heating NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 43 of 1033

A/T Fluid Check

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. Ð for example, mating

surface of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº

position and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

FLUID CONDITION CHECK

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECK

Refer to MA section (ªChecking A/T Fluidº, ªCHASSIS AND

BODY MAINTENANCEº).

Stall Test

STALL TEST PROCEDURE

1. Check A/T and engine fluid levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and

ATF reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during

test.

+It is good practice to put a mark on point of specified

engine rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

+During test, never hold throttle wide open for more than

5 seconds.

Stall revolution:

2,480 - 2,680 rpm

SAT801A

SAT638A

SAT647B

SAT513G

SAT514G

TROUBLE DIAGNOSIS Ð Basic Inspection

AT-1041

Page 235 of 1033

On Board Diagnosis Logic ............................... 1092

DTC Confirmation Procedure .......................... 1092

Wiring Diagram ................................................ 1093

Diagnostic Procedure....................................... 1094

DTC 0104 VEHICLE SPEED SEN...................... 1096

Description ....................................................... 1096

ECM Terminals and Reference Value ............. 1096

On Board Diagnosis Logic ............................... 1096

Overall Function Check ................................... 1097

Wiring Diagram ................................................ 1098

Diagnostic Procedure....................................... 1099

DTC 0203 ACCEL POS SW (F/C)...................... 1100

Description ....................................................... 1100

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1100

ECM Terminals and Reference Value ............. 1100

On Board Diagnosis Logic ............................... 1100

DTC Confirmation Procedure .......................... 1101

Wiring Diagram ................................................ 1102

Diagnostic Procedure....................................... 1103

DTC 0208 OVER HEAT....................................... 1105

Description ....................................................... 1105

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1105

ECM Terminals and Reference Value ............. 1106

On Board Diagnosis Logic ............................... 1106

Overall Function Check ................................... 1107

Wiring Diagram ................................................ 1108

Diagnostic Procedure....................................... 1109

Main 12 Causes of Overheating ...................... 1116

DTC 0301 ECM 2, DTC 0901 ECM 12............... 1117

Description ....................................................... 1117

On Board Diagnosis Logic ............................... 1117

DTC Confirmation Procedure .......................... 1117

Diagnostic Procedure....................................... 1118

DTC 0402 P9zFUEL TEMP SEN......................... 1119

Description ....................................................... 1119

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1120

ECM Terminals and Reference Value ............. 1120

On Board Diagnosis Logic ............................... 1120

DTC Confirmation Procedure .......................... 1121

Wiring Diagram ................................................ 1122

Diagnostic Procedure....................................... 1123

DTC 0403 ACCEL POS SENSOR...................... 1125

Description ....................................................... 1125

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1125

ECM Terminals and Reference Value ............. 1126

On Board Diagnosis Logic ............................... 1126

DTC Confirmation Procedure .......................... 1127

Wiring Diagram ................................................ 1128

Diagnostic Procedure....................................... 1130

DTC 0406 INT AIR VOL...................................... 1138On Board Diagnosis Logic ............................... 1138

