)

.........J Free-running hub grease

Inspect Every 15,000 km (9,000 miles)

......GH.. Steering gear & linkage, axle & suspension parts,

propeller shaft & exhaust system

Inspect Every 15,000 km (9,000 miles)

PERIODIC MAINTENANCE

MA-1007

Page 906 of 1033

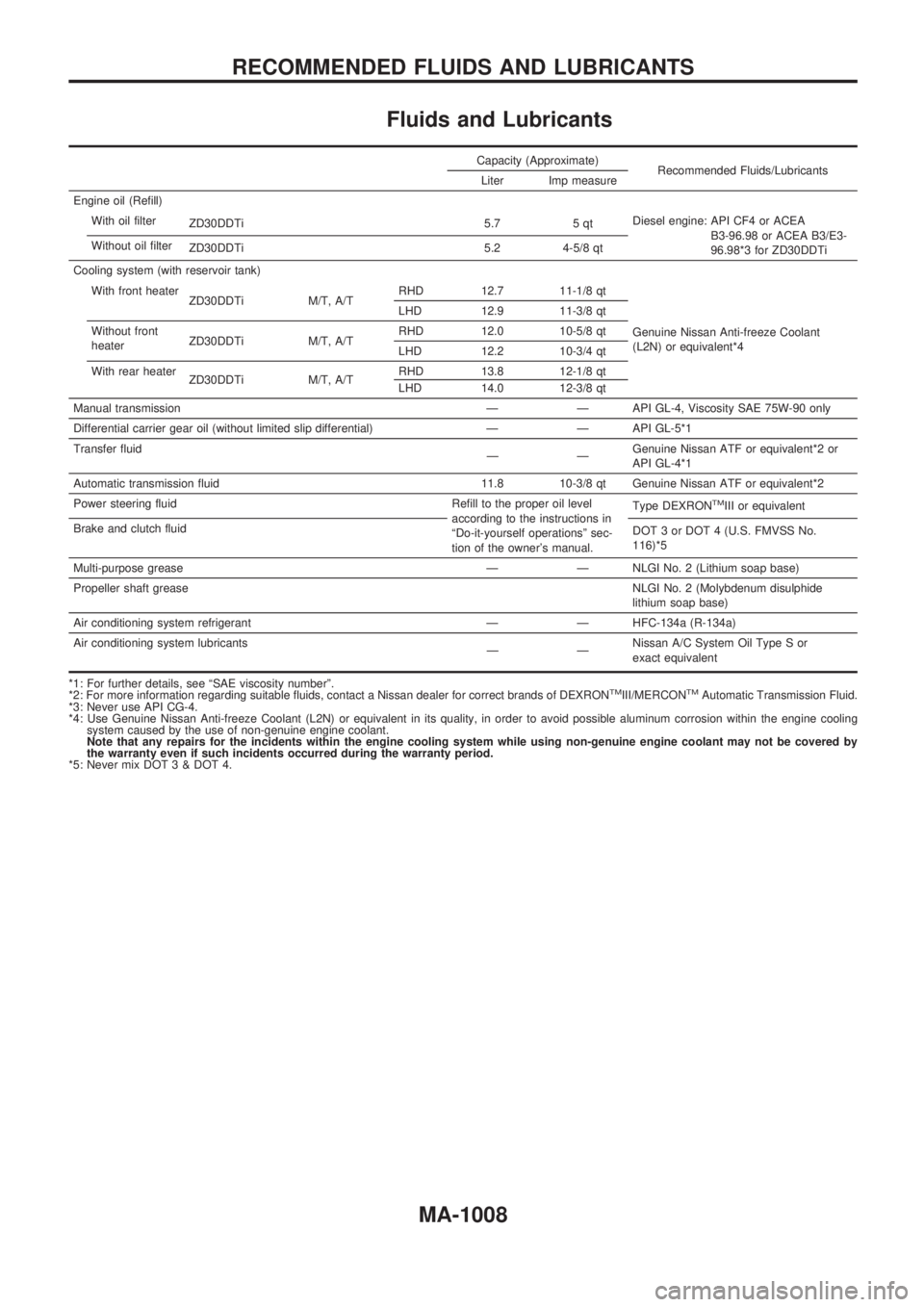

Fluids and Lubricants

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter Imp measure

Engine oil (Refill)