DTC Confirmation Procedure .......................... 1138

Diagnostic Procedure....................................... 1139

DTC 0407 CRANK POS SEN (TDC).................. 1140

Description ....................................................... 1140

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1140

ECM Terminals and Reference Value ............. 1140

On Board Diagnosis Logic ............................... 1141

DTC Confirmation Procedure .......................... 1141

Wiring Diagram ................................................ 1142

Diagnostic Procedure....................................... 1143

DTC 0502 BATTERY VOLTAGE........................ 1146

On Board Diagnosis Logic ............................... 1146

DTC Confirmation Procedure .......................... 1146

Diagnostic Procedure....................................... 1146

DTC 0504 A/T COMM LINE................................ 1148

System Description .......................................... 1148

ECM Terminals and Reference Value ............. 1148

On Board Diagnosis Logic ............................... 1148

DTC Confirmation Procedure .......................... 1149

Overall Function Check ................................... 1149

Wiring Diagram ................................................ 1150

Diagnostic Procedure....................................... 1151

DTC 0701 P1zCAM POS SEN............................. 1153

Description ....................................................... 1153

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1154

ECM Terminals and Reference Value ............. 1154

On Board Diagnosis Logic ............................... 1154

DTC Confirmation Procedure .......................... 1155

Wiring Diagram ................................................ 1156

Diagnostic Procedure....................................... 1157

DTC 0702 P2zTDC PULSE SIG........................... 1159

Description ....................................................... 1159

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1160

ECM Terminals and Reference Value ............. 1160

On Board Diagnosis Logic ............................... 1160

DTC Confirmation Procedure .......................... 1161

Wiring Diagram ................................................ 1162

Diagnostic Procedure....................................... 1163

DTC 0703 P3zPUMP COMM LINE...................... 1165

Description ....................................................... 1165

CONSULT-II Reference Value in Data Monitor

Mode ................................................................ 1166

ECM Terminals and Reference Value ............. 1166

On Board Diagnosis Logic ............................... 1166

DTC Confirmation Procedure .......................... 1167

Wiring Diagram ................................................ 1168

Diagnostic Procedure....................................... 1169

DTC 0704 P4zSPILL/V CIRC, DTC 0706

P6zSPILL VALVE................................................. 1171

Description ....................................................... 1171

EC-1002

Page 339 of 1033

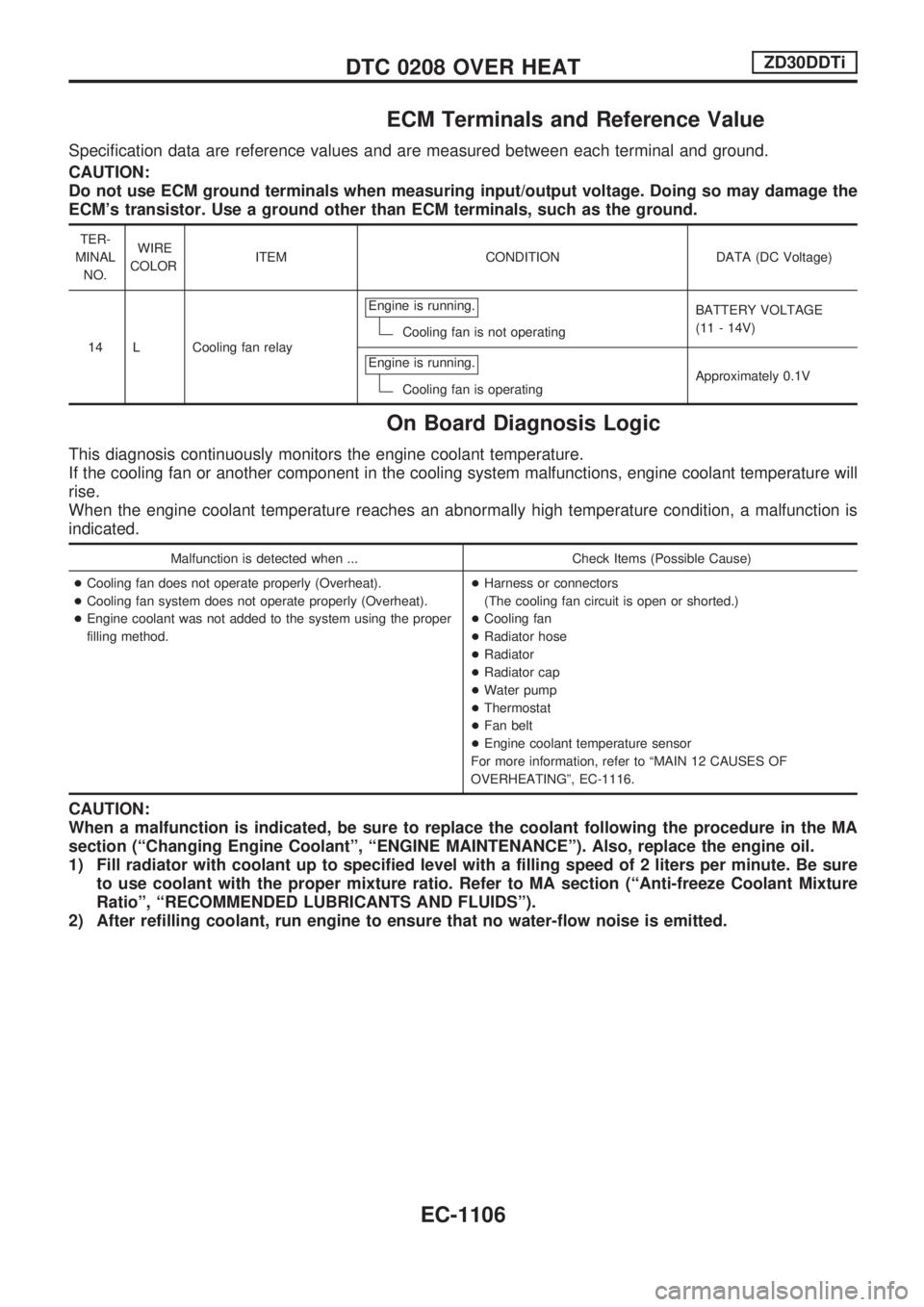

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 L Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Overheat).

+Engine coolant was not added to the system using the proper

filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Fan belt

+Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-1116.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATZD30DDTi