With oil filter

ZD30DDTi 5.7 5 qtDiesel engine: API CF4 or ACEA

B3-96.98 or ACEA B3/E3-

96.98*3 for ZD30DDTi Without oil filter

ZD30DDTi 5.2 4-5/8 qt

Cooling system (with reservoir tank)

With front heater

ZD30DDTi M/T, A/TRHD 12.7 11-1/8 qt

Genuine Nissan Anti-freeze Coolant

(L2N) or equivalent*4 LHD 12.9 11-3/8 qt

Without front

heaterZD30DDTi M/T, A/TRHD 12.0 10-5/8 qt

LHD 12.2 10-3/4 qt

With rear heater

ZD30DDTi M/T, A/TRHD 13.8 12-1/8 qt

LHD 14.0 12-3/8 qt

Manual transmission Ð Ð API GL-4, Viscosity SAE 75W-90 only

Differential carrier gear oil (without limited slip differential) Ð Ð API GL-5*1

Transfer fluid

ÐÐGenuine Nissan ATF or equivalent*2 or

API GL-4*1

Automatic transmission fluid 11.8 10-3/8 qt Genuine Nissan ATF or equivalent*2

Power steering fluid Refill to the proper oil level

according to the instructions in

ªDo-it-yourself operationsº sec-

tion of the owner's manual.Type DEXRON

TMIII or equivalent

Brake and clutch fluid

DOT 3 or DOT 4 (U.S. FMVSS No.

116)*5

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

Propeller shaft greaseNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Air conditioning system refrigerant Ð Ð HFC-134a (R-134a)

Air conditioning system lubricants

ÐÐNissan A/C System Oil Type S or

exact equivalent

*1: For further details, see ªSAE viscosity numberº.

*2: For more information regarding suitable fluids, contact a Nissan dealer for correct brands of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: Never use API CG-4.

*4: Use Genuine Nissan Anti-freeze Coolant (L2N) or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine cooling

system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be covered by

the warranty even if such incidents occurred during the warranty period.

*5: Never mix DOT 3 & DOT 4.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-1008