EC-1106

Page 349 of 1033

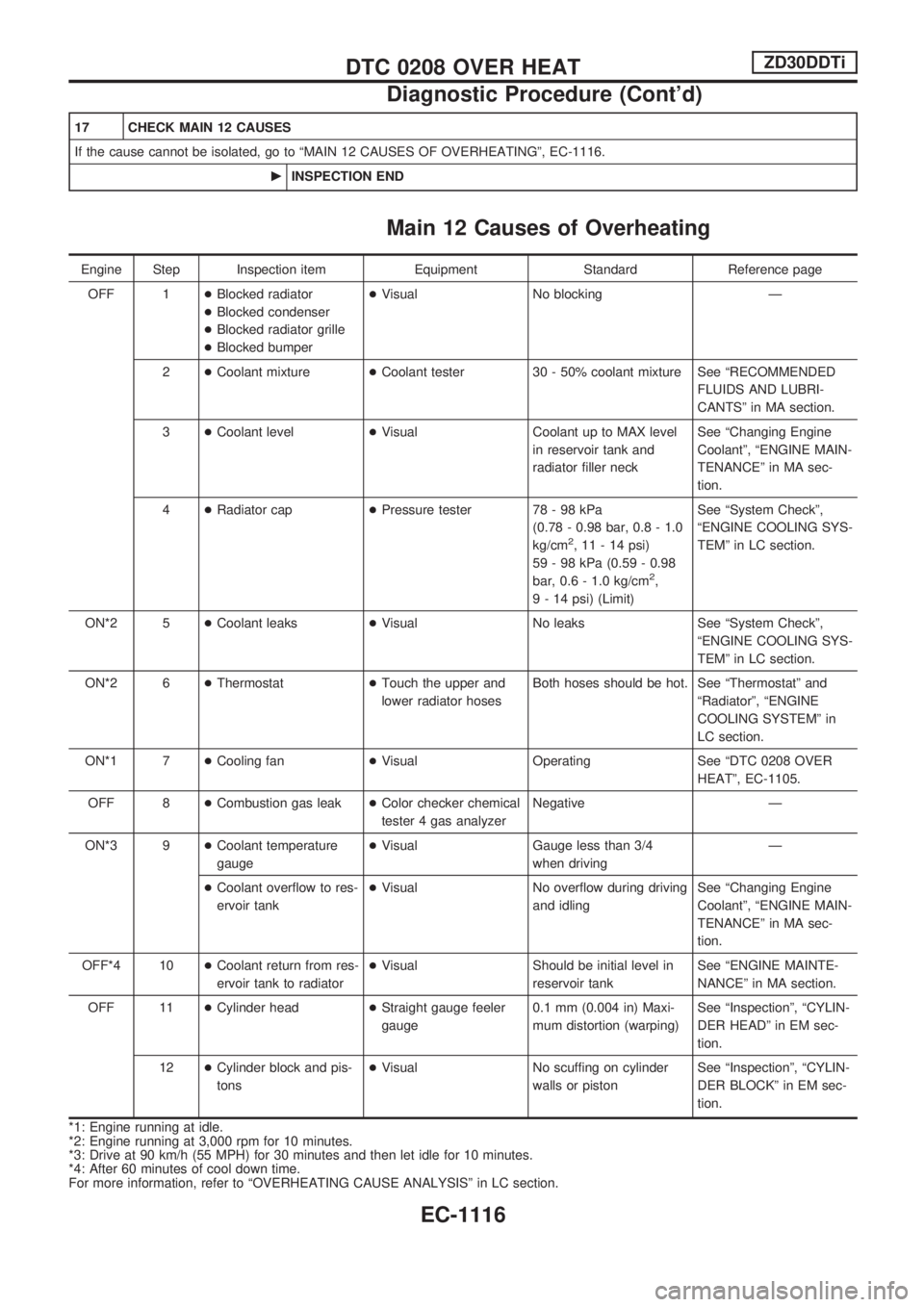

17 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-1116.

cINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº, EC-1105.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1116

Page 454 of 1033

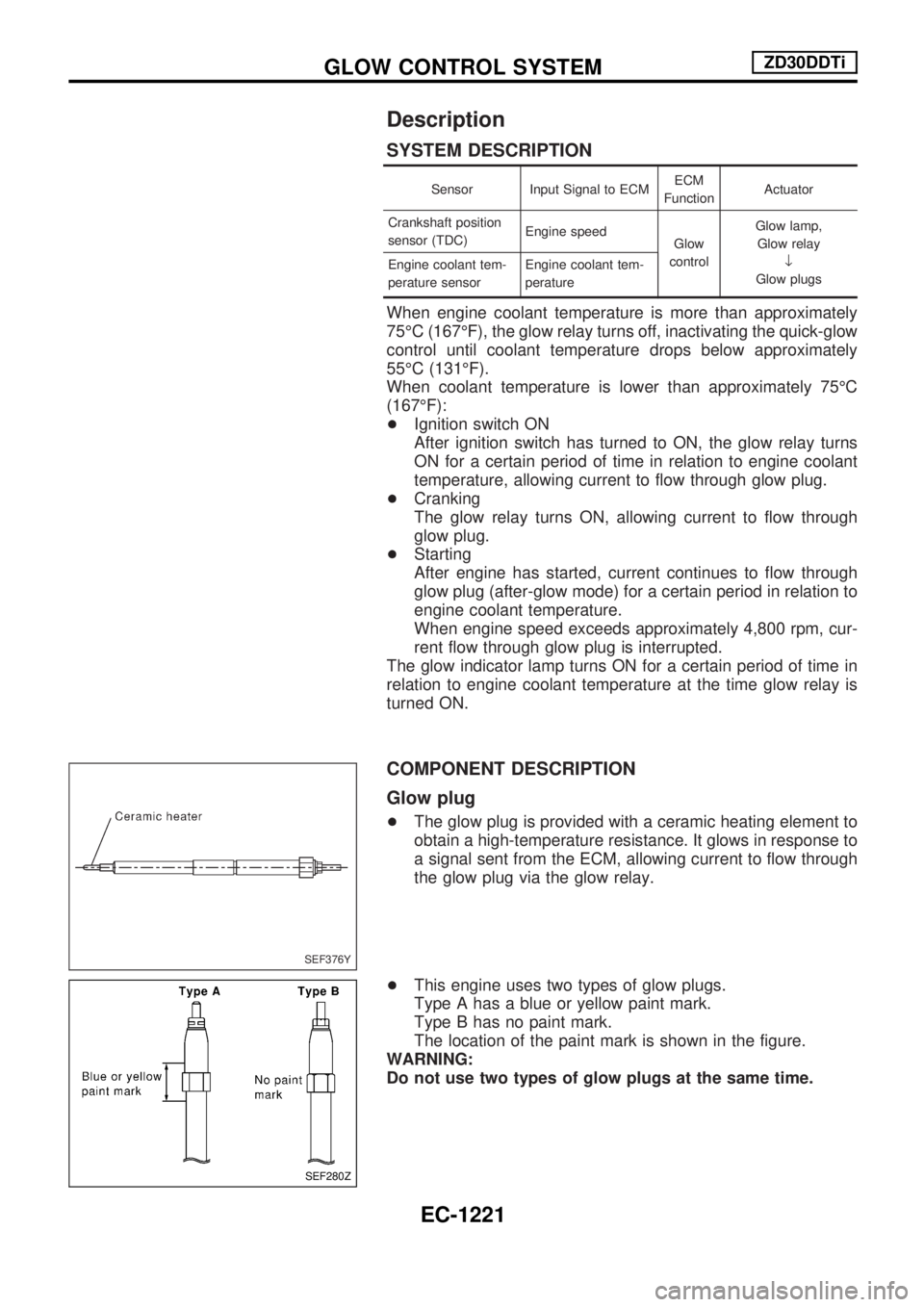

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Crankshaft position

sensor (TDC)Engine speed

Glow

controlGlow lamp,

Glow relay

¯

Glow plugs Engine coolant tem-

perature sensorEngine coolant tem-

perature

When engine coolant temperature is more than approximately

75ÉC (167ÉF), the glow relay turns off, inactivating the quick-glow

control until coolant temperature drops below approximately

55ÉC (131ÉF).

When coolant temperature is lower than approximately 75ÉC

(167ÉF):

+Ignition switch ON

After ignition switch has turned to ON, the glow relay turns

ON for a certain period of time in relation to engine coolant

temperature, allowing current to flow through glow plug.

+Cranking

The glow relay turns ON, allowing current to flow through

glow plug.

+Starting

After engine has started, current continues to flow through

glow plug (after-glow mode) for a certain period in relation to

engine coolant temperature.

When engine speed exceeds approximately 4,800 rpm, cur-

rent flow through glow plug is interrupted.

The glow indicator lamp turns ON for a certain period of time in

relation to engine coolant temperature at the time glow relay is

turned ON.

COMPONENT DESCRIPTION

Glow plug

+The glow plug is provided with a ceramic heating element to

obtain a high-temperature resistance. It glows in response to

a signal sent from the ECM, allowing current to flow through

the glow plug via the glow relay.

+This engine uses two types of glow plugs.

Type A has a blue or yellow paint mark.

Type B has no paint mark.

The location of the paint mark is shown in the figure.

WARNING:

Do not use two types of glow plugs at the same time.