Page 907 of 1033

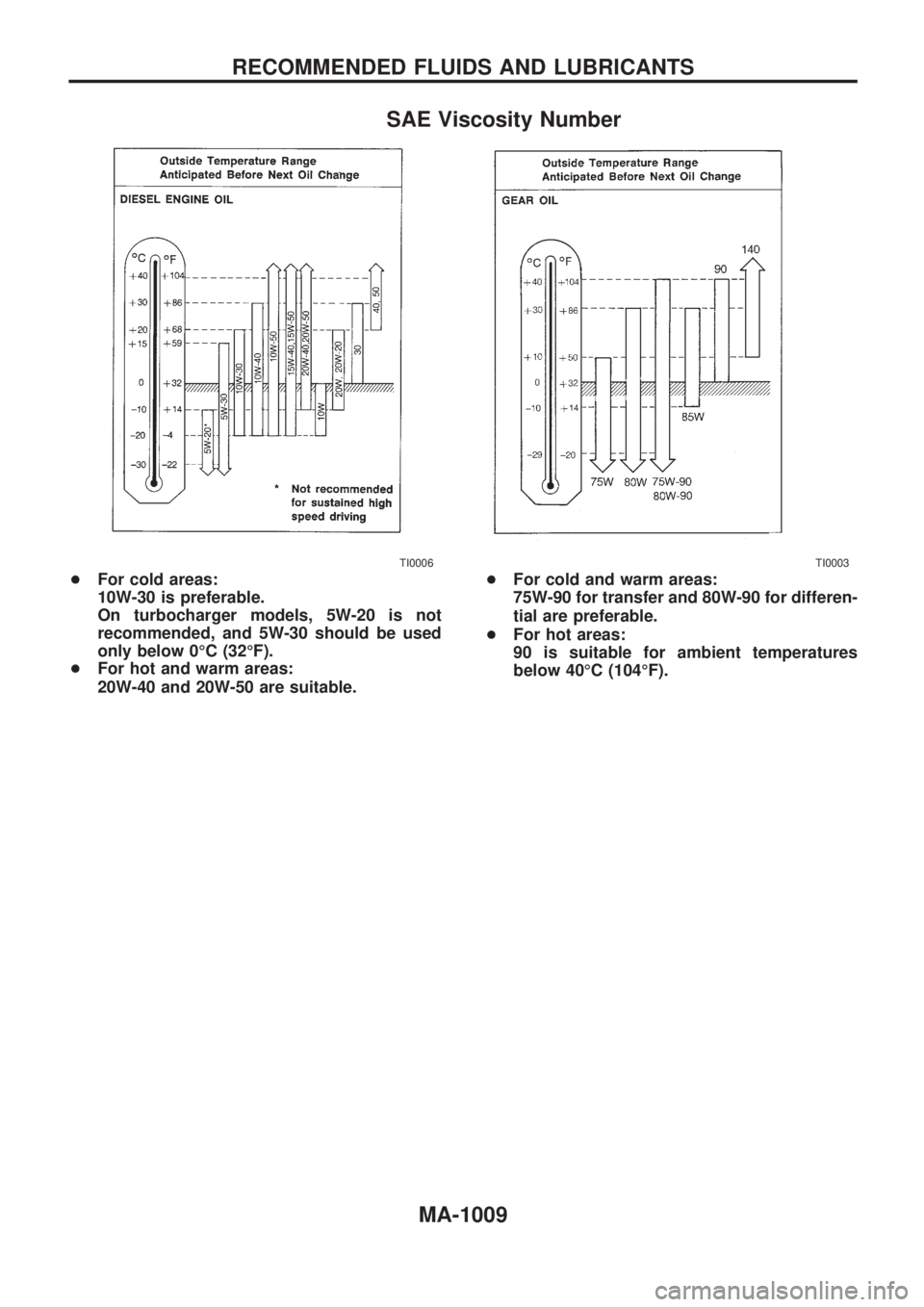

SAE Viscosity Number

+For cold areas:

10W-30 is preferable.

On turbocharger models, 5W-20 is not

recommended, and 5W-30 should be used

only below 0ÉC (32ÉF).

+For hot and warm areas:

20W-40 and 20W-50 are suitable.+For cold and warm areas:

75W-90 for transfer and 80W-90 for differen-

tial are preferable.

+For hot areas:

90 is suitable for ambient temperatures

below 40ÉC (104ÉF).