SEF376Y

SEF280Z

GLOW CONTROL SYSTEMZD30DDTi

EC-1221

Page 462 of 1033

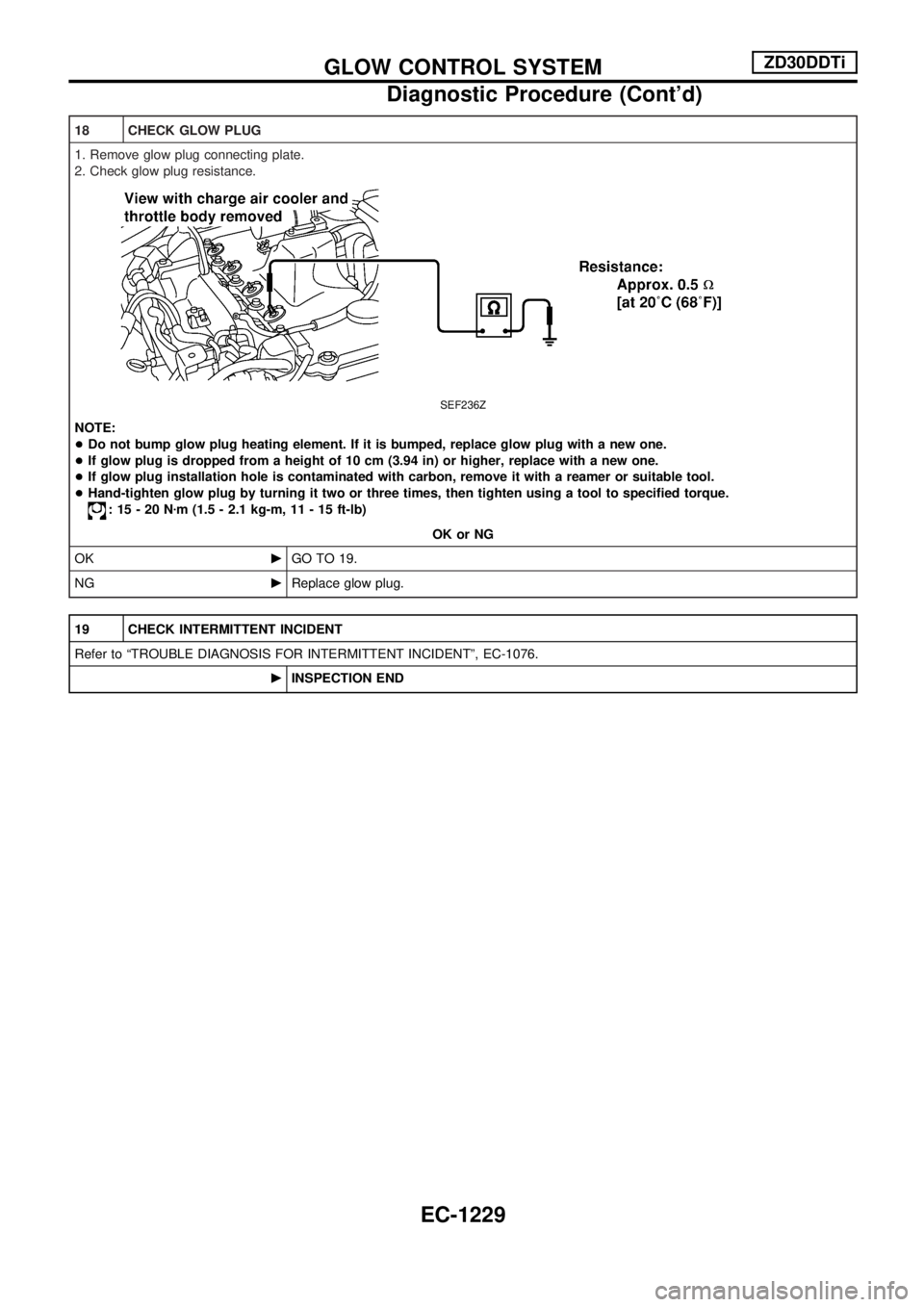

18 CHECK GLOW PLUG

1. Remove glow plug connecting plate.

2. Check glow plug resistance.

SEF236Z

NOTE:

+Do not bump glow plug heating element. If it is bumped, replace glow plug with a new one.

+If glow plug is dropped from a height of 10 cm (3.94 in) or higher, replace with a new one.

+If glow plug installation hole is contaminated with carbon, remove it with a reamer or suitable tool.

+Hand-tighten glow plug by turning it two or three times, then tighten using a tool to specified torque.

:15-20Nzm (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

OK or NG

OKcGO TO 19.

NGcReplace glow plug.

19 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

GLOW CONTROL SYSTEMZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1229

Page 502 of 1033

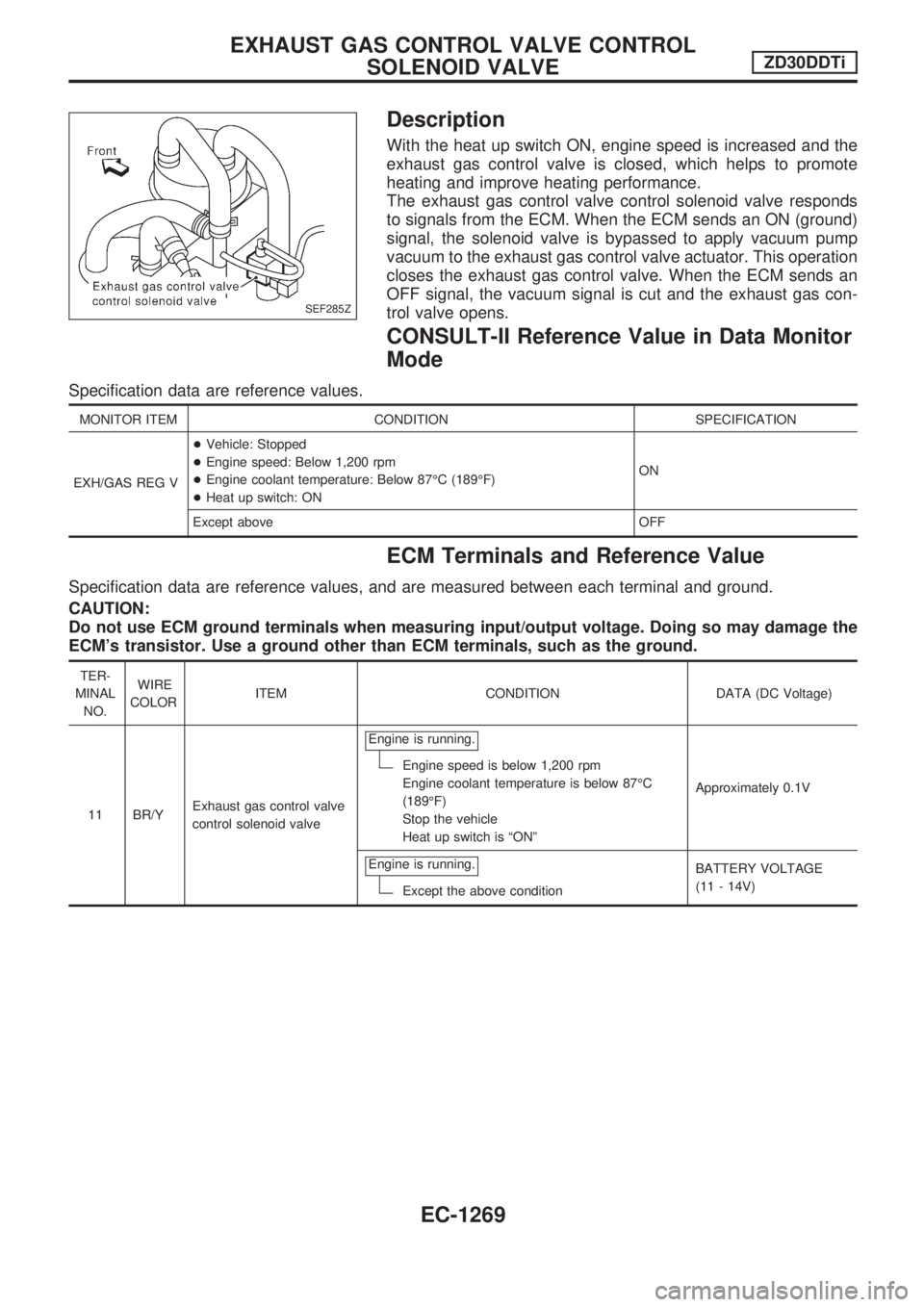

Description

With the heat up switch ON, engine speed is increased and the

exhaust gas control valve is closed, which helps to promote

heating and improve heating performance.

The exhaust gas control valve control solenoid valve responds

to signals from the ECM. When the ECM sends an ON (ground)

signal, the solenoid valve is bypassed to apply vacuum pump

vacuum to the exhaust gas control valve actuator. This operation

closes the exhaust gas control valve. When the ECM sends an

OFF signal, the vacuum signal is cut and the exhaust gas con-

trol valve opens.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EXH/GAS REG V+Vehicle: Stopped

+Engine speed: Below 1,200 rpm

+Engine coolant temperature: Below 87ÉC (189ÉF)

+Heat up switch: ONON

Except above OFF

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

11 BR/YExhaust gas control valve

control solenoid valveEngine is running.

Engine speed is below 1,200 rpm

Engine coolant temperature is below 87ÉC

(189ÉF)

Stop the vehicle

Heat up switch is ªONºApproximately 0.1V

Engine is running.

Except the above conditionBATTERY VOLTAGE

(11 - 14V)

SEF285Z

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1269

Page 803 of 1033

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor

and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix

it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move

harnesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mount-

ing bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to

transmission.