TI0006TI0003

RECOMMENDED FLUIDS AND LUBRICANTS

MA-1009

Page 950 of 1033

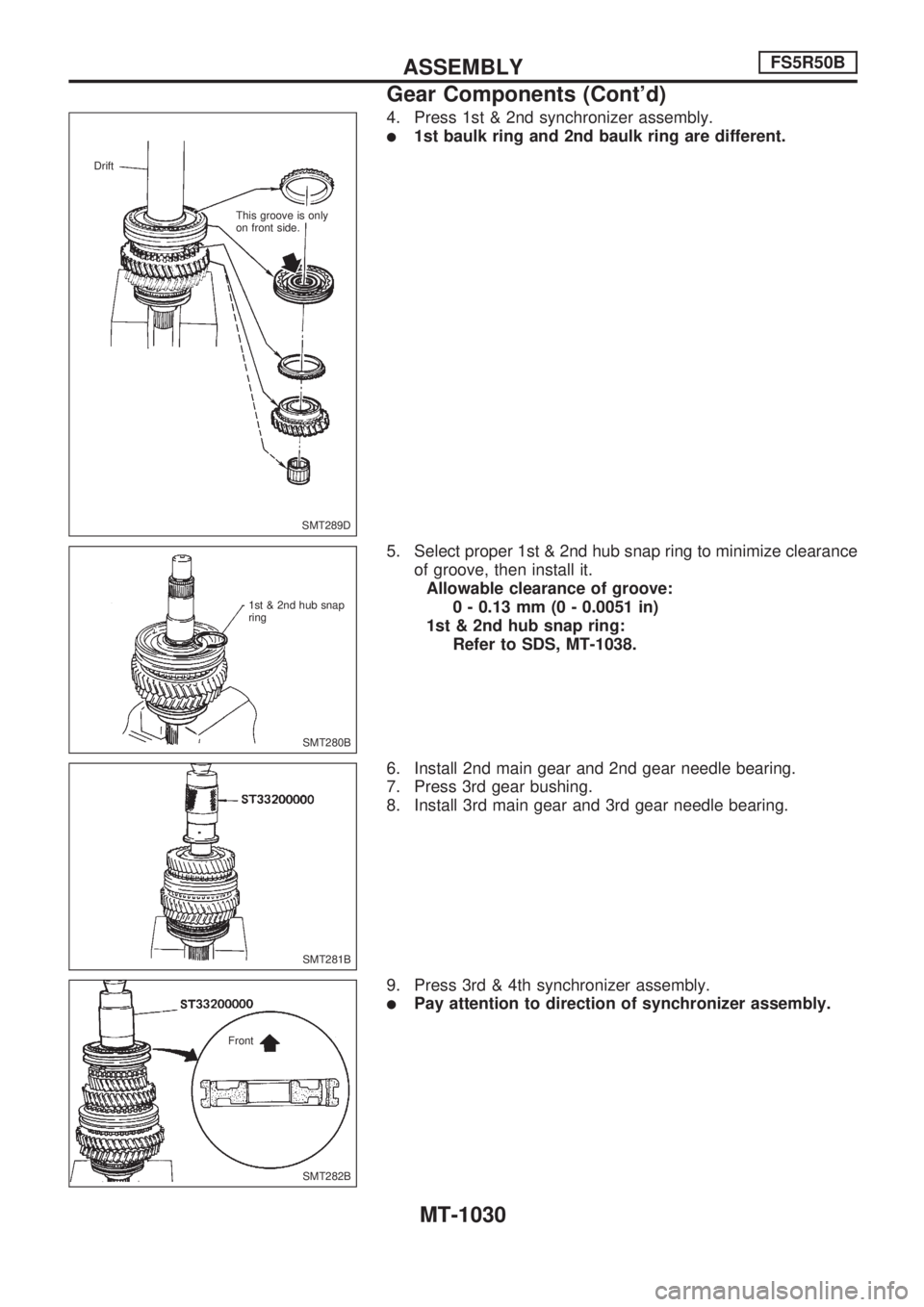

4. Press 1st & 2nd synchronizer assembly.

l1st baulk ring and 2nd baulk ring are different.

5. Select proper 1st & 2nd hub snap ring to minimize clearance

of groove, then install it.

Allowable clearance of groove:

0 - 0.13 mm (0 - 0.0051 in)

1st & 2nd hub snap ring:

Refer to SDS, MT-1038.

6. Install 2nd main gear and 2nd gear needle bearing.

7. Press 3rd gear bushing.

8. Install 3rd main gear and 3rd gear needle bearing.

9. Press 3rd & 4th synchronizer assembly.

lPay attention to direction of synchronizer assembly.

SMT289D Drift

This groove is only

on front side.

SMT280B 1st & 2nd hub snap

ring

SMT281B

SMT282B Front

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1030

Page 959 of 1033

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

MODIFICATION NOTICE:

+ ZD30ETi engine has been adopted.

CONTENTS

PROPELLER SHAFT .......................................... 1002

On-vehicle Service ........................................... 1003

FRONT FINAL DRIVE ......................................... 1004

REAR FINAL DRIVE ........................................... 1005

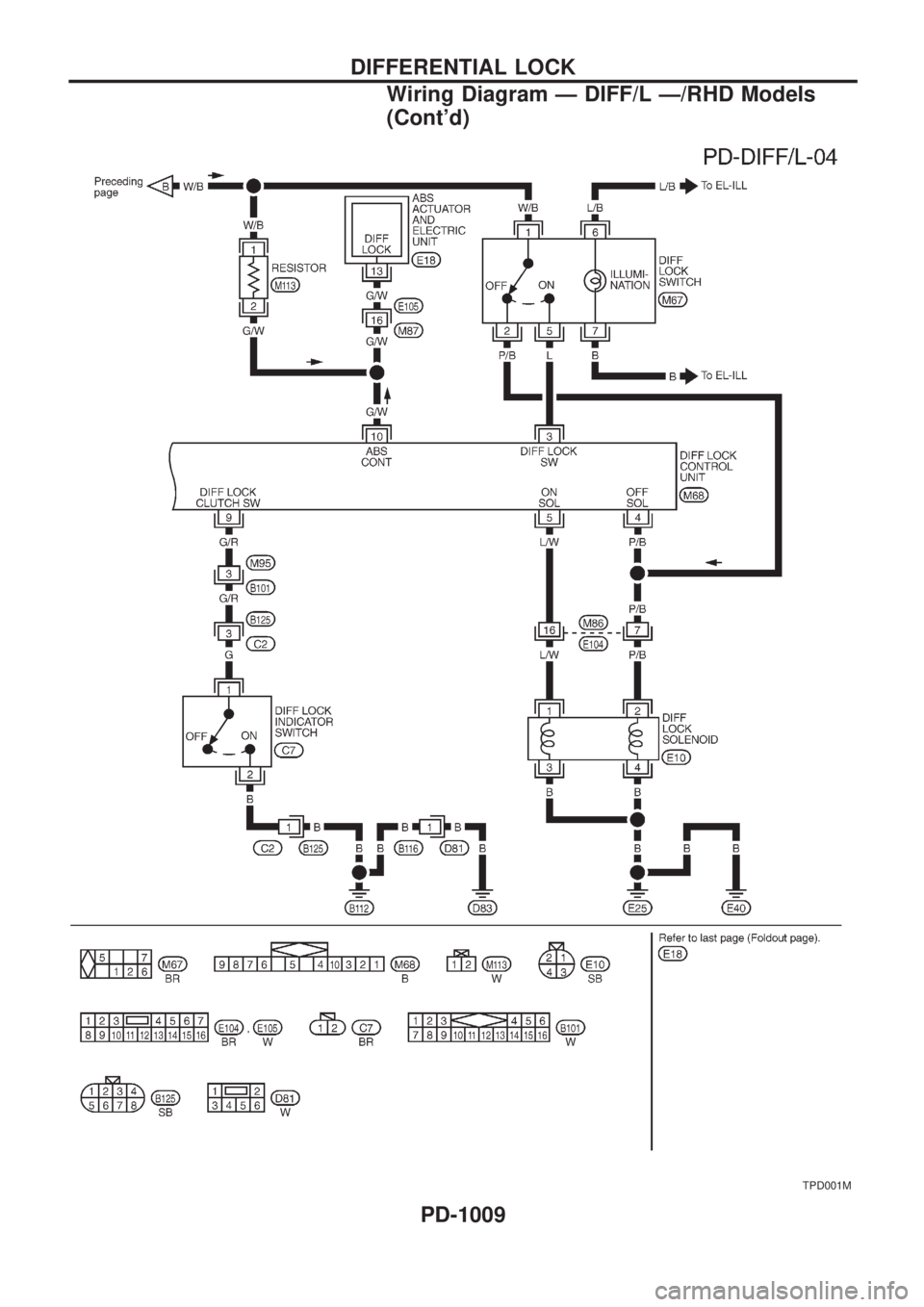

DIFFERENTIAL LOCK ........................................ 1006

Wiring Diagram Ð DIFF/L Ð/LHD Models ..... 1006 Wiring Diagram Ð DIFF/L Ð/RHD Models ..... 1008