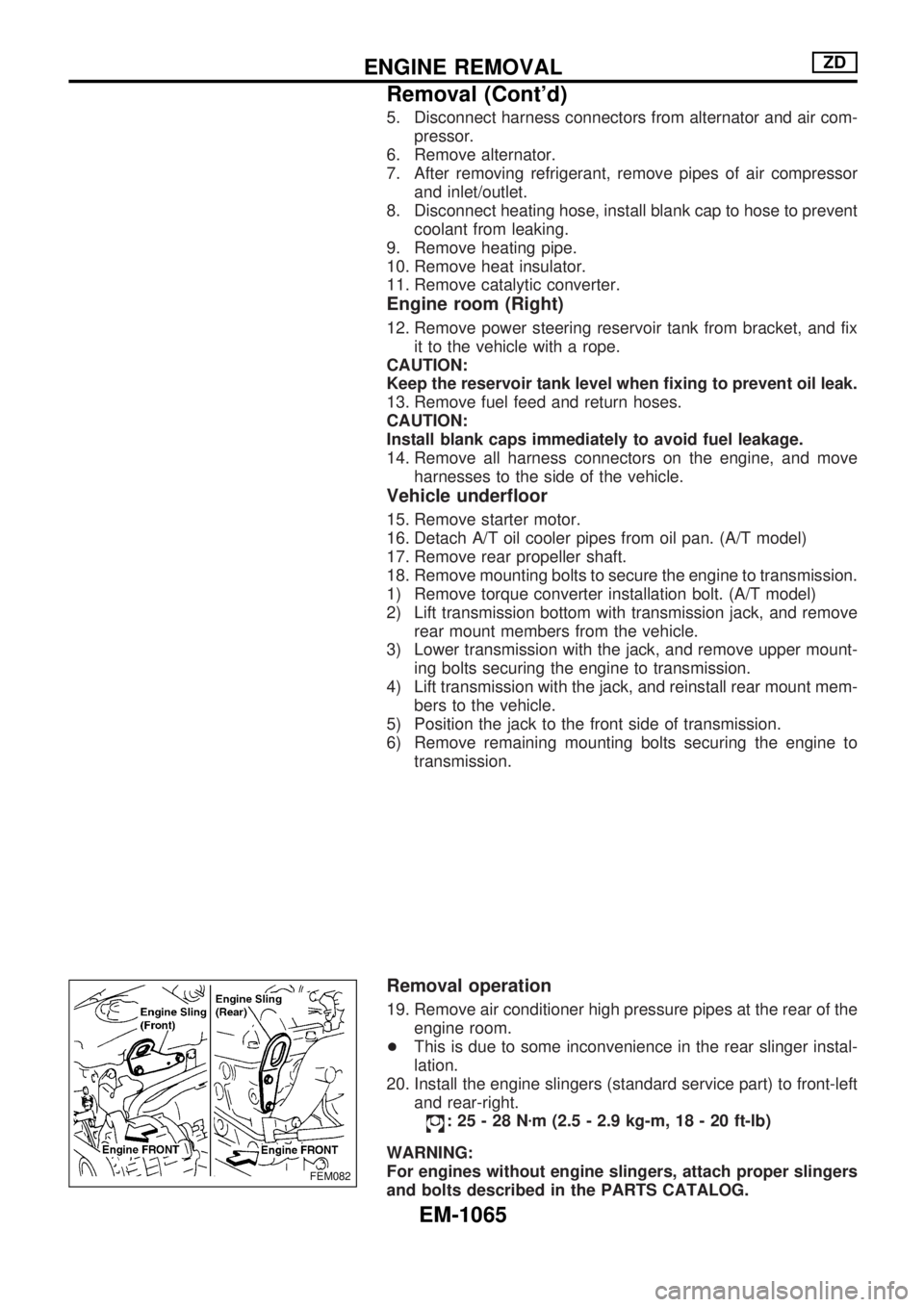

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

+This is due to some inconvenience in the rear slinger instal-

lation.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28Nzm (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-1065

Page 847 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Fuel

DIESEL ENGINE*:

Diesel fuel of at least 50 cetane for ZD30DDTi engine

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

+Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

+Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

+Do not use summer fuel at temperature below þ7ÉC

(20ÉF). The cold temperature will cause wax to form in

the fuel. As a result, it may prevent the engine from run-

ning smoothly.

+Do not add gasoline or other alternate fuels to diesel

fuel.

PRECAUTIONS AND PREPARATION

GI-1002