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................... 1010

Propeller Shaft ................................................. 1010

Final Drive ........................................................ 1011

PD

Page 964 of 1033

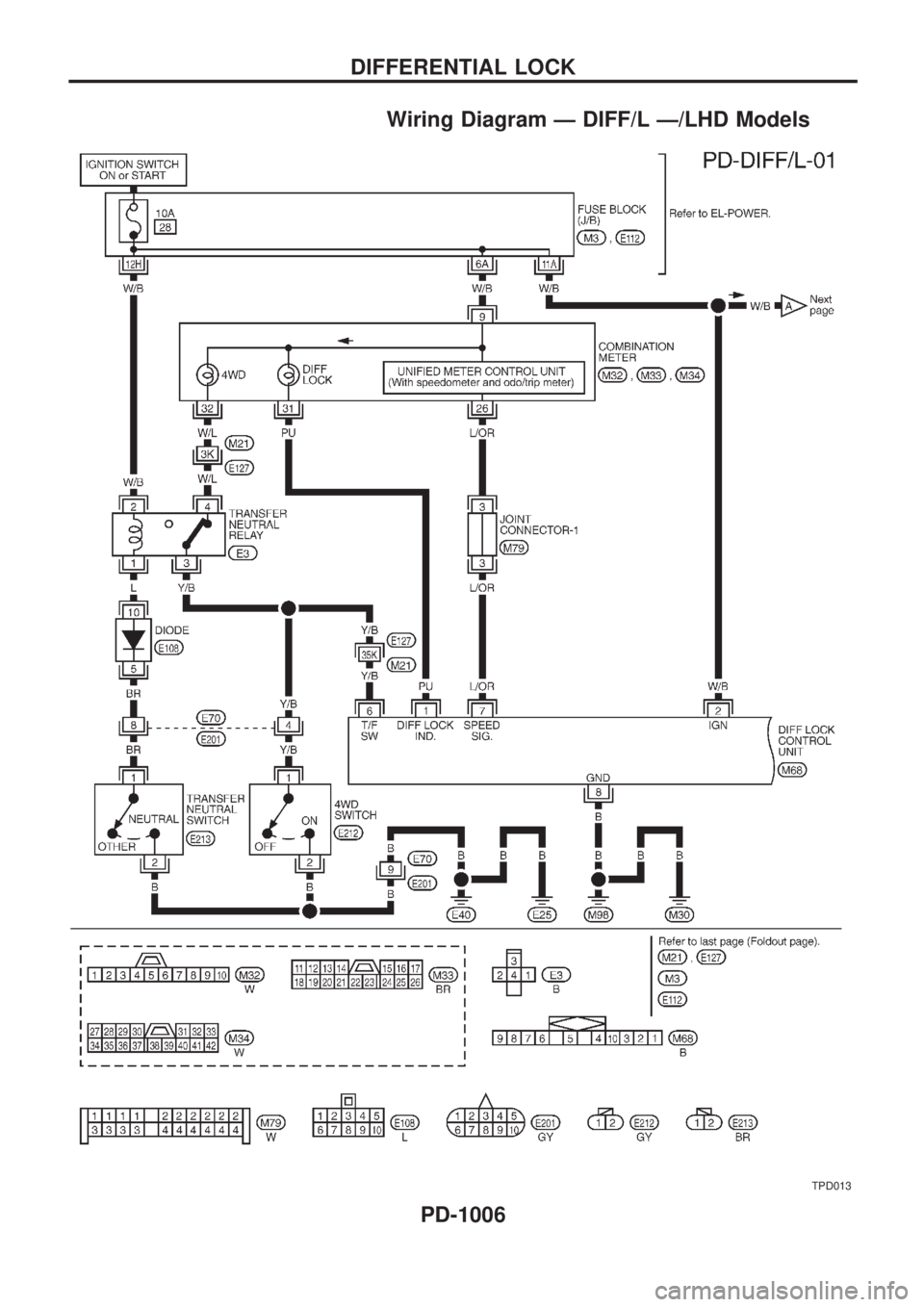

Wiring Diagram Ð DIFF/L Ð/LHD Models

TPD013

DIFFERENTIAL LOCK

PD-1006

Page 965 of 1033

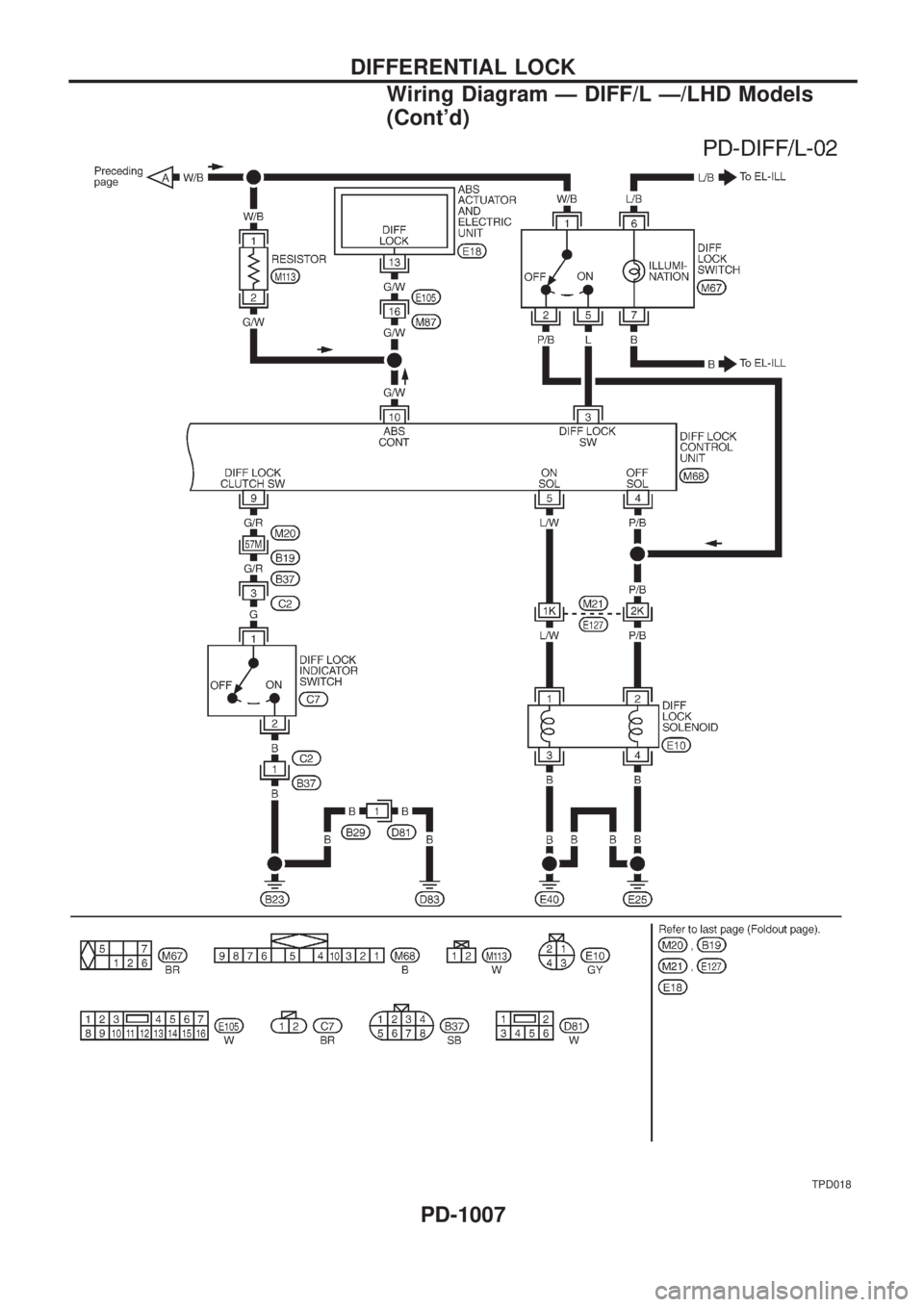

TPD018

DIFFERENTIAL LOCK

Wiring Diagram Ð DIFF/L Ð/LHD Models

(Cont'd)PD-1007

Page 966 of 1033

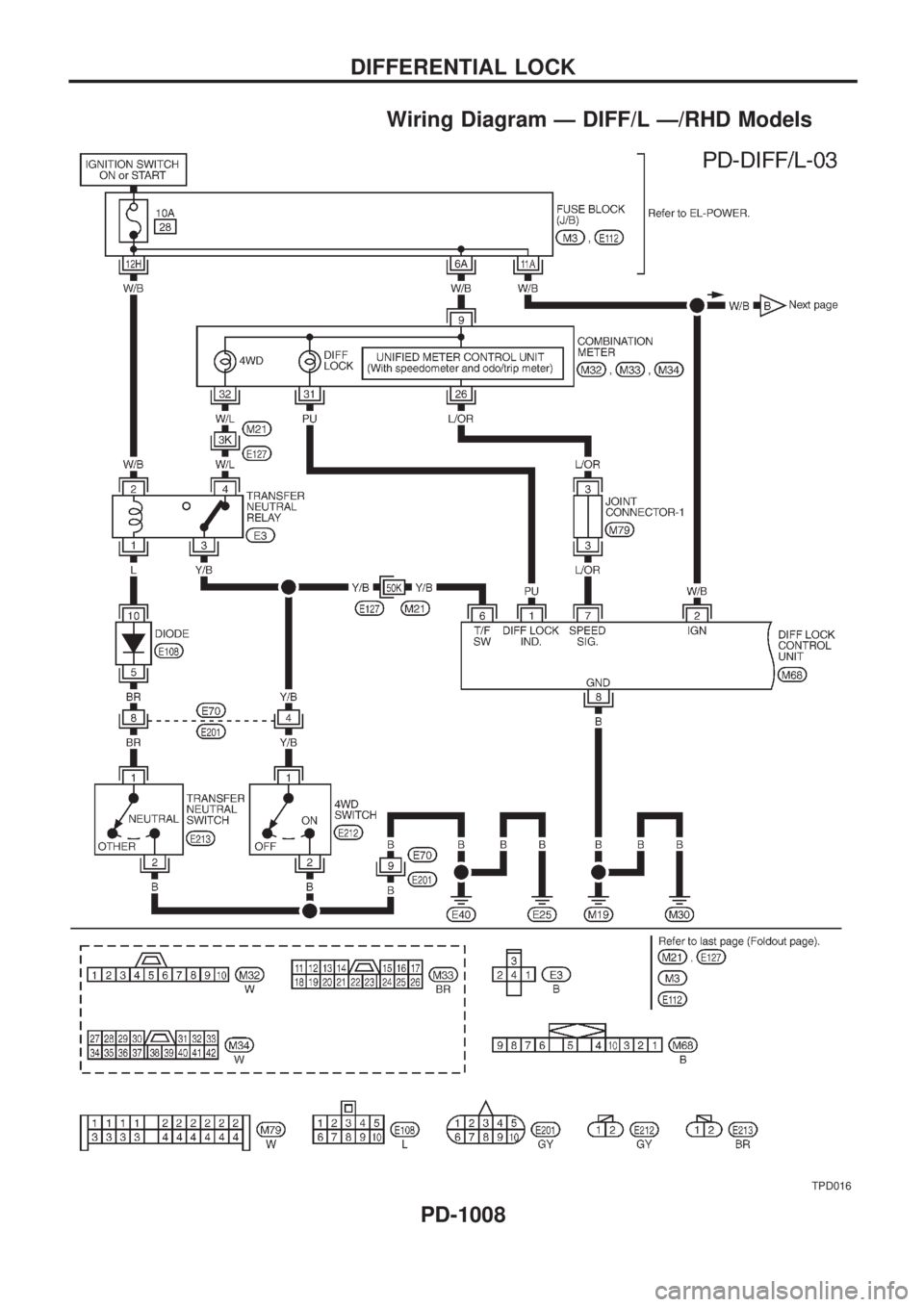

Wiring Diagram Ð DIFF/L Ð/RHD Models

TPD016

DIFFERENTIAL LOCK

PD-1008

Page 967 of 1033

TPD001M

DIFFERENTIAL LOCK

Wiring Diagram Ð DIFF/L Ð/RHD Models

(Cont'd)PD-1009